Patents

Literature

91 results about "Bagasse pulp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bagasse is a natural byproduct of sugarcane refinement. Bagasse is the fiber that remains after sugarcane stalks are crushed to extract their juice. Bagasse pulp requires minimal processing and elemental chlorine free (ECF) bleaching to turn it into a woven high-strength paper that is biodegradable and compostable.

Method for dissolving cellulose

The invention discloses a method for dissolving cellulose, characterized by: using at least one from the group consisting of wood pulp, cotton pulp, hemp pulp, bamboo pulp, bagasse pulp, grass fibered pulp, cellulose non-woven fabric or steam exploded cellulose pulp as cellulose raw material, uniformly stirring the cellulose raw material, NaOH and water at a temperature of -15-50 DEG C to obtain a cellulose solution. The prepared cellulose concentrated solution has good spinnability and film forming property. The method breaks through a dissolution method of traditional gluing technology, does not relate to carbon disulfide and other substance causing serious environmental pollution, and is green and environmentally friendly. According to the invention, the cellulose raw material can be directly rapidly dissolved at room temperature, without heating or precooling a solvent. The method has the advantages of saving energy, and reducing energy consumption. By using raw materials having low cost, the method has the advantages of simple operation, small investment, high productivity, and is easy to realize large-scale industrial production.

Owner:NANHUA UNIV +1

Method for producing 20 tons of molded pulp products per day

InactiveCN105568777AEasy to degradeNo pollution in the processWater-repelling agents additionReinforcing agents additionMolded pulpFiber

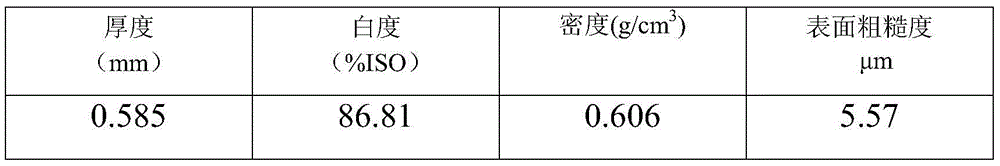

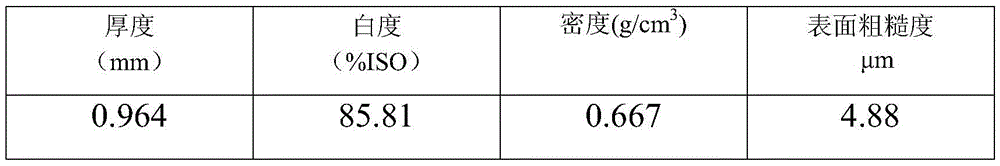

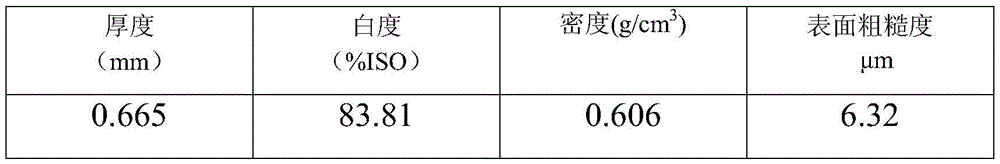

The invention belongs to the technical field of molded pulp packaging materials and particularly relates to a method for producing 20 tons of molded pulp products per day. The method adopts plant fiber materials as raw materials; with adoption of the method, wood pulp, bamboo pulp and bagasse pulp can be mixed and pulped on the premise of control of lower production cost, the beating degree is about 20-25 degrees SR, then a waterproof agent and a reinforcing agent are added to the mixed pulp, then an easy-to-degrade paper high-end packaging material is prepared from the mixed pulp through a molded pulp molding machine, and finished products of the molded pulp products are obtained finally through die cutting. The whiteness of the finished products is as high as 84%-86% ISO, and the surface roughness is 4-6 mu m. The prepared molded pulp products belong to green packaging, and wood pulp is not used in the raw materials, so that good environmental protection effect is realized; the produced materials are easy to degrade, are free of environmental pollution, have good durability and sufficiently meet the ideas of environmental protection and sustainable development.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing translucent paper by utilizing bagasse pulp

InactiveCN103031778AQuality assuranceReduce consumptionSpecial paperReinforcing agents additionState of artWet strength

The invention discloses a method for producing translucent paper by utilizing bagasse pulp. The method comprises the following steps: the bagasse pulp is used as a main raw material and is mixed with partial coniferous wood pulp; and a wet strength agent and a water repellent agent are added to the mixing pulp, wherein the translucent paper comprises the following parts by weight of components: 50 to 60 parts of the bagasse pulp and 40 to 50 parts of wood pulp. Compared with the prior art, the method has the advantages that the quality of the translucent paper is ensured and the consumption of wood materials is reduced, so that the production cost is lowered.

Owner:GUILIN QIFENG PAPER

ClO2 bleaching method of bagasse pulp

ActiveCN101545229ATo achieve the effect of lignin removalAchieve whitening effectPulp bleachingChlorine dioxideBagasse pulp

The invention relates to a clO2 bleaching method of bagasse pulp, which indicates 1) preparing the ponderance concentration of the bagasse fundamental colour pulp as 10%, and then getting d>=[0]albefaction pulp by mixing the aforementioned fundamental colour pulp with clo2 containing available chlorine of 2.5%-3.5% of the fundamental colour pulp by weight. 2) preparing the ponderance concentration of the aforementionedd>=[0]albefaction pulp as 10% after washing it, then gettinge>=[p]extraction pulp by addingh>=[2]o>=[2]which is 0.3%-0.5% of the fundamental colour pulp by weight and NaOH which is 1.5%-2.5% of the fundamental colour pulp by weight and carrying them into intensification alkalis reaction. 3) preparing the ponderance concentration of the aforementioned E>=[P]albefaction pulp as 10% after washing it, and then getting d>=[1]albefaction pulp by mixing the aforementioned fundamental colour pulp with clo2 containing available chlorine of 1.0%-1.5% of the fundamental colour pulp by weight. 4) In the end getting the high white content albefaction pulp with white content of 81%-87% ISO and yield rate of 90%-92% by diluting the aforementionedd>=[1]albefaction pulp and washing it.

