Hydrogasification semi-coke pulping apparatus and stable operation method thereof

A hydrogenation gasification and stable operation technology, applied in the field of coal chemical industry, can solve the problems of blockage and damage of the filter 28 and induced draft fan 27, reduce the gasification efficiency of coal-water slurry, affect the gasification process of coal-water slurry, etc., and achieve improvement Pulping effect, improving the utilization rate of semi-coke, and ensuring the effect of continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

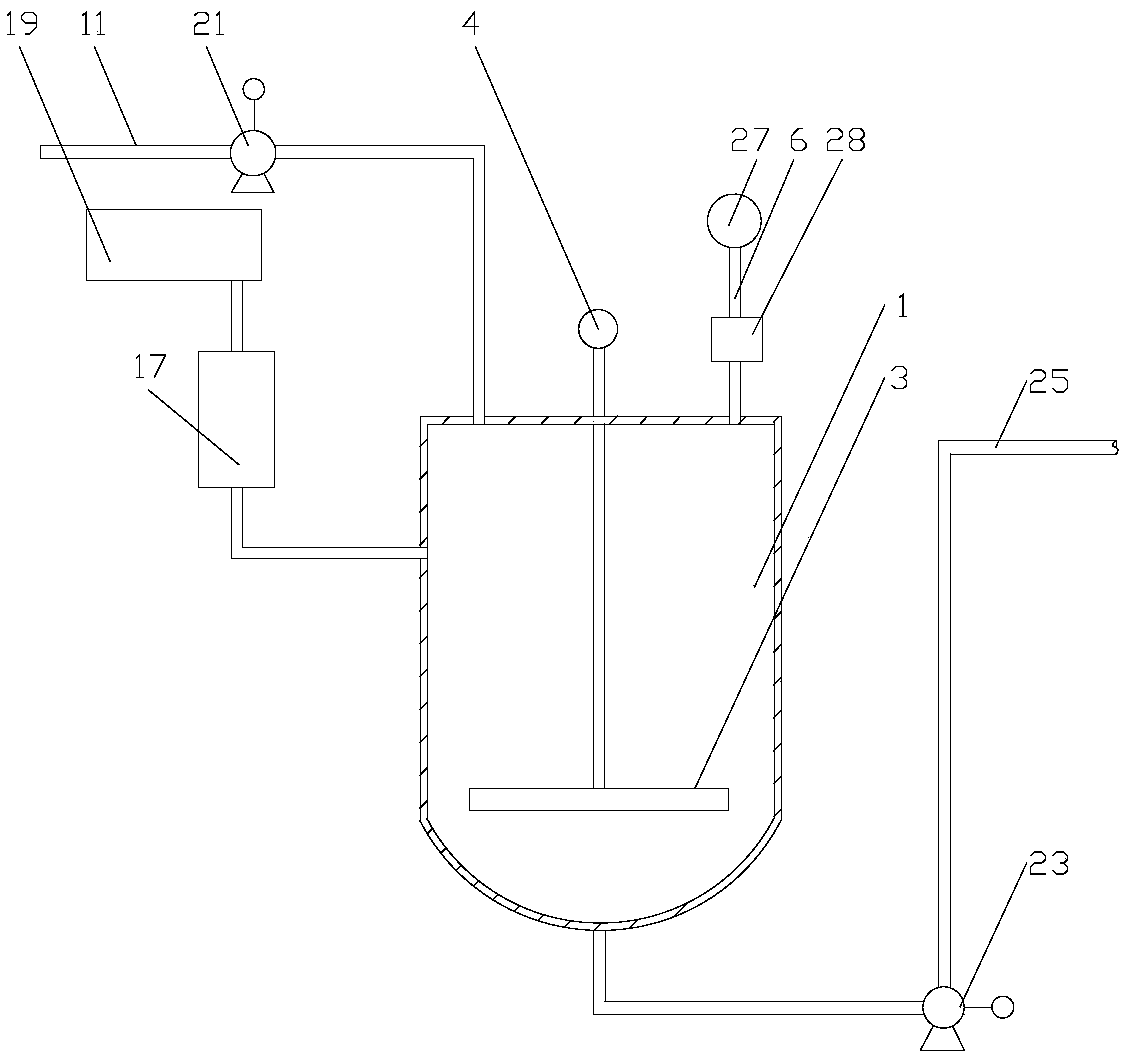

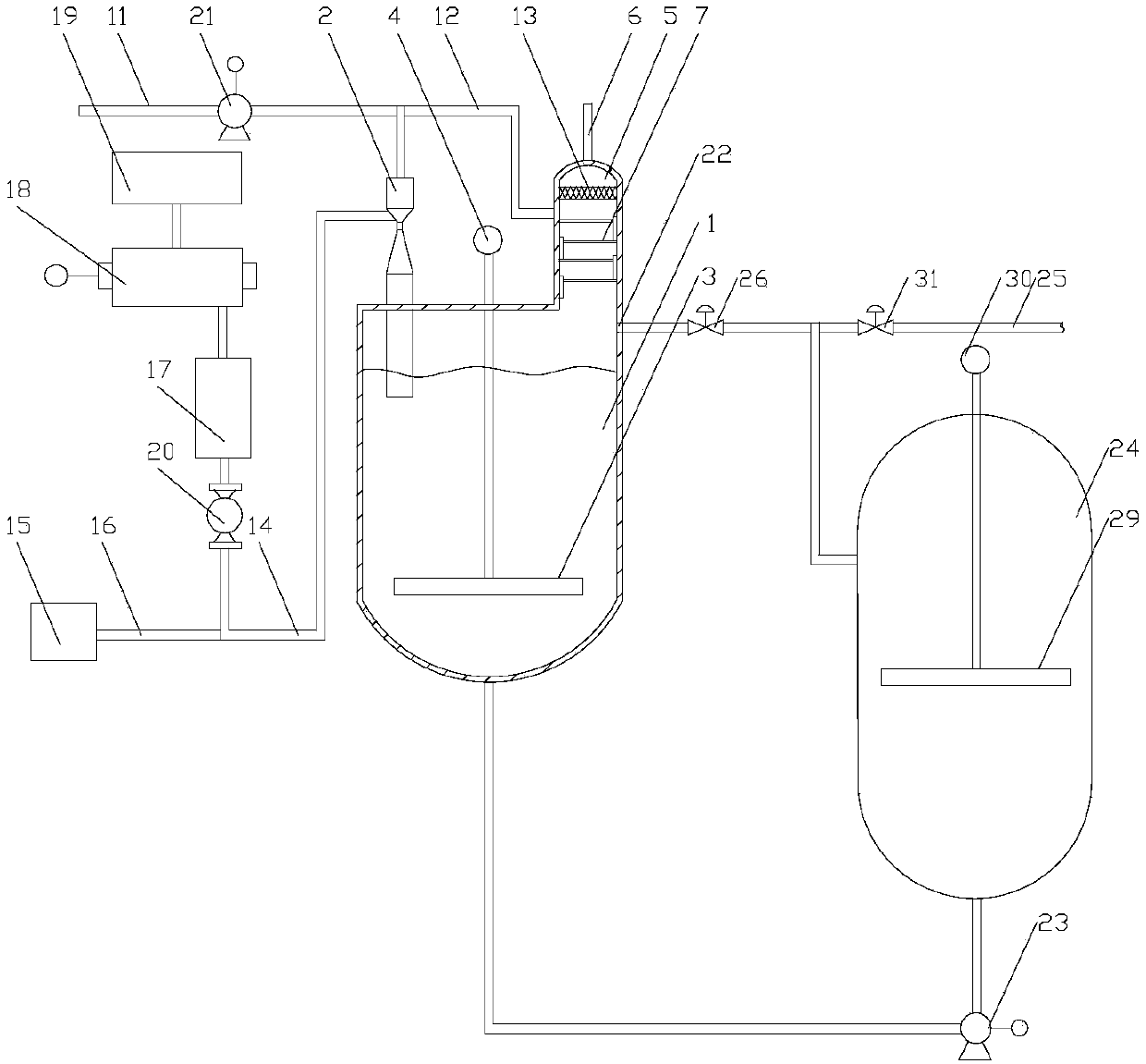

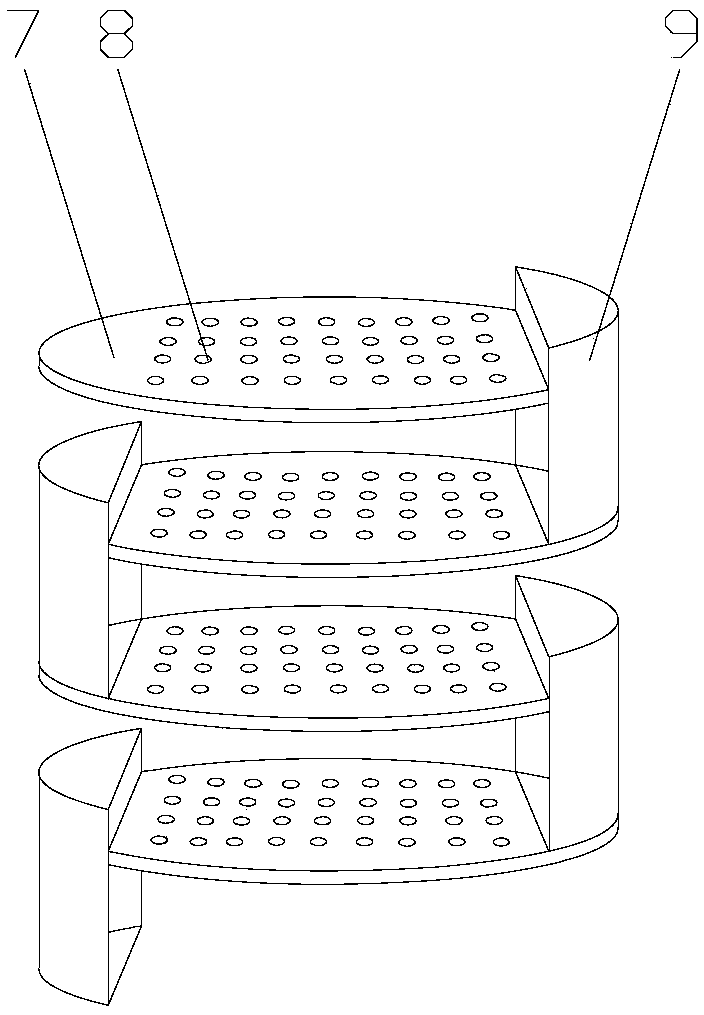

[0024] like Figure 2-3 As shown, the hydrogasification semi-coke pulping device includes a pulping stirring tank 1, a Venturi mixer 2 is provided at the feeding port of the pulping stirring tank 1, and a pulping agitator is arranged in the pulping stirring tank 1 3. The top of the rotating shaft of the pulping agitator 3 passes through the top of the pulping stirring tank 1 and is fixedly connected with the output shaft of the pulping rotating motor 4. The top of the pulping stirring tank 1 is provided with a semi-coke processing chamber 5, which The