Patents

Literature

50results about How to "Easy to shred" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology for cigarette production

InactiveCN103704865AExcellent mechanical processing strengthIncrease lossTobacco preparationTobacco treatmentEngineeringMoisture

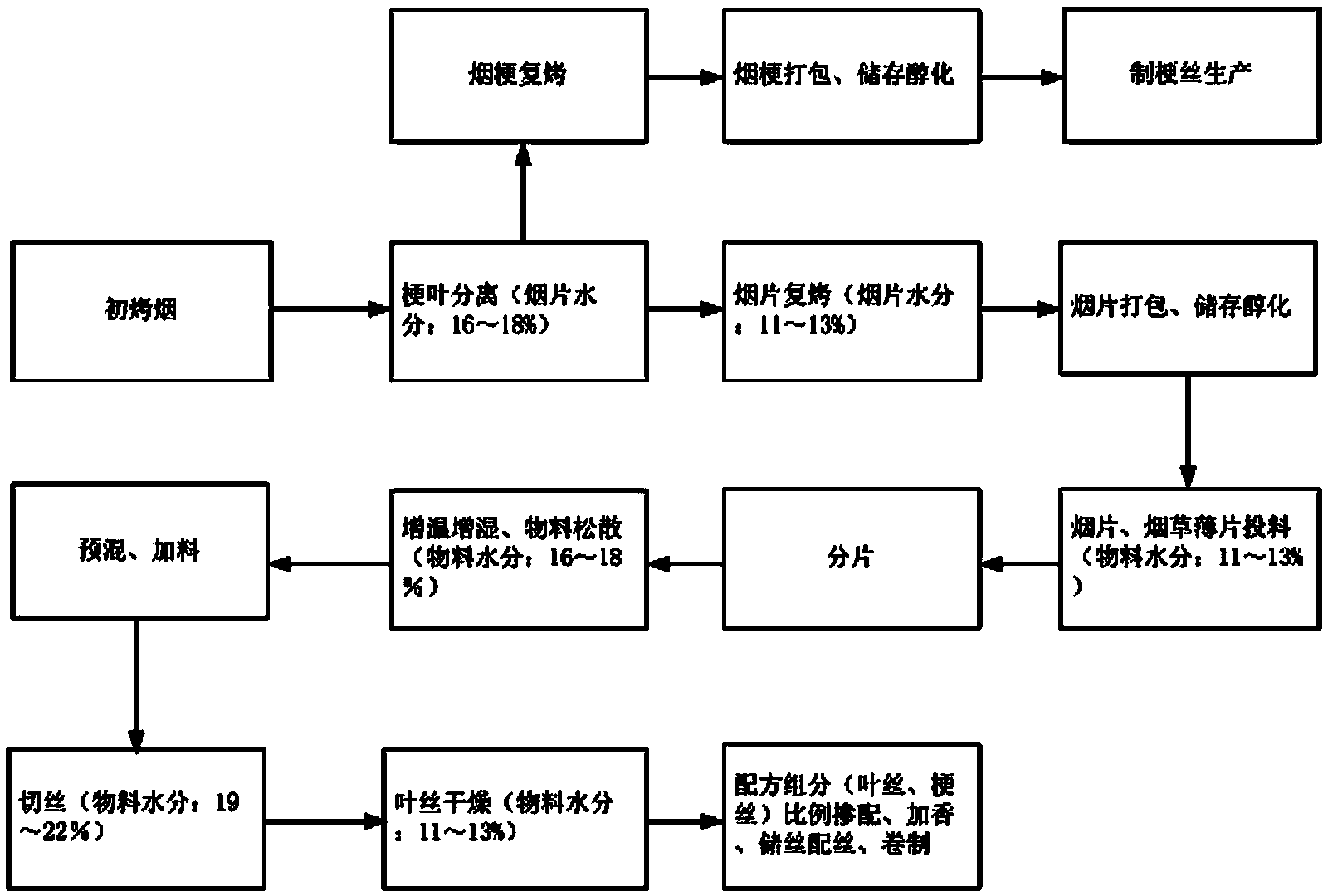

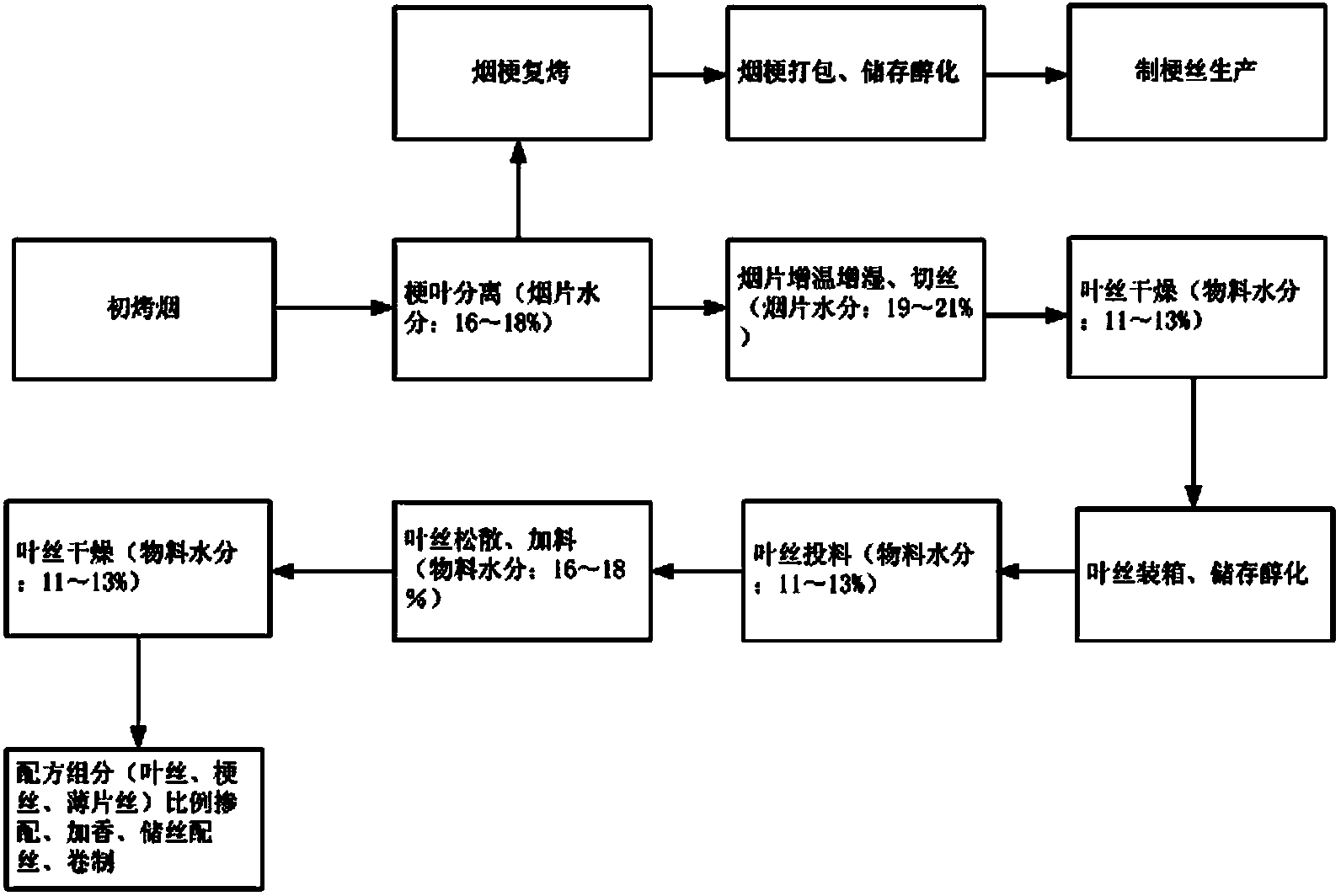

The invention discloses the technology for cigarette production, belongs to a technology for cigarette production, and particularly relates to a method for leaf-beating redrying production, cut leaf storage alcoholization and cut leaf production. According to the technology, the leaf beating redrying production technical process, the storage alcoholization production technical process and the cut leaf production technical process in the prior cigarette production mode are integrated; tobacco flakes obtained after leaves are separated from stems in the redrying process are humidified to the degree that the moisture content is, by weight, 19%-21%; after the tobacco leaves are cut, the tobacco leaves are dried to the degree that the moisture content is, by weight, 11%-13%; the cut tobacco is boxed, stored and alcoholized for 6 months to 24 months in the storage environment that the temperature is lower than or equal to 32 DEG C and the humidity is smaller than or equal to 70% RH; the alcololized cut leaves are processed in a loosened mode; feed liquid is added until the degree that the moisture content is, by weight, 16%-18%; the flow of the cut leaves is controlled and the cut leaves enter a drying device for dehydration to the degree that the moisture content is 11% to 13%; blending, flavoring, cut tobacco storage and matching and coil making are conducted according to a factory formula. The method can effectively simplify production, reduce unreasonable consumption of energy sources and raw materials and improve the economical efficiency of cigarette production.

Owner:HONGTA TOBACCO GRP

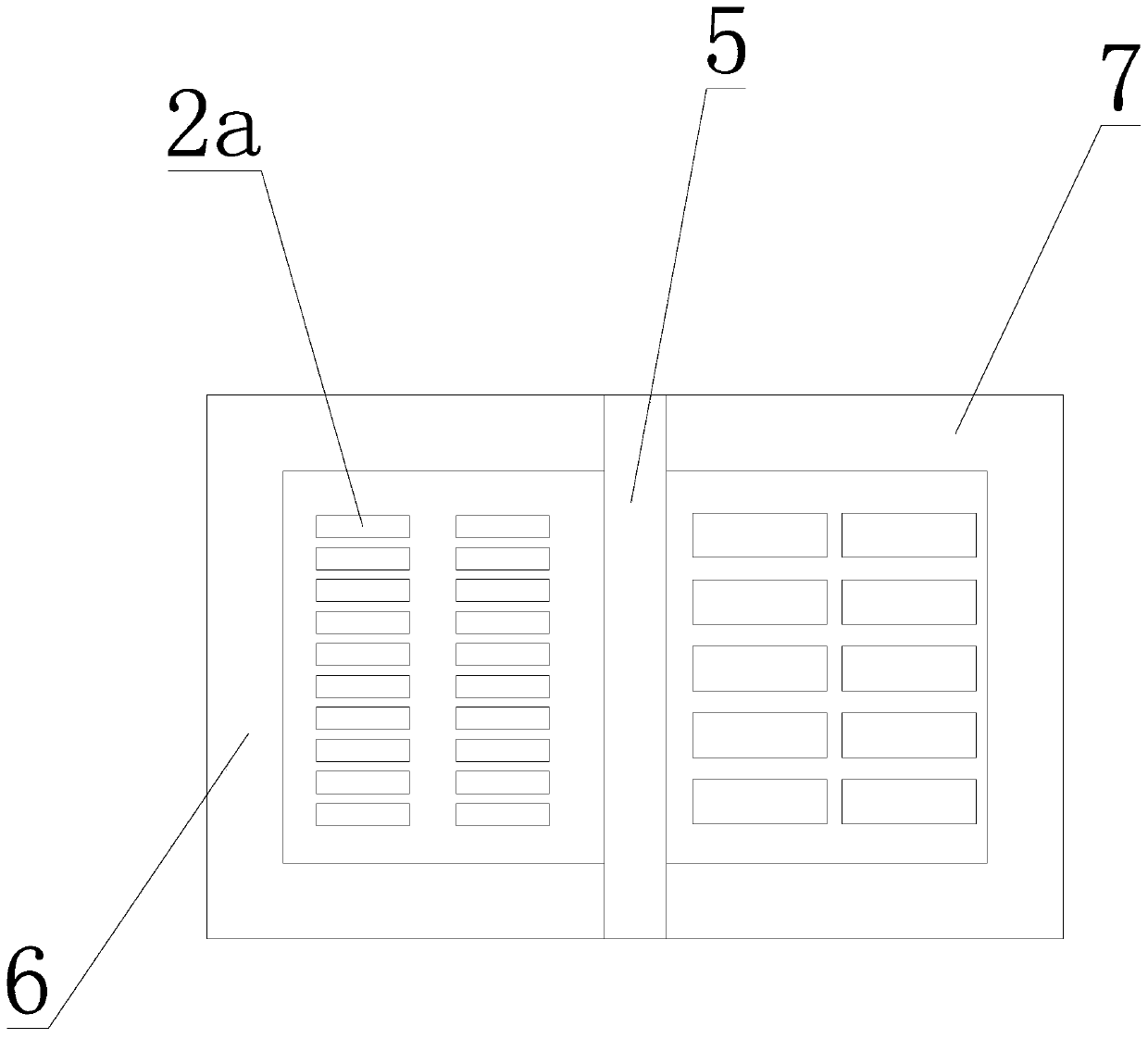

Multi-functional dustbin

InactiveCN107458792AEasy to compressEasy to adjustWaste collection and transferRefuse receptaclesEngineeringSewage

The invention relates to a multi-functional dustbin. The multi-functional dustbin comprises a cylinder 1, a connecting block, a rotating shaft, a fixing block, a label 1, a handle, a sewage purifier, a feeding pipe, a plurality of cutting knives and a stirring shaft, wherein an aspirating plate is fixedly connected with a device main body through a connecting plate, and the purifier is fixedly arranged on the rear end surface of the aspirating plate; a hollow plate is fixedly arranged in the device main body, and the hollow plate is located at the left end of a partition board; an electric motor is fixedly arranged on the upper end surface of the hollow plate, the stirring shaft is mounted at the upper end of a main shaft of the electric motor, and the plurality of cutting knives are symmetrically fixedly arranged at the left and right ends of the stirring shaft; an air pump is mounted in the hollow plate; a press rod is mounted at the right end of a cylinder 2, and a compressing plate is fixedly arranged at the right end of the press rod; and the sewage purifier is fixedly arranged in the device main body, and the sewage purifier is located at the right end of the partition board. The multi-functional dustbin can sort garbage, store garbage and carry out purifying treatment on the garbage and can be easily moved.

Owner:袁敬涛

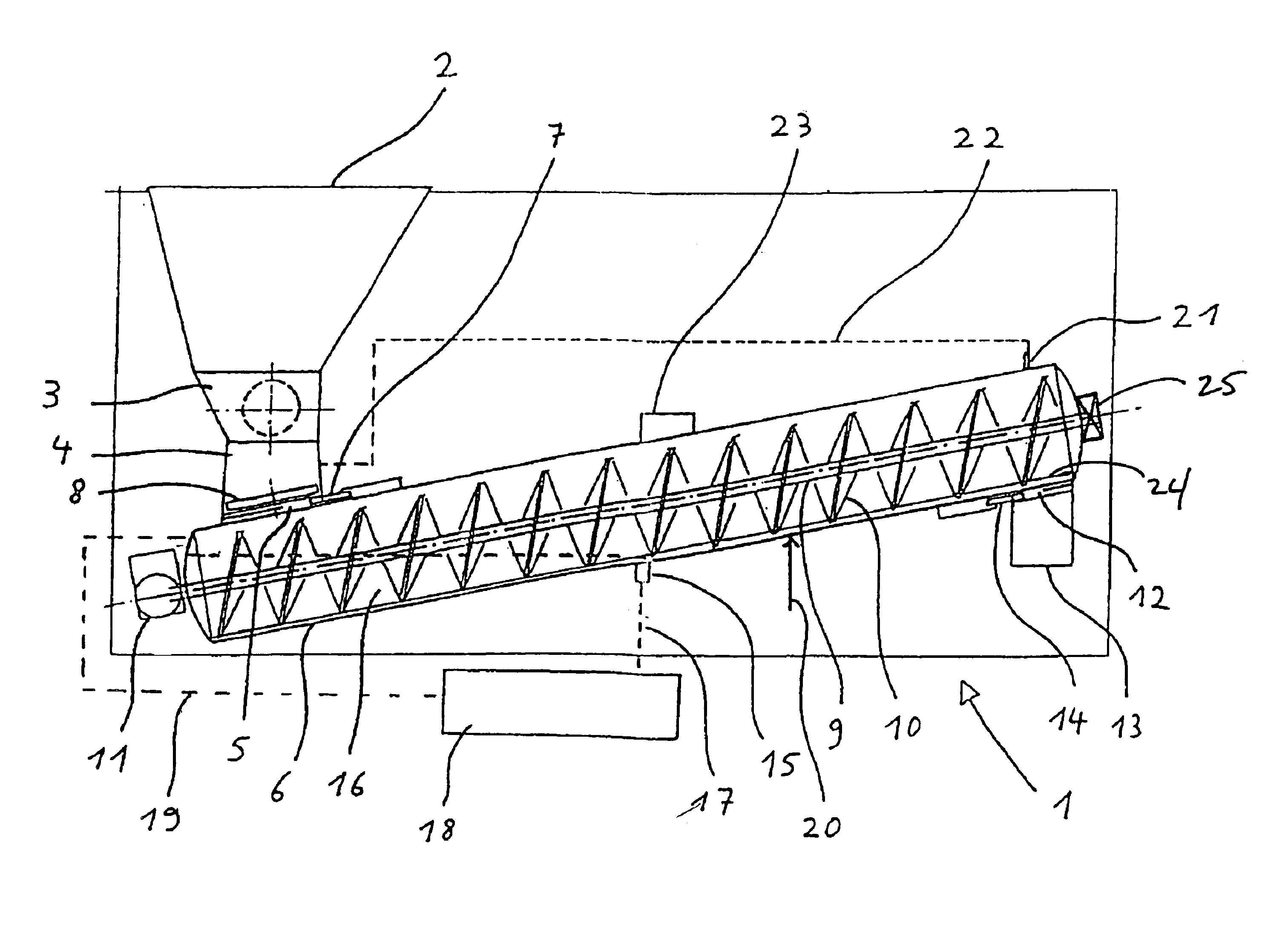

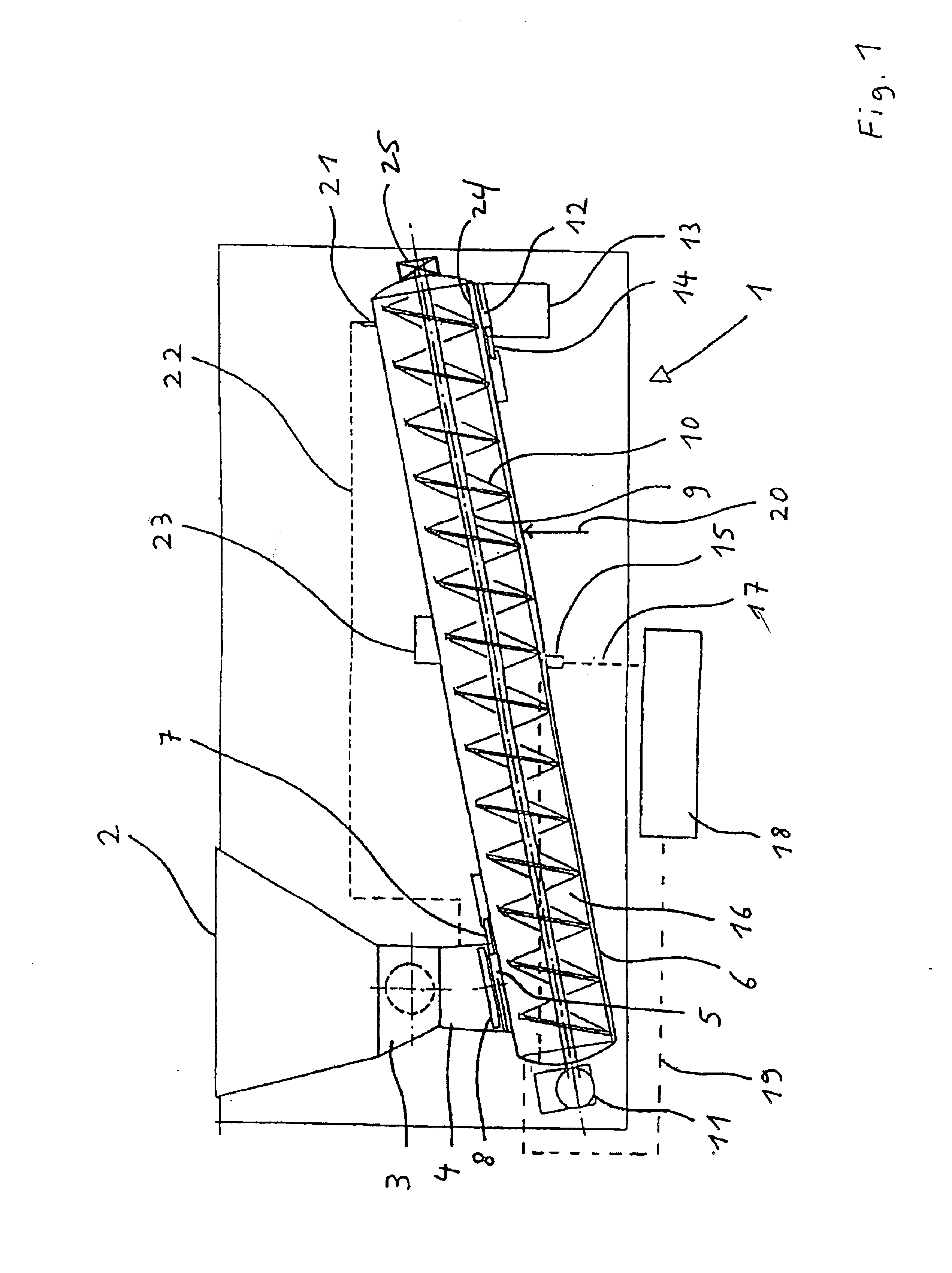

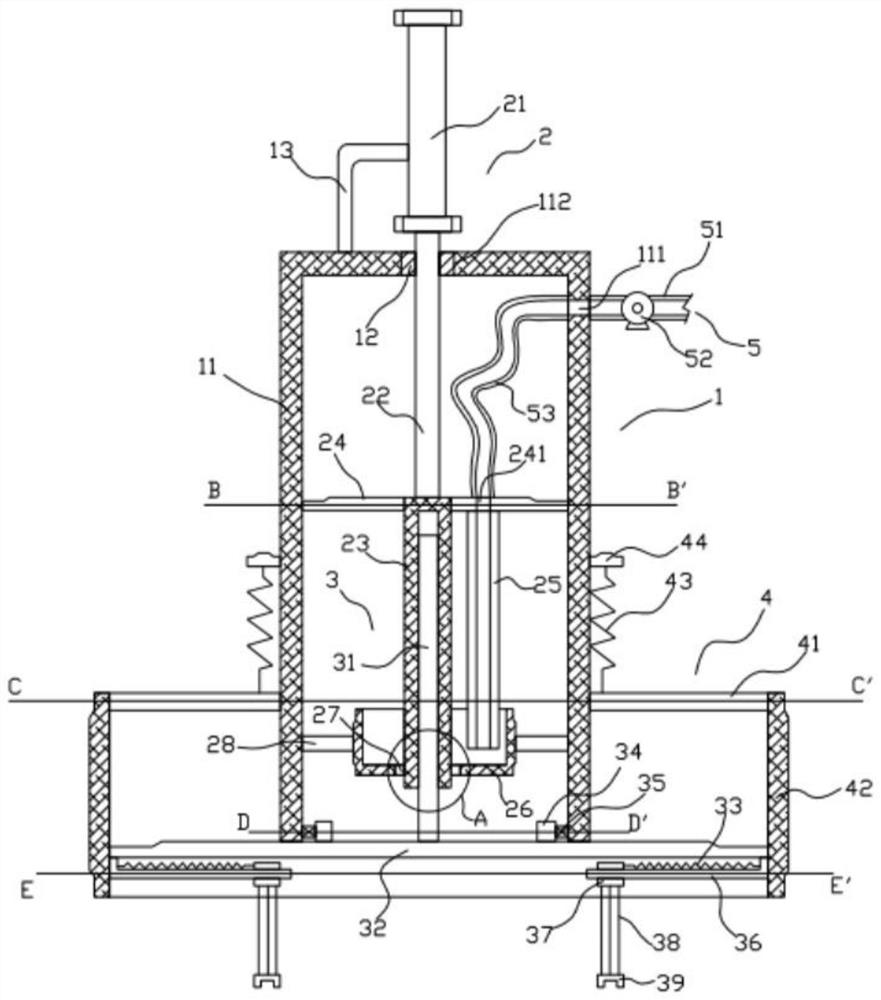

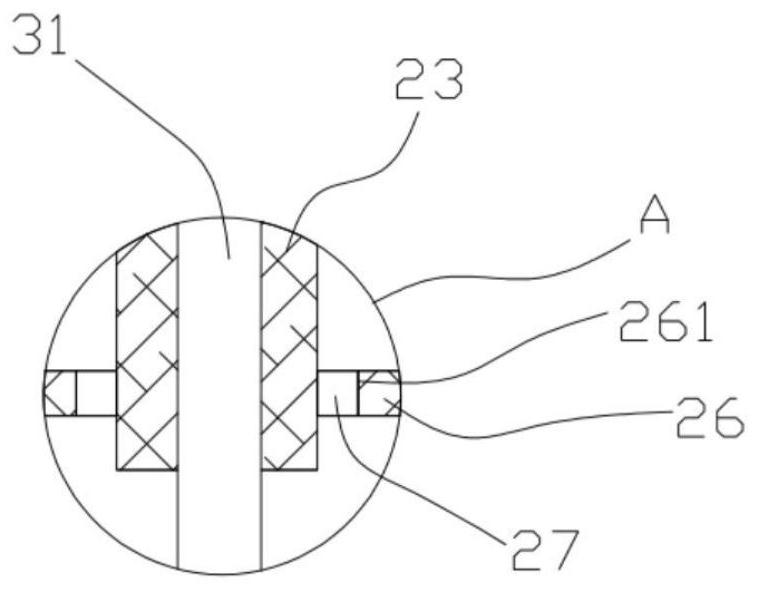

Method and device for treating contaminated materials

InactiveUS6926863B1Reduce pressureEasy to shredLevel controlSolid waste disposalContinuous flowBoiling point

A method and apparatus (1) for treating contaminated materials in which the materials are fed by an input unit (2, 3, 4) to a conveyor system (9) extending through a treatment chamber (6) where they are heated, treated and discharged via a discharge element (12). A liquid reservoir (16) is created in a first treatment area of the treatment chamber (6) by inclining the treatment chamber. The first area is also heated to a temperature below the boiling point of water, and a second area extending from th first treatment area to the top end of the treatment chamber (6) is at least partially heated to a temperature above the boiling point of water. This enables the contaminated material to be treated and compacted in a simpler, more reliable manner and in a (quasi-) continuous flow through several treatment areas.

Owner:LOGTECH PATENT

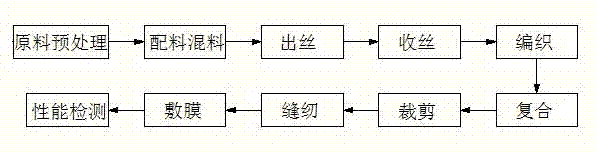

Method for manufacturing plastic package for hazardous chemical substance

InactiveCN102963596AImprove heat resistanceOvercome poor impactBagsSacksPre treatmentChemical substance

The invention discloses a method for manufacturing a plastic package for a hazardous chemical substance. The method is characterized by comprising the following steps: pretreatment of raw materials, dosing and mixing, wire unreeling, wire reeling, weaving, compounding, cutting, sewing, film covering and performance detection. By the method, waste plastic packages can be recycled to serve as raw materials, so as to obviously reduce energy consumption and shorten processing cycle. The physical performance of the plastic package manufactured by the method is over 30 percent better than that of the GB / TB947-1998 standard, so as to ensure the safety of the package of the hazardous chemical substance and meet the requirement of the plastic package of the hazardous chemical substance (comprising export).

