Patents

Literature

54results about How to "Improve pulping performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

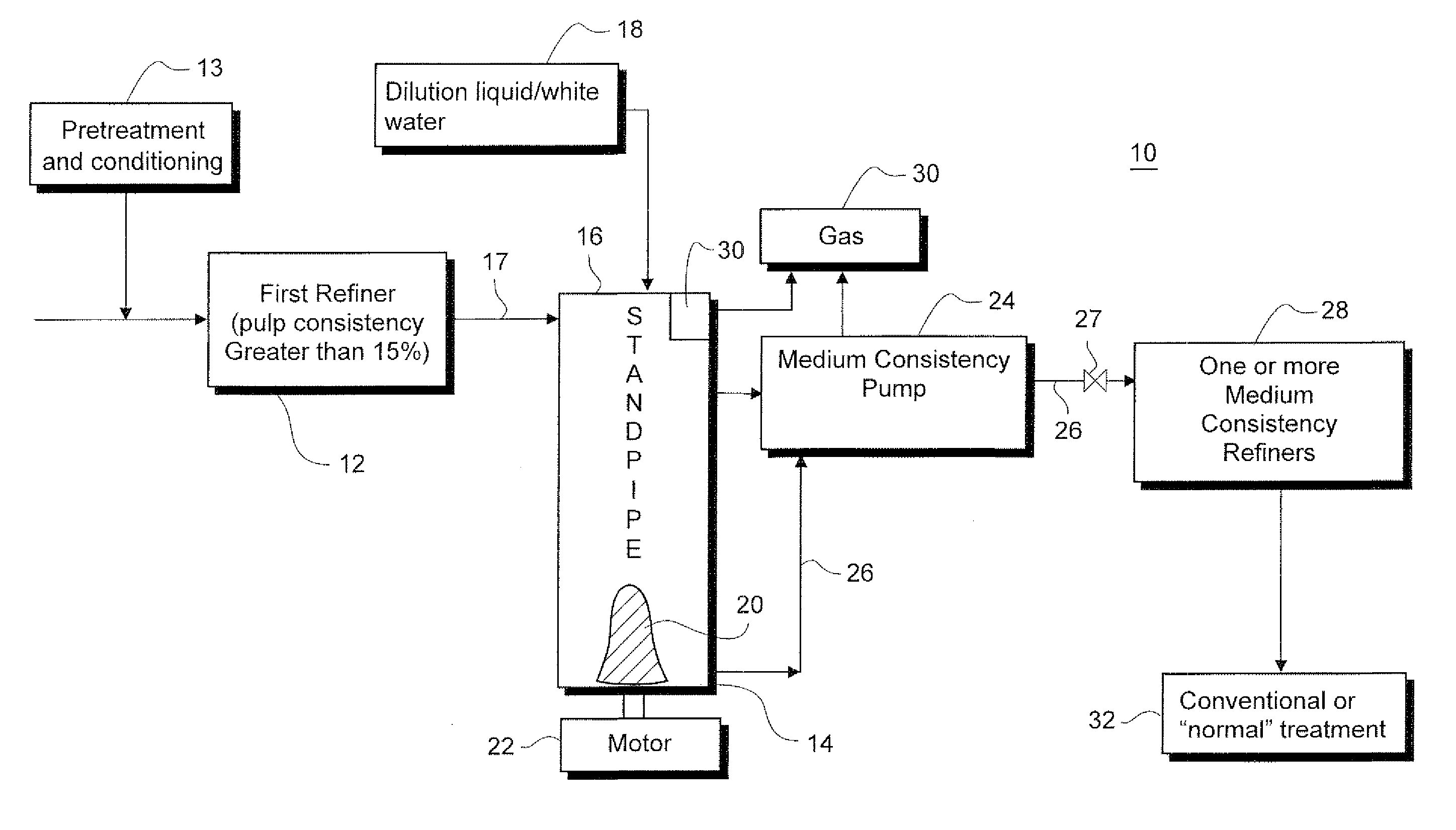

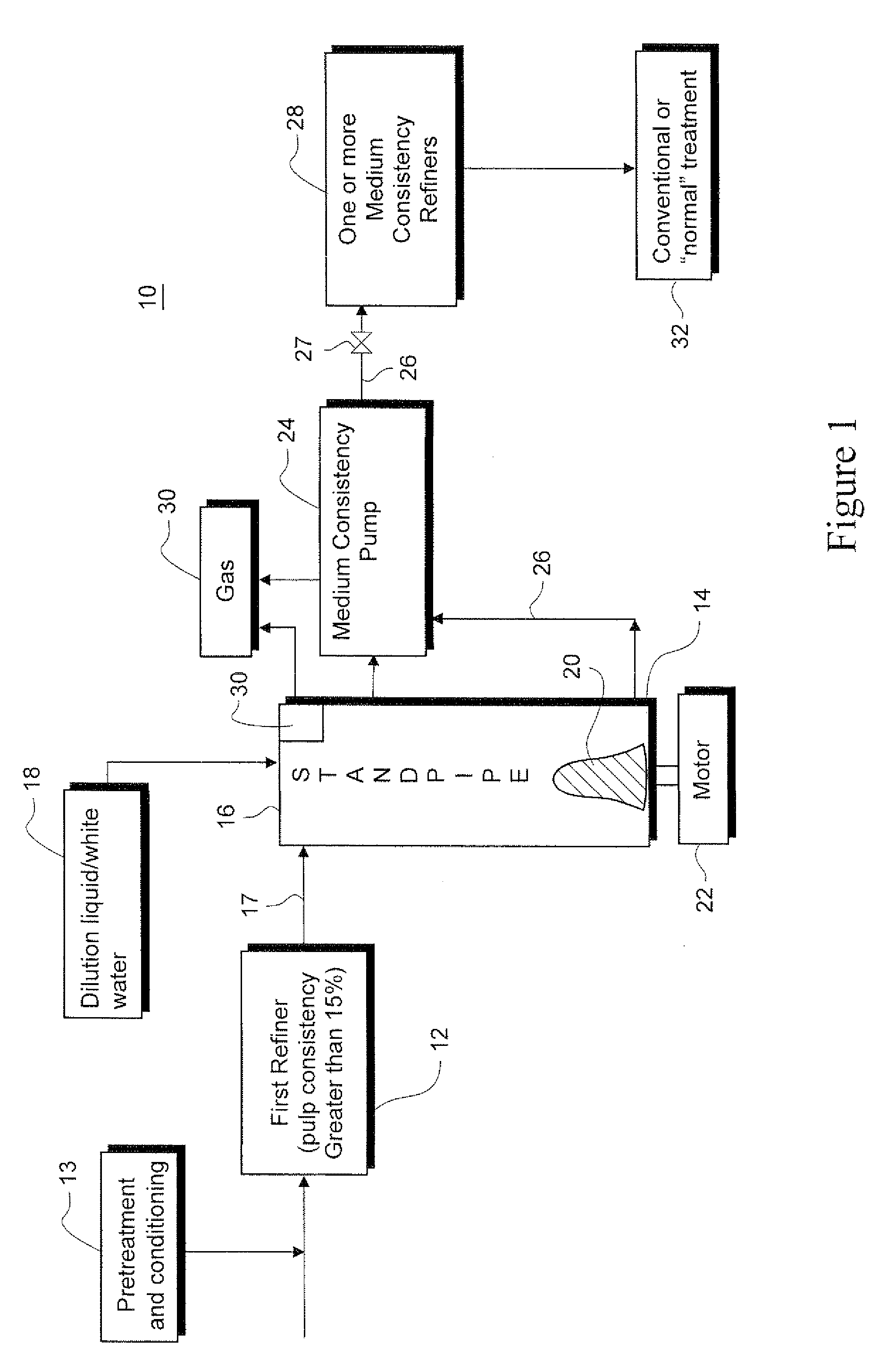

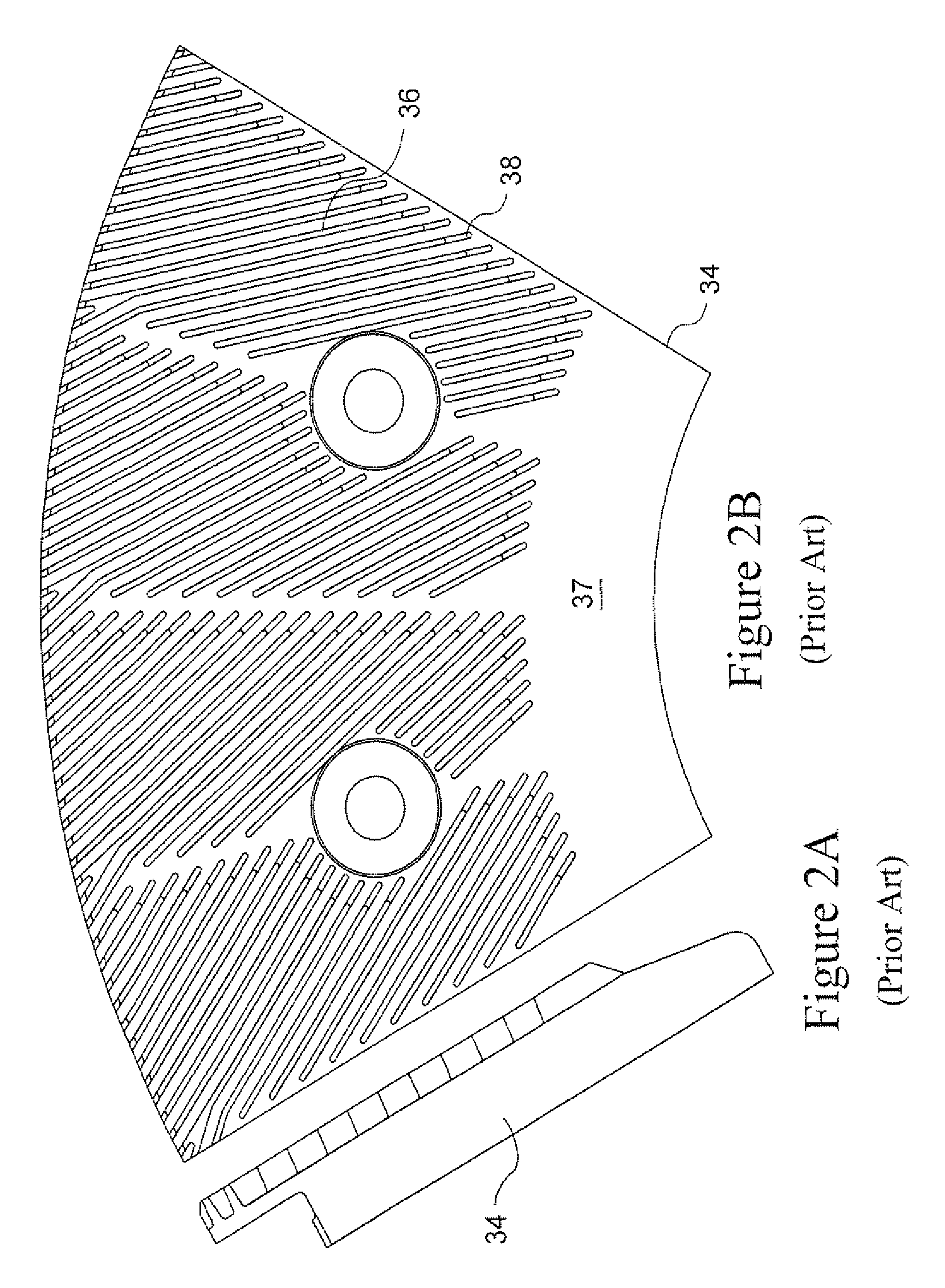

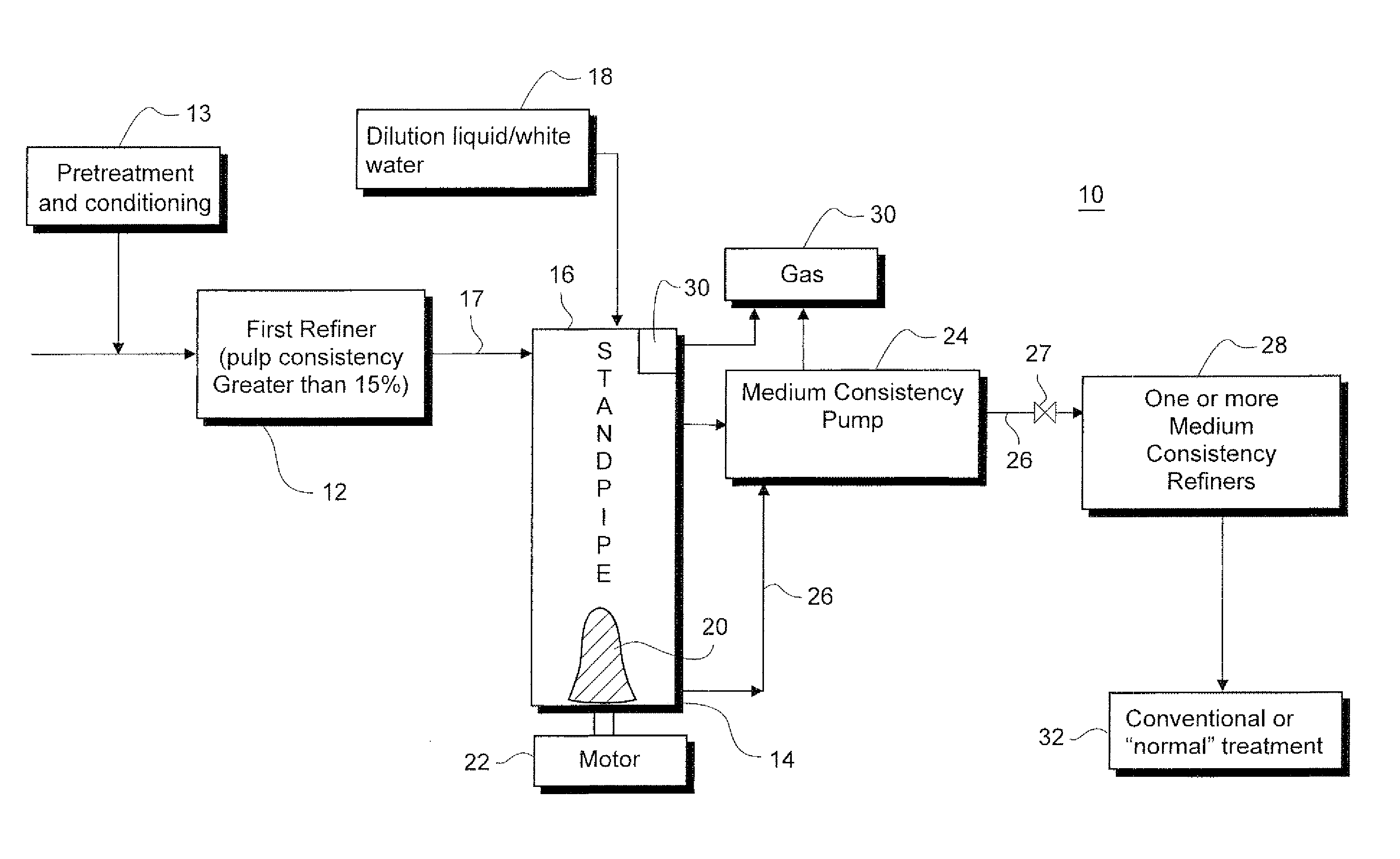

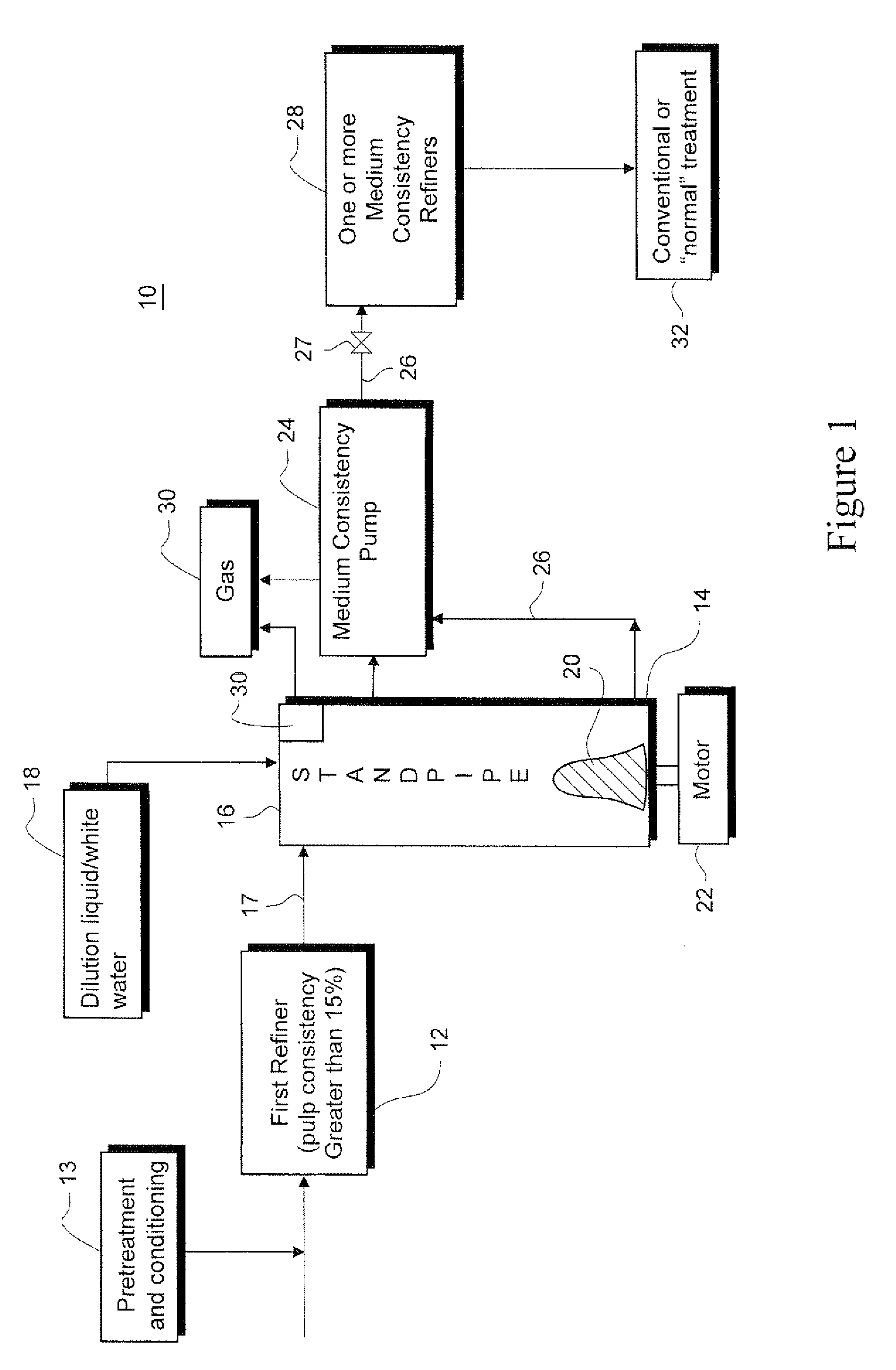

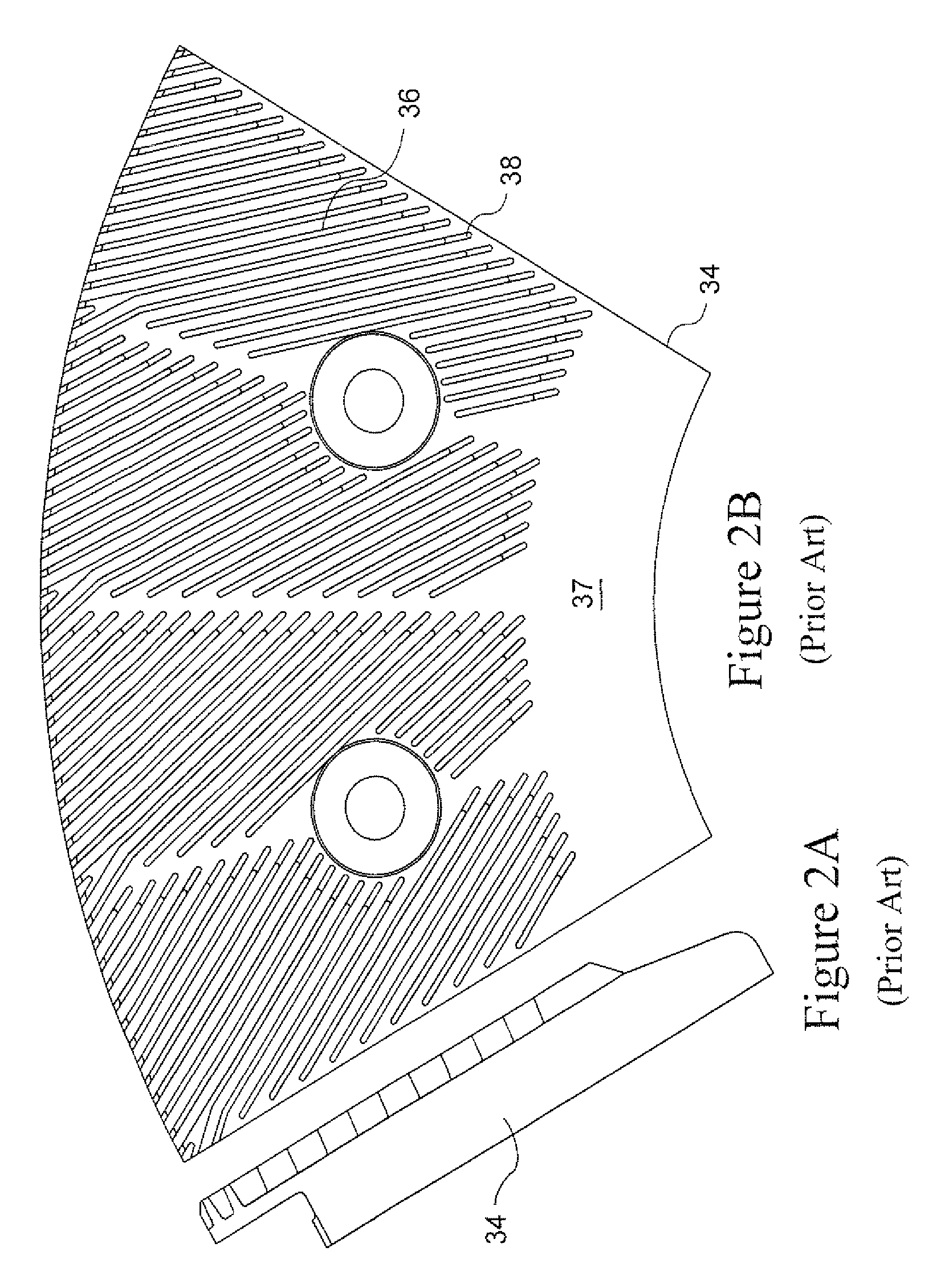

Medium consistency refining method of pulp and system

ActiveUS20090288789A1Improving pulp quality developmentReduce complexityPulp beating/refining methodsMultistage pulping processMaterials science

A thermomechanical pulping method including: refining pulp with a high consistency refining stage, and a medium consistency refining stage processing the refined pulp discharge from the high consistency refining stage. Chemical pretreatments for improving pulp quality development during medium consistency refining can be optionally added at the pressurized chip press, fiberizer pre-refining step, primary high consistency refining step, and / or the standpipe feeding the medium consistency refiner.

