Patents

Literature

56results about How to "Reduce pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance foaming cement and preparation method thereof

The invention relates to high-performance foaming cement, which comprises cement slurry and foams, wherein the cement slurry is prepared from the following raw materials in parts by weight: 100 parts of cement, 10-30 parts of gypsum powder, 10-50 parts of active admixtures, 10-40 parts of mineral admixtures, 1-5 parts of re-dispersible gelatine powder, 0.5-1.5 parts of cellulose ether, 0.2-1.0 part of water reducing agent, 0.1-0.5 part of water repellent and 40-90 parts of water; and the foams are prepared from the following components in parts by weight: 1 part of foaming agent, 0.2-0.8 part of foam stabilizer and 30-50 parts of water. A preparation method of the high-performance foaming cement comprises the steps of: (1) preparing the cement slurry; (2) preparing the foams by using a foaming machine; and (3) mixing and uniformly stirring the cement slurry and the foams according to the weight ratio of 1:(0.1-1), and pouring and molding. The high-performance foaming cement disclosed by the invention has high closed porosity and small shrinkage value, and integrates the performances of heat insulation, sound insulation, water repellent, shock resistance, fire protection, durability, low carbon and environmental protection into a whole.

Owner:辽宁际洲环保节能建材有限公司

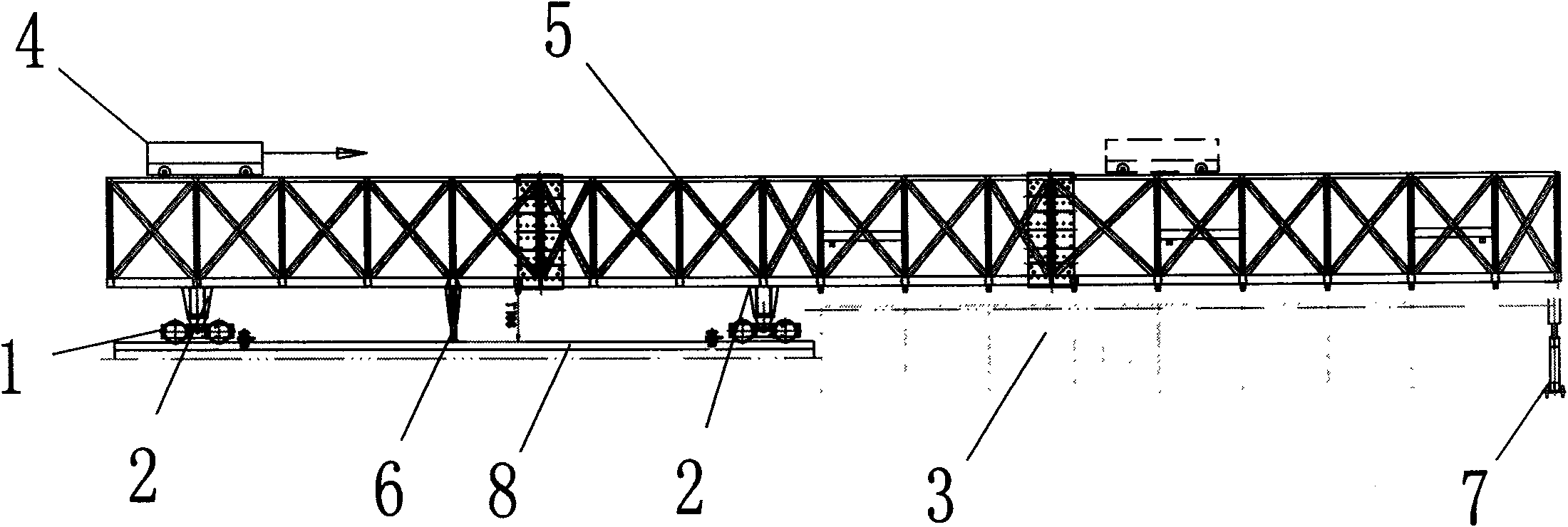

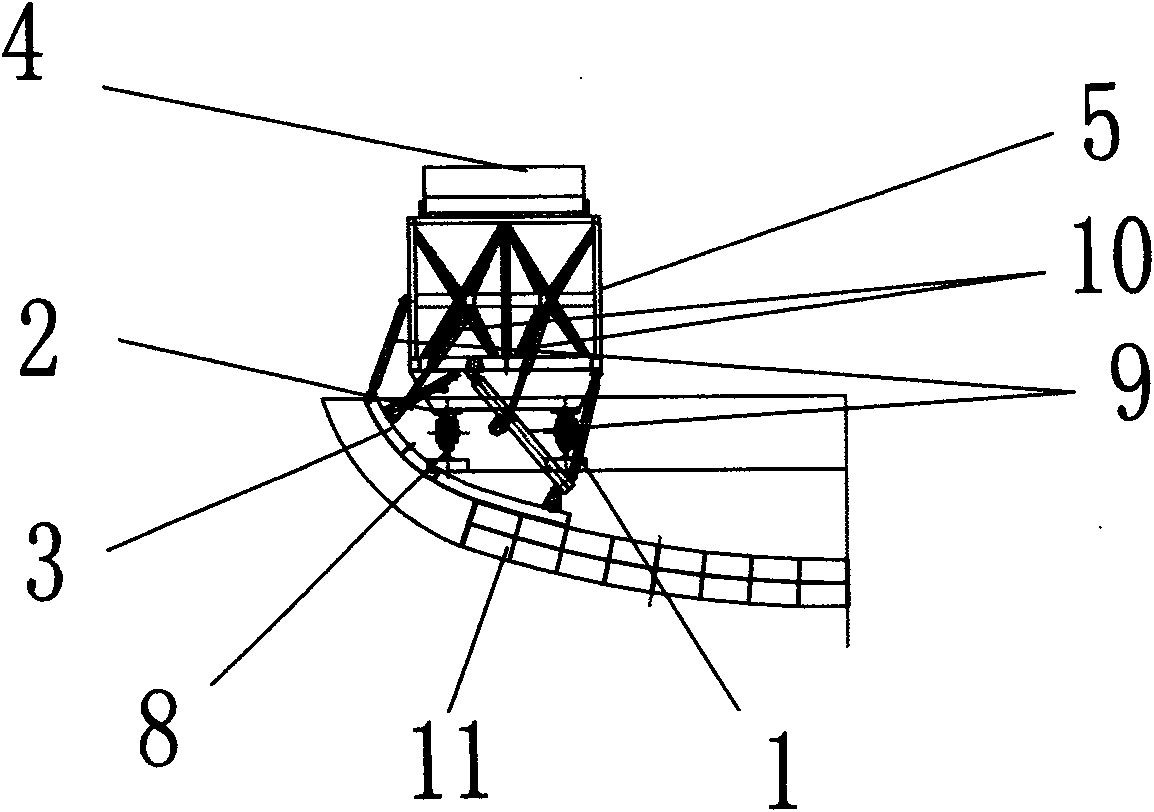

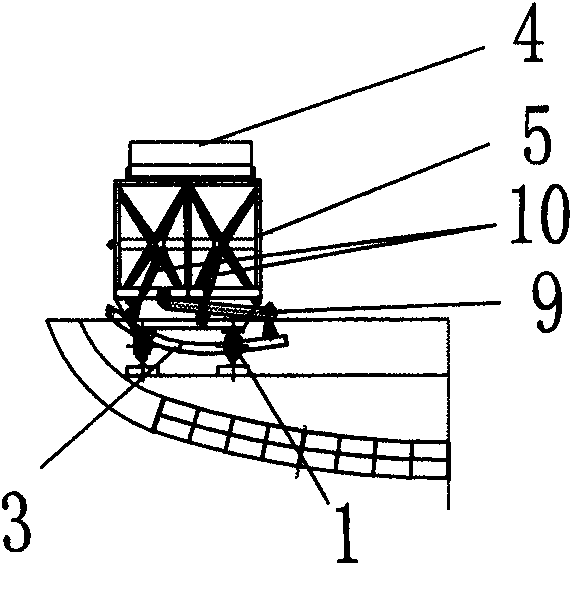

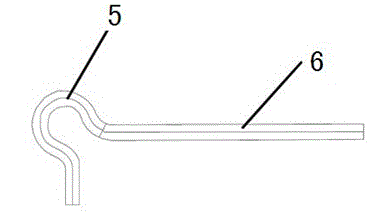

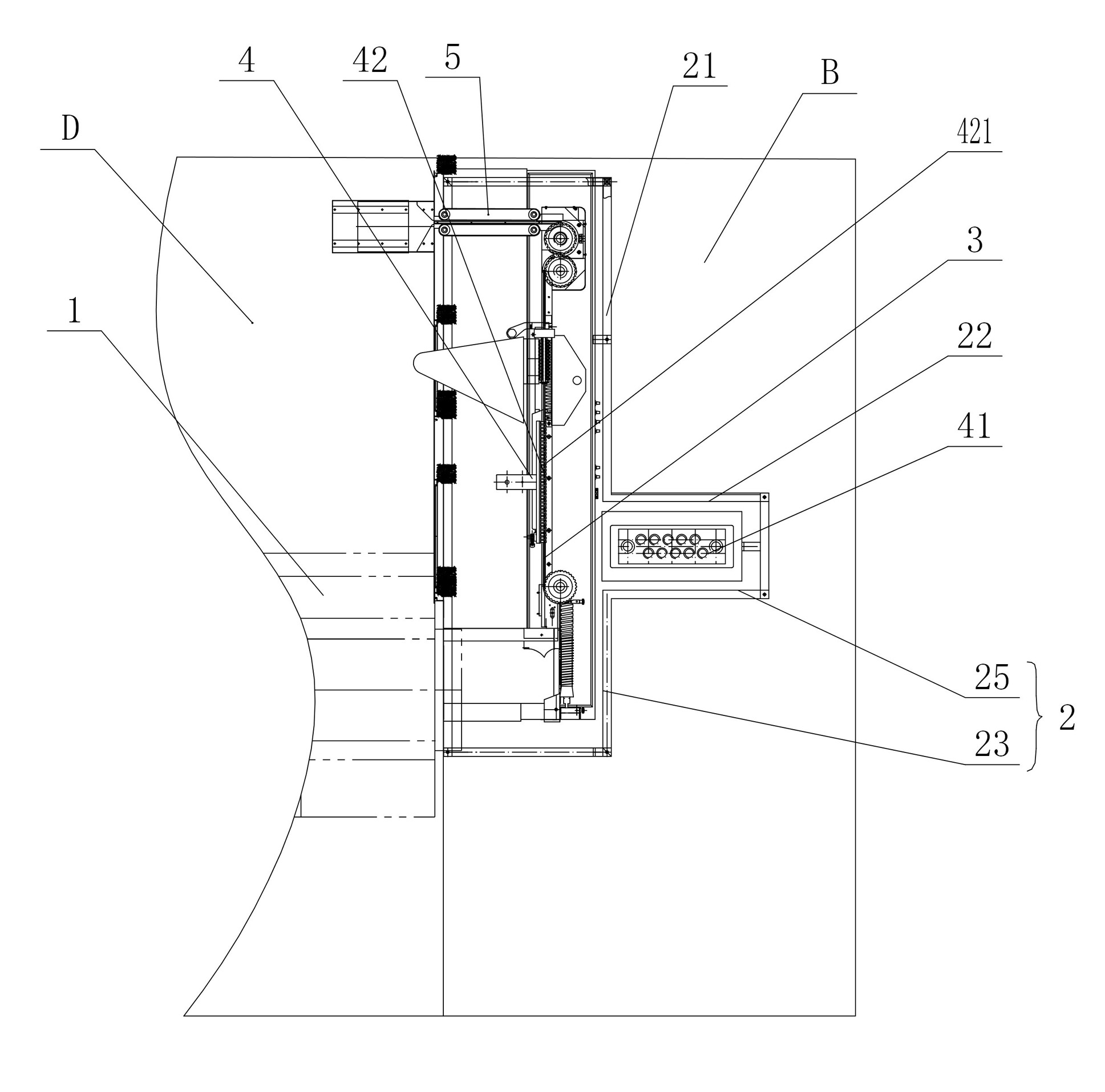

Self-propelled inverted arch template construction method

The invention discloses a self-propelled inverted arch template construction method for a tunnel, which comprises the following construction steps of: setting out a control line for an inverted arch digging section and a longitudinal construction joint according to the design requirement; performing smooth-wall blasting digging on an inverted arch of the tunnel; moving an inverted arch trestle in place; conveying inverted arch stone slag out of the tunnel by using an excavator and a conveying device and abandoning the stone slag in a slag field, and cleaning an inverted arch base; assembling an inverted arch end template; laying