Owner:DEYANG CITY QIMING PLASTIC PACKAGE

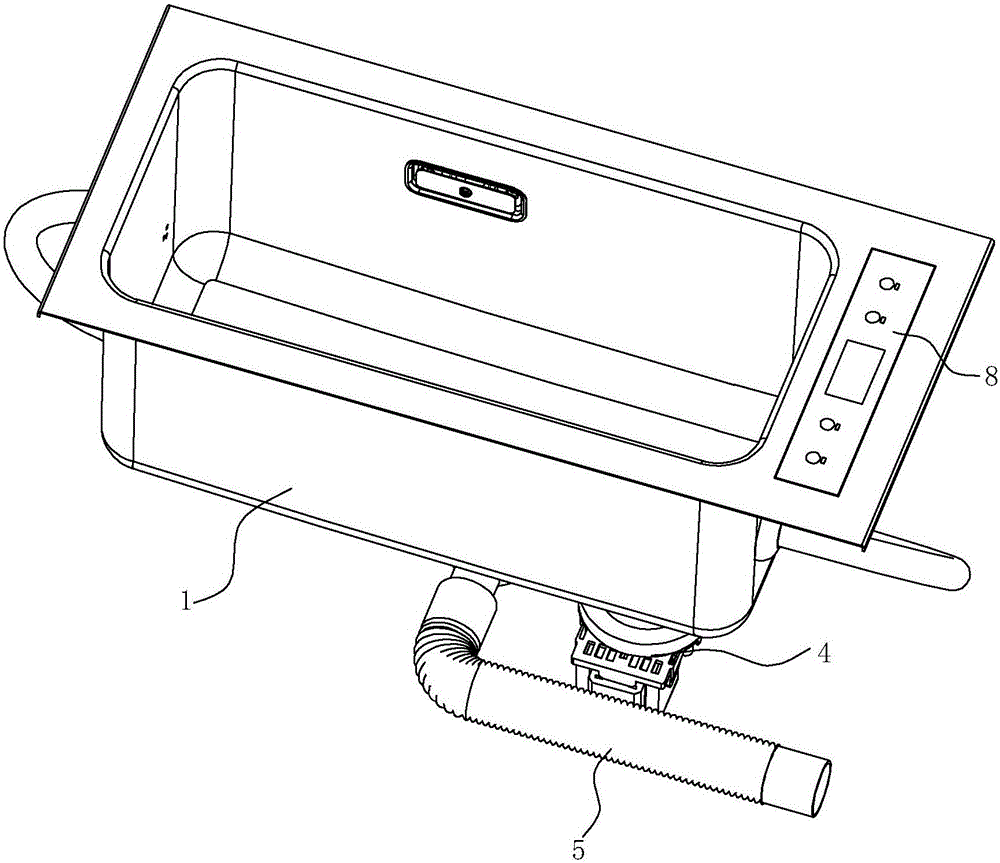

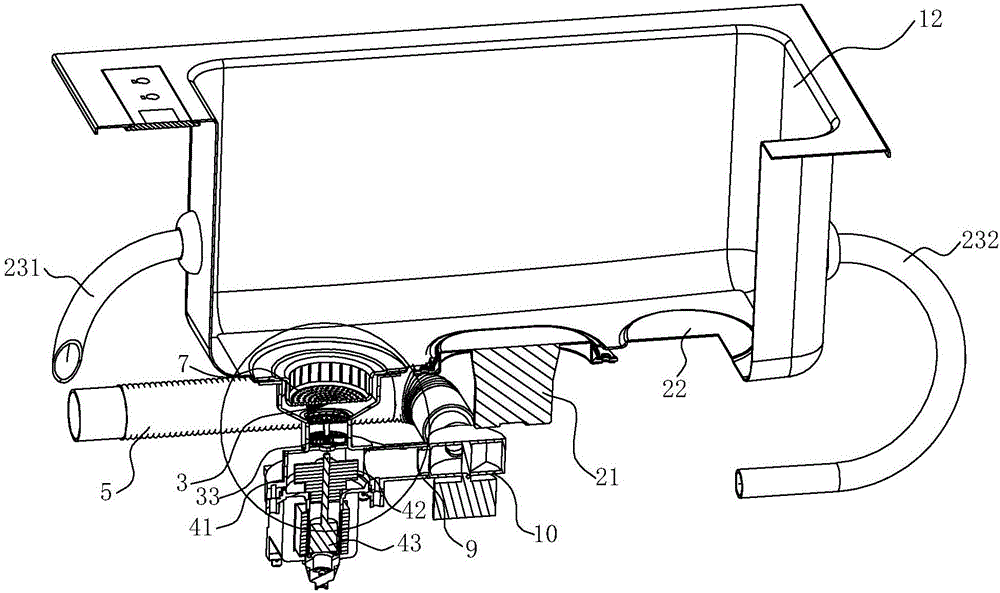

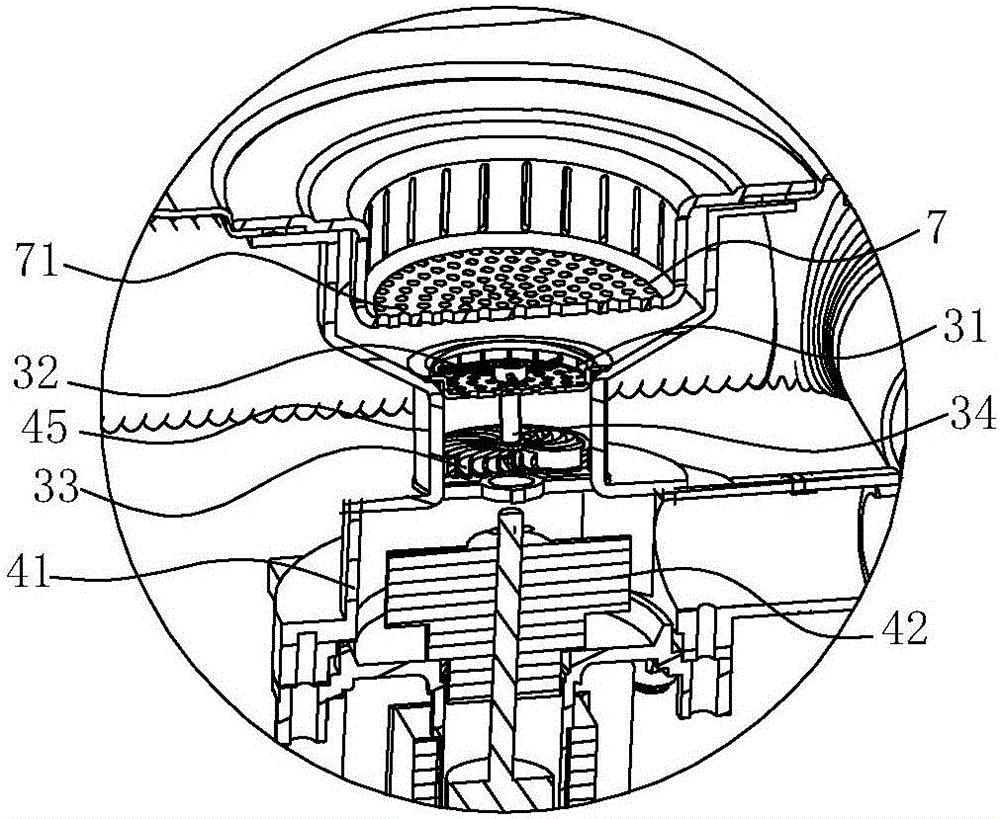

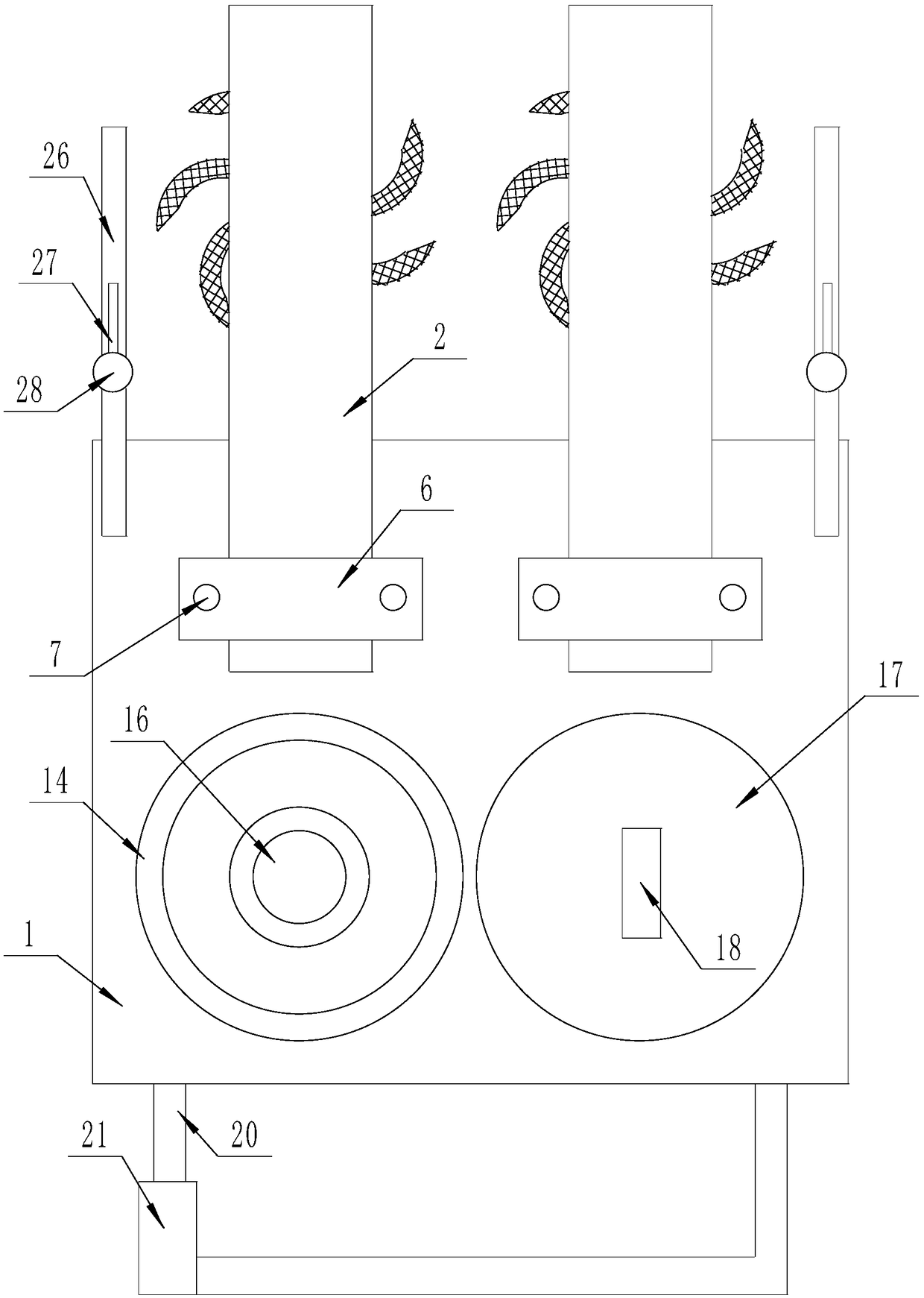

Slag removal mechanism for water tank

ActiveCN106725178AAvoid cloggingImprove mincing effectTableware washing/rinsing machine detailsKitchen equipmentImpellerSlag

The invention discloses a slag removal mechanism for a water tank. The slag removal mechanism for the water tank comprises a draining pump and a slag grinding mechanism, the draining pump comprises a pump case, the slag removal mechanism is characterized in that a pump neck is formed on the pump case, the inner diameter of the pump neck is smaller than the upper side and the lower side, and the slag grinding mechanism is arranged in the pump neck. The slag grinding mechanism is arranged in the pump neck of the pump case, a powerful water flow is formed due to the sudden change of the diameter of the pump neck, then a first hydrodynamic impeller is driven to rotate rapidly, a better slag grinding effect is achieved, and the blockage of a pipeline is avoided; two layers of slag baskets are arranged, meshes of the lower layer are much finer to guarantee smooth drainage, the residue slag entering a circulated pipeline structure or a drainage pipe is reduced to further avoid blockage of the pipeline; two sets of slag grinding knifes and a hydrodynamic impeller structure are arranged, so that the two slag grinding knifes form a shearing force to better cut the residue slag into pieces.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

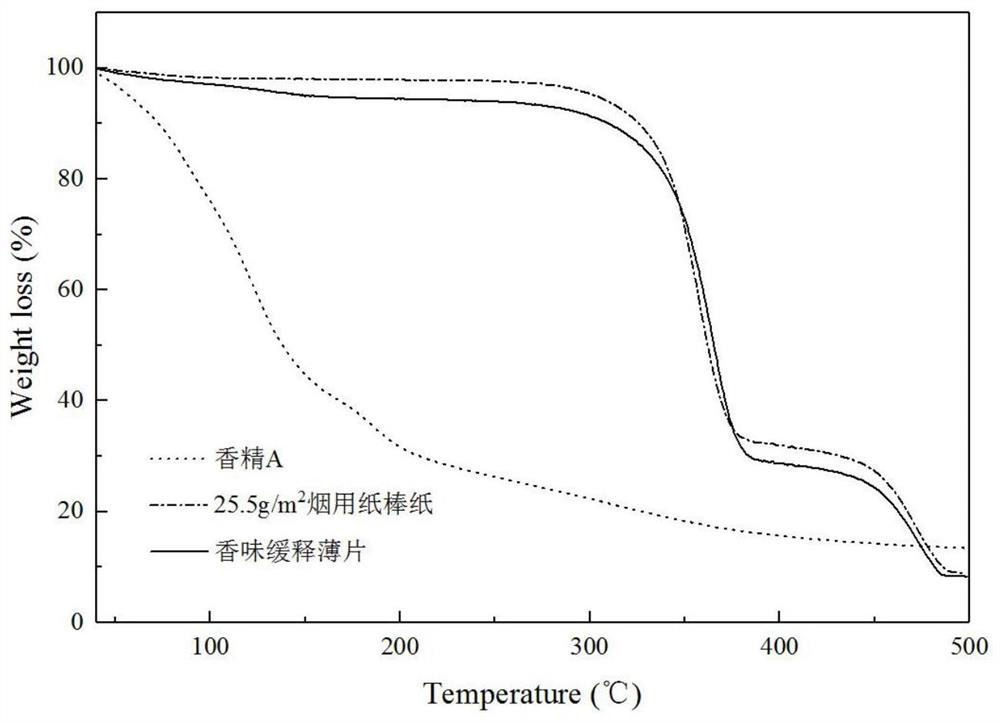

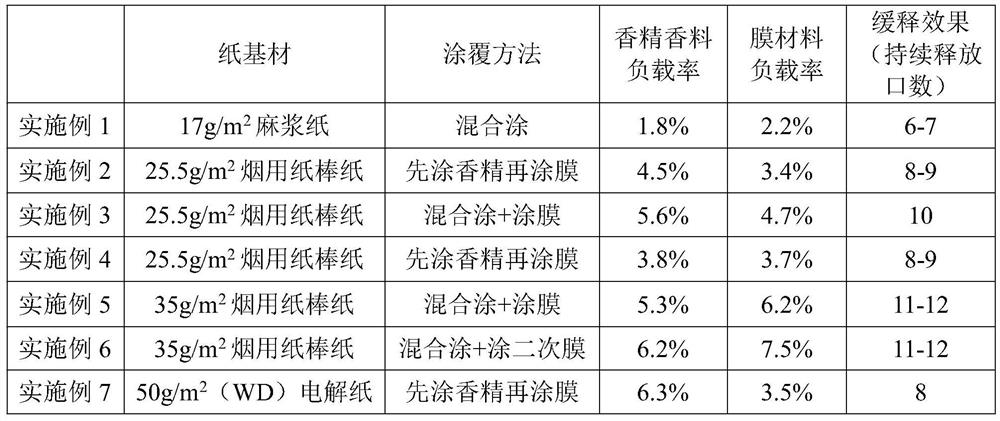

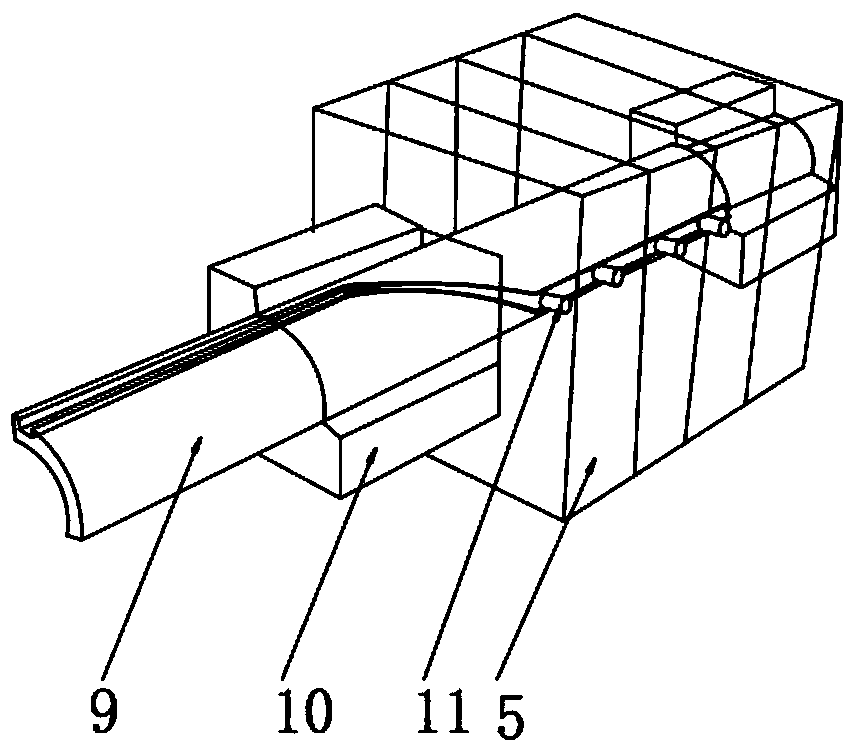

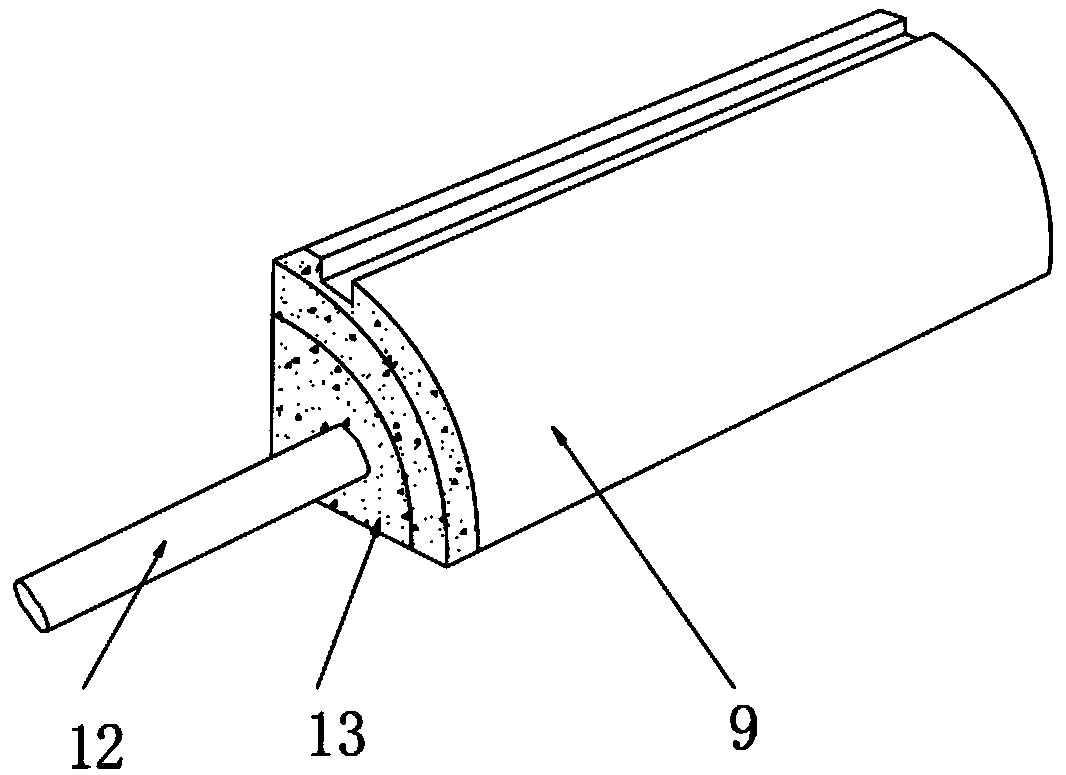

Fragrance slow-release material, heating rod, cigarette holder rod, preparation method thereof and application thereof in heat-not-burn tobacco products

ActiveCN111802702APrevent volatilizationImprove release uniformityTobacco smoke filtersTobacco devicesPolymer sciencePaper based

The invention belongs to the technical field of heat-not-burn tobacco products, and particularly discloses a fragrance slow-release material which comprises a paper base material and a polymer layer compounded on the surface of the paper base material, and the paper base material and / or the polymer layer contain / contains flavors and fragrances. The invention also provides a preparation method andapplication of the fragrance sustained-release material, and also comprises a heating rod and a cigarette holder rod compounded with the fragrance sustained-release material, and a heat-not-burn tobacco product. The invention innovatively discovers that a high-adsorbability paper base material is used as a framework material, the surface of the framework material is coated with a polymer, and flavors and fragrances are distributed in the paper base material and / or the polymer, so that the fragrance sustained-release material is obtained. The paper base material is innovatively used as a bearing material, and the adsorption and encapsulation effects of the paper base material and the polymer on the flavors and fragrances are further utilized, so that the immobilization and slow release of the flavors and fragrances can be effectively realized.

