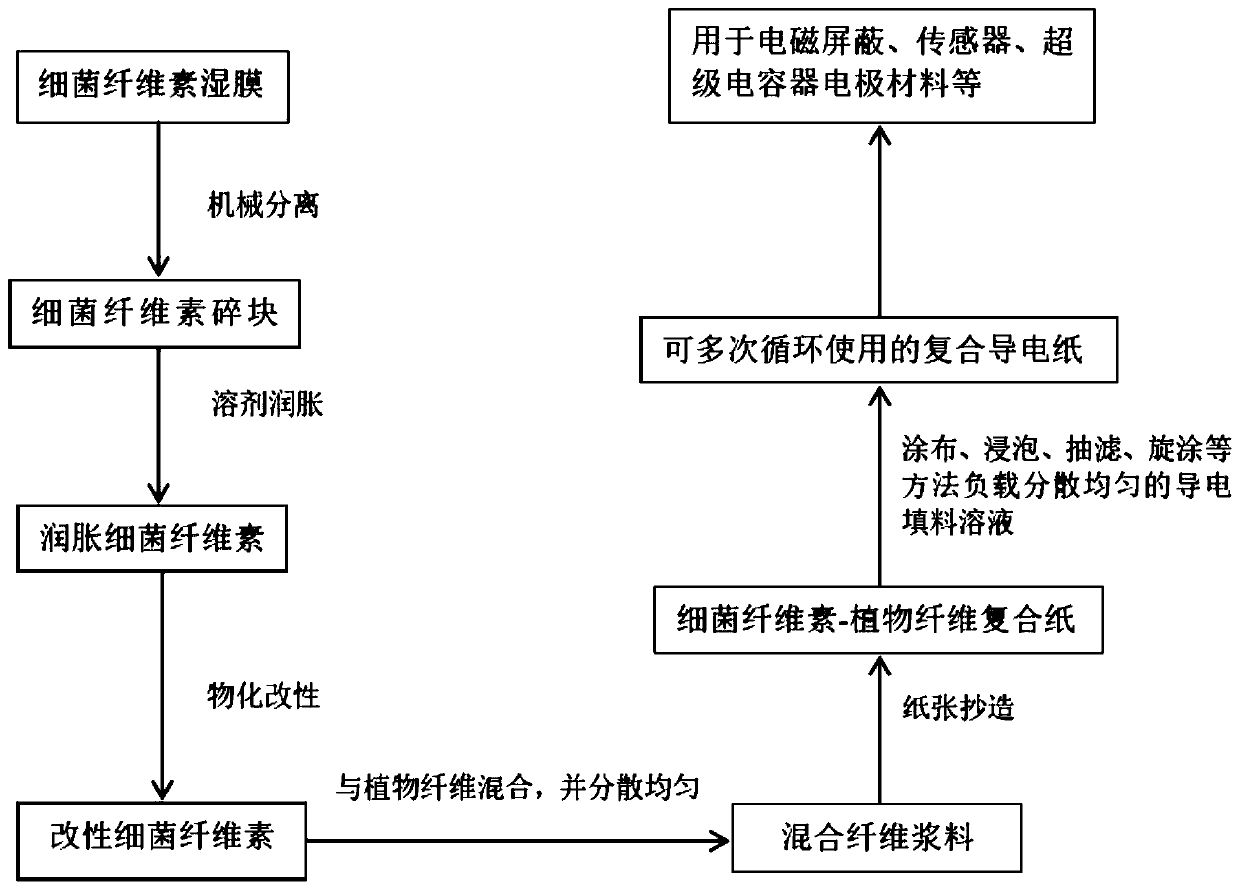

Bacterial cellulose-plant fiber composite conductive paper as well as preparation method and application thereof

A technology of bacterial cellulose and plant fibers, which is applied in non-fibrous pulp addition, fiber raw material treatment, hybrid capacitor electrodes, etc. The effect of improving the specific capacitance retention rate, enhancing the uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Bacterial cellulose is secreted by Glucoacetobacter xylinus. The main components of the bacterial culture medium are: 50 mL of fermented coconut water, 0.1 g of ammonium sulfate, 0.1 g of magnesium sulfate, 0.1 g of potassium dihydrogen phosphate, 3.0 g of sucrose, 50 mL of distilled water, adjust the pH value to 4.1 with NaOH, and sterilize at 100 ° C for 5 min . A static fermentation culture method is adopted, the culture medium is placed in a 250 mL beaker, inoculated with 5% (V / V) gluconacetobacter, and the temperature is 30° C. for static culture for 6 days. The obtained bacterial cellulose wet film had a solid content of 1.5 wt%.

[0037] Cut 30 g of bacterial cellulose (BC) wet film into small pieces of 1 cm × 1 cm × 0.8 mm, and crush it 3 times in the instant mode with a laboratory mixer. The disintegrated BC and 60mL NaOH solution (1M) were mixed and poured into an Erlenmeyer flask, and activated with magnetic stirring at room temperature for 3h. Mix it with...

Embodiment 2

[0041] Bacterial cellulose is secreted by Glucoacetobacter xylinus. The main components of the bacterial culture medium are: 50 mL of fermented coconut water, 0.1 g of ammonium sulfate, 0.1 g of magnesium sulfate, 0.1 g of potassium dihydrogen phosphate, 3.0 g of sucrose, 50 mL of distilled water, adjust the pH value to 4.1 with NaOH, and sterilize at 100 ° C for 5 min . A static fermentation culture method is adopted, the culture medium is placed in a 250 mL beaker, inoculated with 5% (V / V) gluconacetobacter, and the temperature is 30° C. for static culture for 6 days. The obtained bacterial cellulose wet film had a solid content of 1.5 wt%.

[0042] Cut 30 g of bacterial cellulose (BC) wet film into small pieces of 1 cm × 1 cm × 0.8 mm, and crush it 3 times in the instant mode with a laboratory mixer. Suspend the disintegrated BC in 100 mL of aqueous solution containing 0.48 g of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO) and 3 g of sodium bromide, by adding NaCl...

Embodiment 3

[0047] Bacterial cellulose is secreted by Glucoacetobacter xylinus. The main components of the bacterial culture medium are: 50 mL of fermented coconut water, 0.1 g of ammonium sulfate, 0.1 g of magnesium sulfate, 0.1 g of potassium dihydrogen phosphate, 3.0 g of sucrose, 50 mL of distilled water, 5 mL of diethylenetriamine, and sterilized at 100°C for 5 minutes. A static fermentation culture method is adopted, the culture medium is placed in a 250 mL beaker, inoculated with 5% (V / V) gluconacetobacter, and the temperature is 30° C. for static culture for 6 days. The obtained diethylenetriamine-modified bacterial cellulose wet film had a solid content of 2.1 wt%.

[0048] Diethylenetriamine-modified bacterial cellulose (Bacterial Cellulose, BC) wet film 30g was cut into small pieces of 1cm × 1cm × 0.8mm, and crushed 3 times in the instant mode by a laboratory mixer. After the reaction is completed, the product is filtered and washed, mixed with the secondary fiber pulp at a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com