Owner:ANDRITZ INC

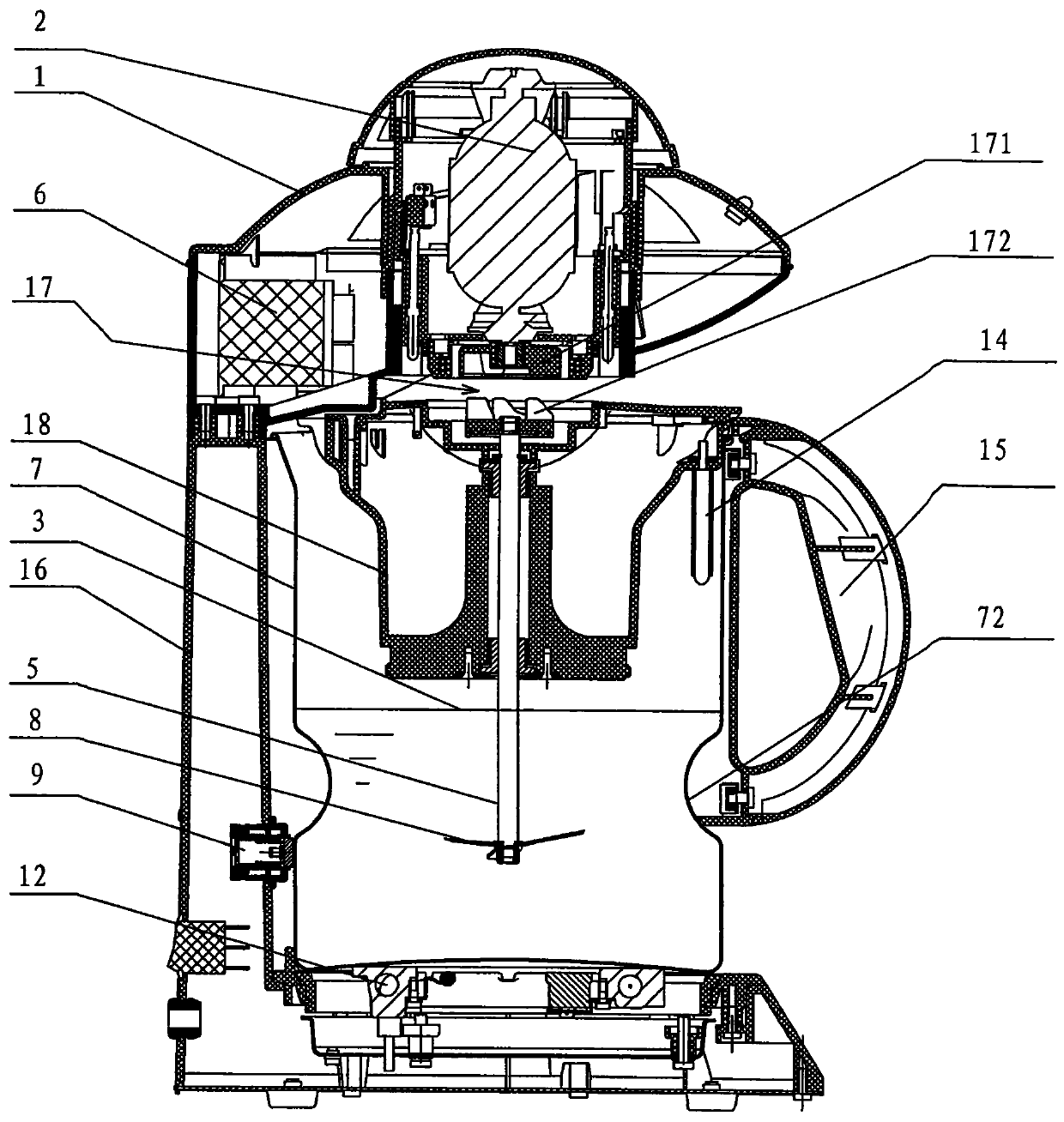

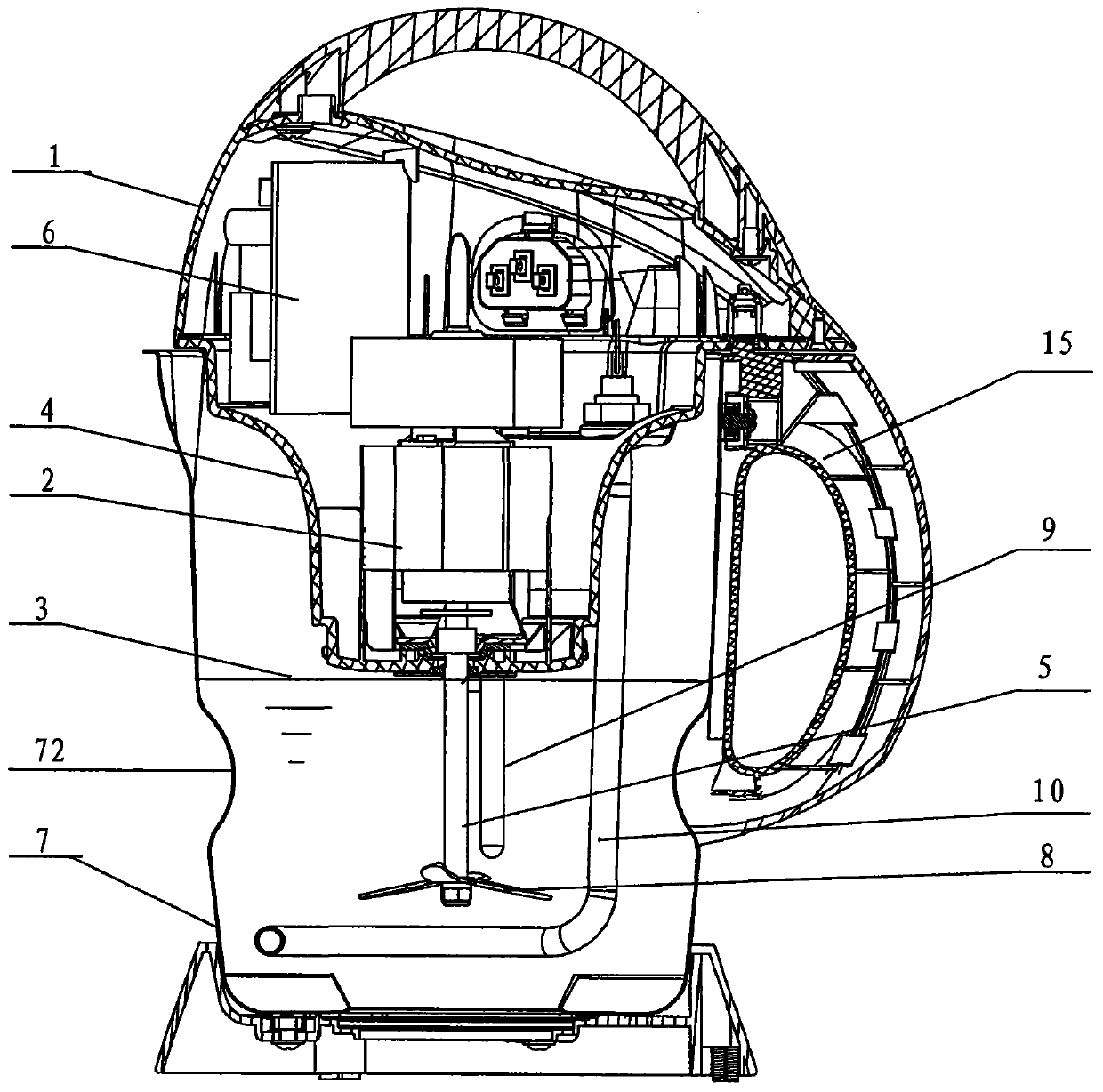

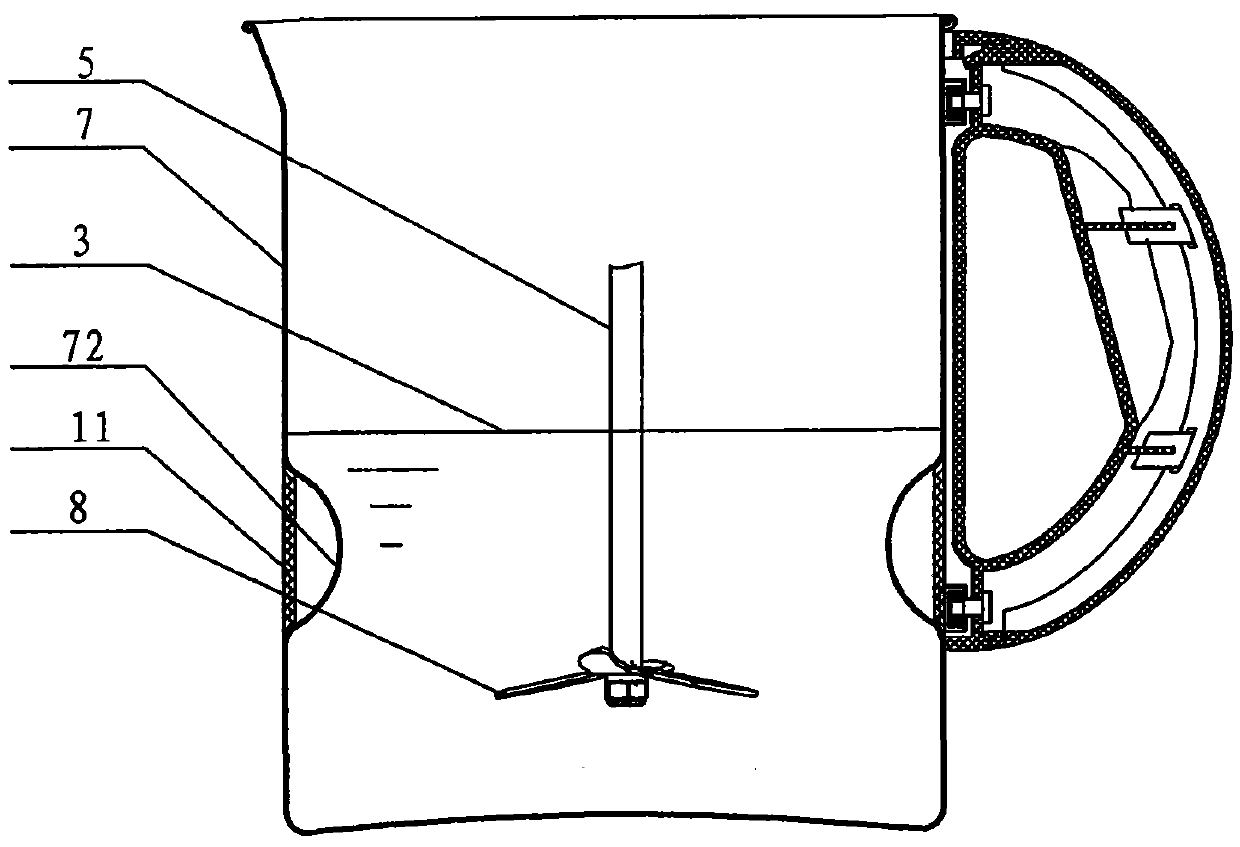

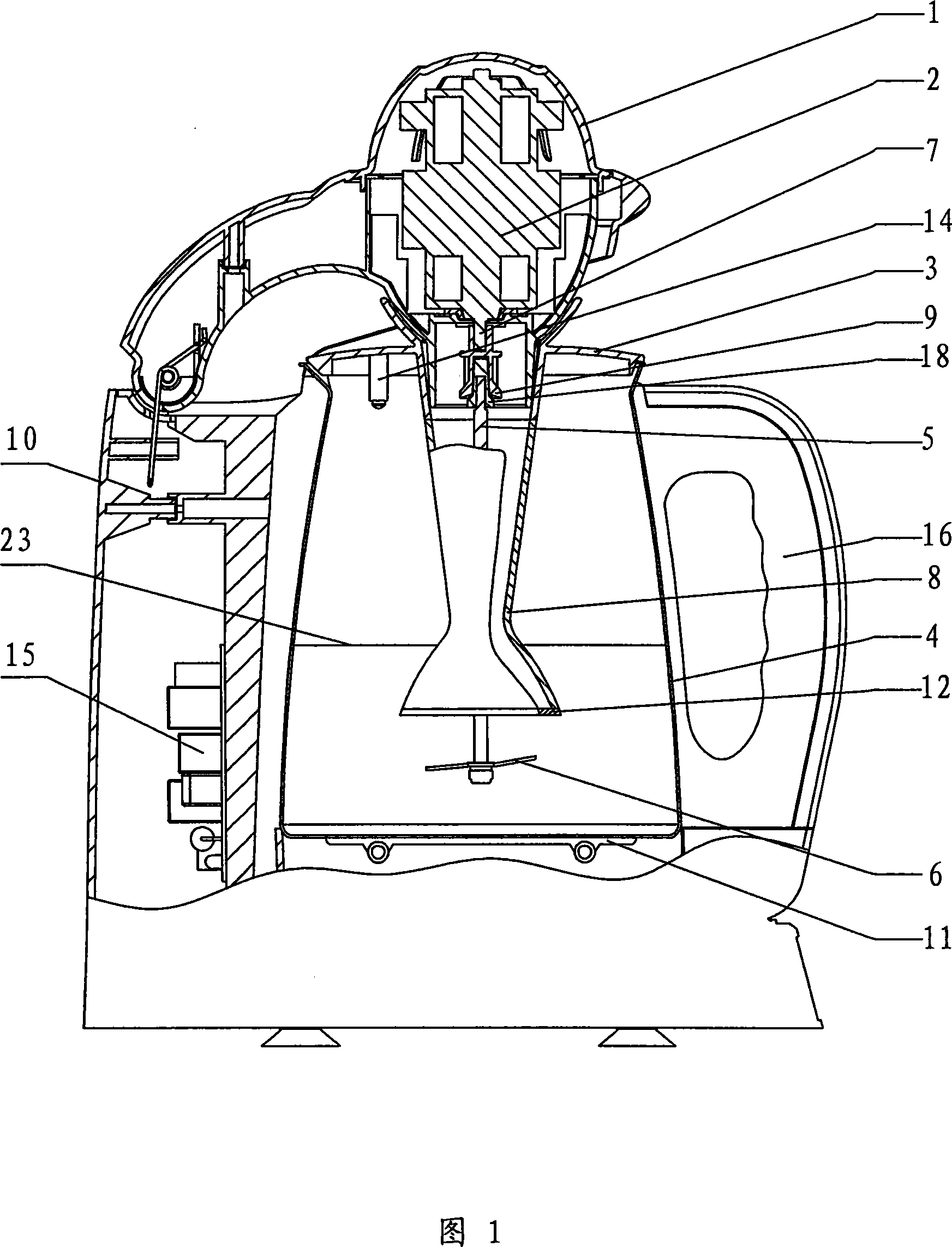

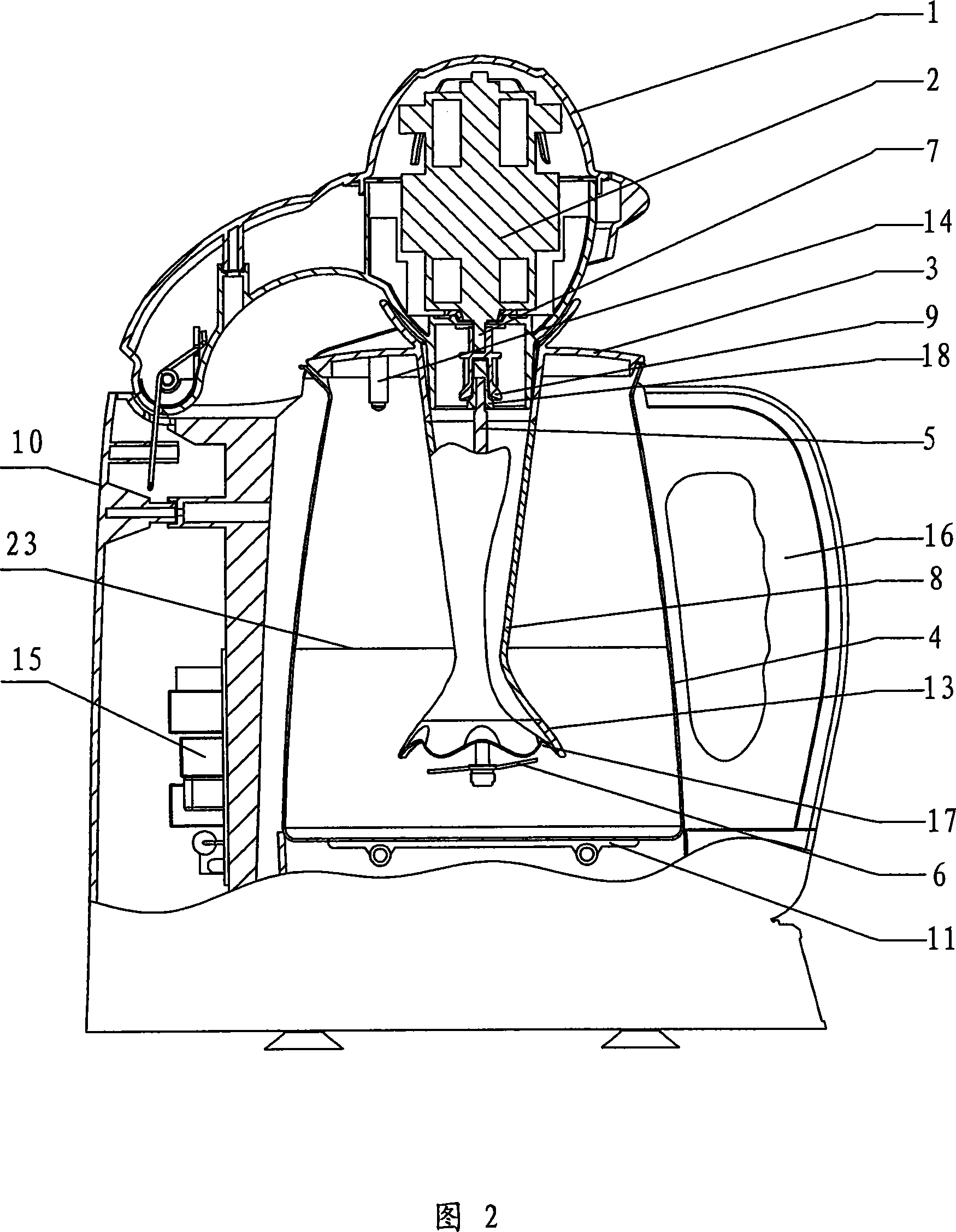

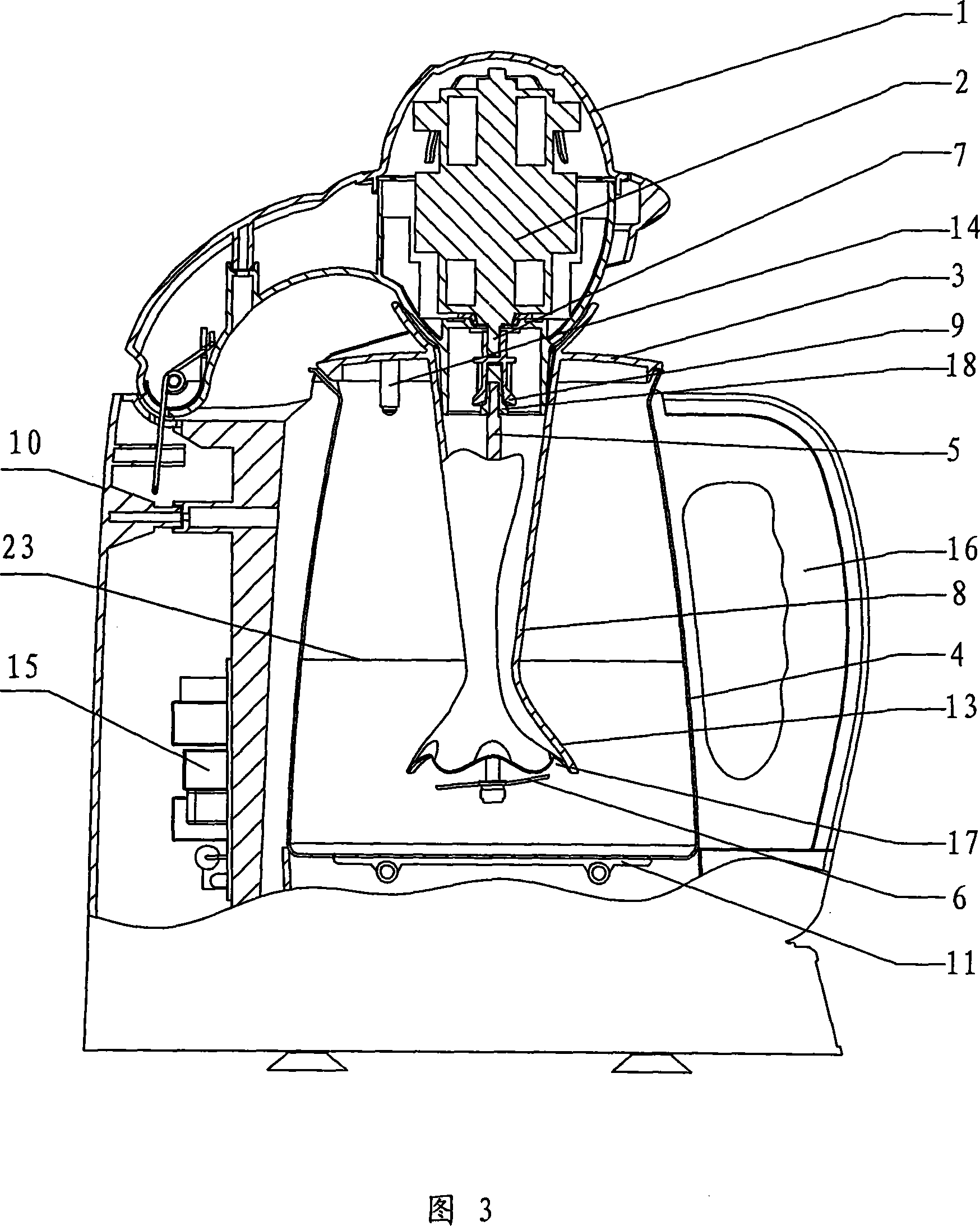

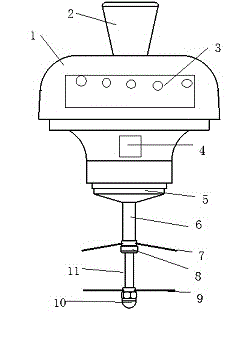

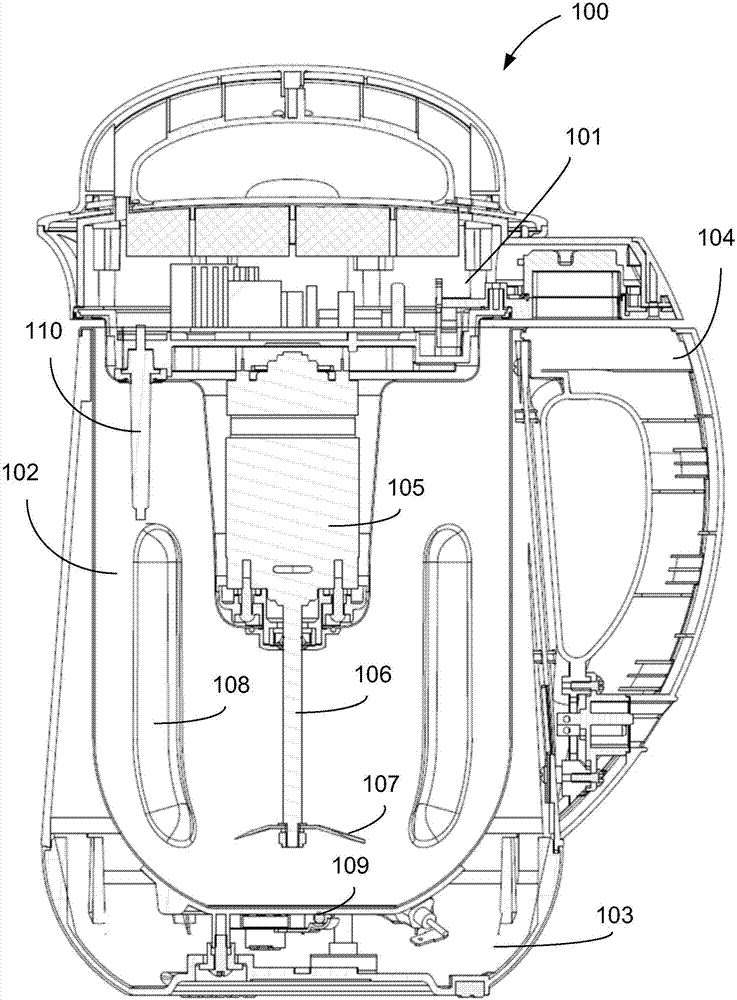

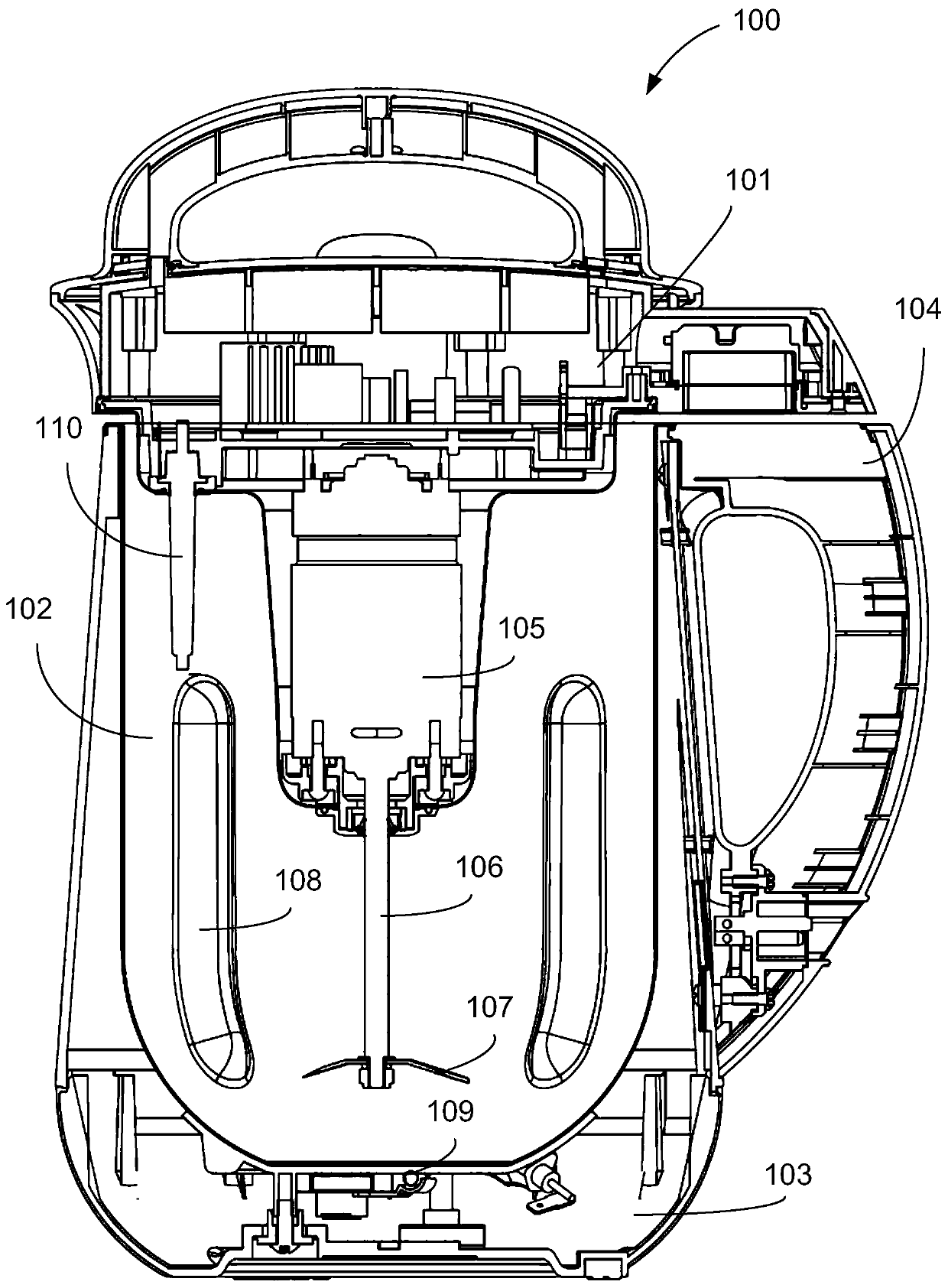

Household soya-bean milk maker

InactiveCN101028170AFully boiledEffective cookingBeverage vesselsFood preparationCouplingEngineering

A domestic soybean milk maker is composed of a cup body with turbolating ring on its inner surface and cover, a main body, a machine head on said cup body and with upper and lower covers, a motor in said machine head, an arbor extended in said cup body, an axle coupling for coupling motor shaft with arbor, breaking cutter installed to front end of arbor, and a control circuit board.