Owner:CHINA TOBACCO HUNAN INDAL CORP

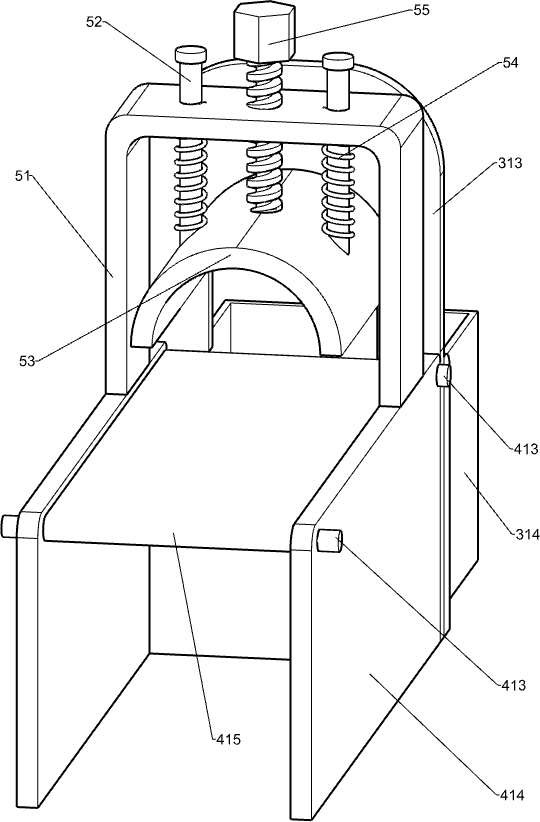

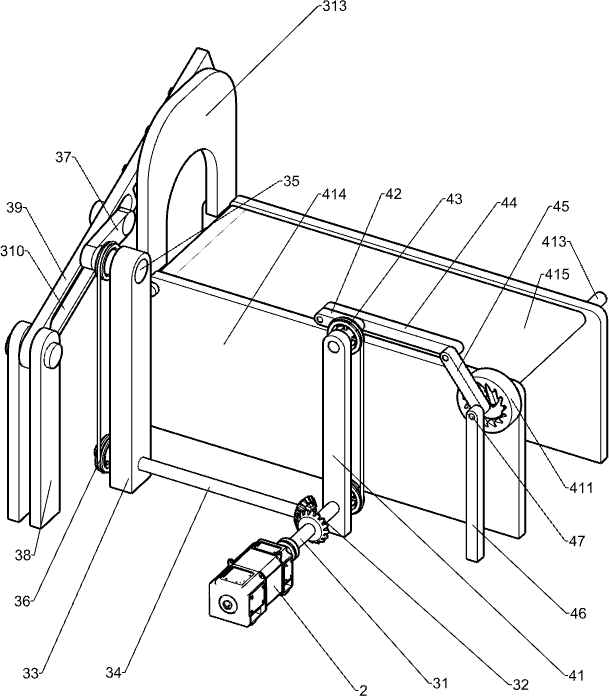

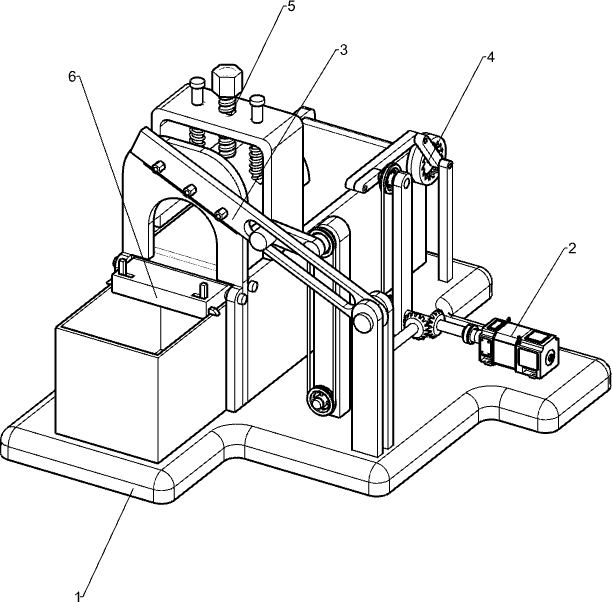

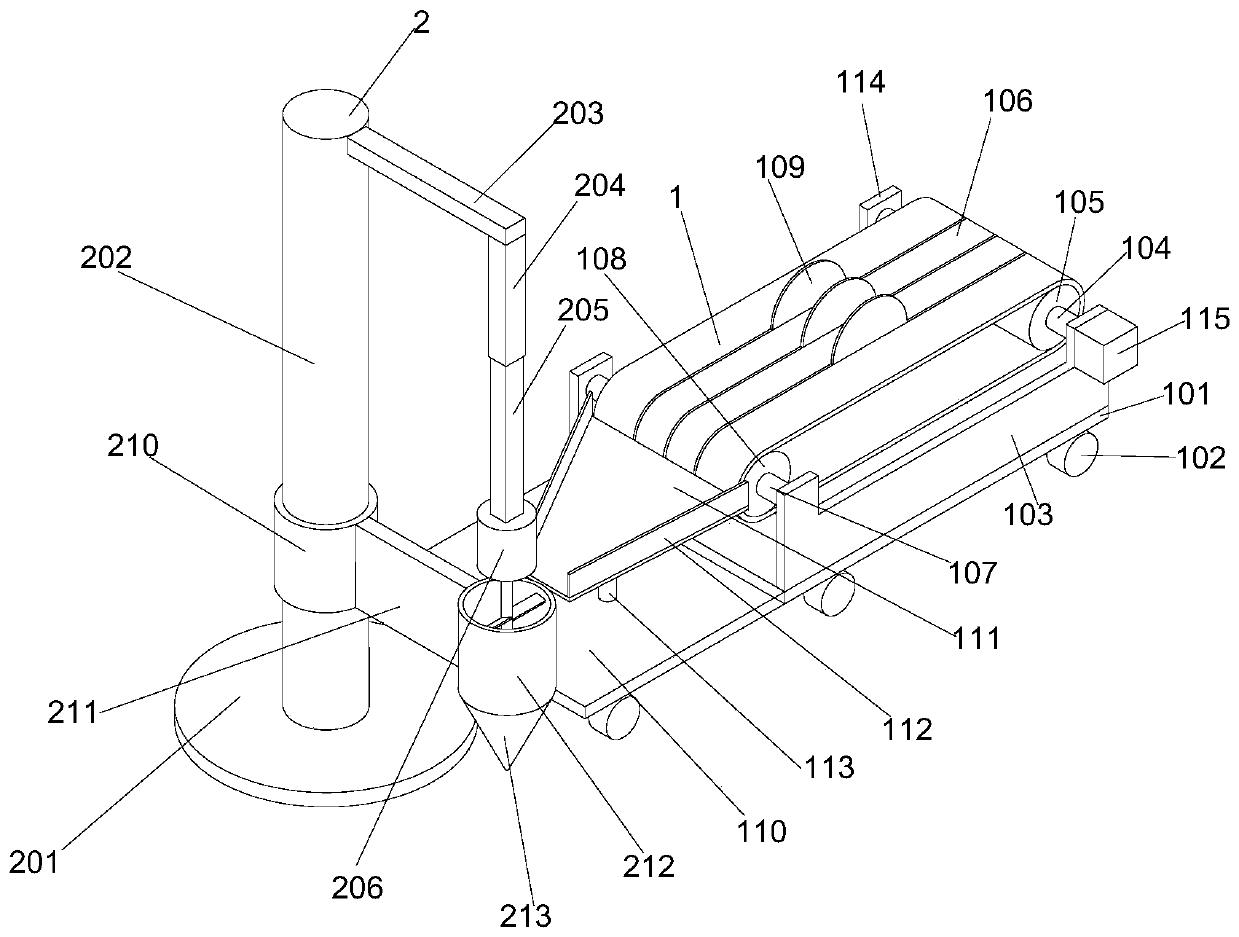

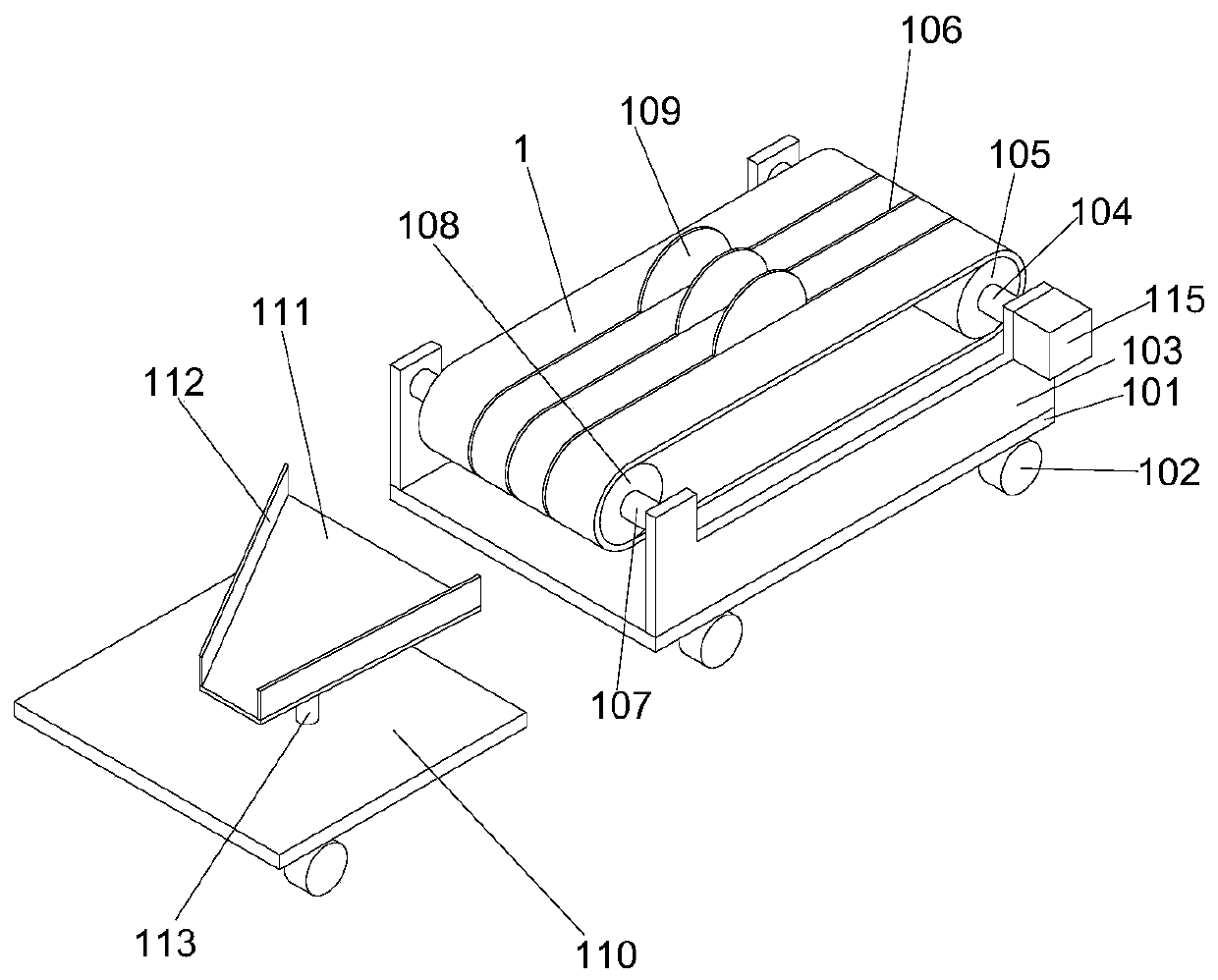

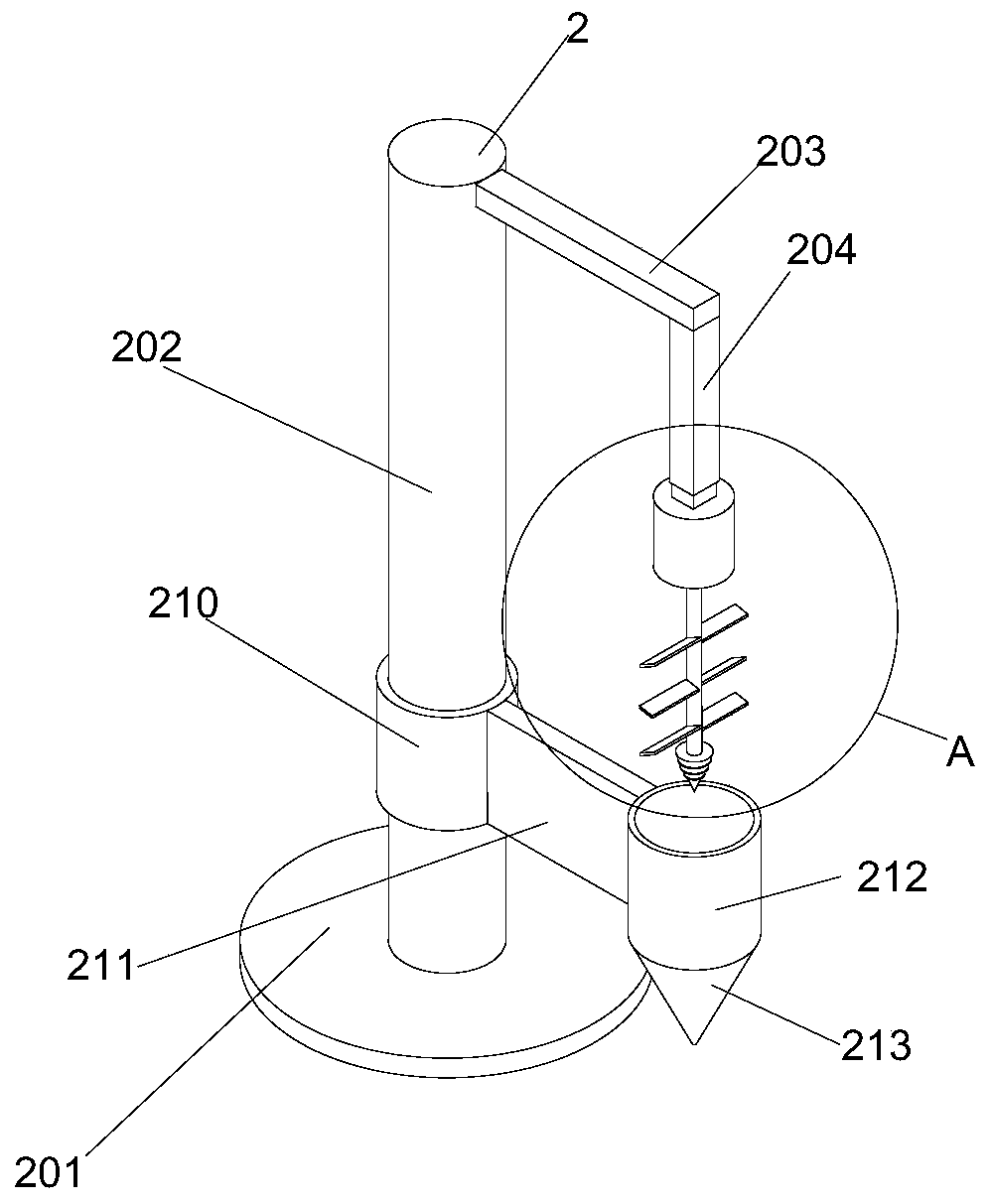

Tobacco cutter

ActiveCN111642784ARealize automatic cuttingReduce manual operationsTobacco treatmentAgricultural engineeringStructural engineering

The invention relates to a tobacco cutter, in particular to a tobacco cutter. According to the technical purpose, the tobacco cutter can automatically cut tobacco leaves, the tobacco leaves can automatically move to the position below a cutting knife, and tobacco shreds can be conveniently and manually collected. According to the technical scheme, the tobacco cutter comprises: a base, wherein a motor is arranged on the side portion of the base, and a cutting mechanism is installed on the front side of the base and connected with the motor; and an automatic material conveying mechanism which isarranged on the left side of the base. According to the invention, the cutter is used, automatic cutting of the tobacco leaves is realized; tobacco leaves do not need to be cut manually through a cutting knife, meanwhile, cut tobacco shreds are collected through a collecting box, intermittent movement of the tobacco leaves is achieved through an automatic material conveying mechanism, the tobaccoleaves automatically move to the position below the cutting knife, the cutting knife can cut the tobacco leaves conveniently, rolled tobacco leaves are clamped through a clamping mechanism, and the rolled tobacco leaves are prevented from being scattered in the cutting process.

Owner:肖锋

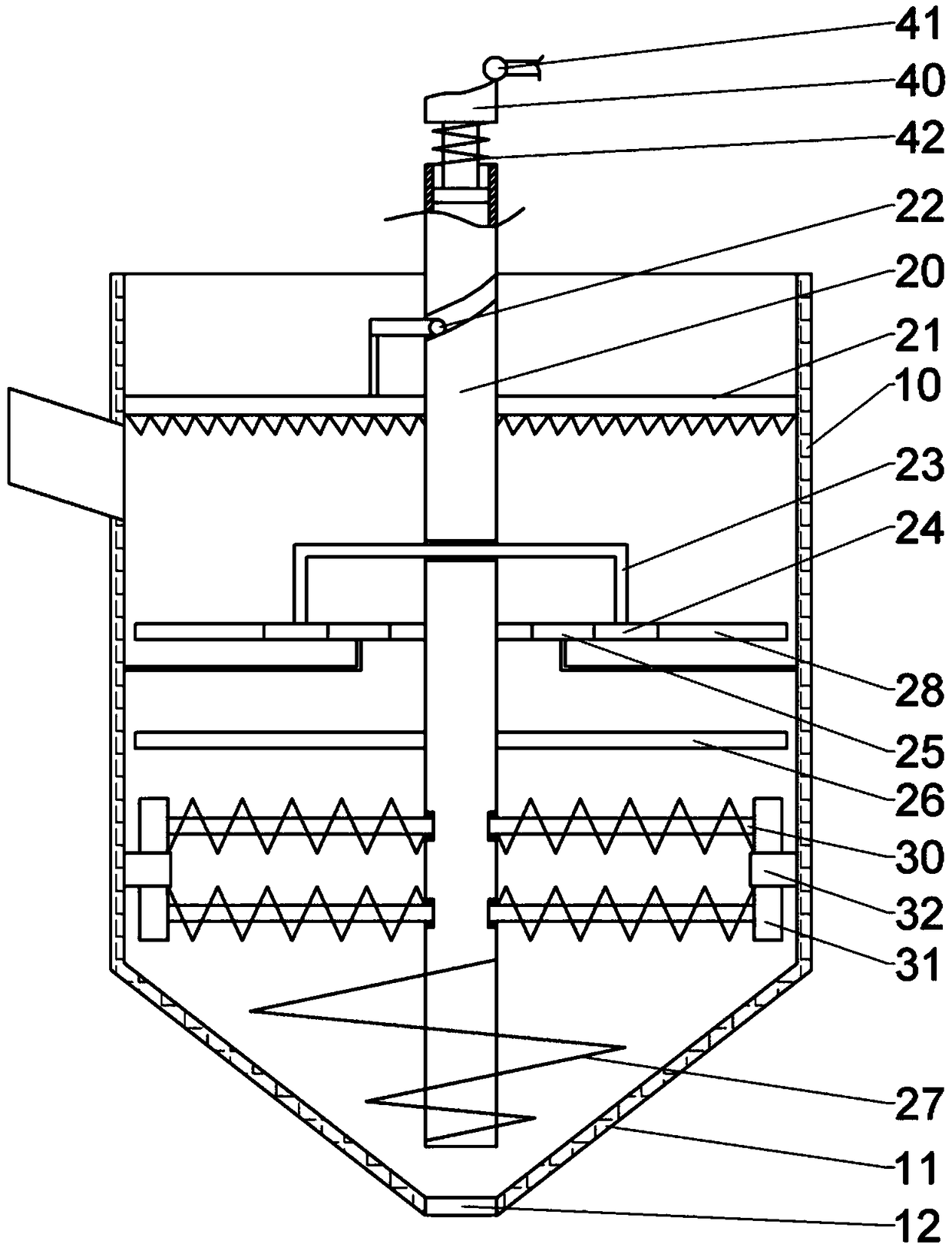

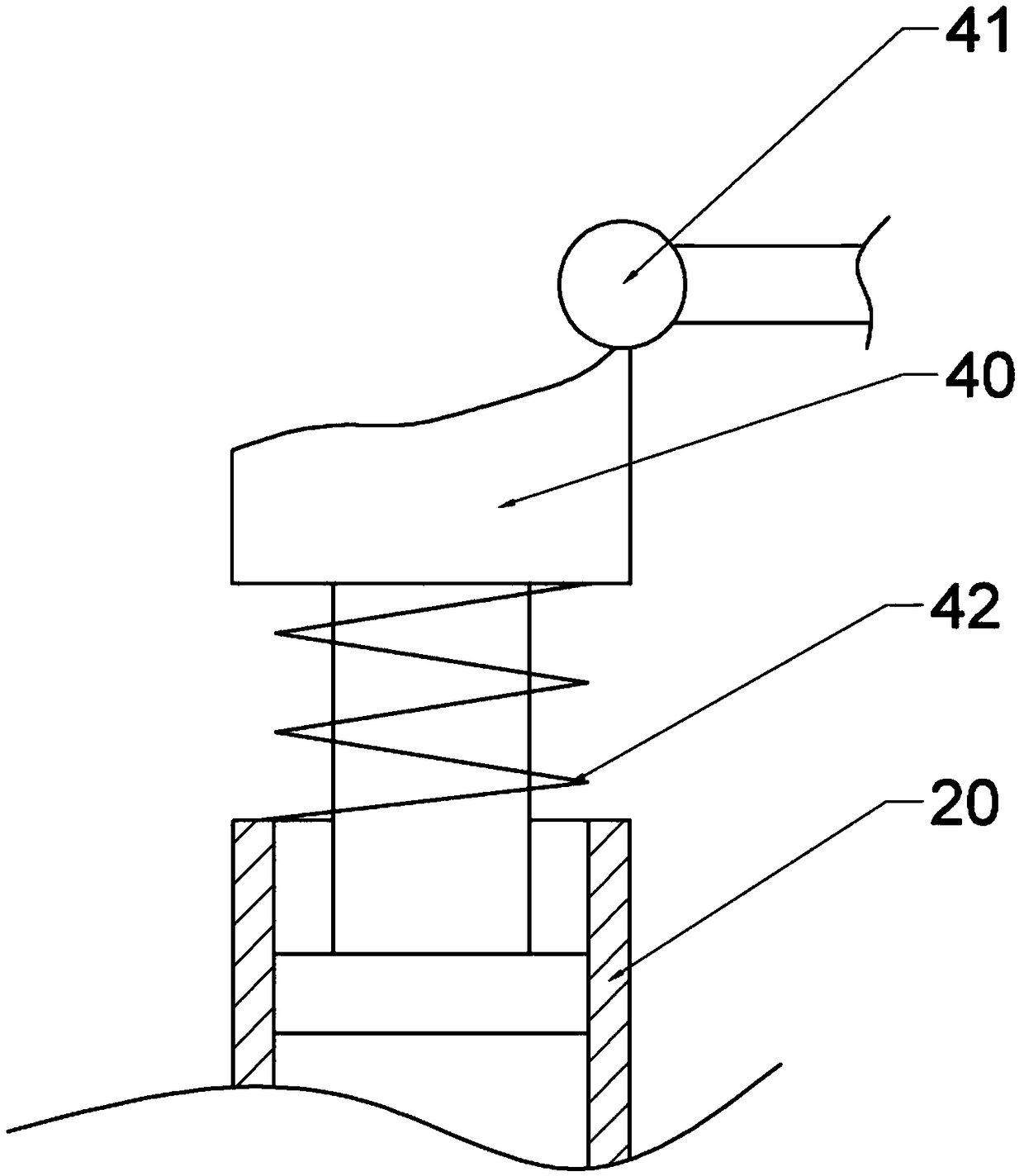

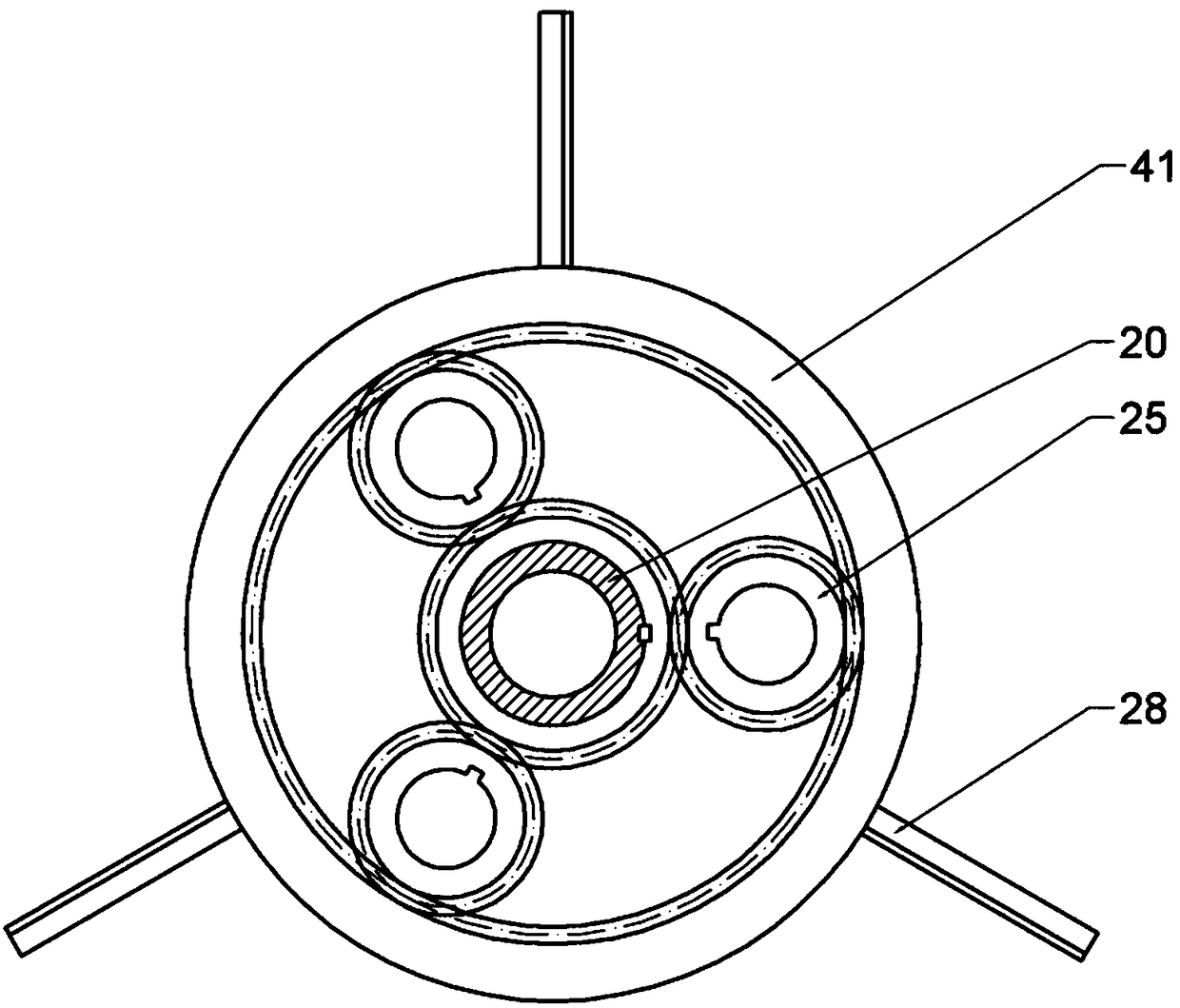

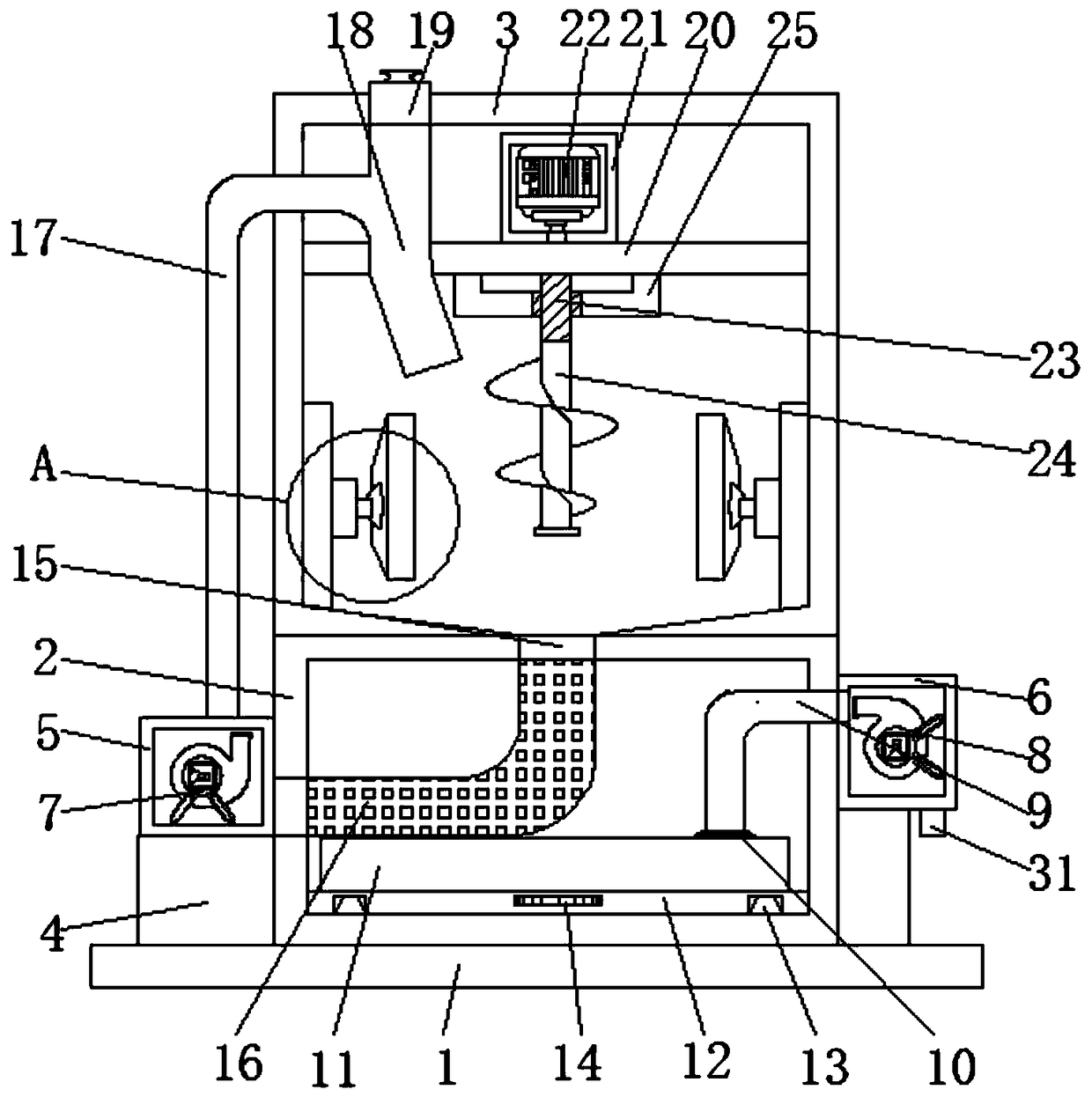

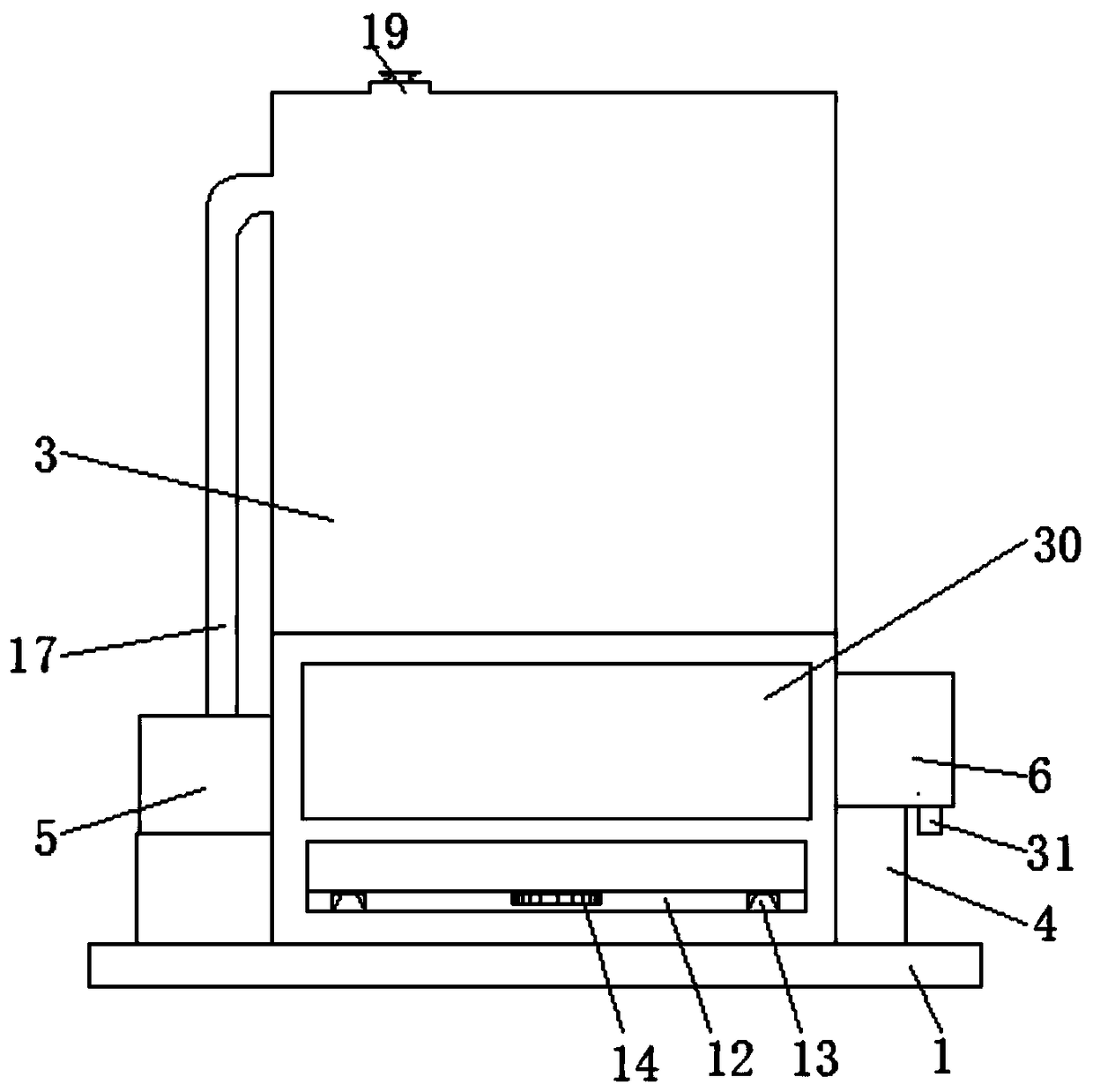

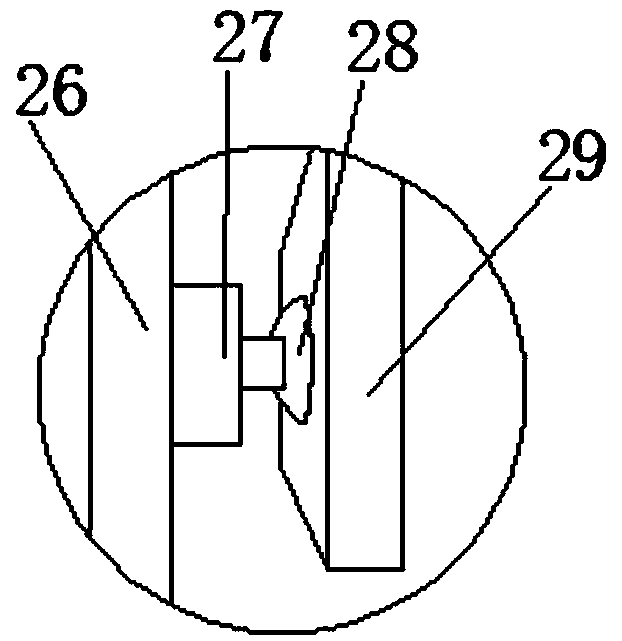

Plastic foam processing device

ActiveCN108890924AIntensified crushIntensify stirring intensityPlastic recyclingMechanical material recoveryEngineeringMechanical engineering

The invention discloses a plastic foam processing device. The device comprises a rack, a main shaft which is arranged on the rack in a rotating manner, a motor which is used for driving the main shaftto rotate and a crushing bin which is fixed on the rack, wherein the main shaft is hollow, and has a closed bottom; and an air-blowing mechanism, a crushing mechanism, a shearing mechanism and a smashing mechanism are sequentially arranged on the main shaft from top to bottom. The plastic foam processing device can be used for improving the plastic foam crushing effect by utilizing mechanical means.

