Processing device for kitchen waste

A technology for kitchen waste and treatment device, which is applied in the field of waste treatment and can solve the problems of odor, garbage polluting the environment, and excess liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical features of the solution can be clearly described, and the solution will be described through specific implementation modes below.

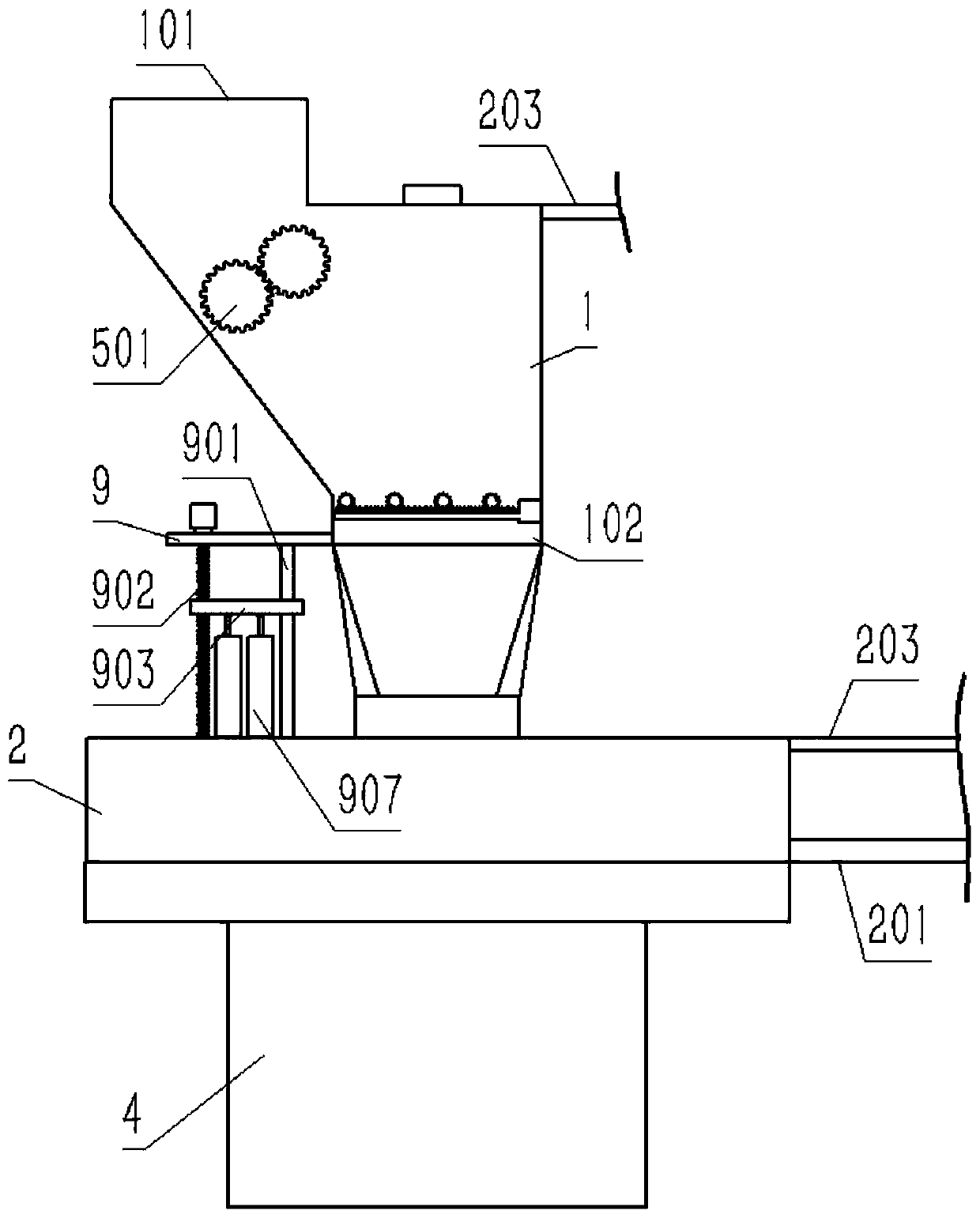

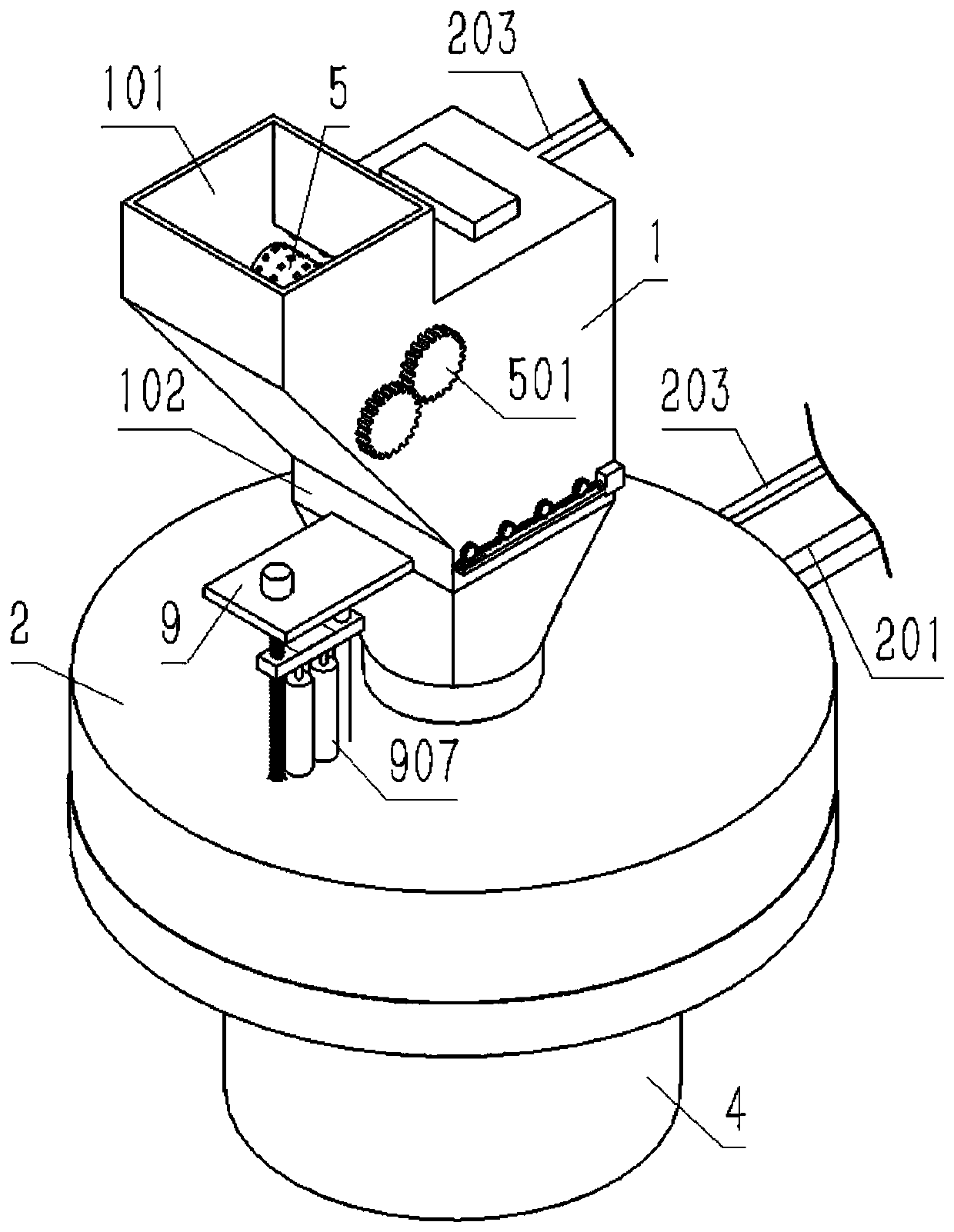

[0047] see Figure 1 to Figure 10 As shown, this embodiment is a kitchen waste treatment device, which includes a crushing tank 1 and a water filter tank 2 that are fixedly connected from top to bottom. Below the feeding port 101, a rolling mechanism is provided.