Owner:SHANDONG JOYOUNG HOUSEHOLD ELECTRICAL APPLIANCES

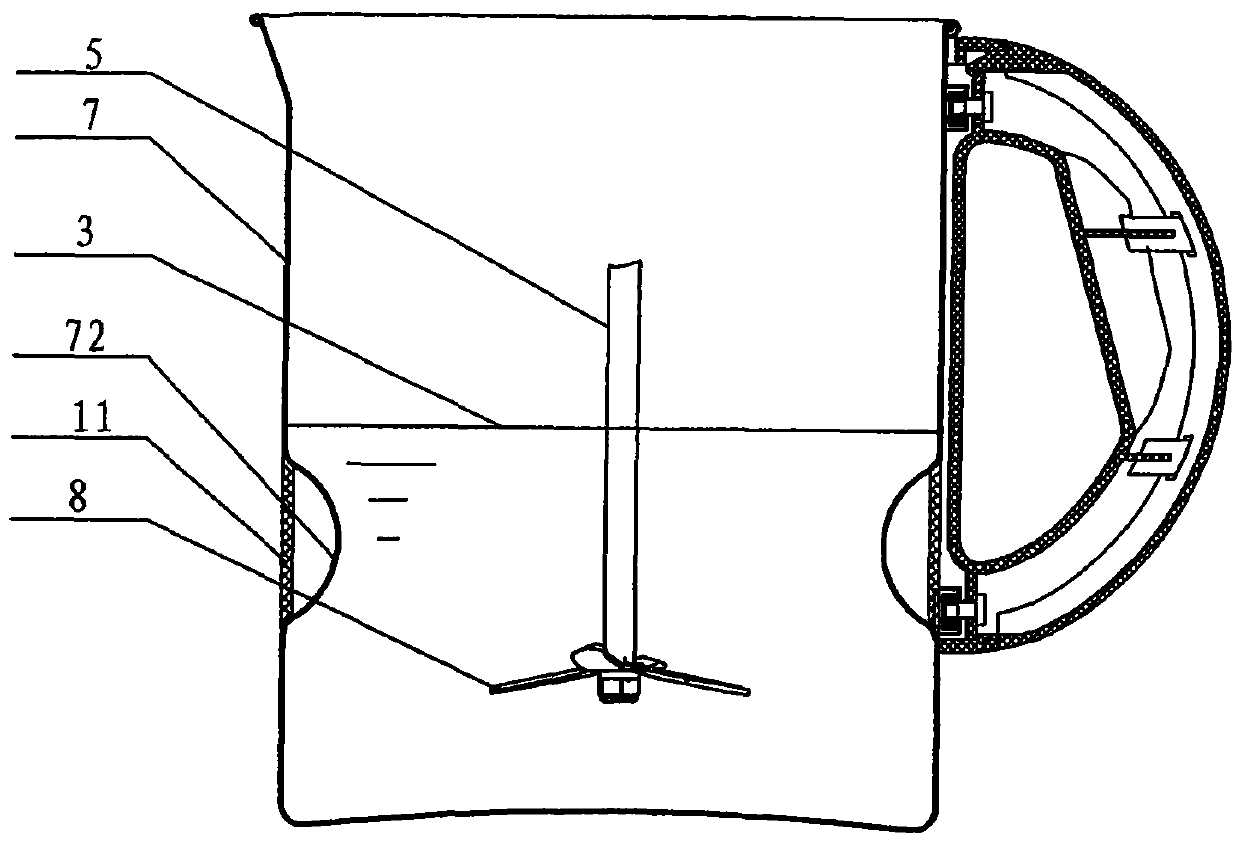

Household souya-bean milk maker

ActiveCN101028169AFully boiledEffective cookingBeverage vesselsFood preparationSlurryControl circuit

A domestic soybean milk maker is composed of a cup body with turbolating ring on its inner surface, a machine head on said cup body and with upper and lower covers, a motor in said machine head, an arbor extended in said cup body, breaking cutter installed to front end of arbor, and a control circuit board.

Owner:JOYOUNG CO LTD

Pulp preparing method for increasing bagasse oxygen-alkali cooking effect

InactiveCN102587178AIncreased cooking fine pulp yieldHigh whitenessPulp bleachingRaw material pretreatmentKappa numberWater consumption

The invention discloses a pulp preparing method for increasing bagasse oxygen-alkali cooking effect, comprising the steps of replacing clear water with bleaching effluents of Eop section and P section of bagasse oxygen-alkali pulp, reusing in wet stockpiling process of bagasse, carrying out oxygen-alkali cooking on the bagasse, washing, selecting, screening and bleaching to finally obtain the pulp. Compared with the yield of pulp obtained through the oxygen-alkali cooking of the bagasse subjected to wet stockpiling and sprayed by using the clear water and the yield of pulp obtained through oxygen-alkali cooking of the bagasse not subjected to wet stockpiling, the pulp obtained by utilizing the method has the advantages that the yield is respectively increased by 1-3 percentage points and 2-6 percentage points and the whiteness of unbleached pulp is increased by 1-3% ISO and the viscosity is increased by 40-110mL / g under the circumstance that pulp kappa numbers are close; the pollution load of middle-stage effluents can be decreased by 20-40%; and the water consumption per ton of pulp is decreased by 5-18m<3>.

Owner:KUNMING UNIV OF SCI & TECH

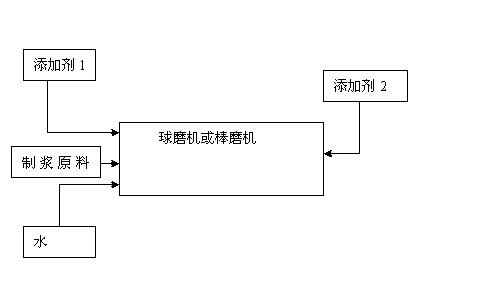

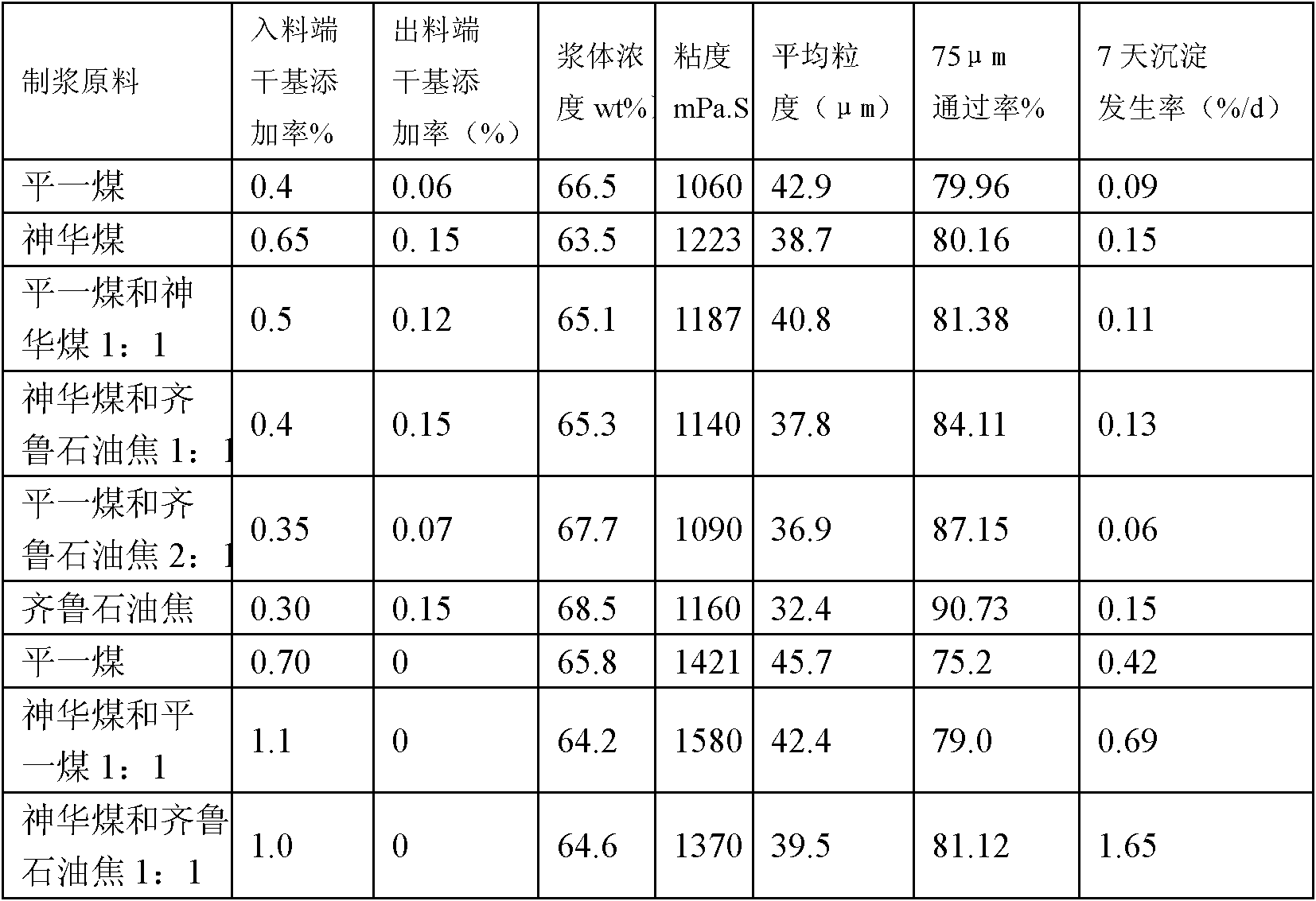

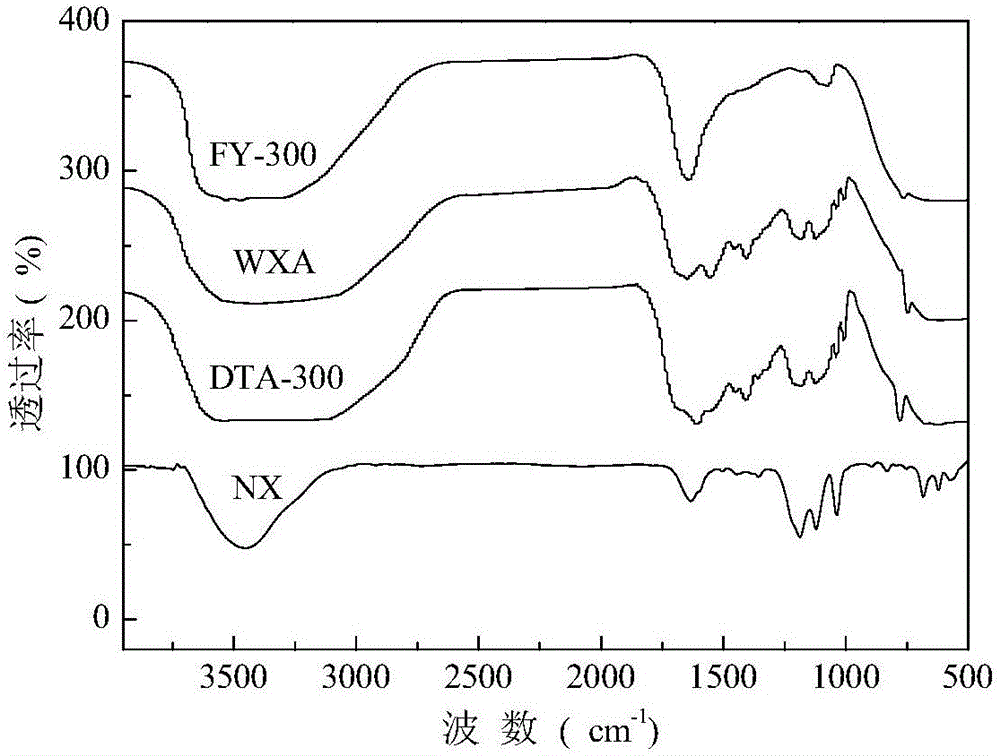

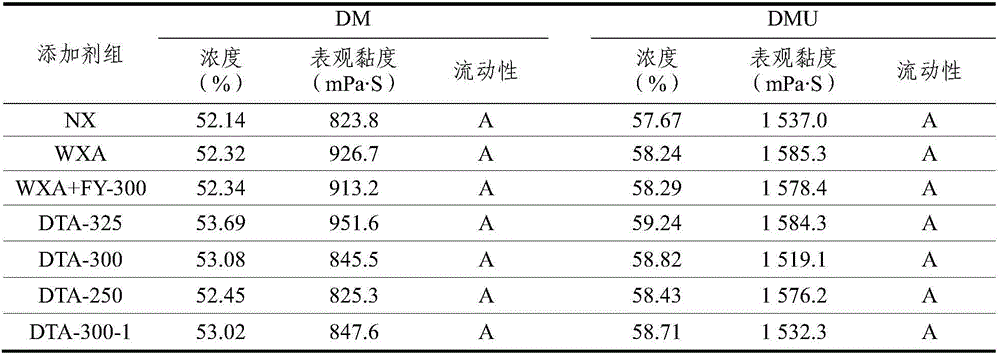

Method for preparation of coal water slurry or water coke slurry by two-stage dosing

InactiveCN103160346AOptimize dwell timeImprove grinding effectLiquid carbonaceous fuelsPetroleum cokeCopolymer

The invention discloses a method for preparation of a coal water slurry or water coke slurry. The method comprises: adding a naphthalene sulfonic acid formaldehyde copolymer, a naphthalene anthracene sulfonic acid formaldehyde copolymer, lignosulfonate and a humate into the feeding end of a mill for grinding coal, petroleum coke or mixed raw materials, with the adding amount accounting for 0.1-1.0% of the total weight of the slurry; and adding hexametaphosphate, sulfonated acetone-formaldehyde copolymer or a polyacrylate at the discharge end of the mill, with the adding amount accounting for 0.02-0.2% of the total weight of the slurry. The stage dosing for preparation of the slurry can improve the ore grinding properties of the mill, broaden the particle size distribution of the slurry, improve the concentration and stability of the slurry, reduce the viscosity of the slurry, and improve the fluidity of the slurry. The method has a stabilizing effect on multiple slurries, can improve slurry stability, adjust slurry particle size distribution, increase slurry concentration, reduce slurry viscosity and enhance mobility. With the advantages of convenient operation, small dosage and low cost, the method has high popularization and application value.

Owner:NANJING UNIV

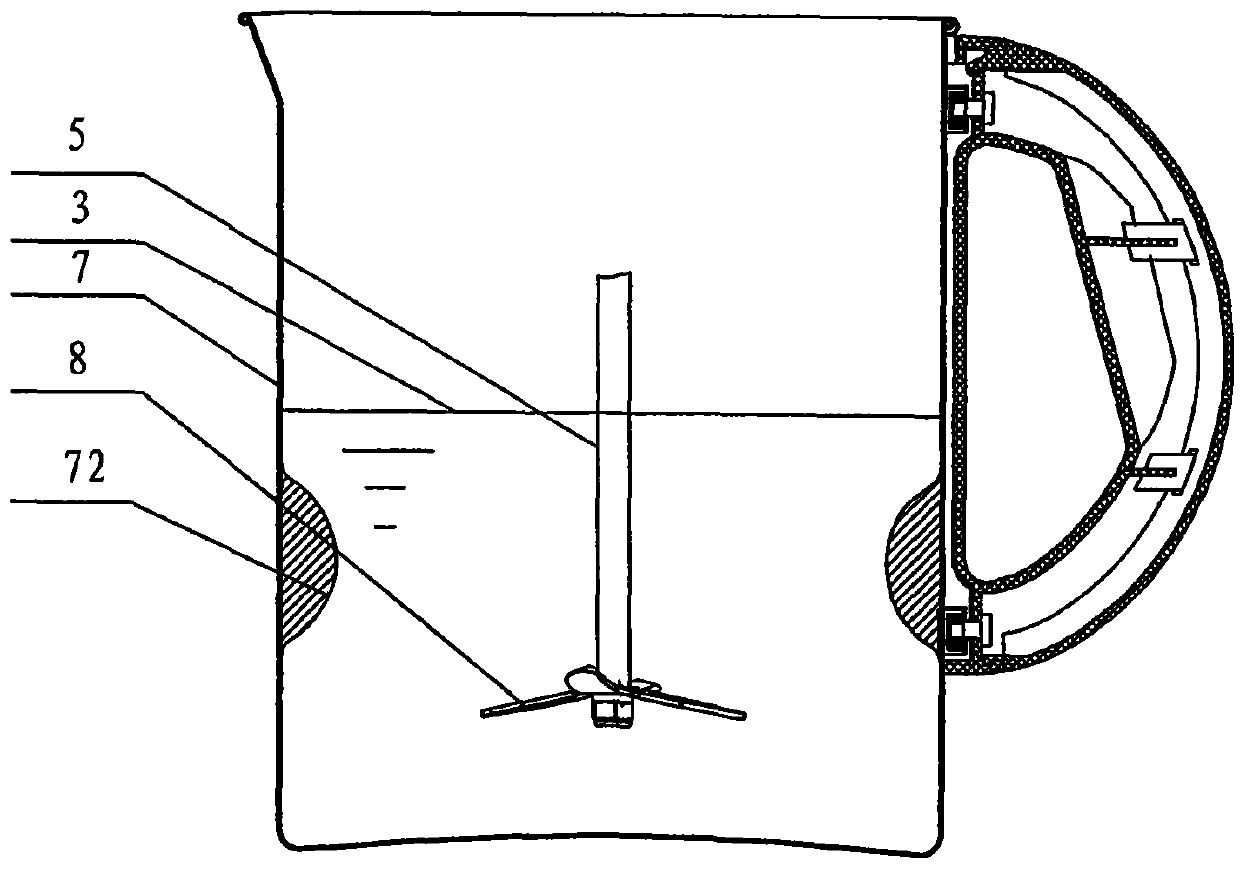

Soya-bean milk machine

The soybean milk machine includes a machine head, a machine body connected movably to the machine head, a motor fixed inside the a machine head, a cup with cover, a knife shaft stretching into the cup, a crushing knife fixed in the front end of the knife shaft, a shaft coupling connecting the motor shaft to the knife shaft, and a control circuit board. It has also a connector fixed in the lower part of the cup cover and stretched into the cup, and a disturbing curved body fixed to the lower end of the connector and located over the crushing knife to form turbulent flow while blocking upward motion of soybean. The soybean milk machine for making soybean milk, has sufficient crushing of soybean, less foam, low noise and easy cleaning, and may be also used in making milk and soup with fruit, vegetable, rice, etc.

Owner:JOYOUNG CO LTD

Medium consistency refining method of pulp and system

ActiveUS8734611B2Improve pulping performanceReduce in quantityPulp beating/refining methodsMultistage pulping processMaterials science

Owner:ANDRITZ INC

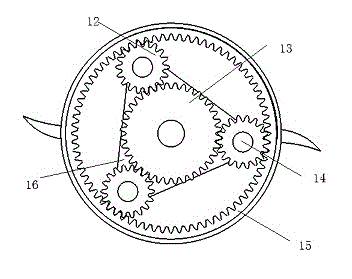

Coaxial dual-spiral domestic soybean milk machine head

InactiveCN104305873AAvoid enteringHelp defoamBeverage vesselsMilk substitutesControl systemDrive shaft

The invention belongs to the field of domestic soybean milk machine equipment, and particularly relates to a coaxial dual-spiral domestic soybean milk machine head. The coaxial dual-spiral domestic soybean milk machine head comprises that a handle is fixed above the soybean milk machine head, a control system is arranged in the soybean milk machine head, a motor is connected with a transmission shaft, a reverse transmission device is arranged in the soybean milk machine head, a sleeve is arranged on the reverse transmission device, the lower end of the sleeve is provided with a lip-shaped seal ring, a reverse blade is fixed at the lower end of the sleeve, and a forward blade is fixed at the lower end of the transmission shaft and is fixed by a locknut. The coaxial dual-spiral domestic soybean milk machine head is simple in structure and high in pertinence, dual-direction rotation of two blades can be realized on the same motor transmission shaft, the shearing effect of beans is improved, the milk making effect of the soybean milk is improved and the coaxial dual-spiral domestic soybean milk machine head has wide market application value.