Owner:GUANGXI UNIV

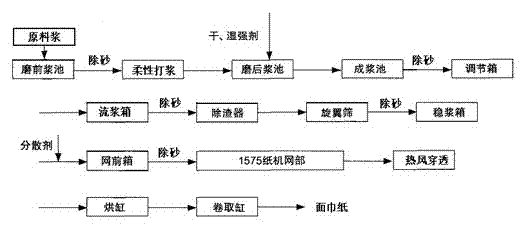

Production method of soft and fluffy facial tissue

ActiveCN103696318AImprove excessive tightness and insufficient bulkinessHigh speedPulp beating methodsDryer sectionPapermakingToughness

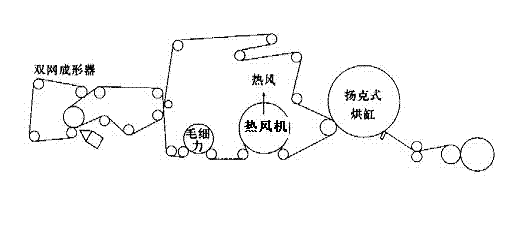

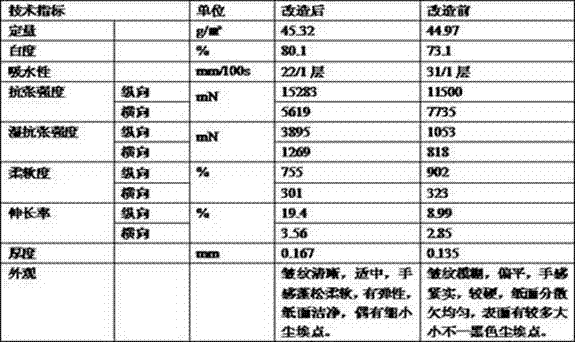

The invention relates to a papermaking method, and particularly relates to a method for producing household paper facial tissue by taking bagasse as a main raw material. The technical scheme is as follows: the bagasse pulp and a small amount of wood pulp at a high ratio are used as main raw materials, wherein the weight ratio of the bagasse pulp to the wood pulp is (65-75):(25-35); five grit removal processes are adopted to adjust the previous and later paper pulp concentration of each piece of equipment; a flexible beating process for fibrillation is adopted; a process of high-speed hot air penetrating through paper sheets is adopted to produce the soft and fluffy facial tissue with high toughness and low cost and meeting the health standard.

Owner:GUANGXI TIANLIFENG ECOLOGICAL MATERIAL

Method and equipment for producing paper hand towel from bagasse pulp

ActiveCN103757973AImprove uniformityGood dry and wet strengthPulp beating/refining methodsPaper-making machinesKraft processPapermaking

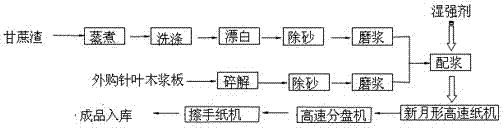

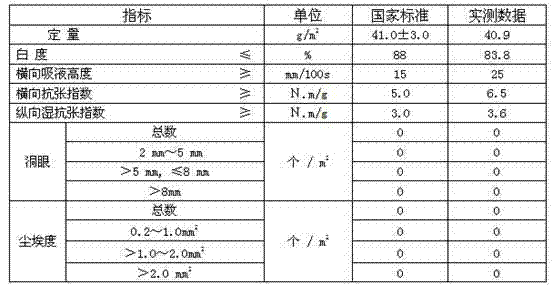

The invention relates to a method for papermaking, and particularly relates to a method and equipment for producing a paper hand towel form bagasse pulp as a main raw material. According to the method, firstly, 80%-90% of bagasse pulp and 10%-20% of softwood pulp are taken as raw materials, wherein the bagasse pulp is boiled by a sulfate process, washed and then bleached so as to obtain bleached bagasse pulp, and the softwood pulp adopts market pulp; secondly, an aquapulper, a high concentration grit separator and a double disc refiner are used; thirdly, a proper wet strength agent is adopted; fourthly, a crescent high speed toilet paper machine is adopted; fifthly, a low beating degree is adopted; sixthly, in the whole process from pulp preparation to paper rolling, automatic operation control with a DCS (distributed control system) is adopted, paper sheet quantification and moisture are monitored on line and regulated automatically by a QCS (quality control system); seventhly, a point-to-point embossing manner is adopted; eighthly, a high-speed rewinding and splitting machine is used. The produced paper hand towel has tensile strength and proper air permeability, and reaches high standards in strength, wet strength, water absorption, air permeability, flexibility and the like.

Owner:广西广业贵糖糖业集团有限公司

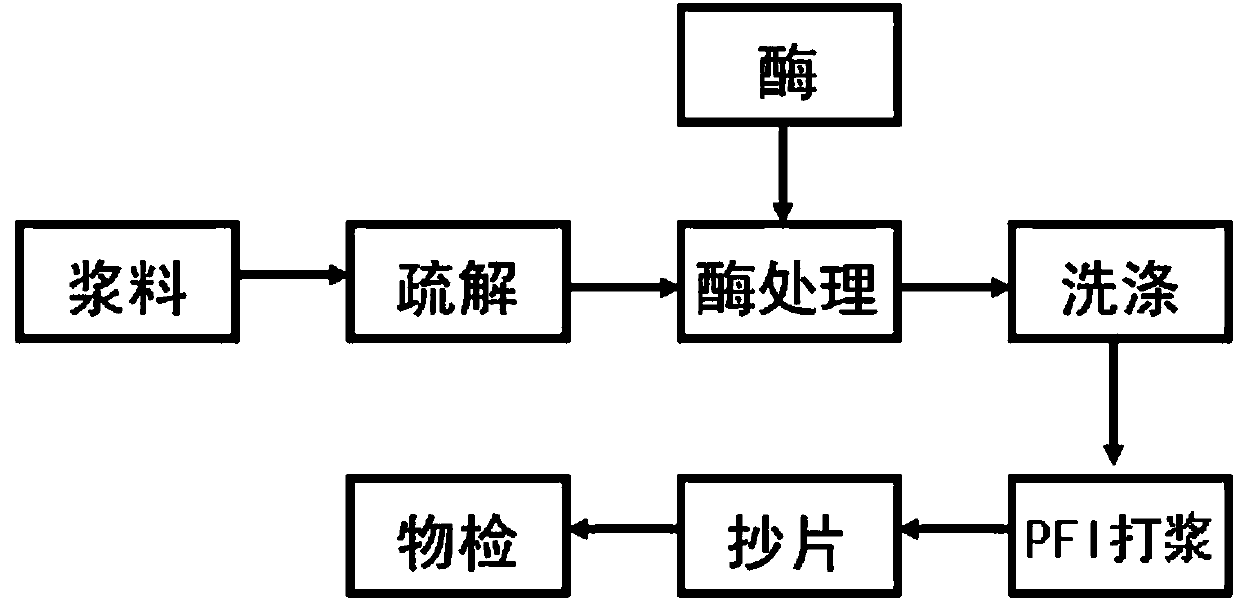

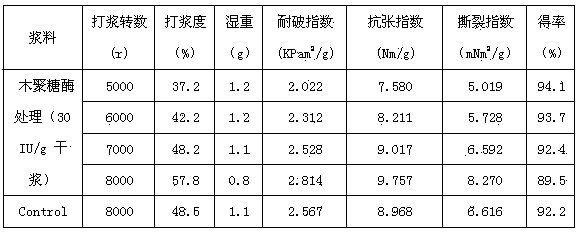

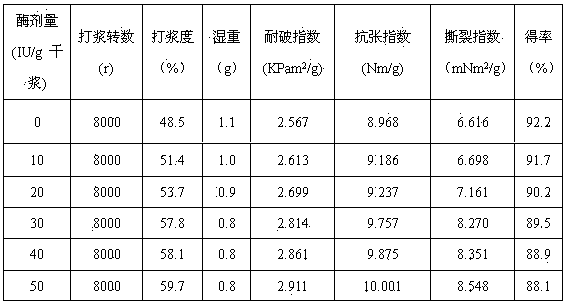

Enzymatic beating process for natural-color bagasse pulp

The invention discloses an enzymatic beating process for natural-color bagasse pulp. Xylanase is used in the enzymatic beating process for the natural-color bagasse pulp. The process comprises the steps of sizing agent defibering, enzyme treatment, washing, PFI beating, sheet making and physical detection. By adopting the process, the beating energy consumption of the natural-color bagasse pulp can be lowered effectively; the beating degree can be increased greatly up to 19.2 percent when enzyme treatment is performed on the xylanase at the dry pulp dosage of 30IU / g; meanwhile bagasse pulp cellulase can be protected from being damaged, and the process has important significance to the production of industrial paper from bagasse pulp.

