Patents

Literature

84results about How to "Optimize dwell time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

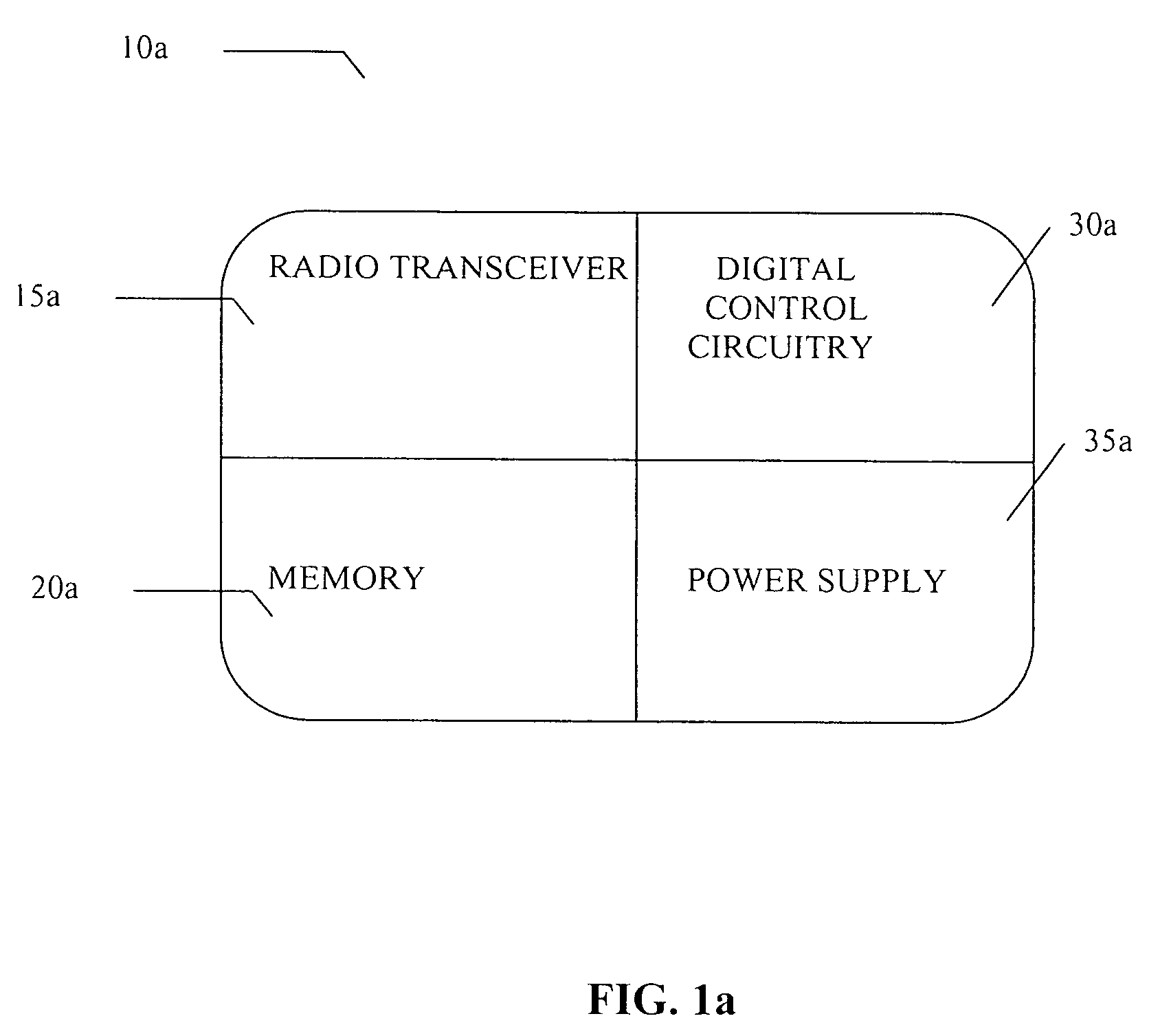

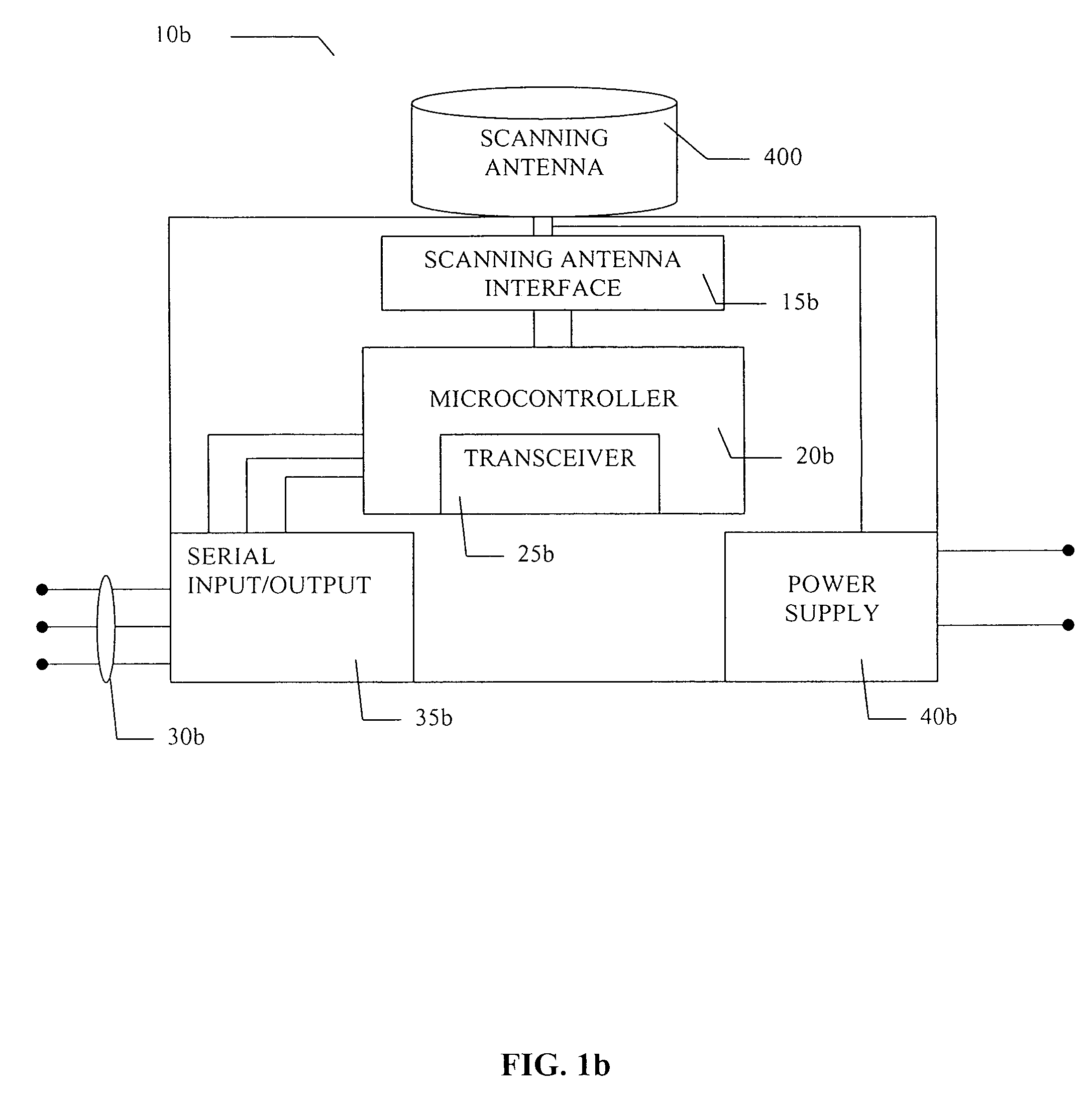

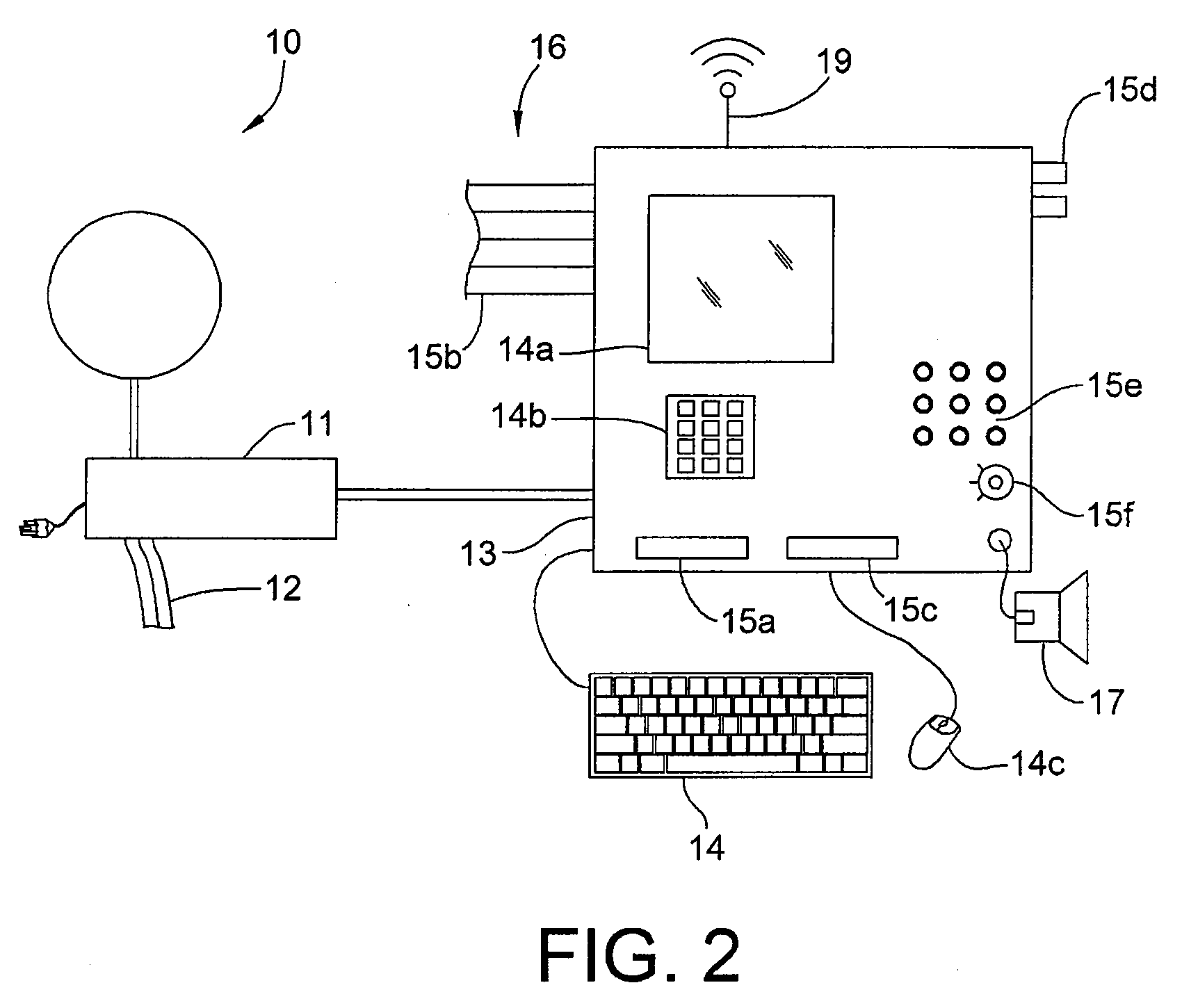

RFID tag reading system and method

ActiveUS20050110641A1Optimize dwell timeNear-field transmissionPosition fixationPhase shiftedTransmitted power