Owner:遵义锦鸿富科技发展有限公司

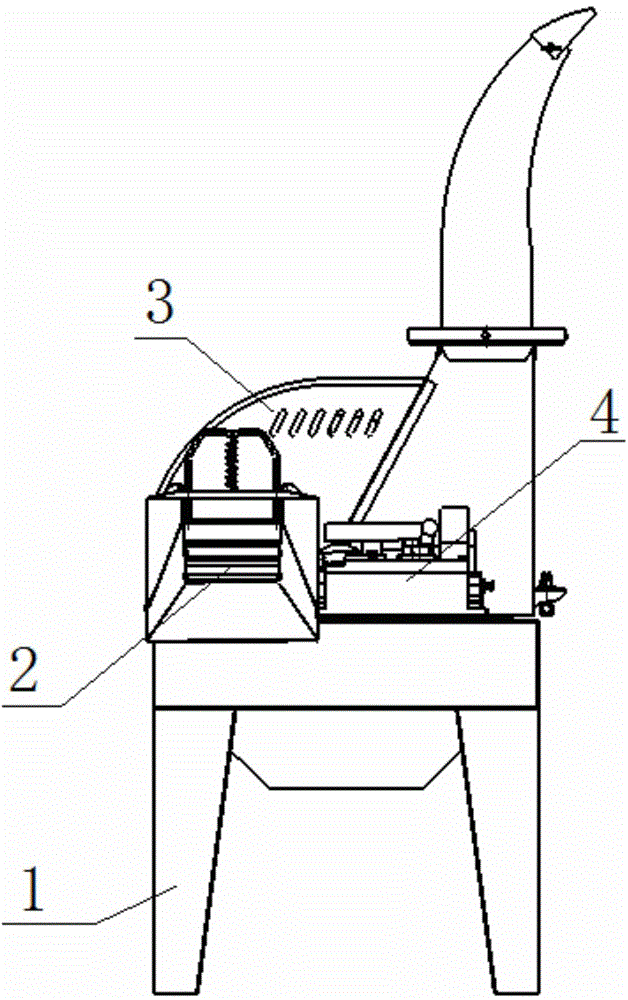

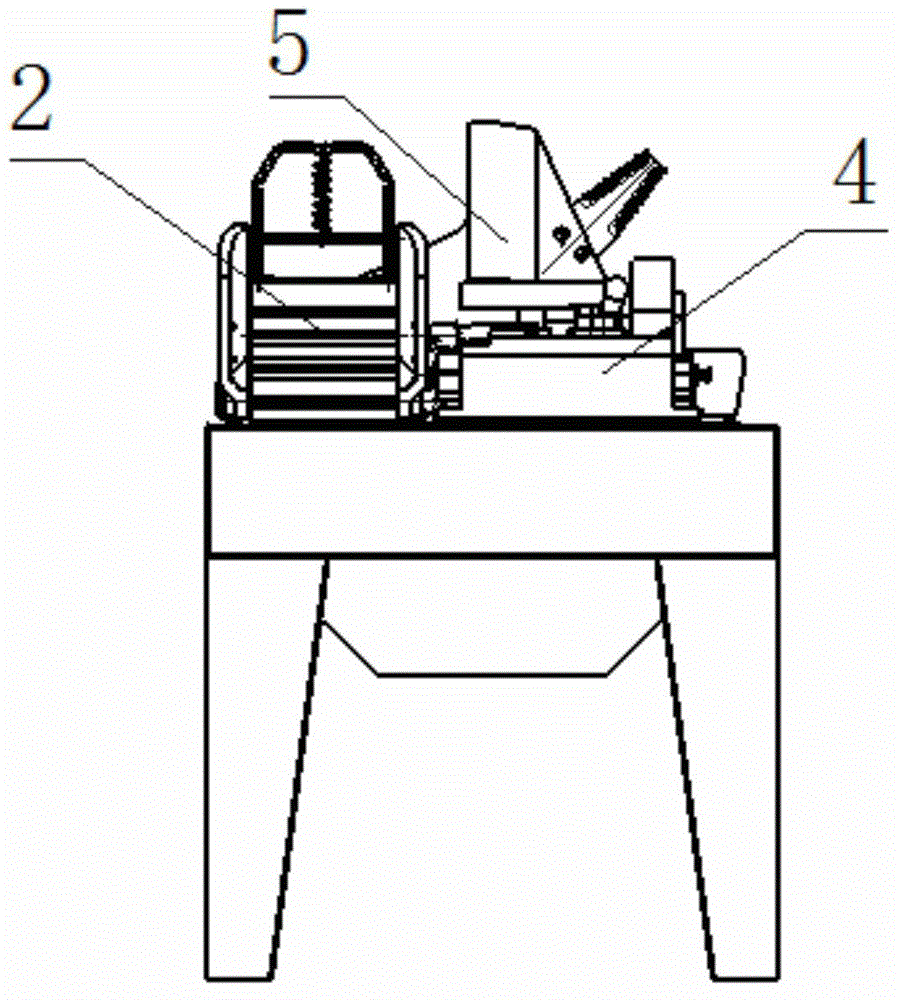

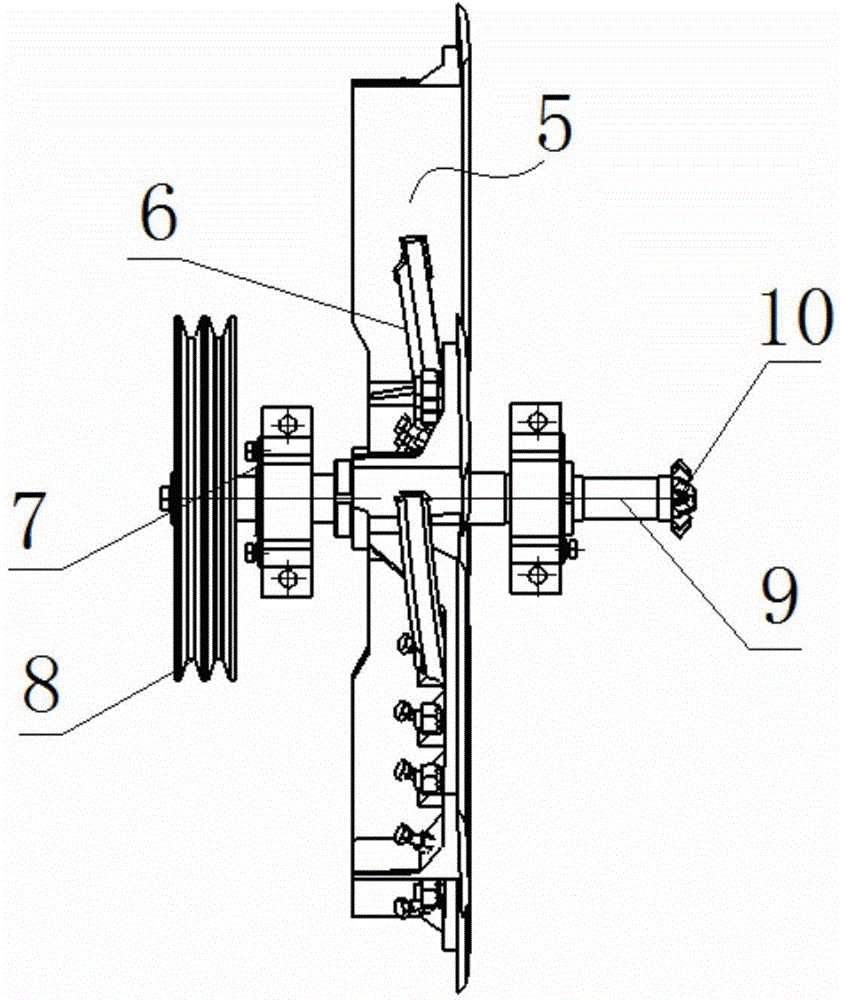

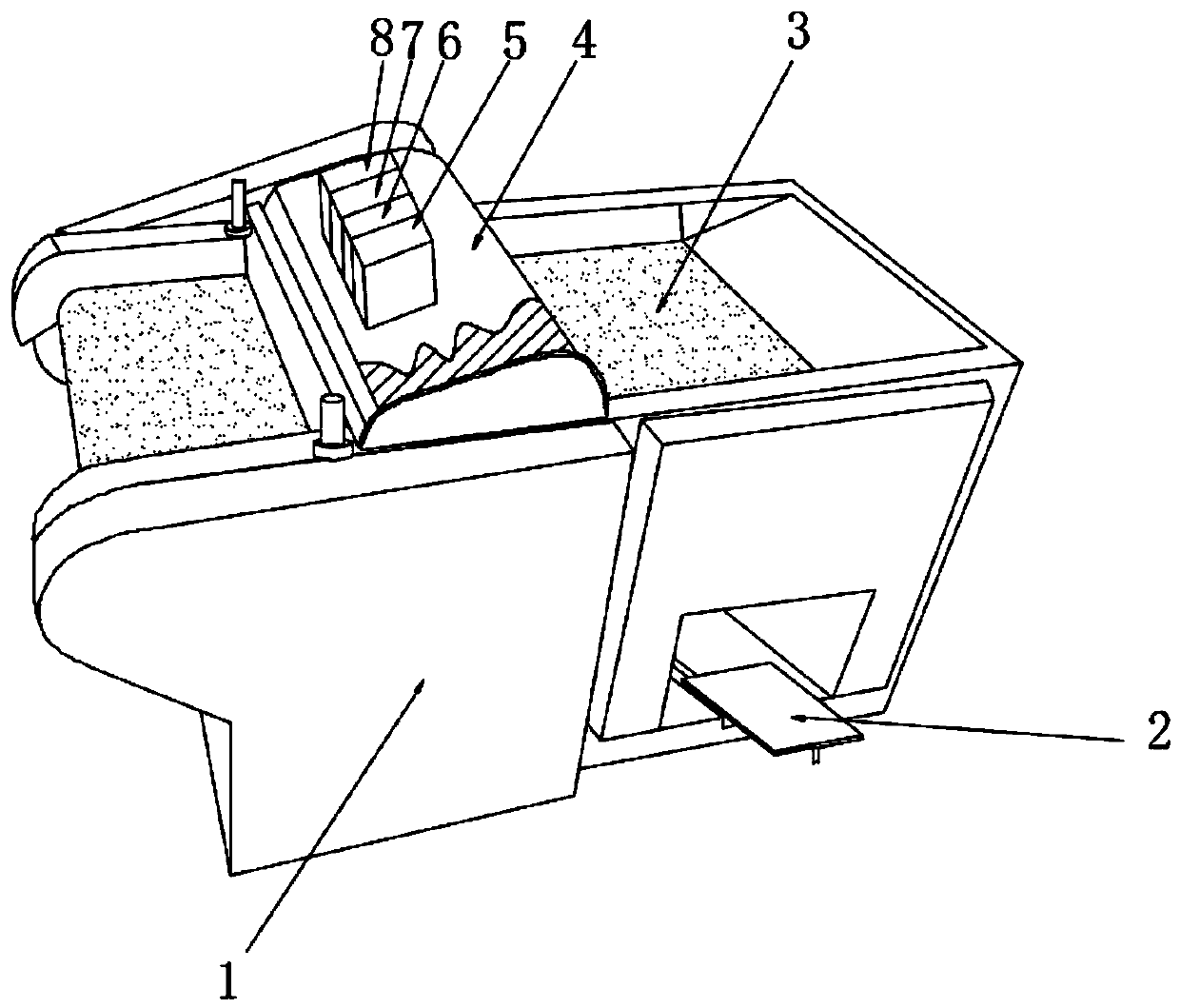

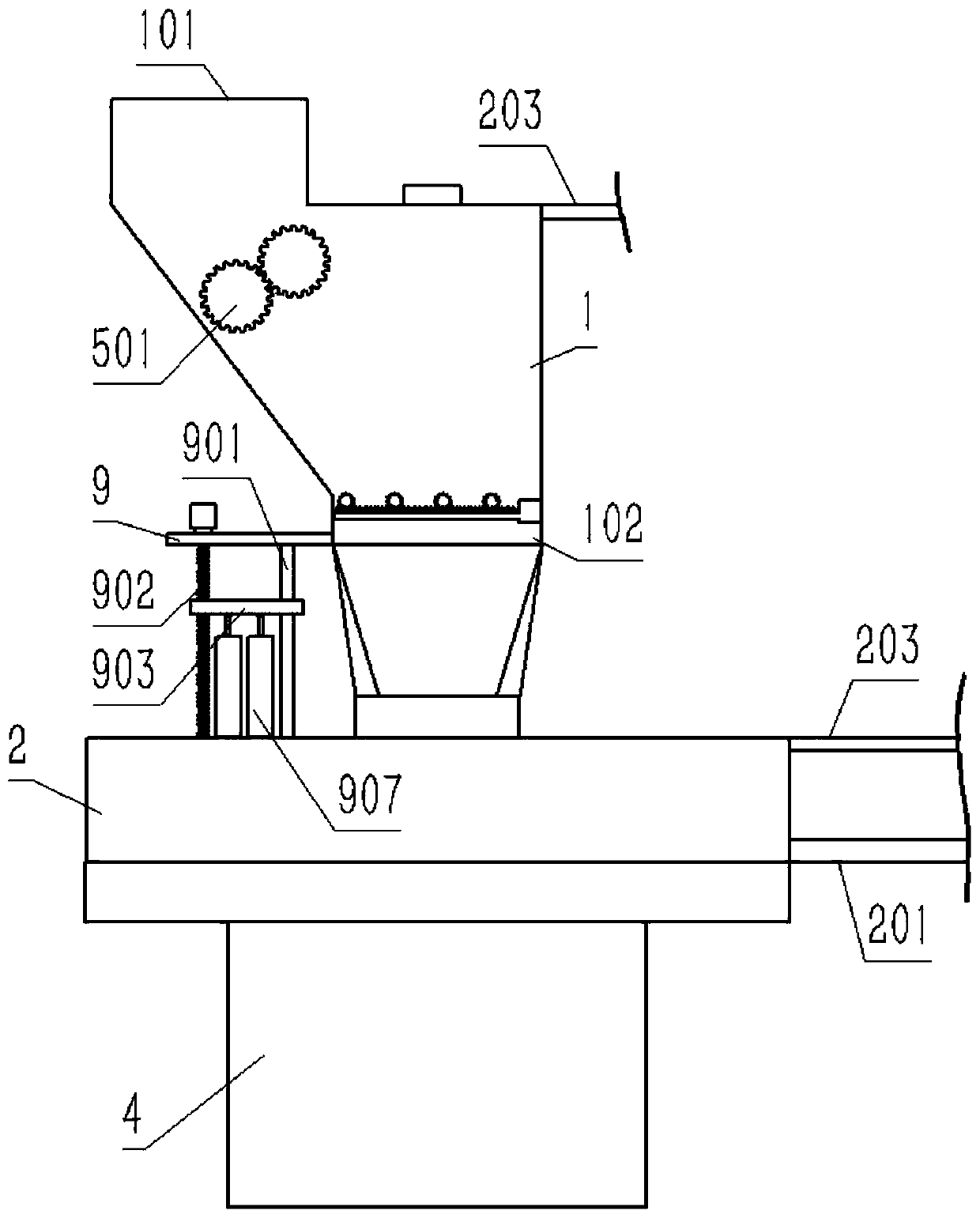

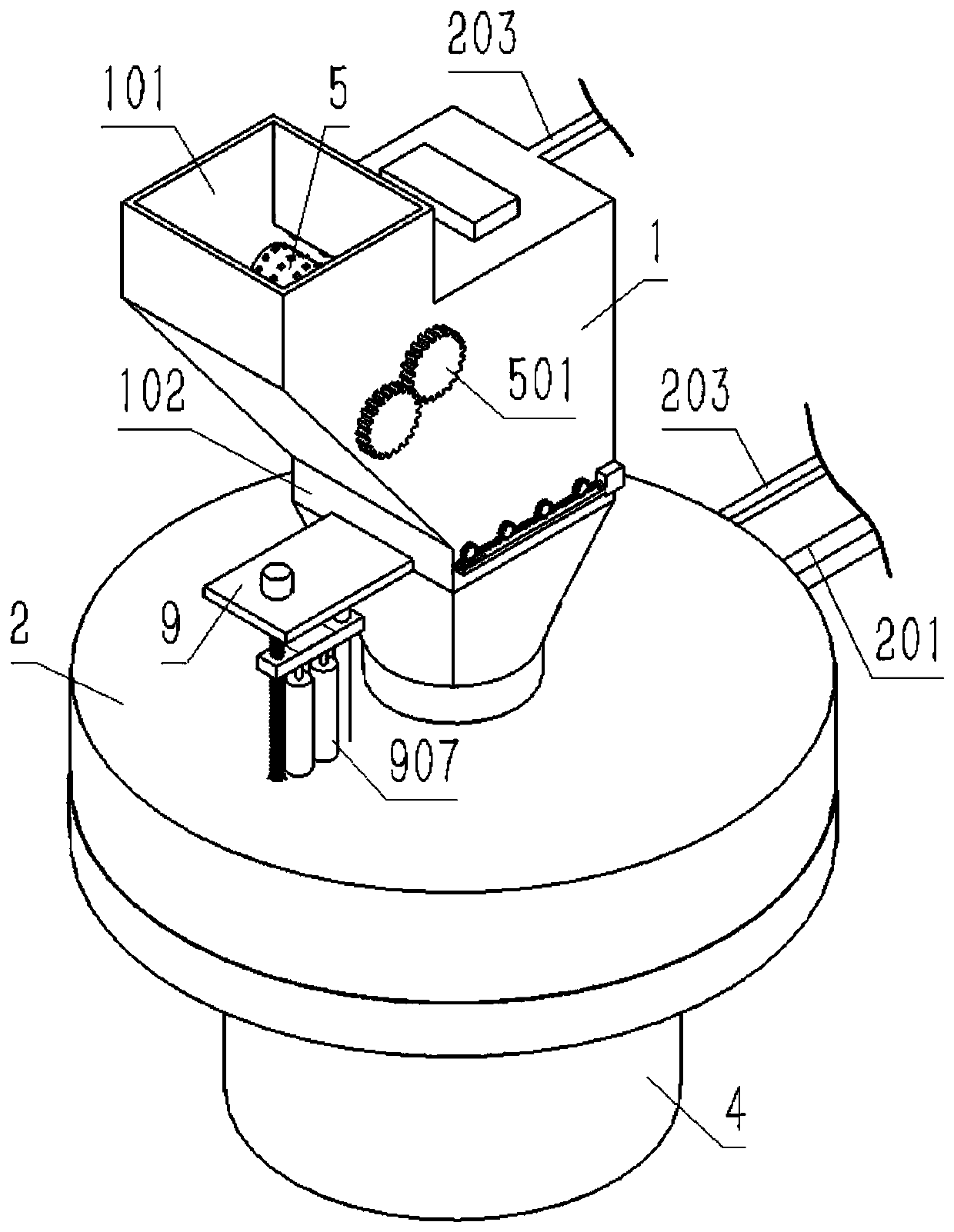

Hay cutting crusher

InactiveCN106031341AHigh processing precisionImprove processing efficiencyCuttersAnimal ForagingEngineering

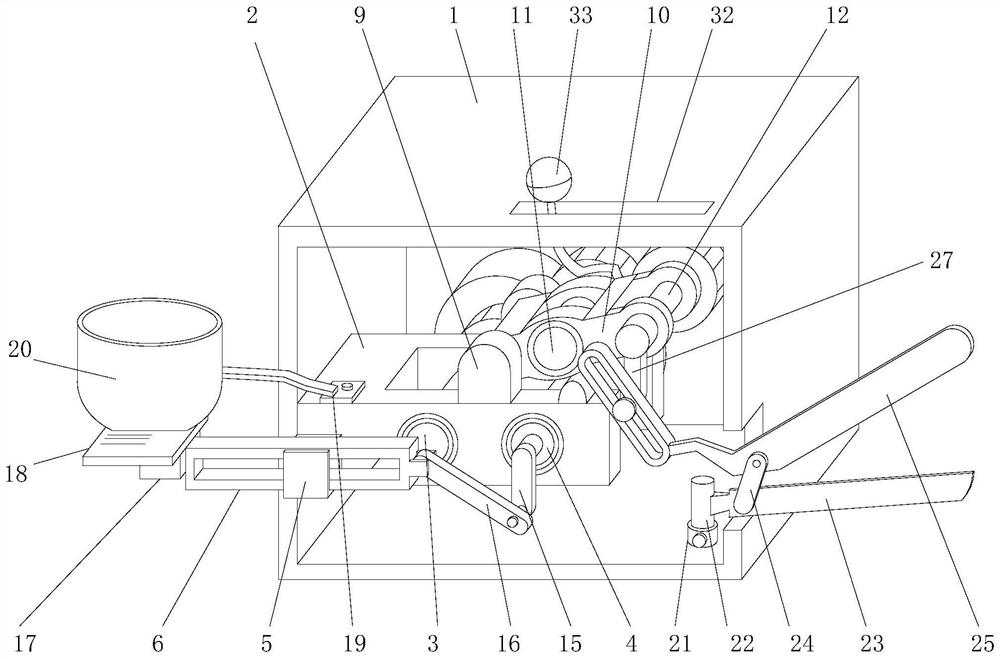

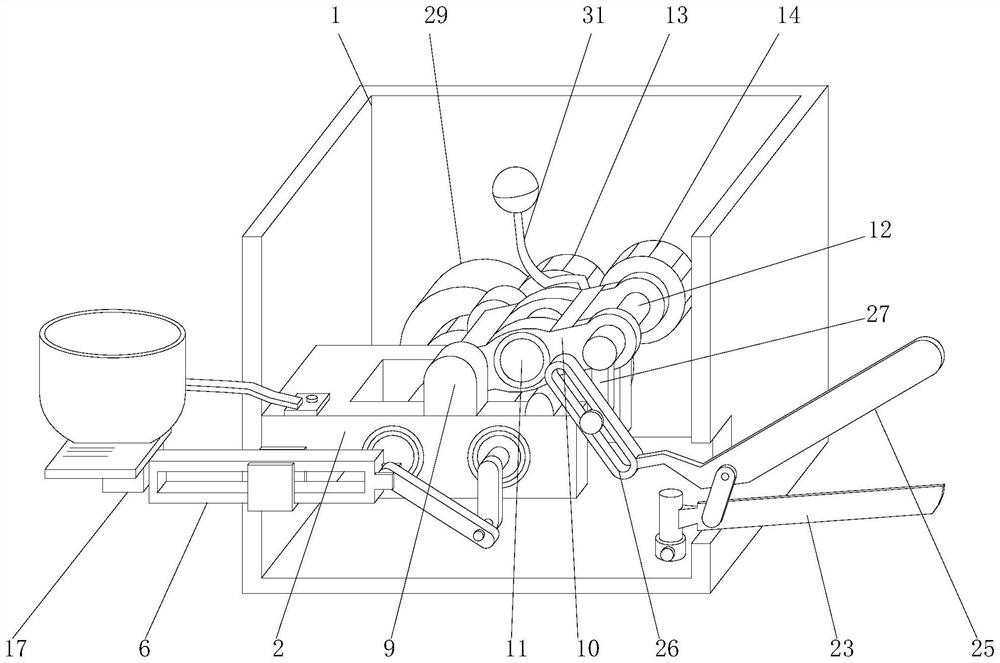

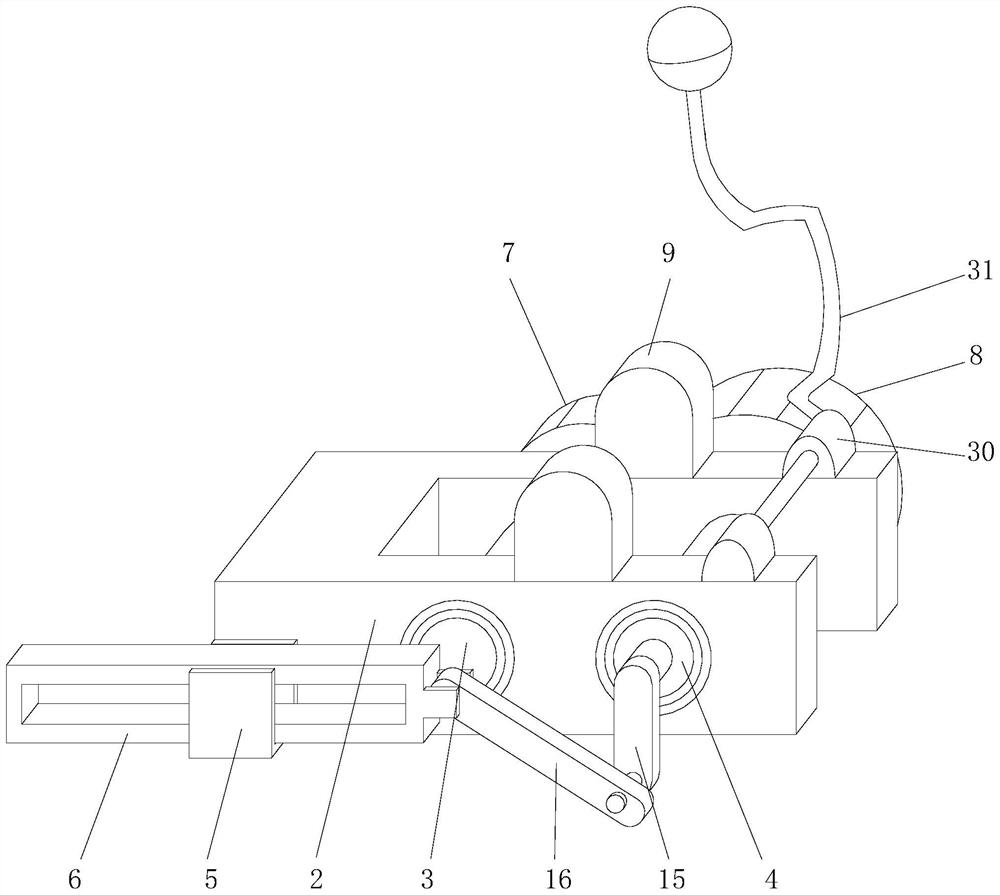

The invention relates to an agricultural machine, and specifically relates to a hay cutting crusher in which a cut-off tool and a crushing knife are used to operate in a combined manner. The hay cutting crusher comprises a base, a feeding mechanism, an upper cover, a speed change mechanism, and a main shaft assembly. The base is provided with a power source driving the main shaft assembly to rotate. The main shaft assembly is provided with a cutter assembly with a fan blade plate. The main shaft assembly is connected with the feeding mechanism through the speed change mechanism. The cutter assembly comprises a cutter, a cut-off tool layer, and a crushing knife layer. The cut-off tool layer formed by a plurality of cut-off tools is arranged on one side of the cutter, close to the feeding mechanism. The crushing knife layer formed by a plurality of crushing knifes is arranged on one side of the cutter, far away from the feeding mechanism. The speed change mechanism comprises a cabinet, a gear shifting transmission mechanism, and a handle assembly. The gear shifting transmission mechanism is arranged in the cabinet and adjusts gears through the handle assembly which is arranged on the upper side of the cabinet. The hay cutting crusher greatly improves forage processing fineness and forage processing efficiency, and realizes diversification of forage processing.

