Corrugated paper produced by steam blasting straw to pulp and its production method

A technology of corrugated base paper and production method, applied in the direction of pulp beating method, pulping with inorganic alkali, paper, etc., can solve the problems that have not reached the level of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

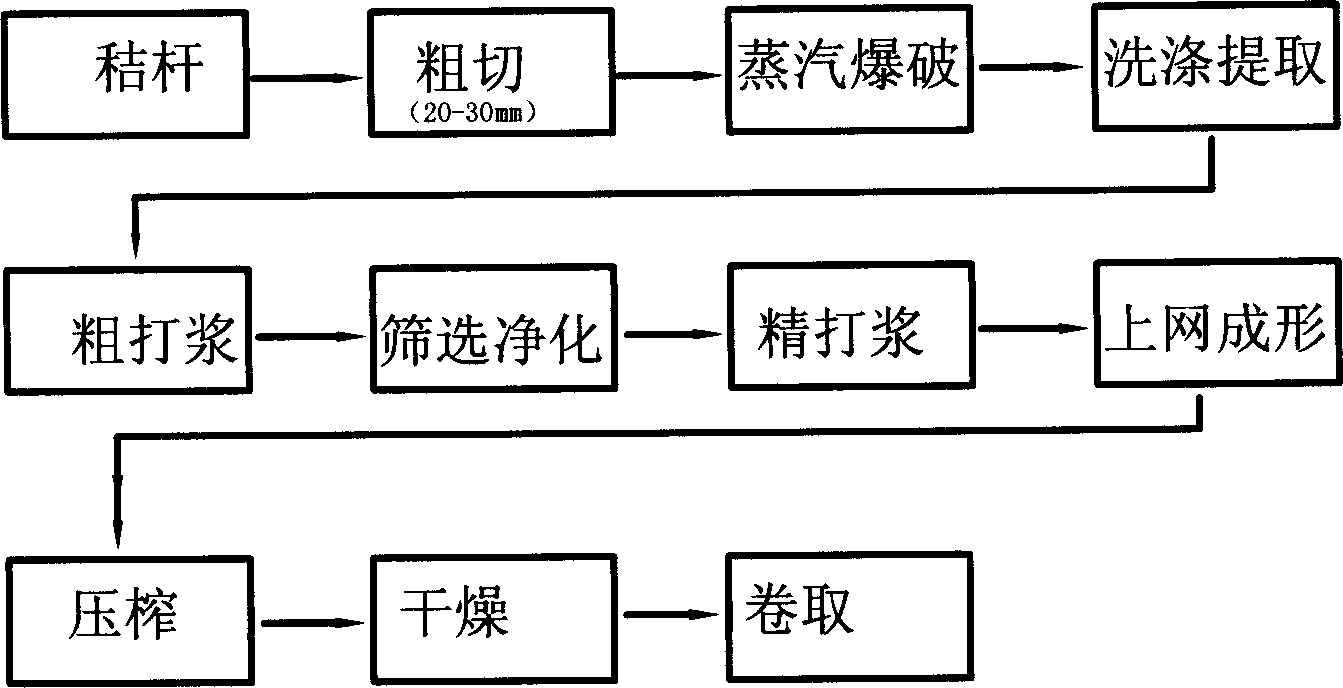

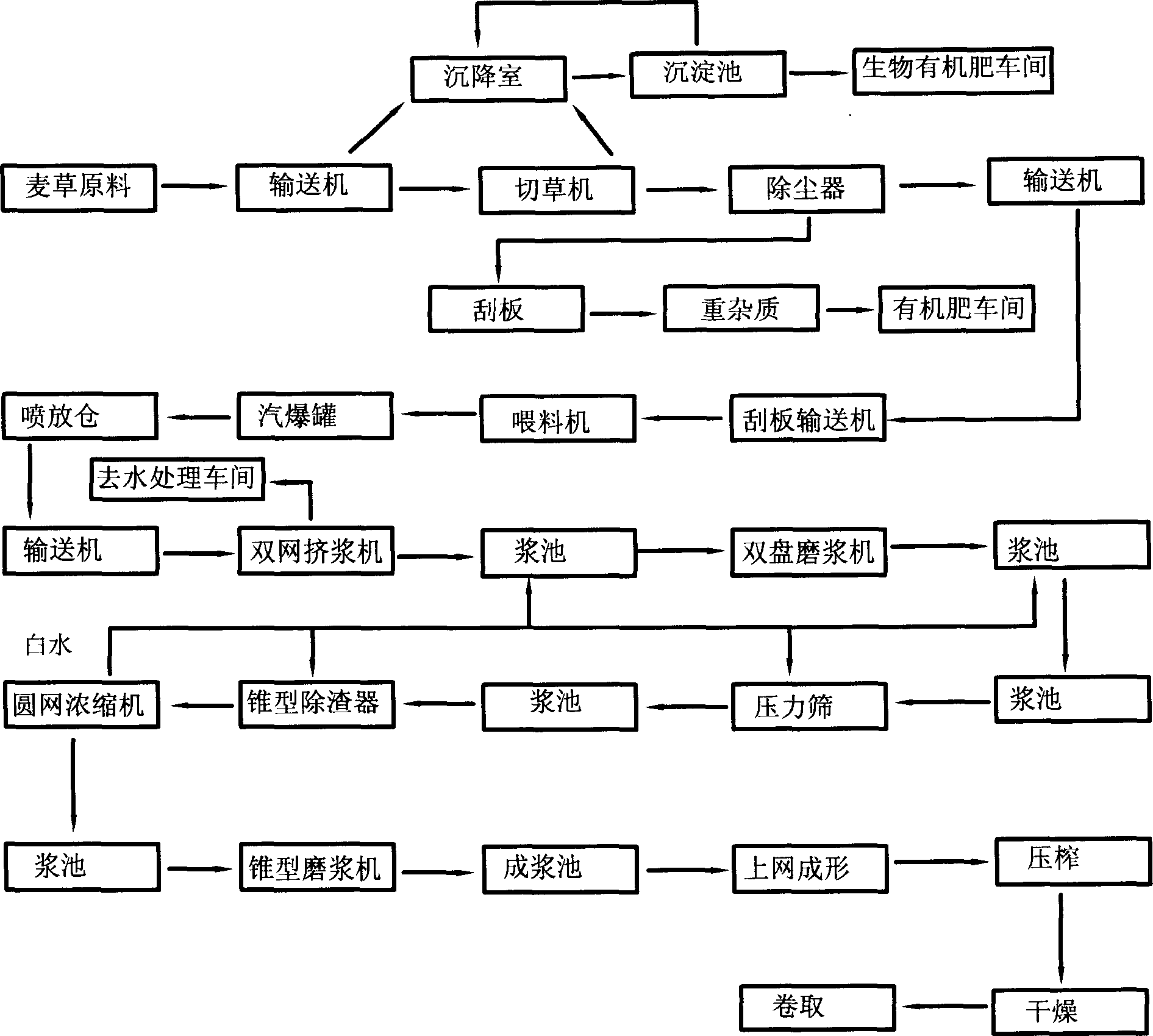

[0050] Preparation process:

[0051] Sheet length 20~30mm

[0052] Dust content ≤4%

[0053] Steam explosion process:

[0054] Among the present invention, steam explosion refers to the stalk of rough cutting (20~30mm long) of packing into the steam explosion tank of certain scale, and adds a small amount of caustic soda, at 145~180 ℃ vapor phase cooking temperature, under 0.9~2MPa pressure 12 to 18 minutes. Preferably, the steam-phase cooking temperature is 150-170° C., and the pressure is 0.9-1.1 MPa for 5 minutes, and then the pressure is 1.4-1.8 MPa for 10 minutes, and then the instant decompression is released to obtain the steam-exploded straw.

[0055] The main equipment of this process is the steam explosion tank and the spraying chamber. After the slurry is put into the spraying chamber after steam explosion, it must pass through four spiral conveyor belts and one main spiral conveyor belt, and a water spray pipe is installed in the second half of the spiral. Feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com