Owner:GUANGXI UNIV

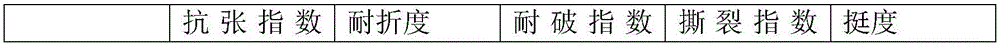

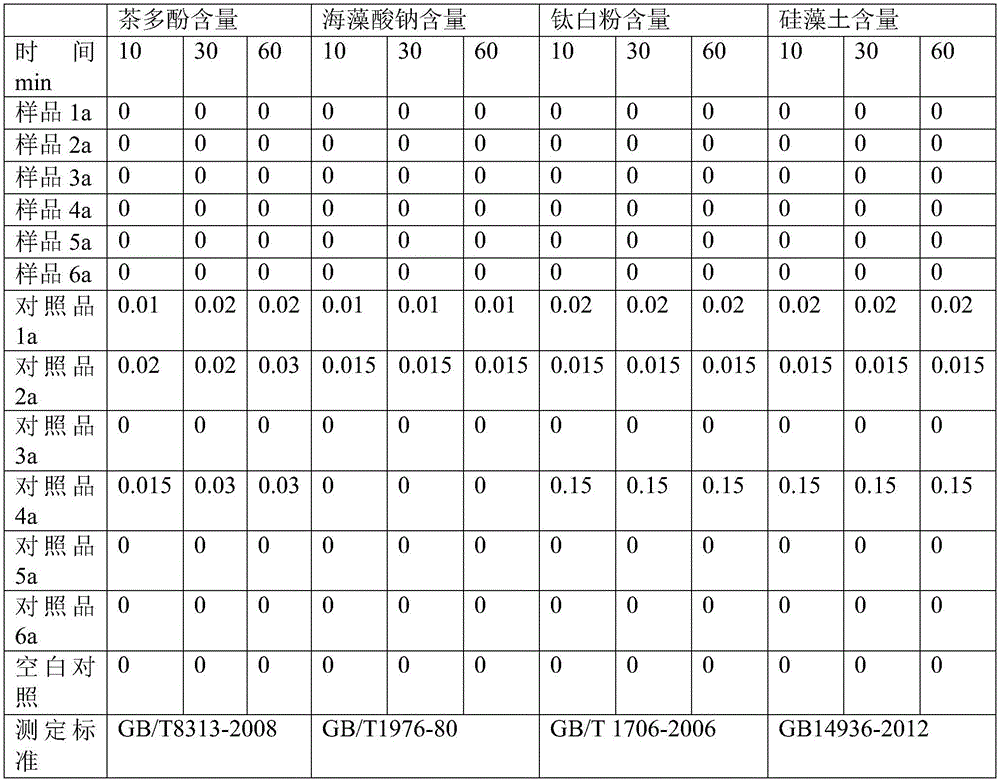

Antibacterial moisture-proof high-quality tipping base paper and preparation method thereof

ActiveCN104005268AImprove the pungent smellEvenly distributedSpecial paperVegetable material additionCalcium silicateFiber

The invention discloses antibacterial moisture-proof high-quality tipping base paper. The antibacterial moisture-proof high-quality tipping base paper is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of calcium silicate, 1-2 parts of a silica-gel drier, 0.8-1 part of sorbic acid, 34-39 parts of bagasse pulp, 49-53 parts of pine pulp, 1-2 parts of calcium peroxide, 1.5-2 parts of starch, 2-3 parts of guar gum, 0.8-1 part of sweetgum resin, 0.7-0.9 part of alkyl ketene dimer, 0.5-0.7 part of sorbitol, 3-4 parts of horseradish, 3-5 parts of shaddock peel, 2-3 parts of calcium carbonate, 1-2 parts of auxiliaries and a proper amount of water. The silica-gel drier is added, so that the tipping paper is safe and nontoxic, and has the moisture-proof effect; the horseradish is added, so that the tipping paper has the antibacterial and smoke purification effects by taking full advantage of the plant characteristics of the horseradish; the auxiliaries are added, so that the pungent smell of smoke is improved, and consequently, the obtained tipping paper is even in fiber distribution, good in air permeability, high in strength, easy to print and high in quality.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Method of producing base paper for foodstuff packaging from high proportion bagasse pulp

InactiveCN1924189AExpand the scope of useReduce consumptionNatural cellulose pulp/paperWater-repelling agents additionBleachFood packaging

This invention relates to one method to process foods package paper by cane trash pastry with high formula, which comprises the following components: bleach needle wood pastry for 30 to 35 percentages, bleach cane trash pastry for 65 to 70 percentages, wherein, the pastry adopts three layers of core, bottom and surface with concentration controlled between 0.5 to 0.6 percentages, wherein, controlling each pastry formula through each pastry net concentration and flow speed; when original paper shapes it adds layer spray starch and then adds SM-I special glue agent to improve original paper anti-transparency to product high quality package materials.

Owner:GUANGXI UNIV +1

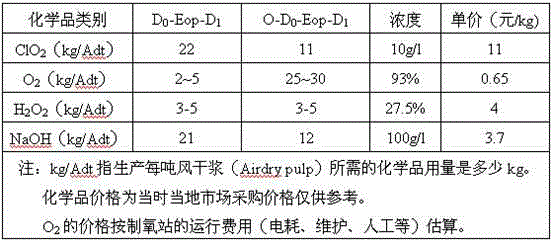

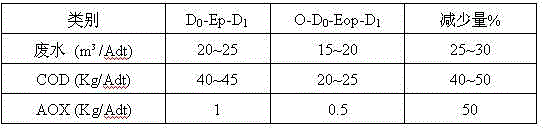

ECF bleaching method for reducing AOX formation amount

The present invention relates to an ECF bleaching method for reducing the AOX formation amount. The method is mainly characterized by comprising: (1) carrying out hemicellulase pretreatment on an unbleached pulp, and (2) in the presence of chlorine dioxide, sodium hydroxide, hydrogen peroxide and potassium sulfide, carrying out ECF bleaching on the bagasse pulp. According to the present invention, the hemicellulase pretreatment is performed on the unbleached bagasse pulp so as to remove hexenuronic acid capable of reacting with chlorine dioxide and concurrently remove hemicelluloses, such that the more residual lignin can be exposed; with the addition of potassium sulfide, the sulfur ions can be provided for the alkali extraction stage, the alkali extraction stage can be strengthened, the dissolution of the lignin is easily achieved, it can be ensured that the chlorine dioxide bleaching stage uses the less chlorine dioxide, and the AOX generated during the bleaching process can be reduced; and compared with the traditional ECF bleaching, the bleaching method of the bagasse pulp in the present invention has the following characteristics that: the chlorine dioxide consumption can be saved by 15-20%, and the AOX formation amount can be reduced by 20-30%.