Owner:范嘉丽

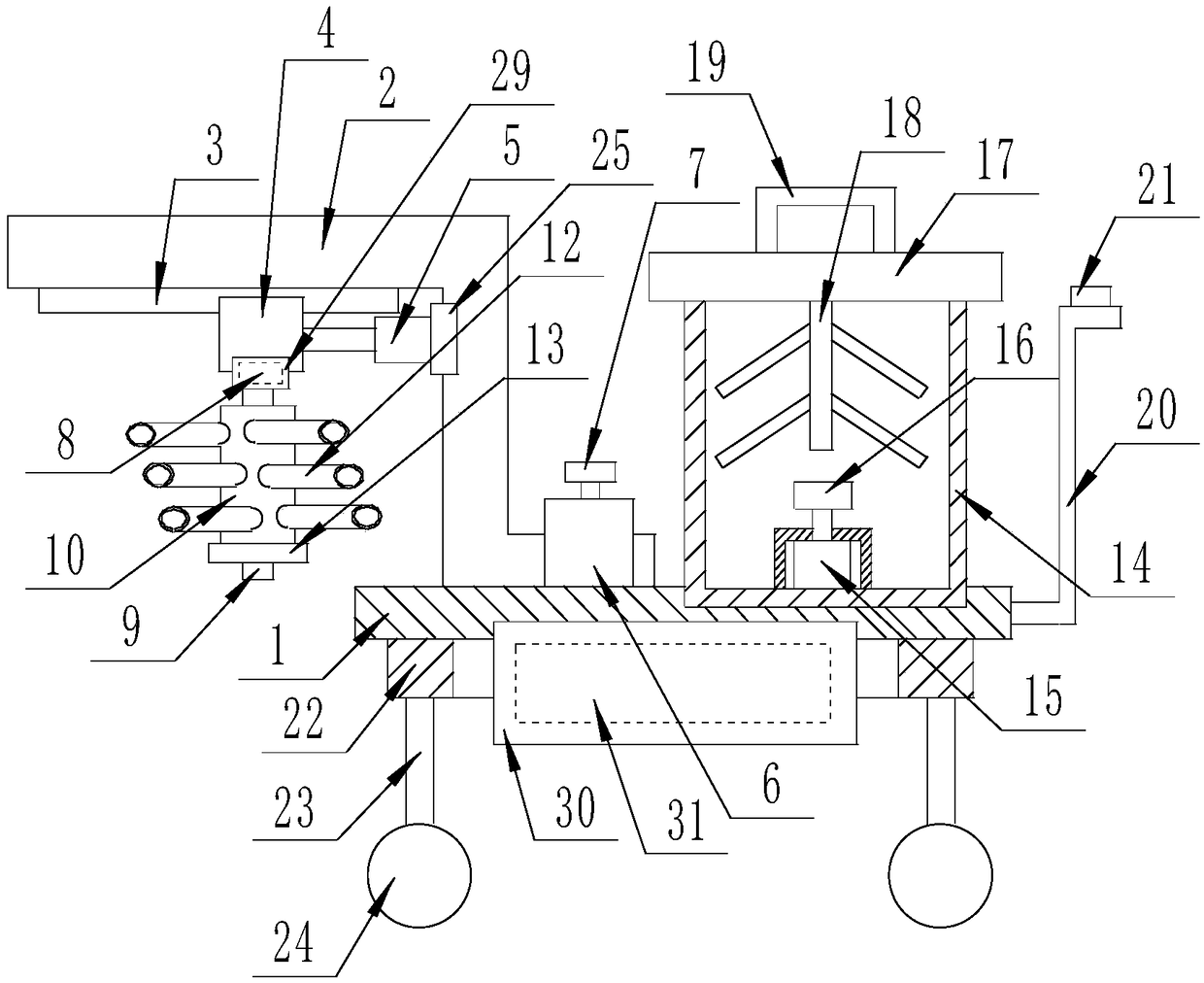

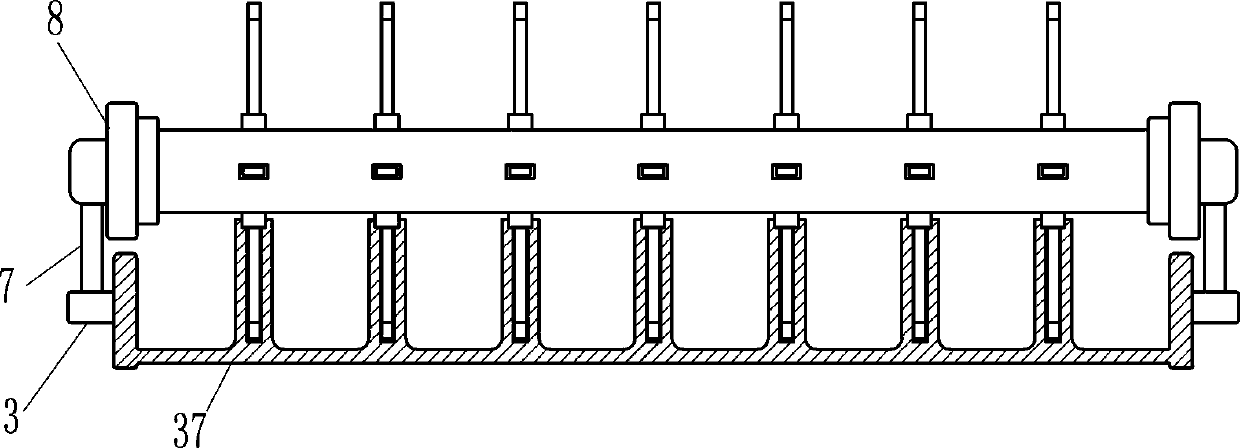

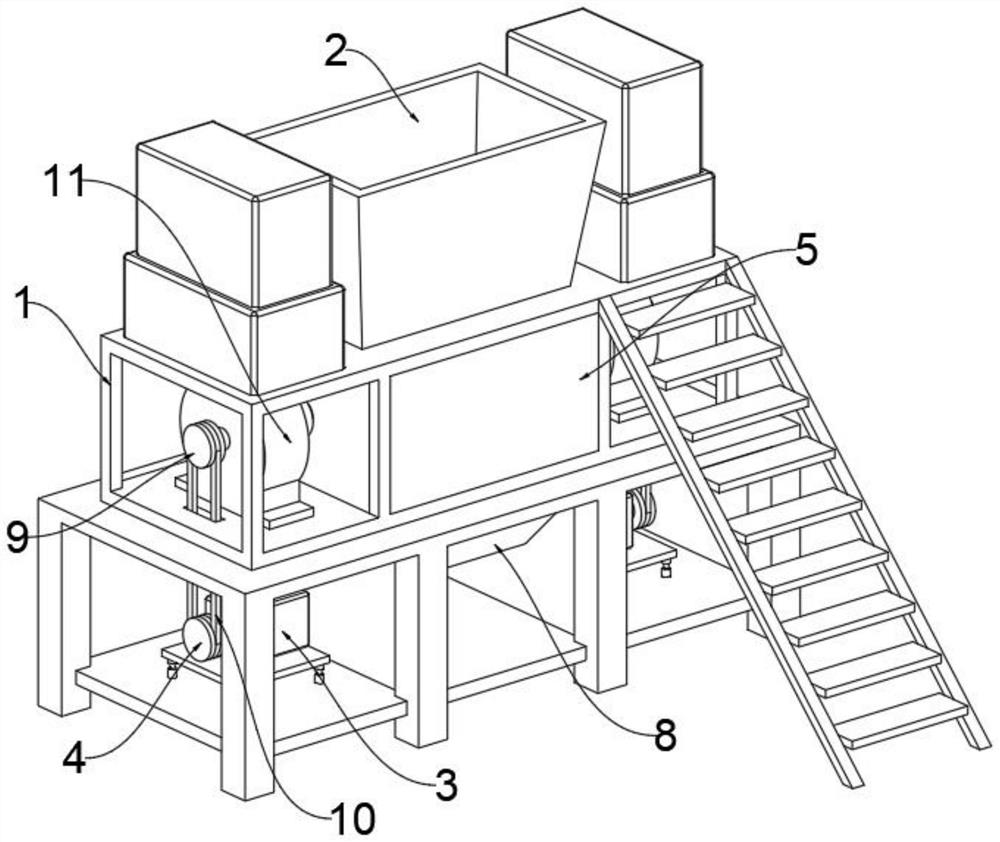

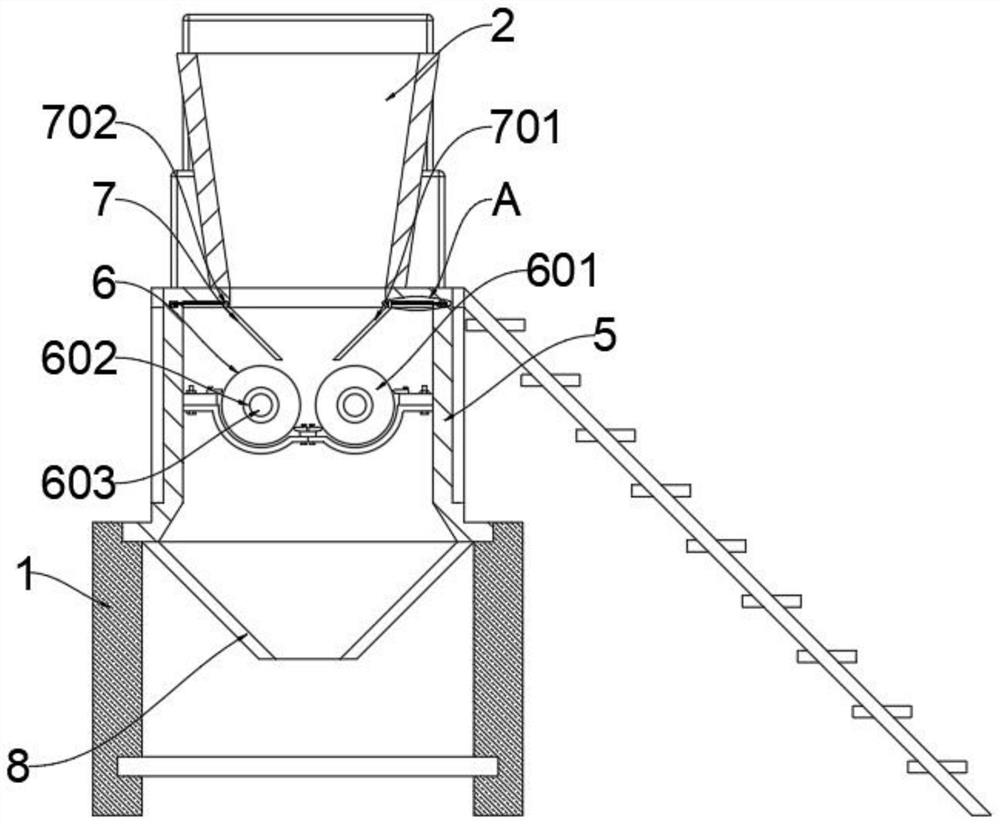

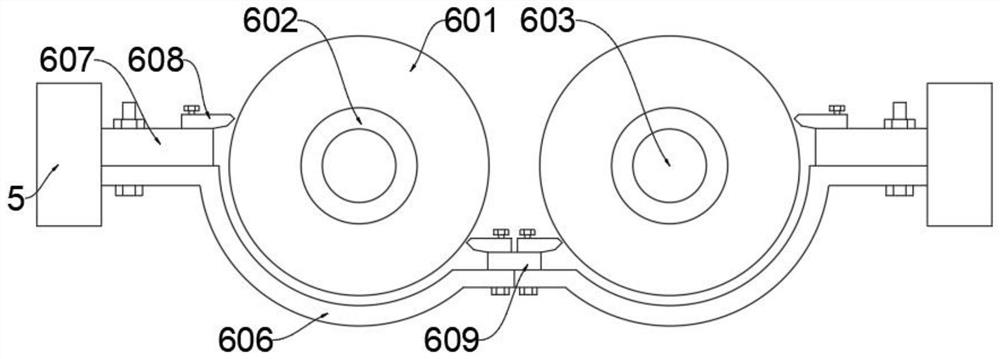

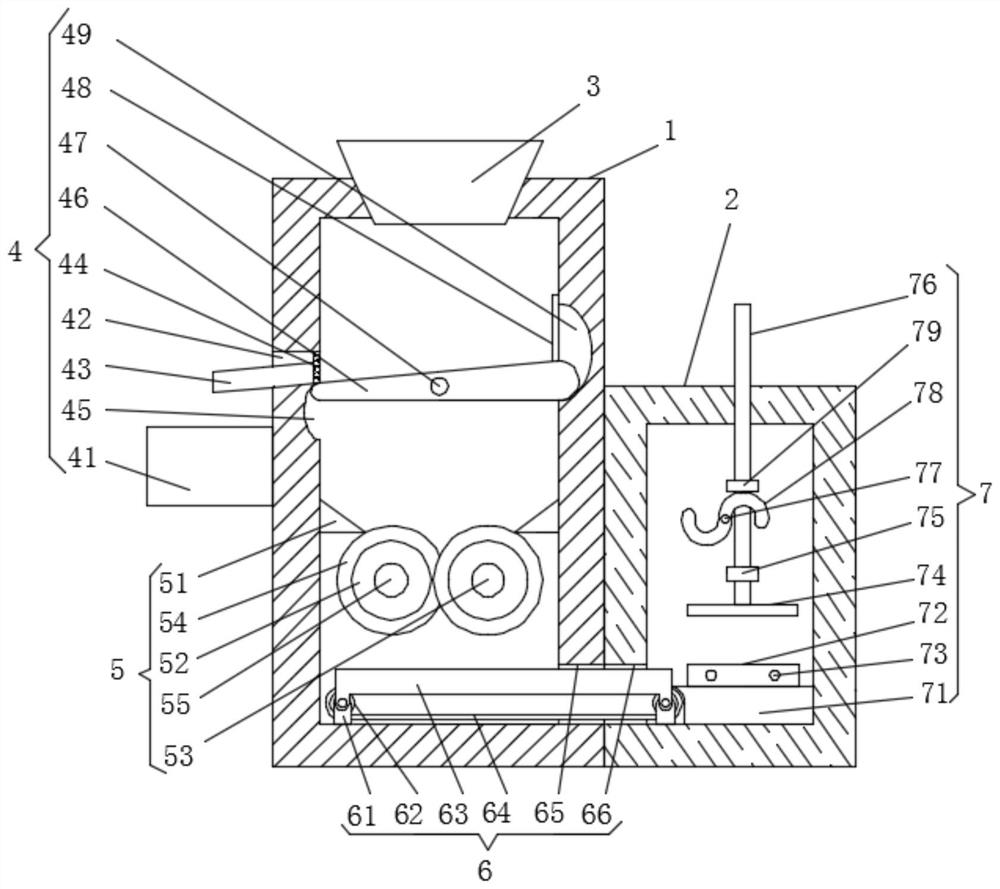

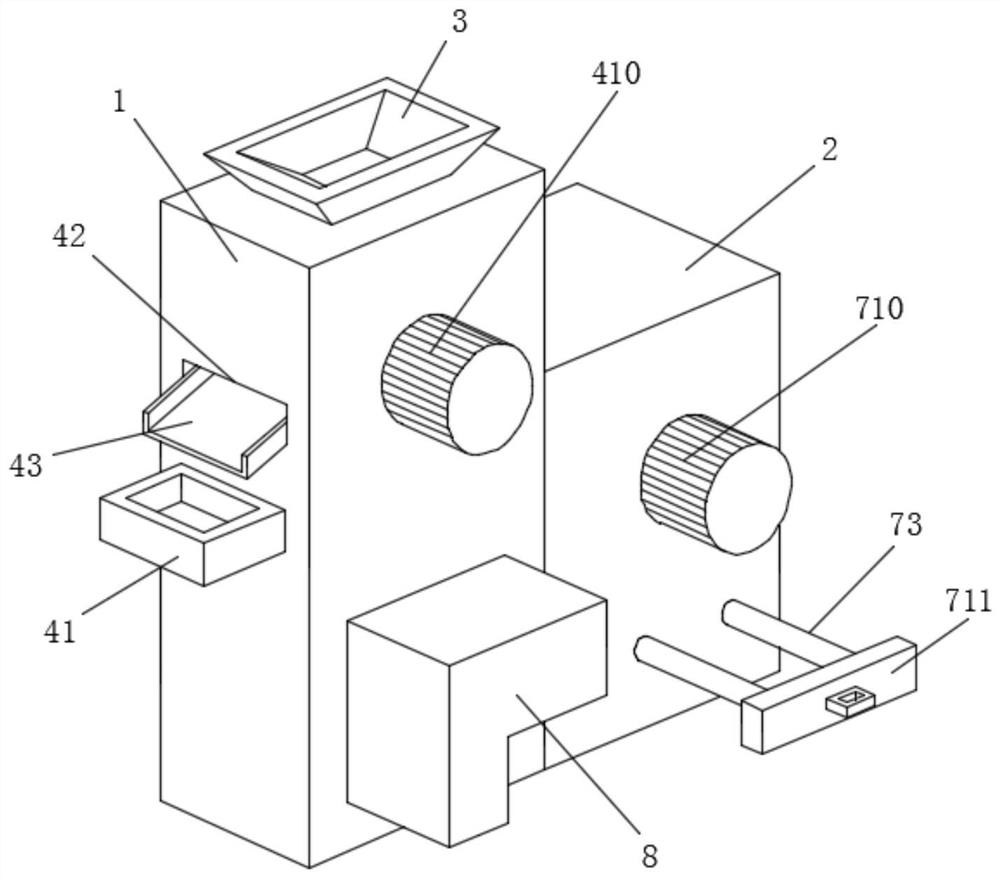

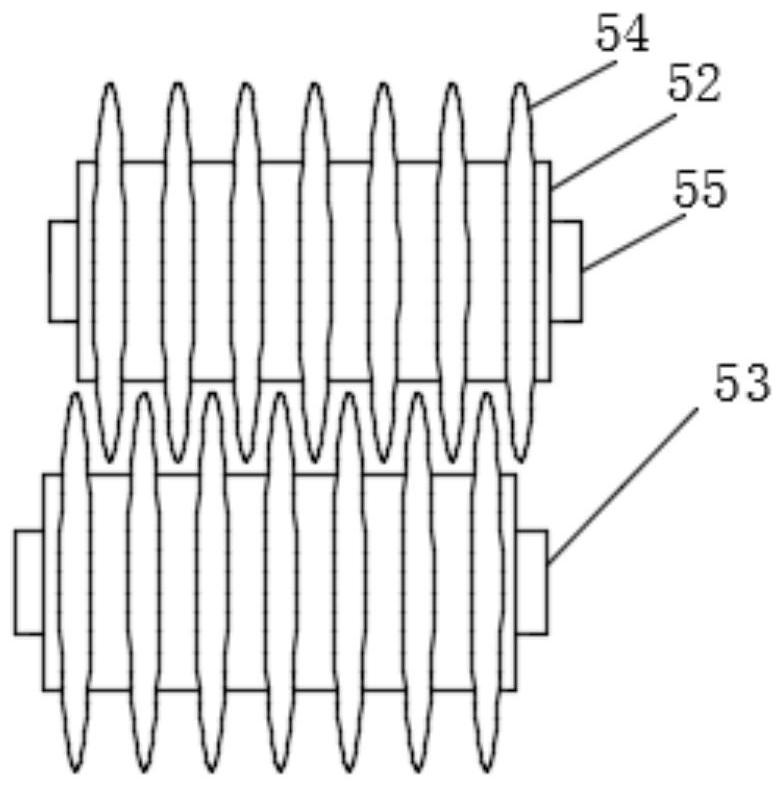

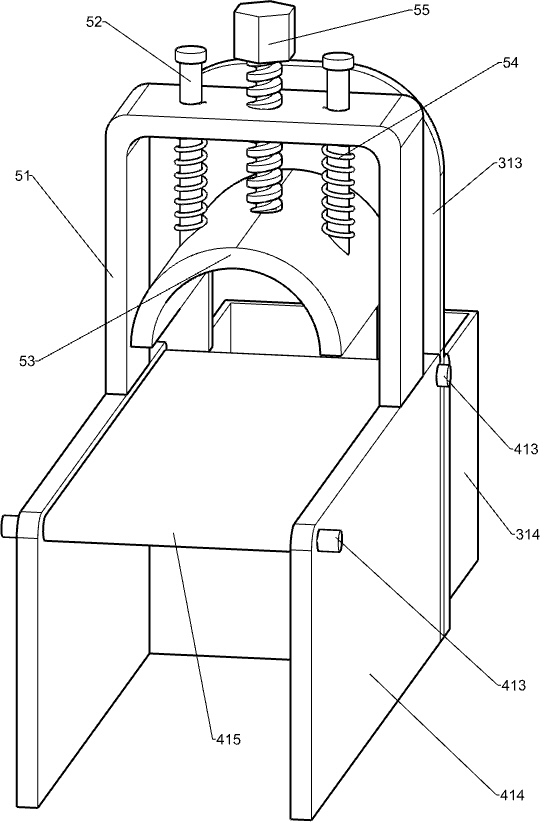

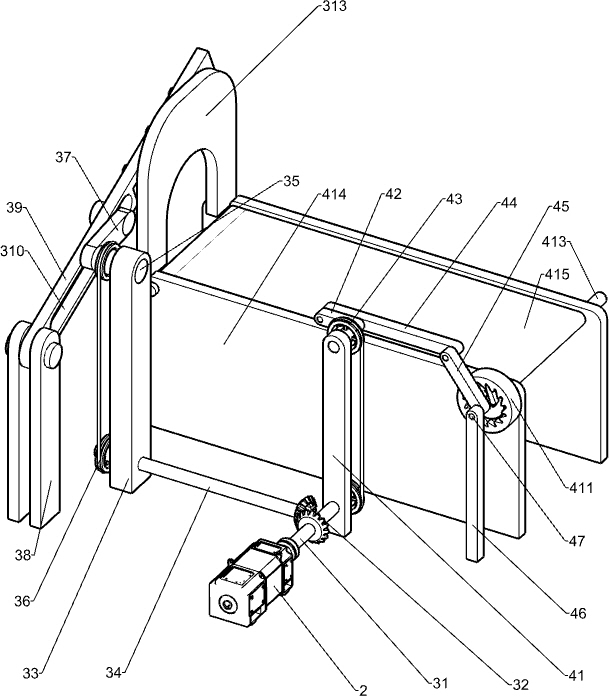

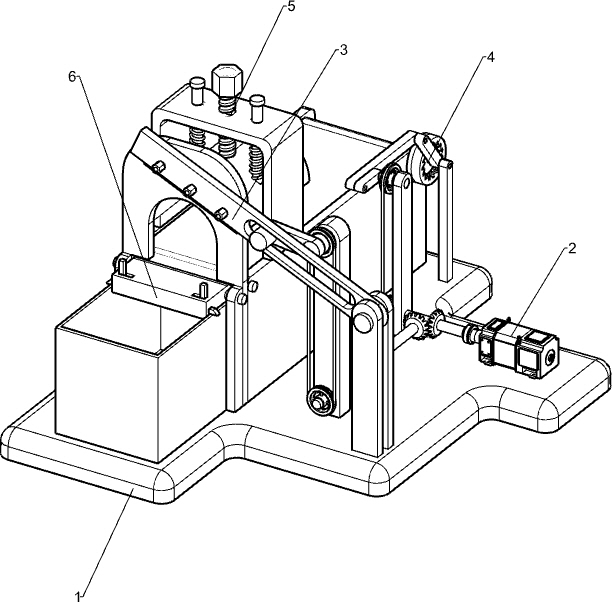

Tobacco production device achieving uniform shredding

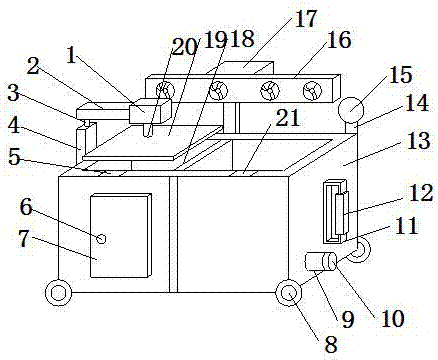

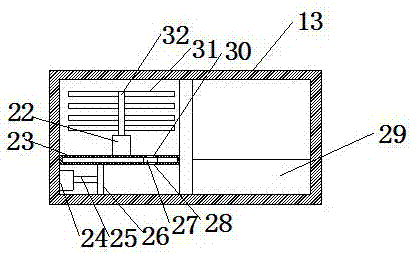

InactiveCN109090694AConvenient automatic feedingEasy to fixTobacco treatmentEngineeringLinear motion

The invention discloses a tobacco production device achieving uniform shredding. The tobacco production device achieving uniform shredding comprises a shredding machine body and a first supporting plate, wherein the first supporting plate is slidingly arranged on the side wall of the shredding machine body, the upper end of the shredding machine body is slidingly provided with a conveying belt, atransmission box is arranged on the conveying belt, a first square cutter is arranged in the transmission box, the inner side wall of the first square cutter is fixedly connected with a cylindrical sliding block, and the two adjacent side walls of the first square cutter are fixedly connected with blades. A user manually separates tobacco leaves, a first hydraulic rod extends and drives a fan-shaped sliding block to move, so that an arc-shaped transmission rod performs linear motion, the cylindrical sliding block slides in a Z-shaped sliding groove formed in the surface of the arc-shaped transmission rod and drives the first square cutter, a second square cutter, a third square cutter and a fourth square cutter to sequentially rotate at 90 degrees and shred the tobacco leaves, and convenience is provided for the user to shred the tobacco leaves.

Owner:XUZHOU FANGDA MOTOR CO LTD

Novel water channel dredging device

ActiveCN111827387AEasy to shredImprove cleaning efficiencyMechanical machines/dredgersSludgeSliding contact

A novel water channel dredging device comprises a shell structure, a pulling structure and a crushing structure. The shell structure comprises a shell and a first through hole, the pulling structure comprises an air cylinder, a pull rod, a lifting frame and a piston, and the crushing structure comprises a connecting shaft, a third filter screen, a positioning frame below the filter screen, a sliding block, a crushing pin and a scraping block. The upper end of the connecting shaft is accommodated in the lifting frame and is in threaded connection with the lifting frame, and the positioning frame penetrates through the left surface and the right surface of the sliding block and is in sliding contact with the sliding block. The upper end of the crushing pin is fixedly connected with the sliding block, and the lower end of the crushing pin is fixedly connected with the scraping block. The air cylinder pulls the pull rod to continuously move up and down, the third filter screen, the positioning frame, the sliding block, the crushing pin and the scraping block periodically rotate accordingly through the lifting frame and the connecting shaft which are in threaded connection, due to the periodic change of rotating directions and rotating speeds, sludge can be crushed, meanwhile, the sliding block moves back and forth on the positioning frame, and the sludge crushing range of the crushing pin can be enlarged.

