Method for processing tobacco stems into shredded stems

A technology for tobacco stems and cut stems, which is applied in the fields of tobacco, tobacco processing, and application, can solve the problems of not fully considering tobacco stems that cannot be used and digested in time, waste of water resources and heating power, and affecting the cleanliness of the production environment. It is convenient for large-scale production and application, improving the quality of cut stems and realizing the effect of clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

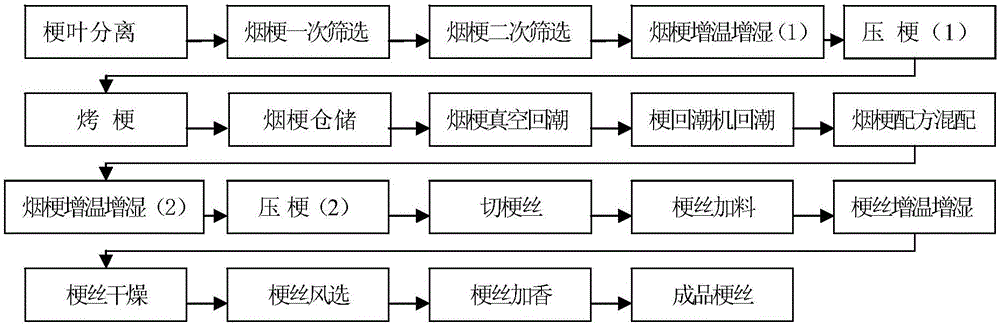

[0033] Production of threshing and re-roasting tobacco stems: after conventional threshing of tobacco leaves, the stem leaves are separated to obtain tobacco stems with a moisture content of 17-24%, and then the tobacco stems are screened once with a sieve with an aperture of 20×5.5mm to remove less than Tobacco stems with an aperture of 20×5.5mm are screened continuously with a sieve of 40×6.0mm to remove stem heads and stem pieces larger than 40×6.0mm. The sieved tobacco stems are quantitatively transported to the temperature increasing and humidifying equipment at a flow rate of 1500kg / hour, and the temperature increasing and humidifying treatment is carried out under the steam pressure of 0.5Mpa, so that the moisture content of the tobacco stems reaches 26-27%, and then the obtained Tobacco stems are pressed with a stem press machine, the gap between the press and stem is 0.8-1.3mm, and the pressed tobacco stems are roasted with a tobacco stem roaster until the moisture req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com