Technology for cigarette production

A process method and cigarette technology, which are applied in the directions of tobacco, tobacco preparation, and tobacco treatment, can solve the problems of complex cigarette production process, increased production energy consumption, long production process, etc. The effect of packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

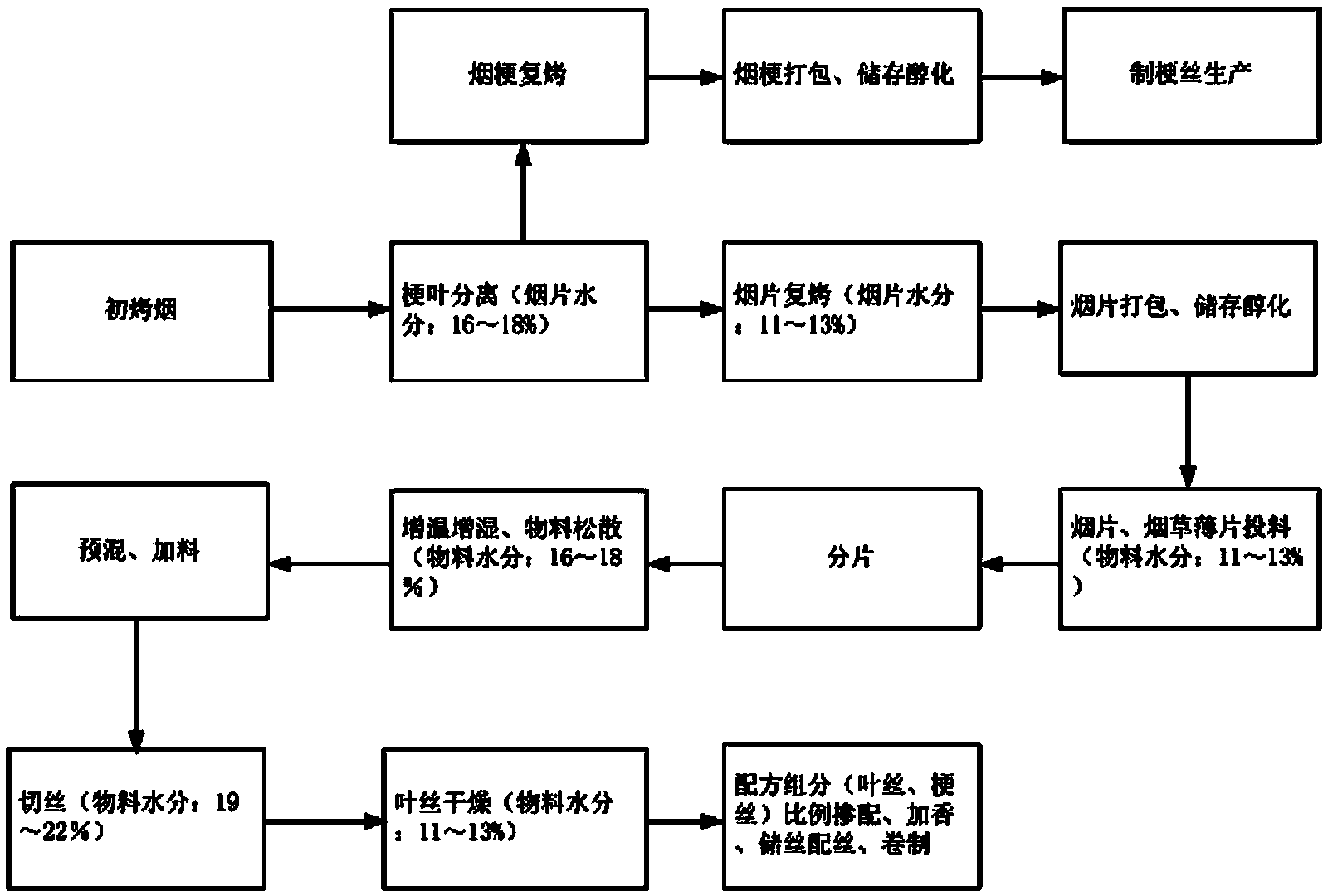

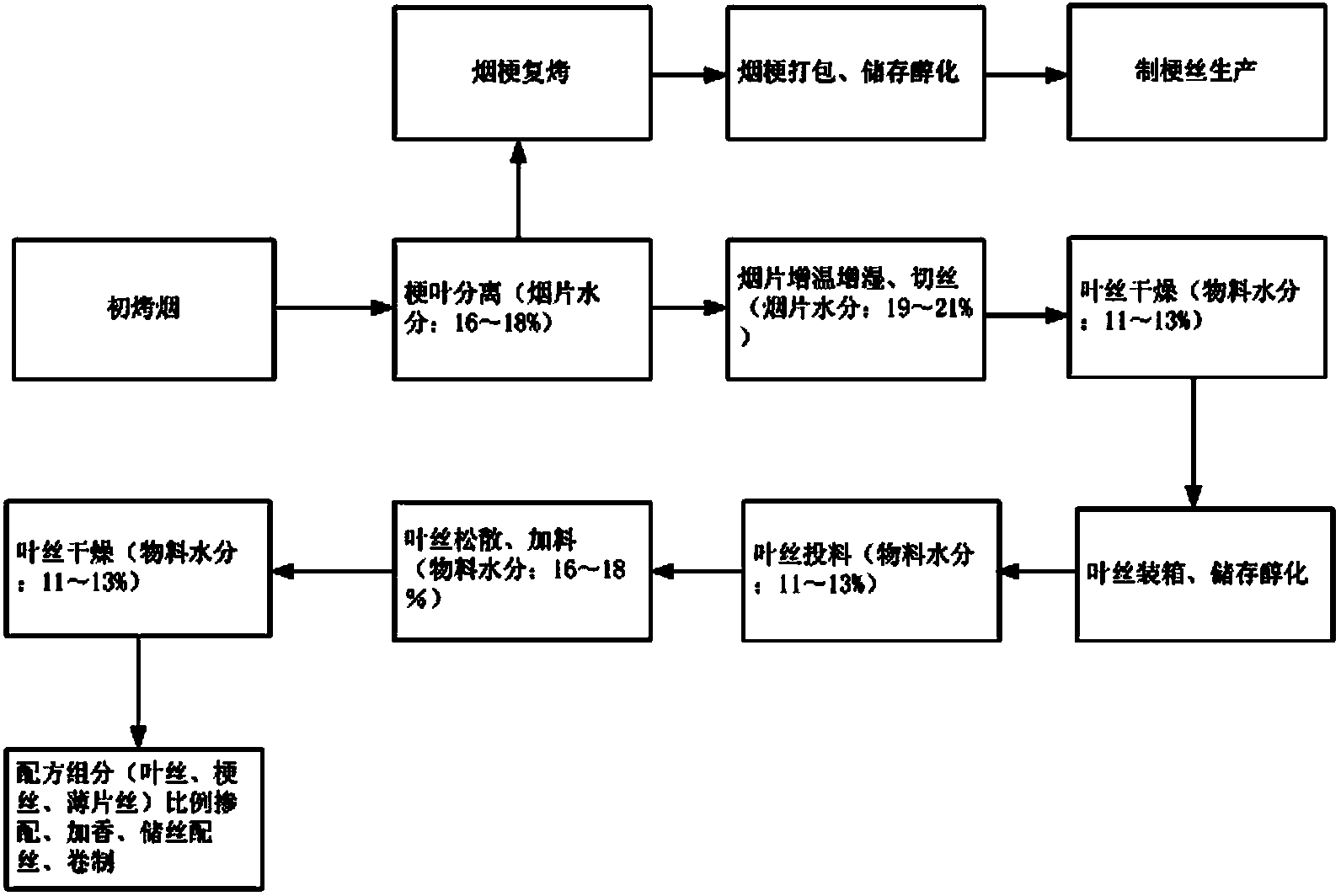

Method used

Image

Examples

Embodiment Construction

[0015] Warming and humidifying (2-4% moisture increase) the tobacco slices (moisture content 16-18%) separated from stems and leaves in the production process of threshing and re-baking so that the tobacco slices meet the shredding process requirements (moisture content 19-21%) %, temperature 20~30℃), the tobacco sheet is cut into a certain width (0.8~1.2mm) by the cutting equipment, and then the moisture is adjusted to 11~ 13%, the dried leaf silk is packed into a special wooden silk storage box and sent to the raw material warehouse for storage and aging. The leaf shreds after storage and alcoholization are put into production according to the brand production formula requirements. They should first be processed by the drum type heating and humidifying equipment through the flow control of the turning box feeder. , and then followed by loosening treatment; the loosened leaf silk enters the drum-type leaf silk feeding equipment through flow control to add feed liquid, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com