Owner:UNIV OF JINAN

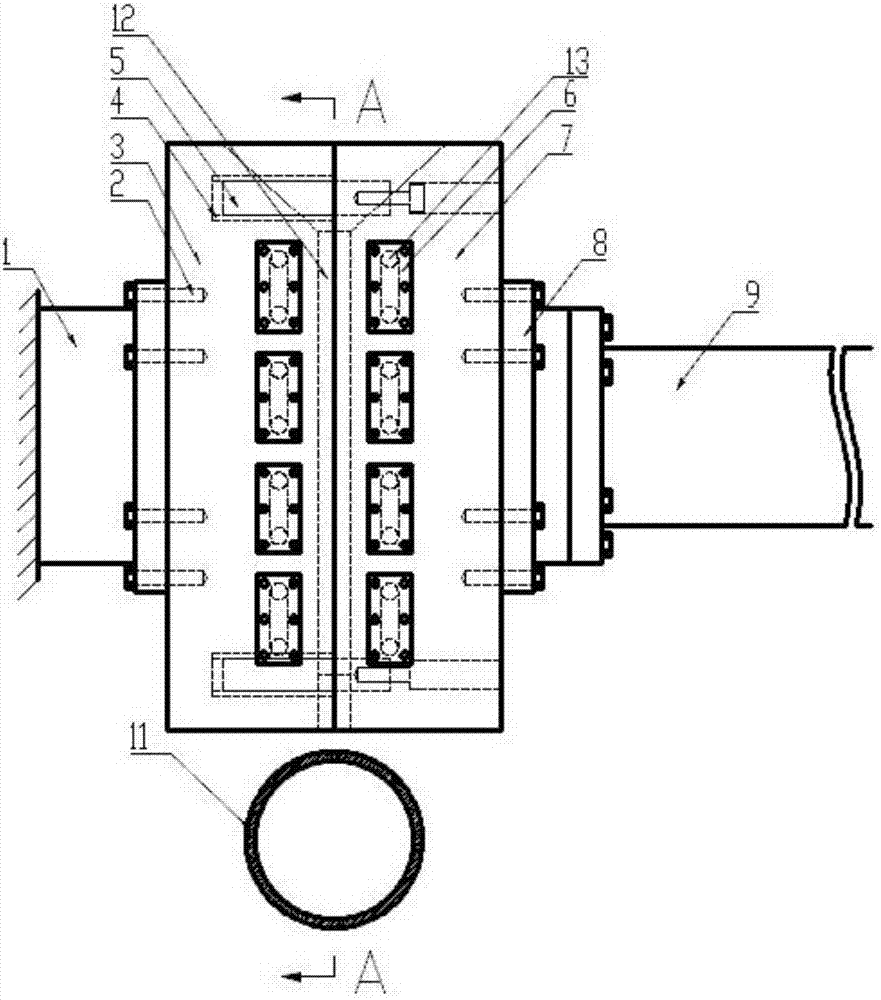

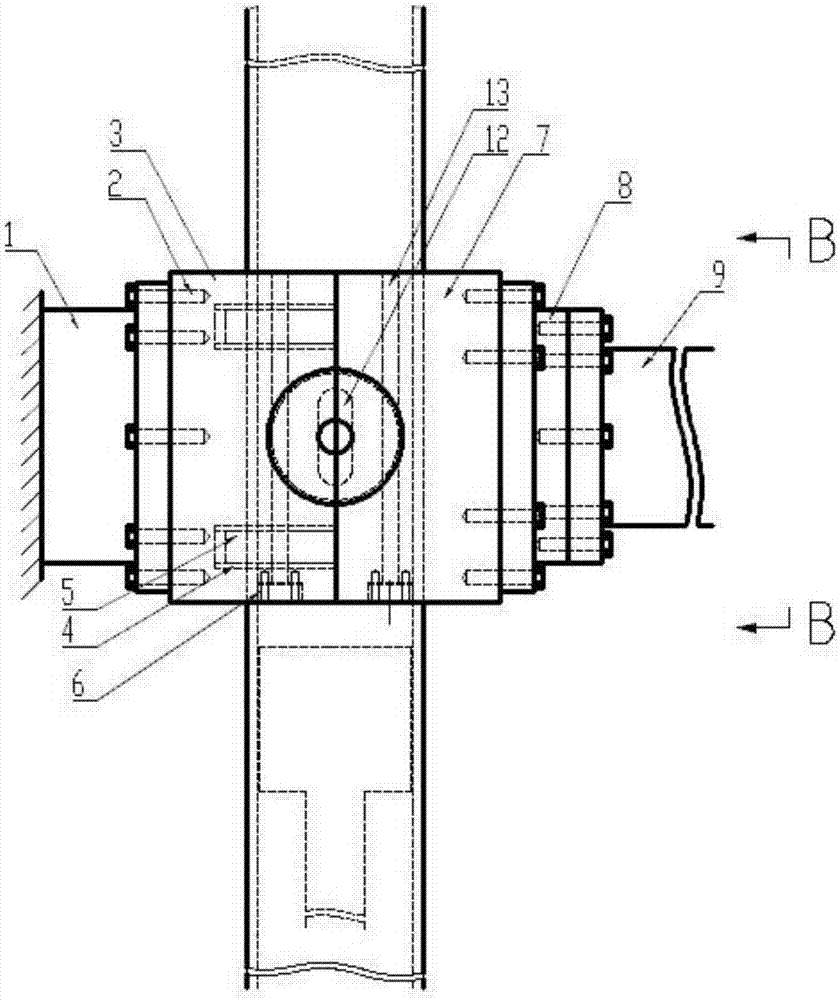

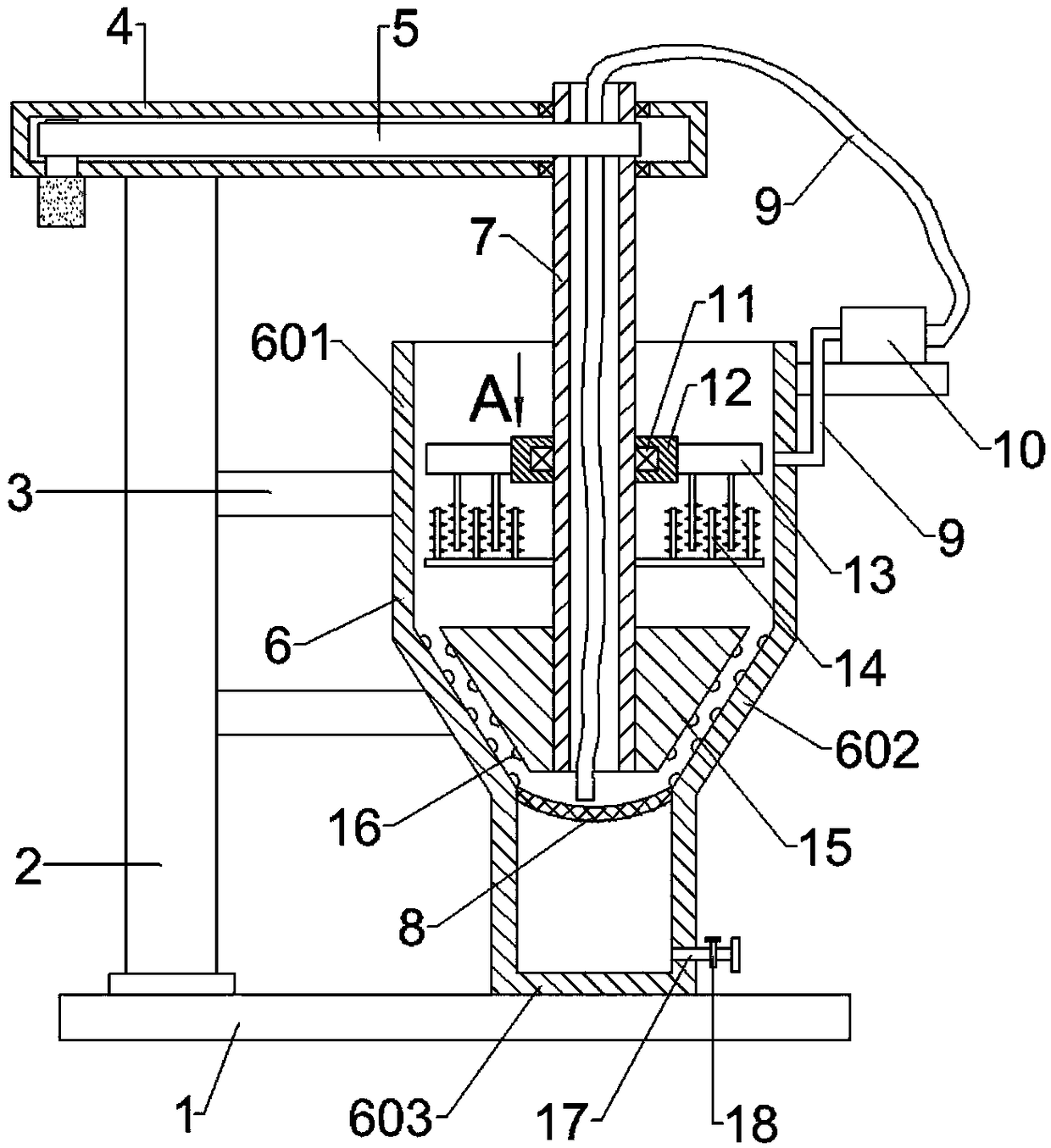

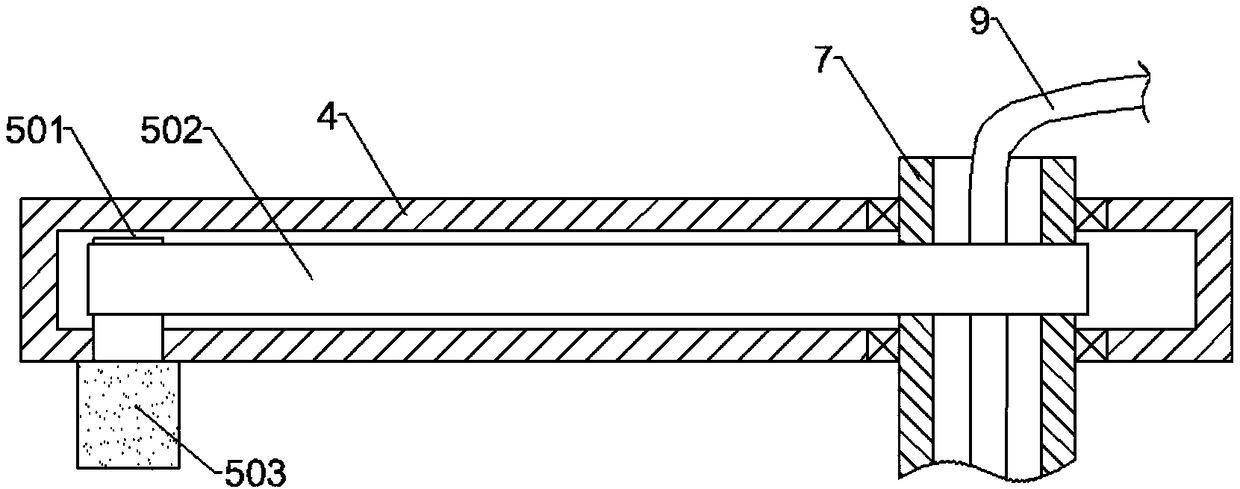

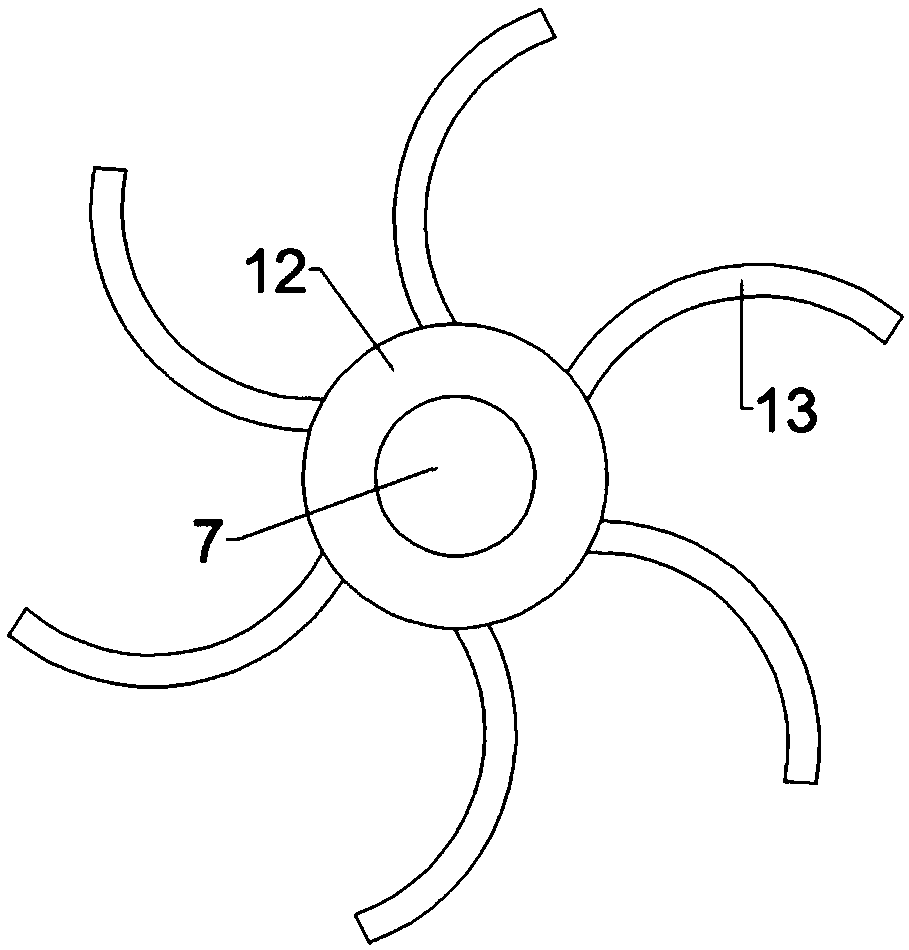

Continuous cooling snake-shaped flow channel semi-solid rheo-die casting device

The invention discloses a continuous cooling snake-shaped flow channel semi-solid rheo-die casting device. The continuous cooling snake-shaped flow channel semi-solid rheo-die casting device comprises a snake-shaped flow channel fixed die and a snake-shaped flow channel moving die. The snake-shaped flow channel fixed die is matched and connected with the snake-shaped flow channel moving die through a guide post. A snake-shaped flow channel is formed at the joint between the snake-shaped flow channel fixed die and the snake-shaped flow channel moving die. The snake-shaped flow channel moving die is connected with an electric cylinder. The snake-shaped flow channel fixed die and the snake-shaped flow channel moving die are each internally provided with a plurality of cooling water channels. Each cooling water channel is of a transverse U-shaped structure. One end of each cooling water channel is provided with a water channel sealing block. According to the continuous cooling snake-shaped flow channel semi-solid rheo-die casting device, the multiple cooling water channels are formed on the periphery of the snake-shaped flow channel; water is used as a cooling medium to continuously cool the snake-shaped flow channel; in the using process, the temperature difference between the snake-shaped flow channel and an alloy solution can be kept large, and then the chilling action of the snake-shaped flow channel dies on the later part of alloy solution is maintained. Nucleation is promoted. The pulp making effect is substantially improved.

Owner:GUANGDONG UNIV OF TECH

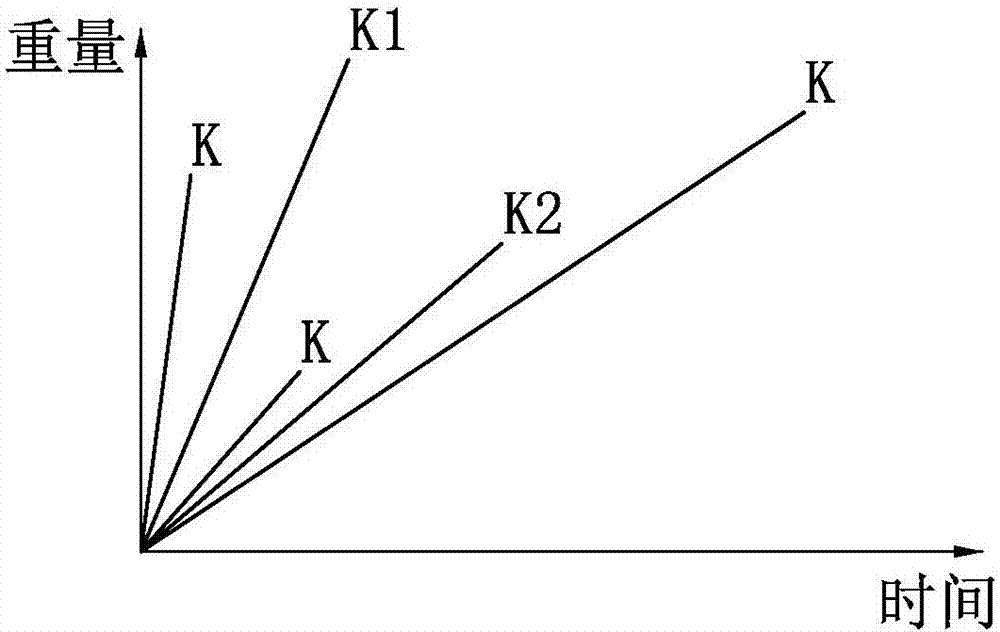

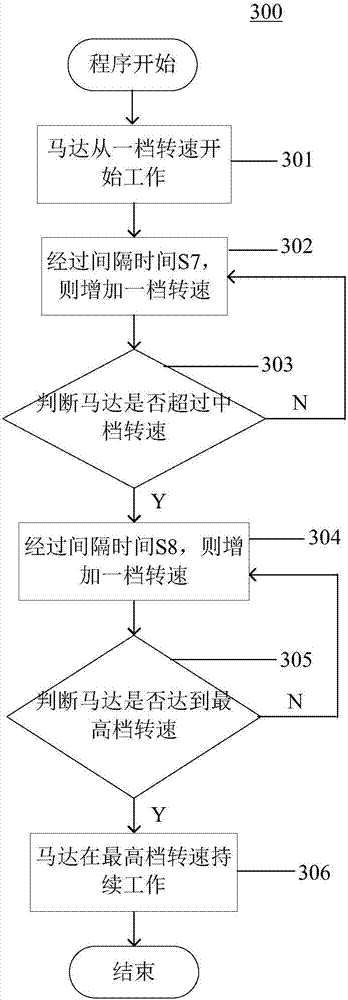

Intelligent control method of soyabean milk machine

ActiveCN107132779AAccurate judgment of timeImprove user experienceProgramme control in sequence/logic controllersEngineeringIntelligent control

The invention discloses an intelligent control method of a soyabean milk machine, belongs to the field of food processing devices, and solves the problem of poor soyabean milk making effect. The technical scheme for solving the problem is mainly realized by the weight change slope K1 and K2 of the preset cup of the soyabean milk machine, K1>K2, and the initial weight of the cup is recorded by the soyabean milk machine; the weight of the cup is changed, and the weight change slope K is obtained by the soyabean milk machine according to the weight change quantity of the cup and the weight change time; the user operation is judged to be placing the machine by the soyabean milk machine when K is greater than K1, the user operation is judged to be putting materials by the soyabean milk machine when K is between K1 and K2, and the user operation is judged to be adding water by the soyabean milk machine when K is less than K2; and the soyabean milk machine makes the soyabean milk after judging that the user performs the operation of putting the materials, adding water and placing the machine. The intelligent control method of the soyabean milk machine is mainly used for enhancing the soyabean milk making effect of the soyabean milk machine.

Owner:JOYOUNG CO LTD

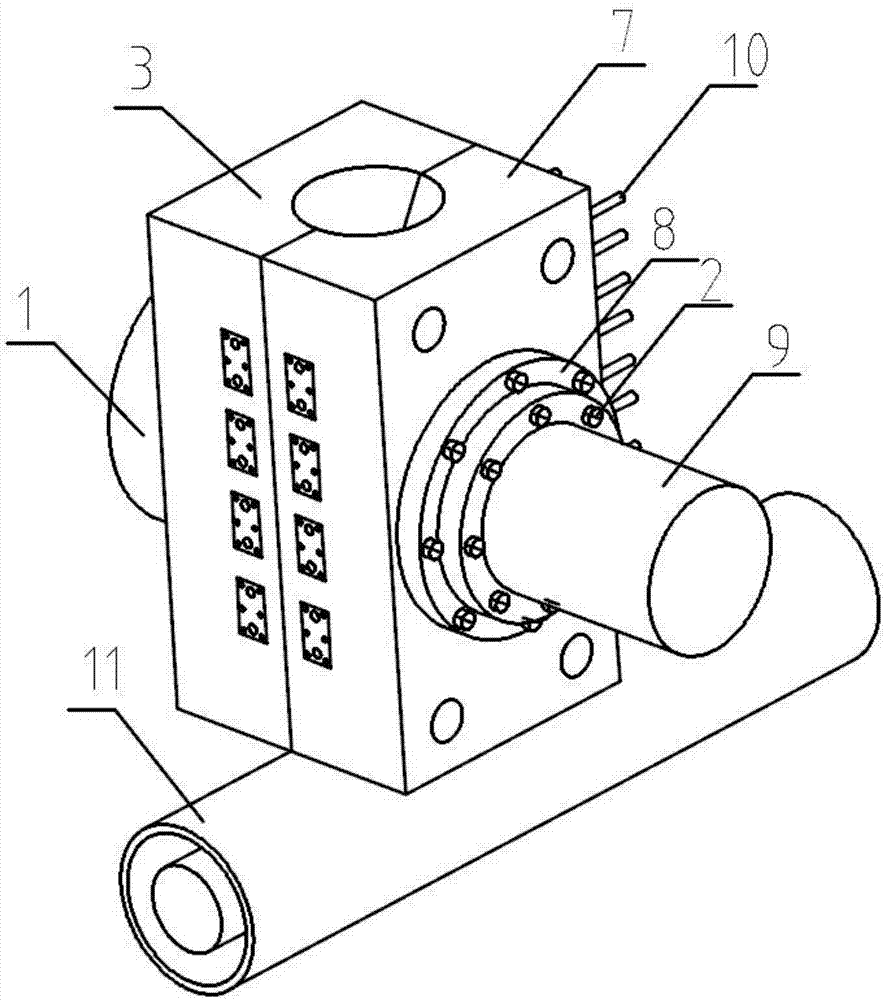

Radix puerariae smashing and syrup making device

InactiveCN107282183AImprove crushing effectImprove pulping performanceJuice extractionRotary stirring mixersMechanical engineeringPueraria

Owner:湖北黄仙洞葛业科技有限公司

Polycarboxylic acid water-coal-slurry additive as well as preparation method and application thereof

InactiveCN106589260APromote engineeringEasy to industrializeLiquid carbonaceous fuelsPolyethylene glycolCis-Butenedioic Acid

The invention discloses a method for preparing a polycarboxylic acid water-coal-slurry additive by using low-rank coal hydrothermal treatment waste liquid. The method comprises the following steps: (1) preparing polyethylene glycol single acetate by carrying out reaction between polyethylene glycol and acetic acid, and then adding acrylic acid and / or maleic acid for esterification to obtain a pre-reaction system; (2) dispersing the prepared pre-reaction system, sodium vinyl sulfonate and / or sodium p-styrenesulfonate and any one of acrylic acid and / or maleic acid into the low-rank coal hydrothermal treatment waste liquid, and carrying out polymerization in the presence of a chain transfer agent and an initiator; and (3) adjusting the pH value of the reaction system prepared in the step (2) to 9 to 11 so as to obtain the polycarboxylic acid water-coal-slurry additive. Compared with a domestic representative commodity additive, the additive disclosed by the invention enables the pulping concentration of low-rank coal such as lignite to be increased by 0.94 to 1.15 percent.

Owner:DATANG INT CHEM TECH RESINST

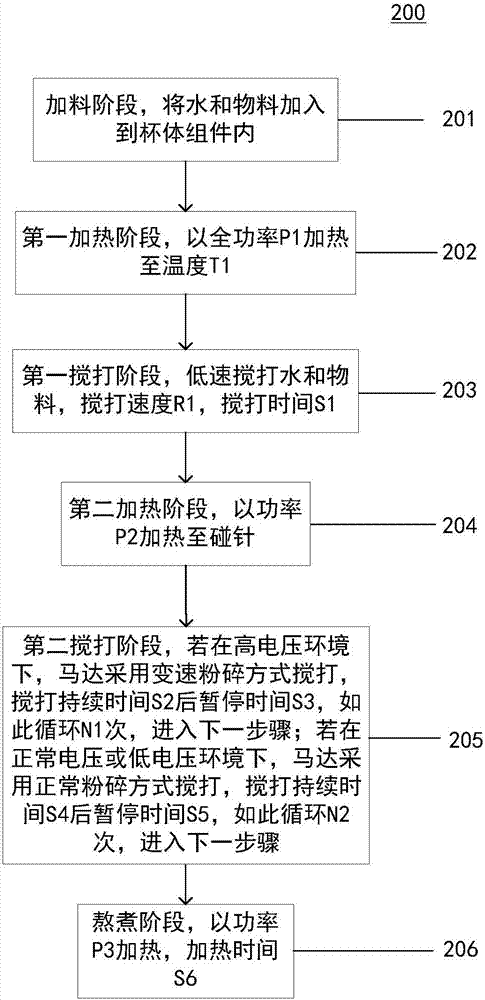

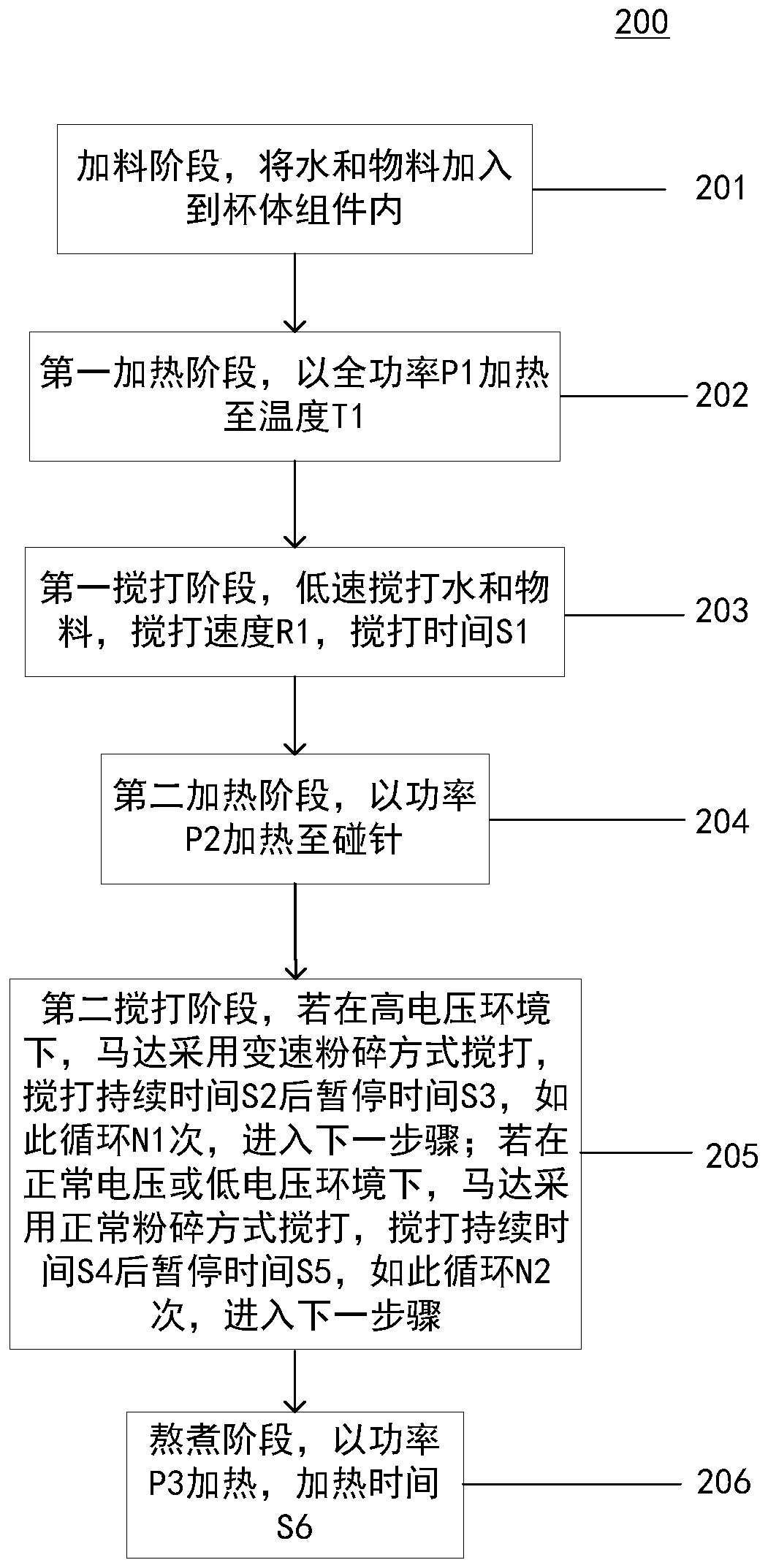

Soybean milk making method

The invention provides a soybean milk making method. The method includes following steps: 1, feeding: adding water and materials into a cup component; 2, heating for the first time: heating at full power P1 to temperature T1; 3, whipping for the first time: whipping the water and the materials at a low speed R1 for whipping time S1; 4, heating for the second time: heating at power P2 to collide with a needle; 5, whipping for the second time: if in a high-voltage environment, enabling a motor to whip by means of speed-variable smashing, stopping whipping for time S3 after continuously whipping for time S2, repeating in this way for N1 times, and then entering a next step; if in a normal-voltage or low-voltage environment, enabling the motor to whip by means of normal smashing, stopping whipping for time S5 after continuously whipping for time S4, repeating in this way for N2 times, and then entering the next step; 6, boiling: heating at power P3 for time S6. By the soybean milk making method, beans can be broken without generating much bean residue, so that soybean milk making effect is improved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