Owner:HEILONGJIANG PROVINCIAL HYDRAULIC RES INST

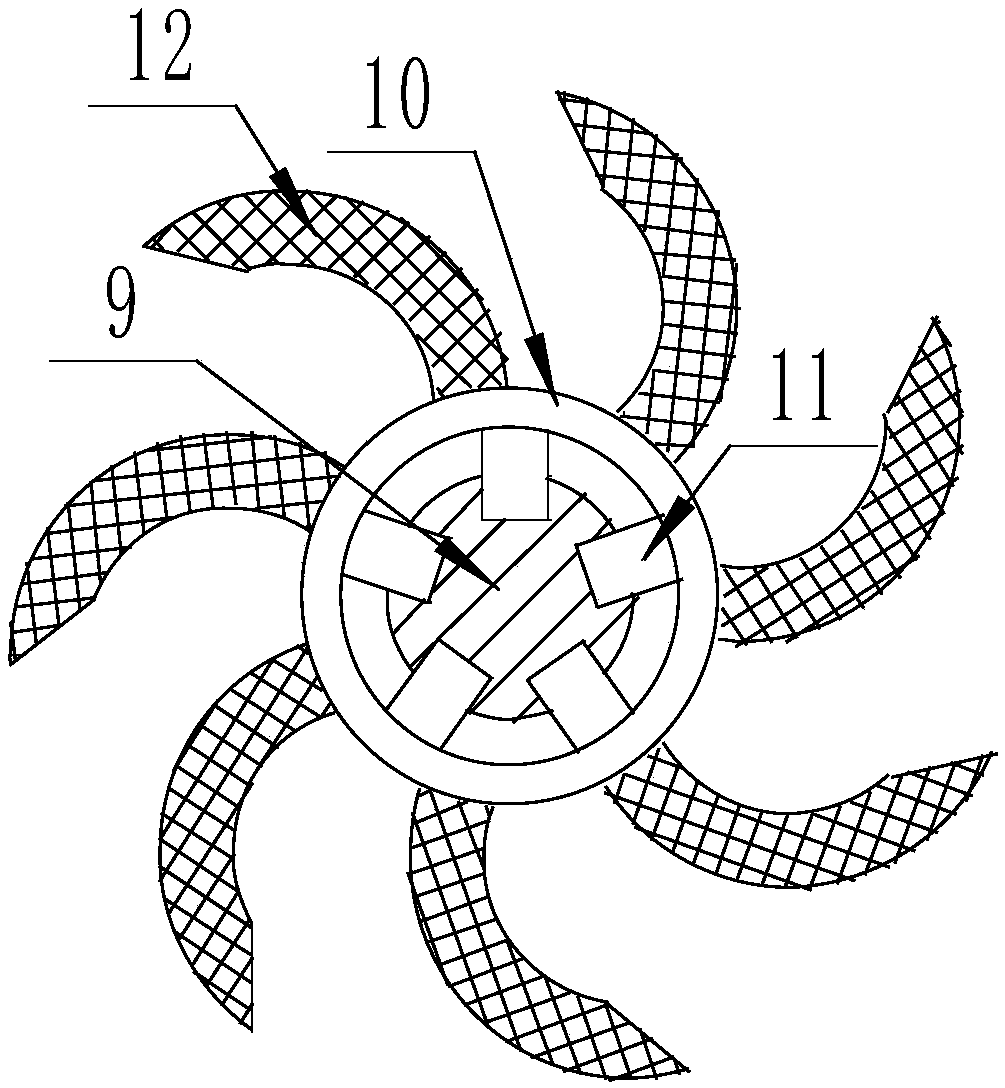

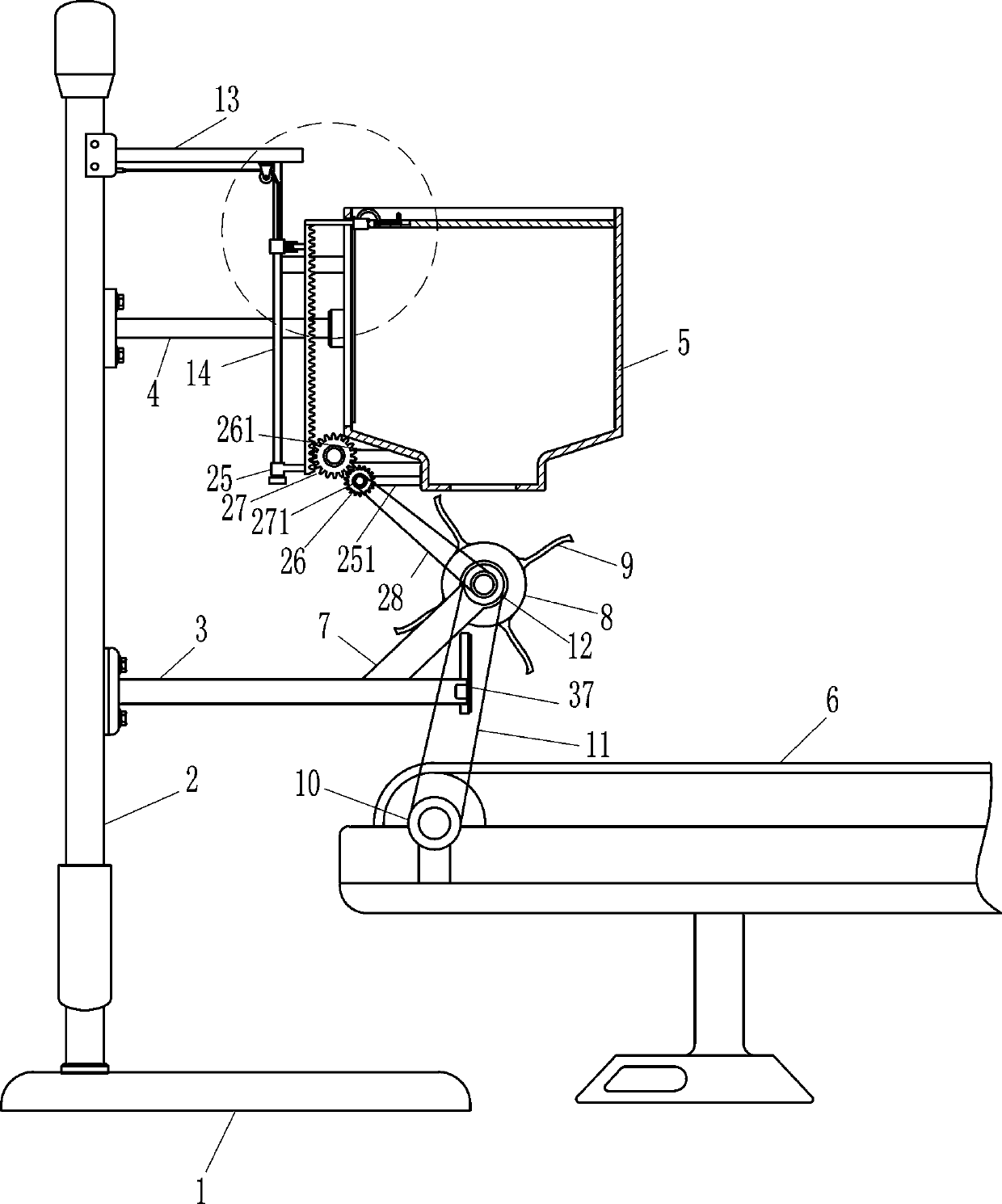

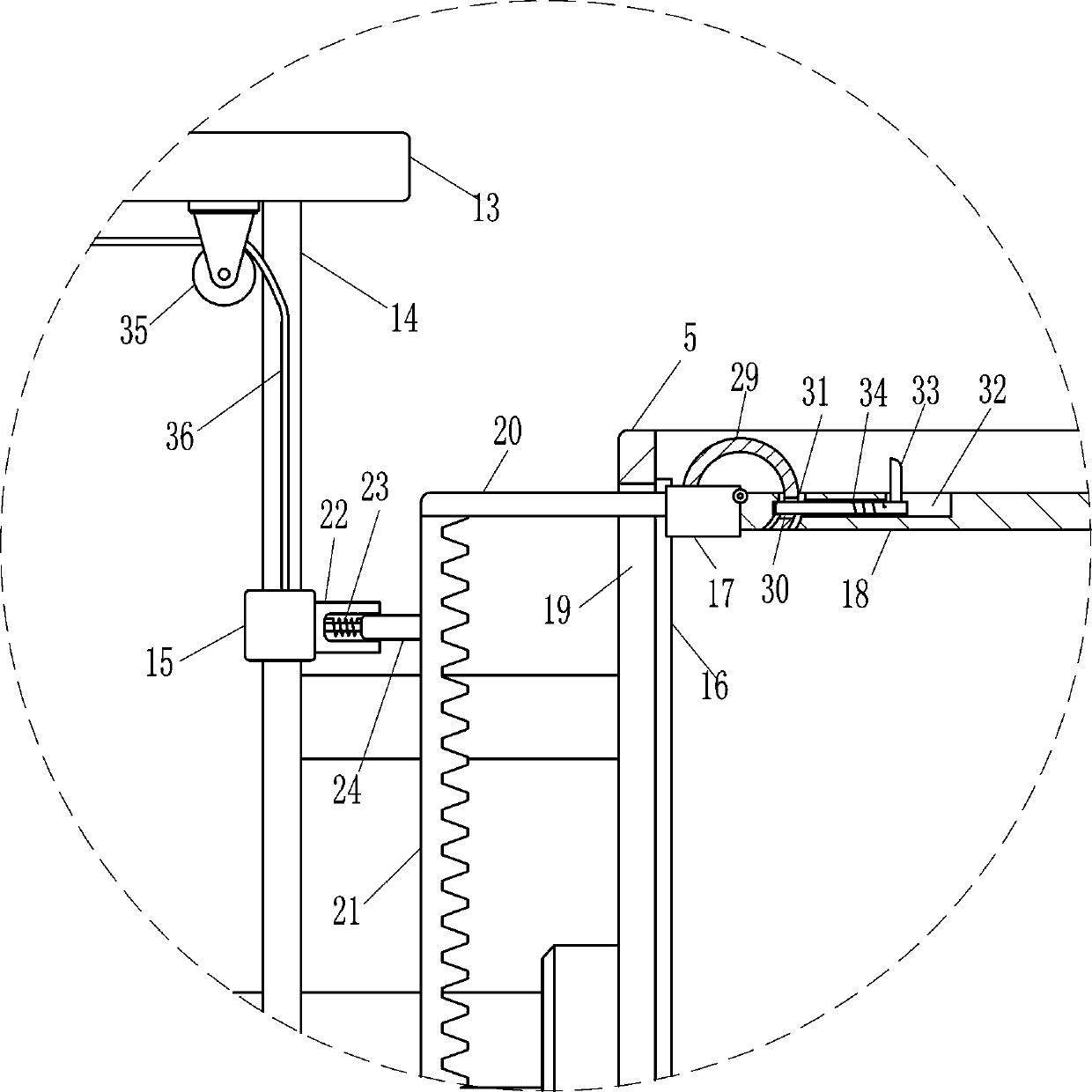

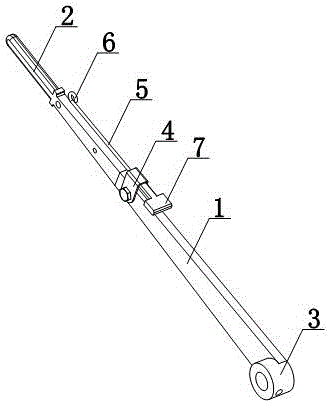

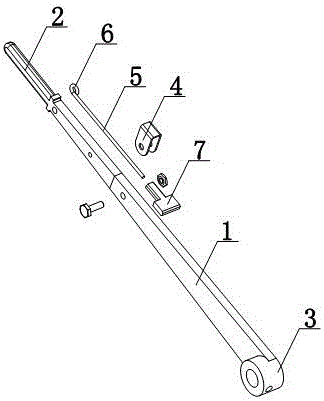

Water tank salvage apparatus for sewage treatment

ActiveCN109019720AEasy to turn and collectEasy to shredWater/sewage treatmentSewage sludge treatmentWater tanks

The invention discloses a water tank salvage apparatus for sewage treatment. The water tank salvage apparatus comprises a bar-shaped carrier foundation support, wherein the upper surface of the bar-shaped carrier foundation support is provided with a salvage treatment mechanism, and the lower surface of the bar-shaped carrier foundation support is provided with a moving mechanism. The water tank salvage apparatus has the beneficial effects that garbage inside a water tank can be collected in a rotating manner, the reverse rotation for unloading can be facilitated, the garbage can be minced tofacilitate the discharge, the manual labor intensity can be alleviated, and the working efficiency can be improved.

Owner:义乌市佳倩科技有限公司

Fruit and vegetable shredding machine

InactiveCN104441036AEfficient cuttingSimple structureMetal working apparatusAgricultural engineeringDrive motor

The invention discloses a fruit and vegetable shredding machine. The fruit and vegetable shredding machine comprises a machine shell, a feeding barrel and a discharging opening; the feeding barrel is arranged on the top of the machine shell; the discharging opening is formed in the lower portion of the machine shell; a spiral feeding mechanism is arranged on the lower portion of the feeding barrel and is located inside the machine shell; a slicing mechanism is arranged below the spiral feeding mechanism; a shredding mechanism is located on the lower portion of the slicing mechanism; a controller is arranged on the right side of the machine shell; a driving motor is arranged on the right side of the machine shell; and the spiral feeding is adopted by the shredding mechanism, and slicing and shredding are carried out successively; and cutting is efficient, convenient and rapid. The high-efficiency cutting characteristic that in the small space, filamentous vegetables can be continuously cut is achieved. The fruit and vegetable shredding machine is a shredding tool for efficiently cutting fruits and vegetables in the catering industry and is simple in structure, convenient to operate and quite suitable for small restaurants.

Owner:HARBIN HONGRUIXIANG TECH DEV CO LTD

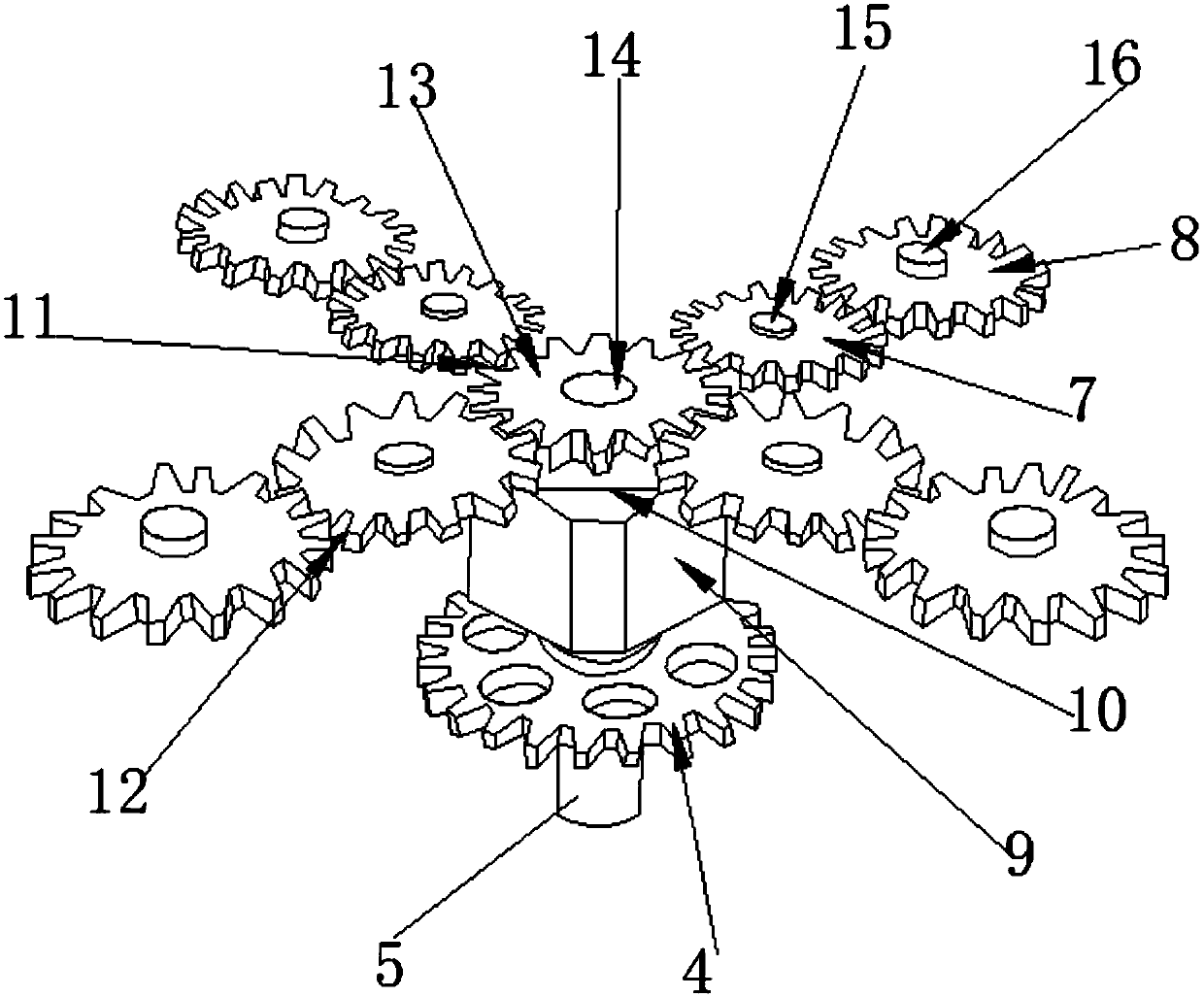

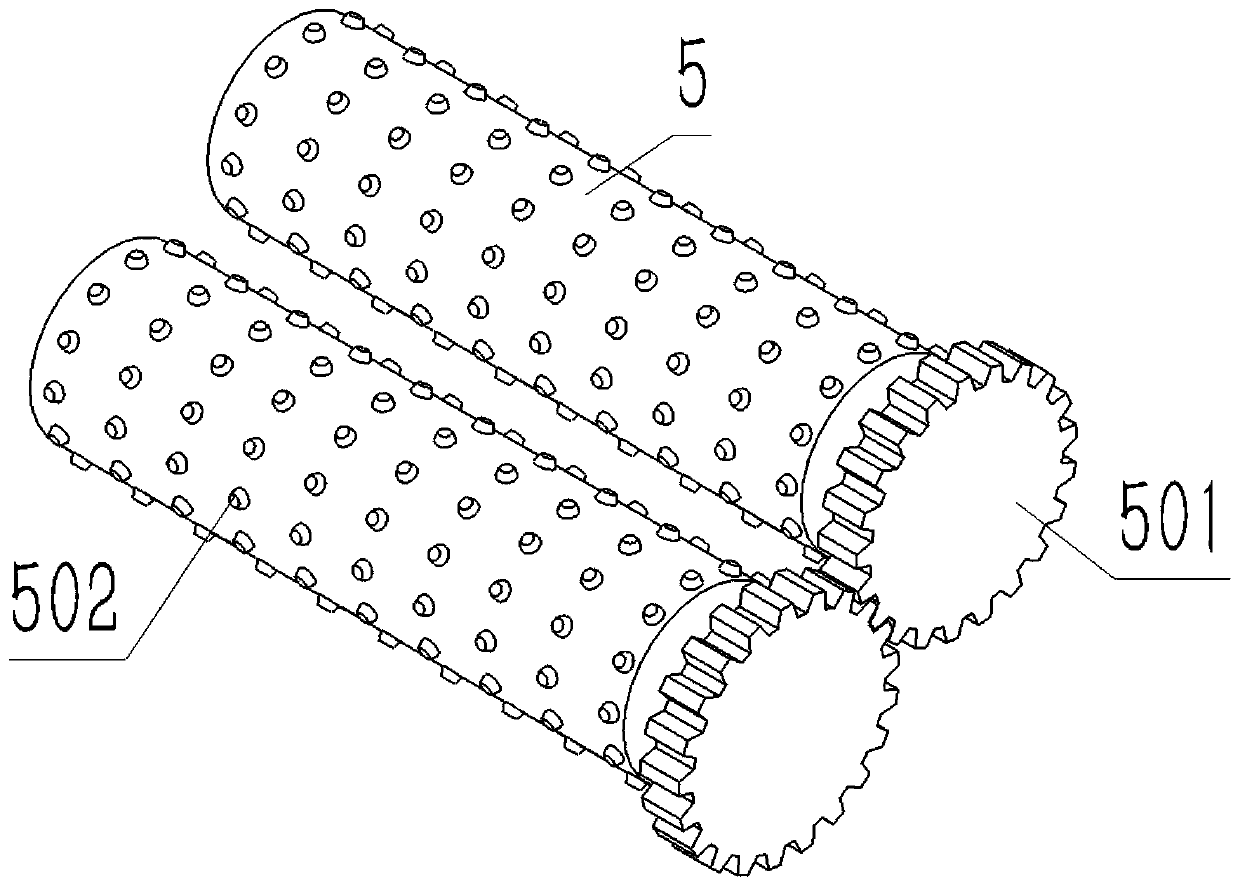

Easy-to-rinse quick meat grinder

PendingCN107616211AEasy to shredEasy to crushMeat tenderisingMeat processing devicesGear wheelEngineering

The invention discloses an easy-to-rinse quick meat grinder. The easy-to-rinse quick meat grinder comprises a housing, wherein a charge hole is formed in one side of the outer part of the housing; a rotary structure is arranged at the top end inside the housing; the rotary structure comprises a rotary wheel, a rotary shaft, a motor I, a gear I and a gear II, wherein the top end of the housing is equipped with the motor I; the top end inside the housing is equipped with the rotary wheel; the rotary shaft is arranged in the rotary wheel; the rotary shaft is rotatably connected with the rotary shaft of the motor I; the bottom end of the rotary wheel is equipped with a fixed block; a through hole adaptive to the rotary shaft is formed in the fixed block; the rotary shaft passes through the topend of the rotary wheel and extends to the bottom end of the fixed block; the bottom end of the fixed block is equipped with a supporting post; the bottom end of the supporting post is equipped witha supporting plate I and a supporting plate II which are crossed; the top end of the supporting plate I and the top end of the supporting plate II are connected with the rotary shaft; the bottom end of a crossed point of the supporting plate I and the supporting plate II is equipped with a fixed wheel. The easy-to-rinse quick meat grinder has the beneficial effects: a blade at the bottom end can grind meat in the housing from different directions, so that the grinding is more complete; a spraying head can ensure that the housing is internally clean and sanitary, so that eating of people is facilitated better.

Owner:金昱轩

Multifunctional vegetable cutter

PendingCN114274190AEasy to shredEasy to useMetal working apparatusAgricultural engineeringStructural engineering

The invention provides a multifunctional vegetable cutter and relates to the technical field of vegetable cutters, the multifunctional vegetable cutter comprises a box body and a mounting block, the mounting block is arranged on one side in the box body, a first rotating shaft and a second rotating shaft are rotatably arranged on the two sides in the mounting block respectively, a sliding groove is formed in one side of the front end of the mounting block, and a sliding rod is movably mounted in the sliding groove; a shredding part is arranged on one side of the sliding rod, the second rotating shaft drives the sliding rod to move, and the rear end of the first rotating shaft and the rear end of the second rotating shaft are connected with a first gear and a second gear respectively. A sliding rod can be pushed to move in a sliding groove through rotation of a second rotating shaft, the shredding part is driven to move, food materials only need to be placed in a material hopper and fall from an opening of the material hopper during use, the shredding part can shred the food materials, the slicing part can be driven to be opened and closed through rotation of a fourth rotating shaft, and a scissor-shaped structure is formed; in conclusion, the shredding and slicing machine can be used for shredding and slicing, and the functions are diversified.

Owner:王誉华

Cotton discharging device of cotton opener

The invention relates to a cotton discharging device, in particular to a cotton discharging device of a cotton opener. By the cotton discharging device of the cotton opener, shredding of large raw materials can be implemented instead of manual operation, the manual workload is relieved, and the raw materials can be laid uniformly. The cotton discharging device of the cotton opener comprises a bottom plate, a mounting plate, first supporting rods, a second supporting rod, a cotton storage frame, a shredding device and the like; the mounting plate is arranged on the top of the bottom plate, thefirst supporting rods are separately arranged on the front side and the back side of the lower portion of the right side of the mounting plate, the second supporting rod is arranged on the upper portion of the right side of the mounting plate, and the cotton storage frame is arranged at the right end of the second supporting rod. By the shredding device, the large raw materials do not need to be shredded by manual operation, the labor workload is relieved, meanwhile, through a downward pressing device, the raw materials in the cotton storage frame can be downwards pressed to the outlet of thecotton storage frame, thus, the shredding device can shred the raw materials well, and the production efficiency is improved.

Owner:张子平

Processing device for kitchen waste

InactiveCN111437919AAchieve cleaningEasy to shredHollow article cleaningGrain treatmentsWater filterEnvironmental engineering

The invention provides a processing device for kitchen waste. The processing device comprises a crushing box and a water filtering box which are connected fixedly from top to bottom; a feeding openingis formed in the top of the crushing box; a grinding mechanism is arranged in the position, located below the feeding opening, inside the crushing box; a cutting mechanism is further arranged insidethe crushing box; a connection channel is arranged at the bottom of the crushing box and communicates with the inside of the water filtering box; a moving door mechanism is arranged inside the connection channel; a rotating drum is rotationally connected inside the water filtering box, is driven by a rotating mechanism to rotate and adopts the hollow structure; a plurality of filtering holes are formed in the side wall; a discharging opening is formed in the bottom of the rotating drum; a door opening mechanism is arranged at the discharging opening; the discharging opening communicates with adischarging channel located at the bottom through the door opening mechanism; and cleaning mechanisms are arranged inside a box body of the crushing box and a box body of the water filtering box. Theprocessing device has the beneficial effects that the processing device is reasonable in design, simple in structure, safe and reliable, cutting processing and solid-liquid separation processing canbe effectively performed on the kitchen waste, and the device can be cleaned.

Owner:闫兰兰

Device for manufacturing concrete building material from construction waste

InactiveCN110947741AChopped fullyImprove efficiencyConstruction waste recoverySolid waste disposalLand resourcesArchitectural engineering

The invention discloses a device for manufacturing a concrete building material from construction waste, and relates to the technical field of construction equipment. The invention discloses a devicefor manufacturing a concrete building material from construction waste. The device comprises a recycling and cutting device and a smashing treatment device; the recovery cutting device is located on the right side of the smashing treatment device; the recovery cutting device is provided with a cutting device and a connecting device; the crushing treatment device is provided with a crushing deviceand an accommodating device; the cutting device comprises a first bottom plate, rolling wheels, a front side plate, a rear side plate and a first motor. Rollers are arranged at four corners of the lower surface of the first bottom plate; the front and rear edges of the upper surface of the first bottom plate are fixedly connected with a front side plate and a rear side plate respectively; and thesurface of the right side of the front side plate is connected with a first rotating shaft through a bearing in a rotating manner. According to the device, the problems that since most of existing construction waste treatment methods are characterized by centralized stacking or landfill, land resources are wasted, the soil environment is greatly polluted, and the construction waste cannot be fullyrecycled are solved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

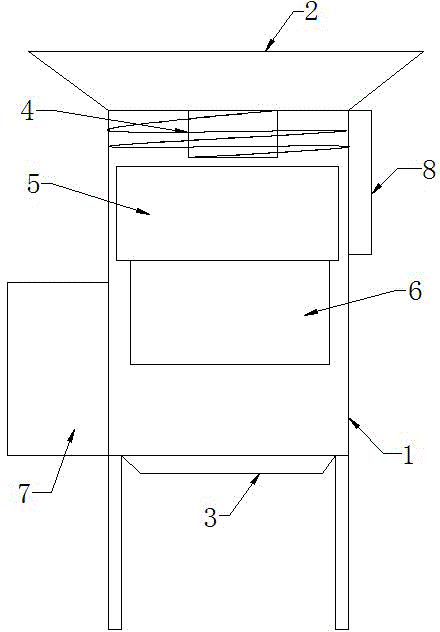

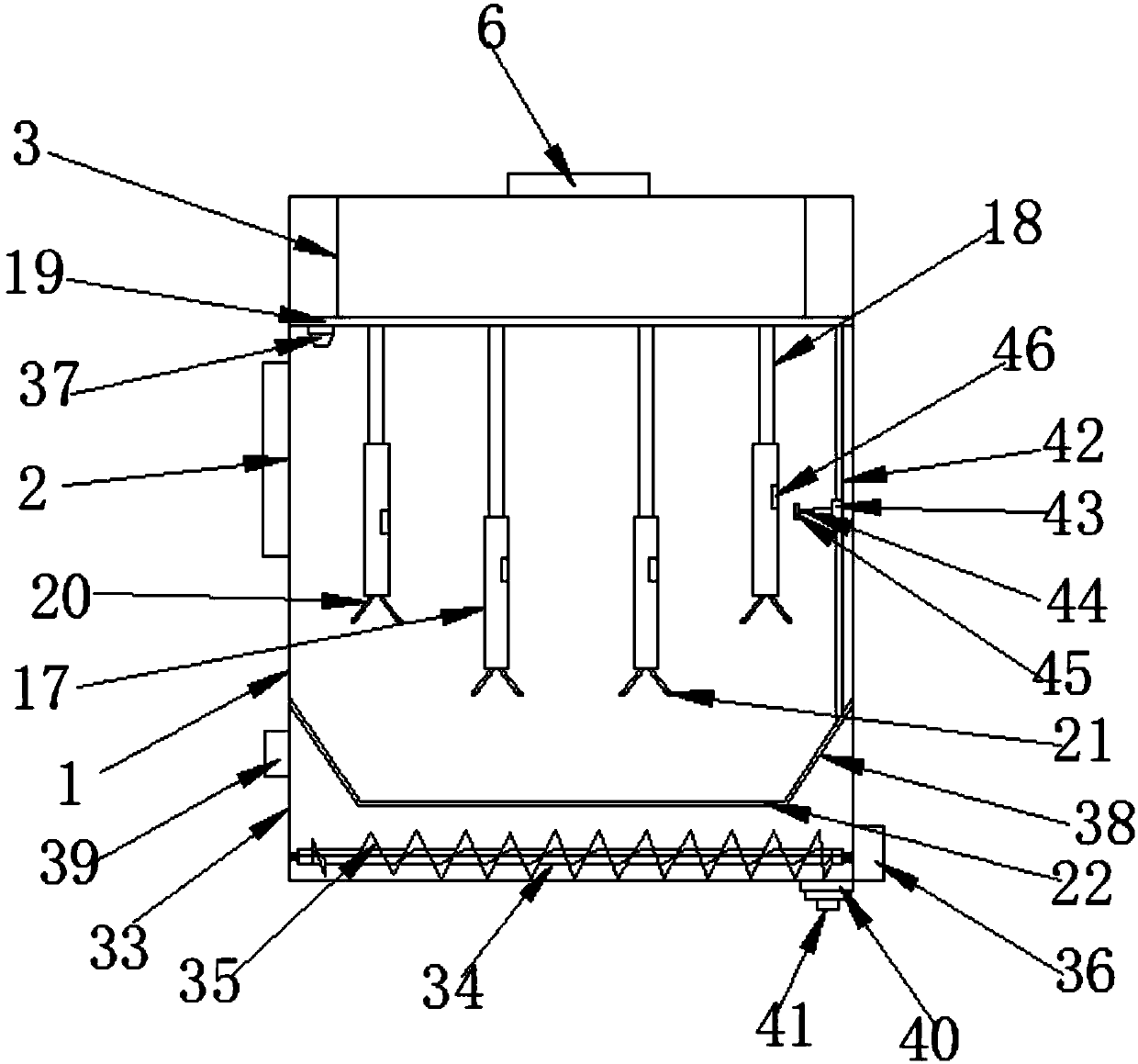

Double-shaft shredding machine

InactiveCN113522484AEfficient shreddingImprove crushing efficiencyGrain treatmentsElectric machineryStructural engineering

The invention discloses a double-shaft shredding machine, and relates to the technical field of solid waste recycling and crushing. The problems that a rubber block is worn by a blade of an existing shredding machine, most parts of the shredding machine need to be disassembled when the blade is replaced, maintenance and replacement are inconvenient, and when the shredding machine works, materials are easy to wind shafts, so that the machine is stuck are solved. The double-shaft shredding machine comprises a machine frame, a feeding hopper is arranged on the surface of the machine frame, a shredding box is arranged below the feeding hopper, the shredding box is located in the middle of the machine frame, a discharging hopper is arranged below the shredding box, and driving motors are arranged on the two sides of the discharging hopper. By arranging a shredding mechanism, a feeding adjusting mechanism and a shredding transmission mechanism, the material crushing efficiency of the shredding machine can be effectively improved, the situation that a shaft of the shredding machine is wound by materials is avoided, the machine is prevented from being stuck, damaged blades are conveniently replaced, and maintenance and overhaul are facilitated.