Owner:GUANGXI UNIV

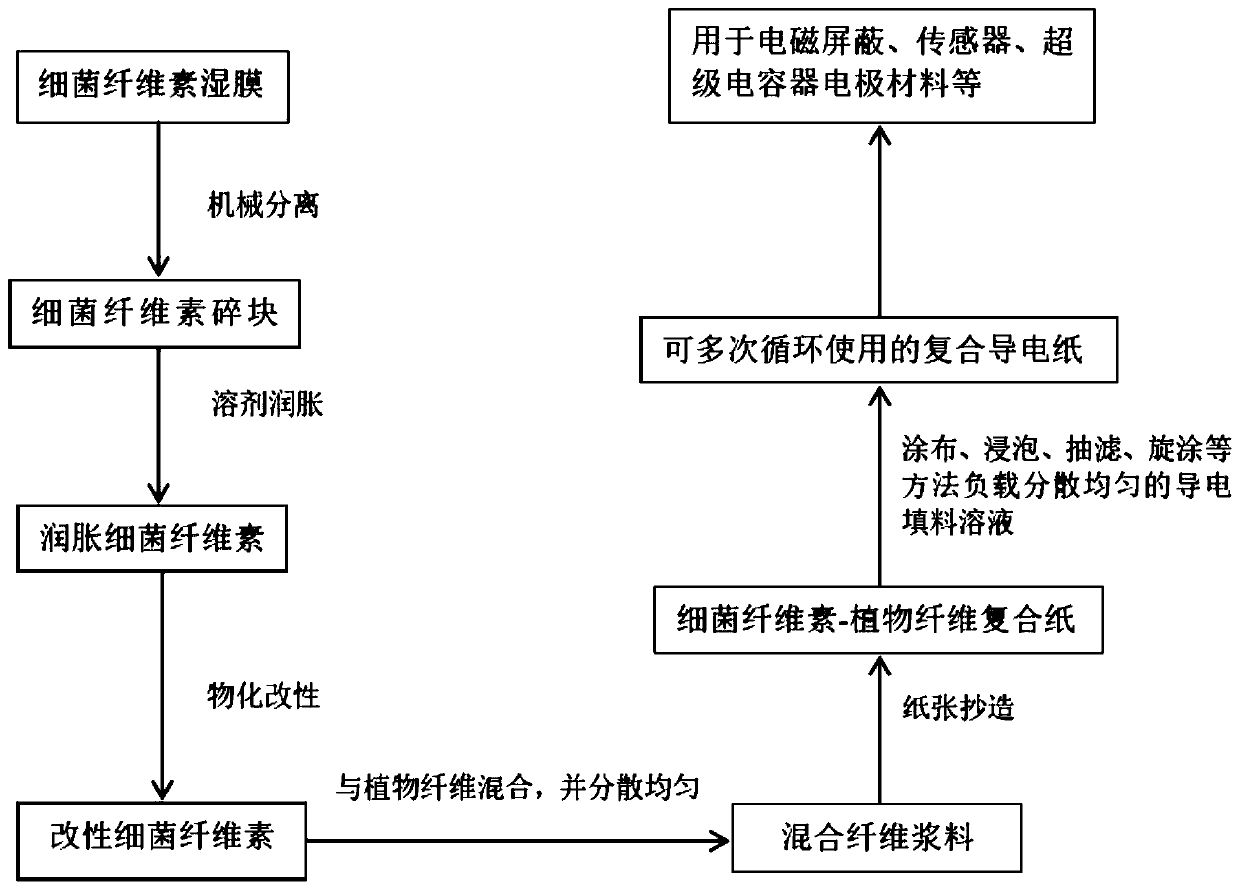

Bacterial cellulose-plant fiber composite conductive paper as well as preparation method and application thereof

ActiveCN111074669AImprove bindingImprove uniformityHybrid capacitor electrodesNon-macromolecular organic additionCarbon fibersPlant fibre

The invention discloses bacterial cellulose-plant fiber composite conductive paper as well as a preparation method and an application thereof. According to the method, bacterial cellulose and plant fibers are compounded into paper, and then conductive filler is loaded on the composite paper through an impregnation method or a coating method to prepare the conductive paper. The bacterial celluloseis cellulose secreted and synthesized by bacterial microorganisms or modified bacterial cellulose. The conductive filler is the filler with conductivity such as carbon nanotubes, silver nanowires, carbon fibers and graphene. The plant fiber pulp is a papermaking pulp raw material prepared from wood fibers, non-wood plant fibers or secondary fibers through a mechanical or chemical pulping method and the like, and comprises hardwood pulp, softwood pulp, bagasse pulp, bamboo pulp, straw pulp, secondary fiber pulp and the like. The conductive paper prepared by the method has the advantages of simplicity in preparation, strong conductivity, high mechanical stability, low leaching rate of the conductive filler, strong recycling capability and the like, and has excellent performance in application of paper-based conductors, paper-based electrodes, paper-based capacitors and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of cellulose nanofiber filament

ActiveCN109295785ALow costImprove thermal stabilityPulp properties modificationCellulose treatment using microorganisms/enzymesCelluloseNanofiber

The invention discloses a preparation method of a cellulose nanofiber filament. Unbleached bagasse pulp is used as a raw material, and the unbleached bagasse pulp is treated through combination of xylanase treatment and cold alkali treatment, and superfine grinding and high-pressure homogenization treatment are carried out in combination, so that the cellulose nanofiber filament is prepared. The diameter of the cellulose nanofiber filament prepared by the preparation method can be controlled to be 20-40 nm, and the maximum pyrolysis rate temperature reaches 355.7-360.2 DEG C. A new way is provided for promoting the high-value utilization of bagasse pulp.

Owner:GUANGXI UNIV

Method for reducing AOX forming amount in chlorine dioxide bleaching process of bagasse pulp

The invention relates to a method for reducing an AOX forming amount in a chlorine dioxide bleaching process of a bagasse pulp. The method is characterized by mainly including the following steps: (1) high temperature acid pretreatment section; (2) biological enzyme pretreatment section; and (3) chlorine dioxide bleaching section. According to the present invention, high temperature acid pretreatment on the unbleached bagasse pulp is mainly to remove the hexenuronic acid in theunbleached pulp, and the use of biological enzyme is to remove the semi-cellulose on the fiber surface and to expose more residual lignin, so as to ensure the less usage of chlorine dioxide in the chlorine dioxide bleaching process, and reduce the AOX generated in the bleaching process. After high temperature acid pretreatment and enzyme pretreatment on the bagasse pulp, the usage amount of chlorine dioxide is saved by 15%-30%, and the forming amount of AOX is reduced by 20%-40%.