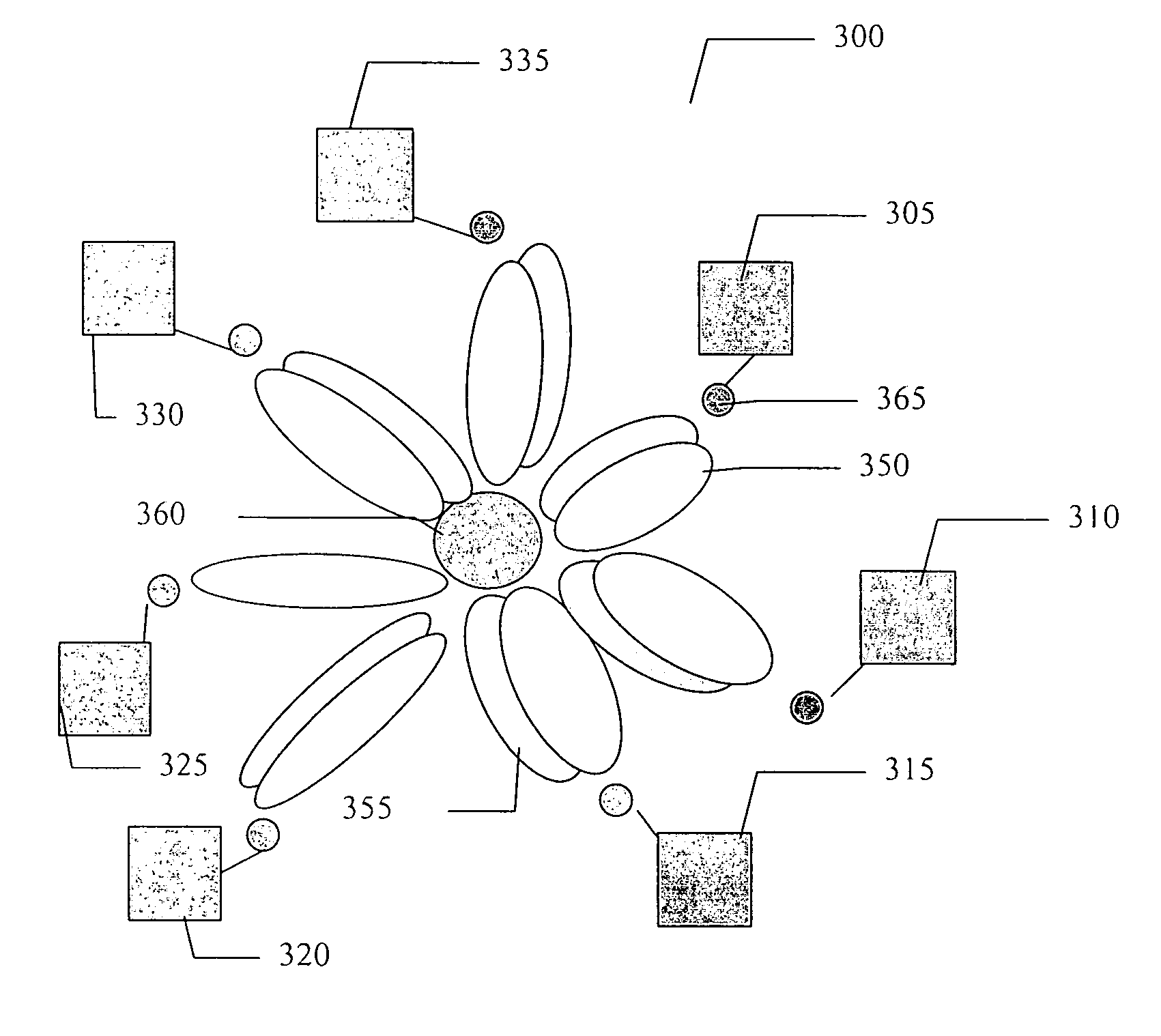

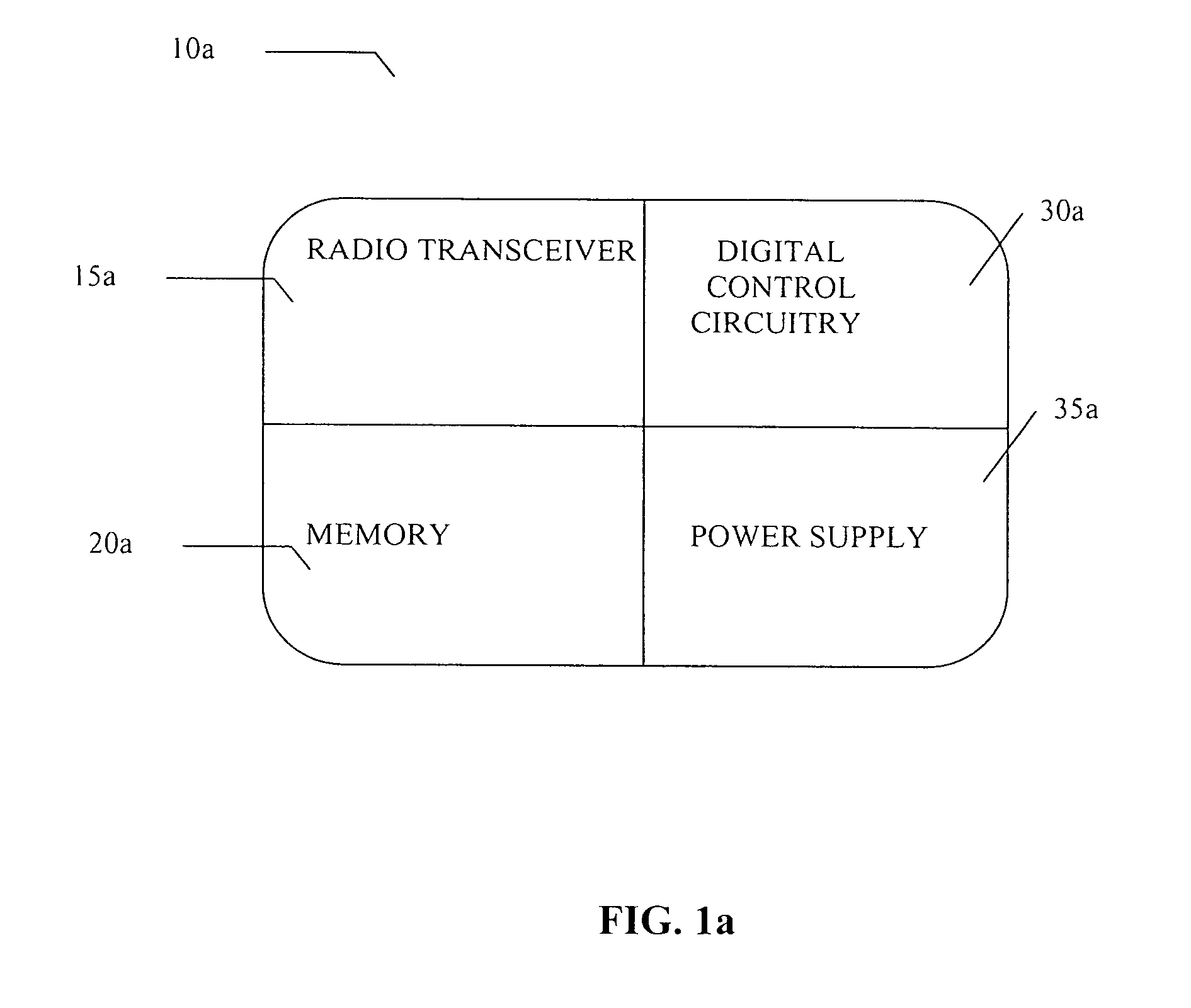

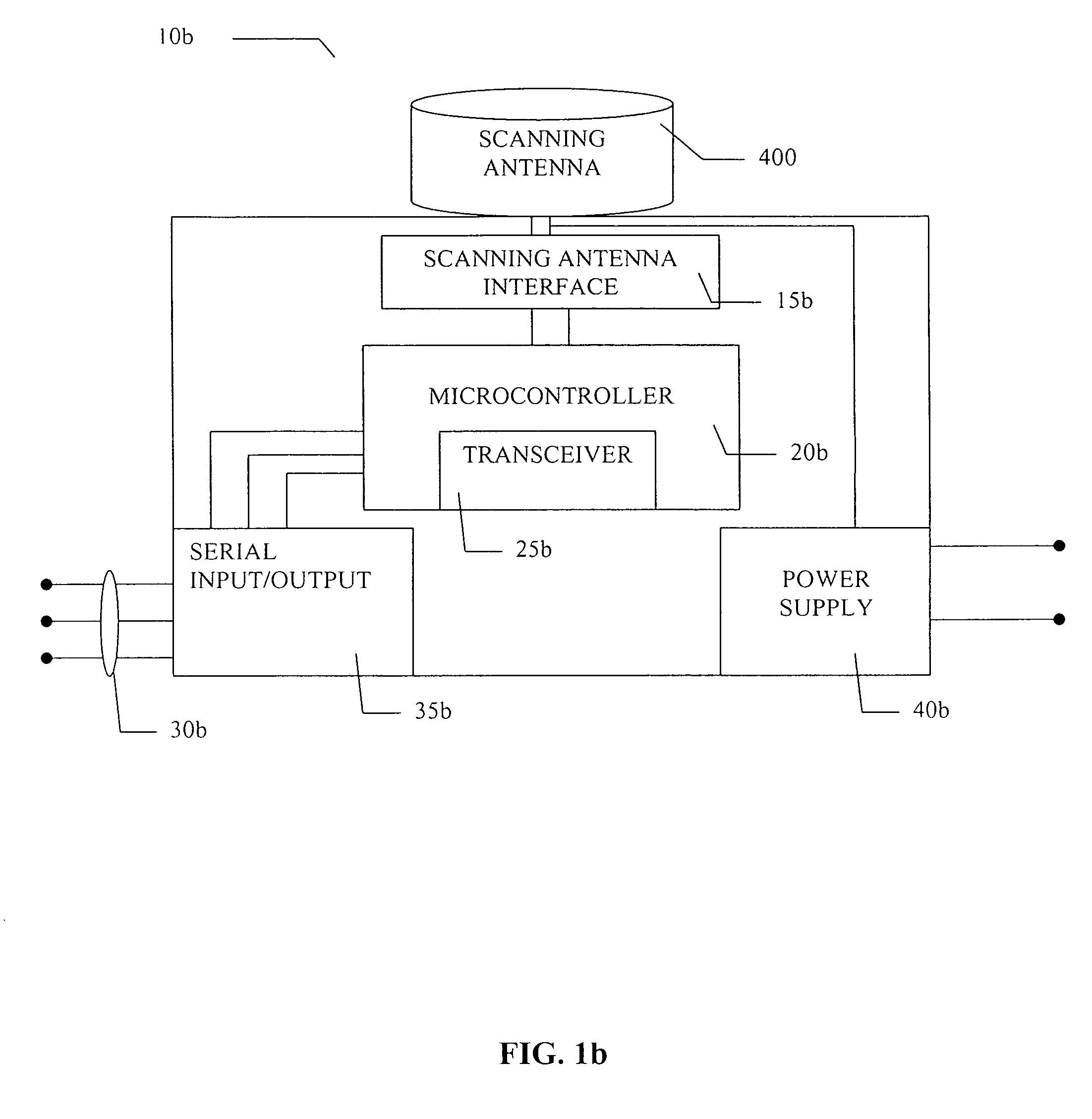

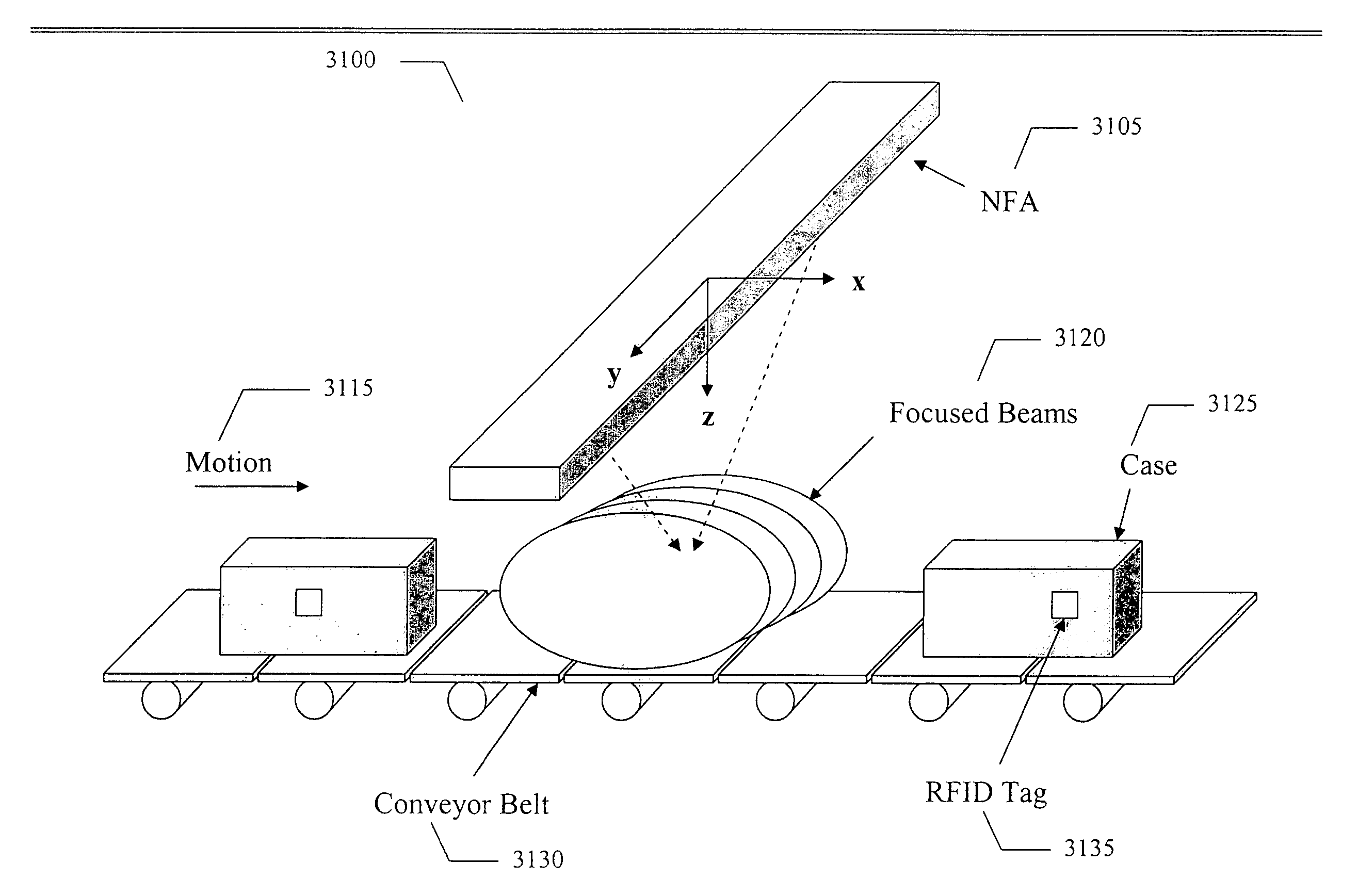

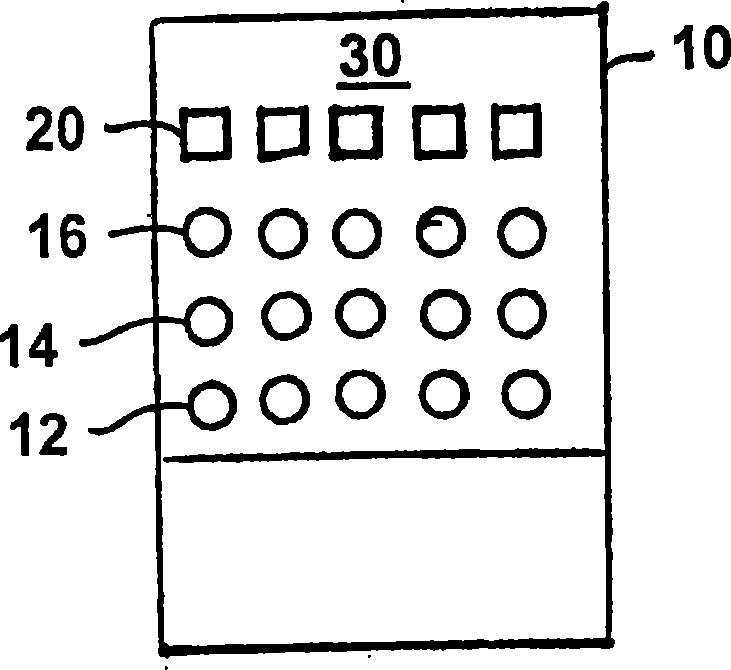

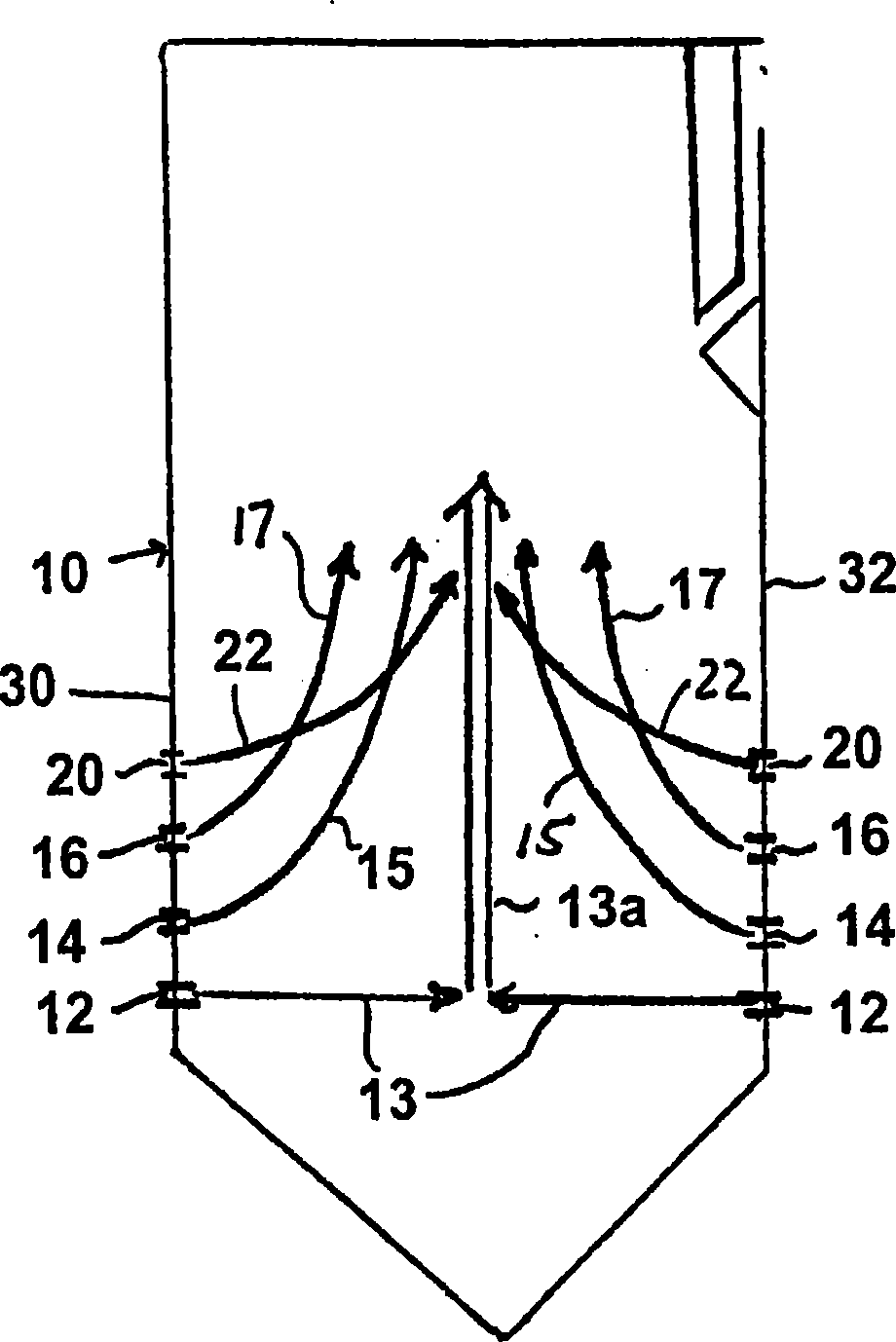

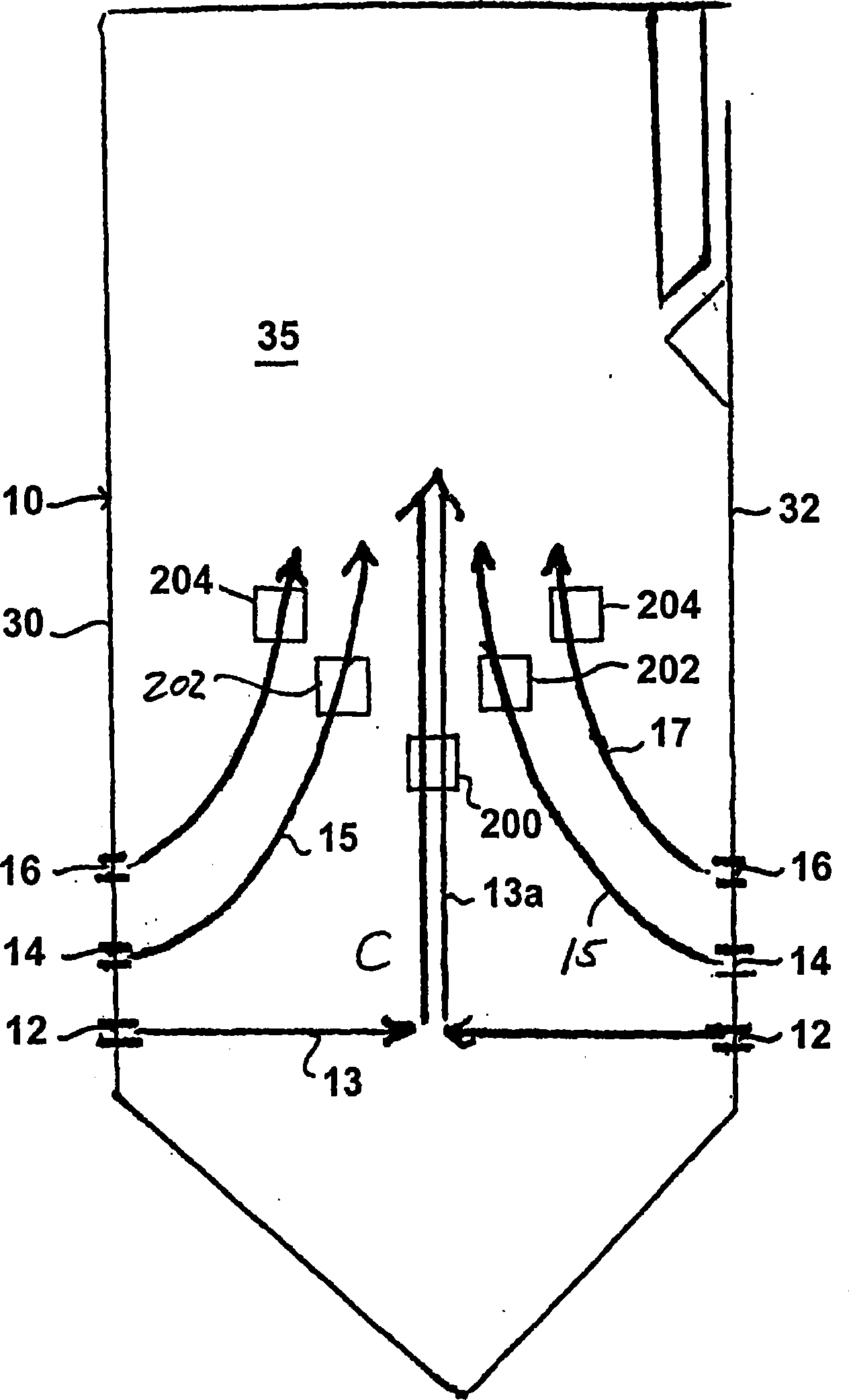

An embodiment of the present invention provides an RFID tag reading system, comprising an antenna system associated with a portal through which said RFID tag may pass, said antenna system comprising: a plurality of non-uniformly spaced antenna elements arranged substantially linearly; a power divider for dividing transmit power thereby coupling signals to said plurality of antenna elements; and a beamforming network capable of phase shifting the signals between the power divider and the plurality of antenna elements such that radiated signals from each antenna element add coherently such that the radiated electromagnetic energy is focused at a focal point in the near field region or in the Fresnel region of said antenna system.

Owner:NXP USA INC

RFID tag reading system and method

InactiveUS7187288B2Optimize dwell timeNear-field transmissionPosition fixationPhase shiftedTransmitted power

An embodiment of the present invention provides an RFID tag reading system, comprising an antenna system associated with a portal through which said RFID tag may pass, said antenna system comprising: a plurality of non-uniformly spaced antenna elements arranged substantially linearly; a power divider for dividing transmit power thereby coupling signals to said plurality of antenna elements; and a beamforming network capable of phase shifting the signals between the power divider and the plurality of antenna elements such that radiated signals from each antenna element add coherently such that the radiated electromagnetic energy is focused at a focal point in the near field region or in the Fresnel region of said antenna system.

Owner:NXP USA INC

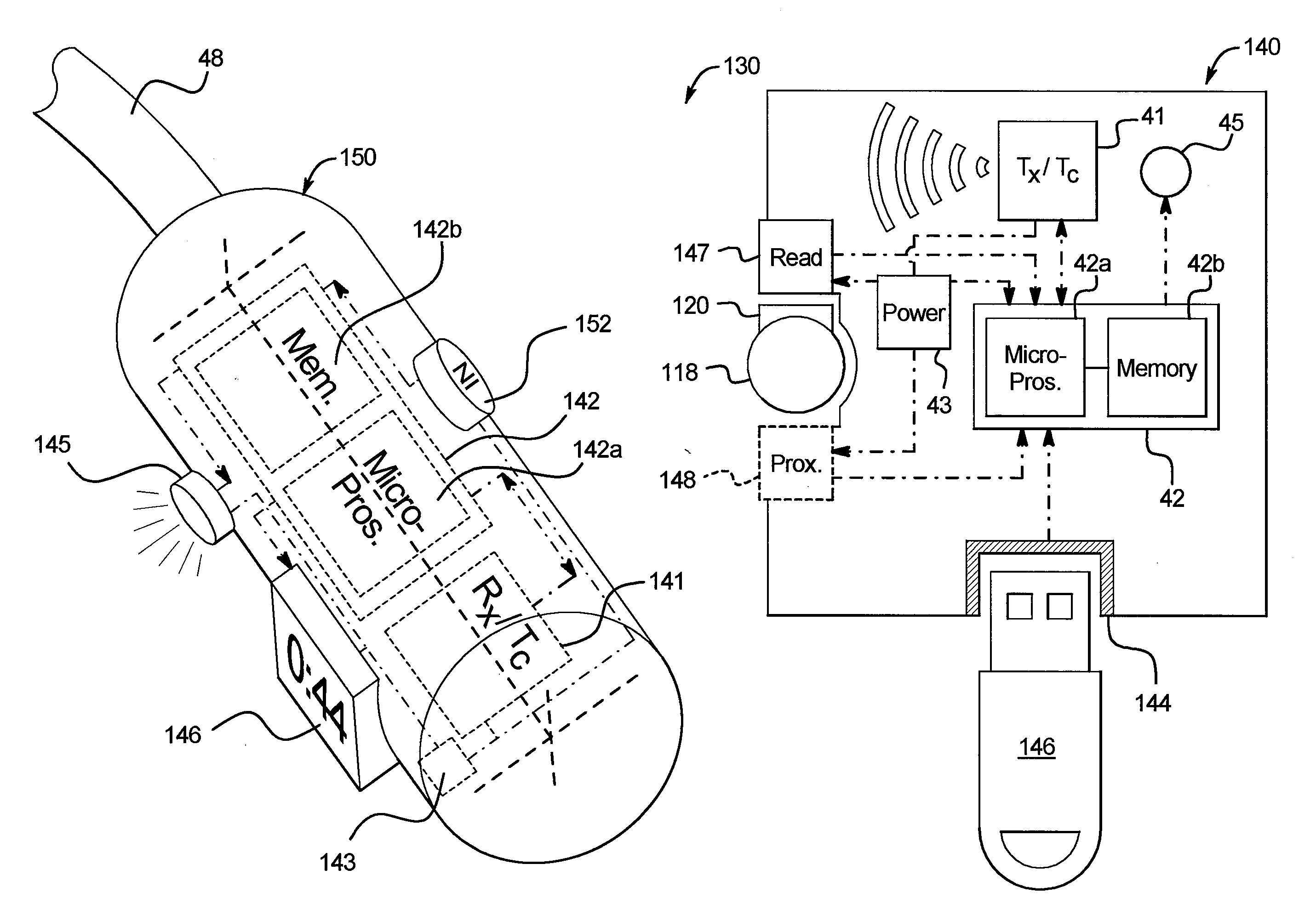

Optimizing therapy outcomes for peritoneal dialysis

ActiveUS20090275881A1Optimize therapy dwell timeStreamline therapy timePerson identificationMedical devicesTherapy OutcomePeritoneal dialysis catheter

Peritoneal dialysis therapy outcomes have been calculated for a variety of dwell times of peritoneal dialysis fluids in the peritoneal cavities of dialysis patients using kinetic modeling. The length of dwell time should not be the same for every patient, but should vary according to the patient condition and needs. Some patients have a potential for expressing greater ultrafiltrate into the dialysis fluid, and these patients can benefit from a longer dwell time, whereas other patients with less potential will not benefit from a longer dwell time. An optimal or peak time is observed for each peritoneal dialysis therapy outcome, such as ultrafiltrate volume rate, urea clearance (Kt / V), and creatinine clearance, while minimizing hydrocarbon absorption. These values and input parameters can be used to tailor the peritoneal dialysis dwell time for each patient, estimating the peak dwell time that will yield the best therapy outcome for each patient.

Owner:BAXTER HEALTHCARE SA +1

Micro particle feed for rockfish fry and its production procss

InactiveCN1442078ASolve the bottleneck of severe shortage of supplyHigh economic valueClimate change adaptationAnimal feeding stuffRockfishAntioxidant

A microgranular bait for the fry of Epinephelus is prepared from crude protein, crude fat, phosphatide, ash, n-3HUFA, DHA / EPA, DHA, and EPA according to a certain proportion through enzymolyzing by proteinase, further adding antioxidizing agent, filtering, and spray drying. Its advantages are rich nutrients, and low settling speed.

Owner:SUN YAT SEN UNIV

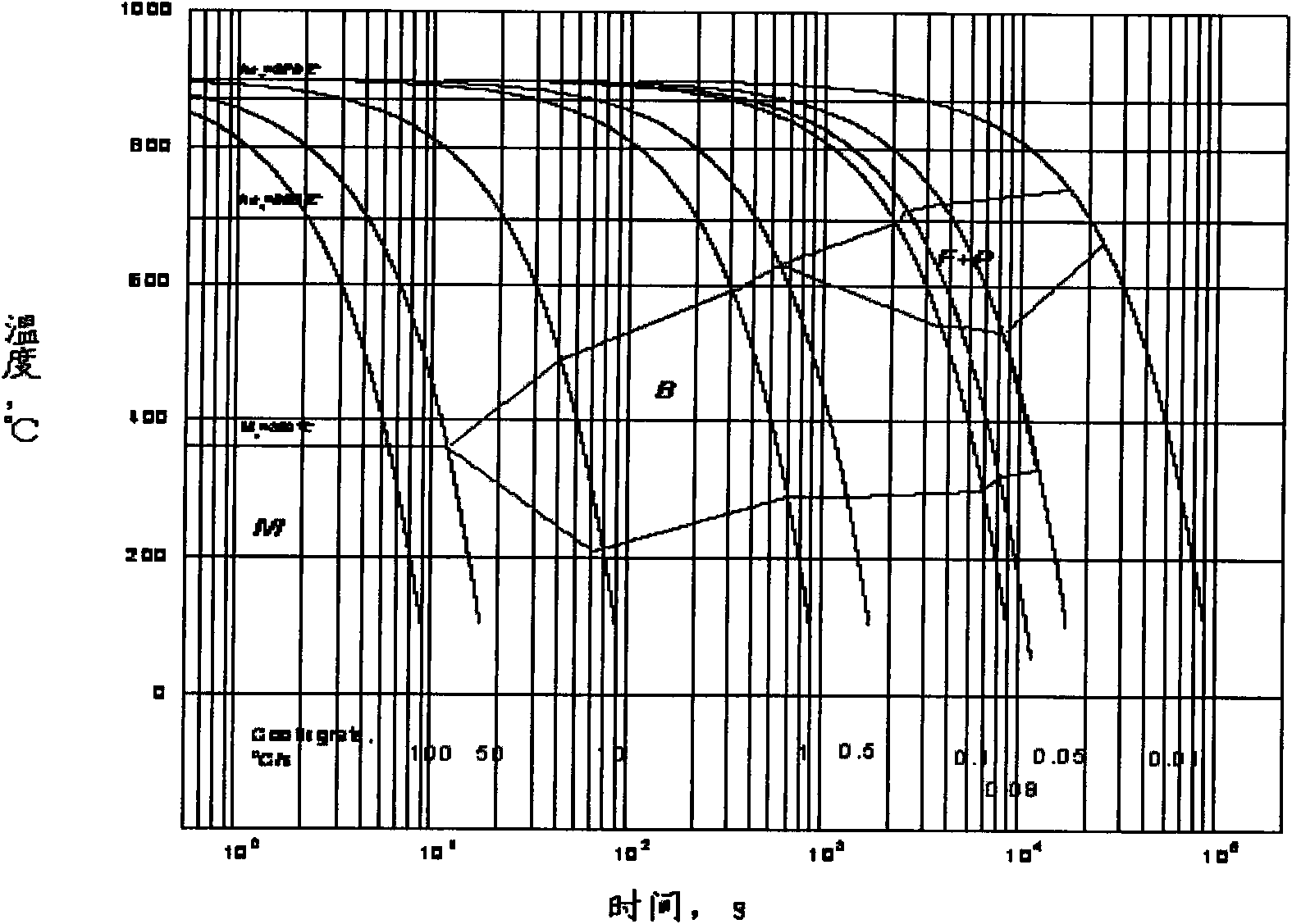

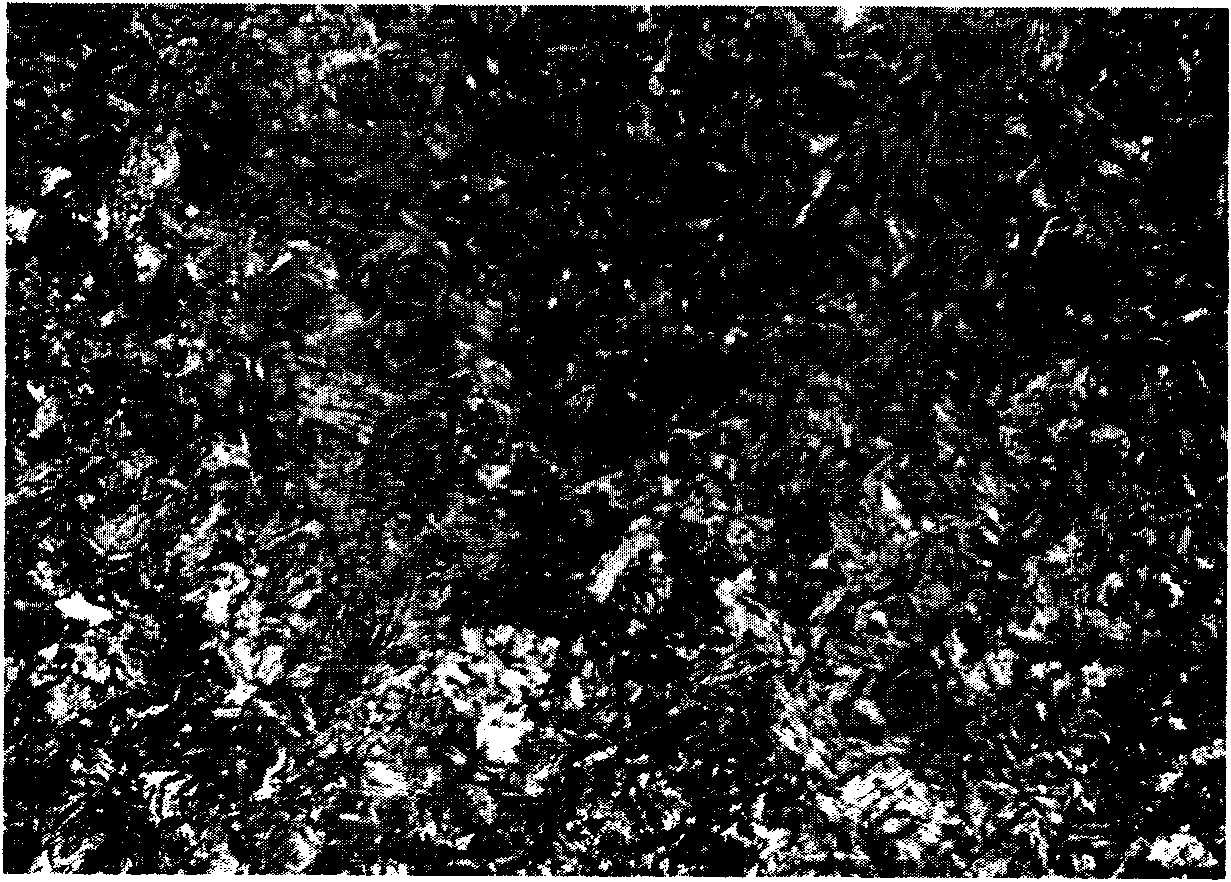

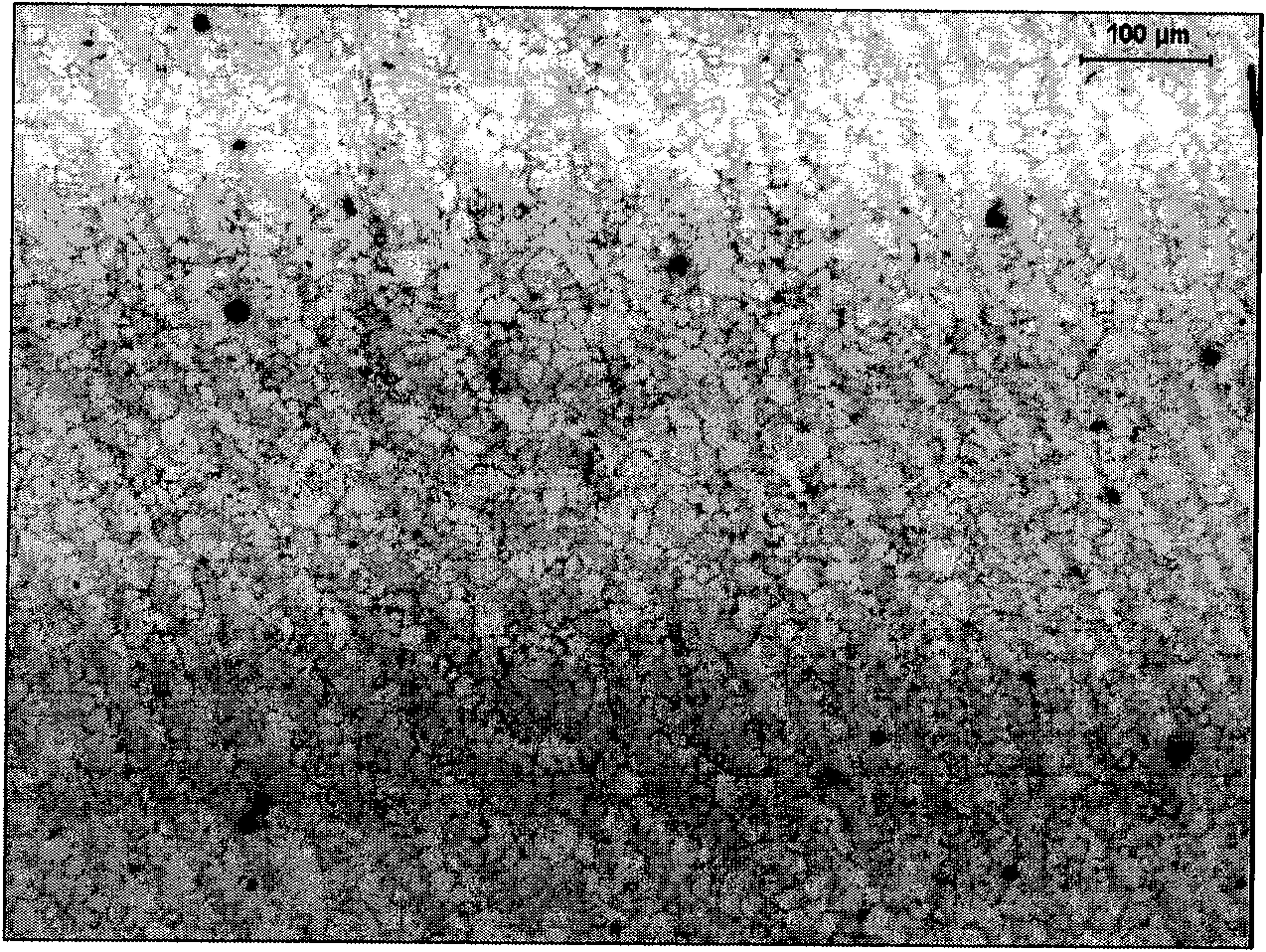

Method for manufacturing wear-resistant steel pipe by using hot-rolling coiled plate

ActiveCN101602079AImprove mechanical propertiesRefined mechanical propertiesFurnace typesIncreasing energy efficiencyWear resistantMartensite

The invention relates to a method for manufacturing a wear-resistant steel pipe by using a hot-rolling coiled plate, comprising a smelting method process, refining outside a furnace and steel blank manufacture. The method is characterized in that a steel blank is rolled and manufactured into a hot-rolling coiled plate blank material by using a hot continuous-rolling machine set or a furnace coiled rolling machine, the hot-rolling coiled plate blank material is rolled and welded into a pipe blank of an ERW steel pipe by using an ERW steel pipe machine set, and heat treatment is carried out after internal and external burrs are removed. The heat treatment method comprises the following steps that: (1) the pipe blank welded into the ERW steel pipe is heated in induction heating equipment to 910 to 960DEG C and austenized, the heating time is 60 to 140s, then the steel pipe with the austenitizing temperature is quenched in a water-cooling or steam-cooling quenching machine set, the quenching and cooling speed is greater than or equal to 10DEG C / S, the steel pipe with a quenched martensite organization is obtained, then induction tempering is carried out, the tempering temperature of the steel pipe is 210DEG C to 320DEG C, the tempering time is 60 to 180s, the quenched martensite is converted into a tempered martensite, and then straightening, flaw detection, surface inspection and sampling inspection are carried out to finally obtain the wear-resistant steel pipe with favorable wear resistance.

