A kind of method that utilizes bamboo pulp to produce high penetrability paper sack paper

A paper bag, high-transparency technology, applied in papermaking, paper, packaging paper, etc., can solve the problems of reducing the performance of paper bag paper tensile strength, energy absorption, etc., and achieve the effect of low bag breakage rate, improved air permeability, and reduced tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

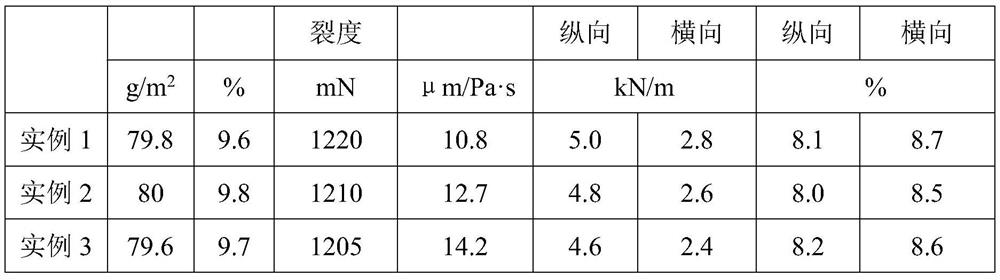

example 1

[0019] A method of utilizing bamboo pulp to produce high-stretch paper sack paper, specifically as follows:

[0020] Using 15% of bamboo chips and 85% of coniferous wood chips to obtain pulp by kraft method to make extensible paper sack paper.

[0021] After the bamboo chips and coniferous wood chips are mixed evenly in proportion, they are sent to the 110m 3 The vertical cooking pot, before cooking, add cooking white liquor (NaOH lye and washing liquid after pulp washing) according to the ratio of additives (bamboo chips and coniferous wood chips) to water weight ratio of 1:3.6, the amount of alkali used 20%, vulcanization degree 32%, mixed with bamboo and wood mixed chips, of which bamboo and wood mixed chips account for 48% of water, and the total liquid is 62m 3 ;Add steam gradually to the set temperature in the cooking pot, the temperature change process and time include: the temperature is raised from 70°C to 120°C by adding the amount of steam, and the time used is 60m...

example 2

[0024] A method of utilizing bamboo pulp to produce high-stretch paper sack paper, specifically as follows:

[0025] Using 20% of bamboo chips and 80% of coniferous wood chips to obtain pulp by kraft method to make extensible paper sack paper.

[0026] After the bamboo chips and coniferous wood chips are mixed evenly in proportion, they are sent to the 110m 3 The vertical cooking pot, before cooking, add cooking white liquor (NaOH lye and washing liquid after pulp washing) according to the ratio of additives (bamboo chips and coniferous wood chips) to water weight ratio of 1:3.6, the amount of alkali used 17%, vulcanization degree 34%, mixed with bamboo and wood mixed chips, of which bamboo and wood mixed chips account for 46% of moisture, and the total liquid is 64m 3 ;Add steam gradually to the set temperature in the cooking pot, the temperature change process and time include: the temperature is raised from 70°C to 120°C by adding the amount of steam, and the time used i...

example 3

[0029] A method of utilizing bamboo pulp to produce high-stretch paper sack paper, specifically as follows:

[0030] Using 25% of bamboo chips and 75% of coniferous wood chips to obtain pulp by kraft method to make extensible paper sack paper.

[0031] After the bamboo chips and coniferous wood chips are mixed evenly in proportion, they are sent to the 110m 3 The vertical cooking pot, before cooking, add cooking white liquor (NaOH lye and washing liquid after pulp washing) according to the ratio of additives (bamboo chips and coniferous wood chips) to water weight ratio of 1:3.6, the amount of alkali used 21%, vulcanization degree 29%, mixed with bamboo and wood mixed chips, of which bamboo and wood mixed chips account for 44% of water, and the total liquid is 66m 3 ;Add steam gradually to the set temperature in the cooking pot, the temperature change process and time include: the temperature is raised from 70°C to 120°C by adding the amount of steam, and the time used is 60m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com