Owner:GUANGXI UNIV

Method for producing paper for daily use by superhigh-concentration grinding technology

ActiveCN103711023AEvenly dispersedClean paperSurfactants additionReinforcing agents additionAutomatic controlControl system

The invention relates to a papermaking method and especially relates to a method for producing paper for daily use from bagasse as a main raw material. The method comprises is characterized in that high-ratio sugarcane pulp and a small amount of wood pulp are used as main raw materials, a superhigh-concentration pulp refining technology is adopted, after pulp washing, the paper pulp is processed to form pulp having water content of 40-60wt% and then the pulp is grinded by a superhigh-concentration grinding machine, simultaneously, the automatic control system of a full-automatic beating and blending pulping technology is adopted, appropriate accessory materials are used, the concentration of paper pulp before and after each equipment treatment is adjusted, and a technology of high-speed hot air penetrating through paper pages is adopted. The method solves the problems of too high bagasse pulp paper tightness, insufficient bulkiness and a slow absorption speed.

Owner:GUANGXI TIANLIFENG ECOLOGICAL MATERIAL

Method for single section bleaching bamboo/bagasse pulp

InactiveCN1587506ASave construction areaReduce consumptionPulp bleachingFinely-divided material pretreatmentPulp and paper industryOxygen

The single section bamboo / bagasse pulp bleaching process includes the following steps: pre-treatment of pulp with chelating agent; adding certain amount of H2O2, NaOH and Na2SiO3; and introducing oxygen to bleach under certain conditions. The single section bamboo / bagasse pulp bleaching process has excellent effect, advanced technological process, short period, low consumption of water, electric power, steam and chemicals and low cost.

Owner:SOUTH CHINA UNIV OF TECH

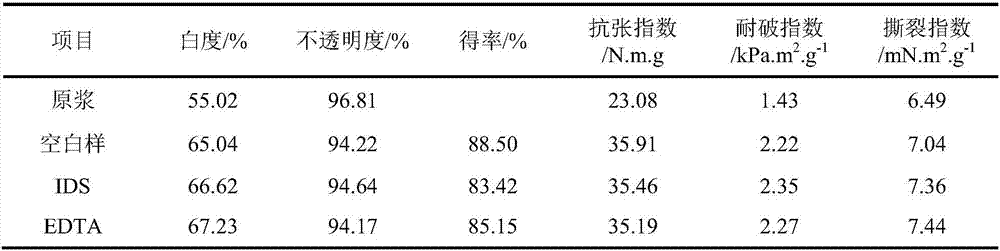

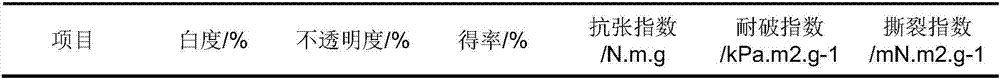

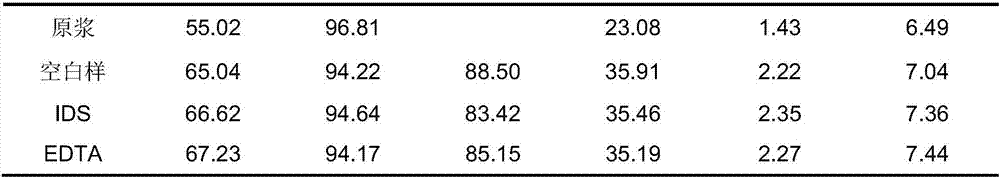

Method of applying green chelating agent in paper pulp hydrogen peroxide bleaching

The invention discloses a method of applying a green chelating agent in paper pulp hydrogen peroxide bleaching, and belongs to the technical fields of pulping and papermaking engineering. Specifically, after paper pulp is diluted to a concentration of 5%-10%, IDS with a mass percentage of 0.8%-1.2% of the absolute dry content of the paper pulp is added, mixing is performed uniformly, at the same time the chelation treatment temperature is controlled at 60-80 DEG C, and the reaction time is 50min-70min. According to the method provided by the invention, the IDS is used as the chelating agent for chelating treatment and pulp hydrogen peroxide bleaching, the bleaching effect is equivalent to that of hydrogen peroxide bleaching used conventional chelating agent EDTA, the whiteness of bagasse pulp can be improved by 2-4%, the tensile index can be improved by 5-6%, the burst resistant index can be improved by 20-23%, and the tear index can be improved by 8-10%; and the whiteness of waste paper deinking pulp can be improved by 2-4%, the burst index can be improved by 6-11%, and the tear index can be improved by 4-6%. The method provided by the invention can be used in the production process of paper pulp hydrogen peroxide bleaching.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of bobbin paper

InactiveCN105951501ALow costSufficient raw materialsSecondary cellulose fibresNon-woody plant/crop pulpCelluloseFiber

The invention discloses a method for preparing bobbin paper, which comprises the following weight ratios: 15-26 parts of bagasse pulp, 8-15 parts of fluff fiber, 28-39 parts of banana stem pulp, and then 15-26 parts of bagasse pulp, Put 8-15 parts of fluff fiber and 28-39 parts of banana stalk pulp into the mixer and stir fully, and raise the temperature to 60°C to activate the internal cellulose, and then go through screen separation, filter cleaning, fiber grinding, dehydration and separation The step of machine dehydration, and then add the following weight ratio: 17-32 parts of American waste paper, 35-52 parts of domestic waste paper, and add water to dilute, the ratio of slurry to water is 3-8:5-12, and then add papermaking Additives and fillers, and heated and stirred, heated to 70 ° C, and then processed, dried and cut into the required bobbin paper. The preparation method of the bobbin paper in the present invention has the advantages of low production cost and good product quality. , The advantage of increasing the value of pulp.

Owner:ZHEJIANG HUACHUAN IND GRP

Highly-breathable flame-retardant tipping base paper and preparation method thereof

ActiveCN104005259AEvenly distributedImprove breathabilityInorganic compound additionPaper-making machinesFiberCarrageenan

The invention discloses highly-breathable flame-retardant tipping base paper. The highly-breathable flame-retardant tipping base paper is characterized by being prepared from the following raw materials in parts by weight: 37-42 parts of bagasse pulp, 54-58 parts of bleached soft wood pulp, 5-6 parts of corn straws, 3-4 parts of spartina anglica, 2-3 parts of polyamide resin, 3-4 parts of polyethylene glycol, 2-3 parts of zirconium oxide, 1-2 parts of aluminum hydroxide, 0.4-0.7 part of citric acid, 0.8-1 part of carrageenan, 2-3 parts of lotus root starch, 1-2 parts of auxiliaries and a proper amount of water. As corn straw fibers are added to the paper pulp, the tipping base paper is even in fiber distribution and good in air permeability; the aluminum hydroxide are added, the tipping base paper has the flame retardant efficiency; the tipping base paper is high in longitudinal tensile strength, not easy to break and moderate in degree of sizing; besides, the auxiliaries are added, so that the pungent smell of the smoke is improved and the adsorption filtration effect is also enhanced.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

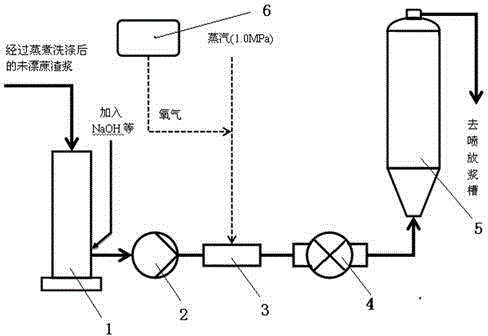

Method and device for oxygen delignification for bagasse pulping

The invention discloses a method and a device for oxygen delignification for bagasse pulping. According to the method, the oxygen delignification procedure is added between the cooking and bleaching of the conventional bagasse pulping process, cooked bagasse pulp is treated by the washing procedure at a washing section, the pulp enters a vertical pipe of a medium-consistency pump through a pulp outlet screw of a pulp washer, a certain amount of NaOH is added on the vertical pipe, then the pulp is conveyed by the medium-consistency pump, enters a steam feeding device where steam and oxygen are added, is mixed uniformly in a mixer and enters an oxygen delignification tower for delignification reaction, and finally the pulp after reaction is filtered and washed to enter a subsequent bleaching section. Based on the method and the technological conditions, residual lignin in the cooked bagasse pulp can be effectively removed, the consumption of chemicals at the bleaching section is reduced, the pollution load of waste water is greatly reduced, and meanwhile, the bagasse pulp has high yield and quality.