Owner:武汉钢实机电设备有限公司

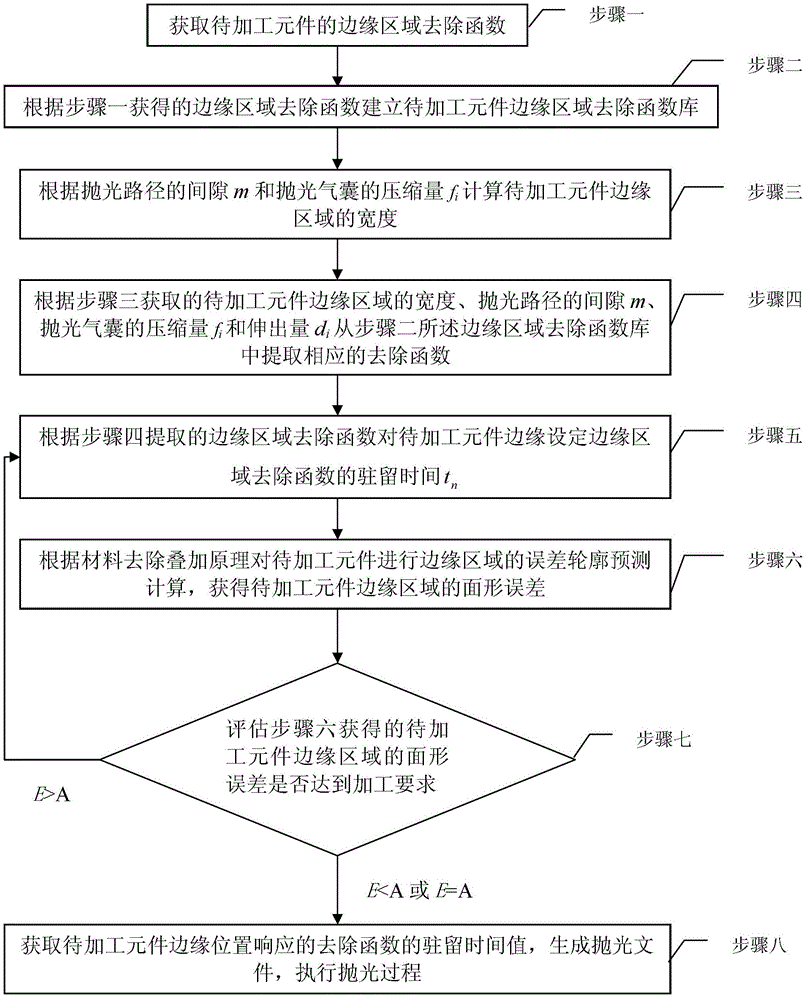

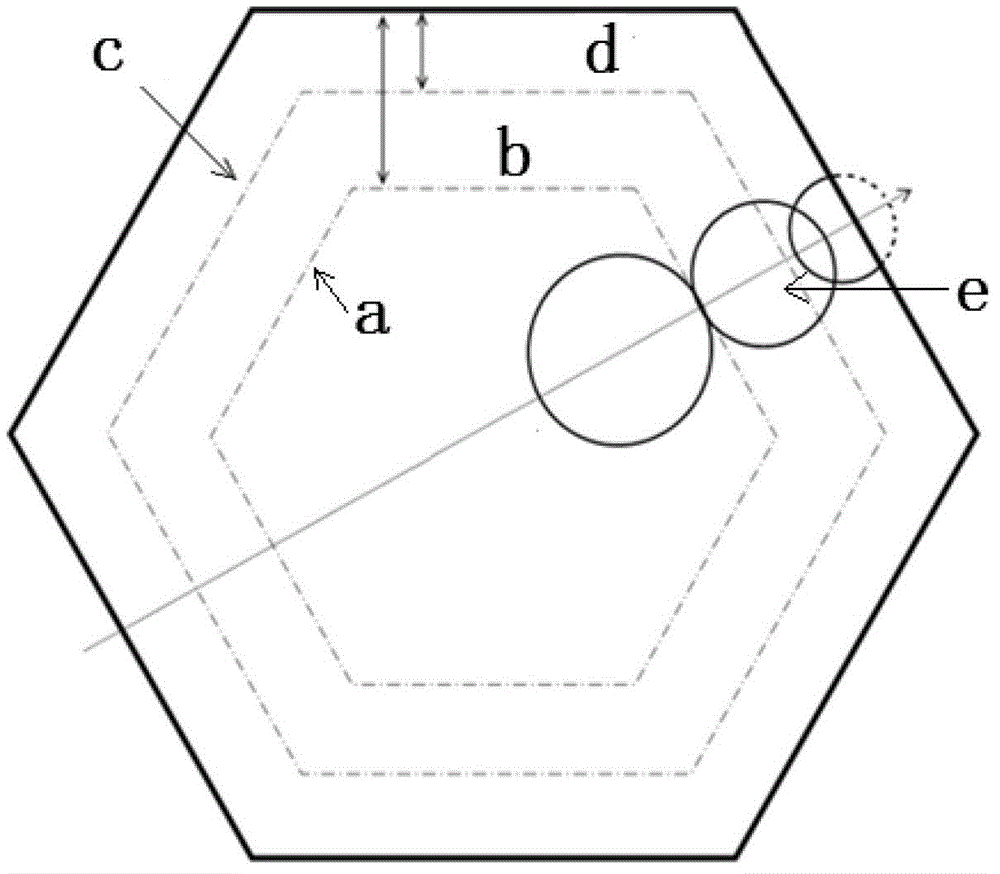

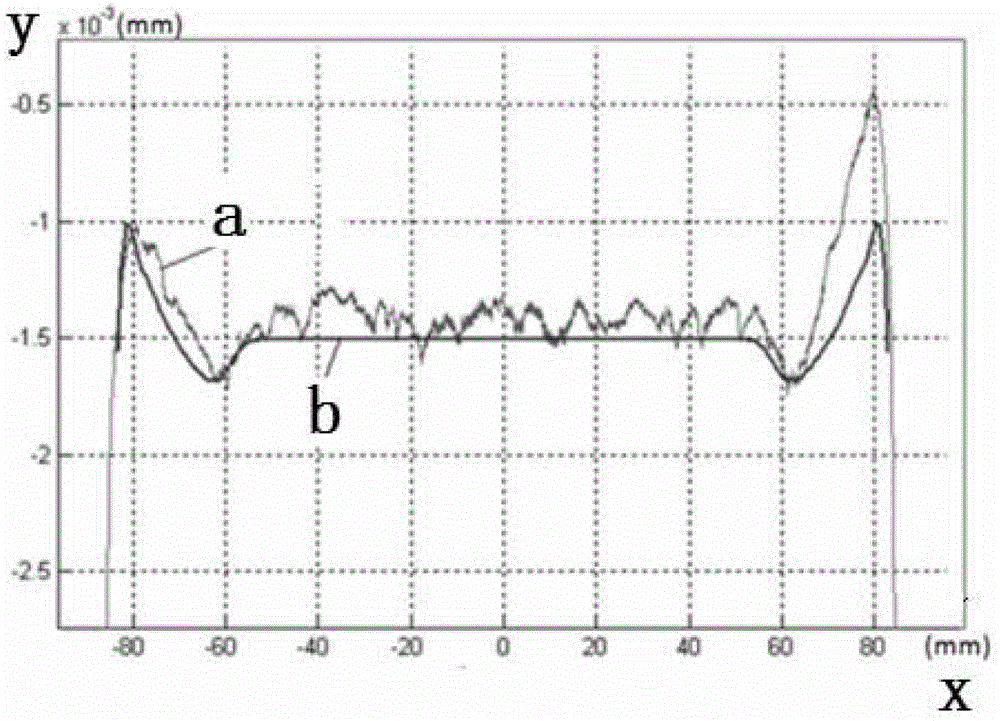

Edge precision control method of large aperture optical element being processed through air bag polishing

ActiveCN103144004AReduce riskPredict and optimize dwell timeOptical surface grinding machinesAutomatic grinding controlEdge effectsOptical processing

The invention discloses an edge precision control method of a large aperture optical element being processed through air bag polishing, and relates to a method for controlling edge precision in an air bag polishing element processing process, belonging to the field of optical processing. With the adoption of the edge precision control method, the problems that in the existing optical element processing process, in order to overcome 'edge effect', the risk of damaging main face precision is high, the cost is high, and the efficiency is low are solved. The method comprises the following steps: acquiring an edge area removing function of materials corresponding to the element to be processed; establishing an edge area removing function library of the element to be processed; calculating the width of an edge area of the element to be processed according to gap m of a polishing path and compression amount fi of a polishing air bag; extracting the corresponding removing function; setting residence time tn of the edge area removing function; carrying out error contour predication calculation on the edge area of the element to be processed, so as to acquire surface-shape error of the edge area of the element to be processed; estimating the surface-shape error; and acquiring a residence time value of the removing function responding to the edge position of the element to be processed, so as to generate a polishing file ,and executing a polishing process. The edge precision control method provided by the invention can be widely applied in the edge precision control processing process of large aperture opt elements.

Owner:HARBIN INST OF TECH

Method for preparing activated kaolin by washing kaolin with water

ActiveCN104045092AOptimizing the firing temperatureOptimize dwell timeSilicon compoundsRebarChemistry

The invention belongs to the technical field of the production process of activated kaolin and in particular relates to a method for preparing activated kaolin by washing kaolin with water. The method comprises the steps of preparing a kaolin filter cake, preparing kaolin dry powder, thermally activating kaolin, and preparing activated kaolin by performing depolymerization and modification on the thermally activated kaolin. Deep treatment is performed on kaolin resources by use of processes such as appropriate-temperature calcination, efficient depolymerization and dispersion and modification on the basis of the traditional treatment process of washing the kaolin with water, therefore, the activated kaolin having the characteristics of volcanic ash can be prepared; the activated kaolin can be applied to the fields such as a high-grade concrete additive, a cable filler, a water-based coating and the like, and has the characteristics of short setting time, high early strength, shrinkage compensation, no corrosion to reinforcements, high resistivity and the like; as a result, the valued added of the kaolin resources can be increased, and the activated kaolin has enormous market space potential.

Owner:北海高岭科技有限公司

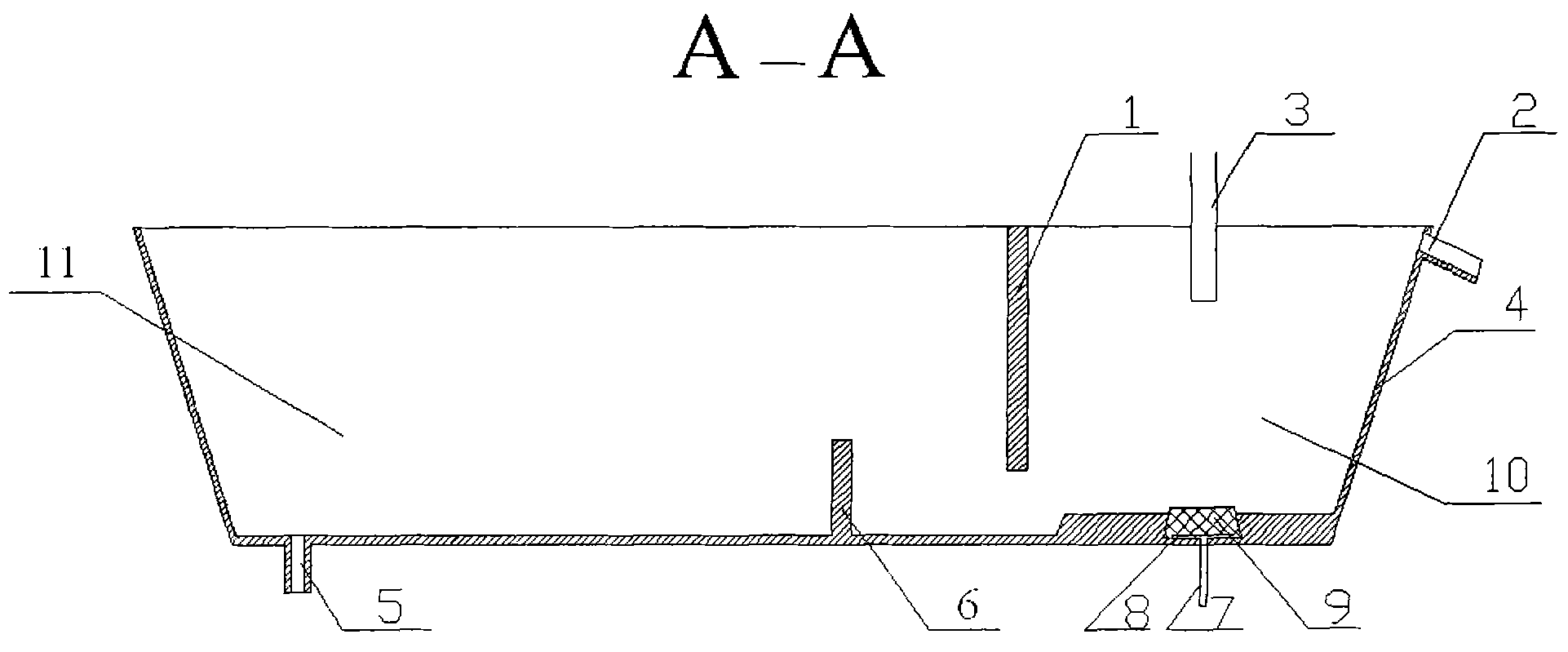

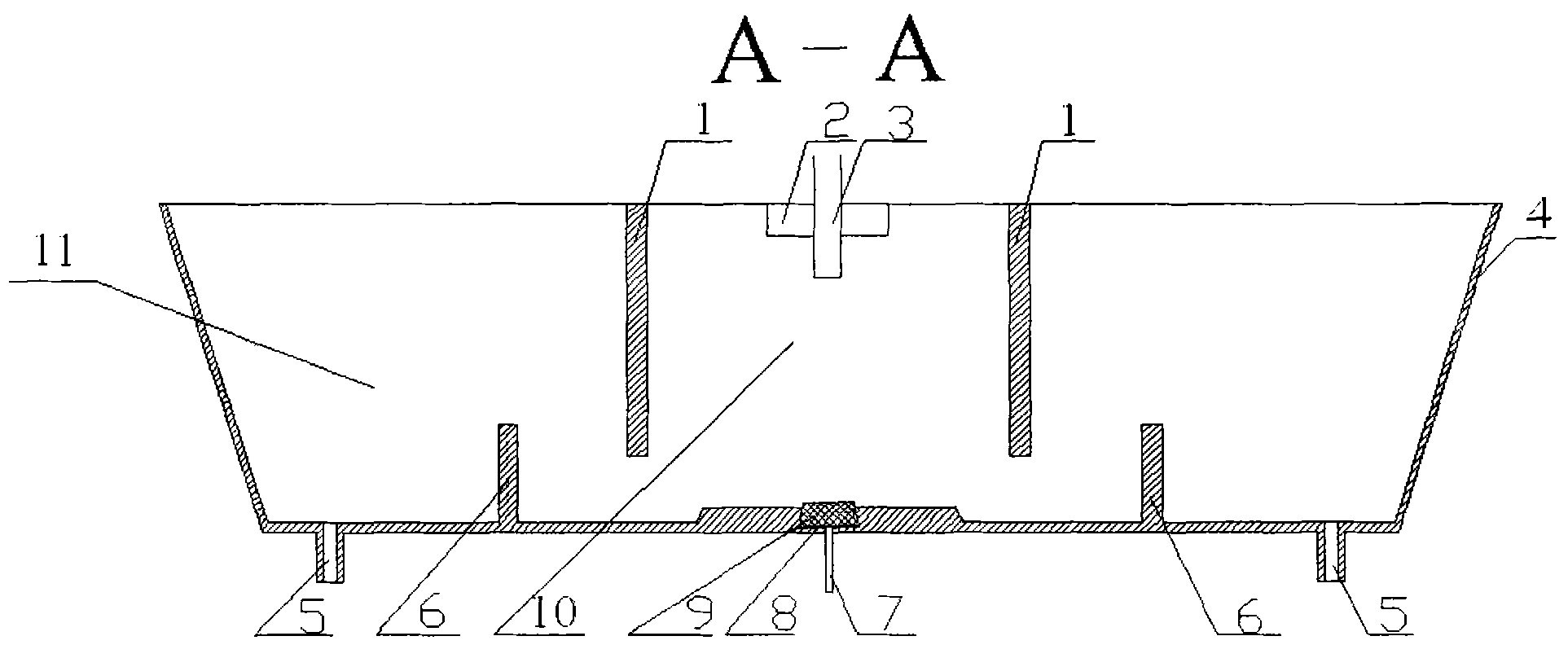

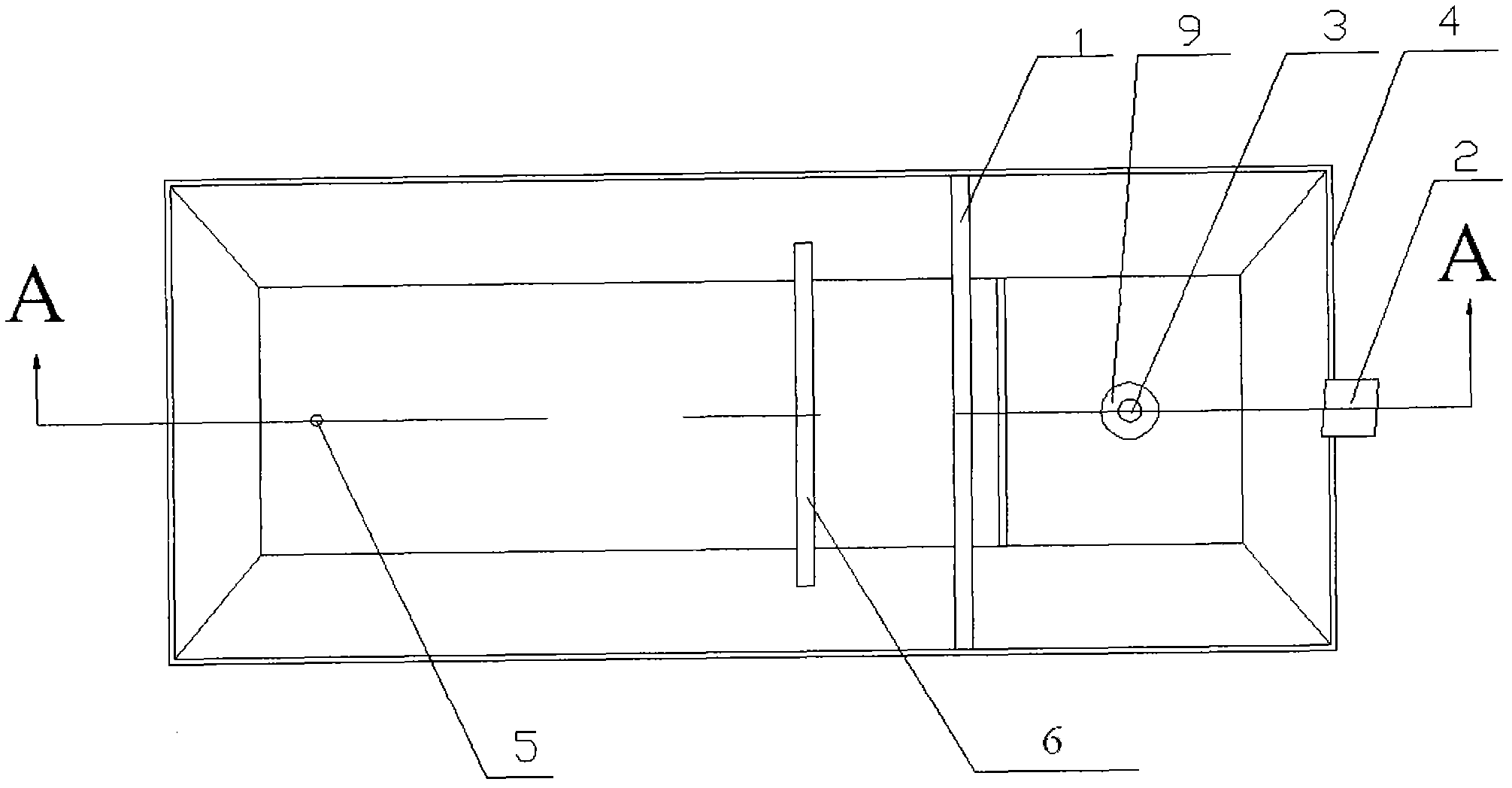

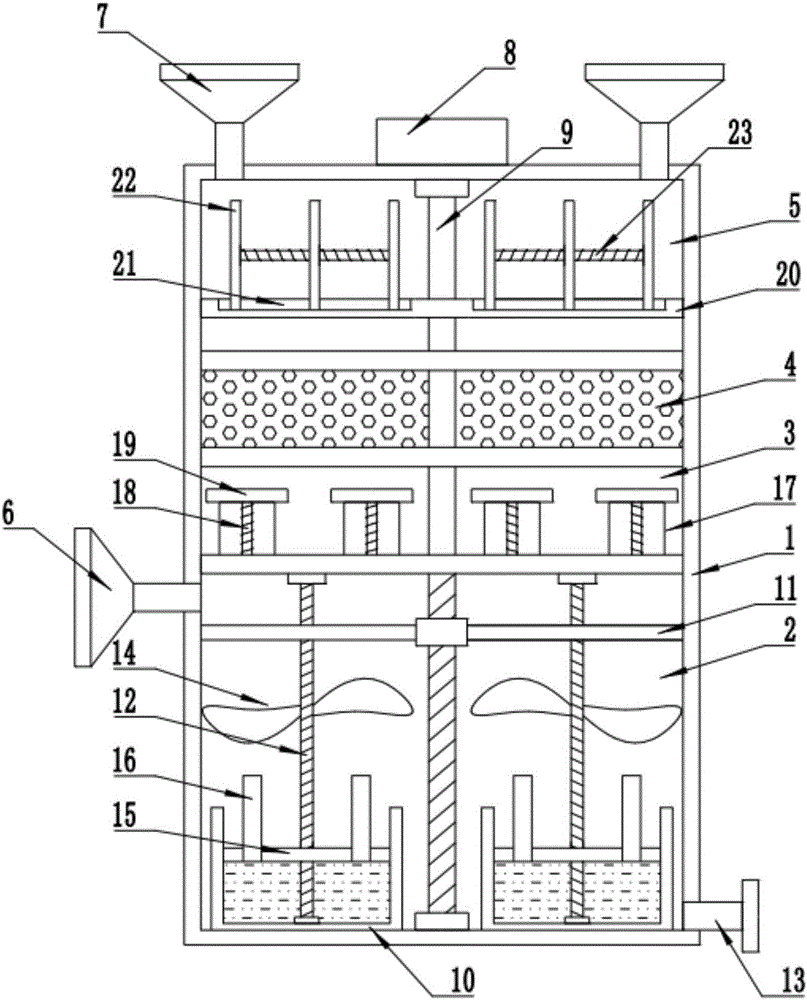

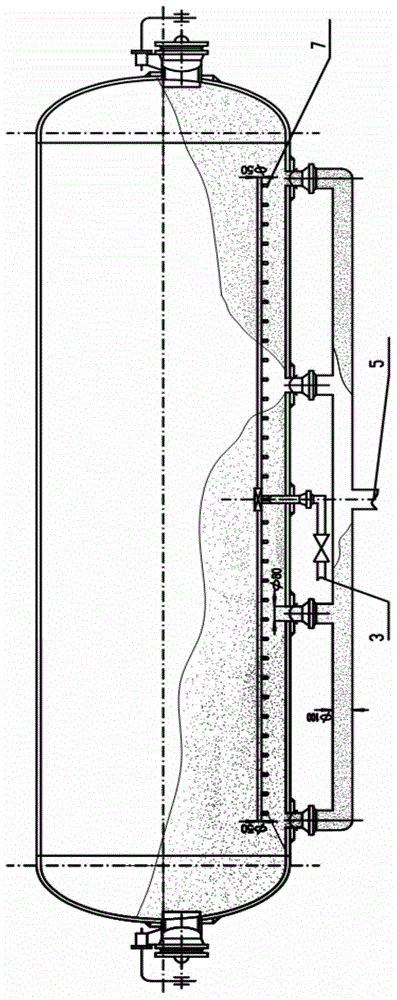

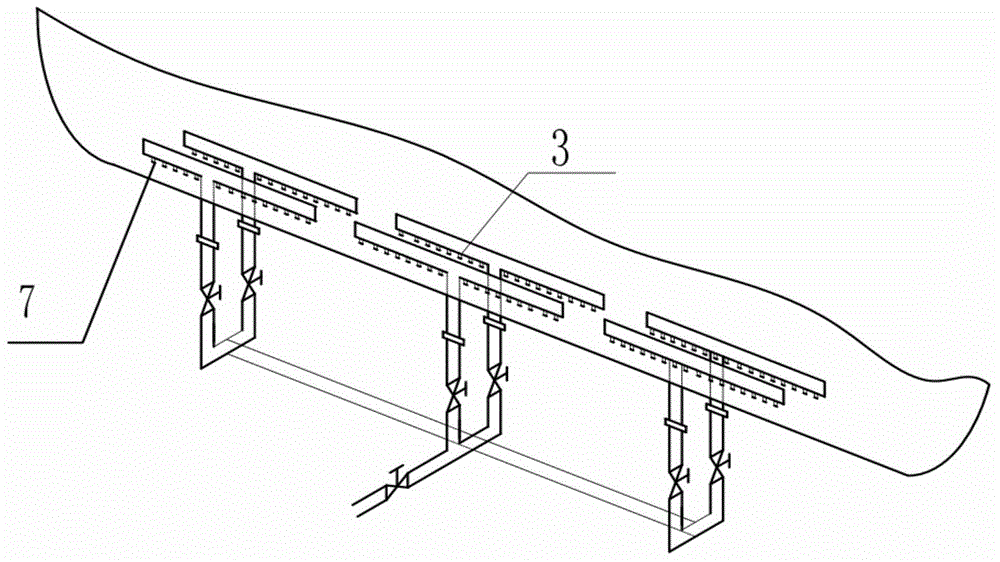

Continuous casting tundish for improving cleanliness of molten steel

The invention discloses a continuous casting tundish for improving cleanliness of molten steel and belongs to the field of ferrous metallurgy technology. The continuous casting tundish comprises a tundish, porous bricks, an overflow groove, a slag blocking wall and a dam. The continuous casting tundish for improving cleanliness of molten steel provided by the invention makes full use of the double effects of argon foam stirring and cleaning, is safe, practical, simple and convenient, can obviously improve the separation effect of impurities and gases in the molten steel and improve the cleanliness of the molten steel and the quality of billet steel and the like.

Owner:SHANDONG IRON & STEEL CO LTD

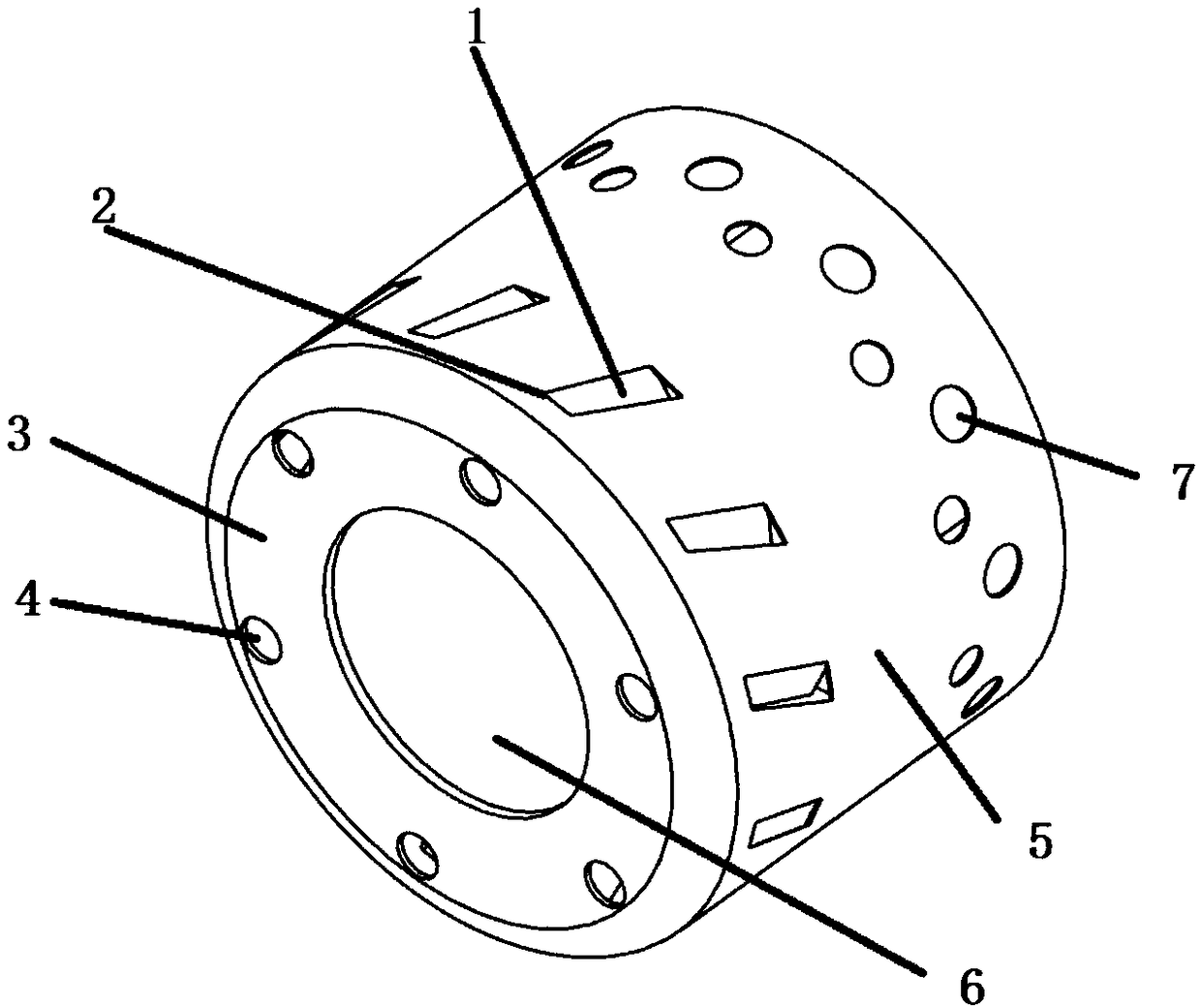

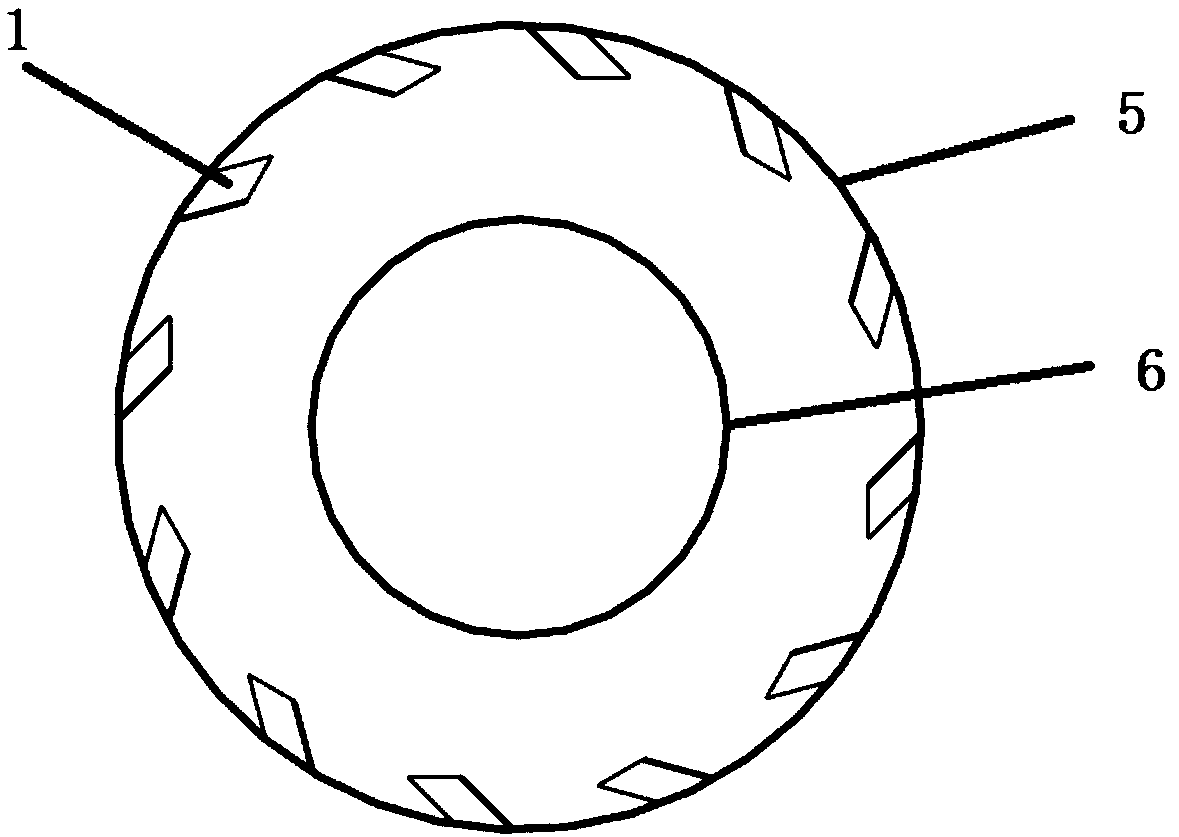

Mini type engine combustion chamber flame barrel with air inlet flow guiding blades