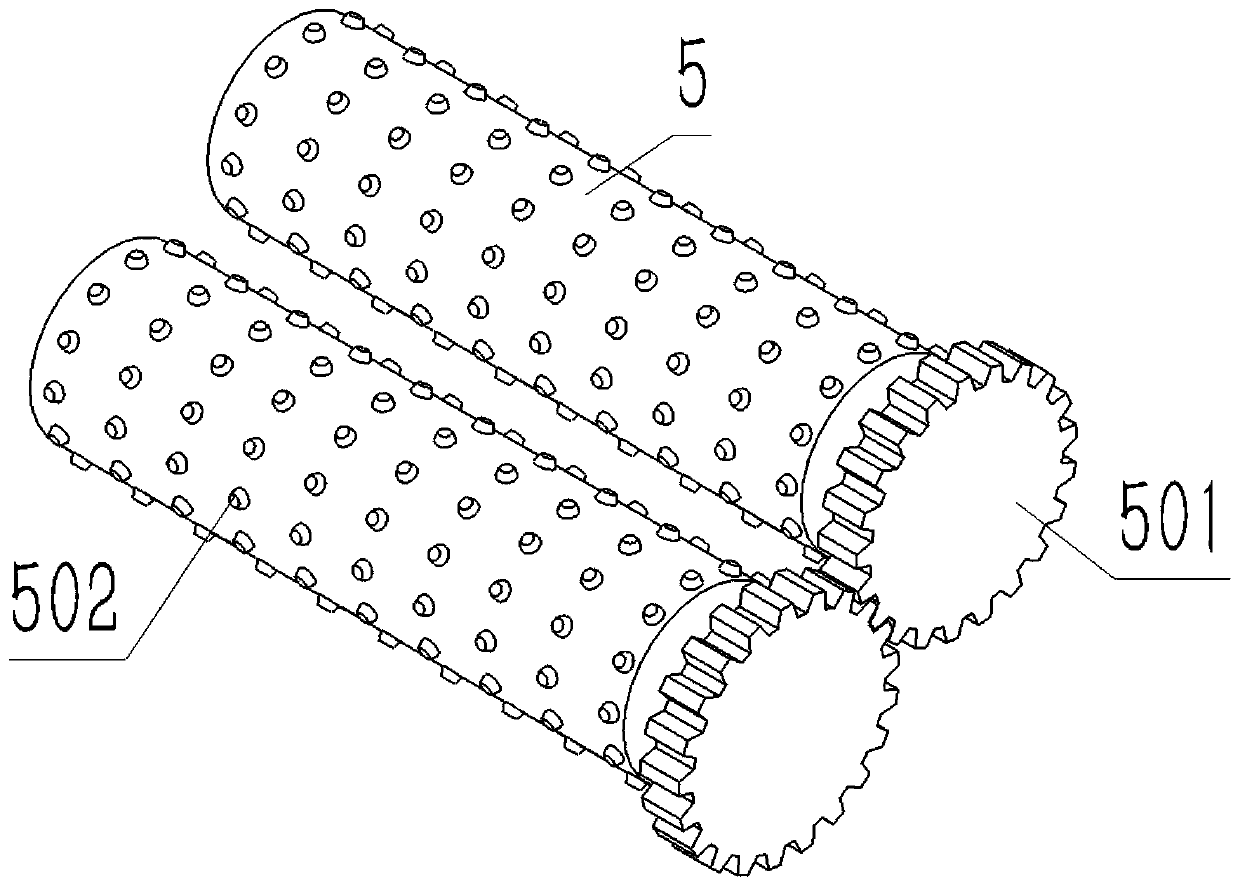

[0048] The crushing mechanism includes two rollers 5 that are rotatably connected to the inner wall of the crushing box 1 and arranged in parallel. The same end of the central shaft of the two rollers 5 runs through the inner wall of the crushing box 1 and extends to the outside of the crushing box 1. The two rollers The roller gear 501 is coaxially arranged at the same end of the rotating shaft outside the crushing box 1, and the two roller gears 501 mesh with each other. The central rotating shaft of one roller 5 is connected with a roller motor, and the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com