Owner:CHINA LIGHT IND NANNING DESIGN ENG

Method for preparing natural colored mechanical pulp by utilizing laccase to treat bagasse

ActiveCN109098025ACatalytic reaction conditions are mildSolve pollutionCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpWater filterChemical agent

The invention discloses a method for preparing natural colored mechanical pulp by utilizing laccase to treat bagasse. According to the technical scheme, the method comprises the steps that hot water pre-extraction is conducted on bagasse, laccase and an interbody are adopted to conduct first-stage laccase biotreatment on the hot water pre-extracted bagasse, the bagasse pulp obtained after first-stage laccase biotreatment is ground, then the filtrate obtained after first-stage laccase biotreatment is adopted to conduct second-stage laccase biotreatment on the ground pulp. The reaction conditions of the method are moderate, the unique product is water, no chemical agent is not used in the whole technological process, the environmental pollution problem is solved, the prepared natural coloredmechanical pulp of the bagasse has good water filtering performance, and the physical properties of prepared paper are high.

Owner:GUANGXI UNIV

Dyed paper as well as preparation method and application thereof

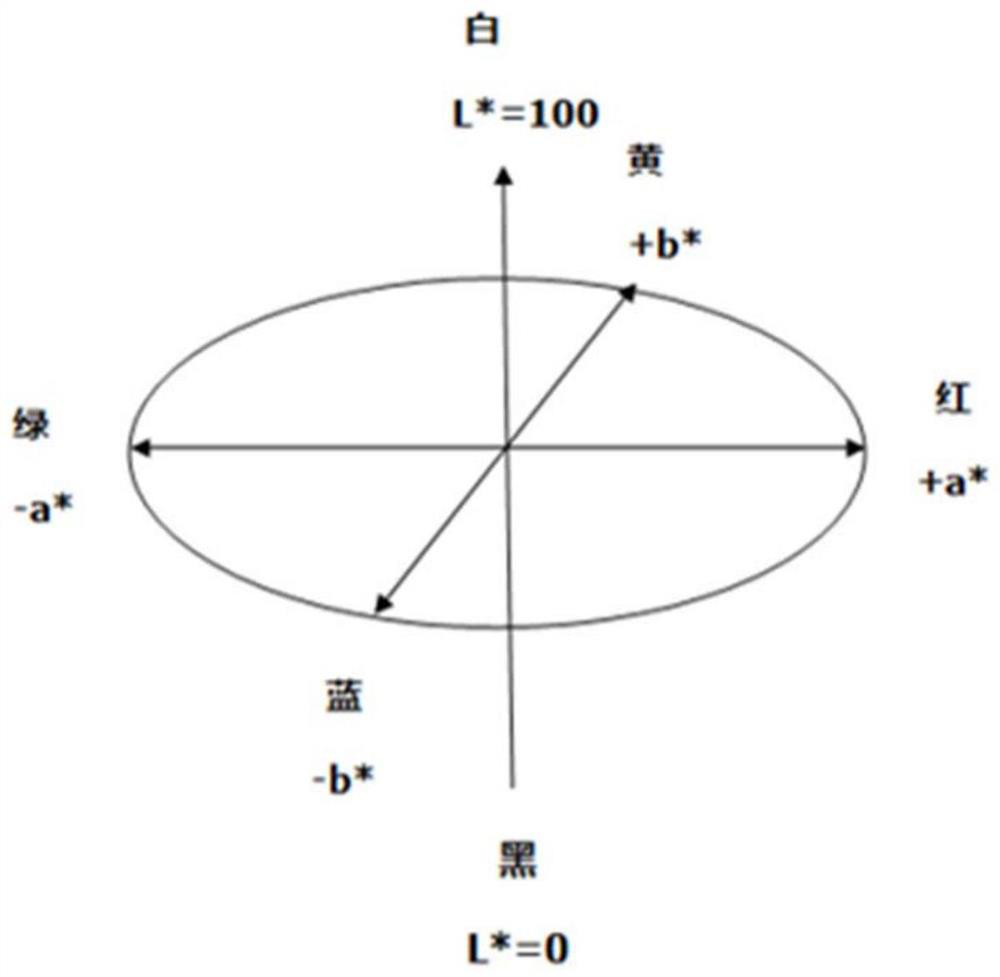

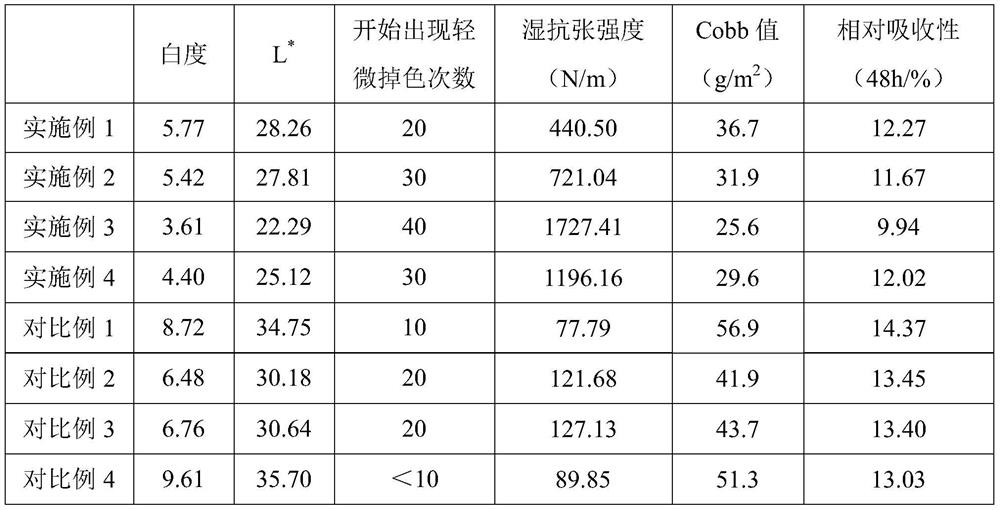

ActiveCN111926613AReduce pollutionReduce consumptionWater-repelling agents additionPaper coatingWet strengthViscose fiber