InactiveCN108151068AIncreased turbulenceOptimize dwell timeContinuous combustion chamberCombustion chamberEngineering

The invention provides a structural design scheme for a mini type engine combustion chamber flame barrel with air inlet flow guiding blades. The air inlet flow guiding blades are arranged at the position, close to the front end of the flame barrel, of a flame barrel shell, so that airflow entering the flame barrel through a main combustion hole has the component of velocity in the axial direction,the radial direction and the circumferential direction, a backflow area can be formed by the rotation airflow in the flame barrel, the airflow structure in the flame barrel is effectively improved, the airflow speed is reduced, and the combustion stability of a mini type engine combustion chamber is improved; and due to existence of the backflow area, the airflow turbulivity is improved, fuel oiland fresh air mixing is more sufficient, combustion is safer, and the combustion efficiency is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

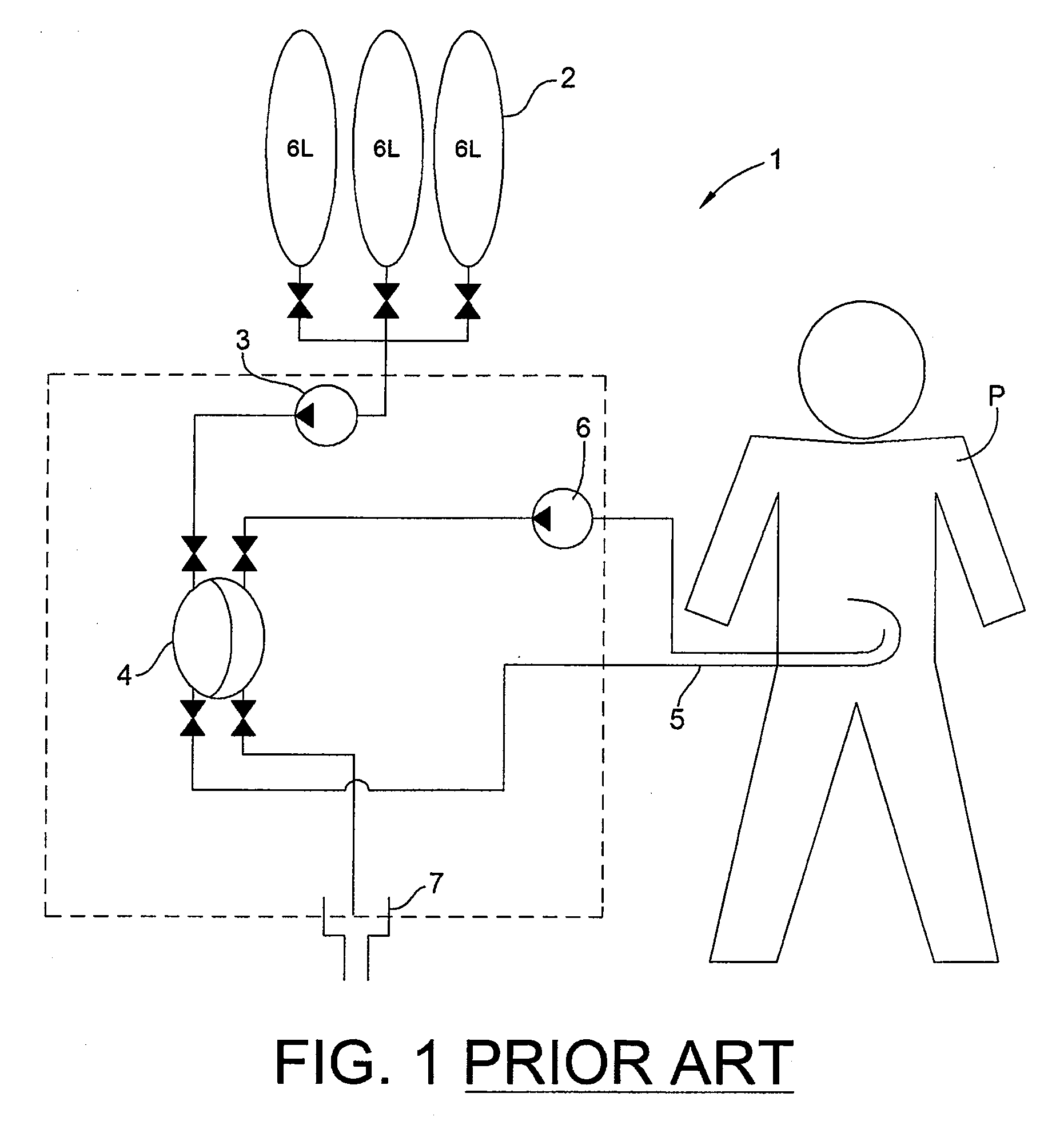

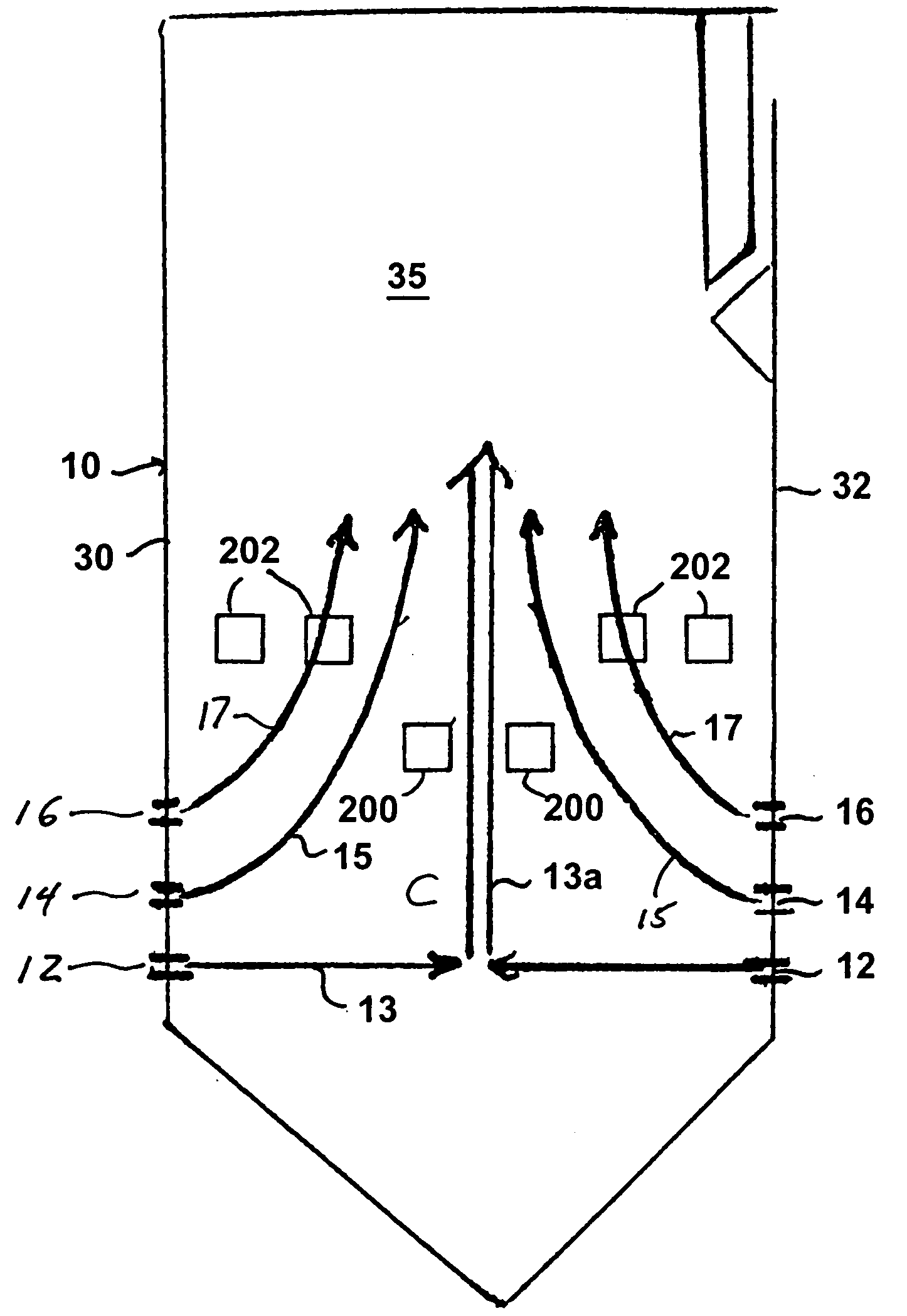

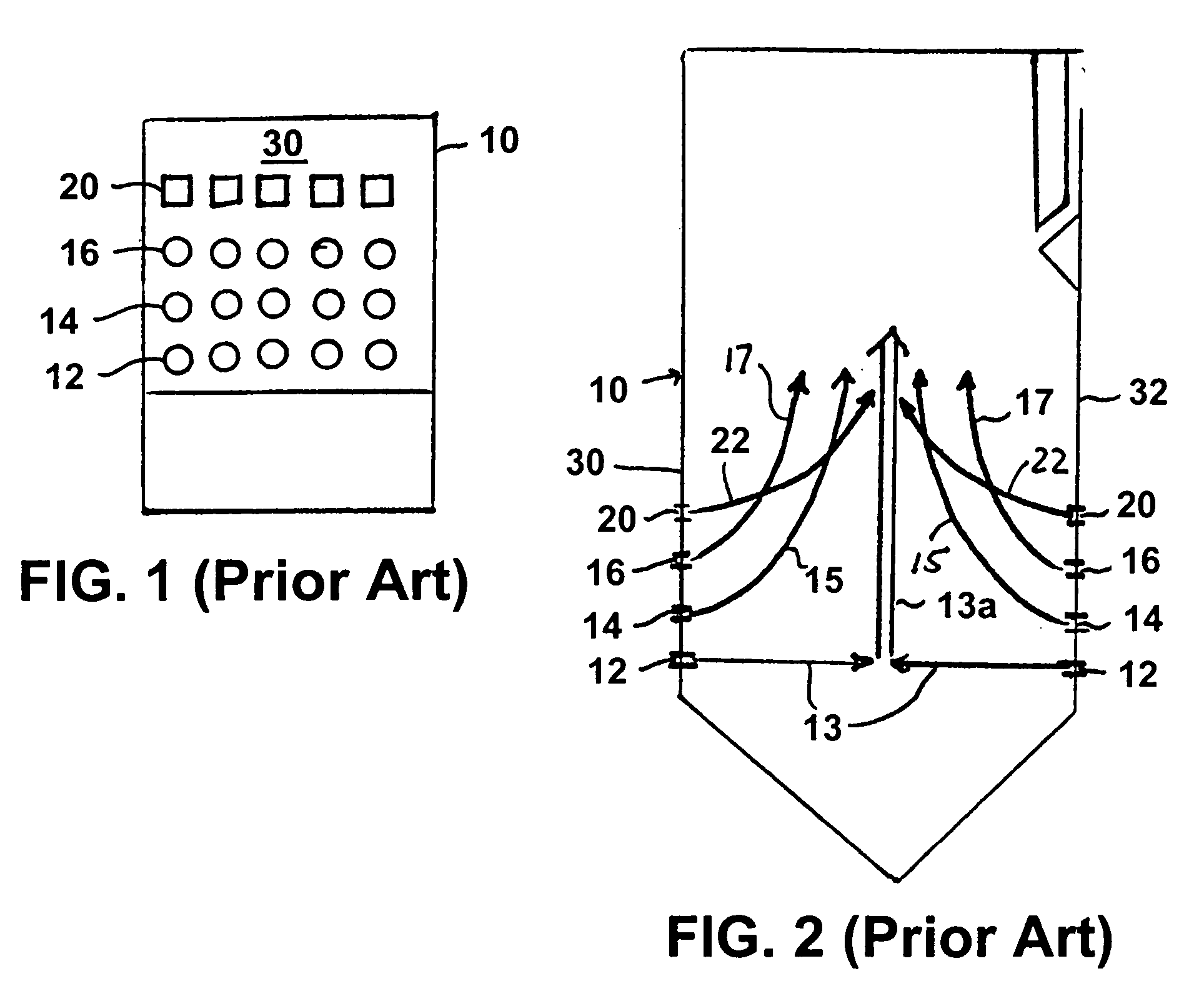

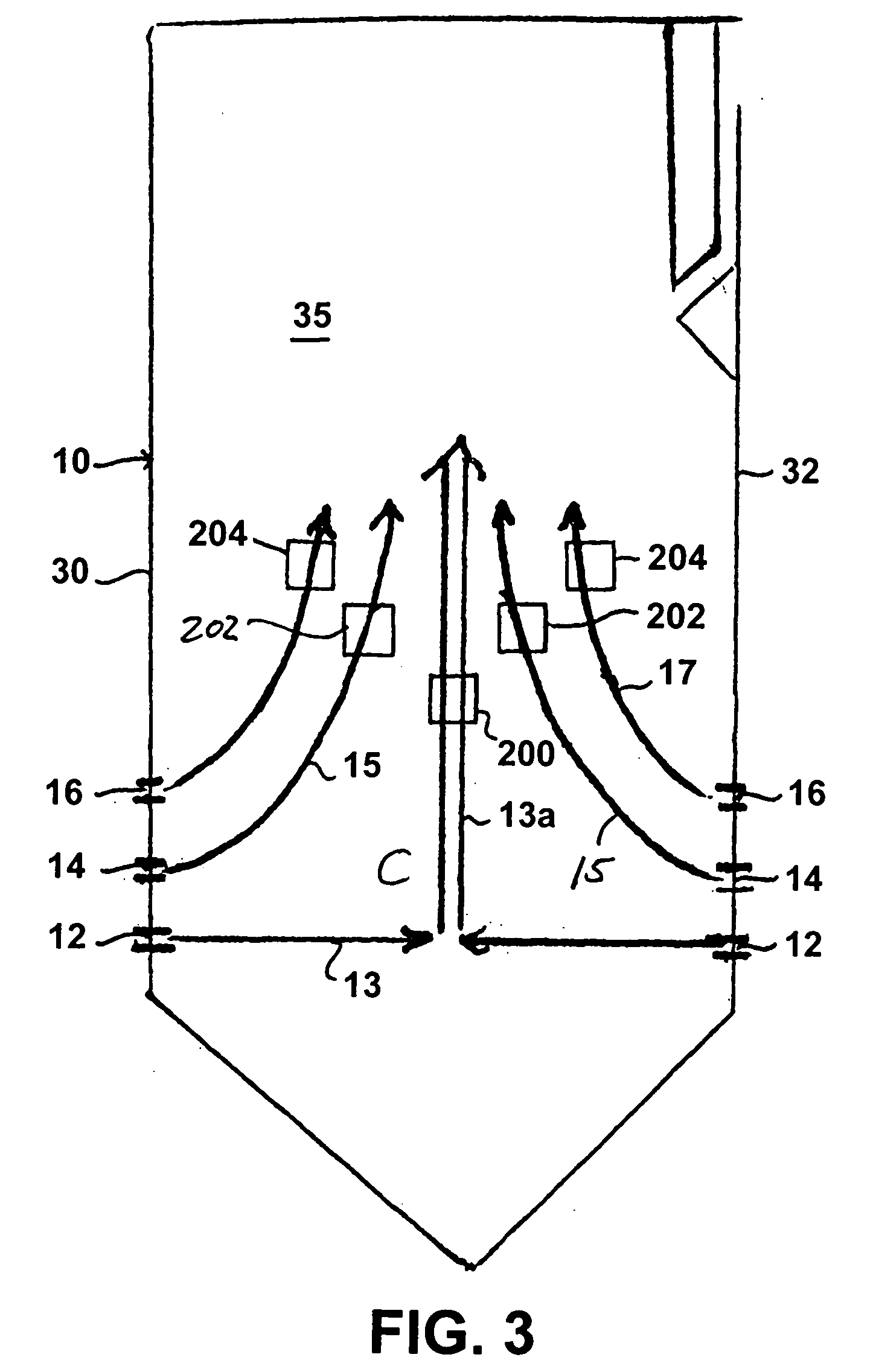

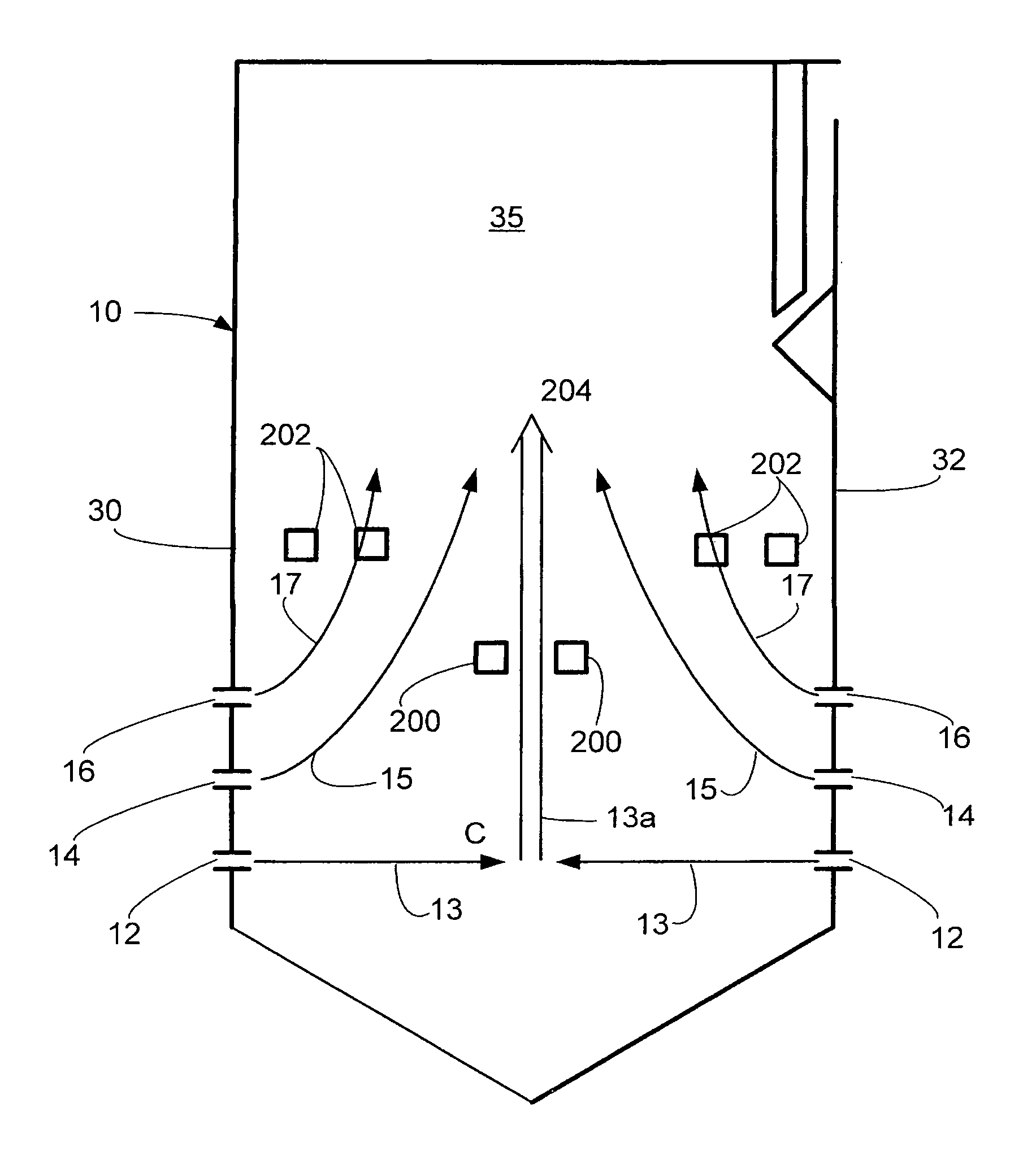

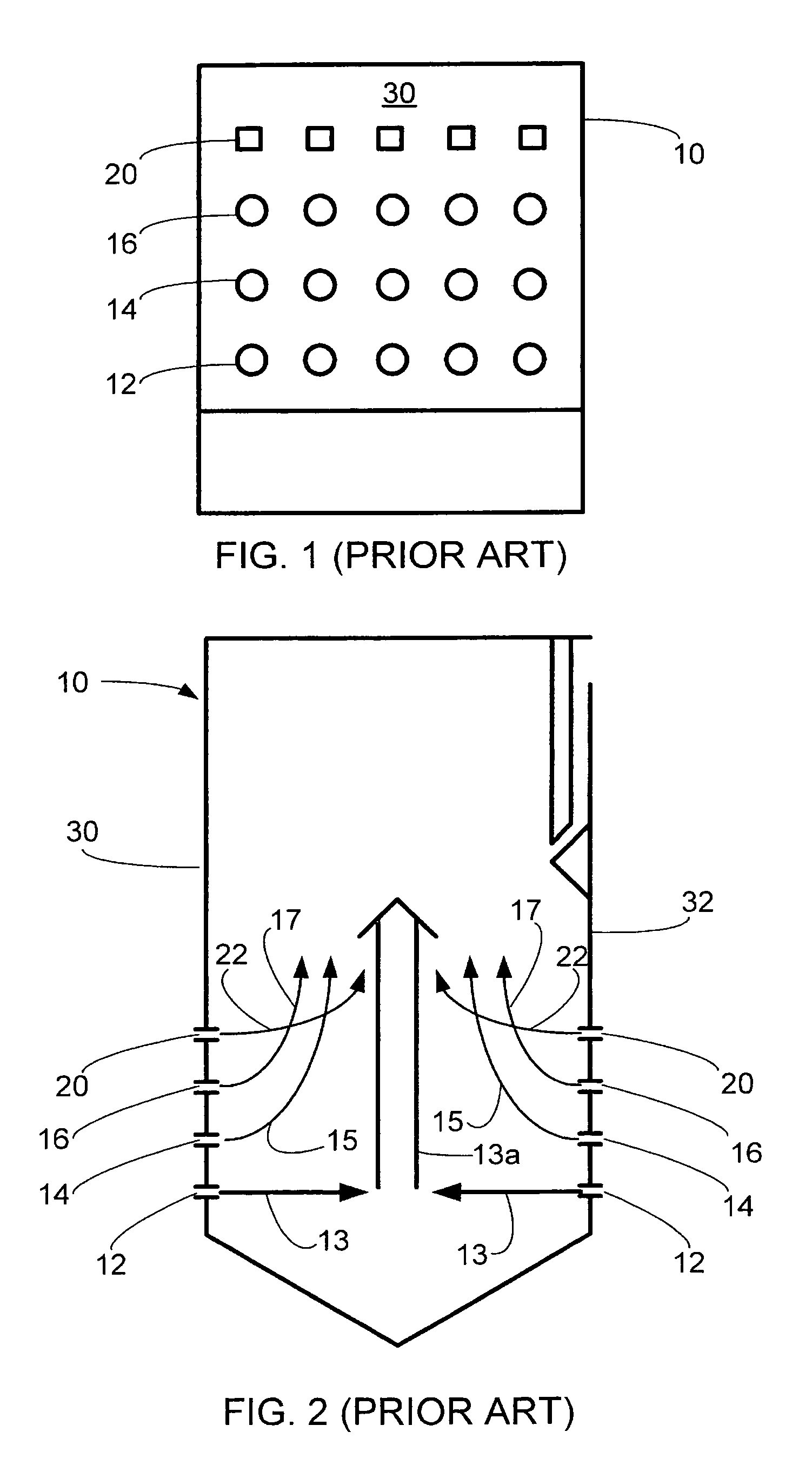

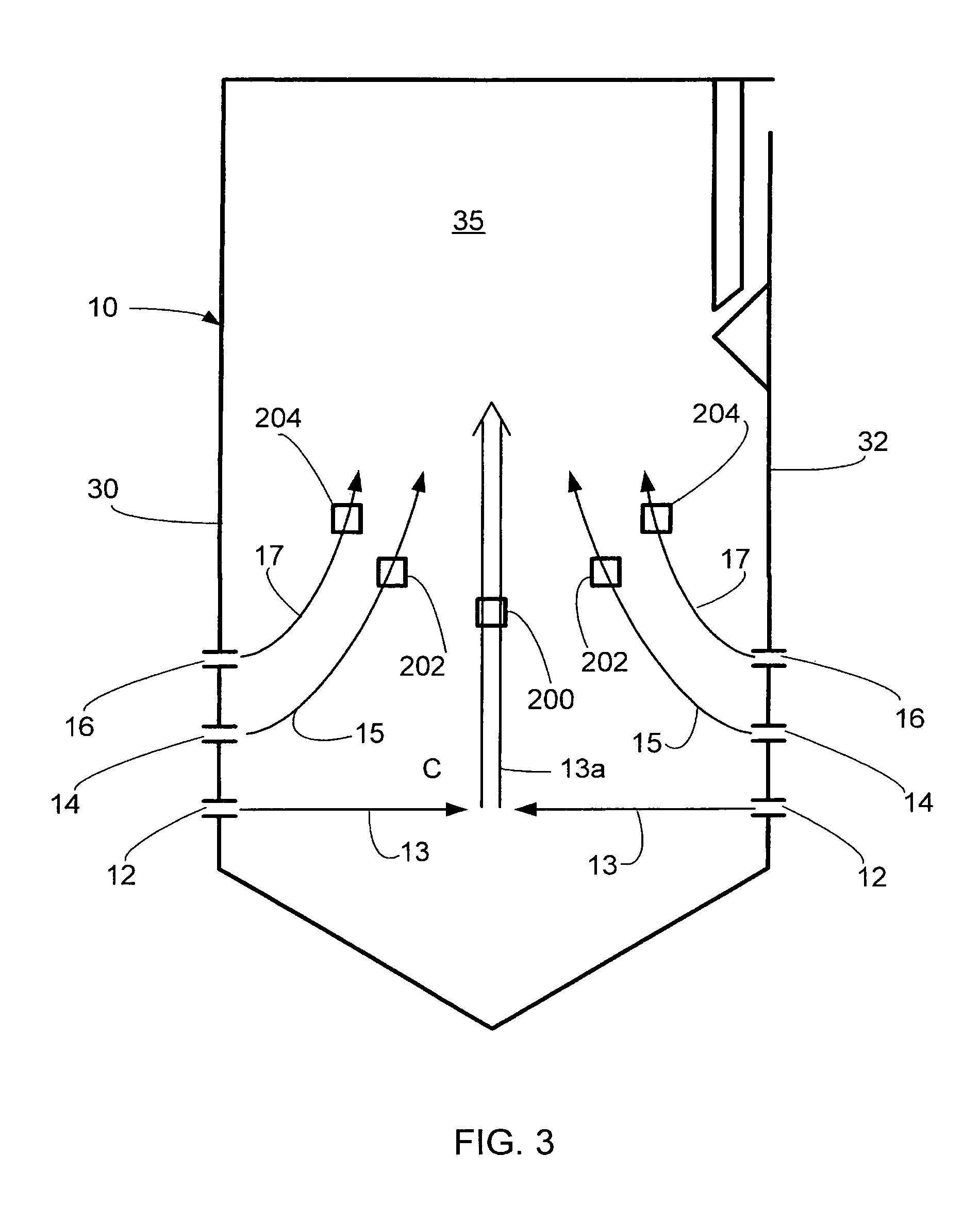

Re-oriented over fire air ports for reduction of NOx production from pulverized coal-fired burners

InactiveUS20050166867A1Reduce NOxNo accumulationPulverulent fuel combustion burnersSteam engine plantsResidence timeCoal fired

An over fire air (OFA) port arrangement for a pulverized coal-fired boiler or furnace has at least one OFA port through each of the sidewalls for injecting OFA to increase residence time for each burner level. Plural OFA ports may be employed, staggered both vertically and horizontally to effectively deliver over fire air to the burner flames at the appropriate time and location to most efficiently reduce the formation of fuel NOx. OFA port configurations for both single-wall and opposed-wall fired furnaces and boilers are provided.

