A method for preparing dissolving pulp from whole cotton stalks

A technology for dissolving pulp and cotton stalks, which is applied in pulping with inorganic alkali, pulping with organic solvents, pulping with cellulose raw materials, etc., can solve the problems of large amount of reaction reagents, long reaction time, complicated production process, etc., and achieve Reduce the amount of alkali and energy consumption, consume a large amount of reagents, and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

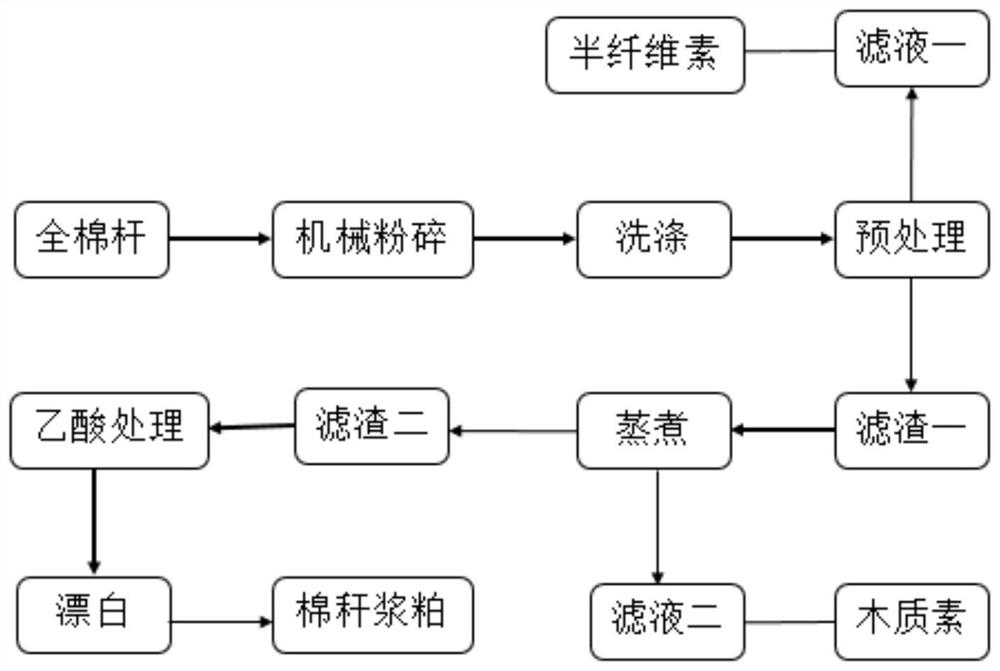

[0051] A. Cotton stalk preparation

[0052] Cotton stalks are mechanically crushed to 5mm, washed with water to remove sand, dust and other impurities, dried at 45°C and packed into bags for later use;

[0053] The main chemical components (%) of cotton stalks are shown in Table 1.

[0054] Table 1

[0055]

[0056]

[0057] The material preparation process in the embodiments is all in this way, and will not be repeated in the following embodiments.

[0058] B. Cotton stalk pretreatment

[0059] Add cotton stalks (40g dry, the same below) to the there-necked bottle, add 3% NaOH (based on the quality of the pretreatment solution, the same below), add 12% ethanol (based on the quality of the pretreatment solution, the same below), add water The concentration of the slurry was adjusted to 10 wt%, mechanical stirring was started, the reaction temperature in the water bath was 50° C., and the reaction time was 80 min.

[0060] After filtering, the pretreatment liquid (fil...

Embodiment 2

[0074] A. Cotton stalk preparation

[0075] With the preparation method in embodiment 1.

[0076] B. Cotton stalk pretreatment

[0077] Add a certain amount of cotton stalks to the three-necked bottle, add 1wt% NaOH, 6wt% absolute ethanol, adjust the solid-liquid ratio (pretreatment reagent to cotton stalk dry mass ratio) to 10:1, and start mechanical stirring. The water bath reaction temperature was 80°C, and the reaction time was 90 minutes.

[0078] Collect the pre-hydrolyzate (filtrate 1) to separate and extract hemicellulose. Add acetic acid to the collected prehydrolyzate to adjust the pH to 6.0-7.0, centrifuge at 4500 rpm for 20 min, and finally filter and separate to obtain hemicellulose.

[0079] The analysis shows that the yield of cotton stalk pulp after prehydrolysis is 76.5% (relative to the absolute dryness of the raw material). According to the relevant standards of TAPPI, the lignin content of the prehydrolyzed cotton stalk pulp is 19.73%, the α-cellulose i...

Embodiment 3

[0092] The cotton stalk dissolving pulp was prepared according to the method and steps disclosed in Example 1, with the difference that absolute ethanol was not added during pretreatment.

[0093] The analysis shows that the yield of cotton stalk pulp after pretreatment is 79.8% (compared to the absolute dryness of the raw material). According to the relevant standards of TAPPI, the lignin content of the pretreated cotton stalk pulp is 20.65%, the α-cellulose content is 67.34%, the pentose polysaccharide content is 5.46%, and the ash content is 3.50%.

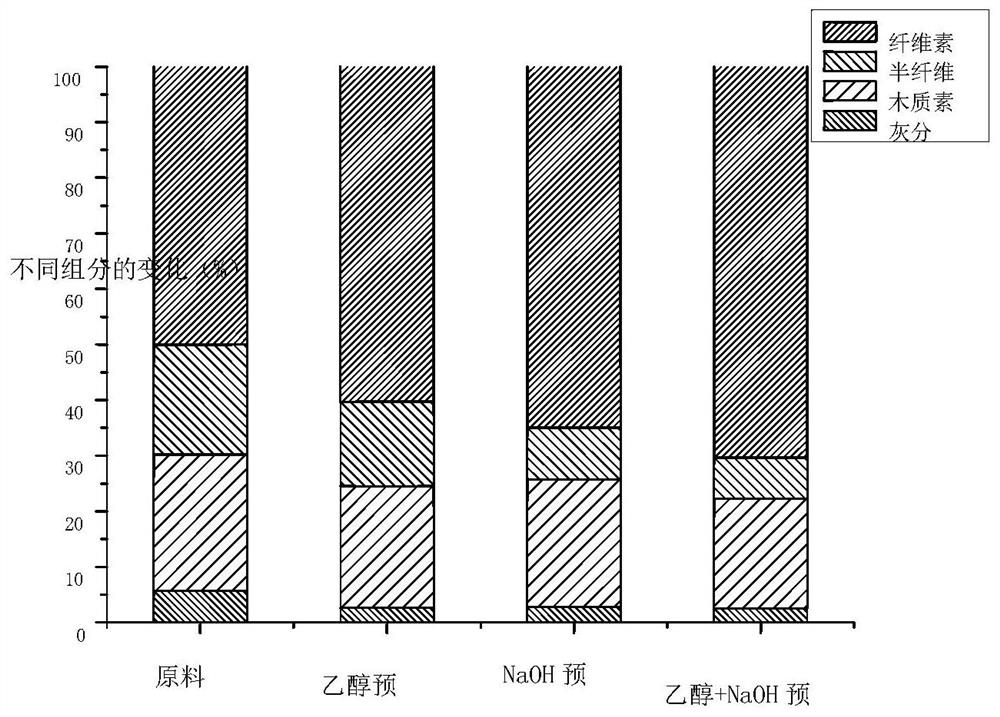

[0094] The experimental effects of adding ethanol auxiliary and no ethanol auxiliary during pretreatment are as follows: figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com