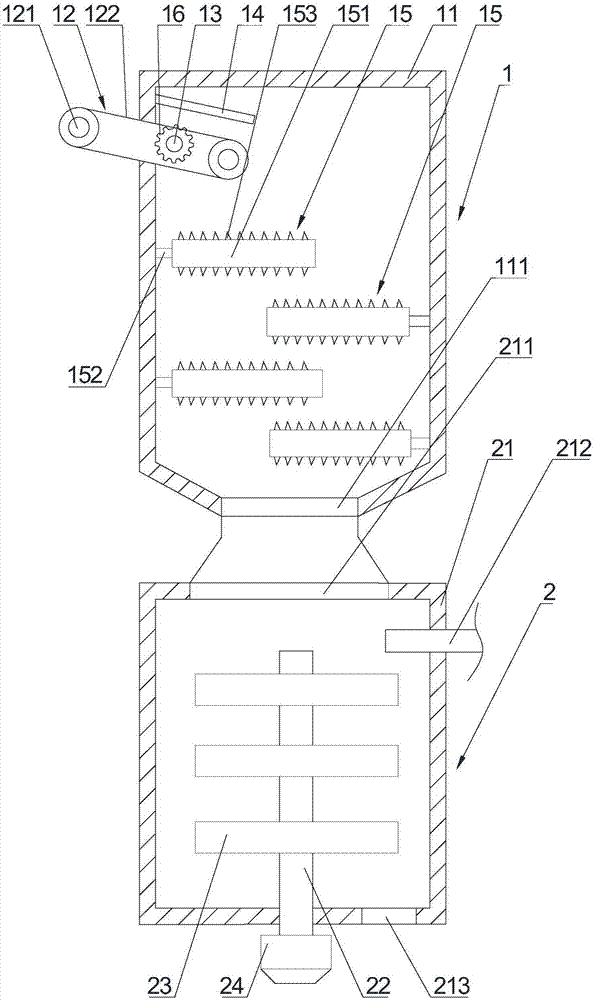

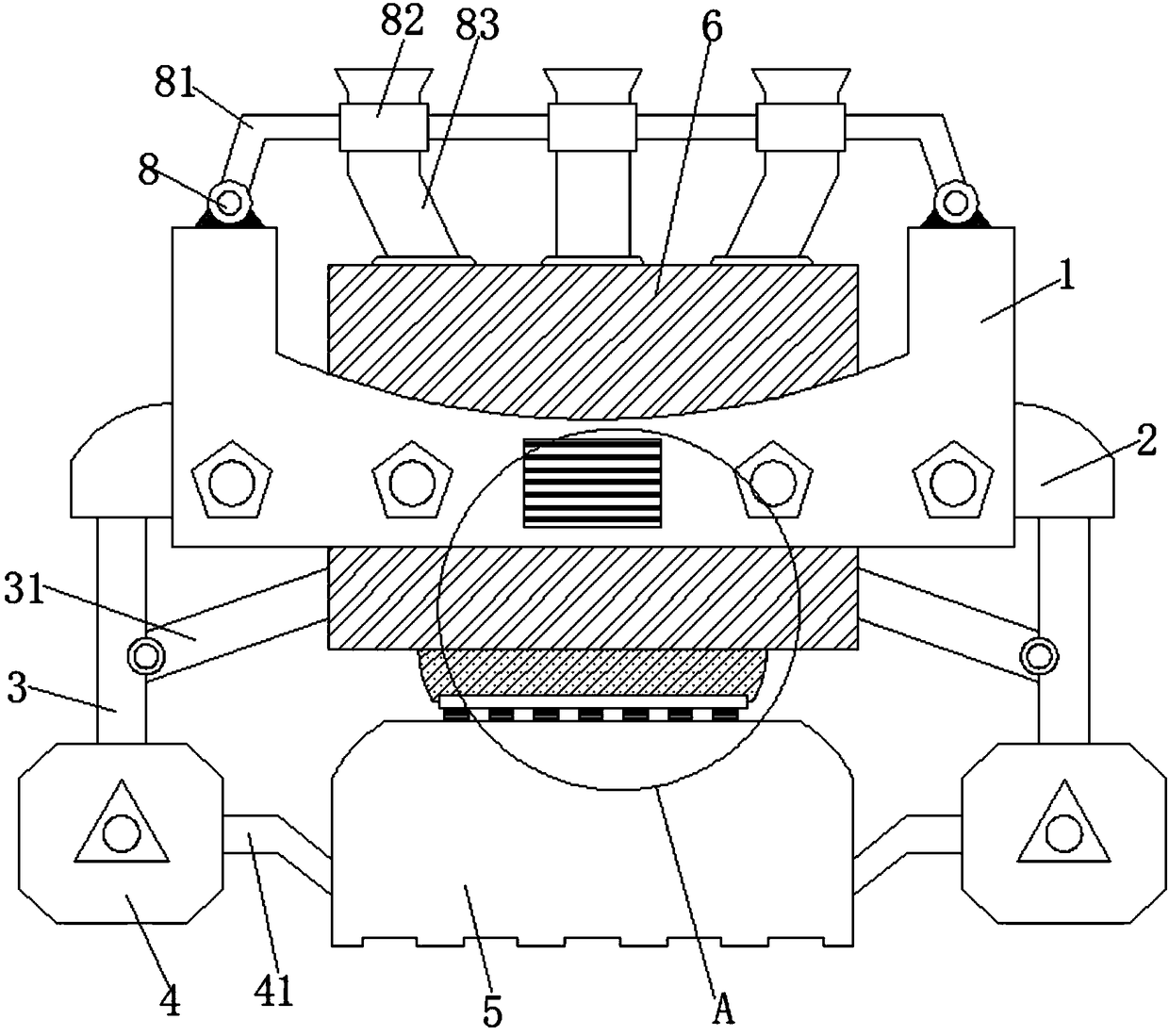

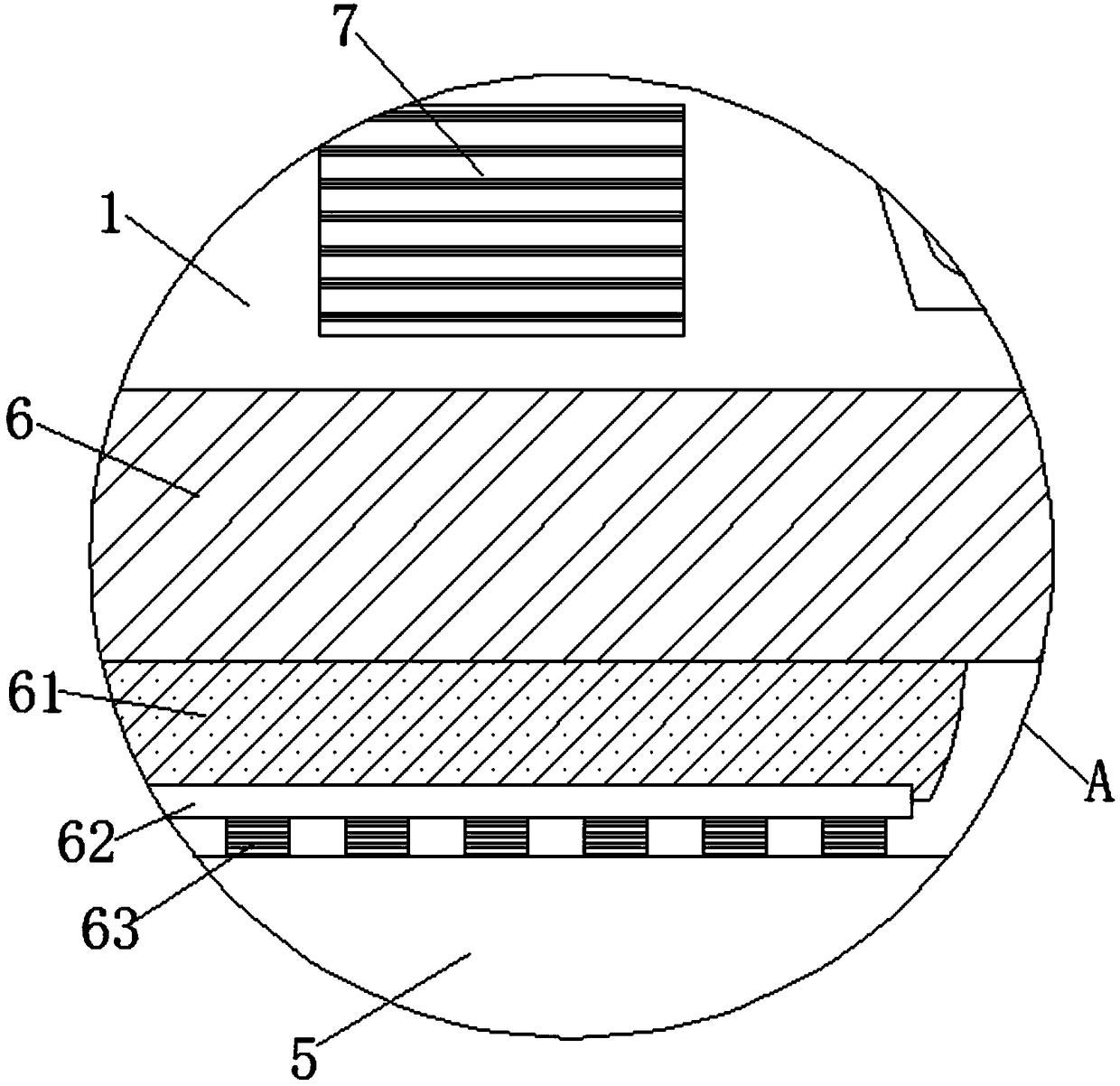

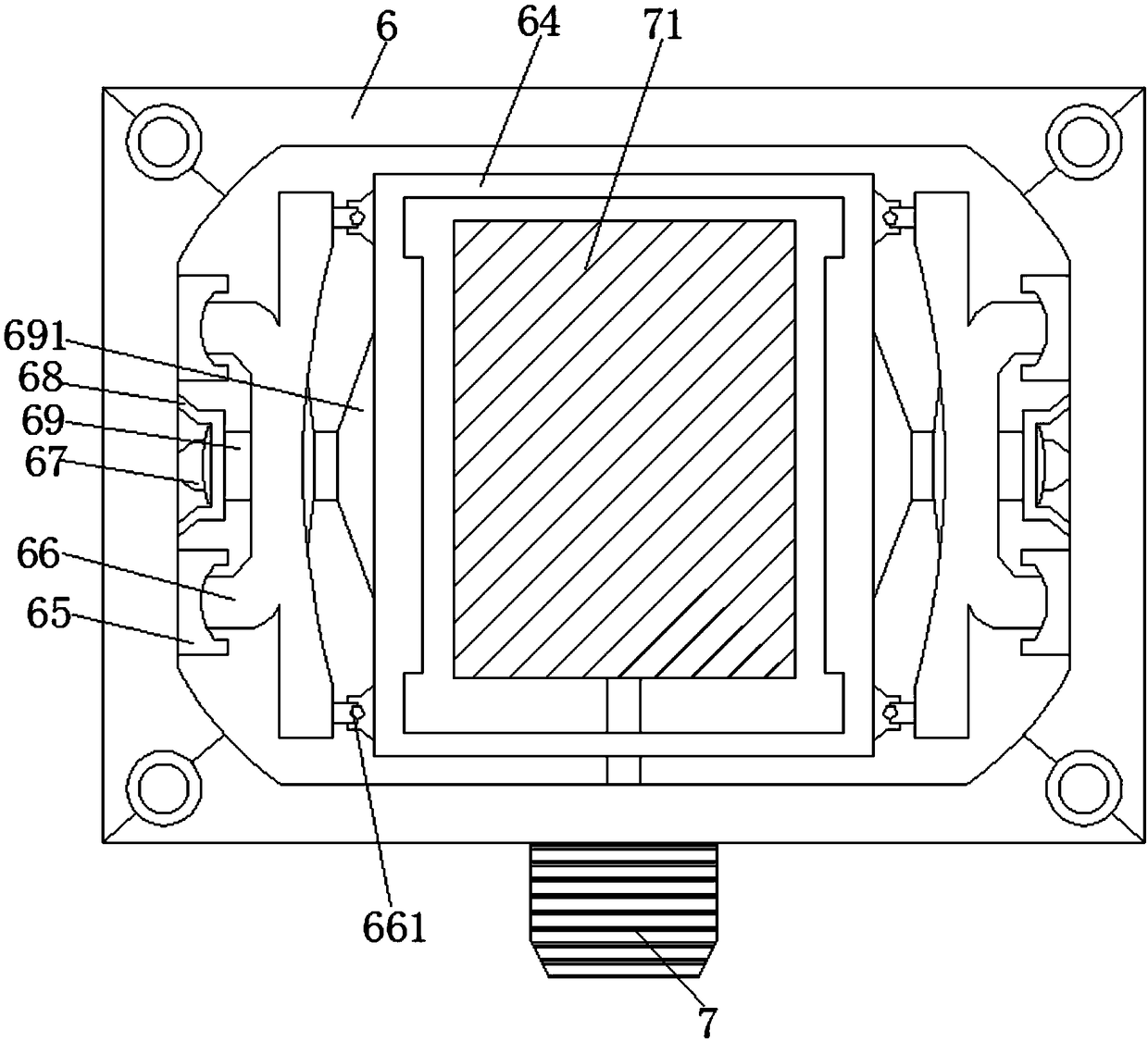

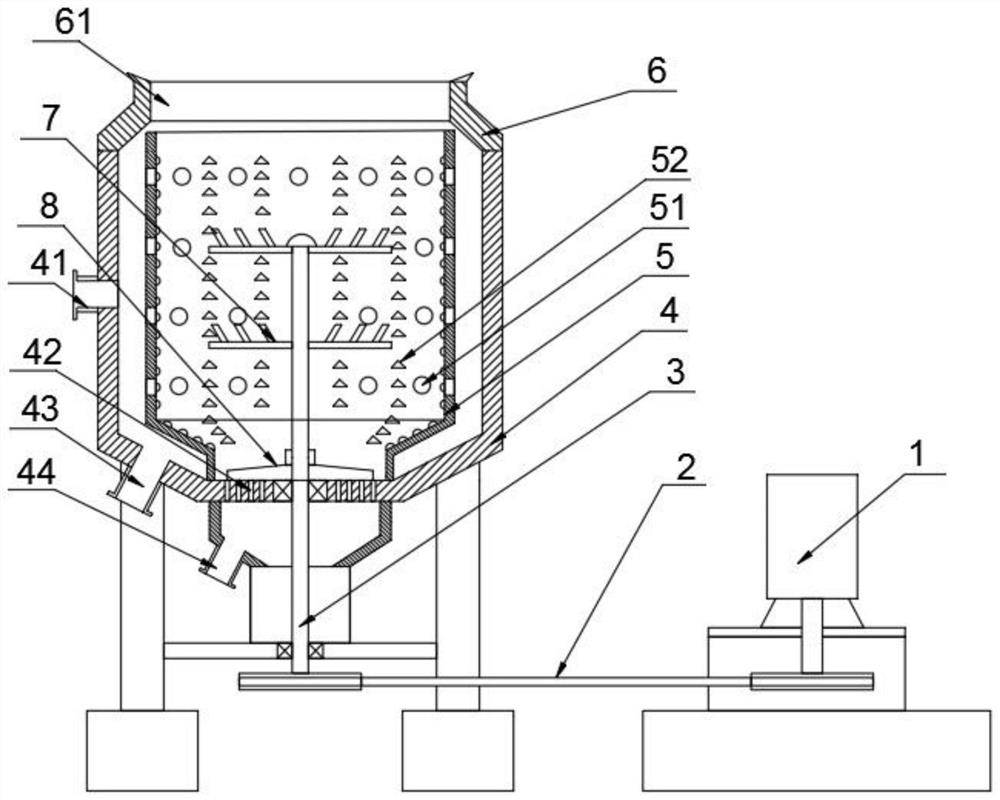

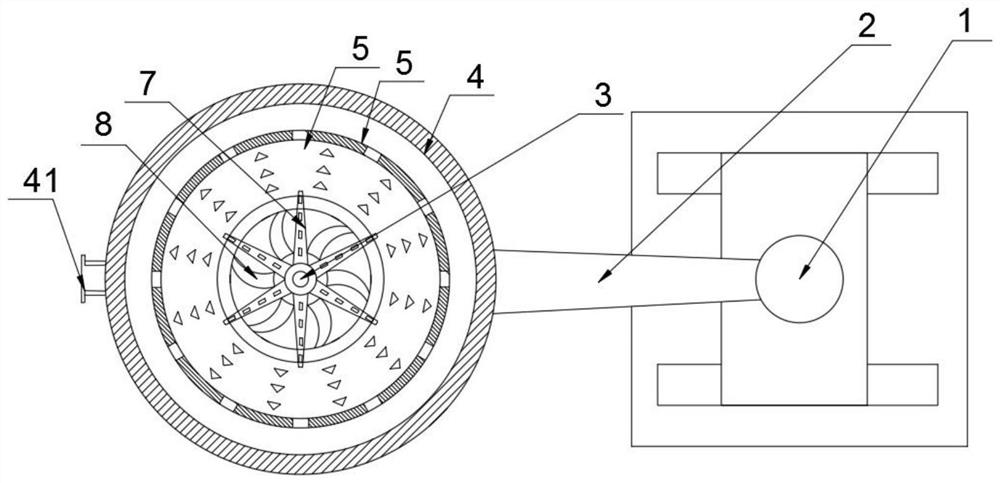

Blanking type environment-friendly papermaking raw material processing and pulping equipment based on three-pipe channel

InactiveCN108411670AReduce deliveryEasy to processRaw material divisionRaw material pretreatmentMotor drivePulp and paper industry

The invention relates to the technical field of environmental protection and discloses blanking type environment-friendly papermaking raw material processing and pulping device based on a three-pipe channel. The equipment comprises a mechanical positioning frame; fixing convex blocks are protruded on the two sides, located on the outer surface, of the mechanical positioning frame respectively; supporting frames are inserted into the bottoms of the inner sides of the two fixing convex blocks respectively; one ends of the bottoms of the two supporting frames penetrate through and extend to the middles of inner cavities of two octagonal supporting bases respectively, and connecting protection frames are welded to one sides of the two octagonal supporting bases respectively; one ends of the two connecting protection frames are welded to the two sides of a material receiving box respectively, and a processing device penetrates through and is connected to the middle of an inner cavity of themechanical positioning frame. According to the blanking type environment-friendly papermaking raw material processing and pulping equipment based on the three-pipe channel, a motor drives a materialstirring device to rotate so that not only can raw materials for pulping be processed, but also impurities attached to the raw materials can be precipitated through a centrifugal force during pulpingto prevent the situation that environmental pollution is caused when the impurities are discharged to the outside.

Owner:闫光

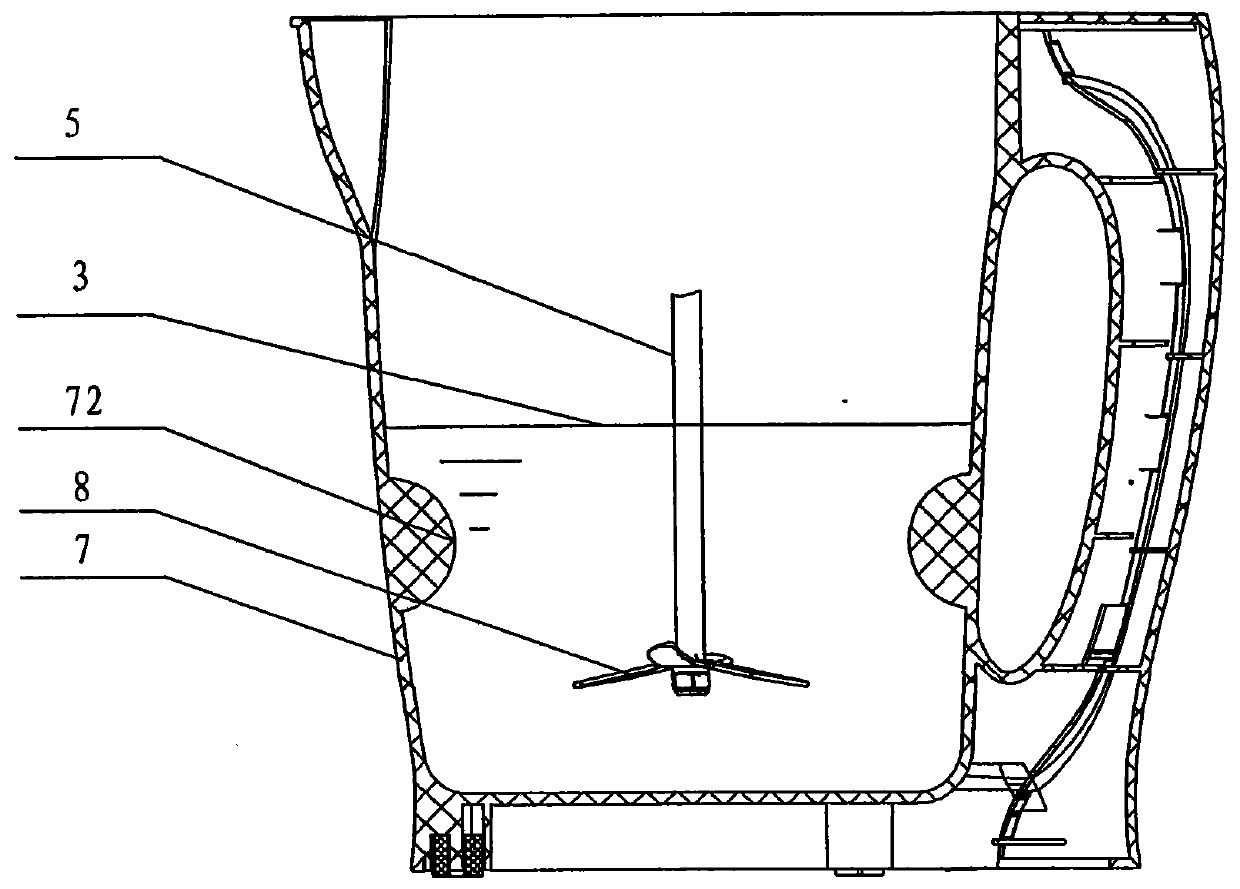

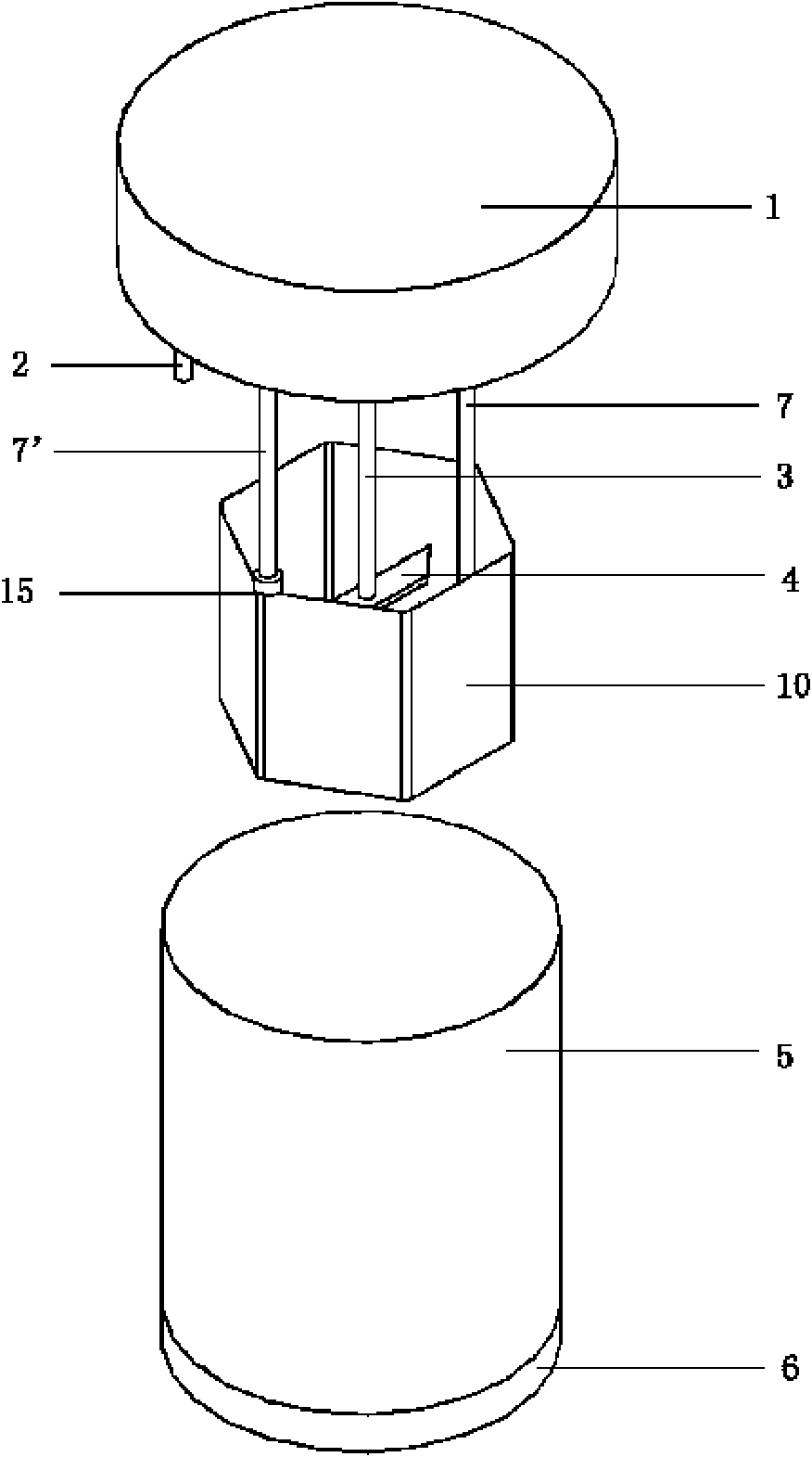

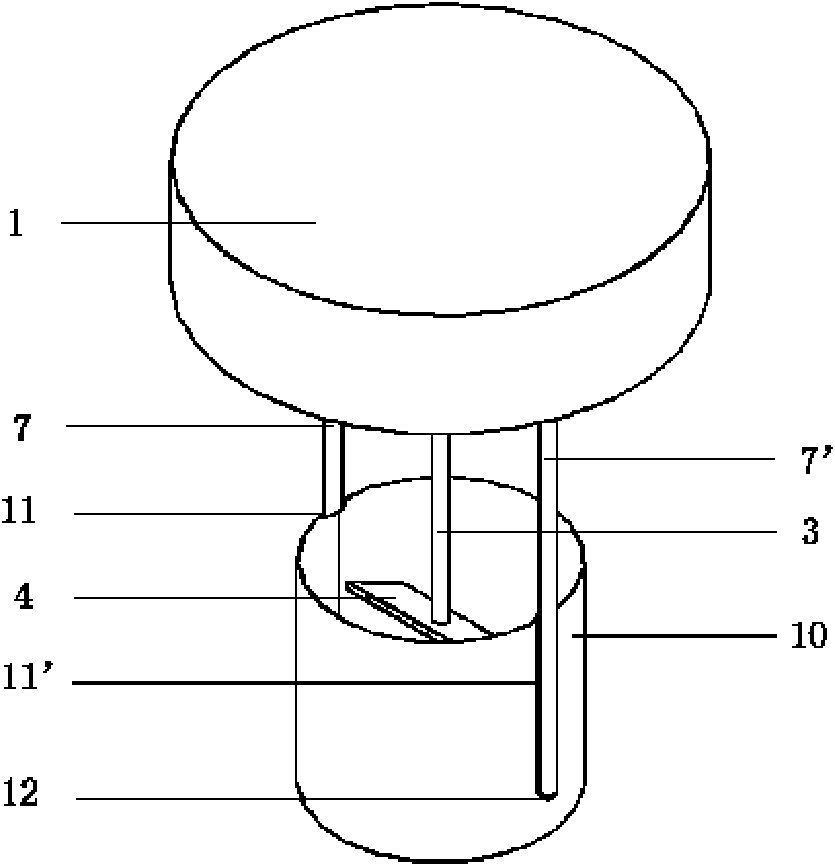

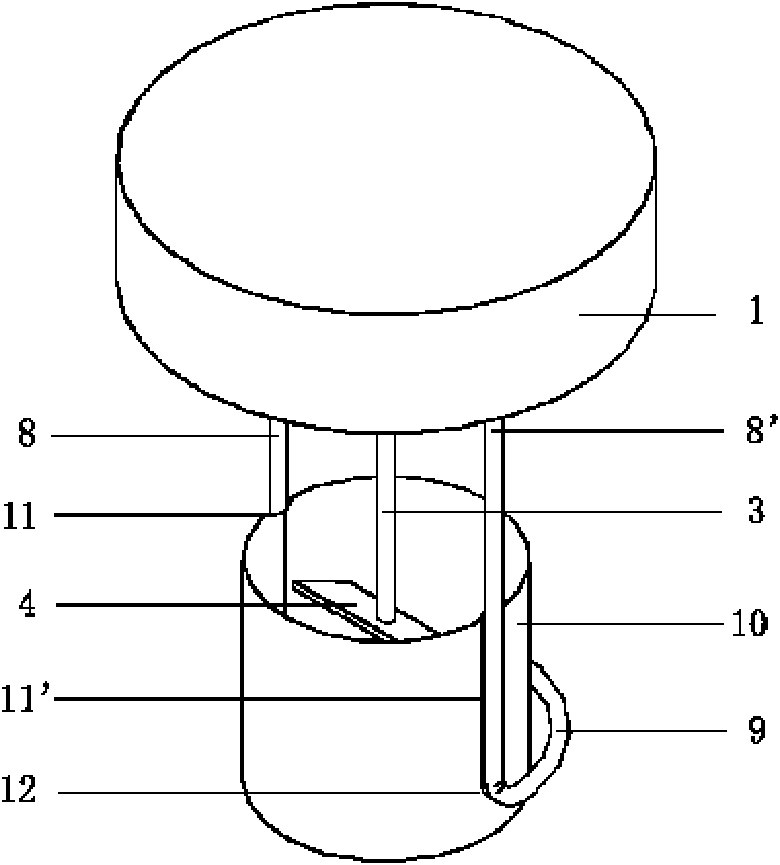

Bean milk machine spliced with thin walled tube

InactiveCN101874526AEasy to cleanImprove pulping performanceBeverage vesselsMilk substitutesMotor driveEngineering