Owner:POLY MED +1

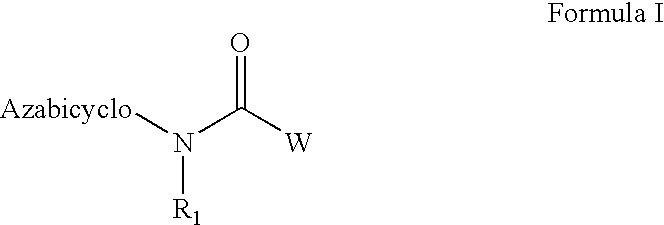

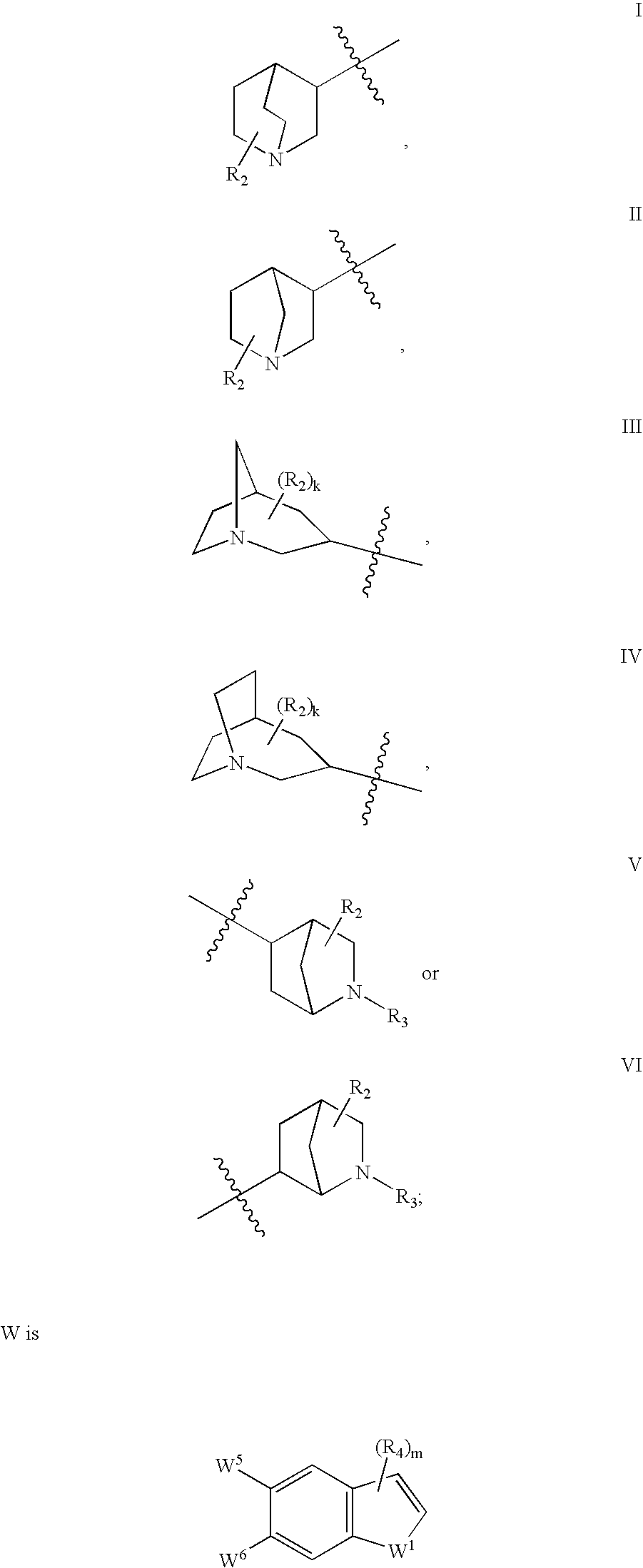

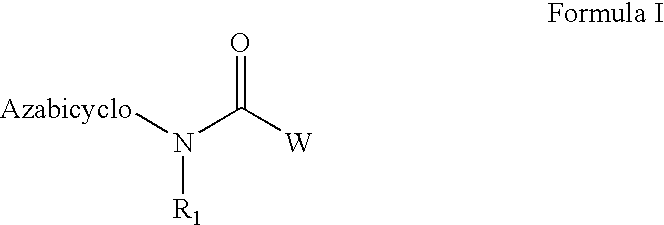

Azabicyclic compounds for the treatment of disease

Owner:PHARMACIA & UPJOHN CO

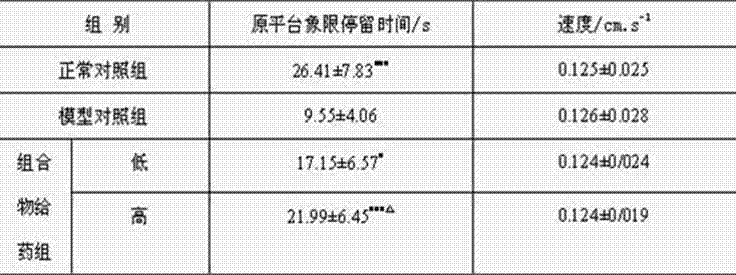

Drug composition conducive to improvement of memory and adjunctive treatment of senile dementia

InactiveCN103041060AImprove bioavailabilityEnhance memoryNervous disorderFood preparationSoftgelHard Capsule

The invention relates to a drug composition conducive to improvement of memory and adjunctive treatment of senile dementia. The drug composition provided by the invention is characterized by being prepared from ginseng, ginkgo leaves, grape seeds, purple perilla seed oil and egg yolk lecithin, and synergistic effects of the components are utilized to prepare oral preparations such as hard capsules, soft capsules, tablets, granules, powder and pills. The drug composition provided by the invention can be applied to a Chinese patent drug or health-care food, and has an effect of being conducive to improvement of memory and adjunctive treatment of senile dementia.

Owner:李庆杰

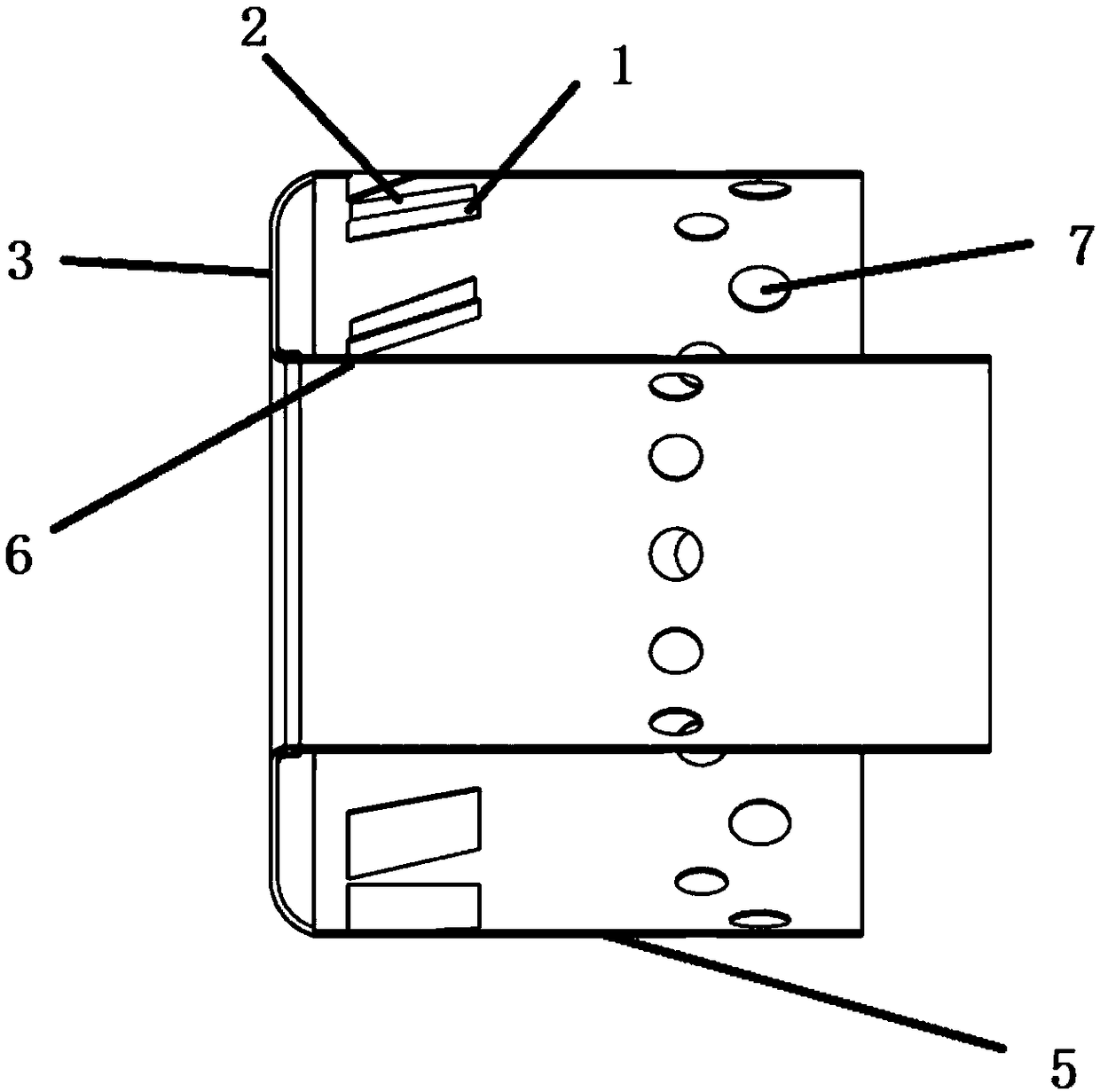

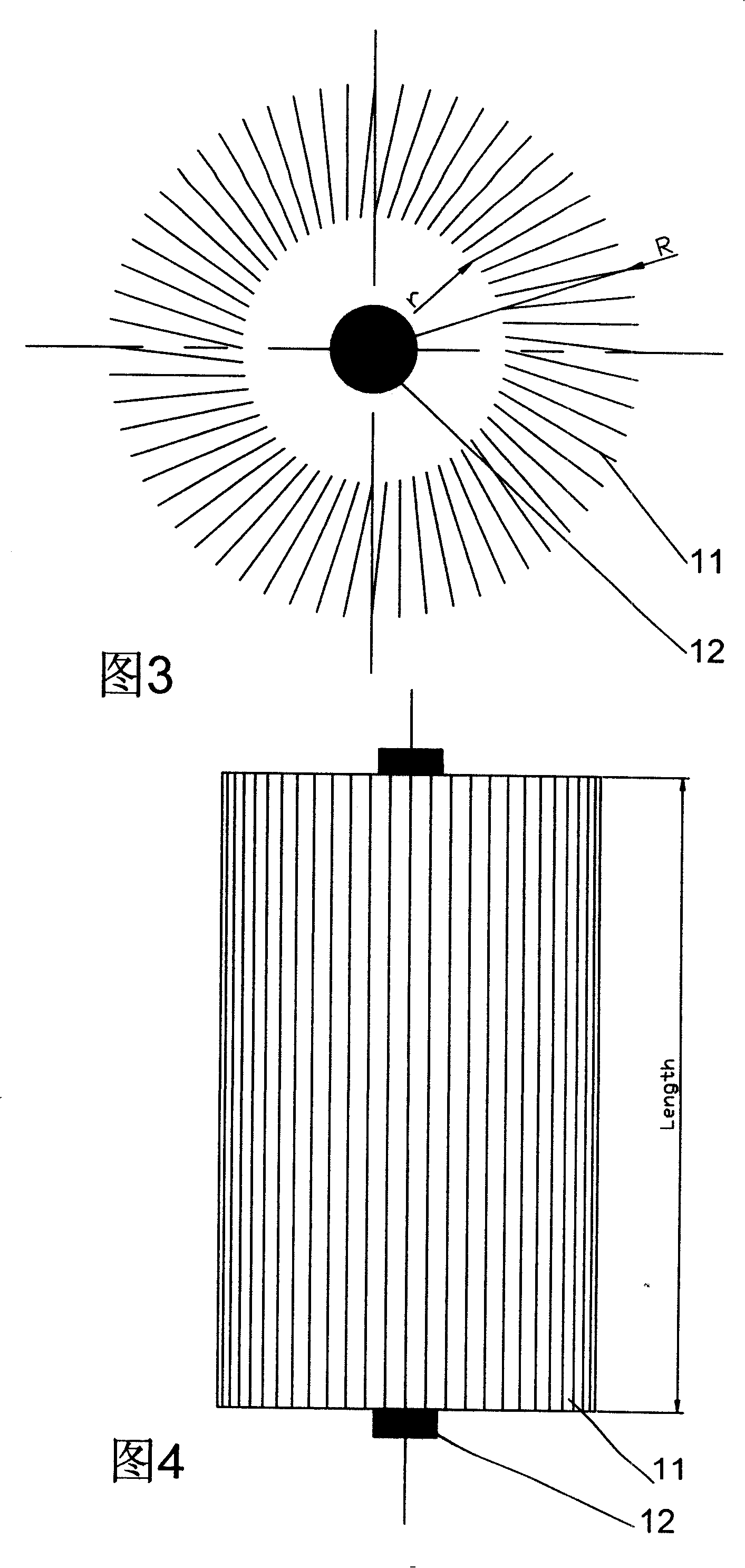

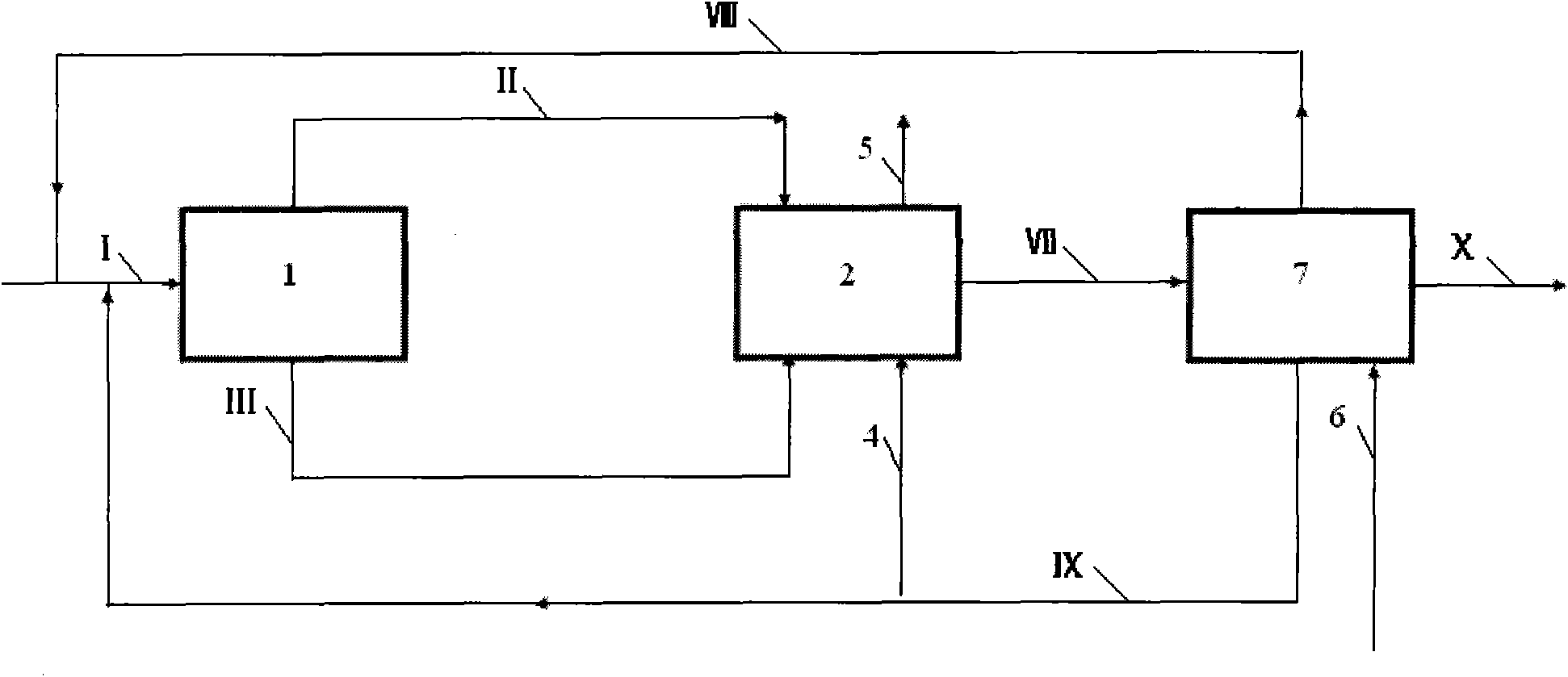

Module combined type photocatalyst pollutant disposal system

InactiveCN101112680ASimple designEasy to handleEnergy based chemical/physical/physico-chemical processesModular compositionStop time

The invention discloses a module combined-typed photocatalyst contamination processing system, which mainly arranges a plurality of photocatalytic carrier structure parts in a shell in the serial way or parallel way or serial and parallel way to constitute the photocatalyst contamination processing system. The contamination processing system can be combined in serial and / or parallel way by selecting and using independent processing modules with suitable quantity according to the design scale of the contamination processing system. The invention simplifies and facilitates the design of the photocatalyst contamination processing system which is the same convenient as the module combination. The contamination processing system with modularization design not only can increase the processing ability of the processing system to the contamination according to the requirement, but also can improve the circulation path of the contamination processing by simple modularization combination, and improve the stopping time of the contamination fluid in the processing system, namely the contacting reaction time with the photocatalyst carrier, thus obtaining more effective contamination processing system.

Owner:杨小明

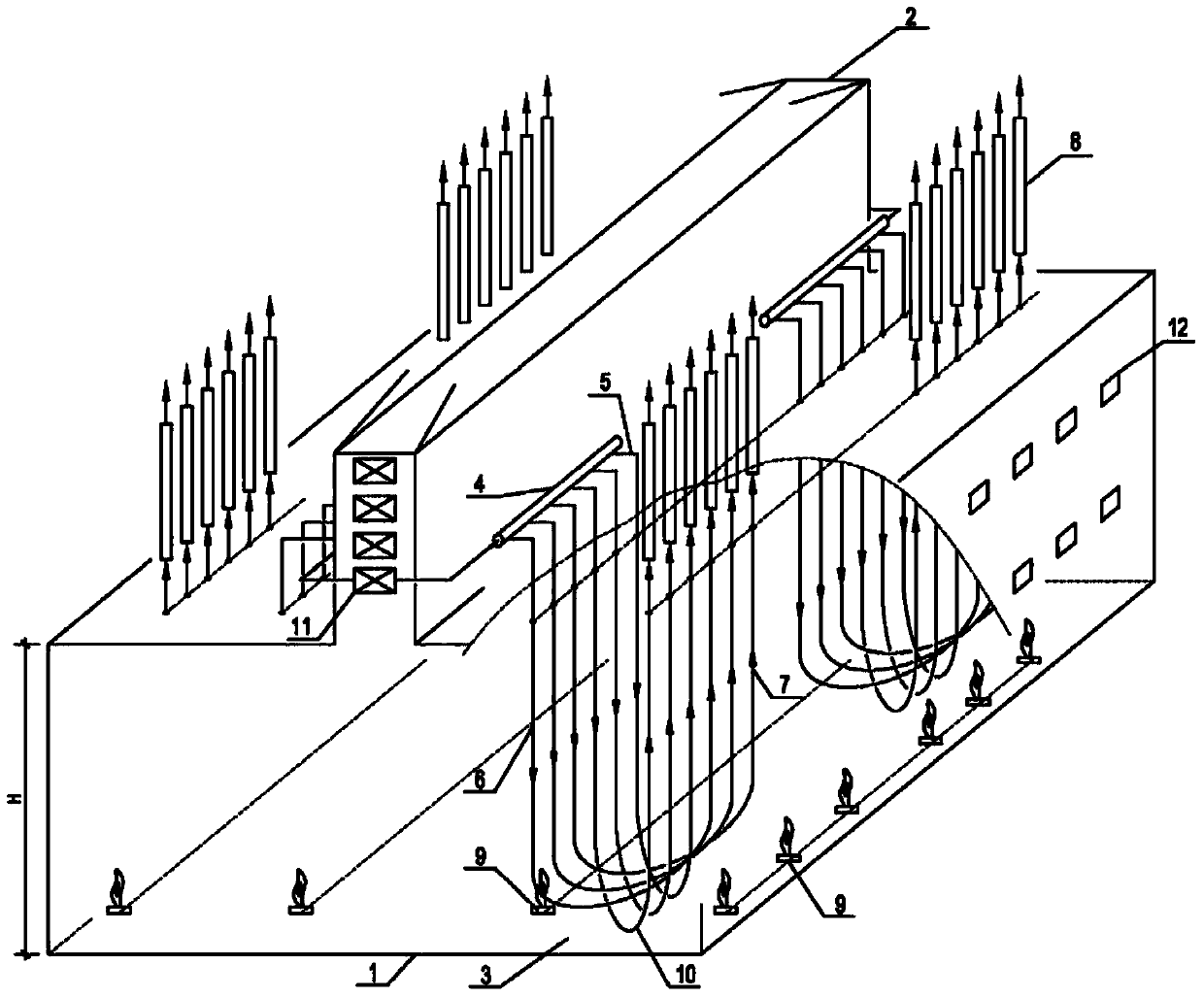

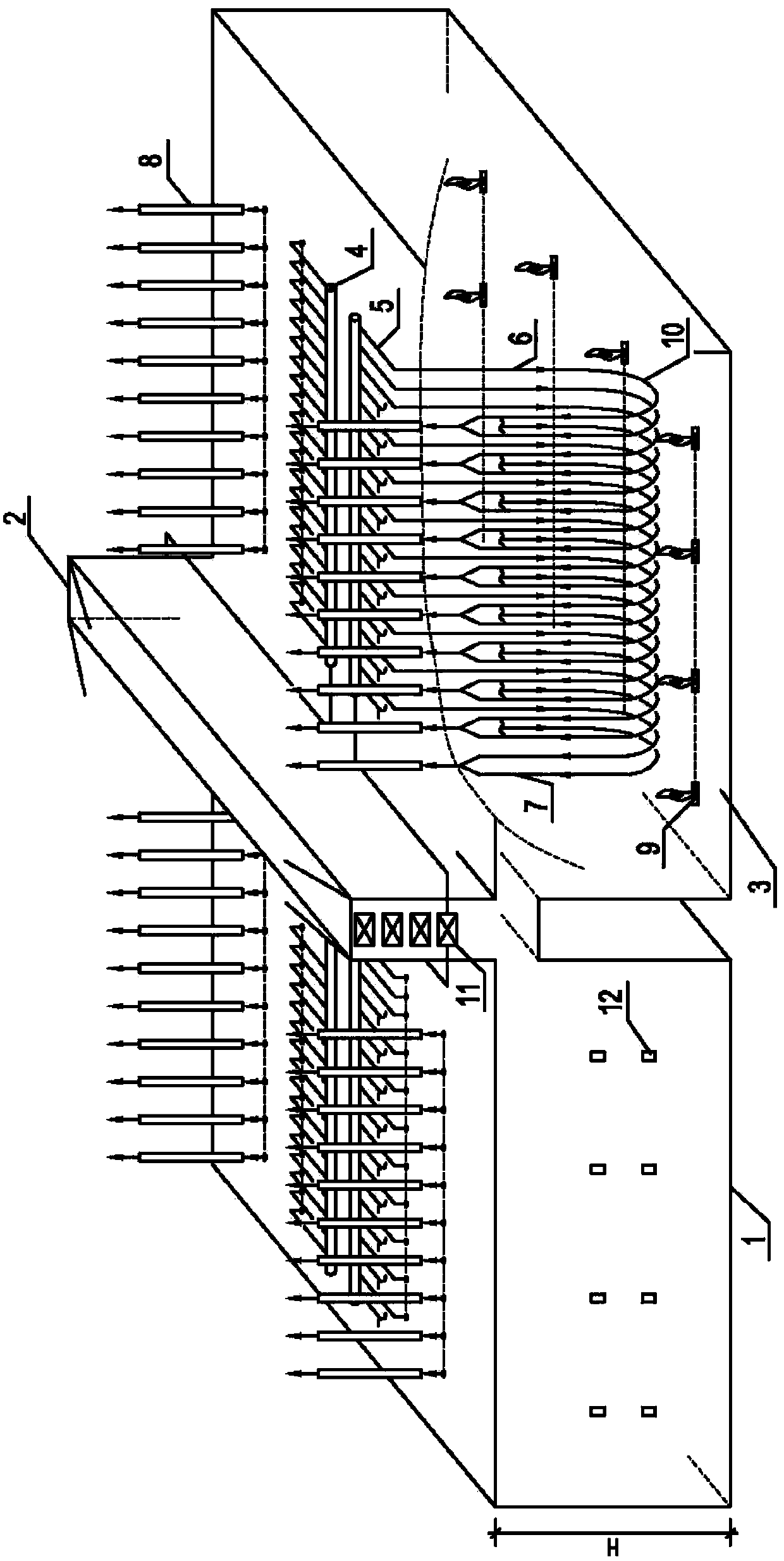

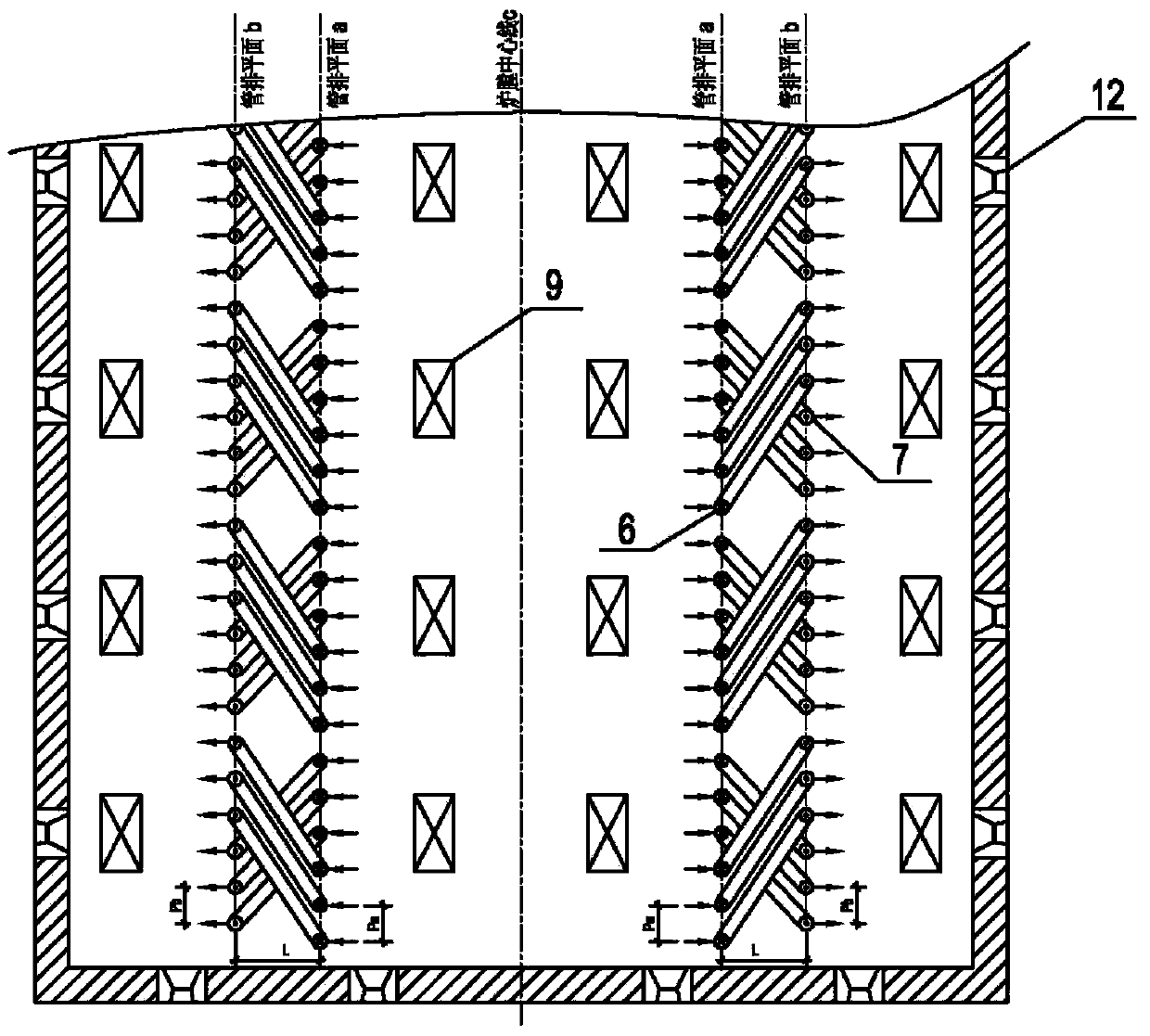

Ethylene cracking furnace

ActiveCN103992812AIncrease production capacityExtended operating cycleThermal non-catalytic crackingChemical/physical processesCombustorOptoelectronics

The invention provides an ethylene cracking furnace. The ethylene cracking furnace mainly comprises a radiation section (1), a convection section (2) and quenching boilers (8), wherein the radiation section (1) is at least provided with a radiation chamber (3); a plurality of burners (9) are arranged at the bottom of the radiation section and are sequentially arranged in four rows in parallel; two rows of first radiation furnace tubes and two rows of second radiation furnace tubes are arranged in the radiation chamber (3), thus four rows of radiation furnace tubes are arranged in the radiation chamber (3). The large-scale cracking furnace is achieved and reduces the floor area and the investment compared with other cracking furnaces on the same scale. Various specific modes of implementation provided by the invention also provide more beneficial technical effects.