Owner:东莞市绿丰环保机械有限公司

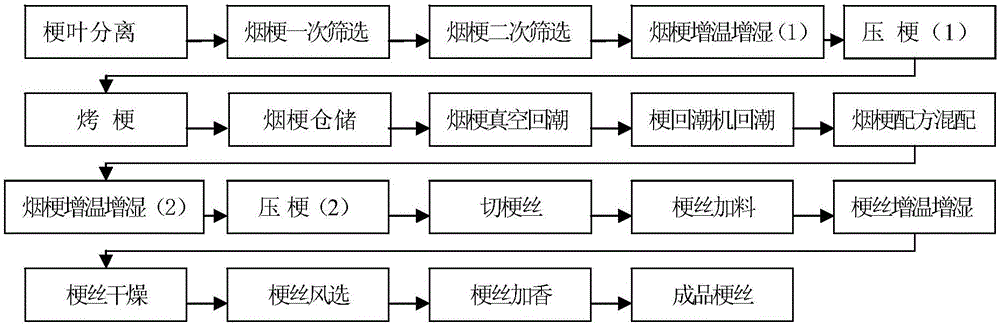

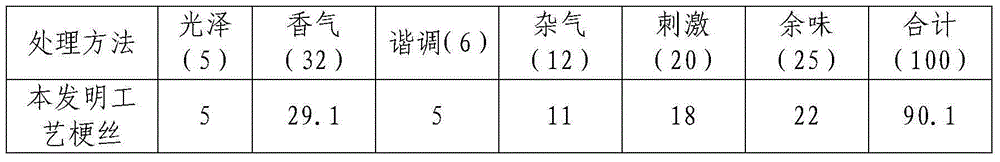

Method for processing tobacco stems into shredded stems

The invention discloses a method for manufacturing stem shreds by processing tobacco stems. The method includes the steps of stem and leaf separating, tobacco stem screening, tobacco stem warming and humidifying, stem pressing, stem roasting, tobacco stem storing, tobacco stem dampening, tobacco stem formula mixing, secondary tobacco stem warming and humidifying, second stem pressing, stem shred cutting, stem shred adding, stem shred warming and humidifying, stem shred drying, stem shred winnowing, perfuming and the like. A whole set of complete new stem shred processing method from leaf hitting tobacco stem re-roasting processing to stem shred manufacturing from the tobacco stems is formed. According to the method, the stem shred production environment is improved; the production cost is reduced; the stem shred quality is improved. The method is easy and convenient, and strong in maneuverability; and large-scale production and application can be conveniently achieved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

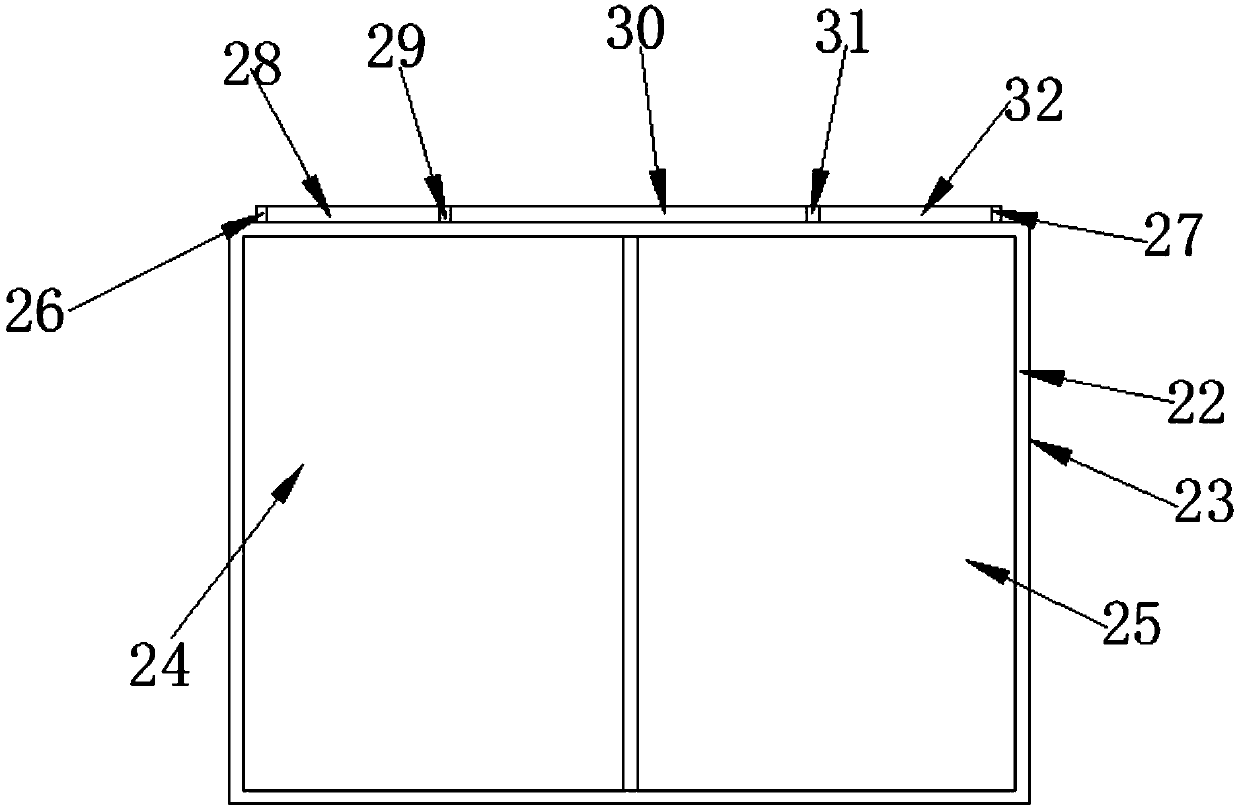

Waste collecting device for ocean-going passenger vessel

InactiveCN111994515AImprove filtering effectEasy to shredAuxillariesSolid waste disposalEnvironmental engineeringPassenger vessel

The invention discloses a waste collecting device for an ocean-going passenger vessel. The waste collecting device comprises a first disposal box, a second disposal box, a liquid filtering mechanism,a smashing mechanism, a conveying mechanism and a compaction mechanism, wherein the top end of the first disposal box is fixedly connected with a feeding hopper, and one end of the first disposal boxis fixedly connected with the second disposal box. By arranging the liquid filtering mechanism, liquid in wastes in the ocean-going passenger vessel can be convenient to filter away, and the situationis prevented that the liquid is accumulated for a long time at a later stage to produce bad smell, and the air environment in the ocean-going passenger vessel is affected; by arranging the smashing mechanism, the wastes are convenient to smash, and the stacking space of the wastes is reduced; by arranging the conveying mechanism and the compaction mechanism, the smashed wastes are convenient to convey into the compaction mechanism, the tiny wastes are compacted together through the compaction mechanism, the area occupied by the wastes can be narrowed, the wastes are convenient to clear away and package, the operation is easier, and the waste collecting device is more convenient to use, more environmentally friendly and more durable and higher in practicability.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