The invention discloses a bean milk machine spliced with a thin walled tube, comprising a container for containing liquid and a machine head arranged at the top of the container, wherein an operating and controlling assembly and a motor are built in the machine head, the motor drives a cutter shaft which extends downwards into the container, a smashing cutter is fixed on the cutter shaft, the lower part of the machine head is also fixed with one or a plurality of rigidity parts extending into the container, a vertical part on the rigidity parts clamps and fixes one thin walled tube which is inserted into the vertical part from bottom to top on a position surrounding the cutter by taking the cutter shaft as an axes, the lower part of the thin walled tube extends below the liquid level of the container, and a flow channel for liquid to flow in and out of the thin walled tube is remained between the bottom of the thin walled tube and the bottom of the container. The thin walled tube enhances the effect for grinding bean milk, the tube wall has no holes, and the installation position is lower, therefore, bean milk dirty is difficult to form, and the thin walled tube is easier to clean.

Owner:陈曙东

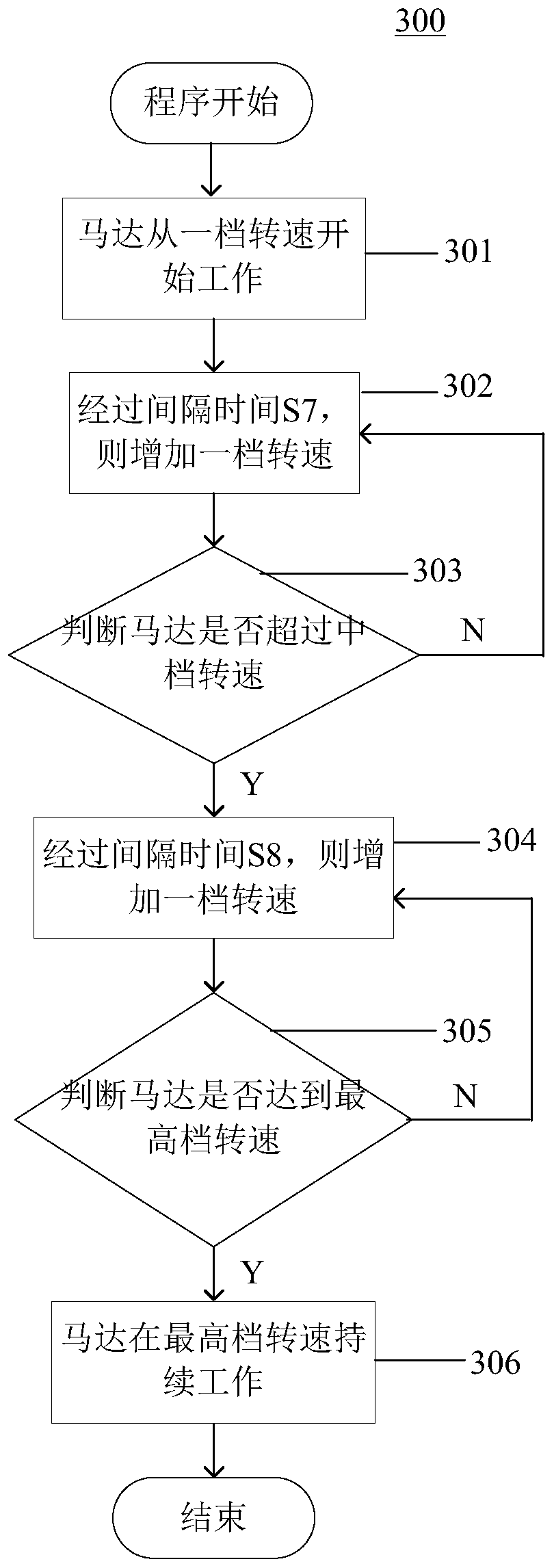

Control method of food processing machine

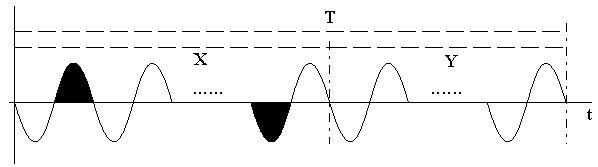

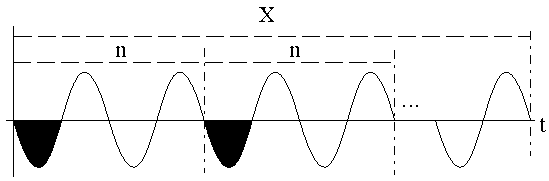

ActiveCN108227574AMeet processing needsImprove qualityProgramme controlComputer controlSilicon-controlled rectifierConstant power

The invention provides a control method of a food processing machine. The food processing machine comprises a control device and a load, wherein the control device is capable of controlling the load to work through a silicon controlled rectifier; the rated power of the load is P0; the control device performs regular control on the silicon controlled rectifier to obtain the load power P, and a power generation unit and a power adjusting unit are arranged in one control cycle T; the cycle of the power generating unit is X, and the cycle of the power adjusting unit is Y; the power generated by the power generating unit is P1; P=(X / (X+Y))*P1; the cycles X and Y are correspondingly the integer multiples of a half-wave cycle. With the adoption of the method, the problem of instability caused byindependently performing a wave losing control mode or a chopping control mode is avoided; the problems such as detection delay of zero-crossing signals and limitation of the accuracy of the machine can be solved; the food processing machine can work with low constant power, and thus the food preparation quality can be improved.

Owner:JOYOUNG CO LTD

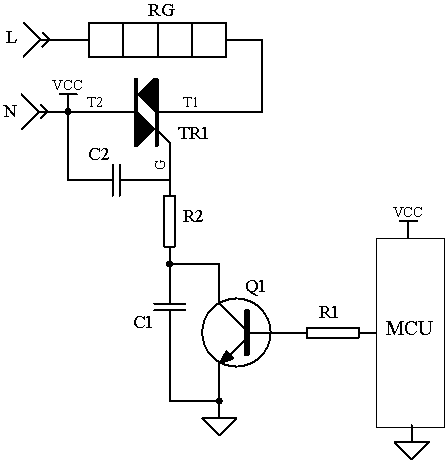

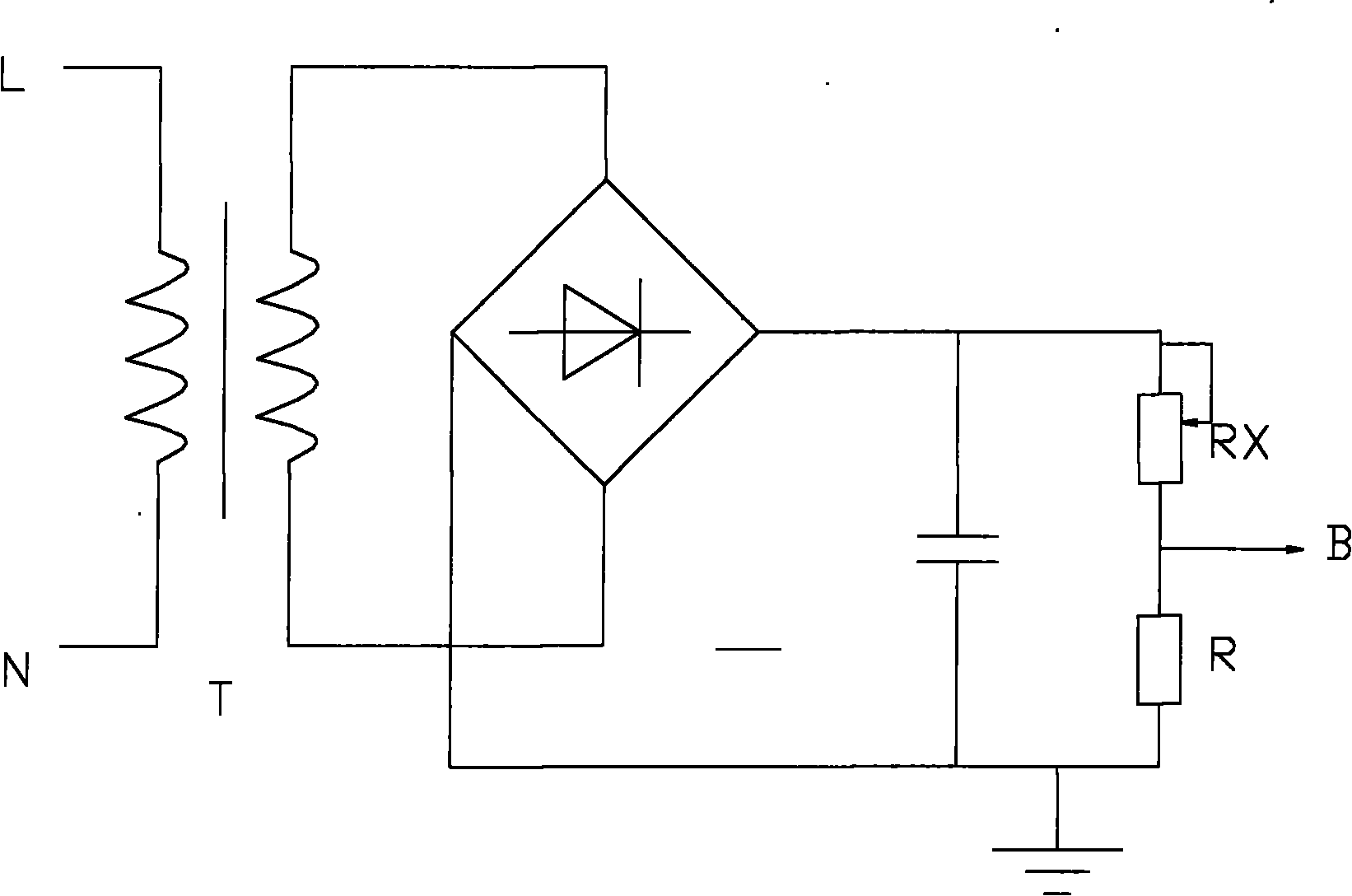

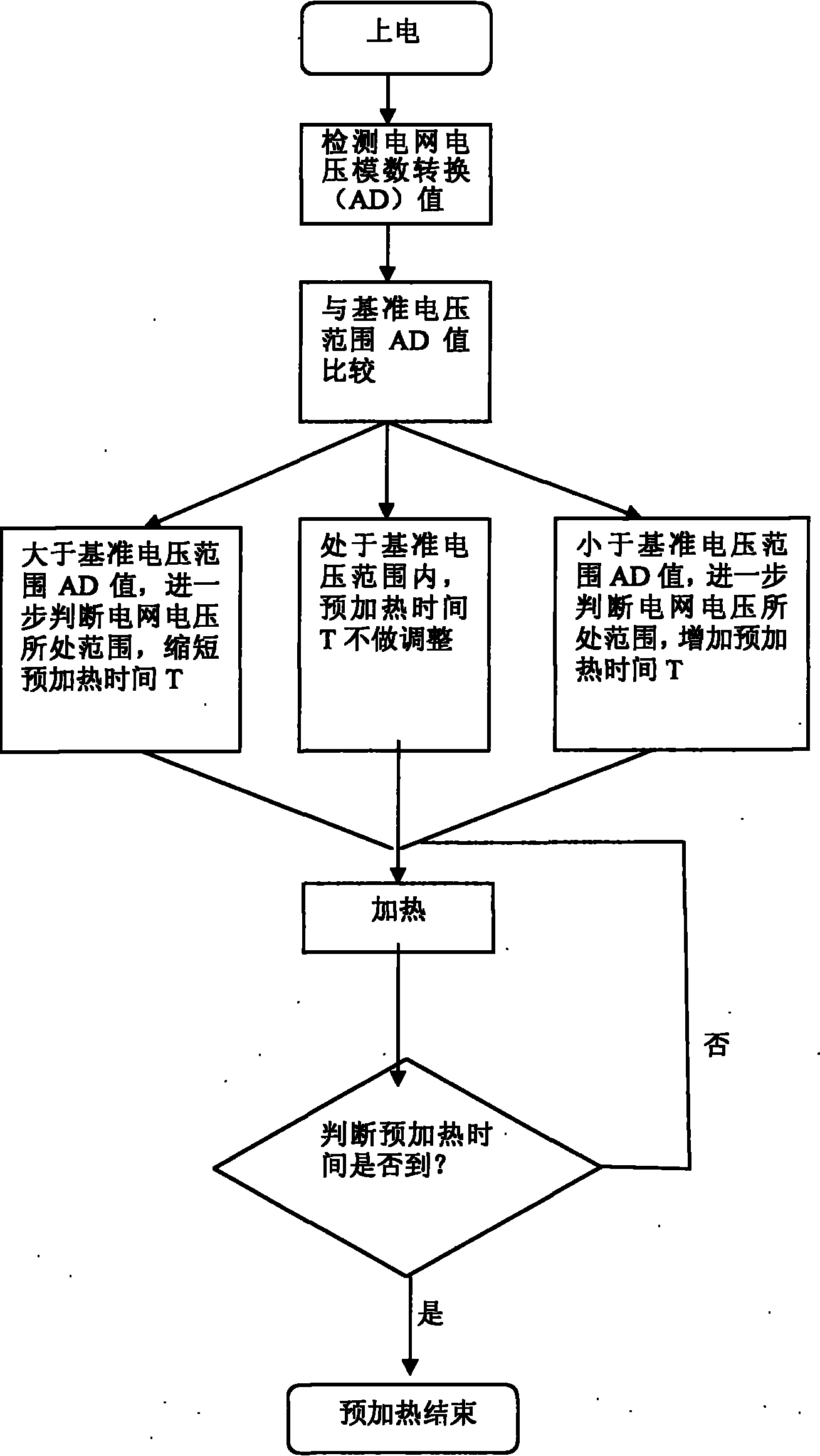

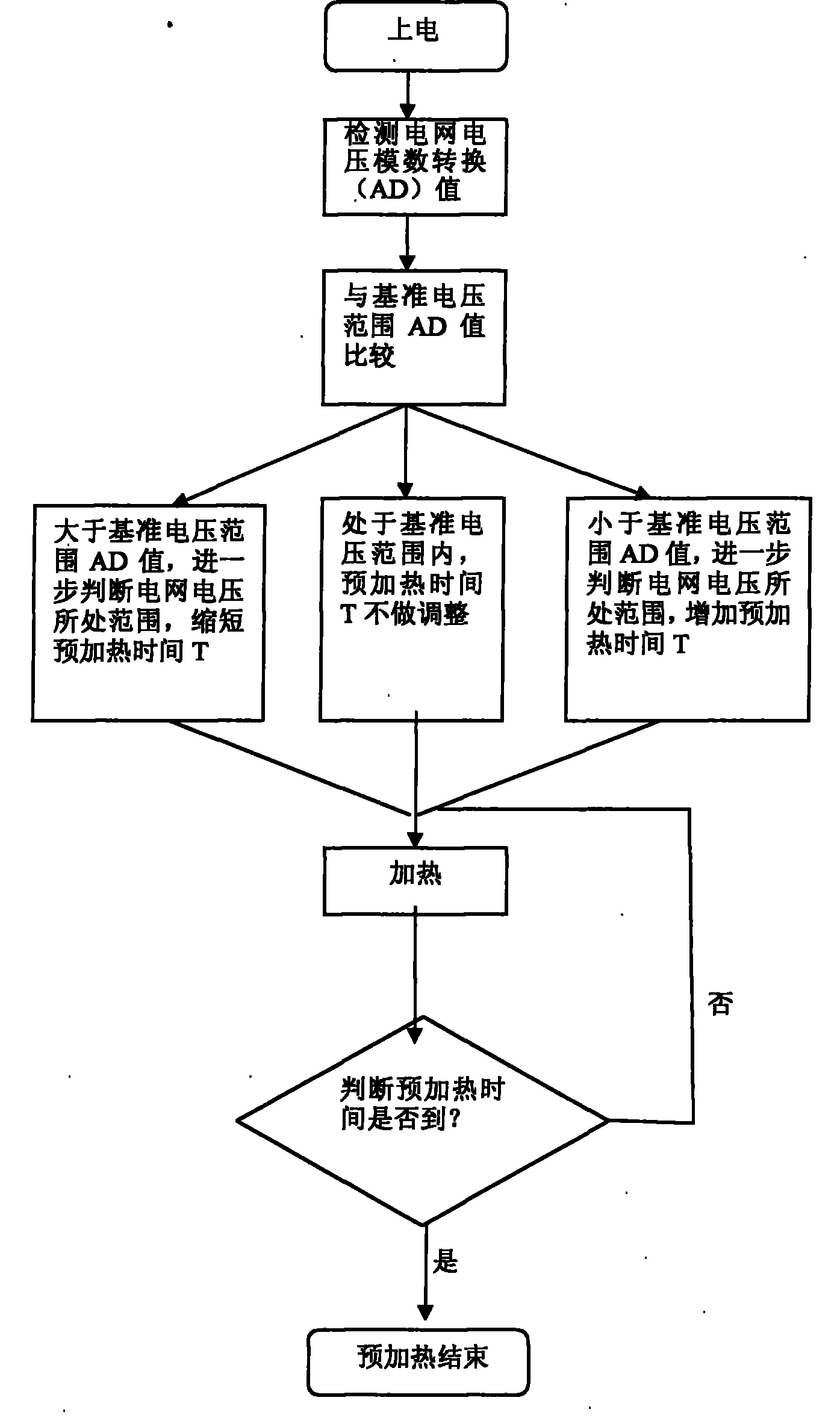

Time control heating method and circuit thereof

InactiveCN101807055ALow costGuaranteed heating effectComputer controlSimulator controlEngineeringHeating effect

The invention relates to a time control heating method and a circuit thereof, wherein the circuit comprises a voltage detection unit, a control unit, a heating unit and a conducting switch; the method comprises the steps of identifying an actual working voltage of the heating unit by the voltage detection unit and reversely adjusting the conducting time of the heating unit according to the actual working voltage. The time control heating method and the circuit thereof do not need a temperature sensor to measure the temperature to heat, can save cost and also can achieve good heating effect.

Owner:DONGGUAN BBK HOUSEHOLD ELECTRICAL APPLICANCES

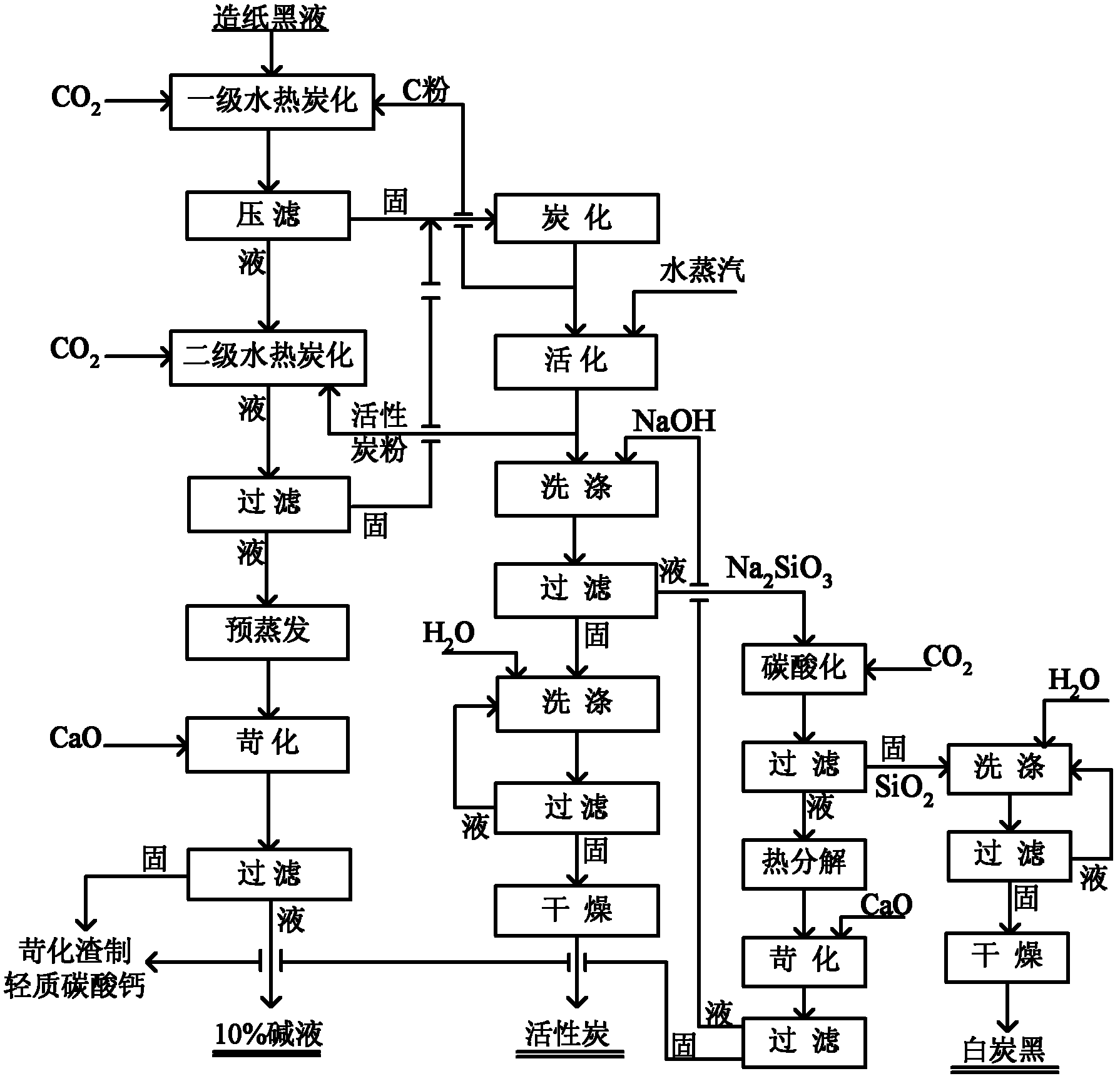

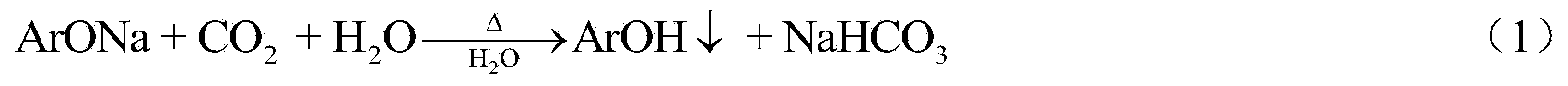

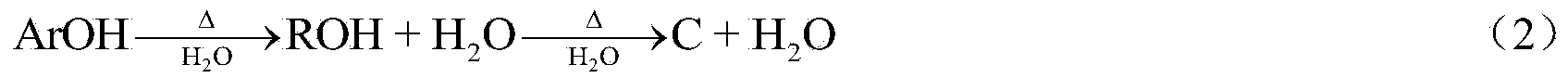

Alkali recovery method for by-producing activated carbon and white carbon black by using paper making black liquid