Owner:WISON ENG

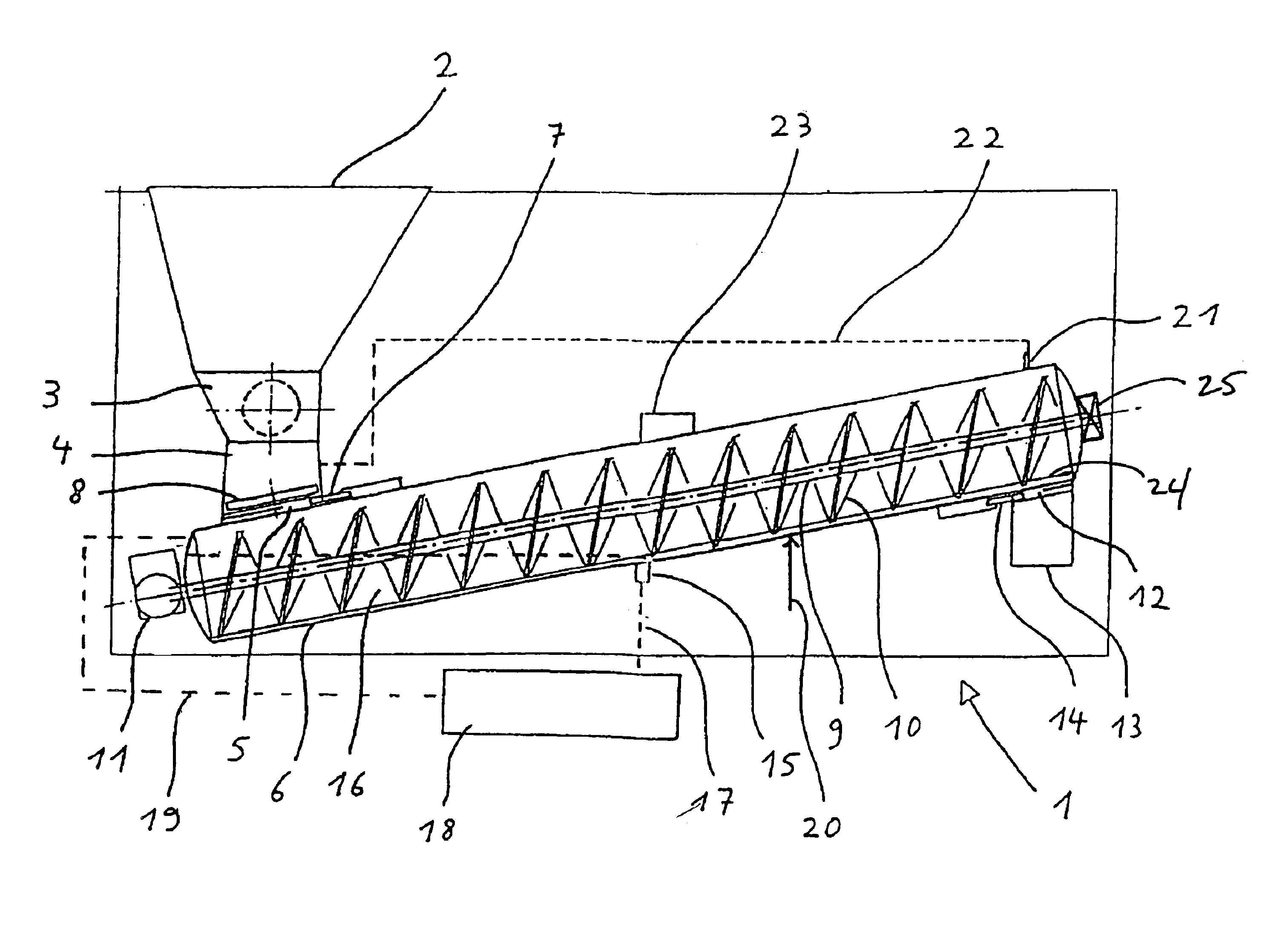

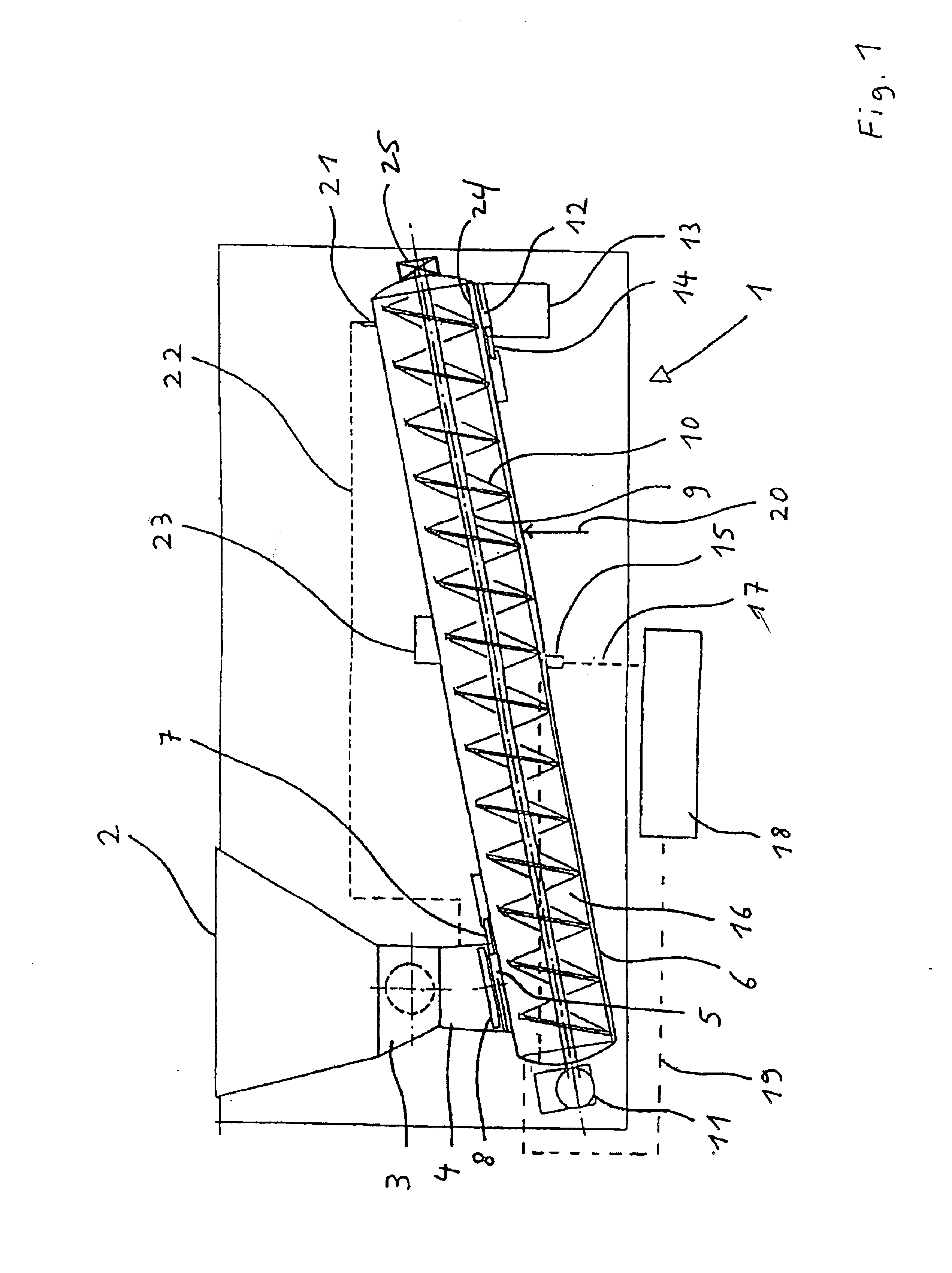

Method and device for treating contaminated materials

InactiveUS6926863B1Reduce pressureEasy to shredLevel controlSolid waste disposalContinuous flowBoiling point

A method and apparatus (1) for treating contaminated materials in which the materials are fed by an input unit (2, 3, 4) to a conveyor system (9) extending through a treatment chamber (6) where they are heated, treated and discharged via a discharge element (12). A liquid reservoir (16) is created in a first treatment area of the treatment chamber (6) by inclining the treatment chamber. The first area is also heated to a temperature below the boiling point of water, and a second area extending from th first treatment area to the top end of the treatment chamber (6) is at least partially heated to a temperature above the boiling point of water. This enables the contaminated material to be treated and compacted in a simpler, more reliable manner and in a (quasi-) continuous flow through several treatment areas.

Owner:LOGTECH PATENT

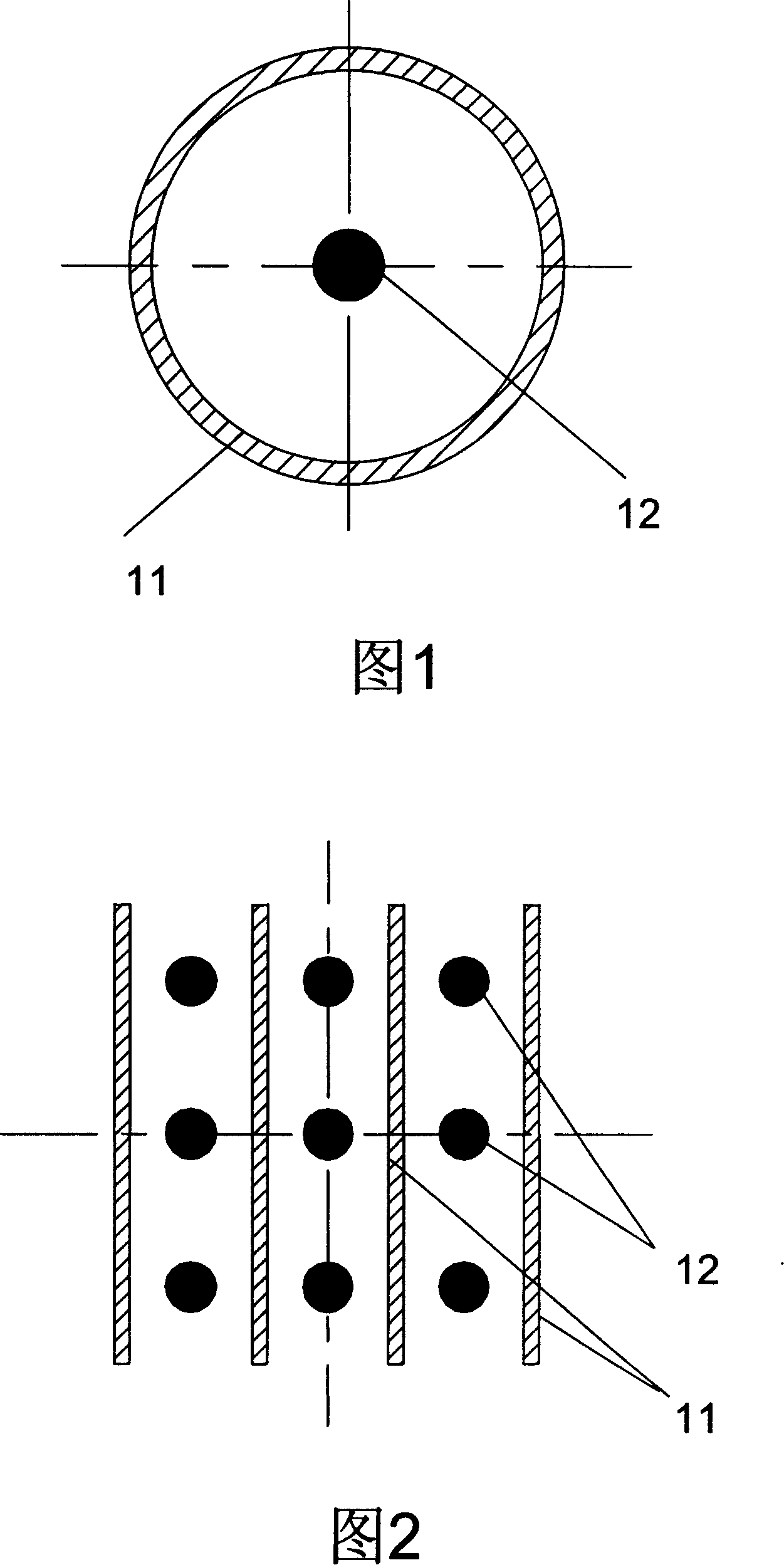

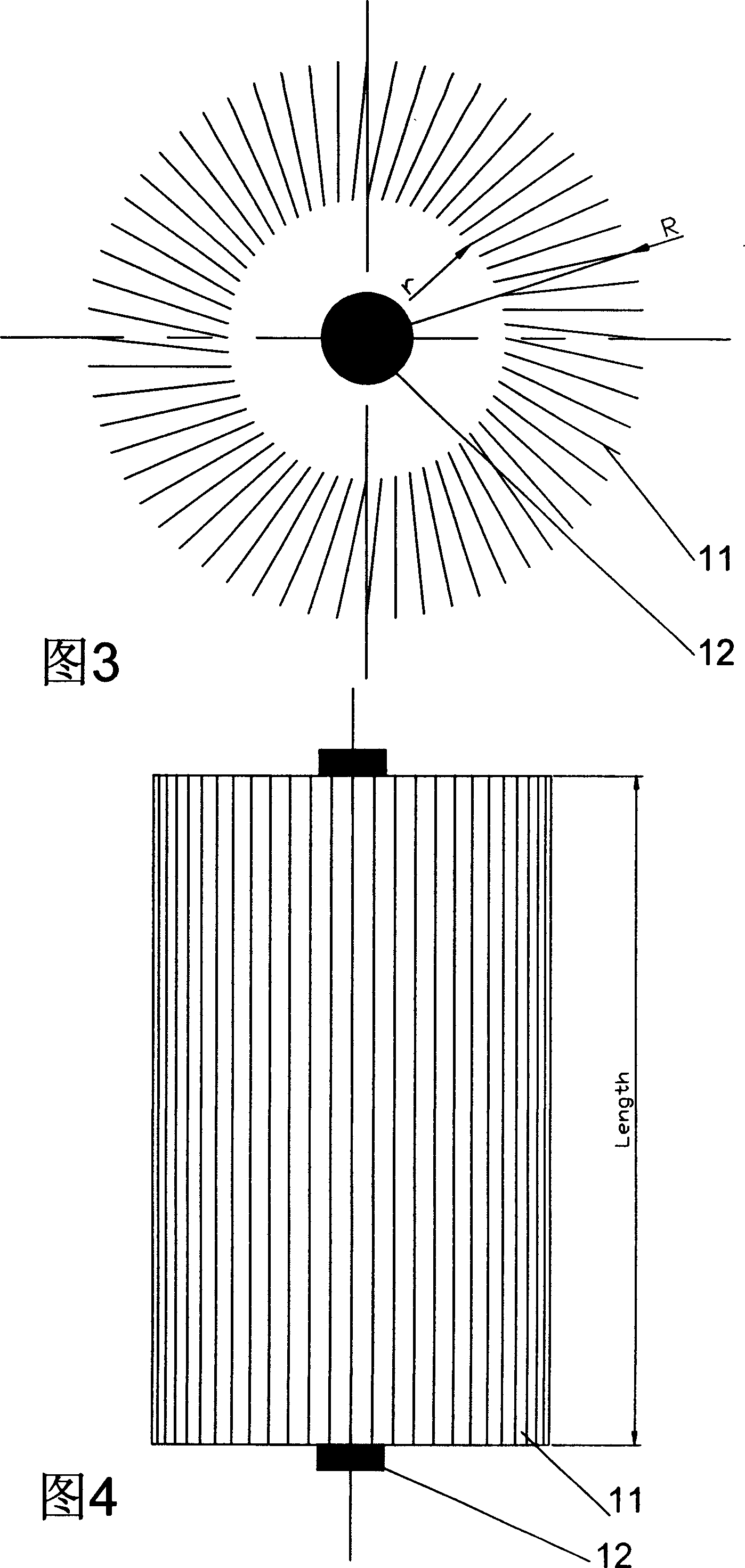

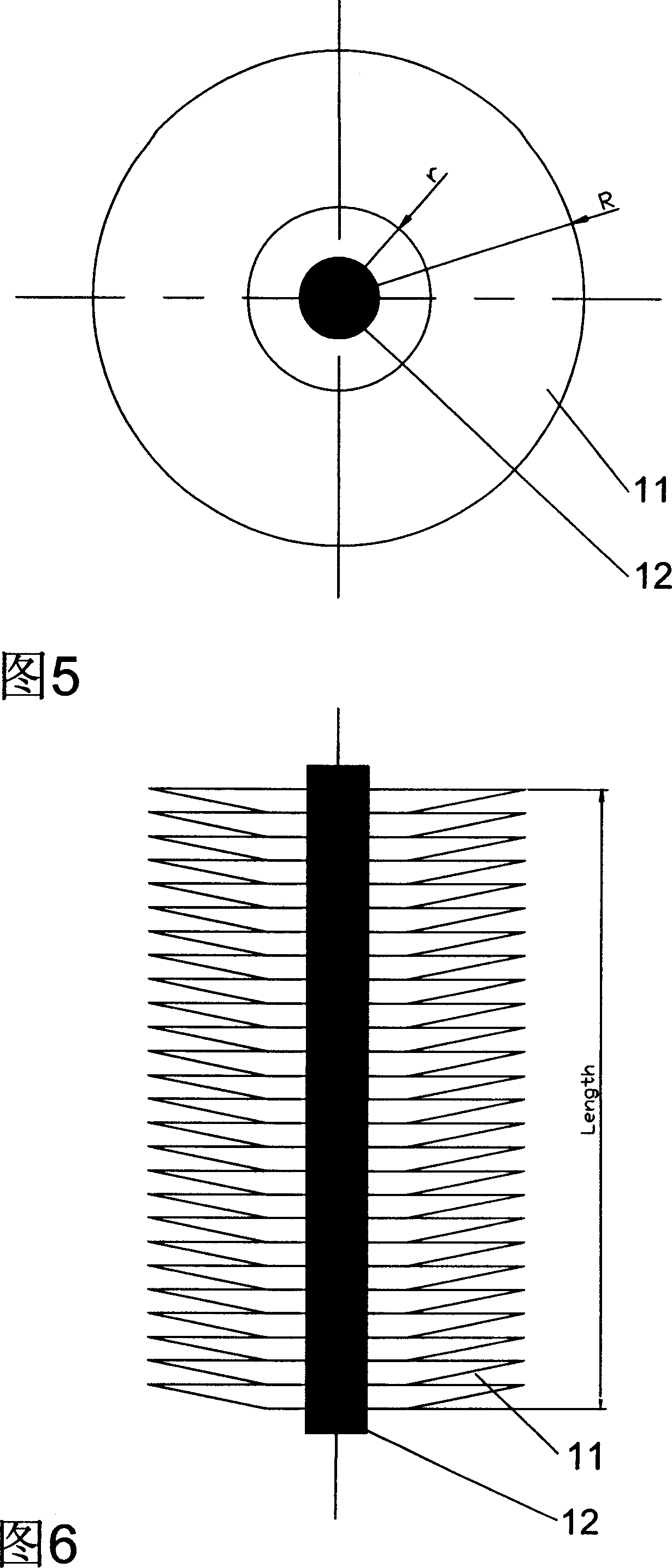

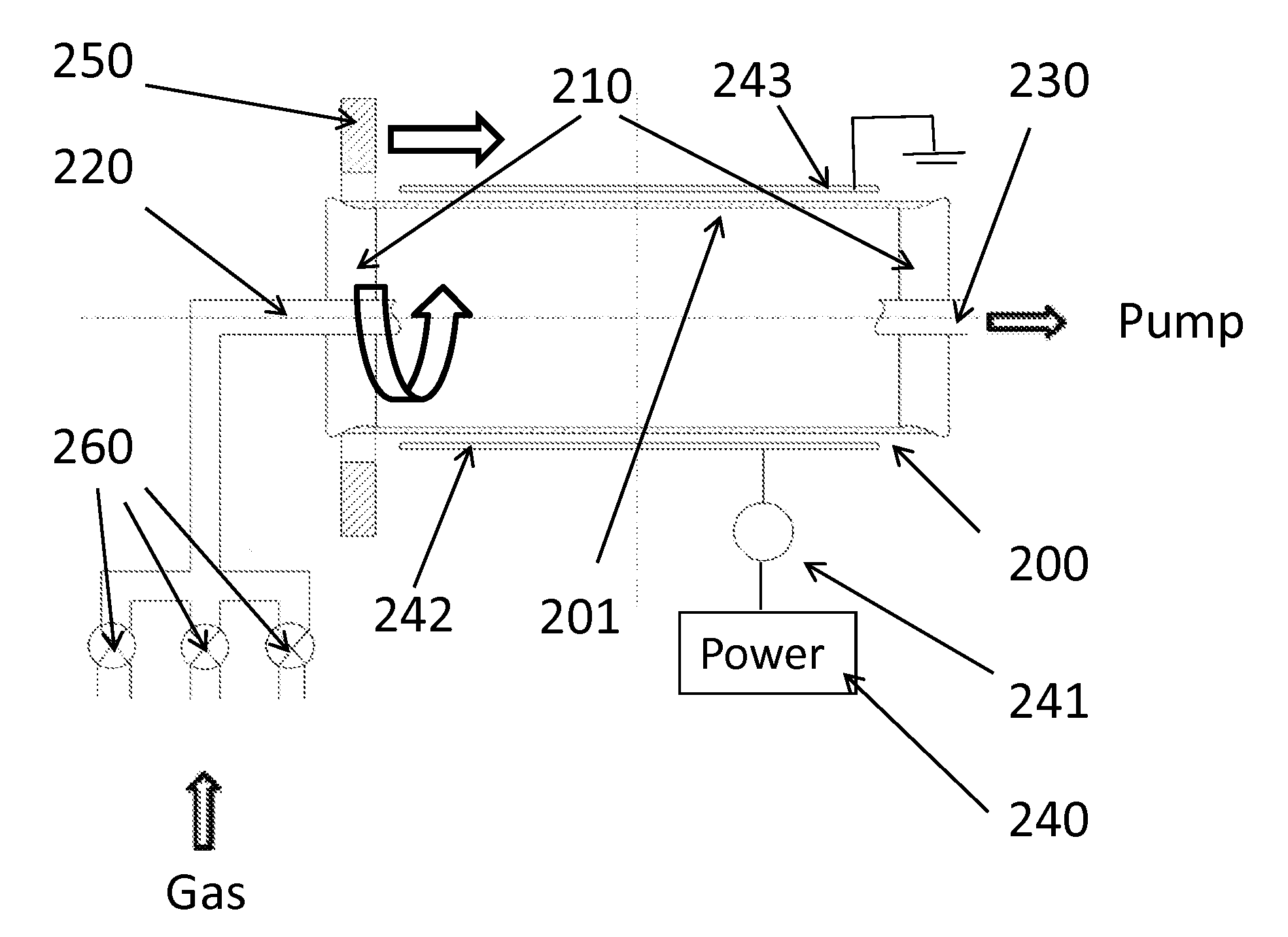

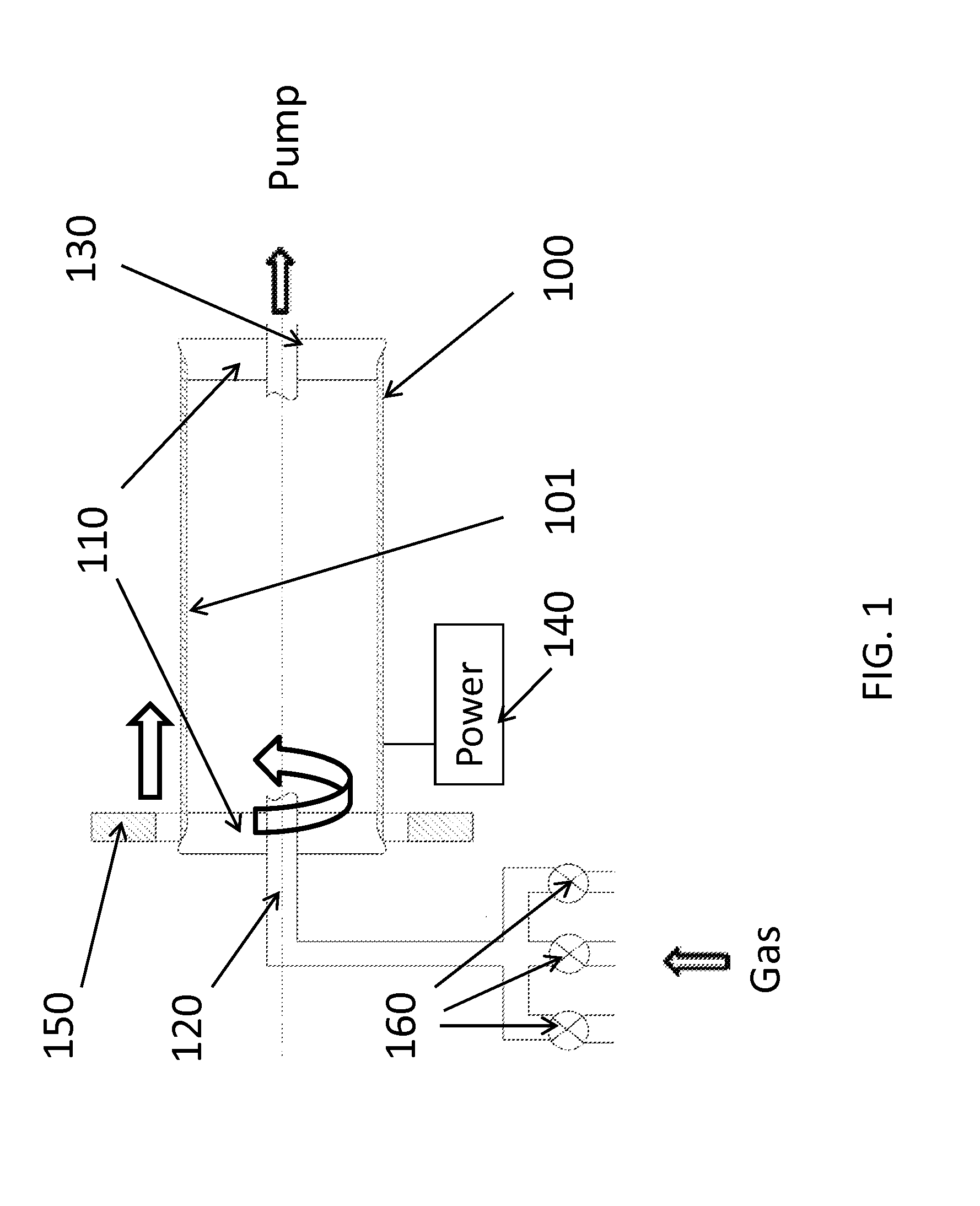

Magnetically Enhanced Thin Film Coating Method and Apparatus

InactiveUS20120312233A1High aspect ratioEnhance glow dischargeElectric discharge tubesChemical vapor deposition coatingEngineeringMagnetic flux

Methods and apparatuses for implementing magnetic field to assist PECVD to locally or globally coat the internal surface of the work piece are presented. Several permanent magnet assembly designs have been presented to provide efficient and effective magnetic field inside the work piece, which acts partially as the working chamber. The magnet assembly generates magnetic flux inside the working chamber, which increases the efficiency of PECVD process, enable PECVD process under higher gas pressure and to improve the uniformity, deposition rate, better adhesion and reduce the process temperature.

