Method for bleaching bamboo pulp

A technology of bamboo pulp and bleaching agent, applied in pulp bleaching, chemical/chemical mechanical pulp, textiles and papermaking, etc., can solve the problems of relatively high requirements for experimental conditions, stimulation of respiratory mucosa, and increased economic costs, and achieve good selectivity, The effect of avoiding damage and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

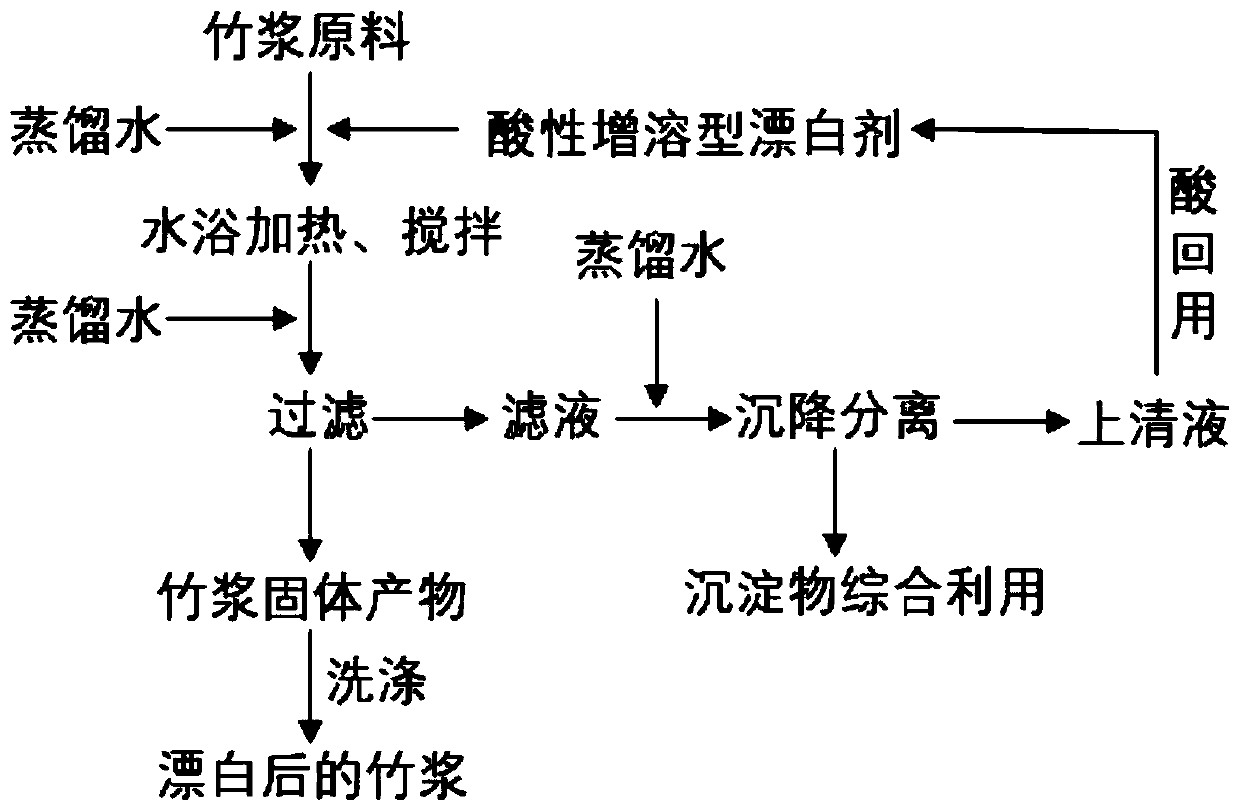

Method used

Image

Examples

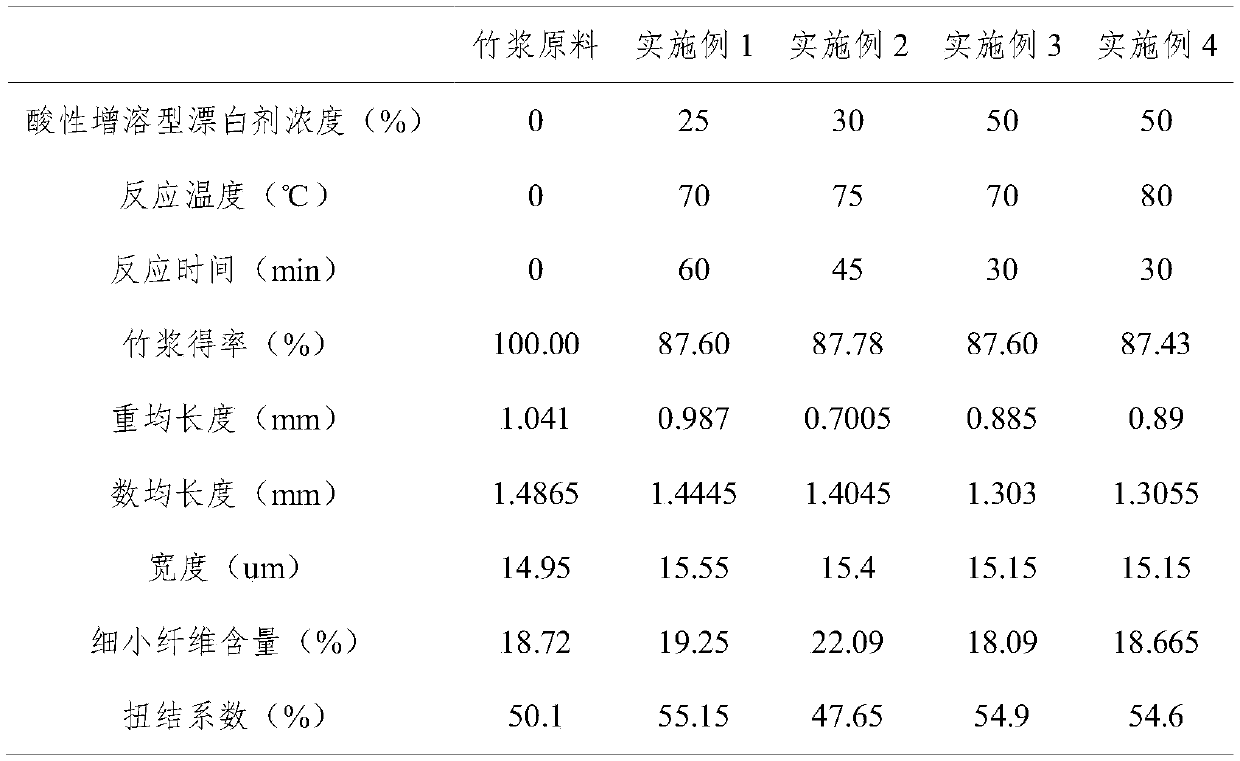

Embodiment 1

[0032] The total weight of the experiment is 200g, and the ratio of raw material weight of unbleached bamboo pulp to the total weight is 1:10.

[0033] (1) bleaching reaction: take by weighing the unbleached bamboo pulp raw material that 20g obtains through kraft cooking, 50g p-toluenesulfonic acid and 130g distilled water, wherein p-toluenesulfonic acid accounts for 25% of gross weight, heats in water bath to 70°C, stir for 60 minutes, add 200g of distilled water to the reaction vessel to complete the reaction, and obtain a bamboo pulp suspension for later use;

[0034] Adding distilled water can reduce the temperature rapidly, so that the temperature required for the reaction cannot be reached. This practice can ensure the accuracy of the reaction time.

[0035] (2) Filtration: adopt the bamboo pulp suspension of vacuum filtration step (1) gained, separate and obtain bamboo pulp solid product, standby; Dilute the filtrate that obtains with distilled water, separate by settli...

Embodiment 2