The invention discloses dyed paper as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) shredding natural-color bamboo pulp and natural-color bagasse pulp, adding the shredded natural-color bamboo pulp and natural-color bagasse pulp into water, fully soaking, defibering, fishing out, squeezing to obtain mixed pulp I, adding viscose fibers and a dye, adding water to adjust the concentration of the pulp to 10 + / -2 mass%, and grinding the pulp until the beating degree is 15-30 degrees SR to obtain dyed pulp; (2) heating the dyed pulp to 45-80 DEG C, then sequentially adding a color fixing agent, a wet strength agent and a sizing agent, and continuously stirring uniformly to obtain mixed pulp II; carrying out papermaking to obtain wet paper sheets; and finally, squeezing, drying and calendaring the wet paper sheets to obtain the dyed paper. A series of color fixing agents, wet strength agents and sizing agents are adopted underthe heating condition, paper pulp coloring is facilitated, the dye-uptake rate and color uniformity of paper are improved, paper de-coloration is reduced, dyed paper is endowed with an excellent mechanical performance, and industrialization can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

Stable-quality zirconia-supported air filter paper for automobiles, and making method thereof

InactiveCN103993509ASmall filtration resistanceQuality improvementVegetable material additionFiltration separationPorosityAir filter

The invention discloses a stable-quality zirconia-supported air filter paper for automobiles. The stable-quality zirconia-supported air filter paper is made by using the following raw materials, by weight, 38-41 parts of a bagasse pulp, 54-58 parts of a broad leaf wood pulp, 1-2 parts of sweetcane bark, 2-4 parts of carboxymethyl cellulose, 0.4-0.6 parts of polyoxyethylene fatty alcohol ether, 6-8 parts of liquid silicone rubber, 2-3 parts of attapulgite, 2-3 parts of zirconia, 0.6-0.8 parts of cassava starch, 0.4-0.6 parts of calcium chloride, 0.2-0.3 parts of sesbania gum, 2-4 parts of glycerin, 5-6 parts of alkyl ketene dimer, 1-2 parts of an assistant and a proper amount of water. The zirconia-supported air filter paper has the characteristics of ventilation, small filtering resistance and stable quality; the addition of zirconia and the like makes the air filter paper have a good adsorption effect, a high temperature resistance and stable properties; and the addition of plant particles and the assistant increases the porosity of the filter paper, realizes uniform dispersion of adsorbed components, and improves the filter performance.

Owner:蔡军

Method for bioenzyme-assisted chlorine dioxide bleaching of bagasse pulp

The invention relates to a method for bioenzyme-assisted chlorine dioxide bleaching of bagasse pulp. The method comprises the following steps: (1) performing hemicellulase pretreatment; (2) performing ligninase pretreatment; (3) performing chlorine dioxide bleaching. According to the method, hexenuronic acid and hemicellulose in unbleached bagasse pulp are removed through the hemicellulase pretreatment of the unbleached bagasse pulp, so that more residual lignin is exposed; lignin exposed on the fiber surface is removed by using ligninase, so that less chlorine dioxide is used in a chlorine dioxide bleaching section and AOX (adsorbable organic halogen) generated in the bleaching process is reduced; after the bagasse pulp is subjected to bioenzyme pretreatment, the consumption of chlorine dioxide is saved by 30%-50% and the forming amount of AOX is reduced by 40%-60%.

Owner:GUANGXI UNIV

Method for improving bagasse alkaline cooking effect through wet process with CEH bleaching waste liquor

InactiveCN101545226AReduce the amount requiredImprove pulping performancePulp liquors combustionWashing/displacing pulp-treating liquorsLiquid ratioOrganic chloride compound

The invention discloses a method for wet-process pile-up of bagasse in pretreatment of bagasse alkaline cooking, wherein CEH bleaching wastewater of bagasse pulp replaces clear water and is recycled in the process of the wet-process pile-up of the bagasse, and then the bagasse alkaline cooking is performed. The method comprises the following process steps: spraying bleaching washing wastewater from C, E and H three sections on bagasse piles in piled up in a stock ground until percolating water flows out of a bottom layer; after 10 to 20 piles are sprayed, discharging, conveying, washing and dehydrating the bagasse, and then conveying the bagasse into a pulp digester; and digesting the bagasse under the condition that the dosage of NaOH is between 14 and 16 percent, the dosage of anthraquinone is between 0.01 and 0.3 percent, the weight liquid ratio is 1:3-6, the digesting temperature is between 155 and 160 DEG C, the temperature is raised for 70 to 110 minutes, and the temperature is kept for 60 to 90 minutes. The method can improve the yield of the bagasse pulp by 2 to 5 percentage points, reduce organic chloride by 22 to 31 percent, and reduce the water consumption by one ton of the pulp by 8 to 15 m<3>.

Owner:KUNMING UNIV OF SCI & TECH

Method for dissolving cellulose

The invention discloses a method for dissolving cellulose, characterized by: using at least one from the group consisting of wood pulp, cotton pulp, hemp pulp, bamboo pulp, bagasse pulp, grass fibered pulp, cellulose non-woven fabric or steam exploded cellulose pulp as cellulose raw material, uniformly stirring the cellulose raw material, NaOH and water at a temperature of -15-50 DEG C to obtain a cellulose solution. The prepared cellulose concentrated solution has good spinnability and film forming property. The method breaks through a dissolution method of traditional gluing technology, does not relate to carbon disulfide and other substance causing serious environmental pollution, and is green and environmentally friendly. According to the invention, the cellulose raw material can be directly rapidly dissolved at room temperature, without heating or precooling a solvent. The method has the advantages of saving energy, and reducing energy consumption. By using raw materials having low cost, the method has the advantages of simple operation, small investment, high productivity, and is easy to realize large-scale industrial production.

Owner:NANHUA UNIV +1

Sound-absorbing waterproof PVC(polyvinyl chloride) wallpaper base paper and preparation method thereof

InactiveCN104452421AGood physical propertiesEasy post-processingCoatings with pigmentsCoatingsFiberAdhesive

The invention relates to wallpaper base paper, in particular to a sound-absorbing waterproof PVC(polyvinyl chloride) wallpaper base paper and a preparation method thereof. The base paper is made from the following raw materials in parts by weight: 18-22 parts of bleached bagasse pulp, 30-40 parts of chemical bleached bamboo fiber pulp, 20-30 parts of poplar chemi-mechanical pulp, 3-5 parts of Fischer-tropsch wax of which the solid content is 20-25%, 10-13 parts of trepanned expanded perlite of 600-800 meshes, 1-1.5 parts of sodium borate, 1-2 parts of nekal, 1-2 parts of an aqueous antifoaming agent, 5-7 parts of a PAE(polyarylether) wet strength agent, 12-15 parts of environment-friendly pigment of 800-1250 meshes, 10-15 parts of an adhesive and 3-5 parts of an addition agent. For the base paper disclosed by the invention, the sodium borate is added in the process of pulping wood pulp, so that the water resistant capacity and the antiseptic capacity of the paper are improved; materials such as Fischer-tropsch wax aqueous emulsion and the trepanned expanded perlite are also combined, so that the semi-finished base paper has certain efficacies of water resistance, sound absorption and noise isolation; compound surface coating liquid on the surface of the semi-finished base paper can be effectively coated, the glued base paper is non-toxic, environment-friendly, stiff, smooth and level, the physical properties are good, the follow-up processing is facilitated, and basis is established for producing high-quality wallpaper finished products.