inside of 5 communicates with the inside of the pulping stirring tank 1, the bottom of the semi-coke processing chamber 5 is connected with the top of the pulping stirring tank 1, and the top of the semi-coke processing chamber 5 is provided with an emptying pipe 6; There are at least two trays 7 in the shape of a superior arc in a staggered manner. In this embodiment, the number of trays 7 is 4, and the trays 7 are arranged hori...

Embodiment 2

[0027] Using the stable operation method of the hydrogasification semi-coke pulping device carried out in Example 1, the semi-coke is pneumatically transported into the Venturi mixer 2 and mixed with the industrial fresh water transported into the Venturi mixer 2, and the pressure of the pneumatic transport is The operating pressure of pulping stirring tank 1 is 0.1MPa, the mixing mass ratio of semi-coke and industrial fresh water of Venturi mixer 2 is 1:0.8, and the outlet of Venturi mixer 2 is placed in pulping stirring tank 1 Below the inner liquid level, the pre-pulp is obtained after mixing; the pre-pulp enters the slurry mixing tank 1 for stirring, and the stirring speed is 30r / min; during the stirring process, the industrial fresh water is passed into the semi-coke processing chamber 5 , the mixed mass ratio of the pneumatically conveyed semi-coke and the industrial fresh water passing into the semi-coke treatment chamber 5 is 1:0.8, and the industrial fresh water flows ...

Embodiment 3

[0033] Using the stable operation method of the hydrogasification semi-coke pulping device carried out in Example 1, the semi-coke is pneumatically transported into the Venturi mixer 2 and mixed with the industrial fresh water transported into the Venturi mixer 2, and the pressure of the pneumatic transport is The operating pressure of pulping stirring tank 1 is 0.15MPa, the mixing mass ratio of semi-coke and industrial fresh water of Venturi mixer 2 is 1:0.9, and the outlet of Venturi mixer 2 is placed in pulping stirring tank 1 Below the inner liquid level, pre-pulp is obtained after mixing; the pre-pulp enters the pulping mixing tank 1 for stirring, and the stirring speed is 40r / min; during the stirring process, pass industrial fresh water into the semi-coke processing chamber 5 , the industrial fresh water flows along the upper surface of the tray 7, forming a layer of water film on the upper surface of the tray 7, part of the semi-coke that has not been mixed with the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com