[0041] The total weight of the experiment is 200g, and the ratio of raw material weight of unbleached bamboo pulp to the total weight is 1:10.

[0042] (1) bleaching reaction: take by weighing the unbleached bamboo pulp raw material that 20g obtains through kraft cooking, 60g p-toluenesulfonic acid and 120g distilled water, wherein p-toluenesulfonic acid accounts for 30% of gross weight, heats in water bath to 75°C, stir for 45 minutes, add 200g of distilled water to the reaction vessel to complete the reaction, and obtain a bamboo pulp suspension for later use;

[0043] (2) filter: method is with embodiment 1;

[0044] (3) Washing: the method is the same as in Example 1.

[0045] After washing, the yield of the obtained bleached bamboo pulp is 87.78%.

Embodiment 3

[0047] The total weight of the experiment is 200g, and the ratio of raw material weight of unbleached bamboo pulp to the total weight is 1:10.

[0048] (1) bleaching reaction: take by weighing the unbleached bamboo pulp raw material that 20g obtains through kraft method cooking, 100g p-toluenesulfonic acid and 80g distilled water, wherein p-toluenesulfonic acid accounts for 50% of gross weight, heats in water bath to 70°C, stir for 30 minutes, add 200 g of distilled water to the reaction vessel to complete the reaction, and prepare a bamboo pulp suspension for later use;

[0049] (2) filter: method is with embodiment 1;

[0050] (3) Washing: the method is the same as in Example 1.

[0051] After washing, the yield of the bleached bamboo pulp obtained is 87.60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com