Owner:GE YI +1

Reoriented overheat air vent for reducing NO2 produced from coal powder burner

InactiveCN1873325AOptimize dwell timeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorNOx

The present invention relates to an overfired air (OFA) nozzle for coal powder boiler or furnace; said overfire air (OFA) nozzle can be used for injecting overfined air (OFA) from side wall so as to increase stationary time of burner layer. Said invention can use several OFA nozzles, and said OFA nozzles can be vertically and horizontally alternatively arranged, so that in the proper time and position the overfired air can be effectively inputted into the burner flame so as to effectively reduce formation of fuel NOx. Said invention also provides the OFA structure for single-wall type or opposed-wall type boiler and furnace.

Owner:THE BABCOCK & WILCOX CO

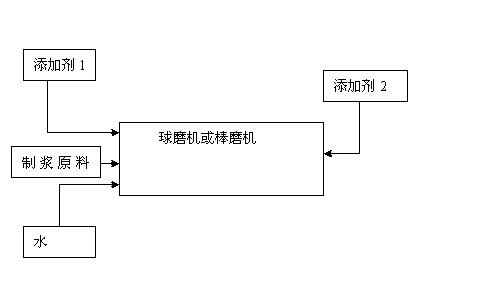

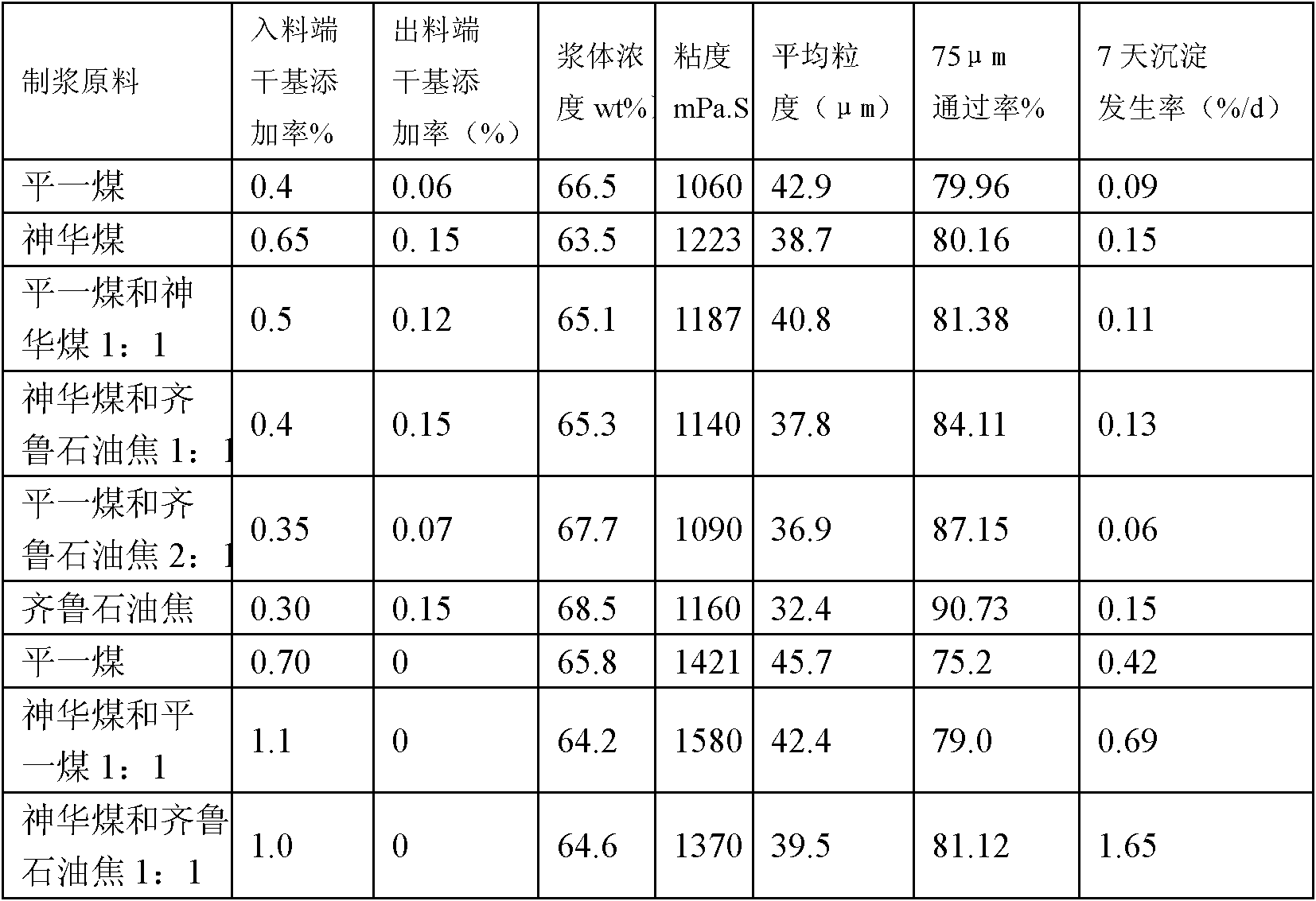

Method for preparation of coal water slurry or water coke slurry by two-stage dosing

InactiveCN103160346AOptimize dwell timeImprove grinding effectLiquid carbonaceous fuelsPetroleum cokeCopolymer

The invention discloses a method for preparation of a coal water slurry or water coke slurry. The method comprises: adding a naphthalene sulfonic acid formaldehyde copolymer, a naphthalene anthracene sulfonic acid formaldehyde copolymer, lignosulfonate and a humate into the feeding end of a mill for grinding coal, petroleum coke or mixed raw materials, with the adding amount accounting for 0.1-1.0% of the total weight of the slurry; and adding hexametaphosphate, sulfonated acetone-formaldehyde copolymer or a polyacrylate at the discharge end of the mill, with the adding amount accounting for 0.02-0.2% of the total weight of the slurry. The stage dosing for preparation of the slurry can improve the ore grinding properties of the mill, broaden the particle size distribution of the slurry, improve the concentration and stability of the slurry, reduce the viscosity of the slurry, and improve the fluidity of the slurry. The method has a stabilizing effect on multiple slurries, can improve slurry stability, adjust slurry particle size distribution, increase slurry concentration, reduce slurry viscosity and enhance mobility. With the advantages of convenient operation, small dosage and low cost, the method has high popularization and application value.

Owner:NANJING UNIV

Re-oriented over fire air ports for reduction of NOx production from pulverized coal-fired burners

InactiveUS7624707B2No accumulationExtended stayFluidized bed combustionPulverulent fuel combustion burnersCombustorResidence time

An over fire air (OFA) port arrangement for a pulverized coal-fired boiler or furnace has at least one OFA port through each of the sidewalls for injecting OFA to increase residence time for each burner level. Plural OFA ports may be employed, staggered both vertically and horizontally to effectively deliver over fire air to the burner flames at the appropriate time and location to most efficiently reduce the formation of fuel NOx. OFA port configurations for both single-wall and opposed-wall fired furnaces and boilers are provided.

Owner:POLY MED +1

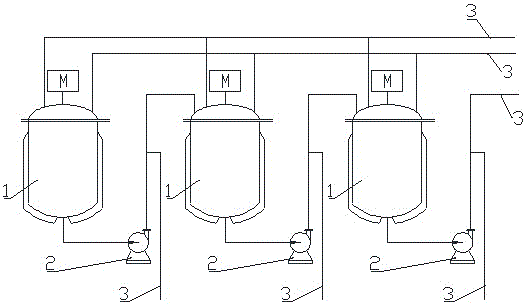

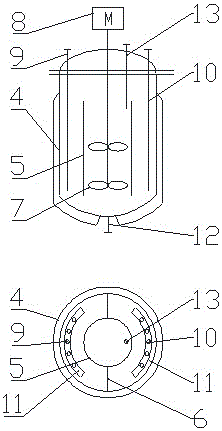

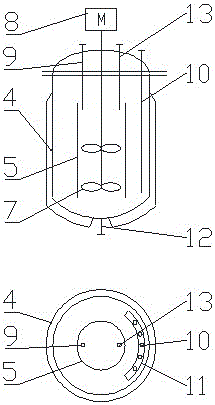

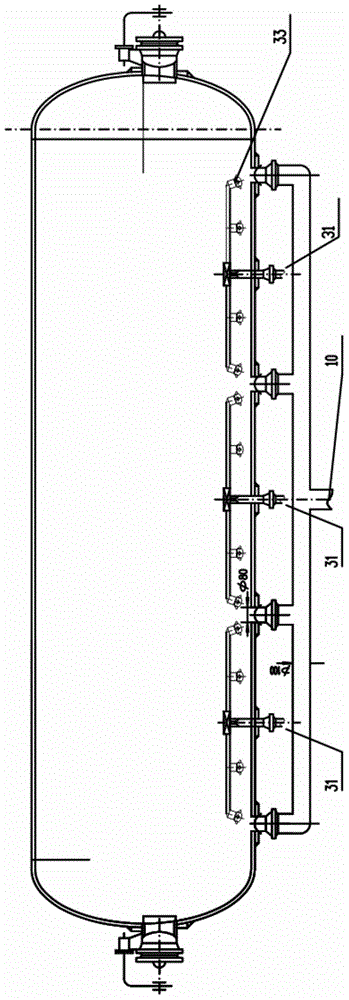

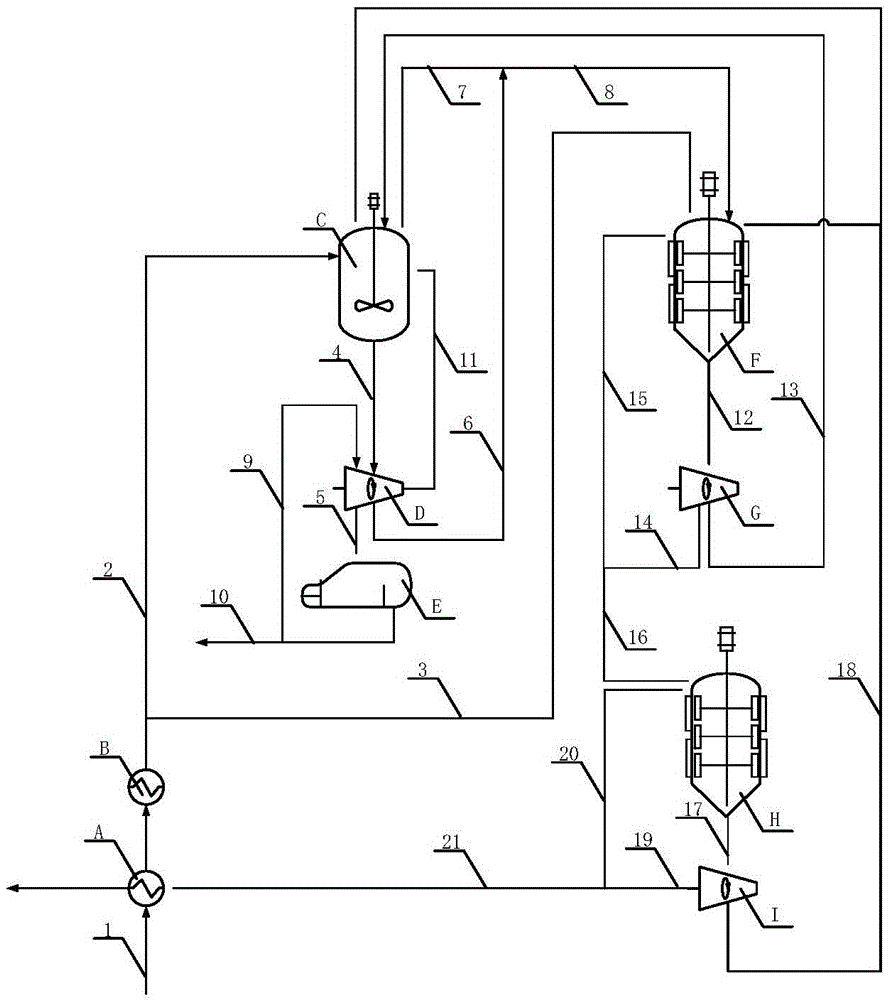

Granularity-controllable magnesium hydroxide reaction crystallization apparatus and process

ActiveCN106745108ANarrow particle size distributionImprove concentration distributionSolution crystallizationCrystallization by component evaporationMagnesiumParticle-size distribution

The invention discloses a granularity-controllable magnesium hydroxide reaction crystallization apparatus and process. The reaction crystallization apparatus consists of a reaction crystallizer (1), a conveying pump (2) and a pipeline (3). The reaction crystallizer (1) comprises a jacket-type kettle body (4), a guide barrel (5), a longitudinal separation plate (6), a stirring paddle (7), an electric stirrer (8), a magnesium chloride feeding pipe (9), a sodium hydroxide feeding pipe (10), a feed distributor (11), a magnesium hydroxide discharging pipe (12) and a magnesium hydroxide feeding pipe (13). The invention also provides the magnesium hydroxide reaction crystallization process. By utilizing the apparatus and the process provided by the invention, the granularity-controllable production of the magnesium hydroxide can be realized, the magnesium hydroxide with different granularities can be prepared, and the requirements of different users on the granularity of a magnesium hydroxide product can be met. The granularity-controllable magnesium hydroxide reaction crystallization apparatus and process have the advantages of flexibility and adjustability in product granularity and narrow granularity distribution.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Supercharged atomization dust fall type electrostatic dust collection device

InactiveCN106669328AExtended stayOptimize dwell timeElectrostatic separationUsing liquid separation agentRetention timeEngineering

The invention discloses a supercharged atomization dust fall type electrostatic dust collection device, comprising a device body which is mainly composed of a dust fall area, a supercharged depression area, a drying area, an electrostatic adsorption area, a smoke inlet, an exhaust outlet and a slurry outlet, wherein a rotating shaft is vertically arranged in the device body; the rotating shaft is positioned in the atomization dust fall area and provided with external threads on the surface; a moving component is arranged on the rotating shaft in a sleeved manner; the moving component is fixedly connected with a sliding plate; a water tank is arranged at the bottom in the atomization depression area; a piston plate is arranged in the water tank; a lead screw is vertically arranged in the atomization dust fall area; a through hole is formed in the sliding plate; internal threads are formed in the through hole; the lead screw is in threaded connection with the through hole; the lead screw is in threaded connection with the piston plate; a rotating disk is arranged in the electrostatic adsorption area; the rotating disk is fixedly connected with the rotating shaft; a slide rail is arranged on the rotating disk; and the inner part of the slide rail is in slip connection with an electrostatic plate. The device has a good dedusting effect on smoke, long retention time and dead angle-free electrostatic adsorption.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Heavy oil electro-desalting back-washing system and method thereof

InactiveCN105583178ARemoval of sediment and siltOptimize dwell timeRefining by electric/magnetic meansCleaning using liquidsNozzleWaste management

The invention discloses a heavy oil electro-desalting back-washing system. The heavy oil electro-desalting back-washing system is arranged in a back-washing tank body and comprises a dewatering pipe, a support and a plurality of all-dimensional rotary jets. The multiple all-dimensional rotary jets are arranged on the support. Each all-dimensional rotary jet further comprises a plurality of back-washing pipes, a plurality of back-washing branch pipes and rotary nozzles. Each back-washing pipe is evenly provided with the corresponding multiple back-washing branch pipes. One rotary nozzle adopting a rotary forced injection mode is arranged at the tail end of each back-washing branch pipe. The invention further discloses a heavy oil electro-desalting back-washing method.

Owner:PETROCHINA CO LTD

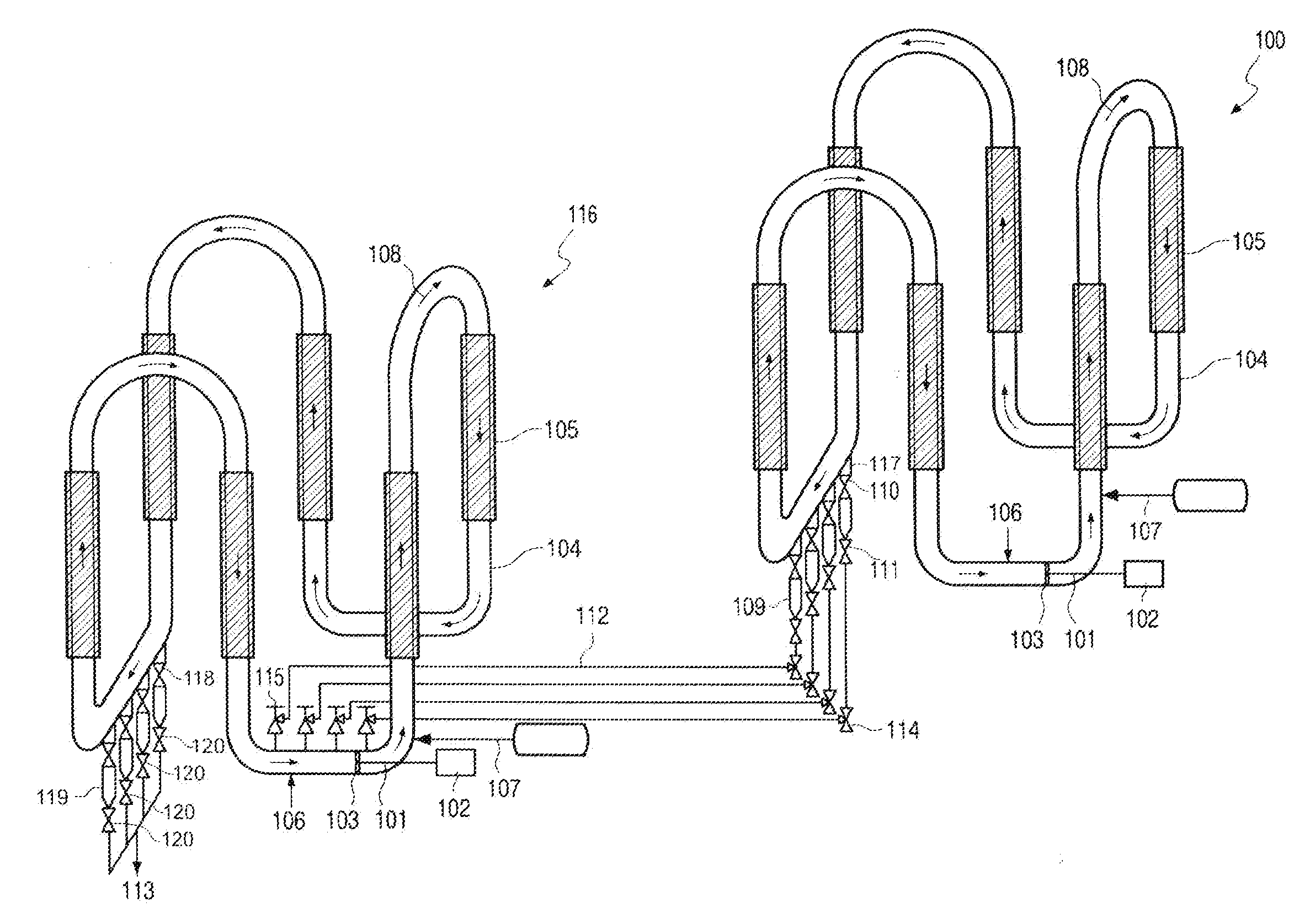

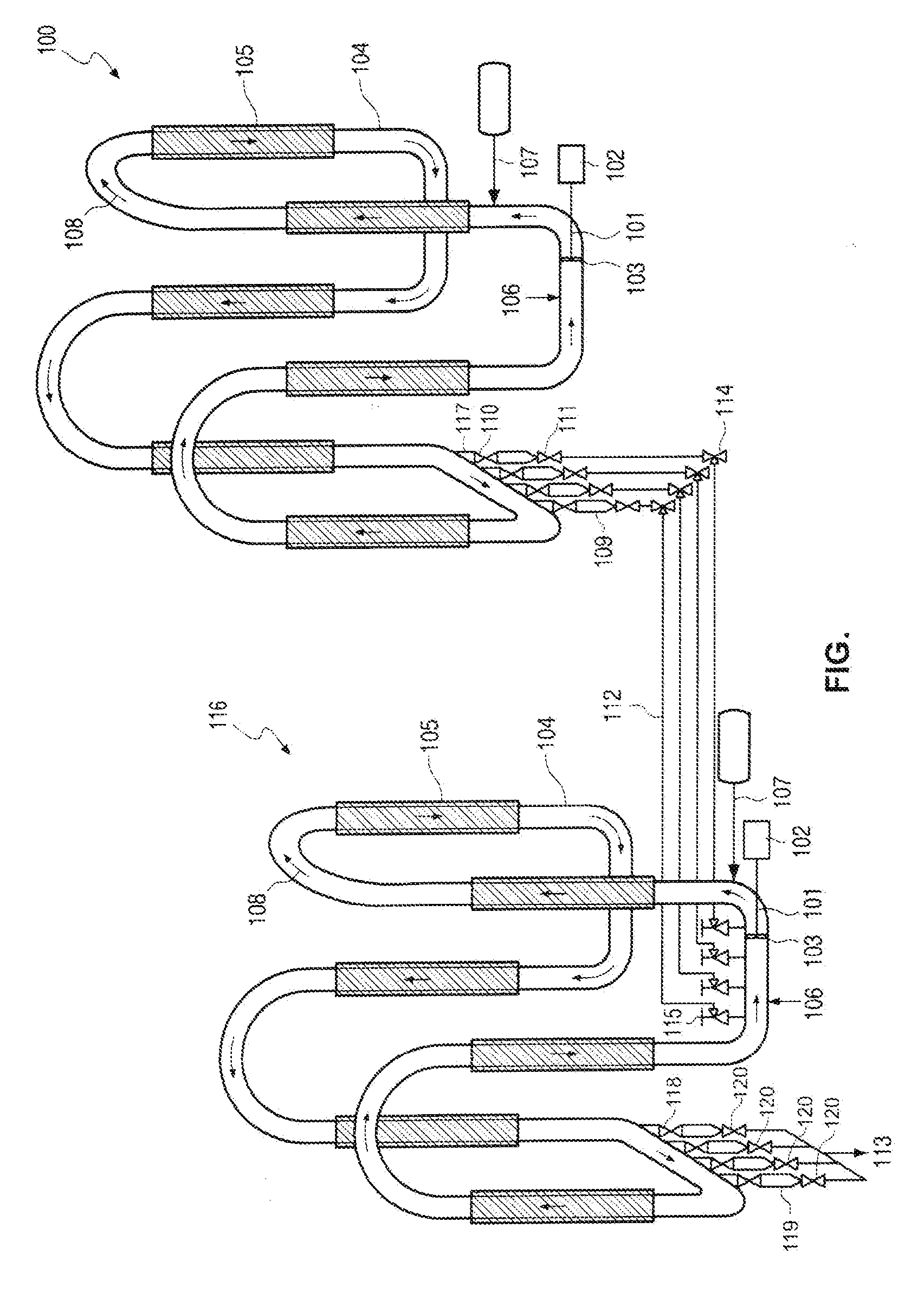

Olefin Polymerization Process With Continuous Transfer

A process for the preparation of a polyolefin in at least two slurry loop reactors including a first loop reactor connected in series with a second loop reactor includes introducing olefin reactants, diluents and polymerization catalyst into the first loop reactor while circulating. The process includes polymerizing the olefin reactants to produce a polyolefin slurry, withdrawing the polyolefin slurry from the first loop reactor, and introducing withdrawn articles into the second loop reactor by means of settling legs. Each settling leg has an inlet connected to the first loop reactor and an outlet connected to the second loop reactor by means of a transfer line. At least one settling leg is continuously open allowing continuous transfer of solid olefin polymer particles from the first to the second loop reactor. The process includes controlling the continuous transfer of solid olefin polymer particles by the at least one continuously open settling leg.

Owner:TOTAL RES & TECH FELUY

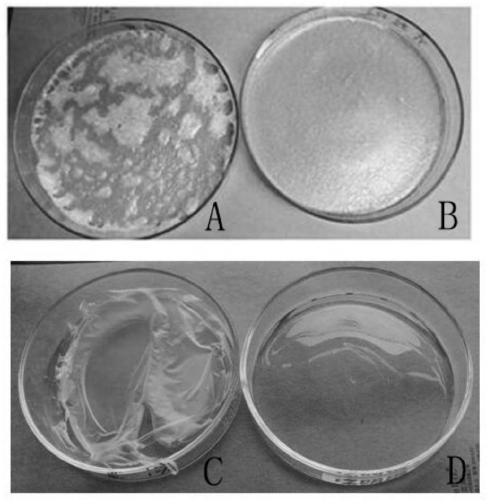

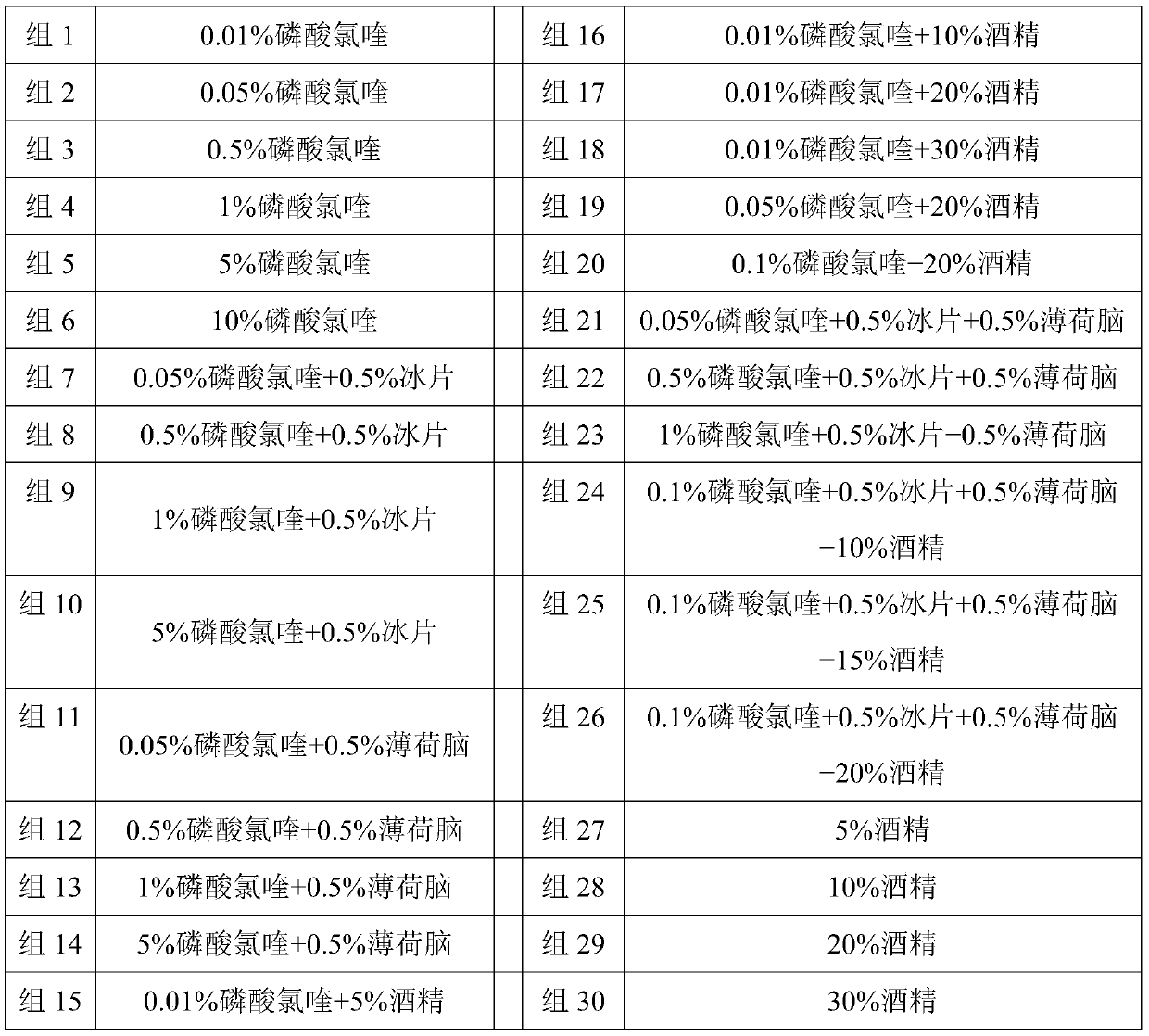

Chloroquine spray and preparation method thereof

PendingCN111419787APromote absorption timeOptimize dwell timeAntibacterial agentsHydroxy compound active ingredientsPharmacologyCoronavirus

The invention discloses a chloroquine spray and a preparation method thereof. The spray consists of a powder and a solution, wherein the powder contains chloroquine or a chloroquine derivative, a carrier macromolecular material and a sweetening agent, and the solution is a salt solution containing borneol and / or menthol. The spray containing a chloroquine medicament is developed for the first time, has small toxic and side effects, can be directly used for antibacterial and antiviral protection of the oral and nasopharynx, can be used for clearing the nose and cleaning the pharynx and throat,and has the original clinical treatment application. Meanwhile, the method utilizes the carrier macromolecular material to wrap the chloroquine, prolongs the retention time of the chloroquine spray in the oral mucosa or the nasal mucosa to achieve the effect of slow release and long-acting, and can obviously improve the bacteriostatic disinfection effect of the chloroquine by being supplemented with menthol, borneol and ethanol. The chloroquine spray is mild and non-irritating, has good taste and convenient use, and can provide normal care for healthy people and more effective prevention andtreatment measures for infected or latent people in the aspects of virus protection such as novel coronavirus and the like.