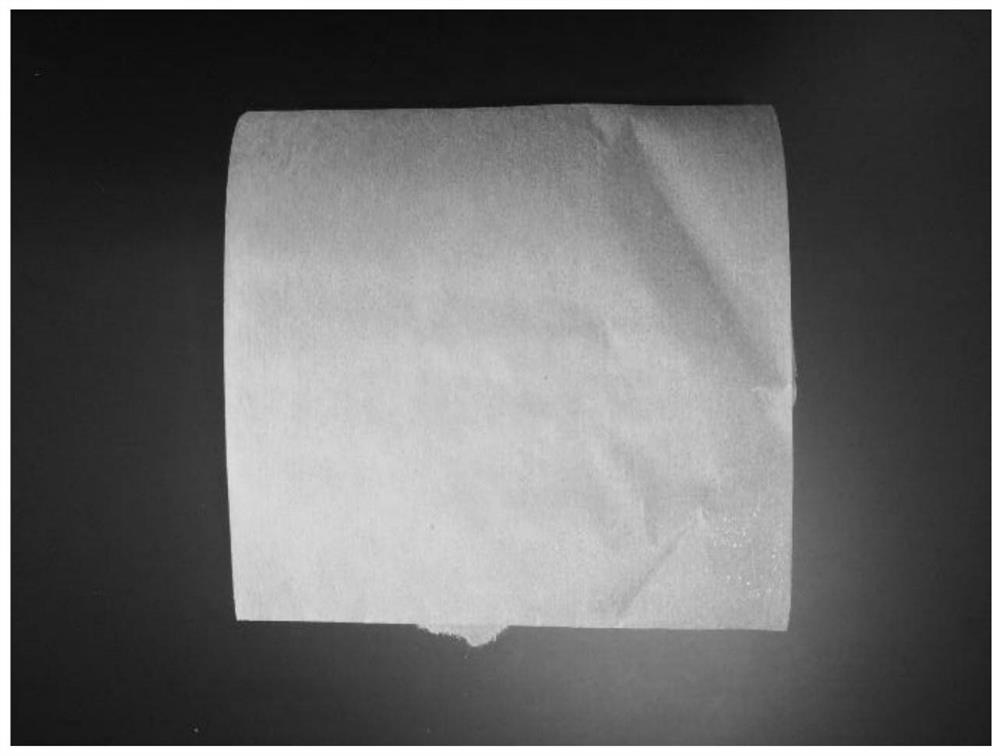

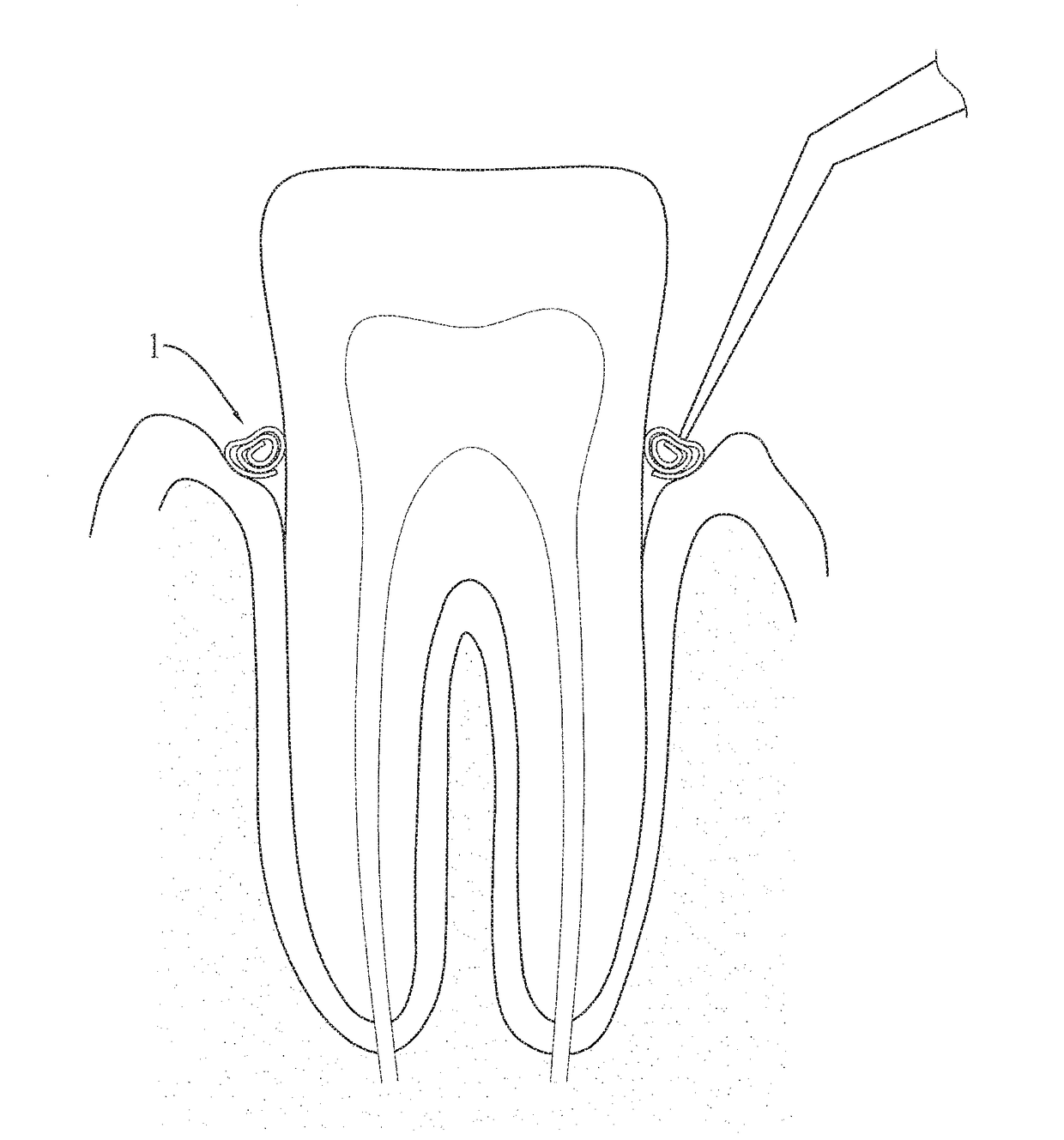

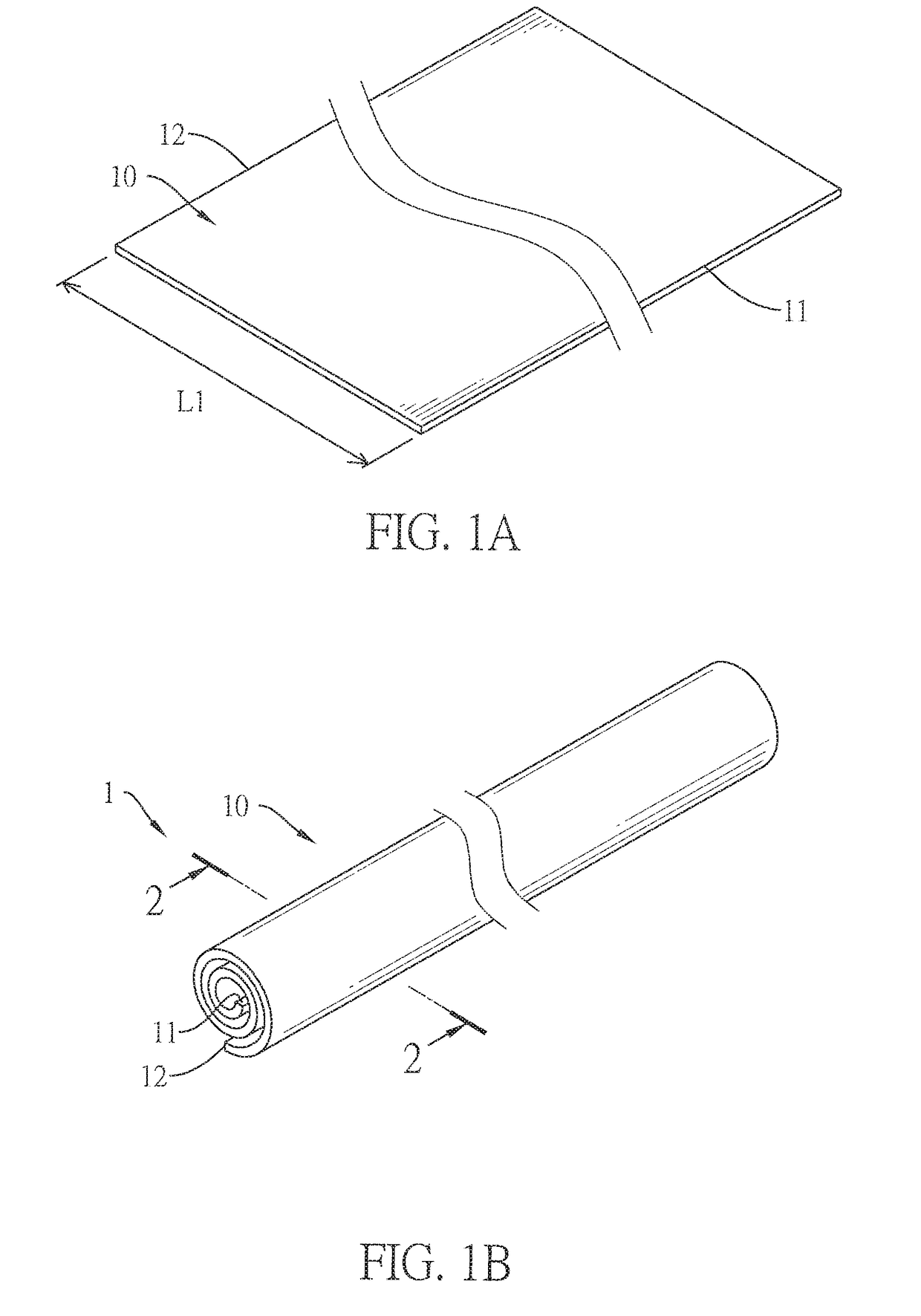

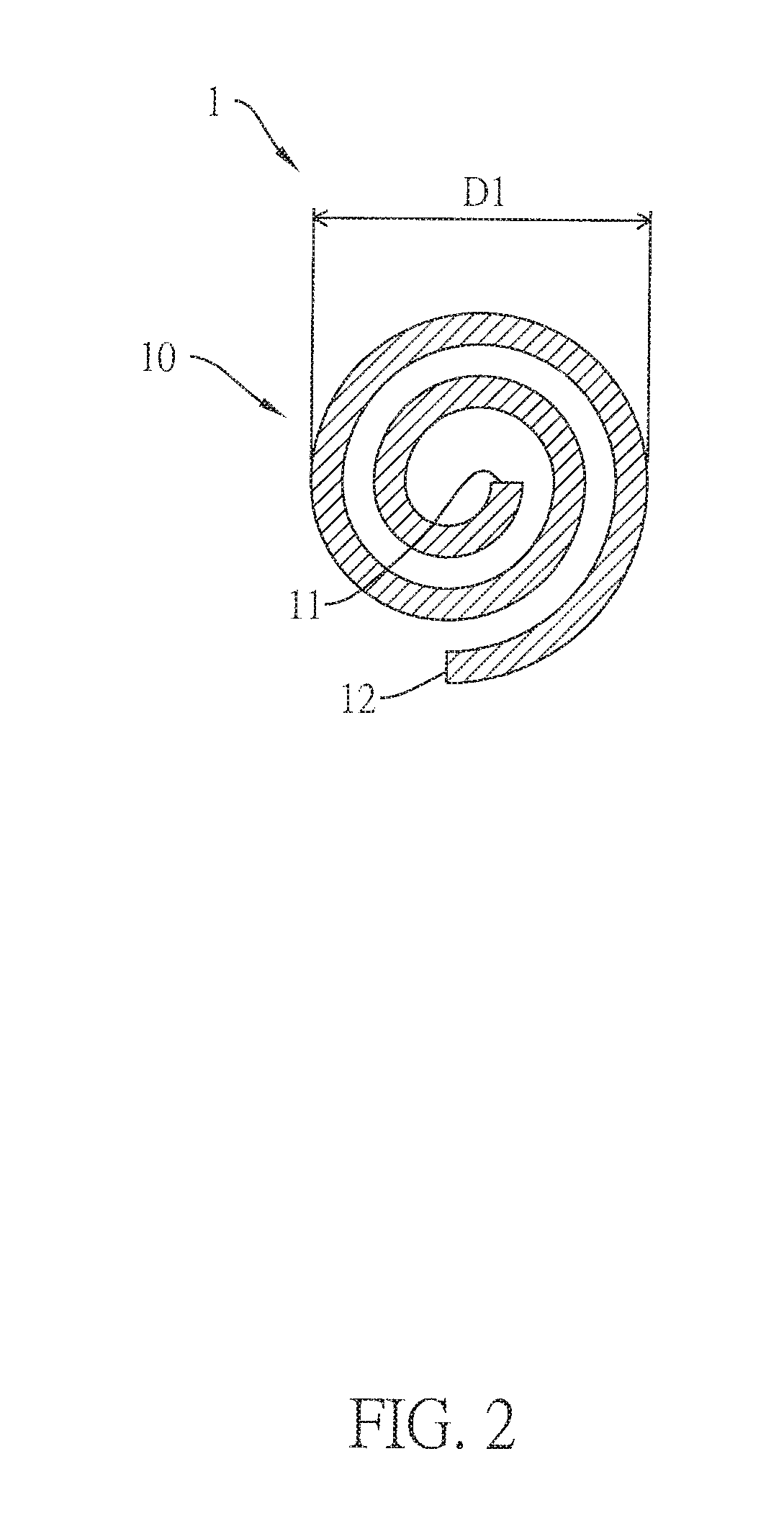

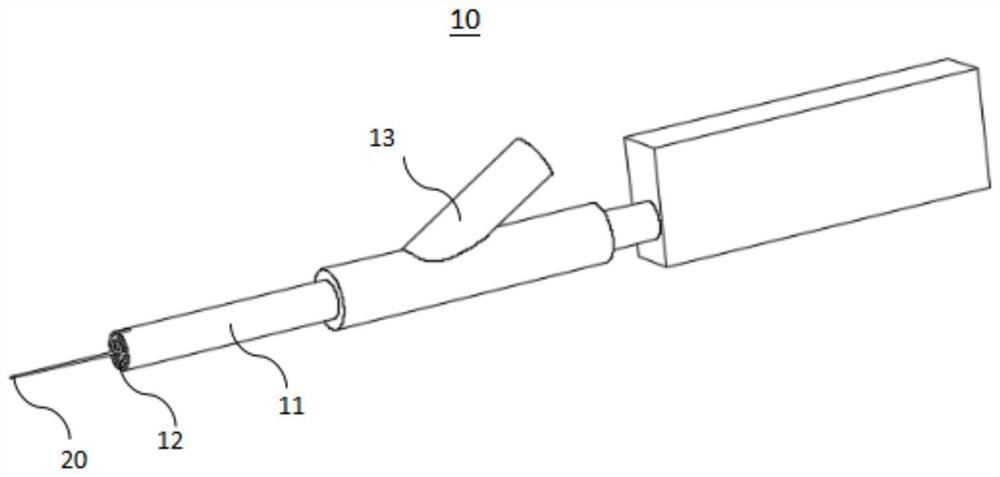

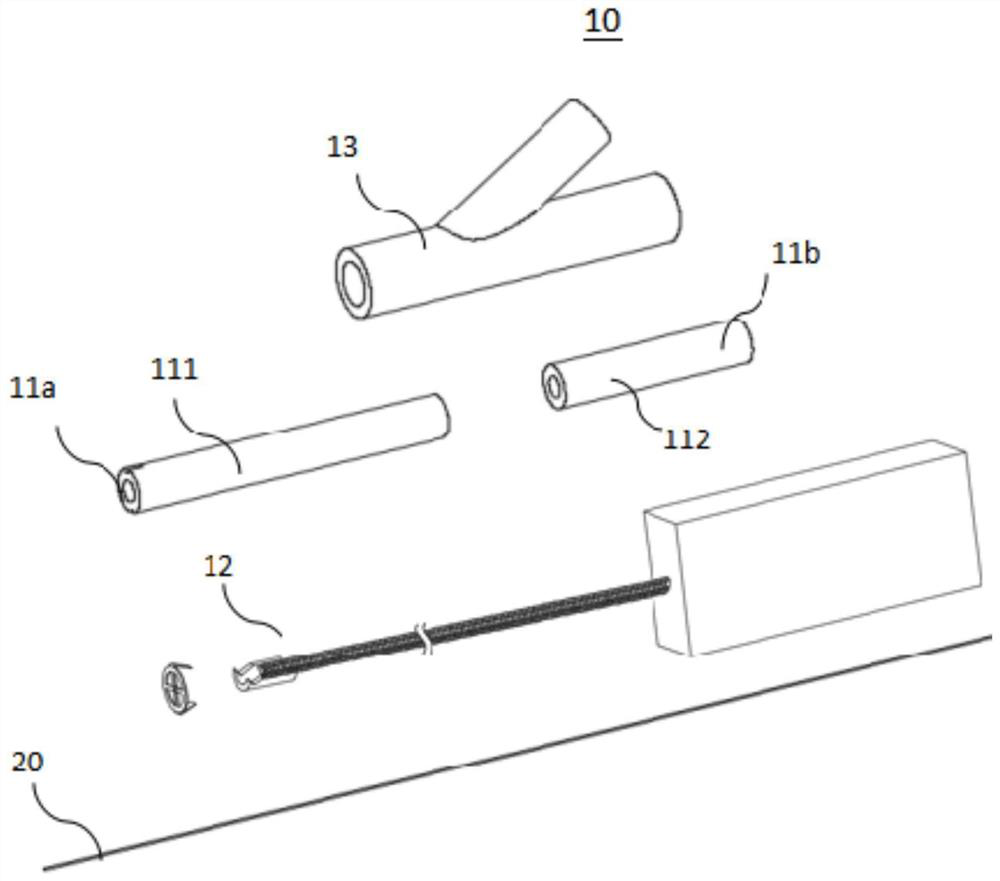

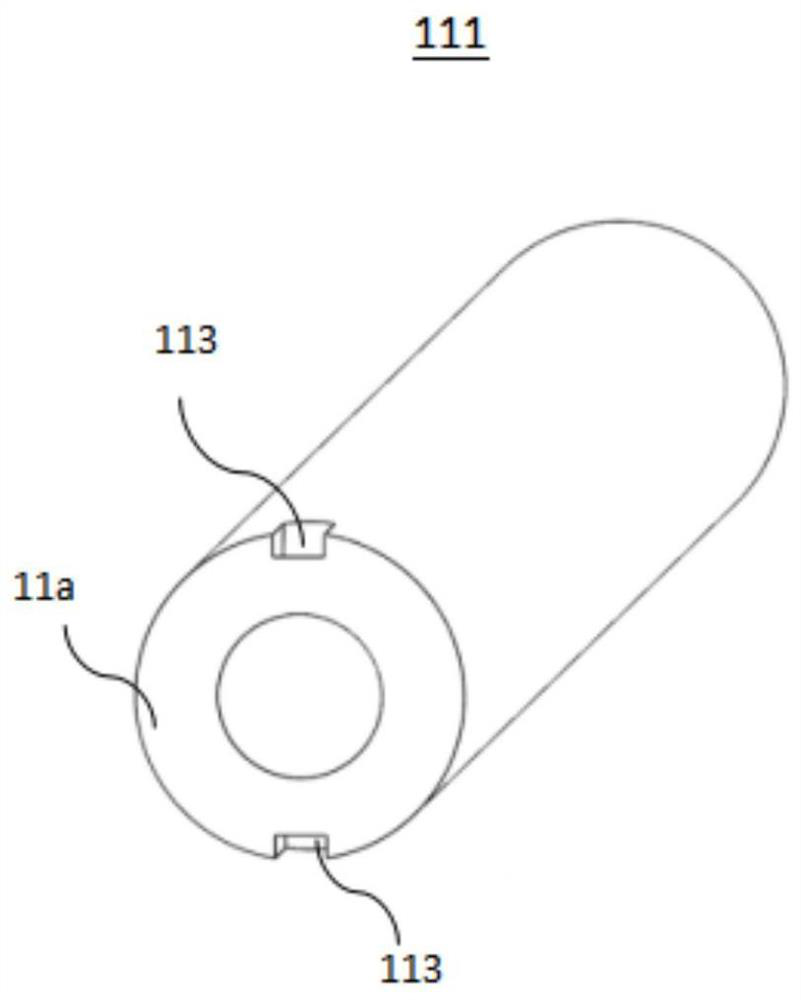

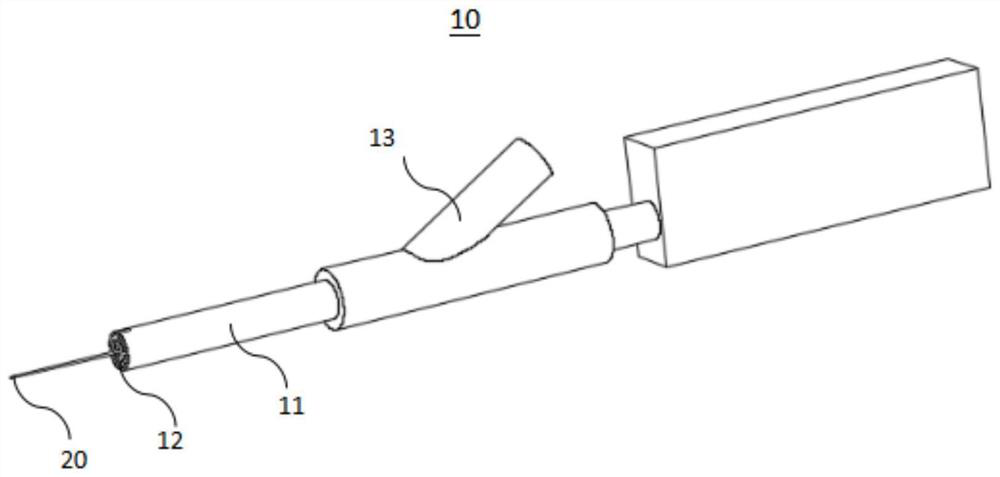

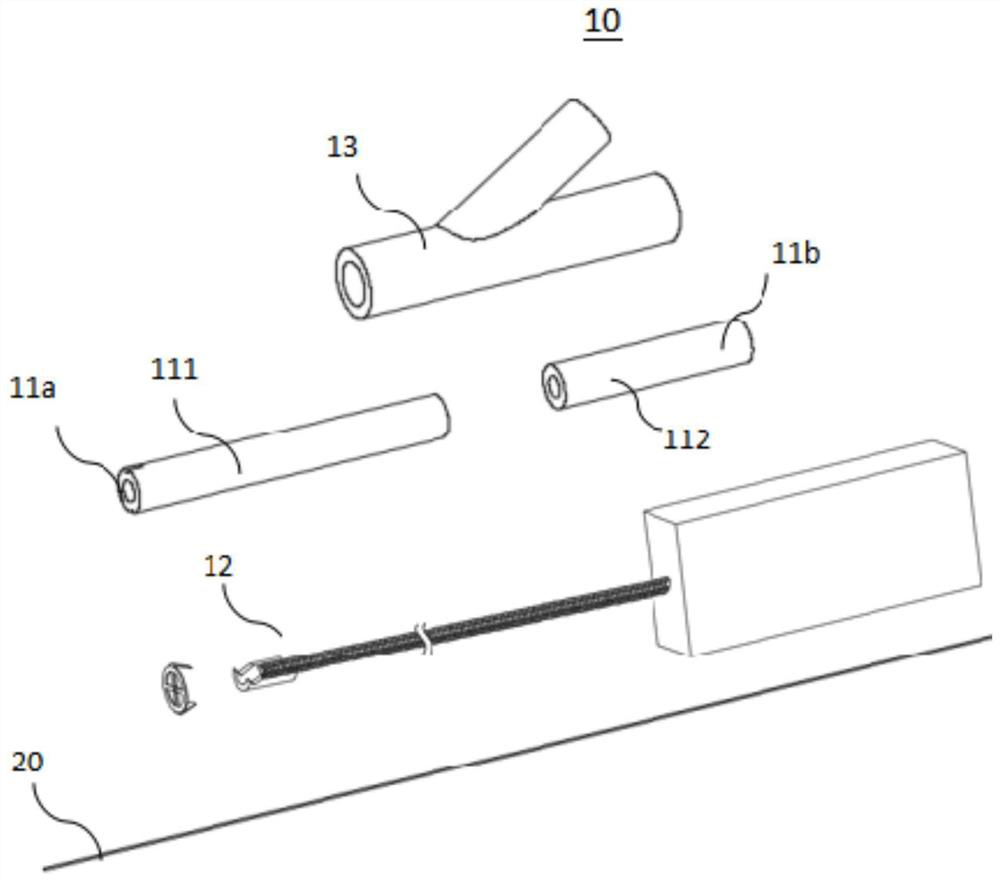

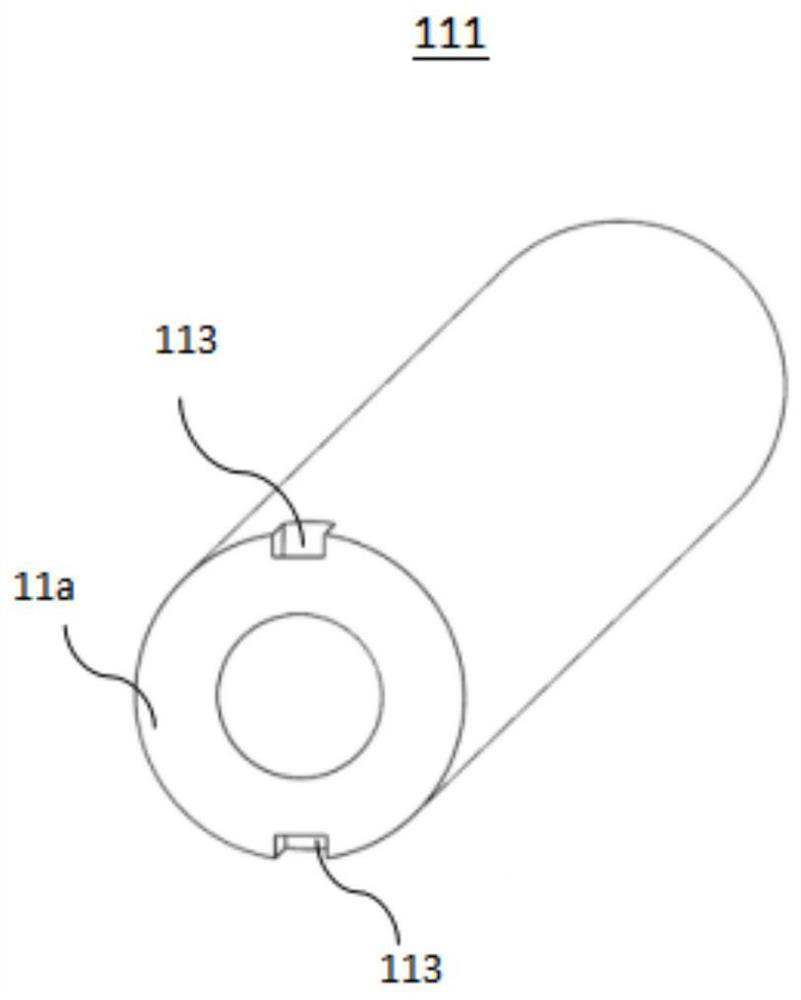

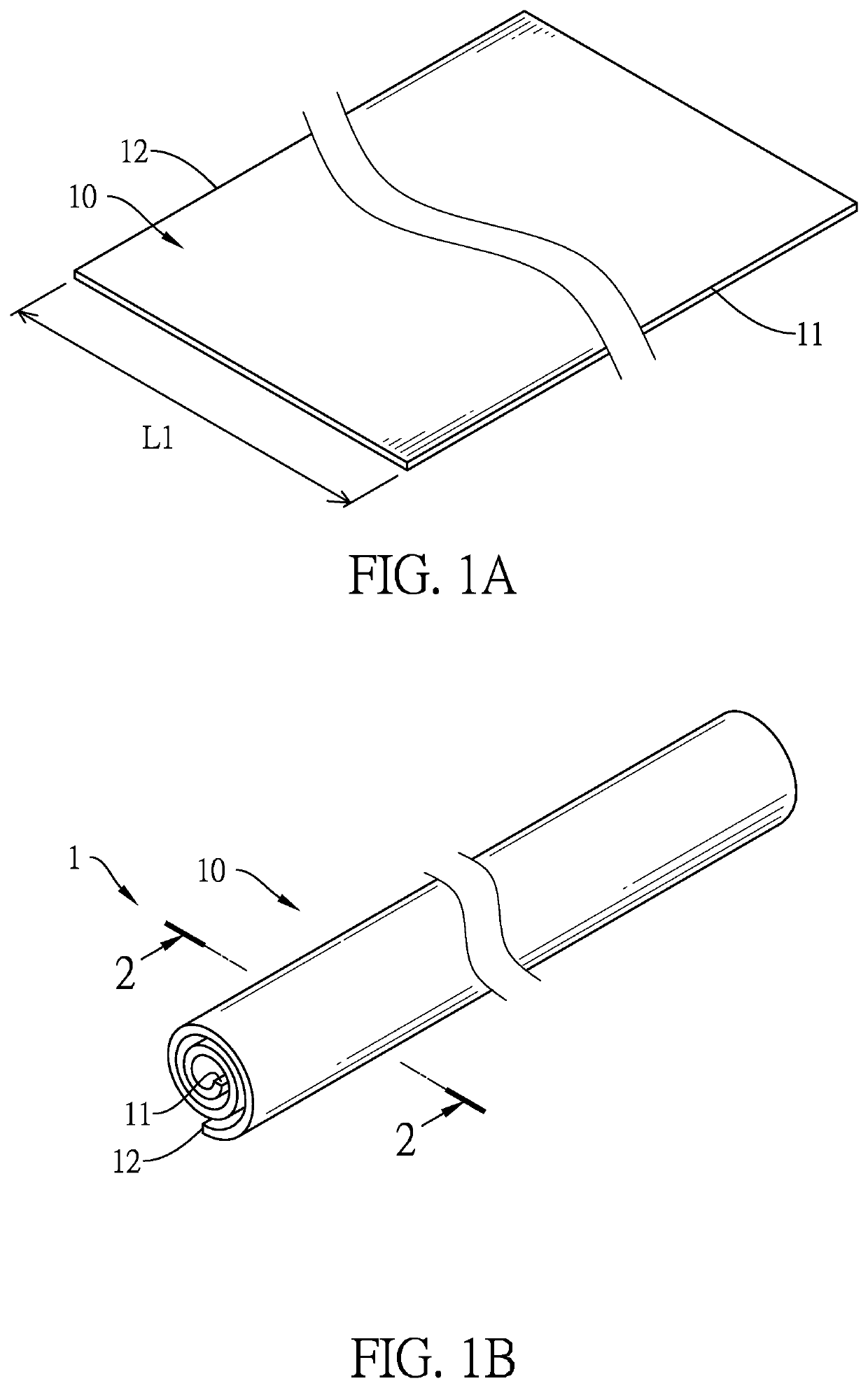

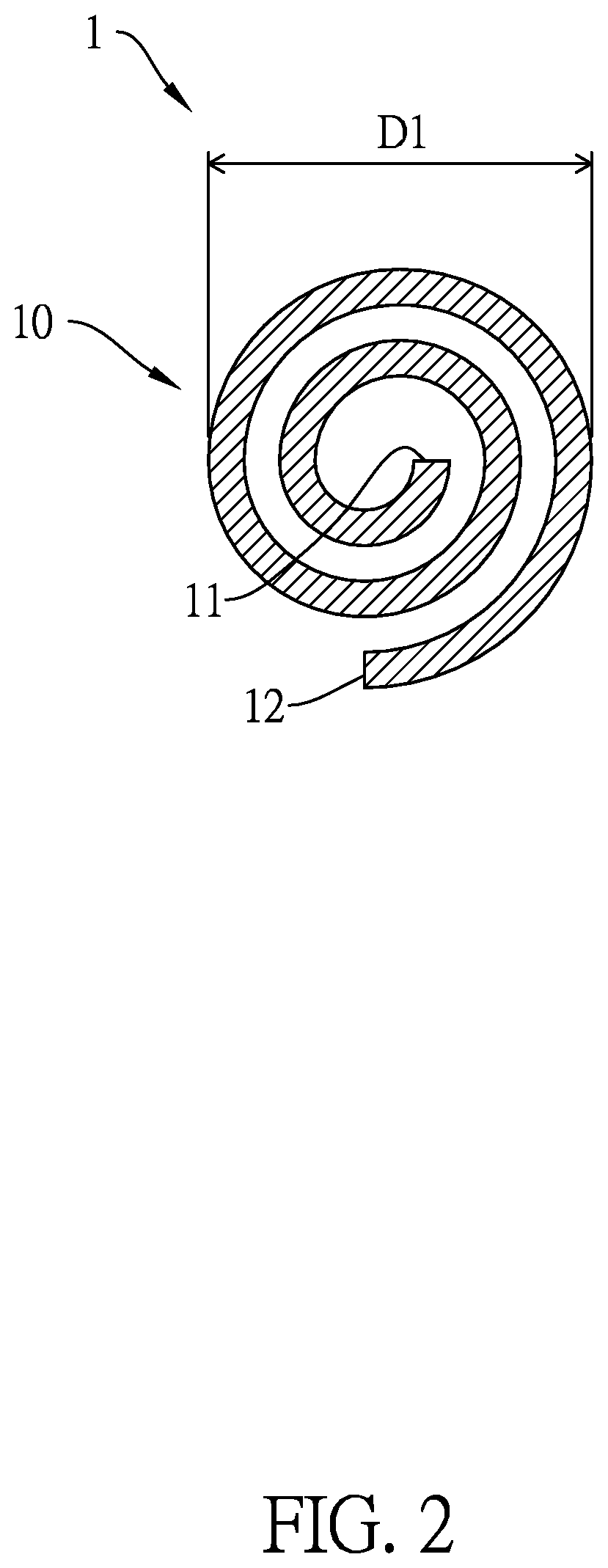

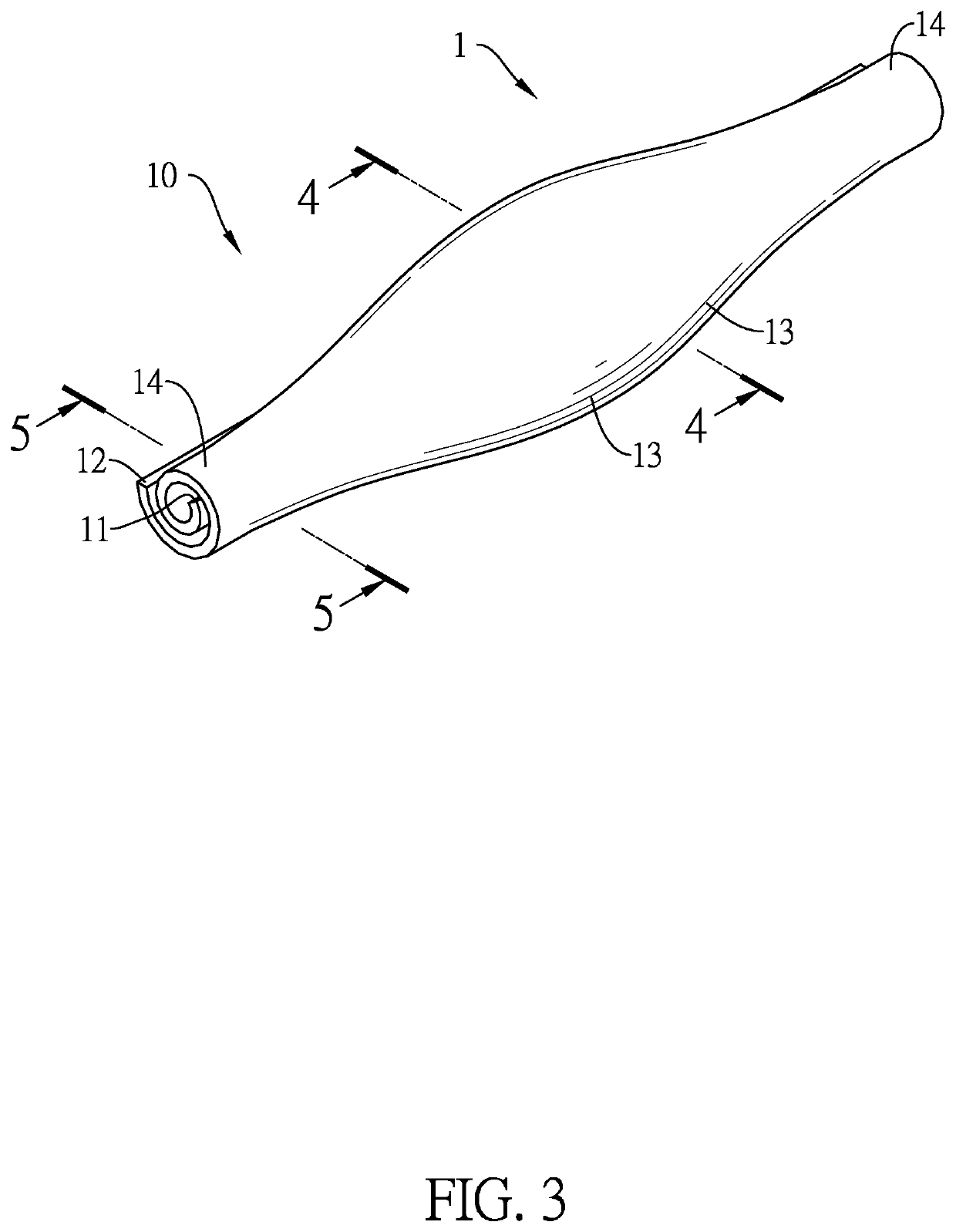

Rolled retraction cord and method for manufacturing the same

InactiveUS20180318052A1Reduced deformabilityEasy to shredImpression capsDomestic articlesStructural engineeringRetraction cord

Provided is a rolled retraction cord, which has flexibility and is made of a sheet rolled into a non-firm multilayer strip. The sheet has a first side edge and a second side edge, the first side edge and the second side edge are opposite and parallel to each other, and the rolled retraction cord is formed by rolling the first side edge of the sheet toward the second side edge of the sheet. Further provided is a method for manufacturing the rolled retraction cord.

Owner:CHANG FU LONG +1

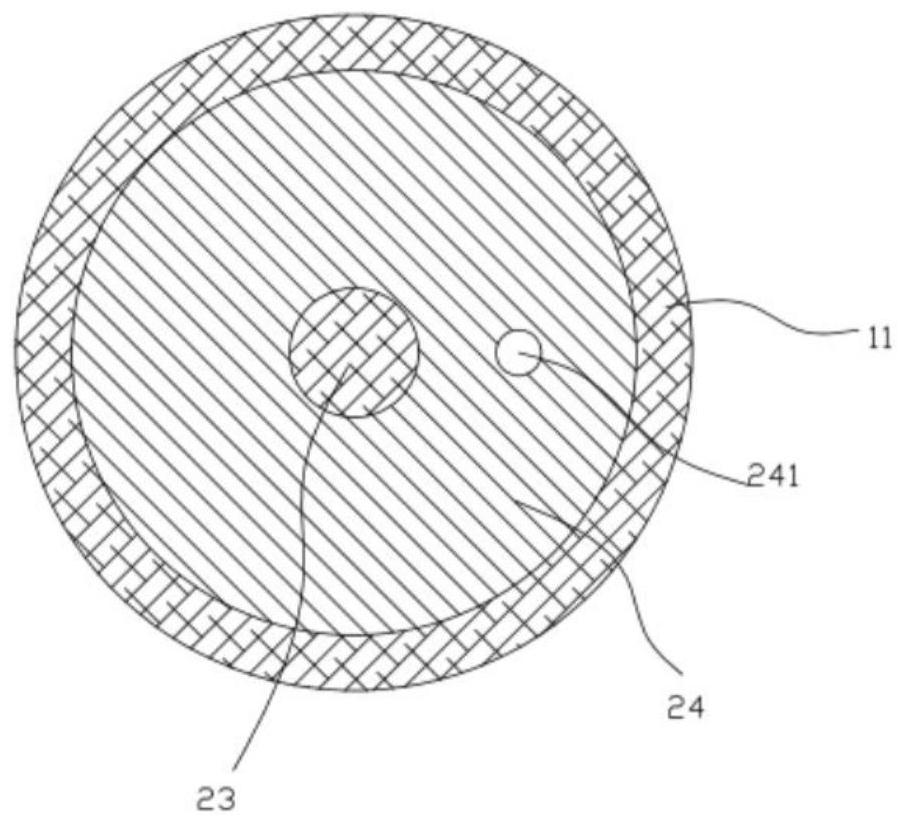

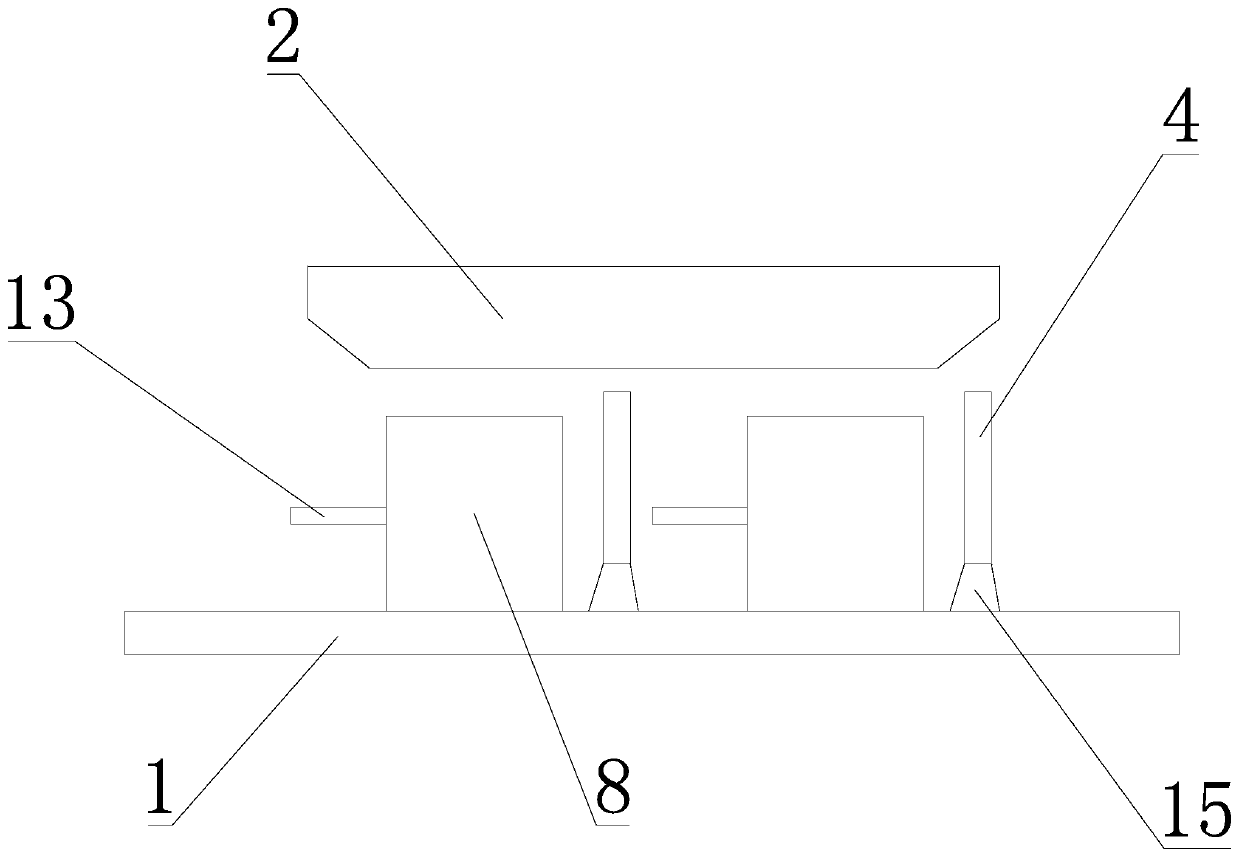

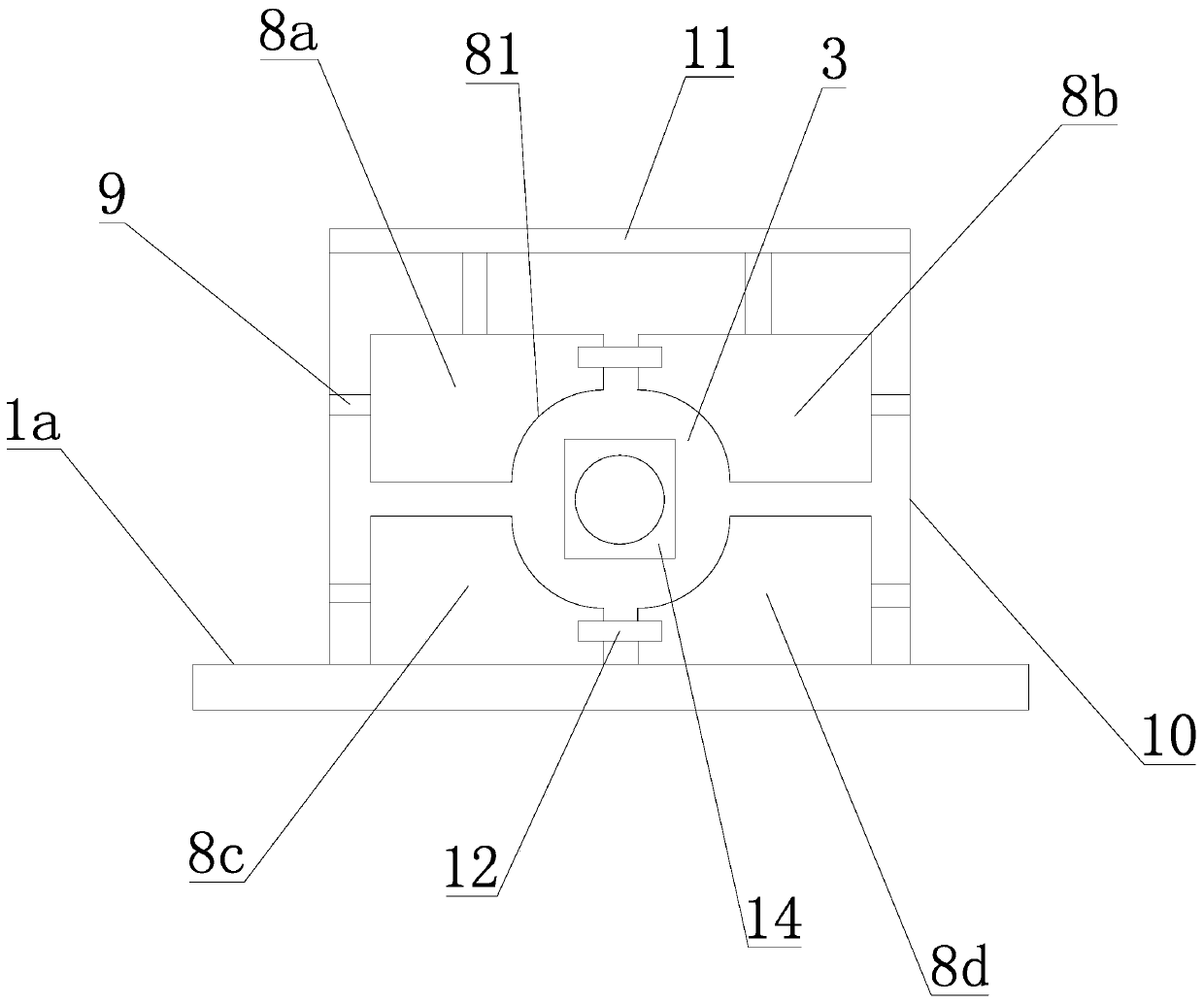

Thrombus resection device

The invention provides a thrombus resection device. The thrombus resection device comprises a catheter and a resection assembly, wherein the resection assembly comprises a knife net, a knife head, a transmission shaft and a power source; the knife net is fixed to the end face of the catheter; a hollowed-out part is arranged on the knife net; the knife head is connected to one end of the transmission shaft, and the power source is connected to the other end of the transmission shaft; the tool bit and at least part of the transmission shaft are located in the catheter, and the power source drives the knife head to rotate in the catheter through the transmission shaft; the knife head is a semi-circular-ring-like body, the surface, close to the knife net, of the knife head is the first surface, and the first edge and the third edge of the knife head are connected with the two ends of the second edge and the fourth edge respectively; and the knife head and the knife net form a cutting structure, the cutting structure comprises a first cutting edge and a second cutting edge, the first cutting edge is formed by the first edge and the third edge of the knife head, and the second cutting edge is located on the knife net. The thrombus resection device has the advantages of good thrombus resection effect and the like.

Owner:嘉兴嘉创智医疗设备有限公司

Shredding device of squid tentacles

ActiveCN110402995AImprove screening efficiencyArranged in orderCephalopods processingSquidEngineering

The invention relates to a shredding device of squid tentacles, and aims to solve the technical problem that in the prior art, the shape of the squid tentacles is fine and long, and shredding processing is not convenient, so that in the shredding processing of squids, the squid tentacles are often abandoned. The shredding device comprises a sieving device which is arranged on a machine frame and is used for sieving materials according to the dimension of the materials, wherein a material pressing device for fixing the sieved materials is arranged below the sieving device; the material pressingdevice is mounted on the mounting surface of the machine frame; the sieving device comprises a material sieving plate; materials fall into a material placing tank of the material pressing device through material sieving holes in the material sieving plate; and cutter heads for cutting the materials are located at one end of the material placing tank in the length direction of the material placingtank, and a pushing device for pushing the materials to slide along the material placing tank is arranged at the other end of the material placing tank. The shredding device of the squid tentacles disclosed by the invention can perform shredding processing on the squid tentacles of different thicknesses and different lengths; and the shredding process is simple, and the automation degree of the shredding device is high.

Owner:ZHEJIANG OCEAN UNIV

a thrombectomy device

Owner:JIAXING JIACHUANGZHI MEDICAL EQUIP CO LTD

Agricultural straw pulverizing equipment

The invention discloses agricultural straw pulverizing equipment. The equipment comprises a bottom plate, a collecting box and a pulverizing box, the top of the bottom plate is fixedly connected withthe bottom of the collecting box, the top of the collecting box is fixedly connected with the bottom of the pulverizing box, fixing blocks are fixedly connected with the parts, located on both left and right sides of the top of the bottom plate, of both left and right sides of the collecting box, the tops of the two fixing blocks are fixedly connected with a first air pump box and a second air pump box respectively, the interiors of the first and a second air pump boxes are fixedly connected with a first air pump and a second air pump respectively, and the bottoms of the air pumps are communicated with vacuum boxes through connecting nets. The invention relates to the technical field of pulverizing. The equipment has the advantages that by the cooperatively use of the first air pump, the second air pump, a filtering pipe and the vacuum boxes, materials with proper sizes are screened out, vacuum treatment is conducted under the action of the second air pump, fuel is directly produced, the fuel production cost is reduced, and the working efficiency is improved.

Owner:肥西县堰丰农业农民专业合作社

Making technology of honey sweet potato cake slices

ActiveCN108935577AEasy to processAutomate operationDough treatmentModified nutritive productsEngineeringPotato cakes

The invention relates to a making technology of honey sweet potato cake slices. The making technology is characterized by comprising the technological steps of cleaning sweet potatoes with seedlings;performing peeling, and performing rinsing to obtain shreds; immersing the shreds, and cutting the immersed shreds; performing pressing to obtain slices, and performing baking; performing atomizationand performing resurgence; and performing cutting to obtain slices, performing packaging and the like. Through adoption of the making technology disclosed by the invention, the original raw sweet potatoes are converted into small sweet potato cake slices, and then honey is combined, so that the honey sweet potato cake slices are plump in mouth feel, attractively in color, and convenient to carry and store. A special making technology is adopted, so that the sweet potato cake slices are moderate in soft and hard degree, rich in nutrients, unique in mouth feel and chewy.

Owner:湖南蜜蜂哥哥蜂业有限公司

Method for manufacturing rolled retraction cord

PendingUS20210059794A1Reduced deformabilityEasy to shredImpression capsDomestic articlesStructural engineeringRetraction cord

Owner:CHANG FU LONG

Cloth tearing pushing-pulling mechanism

The invention discloses a cloth tearing push-pull mechanism, which comprises a guide rod, the rear end of the guide rod is provided with a grip rod, the front end of the guide rod is provided with a connecting pipe, the guide rod is provided with a guide buckle, and the guide rod is provided with a push rod , the push rod passes through the guide buckle, and the front end of the push rod is provided with a push block. In the present invention, one end of the cloth can be connected with the connecting pipe, and the other end of the cloth can be connected with the push block, and the push rod can be pulled along the guide bar, so that the cloth can be shredded conveniently.

Owner:胡和萍

A tobacco shredding machine

ActiveCN111642784BRealize automatic cuttingReduce manual operationsTobacco treatmentAgricultural engineeringElectric machinery

The invention relates to a shredding machine, in particular to a tobacco leaf shredding machine. The technical problem of the present invention is to provide a tobacco shredding machine that can automatically cut the tobacco leaves, so that the tobacco leaves are automatically moved under the cutting knife, so as to facilitate the manual collection of the shredded tobacco. The technical scheme of the present invention is: a tobacco leaf shredder, comprising: a base with a motor on its side, a cutting mechanism installed on the front side of the base, and the cutting mechanism is connected with the motor; an automatic feeding mechanism, the left side of the base is provided with Automatic feeding mechanism. The present invention realizes the automatic cutting of tobacco leaves through the cutting mechanism, and does not need to manually use a cutting knife to cut the tobacco leaves. At the same time, the cut tobacco is collected through the collection box, and the automatic feeding mechanism realizes the intermittent movement of the tobacco leaves, so that the tobacco leaves can be moved intermittently. Automatically move to the bottom of the cutting knife, which is convenient for the cutting knife to cut, and the rolled tobacco leaves are clamped by the clamping mechanism to prevent the rolled tobacco leaves from being scattered during the cutting process.

Owner:肖锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com