InactiveCN102587187BImprove evaporation efficiencyReduce energy consumptionSilicaCarbon compoundsRecovery methodActivated carbon

The invention relates to paper making industry clean production, in particular to an alkali recovery method based on paper making black liquid. The method comprises the following steps of: 1) adding carbon powder in paper making black liquid, introducing CO2 gas for carrying out primary hydrothermal carbonization, and carrying out filtering to obtain primary hydrothermal carbonization liquid and primary hydrothermal carbonization materials; 2) adding crude activated carbon into the primary hydrothermal carbonization liquid obtained in the first step, carrying out secondary hydrothermal carbonization under the CO2 gas introduction condition, carrying out filtering to obtain secondary hydrothermal carbonization liquid and secondary hydrothermal carbonization materials, evaporating the secondary hydrothermal carbonization liquid, regulating the pH (Potential Of Hydrogen), and carrying out causticization treatment to obtain alkali liquid. The method provided by the invention has the advantages that because the alkali recovery work procedure is a bottle neck of most alkali process pulp making paper making plants in prior art, after the efficiency of the process is improved, the pulp making capability of the paper making plants can be greatly improved, meanwhile, the by-production of high-added-value activated carbon and white carbon black can be realized, and further, the scale benefits of the paper making enterprises can be integrally improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

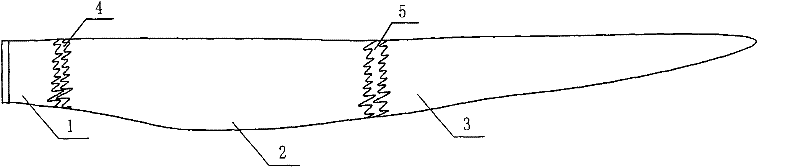

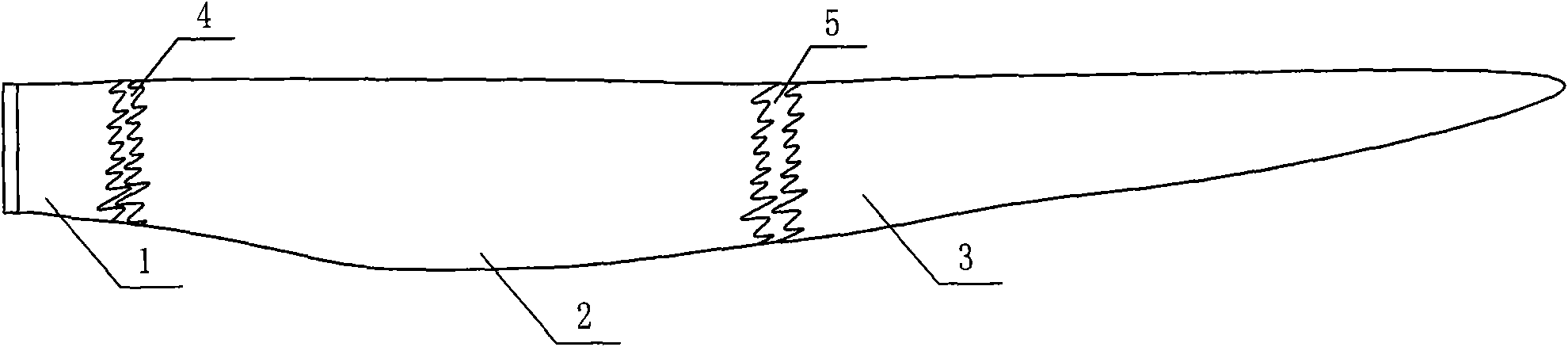

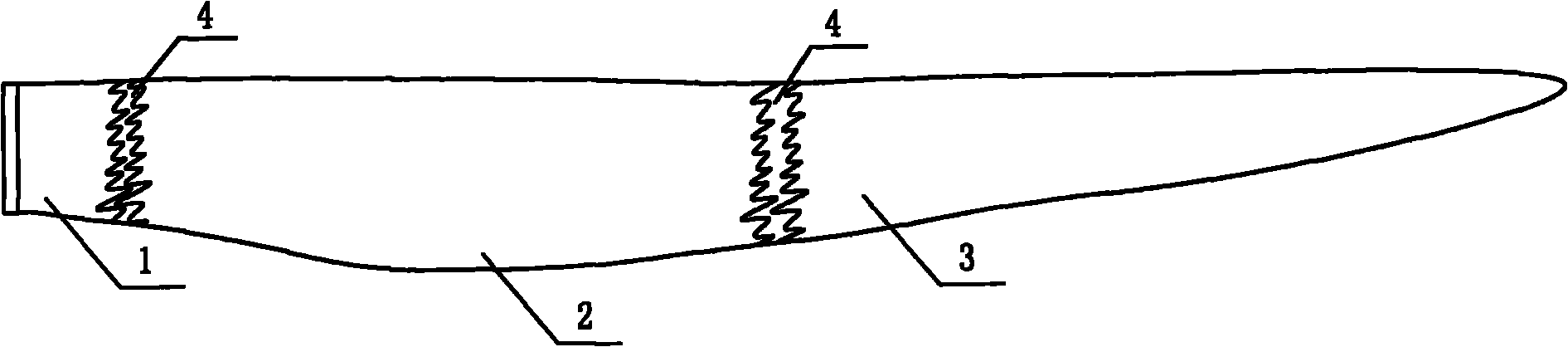

Fan motor blade made of different aluminium casting alloys

InactiveCN101994642BIncrease the lengthImprove pulping performanceMachines/enginesWind energy generationAluminium castingWind power generation

The invention discloses a fan motor blade made of different aluminium casting alloys, belonging to the field of wind power generation equipment parts. The operational performance of a long blade cast from a single aluminium alloy material can be influenced. The invention has the characteristics that the blade is divided into at least two parts which are made of different aluminium casting alloys,every adjacent two parts form a fusion area which constitutes the aluminium casting alloys of the two parts, so that different parts of the blade have different properties and can satisfy the needs for the operation of the long blade.

Owner:ZHEJIANG HENGTONG MACHINERY

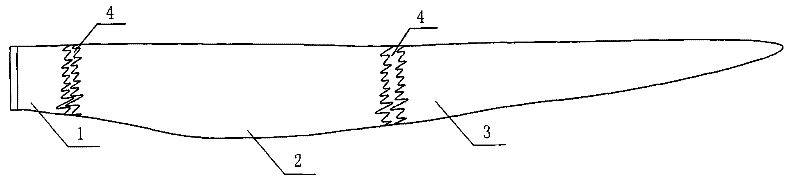

Preparation process of lithium iron phosphate material

ActiveCN105226282AHigh tap densityImprove pulping performanceCell electrodesSecondary cellsLithium electrodeOxalate

The invention relates to the lithium ion battery production field of the field of new energy, in particular to a preparation process of a lithium iron phosphate material. The preparation process of the lithium iron phosphate material comprises the following steps that step one, 18-22% by mass of lithium carbonate, 35-45% by mass of ferrous oxalate and 35-45% by mass of diammonium phosphate are mixed and put into a ball milling tank to perform ball milling for 7-11 hours, the materials are taken out and are sintered under the argon protection for 10-14 hours, and cooling is performed for 5-8 hours to form a mixture; step 2, sugar accounting for 6-8% by mass of the mixture and alcohol with the purity of more than 90% and accounting for 85-11% by mass of the mixture are added into the mixture prepared in the step, ball milling is performed for 7-11 hours, sintering is performed at the temperature of 720 DEG C for 10-14 hours after drying, cooling and smashing are performed, and screening is performed by using a 100-mesh screen. The tap density of material products is effectively increased, the pulping performance of the material in preparation of lithium ion batteries is effectively improved, the specific surface area is increased, and the specific capacity of the material is improved.

Owner:KAIFENG UNIV

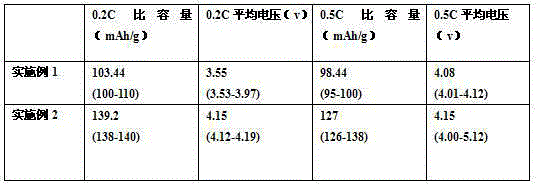

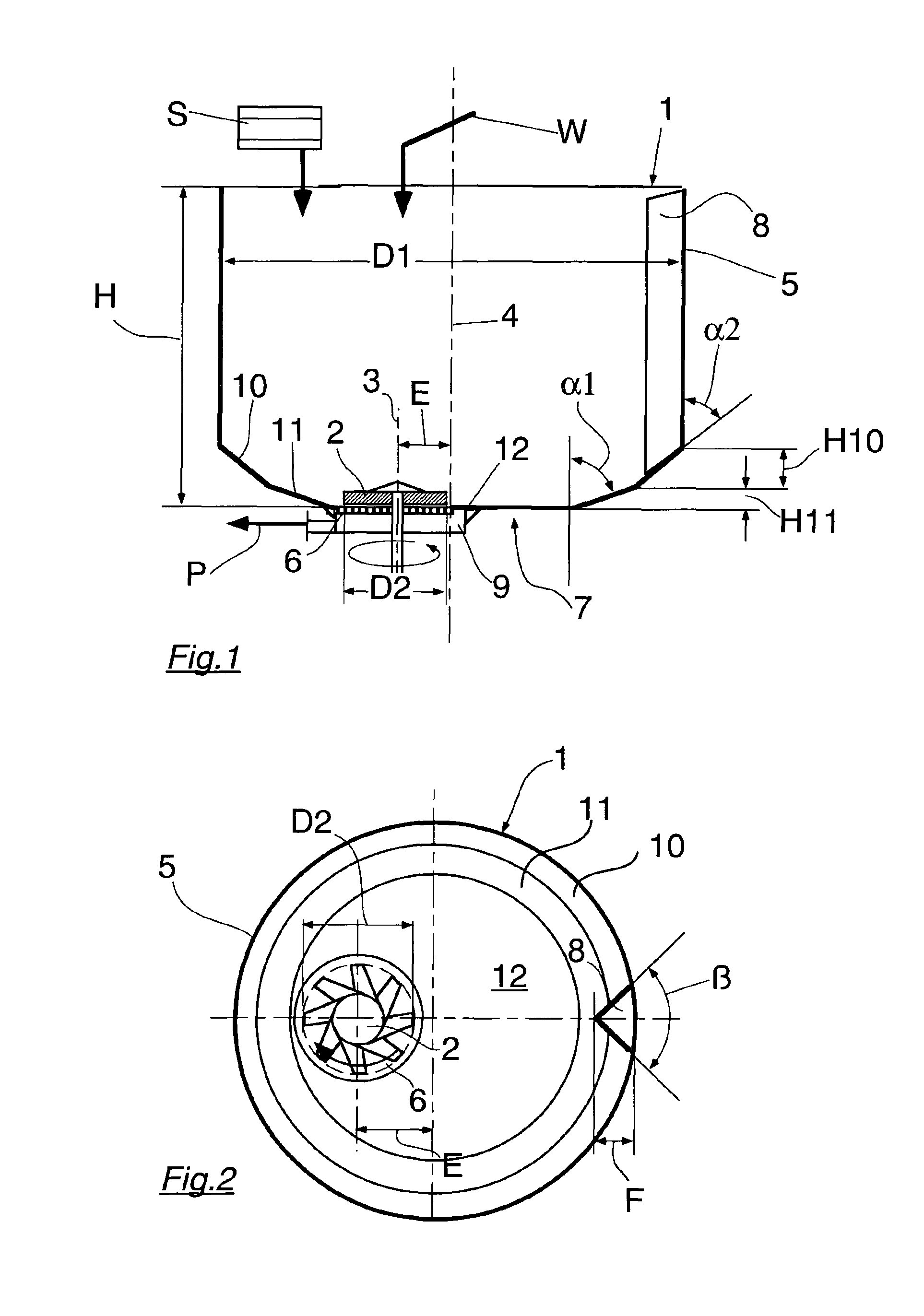

Pulper for comminuting and suspending paper stock and its use

ActiveUS7980497B2Faster entrainmentFast reduction contentGas current separationPaper recyclingEngineeringMechanical engineering

Owner:VOITH PATENT GMBH

Method for preparing lithium ion battery positive electrode material lithium vanadium oxide LiV3O8

InactiveCN109553133AImprove pulping performanceImprove tap densityCell electrodesSecondary cellsAir atmosphereThermal insulation

The invention discloses a method for preparing a lithium ion battery positive electrode material lithium vanadium oxide LiV3O8. The method comprises the following two steps: (1) carrying out ball milling and complete and uniform mixing on a coordination agent and raw materials for preparing a lithium vanadium oxide LiV3O8 by using a solid phase coordination method, placing in a muffle furnace, carrying out thermal insulation at a temperature of 80 DEG C in an air atmosphere, heating to a temperature of 350 DEG C, sintering, cooling, and crushing to form a mixture; and (2) carrying out pair roller pre-pressing on the mixture prepared in the step (1), sintering at a temperature of 550 DEG C, cooling, and crushing to obtain the product. According to the present invention, the target product is synthesized by combining the solid phase coordination method and the post-sintering process, such that the method of the present invention can overcome the disadvantages of insufficient reaction caused by the insufficient atom contact, not good product particle size and the like of the solid phase direct reaction, has advantages of easy operation and easy industrialization compared with the liquid phase reaction, and can obtain good performance products at a temperature lower than the direct solid phase reaction.

Owner:KAIFENG UNIV

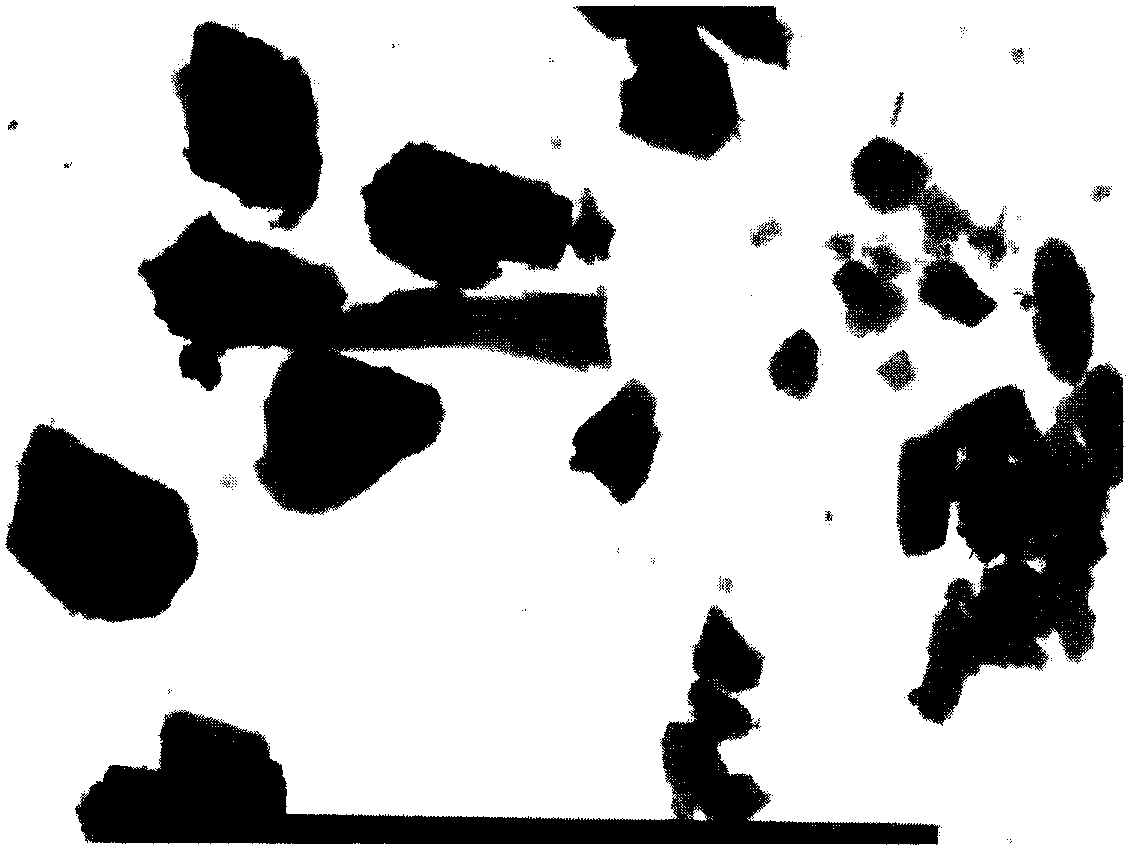

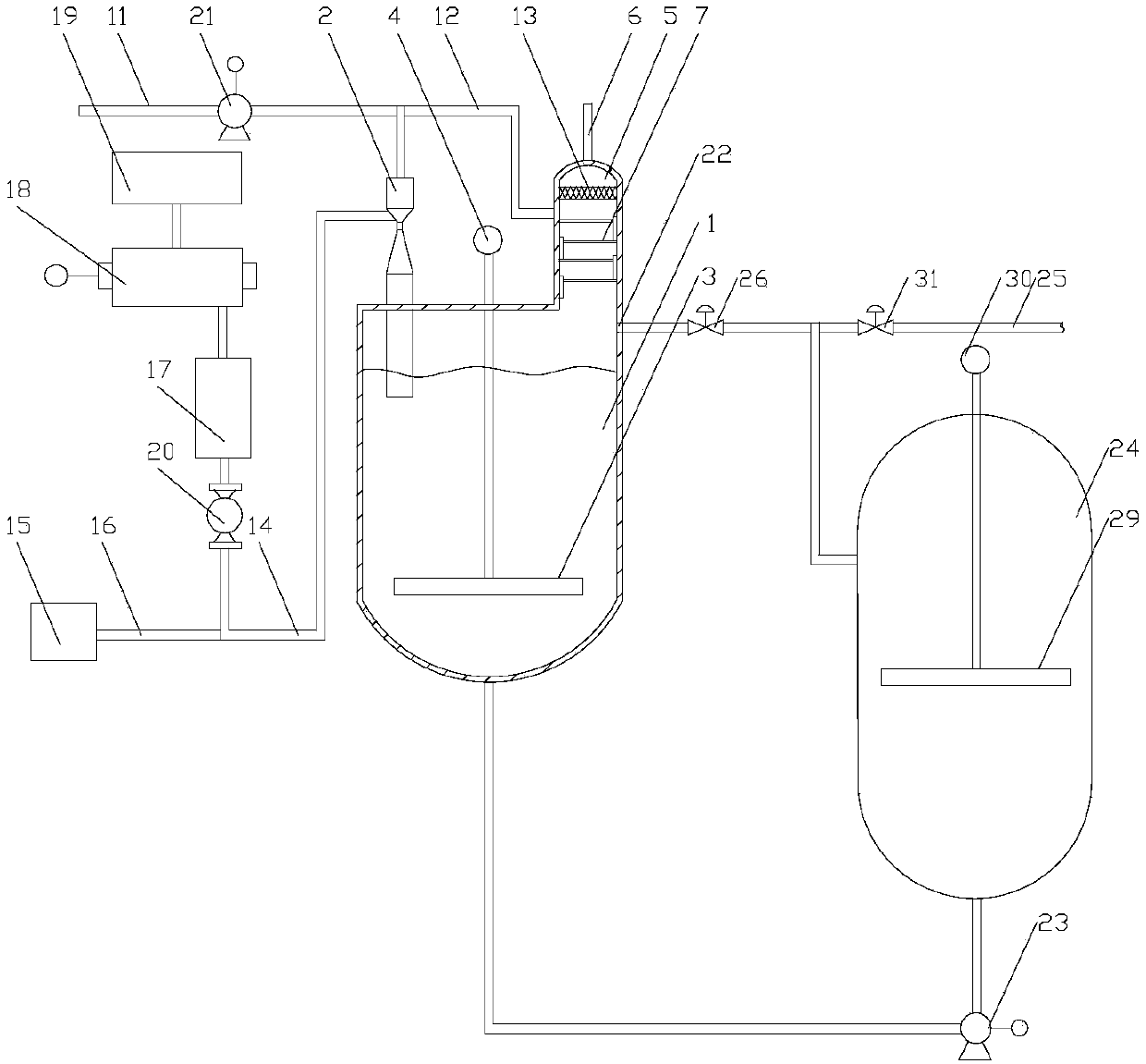

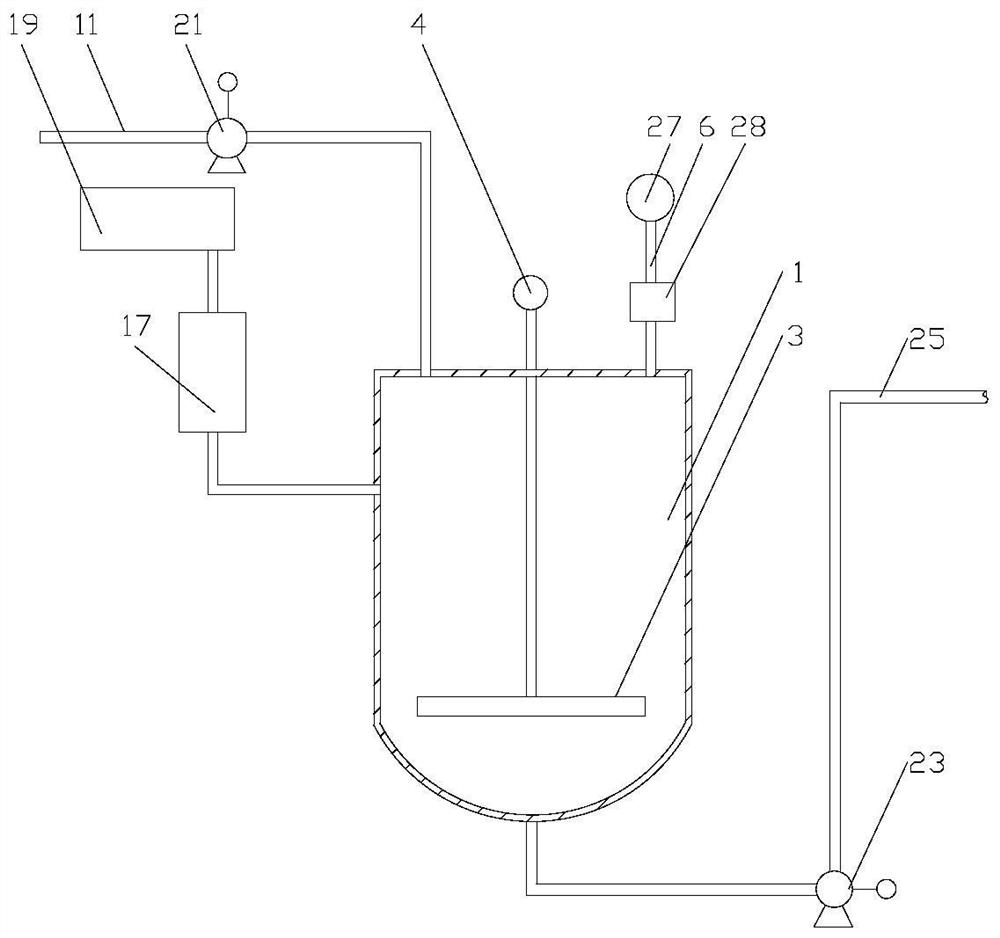

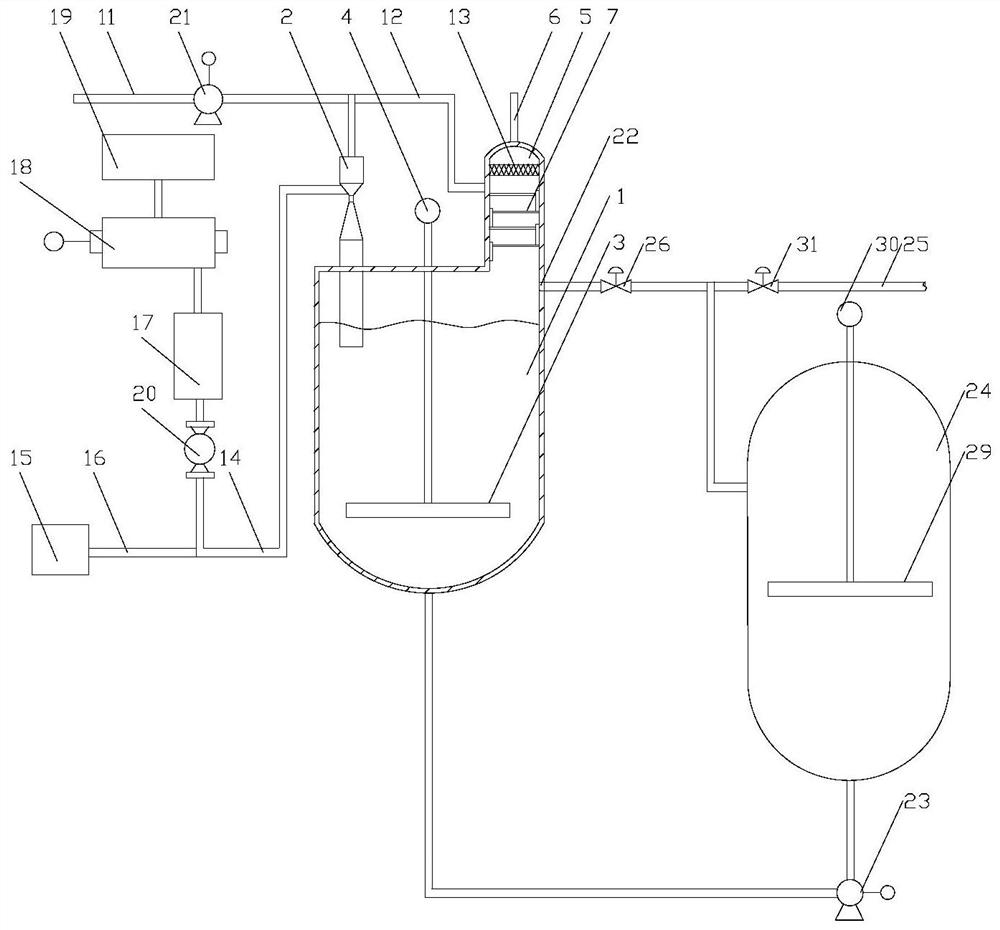

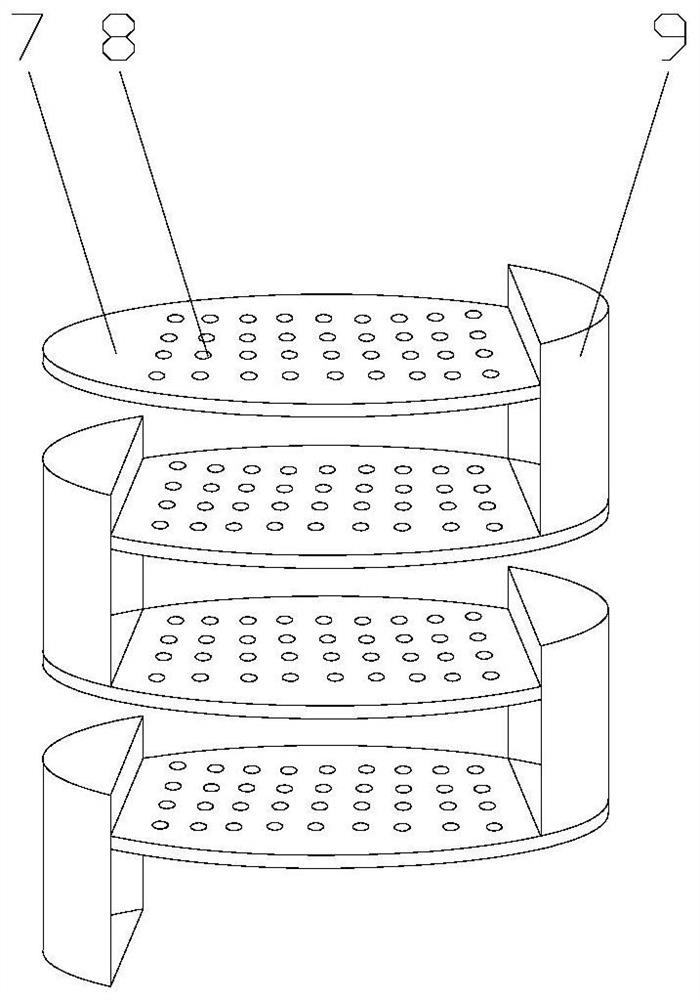

Hydrogasification semi-coke pulping apparatus and stable operation method thereof