Owner:ANHUI SOYA DECORATIVE MATERIALS

High-intensity filling material paper and preparation method thereof

InactiveCN106868925AHigh strengthReduce manufacturing costPaper coatingReinforcing agents additionCelluloseFiber

The invention discloses high-intensity filling material paper, which is prepared from the following raw materials in parts by weight: 20 to 30 parts of needlebush pulp, 20 to 30 parts of bagasse pulp, 40 to 60 parts of composite filling materials, 3 to 5 parts of sugar powder and 1 to 5 parts of auxiliary ingredients, wherein the composite filling material contains filling ingredients, fiber ingredients and retention aids. The invention also discloses a preparation method of the high-intensity filling material paper. The filling ingredients, the fiber ingredients and the retention aids are matched to be used as the slurry composite slurry; a cellulose-sugar compound is formed through sugar solution seepage on the surface of wet paper; the paper intensity is enhanced; the production cost is reduced; the preparation method is simple; the industrial production is facilitated.

Owner:芜湖市哈贝纸业有限公司

Film coatedbasepaper and bagasse pulp for film coatedbasepaper

InactiveCN106638109AHigh whitenessHigh viscosityPulp bleachingNon-woody plant/crop pulpBlack liquorThermal insulation

The invention discloses a bagasse pulp for a film coatedbasepaper. The bagasse pulp is obtained by the following steps that: step 1, after drying the bagasse, dust and pith are removed from the bagasse, and ammonia, alkali and anthraquinone are added to the bagasse as cooking agents, distilled water is added to immerse the bagasse, and a mixed bagasse is obtained; step 2, the mixed bagasse is put in a digester, temperature is raised to 100-150 DEG C to boil the mixed bagasse, cooling, washing and concentrating are conducted to obtain a coarse bagasse pulp; step 3, hydrogen peroxide and modified zeolite are added to the bagasse pulp, a first adding of an alkali, a first heating to 50-90 DEG C, a first thermal insulation, a second adding of an alkali, a second heating to 70-100 DEG C, and a second thermal insulation are conducted, a bleached bagasse pulp is obtained; step 4, the bleached bagasse pulp is diluted, washed and purified to neutral, and is concentrated to obtain the bagasse pulp for film coatedbasepaper; the invention also discloses a film coatedbasepaper. Base slurry of the film coatedbasepaper is obtained by boiling the bagasse using ammonia method, the cost-recovering of black liquor is reduced, the modified zoelite is used as stabilizer, the efficiency of bleaching is improved, the paper pulp process design is reasonable, and the economic benefits of the film coatedbasepaper is improved.

Owner:芜湖市哈贝纸业有限公司

Abrasion-resistant waterproof bobbin paper and preparation method thereof

InactiveCN110820413AEasy to degradeReduce pollutionInorganic fibres/flakesWater-repelling agents additionCelluloseFiber

The invention discloses abrasion-resistant waterproof bobbin paper and a preparation method thereof. The abrasion-resistant waterproof bobbin paper is composed of the following components in parts byweight: 50-110 parts of wastepaper fibers, 50-110 parts of fluff fibers, 88-125 parts of bagasse pulp, 50-70 parts of clear water, 11-17 parts of silicon dioxide, 1-9 parts of melamine formaldehyde resin, 2-13 parts of calcium carbonate, 3-8 parts of cationic starch, 3-11 parts of polyacrylamide, 1-7 parts of an acrylic polyol and 4-9 parts of carboxymethyl cellulose. The abrasion-resistant waterproof bobbin paper is prepared by using the bagasse pulp, the fluff fibers and the wastepaper fibers as raw materials, so that the production costs are greatly reduced; the method does not use log woodpulp and all use the waste for reproduction, thereby reducing the pollution to the environment, the formed bobbin paper is more easily degraded after use, and the environment is protected; the fiberraw materials used in the method are rich in fiber, and after the raw materials are used to prepare the paper, the paper has excellent compression and tensile resistance, bending degree, and water resistance; and the polyacrylamide, the acrylic polyol and the carboxymethyl cellulose are used as sizing materials, so that the water resistance and abrasion resistance are greatly improved.

Owner:YIWU YINAN PAPER IND CO LTD

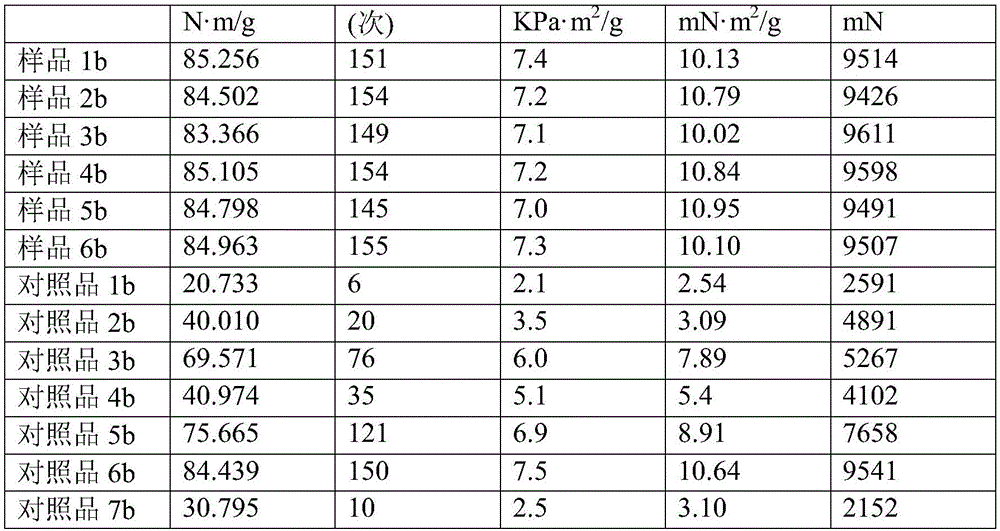

Paper cup cover and manufacturing technology thereof

ActiveCN105780582AReduce crystallinityEasy accessNon-macromolecular organic additionPaper/cardboardManufacturing technologySlurry

The invention discloses a paper cup cover and a manufacturing technology thereof. The paper cup cover comprises, by mass, 90-95 parts of bagasse pulp, 0.5-1 part of tea polyphenol, 0.5-1 part of sodium alginate, 0.5-1 part of titanium dioxide, 3-8 parts of diatomite and 0-1 part of water. A manufacturing technology of the paper cup cover includes the steps of (1), dissolving the sodium alginate into water so as to obtain a sodium alginate water solution; (2), pulping and defibrinating the bagasse pulp; (3), under the condition of stirring, adding the sodium alginate water solution obtained in the step (1) into slurry obtained in the step (2) with uniformly mixing; (4), under the condition of stirring, sequentially adding the titanium dioxide, the diatomite and the tea polyphenol with uniformly mixing; (5), injecting a mixture into a mould of the cup cover and heating to dry for 2-3 minutes at 185-200 DEG C in the pressing and closing state of the mould; (6), trimming edges by an edge trimmer. The paper cup cover is energy saving, environment friendly and excellent in strength performance.

Owner:香河合益包装机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com