Owner:广州康健医学科技有限公司 +2

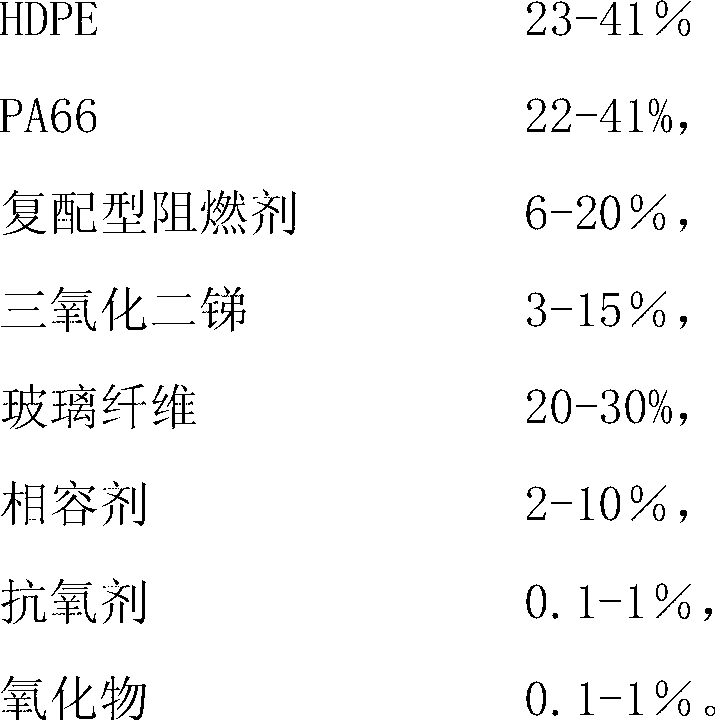

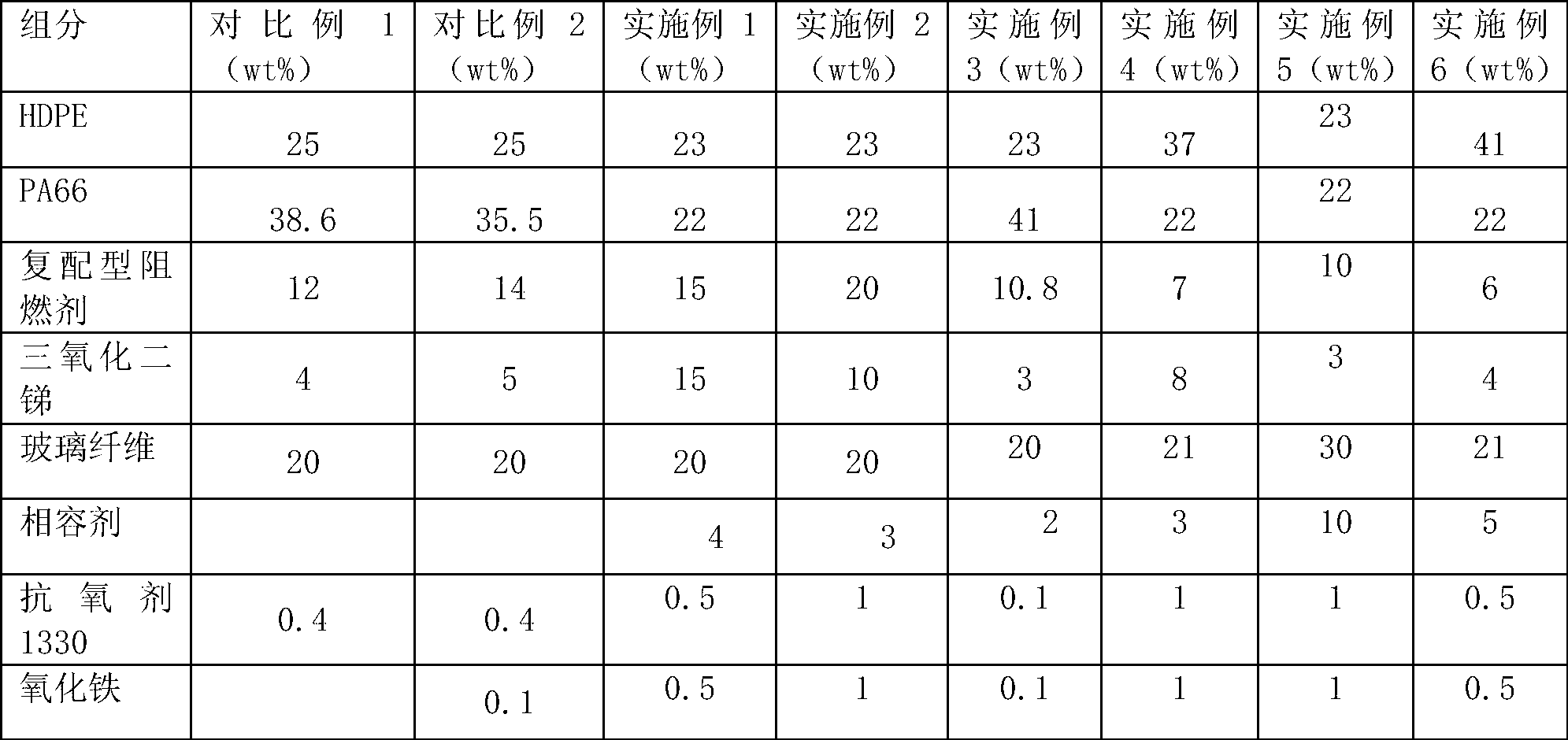

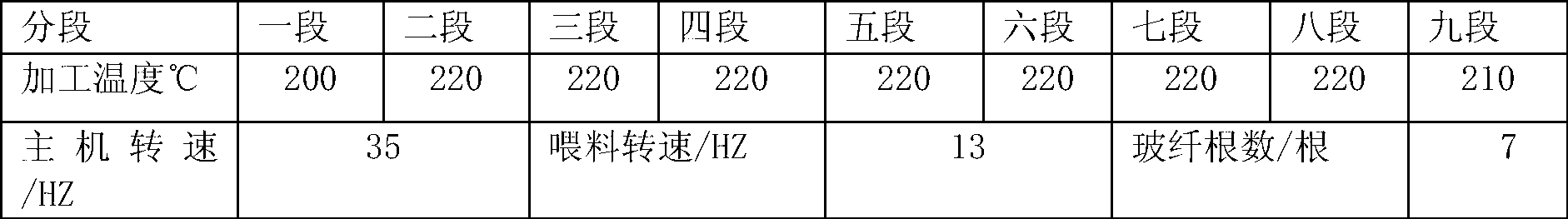

Flame-retardant glass fiber-reinforced HDPE/PA66 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA66 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA66, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 220 to 240 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

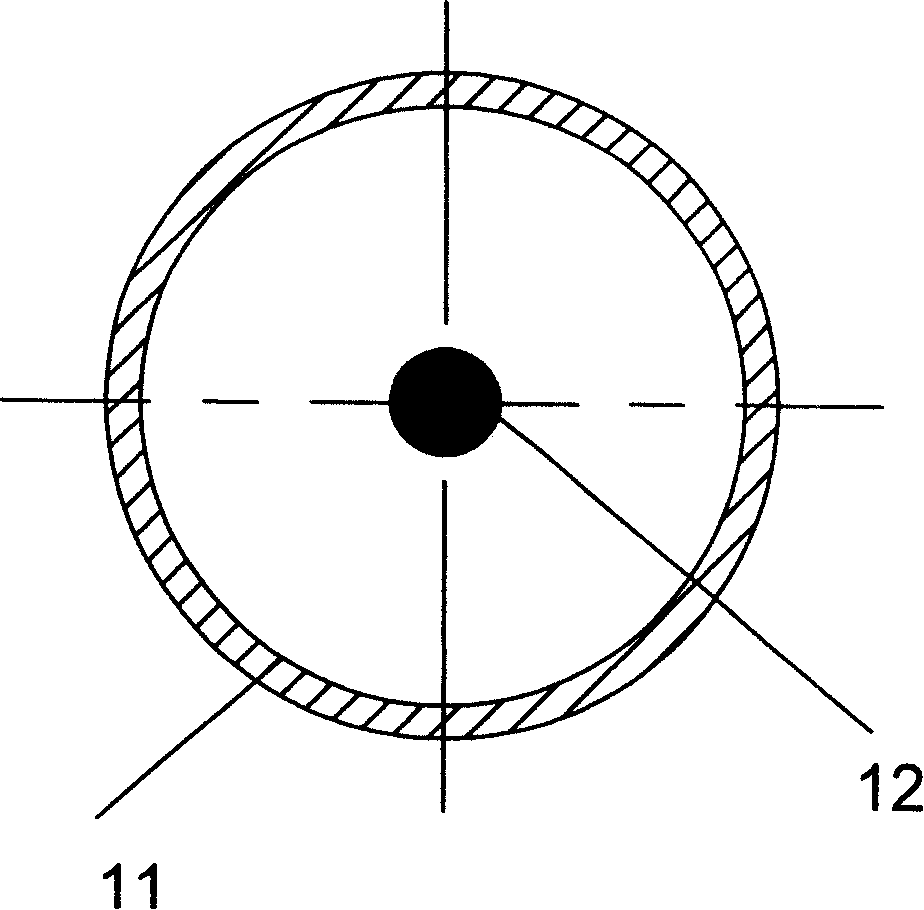

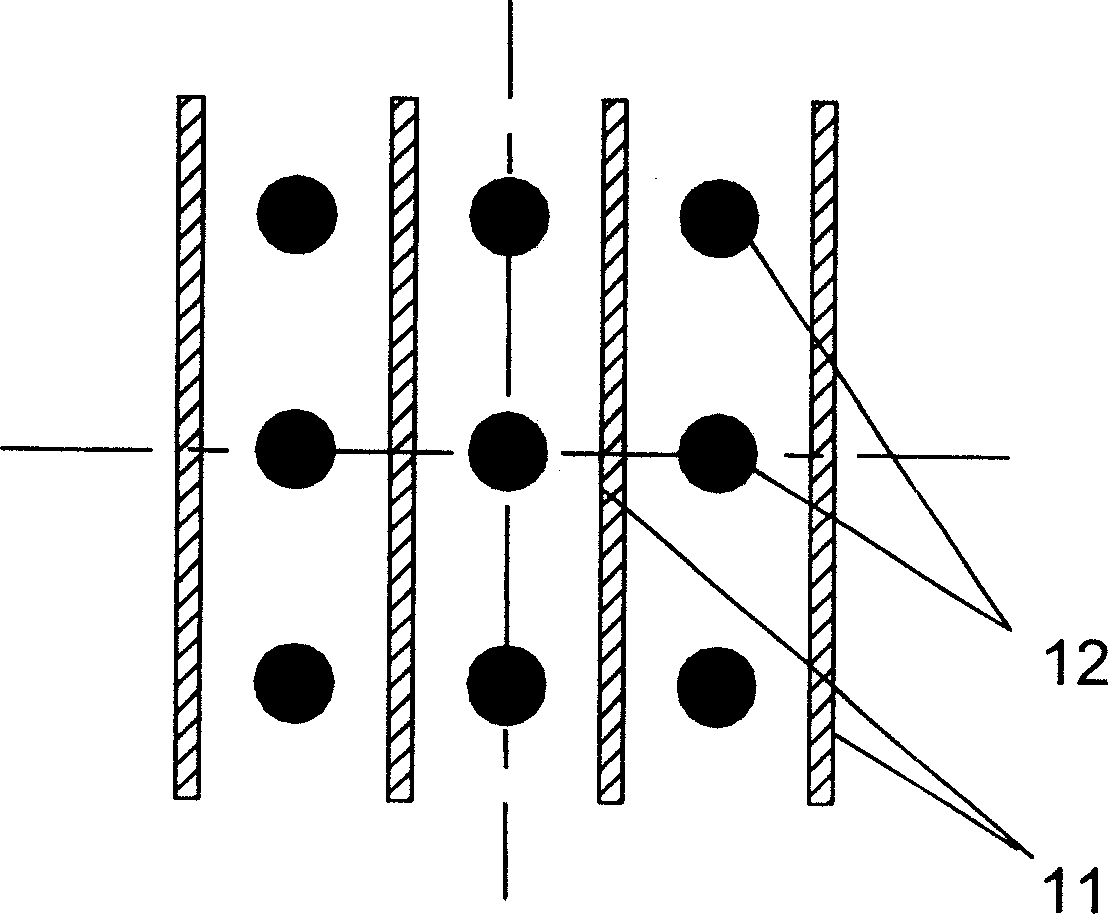

Closed photo catalyst carrier structure and pollutants treatment system thereof

InactiveCN101199922AEasy to handleImprove purification efficiencyCatalyst carriersWater/sewage treatment by irradiationPhoto catalyticUltraviolet

The invention discloses an enclosed-type photo-catalytic-carrier structure and the pollutant disposal system. The structure includes a plurality of photo-catalytic-carrier sheets and ultraviolet sources, wherein, all sheets are photo-catalytic-carrier porosint sheets, with a plurality of sheets are arranged and combined around the ultraviolet source; photo-catalysts are carried on the surface of each sheet; clearances for pollutant fluid to flow are left between each sheet and are enclosed or partly-enclosed. While the pollutant fluid flows through the carrier structure, the pollutant fluid flows from the corresponding clearance after resorting in cavities, so that the circulation path and the residence time of the pollutant fluid are changed. As the photo-catalysts on the carriers can be fully contacted, the contacting probability between the pollutant fluid and photo-catalytic carriers is increased, so that the pollutant disposal capacity is enhanced and the purification efficiency of carrier structure or the pollutant system formed by carrier structures to the pollutant fluid is greatly improved.

Owner:杨小明

Efficient purifying method for exhausted tail gases from firing of gangue baked bricks in portable tunnel kiln

InactiveCN104776727ASolve the problem of desulfurization and purificationSave energyWaste heat treatmentTunnel kilnChemical reaction

The invention discloses an efficient purifying method for exhausted tail gases from firing of gangue baked bricks in a portable tunnel kiln. The efficient purifying method comprises the following process steps of stacking raw materials: stacking green gangue bricks and limestone in an annular kiln bottom between annular tracks of the portable tunnel kiln; roasting the green gangue bricks and the limestone in the kiln to desulfurize: roasting the green gangue bricks and the limestone in an arc kiln body according to a certain temperature raising procedure, and performing primary desulfurization by high-temperature roasting; performing wet flue gas desulfurization: feeding the calcined limestone into a desulfurizing liquid adjusting pool, and adjusting the basic strength in the adjusting pool; introducing tail gases in the kiln body into a desulfurizing tower, sprinkling the desulfurizing liquid in the desulfurizing liquid adjusting pool into the desulfurizing tower, and performing secondary desulfurization by a chemical reaction generated in the desulfurizing tower. According to the efficient purifying method disclosed the invention, by the adoption of a combined desulfurization method of desulfurization by roasting in the kiln and the wet flue gas desulfurization, the problems of desulfurization and purification of the tail gases in the portable tunnel kiln are successfully solved; meanwhile, energy sources can be saved, and the purification cost is reduced.

Owner:HEBEI DINGLEI BUILDING MATERIAL CO LTD

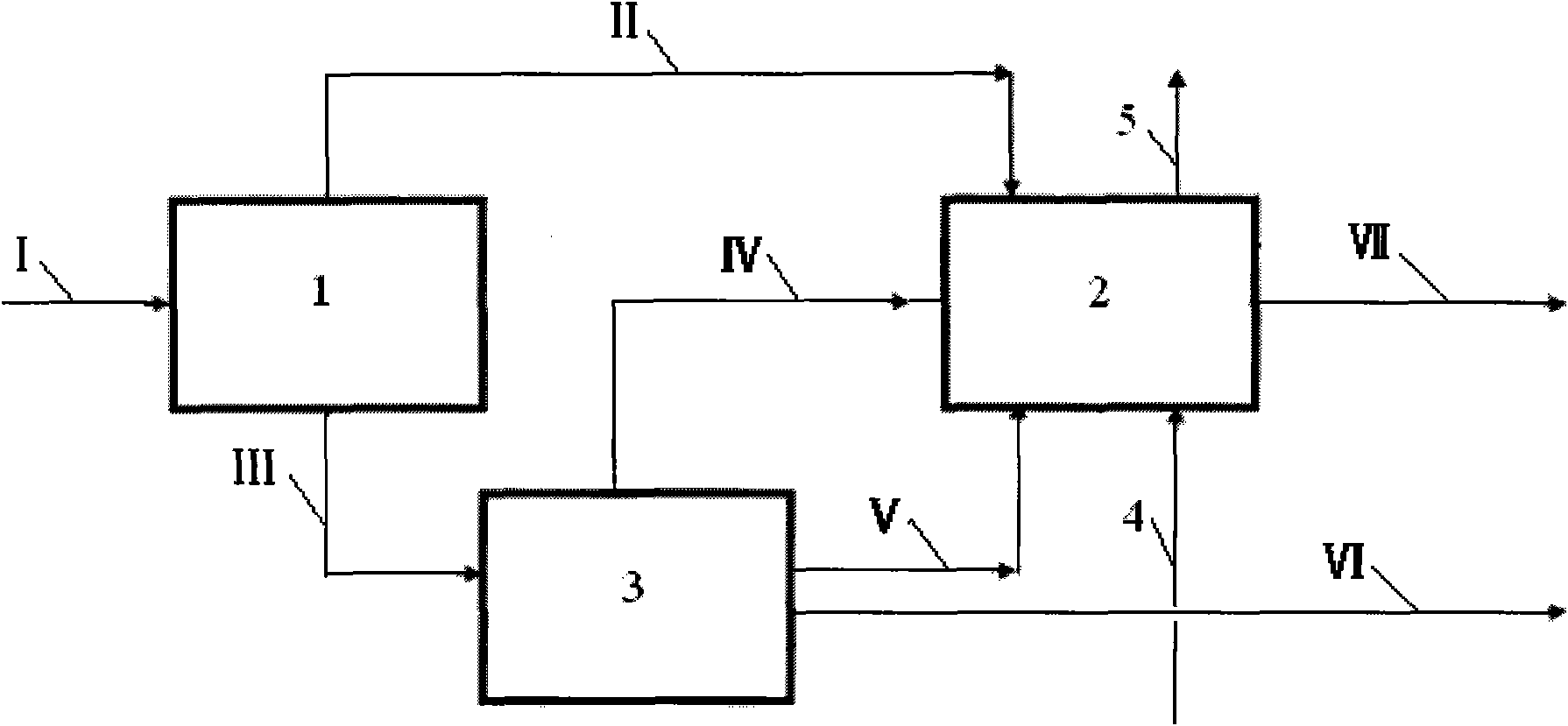

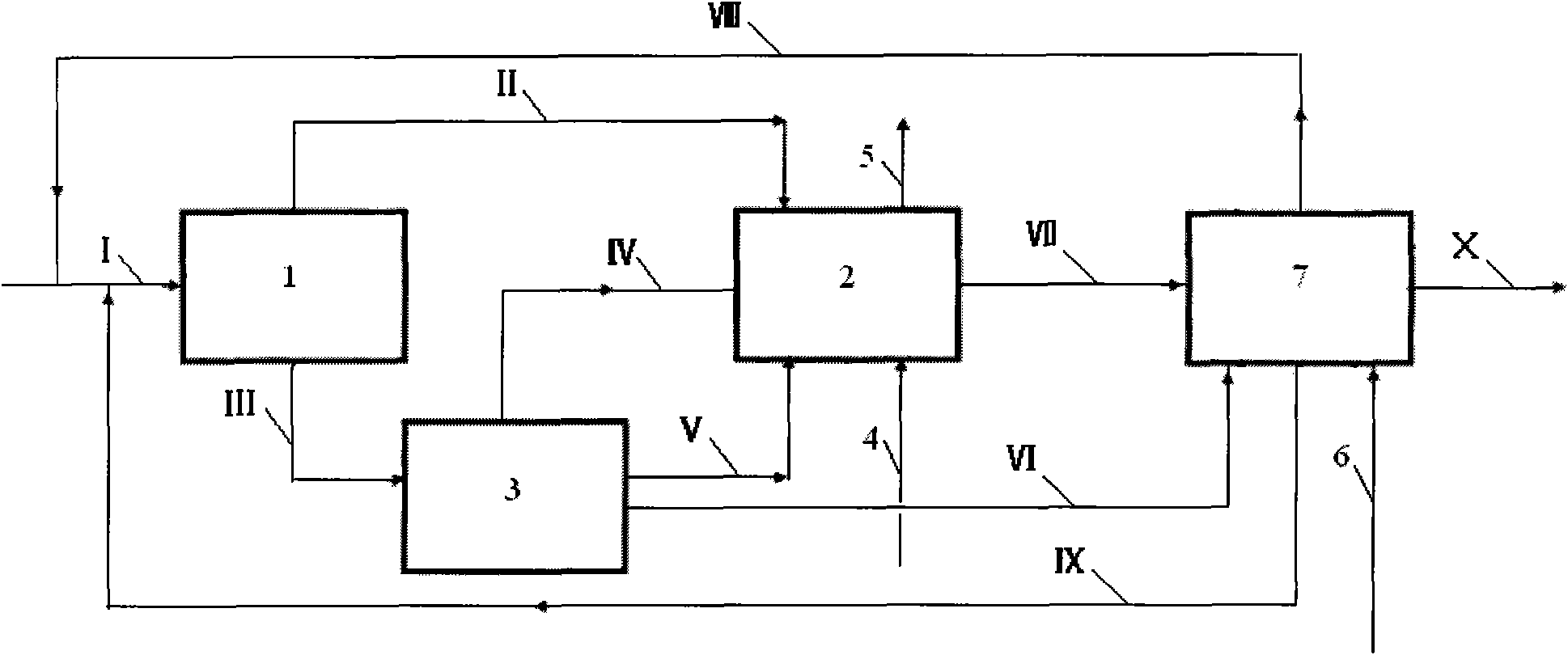

Method for preparing butyraldehyde from propylene and synthesis gas

ActiveCN102311321AIncrease effective dwell timeImprove conversion ratePreparation by carbon monoxide reactionChemical recyclingTowerVapor phase

The invention relates to a method for preparing butyraldehyde from propylene and synthesis gas, and mainly solves the problems that a second reactor has low conversion rate and capacity and a catalyst has short life cycle and high production cost in the prior art. The method comprises the following steps of: a) allowing material flow I containing propylene, synthesis gas and a catalyst to enter a first reactor I, and reacting to obtain vapor phase material flow II on the tower top and liquid phase material flow III on the tower bottom; b) allowing the material flow III to enter a middle separation unit 3, separating to obtain material flow IV containing propylene and butyraldehyde, material flow V containing a catalyst and butyraldehyde, a crude butyraldehyde product material flow VI, and allowing the material flow VI to enter a subsequent process; and c) allowing the material flow II, the material flow IV, the material flow V and make-up synthesis gas to enter a second reactor, and reacting to obtain material flow VII containing butyraldehyde and tail gas 5. The method better solves the problems and can be applied to industrial production of preparing butyraldehyde from propylene and synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

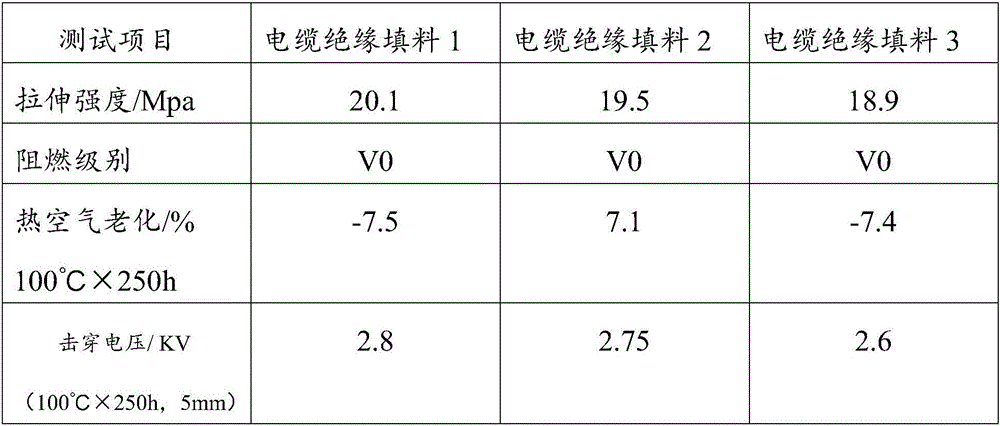

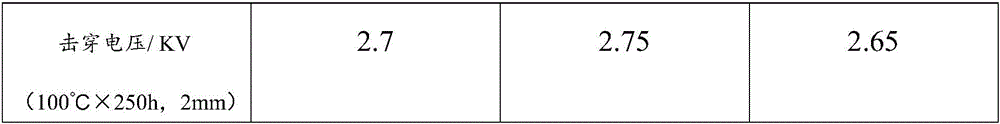

Metakaolin cable insulation packing and preparation method thereof

The invention belongs to the technical field of cable packings and particularly relates to a metakaolin cable insulation packing and a preparation method thereof. The metakaolin cable insulation packing is prepared from, by weight, 90-110 parts of PVC resin, 45-55 parts of plasticizer, 5-7 parts of stabilizer and 6-10 parts of metakaolin. The metakaolin is obtained through dry kaolin powder preparation, kaolin heat activation, depolymerization of the heat activated kaolin and the like. According to the metakaolin cable insulation packing and the preparation method of the packing, suitable and optimized process parameters such as kaolin calcining temperature, standing time and the like are found out, metakaolin modification is achieved in the efficient depolymerization and dispersion process, and the metakaolin is prepared, serves as a cable packing and has very good mechanical strength and electrical strength.

Owner:茂名高岭科技有限公司

Multistage suspension melting crystallization method for separating p-xylene

ActiveCN106831301AIncrease the average particle sizeEasy to operateChemical industryCrystallisation purification/separationChemistryHigh energy

The invention relates to a multistage suspension melting crystallization method for separating p-xylene. The multistage suspension melting crystallization method comprises the following steps: carrying out shunt operation on raw materials, carrying out multistage crystallization on a part of the raw materials, directly obtaining a p-xylene crystal, then using the rest of the raw materials to carry out pulping washing and warming aging on a low-temperature crystal in an aging kettle, and obtaining a p-xylene product. Stable operation of the aging kettle is guaranteed by adjusting the amount and temperature of the raw materials entering the aging kettle, and then the stability of product purity and yield is guaranteed. Through the technical scheme adopted in the invention, the problems of unstable operation of the aging kettle and high energy consumption existing in the prior art are preferably solved, and the method can be used in the crystallization production of the p-xylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com