PendingCN110354741AImprove semi-coke utilizationImprove pulping effectTransportation and packagingRotary stirring mixersUtilization rateLiquid surfaces

The invention discloses a hydrogasification semi-coke pulping apparatus and a stable operation method thereof. The apparatus comprises a pulping stirring tank, a pneumatic conveying device, a venturimixer and a pulp blending tank. The stable operation method comprises that semi-coke is pneumatically conveyed into a venturi mixer, and is mixed with industrial fresh water conveyed to the venturi mixer to obtain a pre-pulp. According to the present invention, semi-coke is conveyed to the venturi mixer through pneumatic conveying, and is mixed with the industrial fresh water, the semi-coke is fully wetted in advance, the wet semi-coke is conveyed to the pulping stirring tank, and the semi-coke directly enters the liquid surface of the pulping stirring tank, and is subjected to stirring pulping with the industrial fresh water in the pulping stirring tank, such that the semi-coke is mixed into the industrial fresh water to the maximal degree so as to improve the utilization rate of the semi-coke and improve the pulping effect.

Owner:XINNENG ENERGY CO LTD

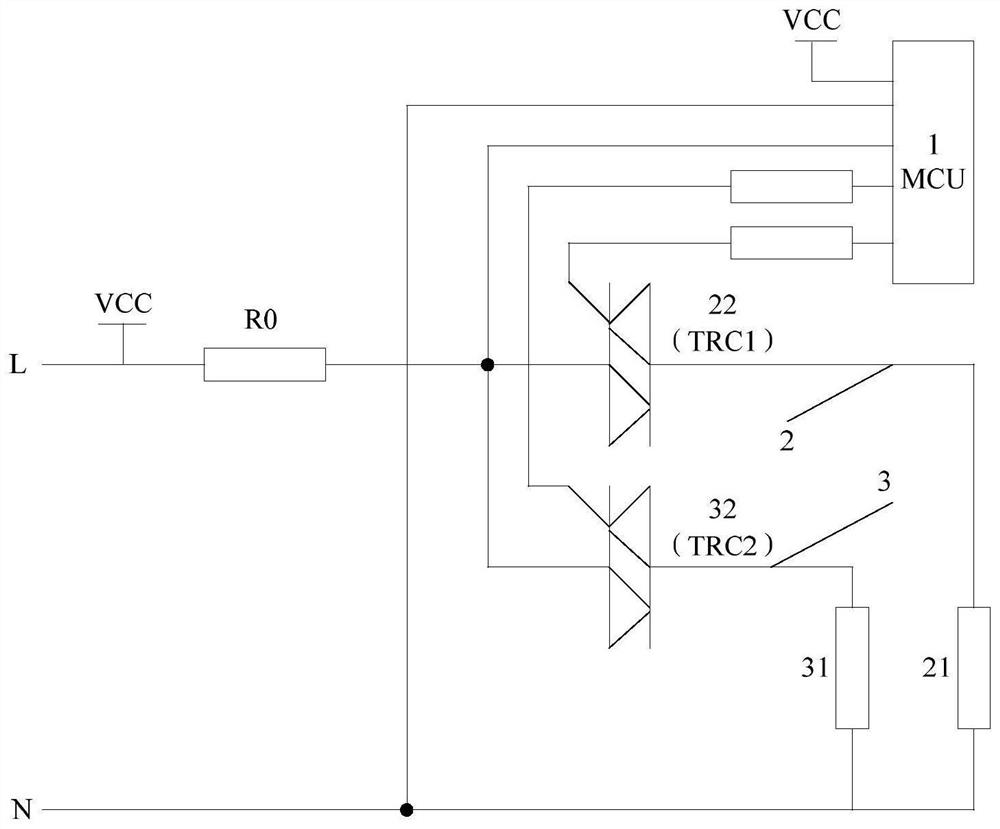

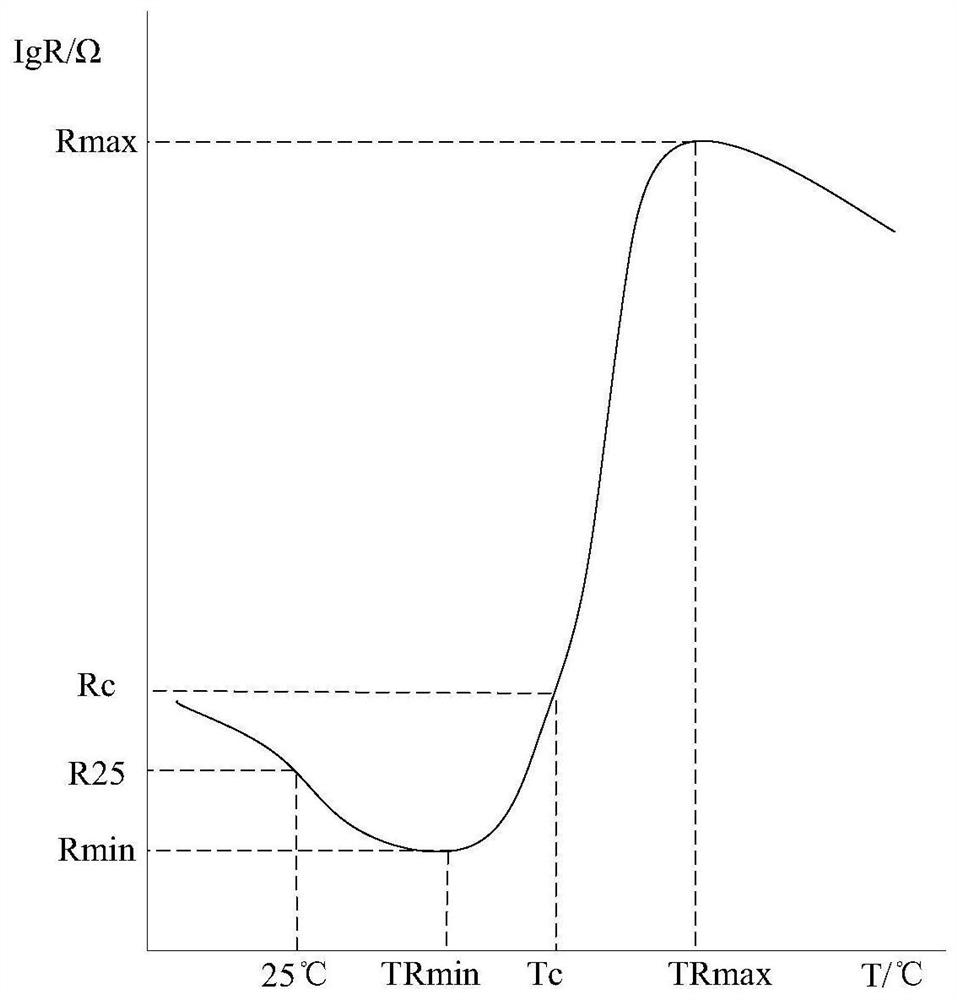

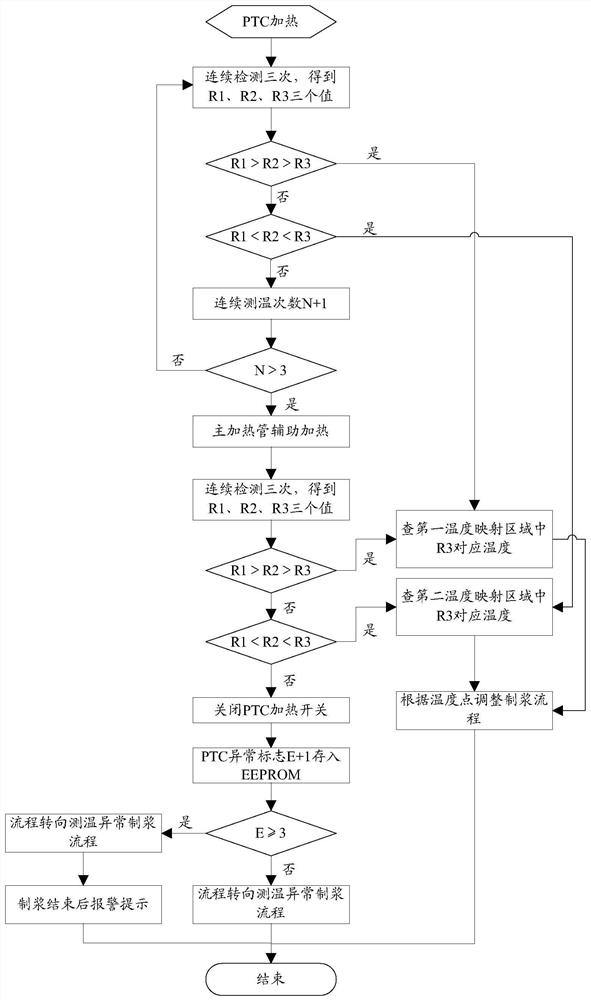

a food processor

ActiveCN107951389BImprove pulping performanceRefined temperature detection methodBeverage vesselsThermodynamicsEngineering

An embodiment of the invention discloses a food processor. The food processor is characterized in that the food processor comprises a main control unit and a first heating circuit, wherein the first heating circuit comprises a first heating device and a sampling resistance which are connected with a power supply in series; the main control unit samples current and voltage values of the first heating device during operation through the sampling resistance; the food processor further comprises a second heating device with positive temperature coefficient PTC; the main control unit is also used for collecting current and voltage values of the second heating device during heating through the sampling resistance; the temperature of a cup body at the location of the second heating device is detected according to the collected current and voltage values; pulping process is regulated, and / or slurry state is detected according to the detected cup temperature. The food processor has the advantages of achieving multiple functions such as cup temperature detection, accurate detection of water level, power-down memory and small power constant temperature detection according to the scheme of the embodiment and based on the application of the heating device with the positive temperature coefficient PTC, and improving pulping effects.

Owner:JOYOUNG CO LTD

A pulping method

ActiveCN107397425BImprove pulping performanceVessels with intergral heatingHeating timeProcess engineering

The invention proposes a pulping method. The pulping method includes steps: 1. Feeding stage, adding water and materials into the cup body assembly; 2. The first heating stage, heating to the temperature T1 with full power P1; 3. The first whipping stage, whipping at a low speed The water and materials, whipping speed R1, whipping time S1; 4. In the second heating stage, heat to the pin with power P2; 5. In the second whipping stage, if it is in a high voltage environment, the motor adopts variable speed crushing Whipping in normal mode, the duration of whipping is S2, and then the pause time is S3, so cycle N1 times, and then enter the next step; if the motor is whipping in the normal or low voltage environment, the motor is whipped in the normal pulverization mode, and the pause time is after the duration of whipping S4 S5, cycle N2 times in this way, and enter the next step; 6. In the boiling stage, heat with power P3, heating time S6. The pulping method provided by the invention can crush beans without producing more bean dregs, and improves the pulping effect.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Hydraulic coal slime crushing and pulping machine

PendingCN113522492ALarge scale useEfficient separationMixer accessoriesGrain treatmentsProcess engineeringMechanical engineering

The invention relates to a hydraulic coal slime crushing and pulping machine. The hydraulic coal slime crushing and pulping machine comprises a pulping structure, the pulping structure comprises a vertically erected barrel body, the side wall of the barrel body is provided with an ore pulp overflow port I, the top of the barrel body is provided with a cover, the cover is provided with a feeding port, a screening barrel is concentrically arranged in the barrel body, a gap is formed between the outer wall of the screening barrel and the inner wall of the barrel body, a plurality of screening holes are evenly formed in the side wall of the screening barrel, a plurality of crushing heads I are uniformly distributed on the inner wall of the screening cylinder, and a hydraulic cyclone structure used for driving water coal slime to rotate is arranged in the screening barrel. According to the hydraulic coal slime crushing and pulping machine, the crushing and pulping effects are achieved by utilizing rotational flow of water, crushing equipment is not blocked, the pulping effect is good, coal and mud are effectively separated, it is guaranteed that no muddy particles exist in the ore pulp, the pulping effect is further improved, the practicability is high, and the machine is worthy of popularization.

Owner:西安一泥科技有限公司

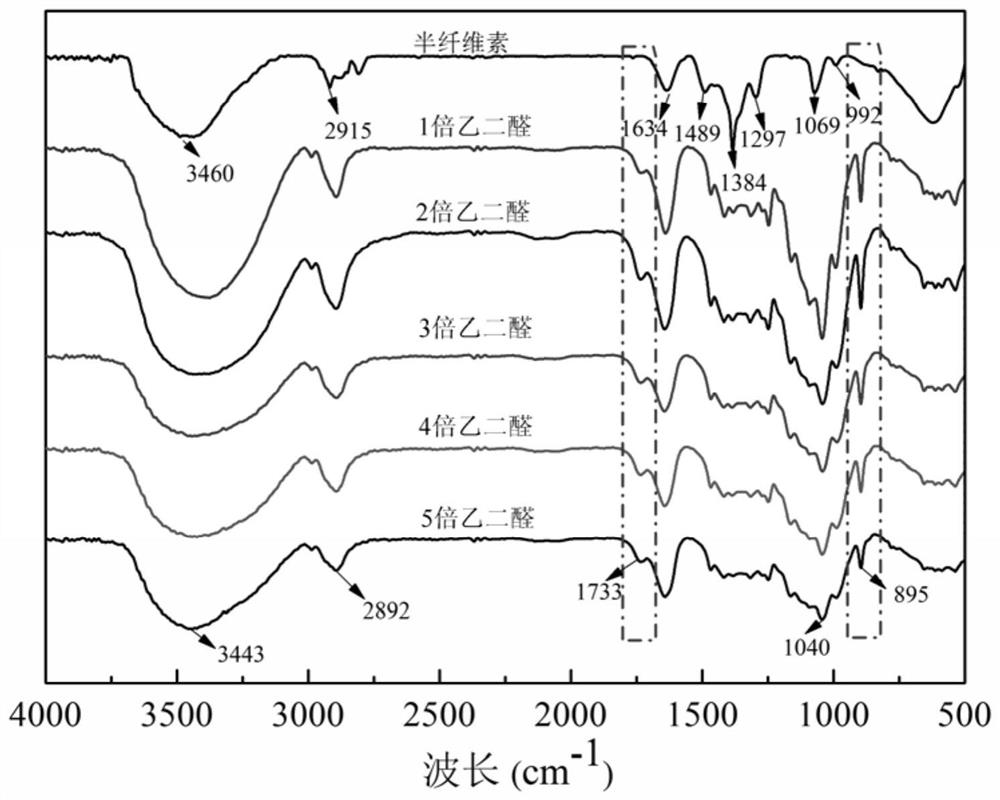

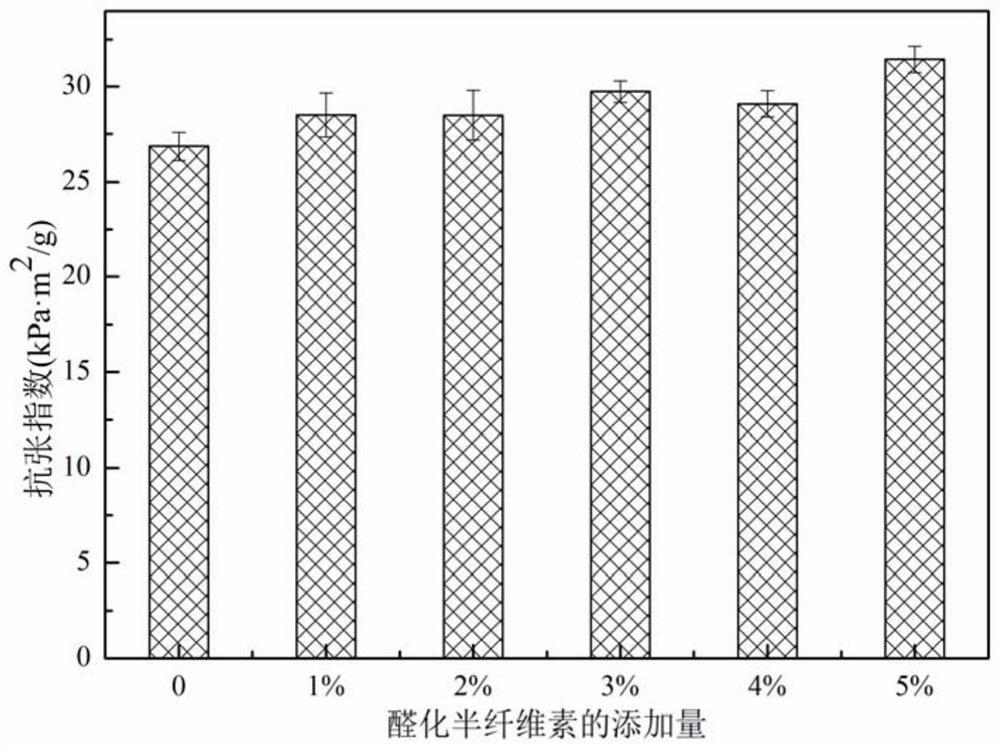

A method for enhancing the performance of waste paper pulp-based paper by using formaldehyde hemicellulose

ActiveCN108221462BWide variety of sourcesNo pollution in the processReinforcing agents additionPaper/cardboardPapermakingHemicellulose

Owner:SOUTH CHINA UNIV OF TECH

Papermaking equipment for paper mill having opposite direction pulping function

InactiveCN108978311AReduce manufacturing costReduce labor costsPulp beating/refining methodsPulp and paper industryCantilever

Papermaking equipment for a paper mill having an opposite direction pulping function, the papermaking equipment includes a pedestal, the upper side of the pedestal is fixedly connected with a cantilever beam through a support pillar, a power unit is arranged in the cantilever beam, the upper side of the base is also fixedly connected with a shell, the shell is fixedly connected with the support pillar through a fixed pillar, the shell is composed of a first sleeve, a transition sleeve and a second sleeve, the transition sleeve is in the shape of a circular truncated cone with a large upper part and a smaller lower part, an upper sleeve and a lower sleeve are connected through the transition sleeve, the shell is internally provided with a rotating shaft, and the top end of the rotating shaft is connected with a power unit; the top of the second sleeve is fixedly provided with an interception filter screen; the rotating shaft is hollow, the rotating shaft is internally provided with a pipeline, and one end of the pipeline is connected with a pump body fixedly arranged on the outer side wall of the first sleeve. The papermaking equipment provided by the invention in reasonable in structural design, convenient to use and high in papermaking efficiency, effectively improves the papermaking efficiency, reduces the production cost of enterprises and saves the labor force expenditure of enterprises, and thus has wide popularization and application value.

Owner:佛山市北科科技创新服务中心

Fan motor blade made of different aluminium casting alloys

InactiveCN101994642AIncrease the lengthImprove pulping performanceMachines/enginesWind energy generationAluminium castingWind power generation

The invention discloses a fan motor blade made of different aluminium casting alloys, belonging to the field of wind power generation equipment parts. The operational performance of a long blade cast from a single aluminium alloy material can be influenced. The invention has the characteristics that the blade is divided into at least two parts which are made of different aluminium casting alloys, every adjacent two parts form a fusion area which constitutes the aluminium casting alloys of the two parts, so that different parts of the blade have different properties and can satisfy the needs for the operation of the long blade.

Owner:ZHEJIANG HENGTONG MACHINERY

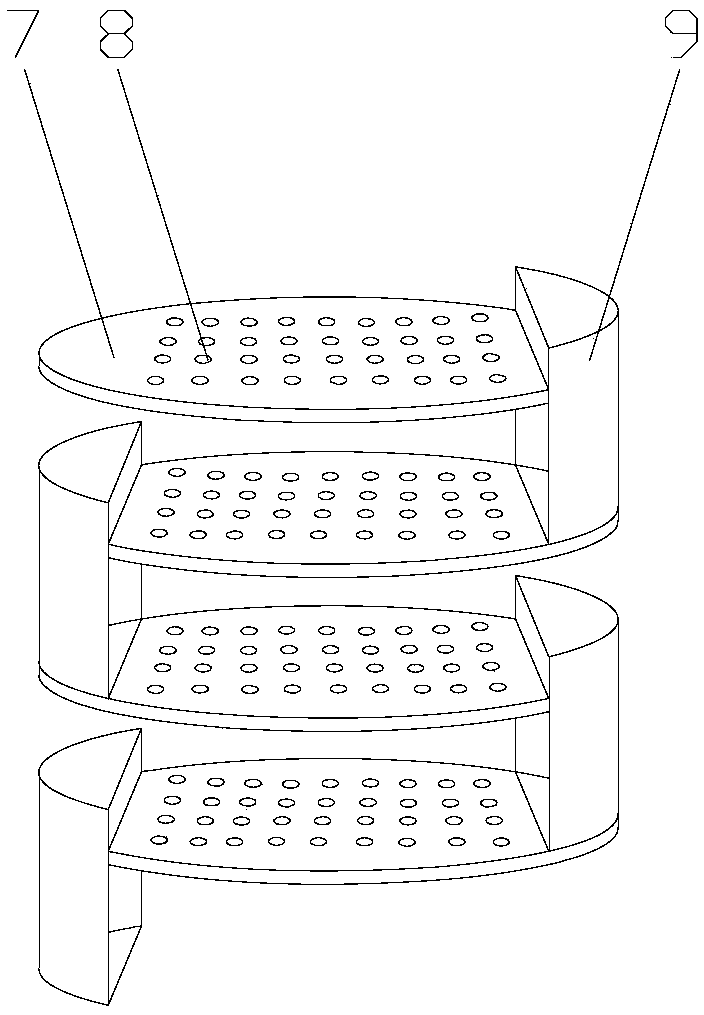

Hydrogasification semi-coke pulping method

ActiveCN110055116BGuarantee continuous and stable operationGasification process goes wellTransportation and packagingMixersCokeProcess engineering

The invention discloses a hydrogasification semi-coke pulping method, which includes a start-up stage and a stable operation stage. The advantage of the present invention is that, through pneumatic conveying, the semi-coke is transported to the Venturi mixer to be mixed with industrial fresh water, the semi-coke is fully wetted in advance, and then the wetted semi-coke is transported to the slurry mixing tank, and the semi-coke is Coke directly enters under the liquid level of the pulping mixing tank, and is stirred with the industrial fresh water in the pulping mixing tank to make pulp, ensuring that the semi-coke is mixed into the industrial fresh water to the greatest extent, improving the utilization rate of the semi-coke and improving the pulping effect; mixing After the compressed gas with semi-coke enters the semi-coke treatment chamber, it moves upwards through the through hole of the tray. The semi-coke contacts the water film on the tray, and the semi-coke is intercepted by the water film and falls back to the pulping process with the flowing industrial fresh water. In the mixing tank, pulping is carried out, and the utilization rate of semi-coke is increased to 99%, which avoids the waste of semi-coke caused by emptying, and reduces the cost of semi-coke pulping.

Owner:XINNENG ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com