steel rails, and moving the inverted arch template to longitudinally move in place per se; starting a hydraulic device to lower the inverted arch template, and supporting the template firmly by using a screw jack; pouring inverted arch concrete; and curing the concrete with equal strength, folding the screw jack, withdrawing a hydraulic cylinder, and releasing a die. The construction method has low cost, is convenient to operate, and improves the construction efficiency; and the longitudinal construction joint is vibrated densely compared with common template construction, and has positive effect of improving the construction quality of tunnel engineering.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

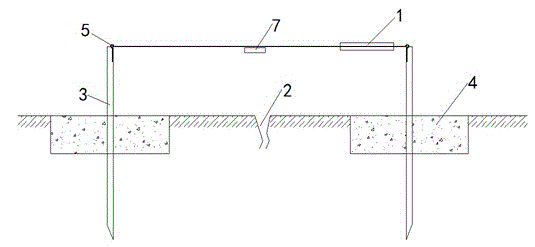

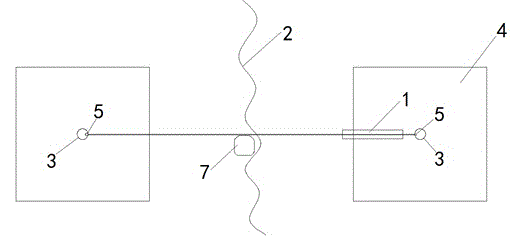

Simple monitoring device for earth surface cracks

InactiveCN104898180AImprove stabilityIncrease the scope of applicationGeological measurementsSteel tubeEngineering

The invention discloses a simple monitoring device for earth surface cracks. The device includes a convergence instrument, a geological compass and two fixed rods, the two fixed rods are located at two sides of an earth surface crack, and a connecting line of the two fixed rods is vertical to an earth surface crack trend; hooks on two ends of the convergence instrument are hung on the tops of the two fixed rods, and the geological compass is close to a steel ruler of the convergence instrument too measure an azimuth angle of the connecting line of the fixed rods; the fixed rods adopt hollow stainless steel tubes, reflective paints are painted on surfaces of upper parts of the stainless steel tubes, and tail ends of the stainless steel tubes are diagonal planes convenient to insert in soil mass; the stainless steel tube and an edge of the earth surface crack of the same side have an interval of at least 1m; the tops of the stainless steel tubes are 0.3 to 0.7m from an earth surface; and the hook of one end of the convergence instrument is extended through a connecting rod. The simple monitoring device for earth surface cracks only needs to firmly hammer the stainless steel tubes into the soil mass, and thus construction is very simple; and the device can be used repeatedly, thereby reducing monitoring cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

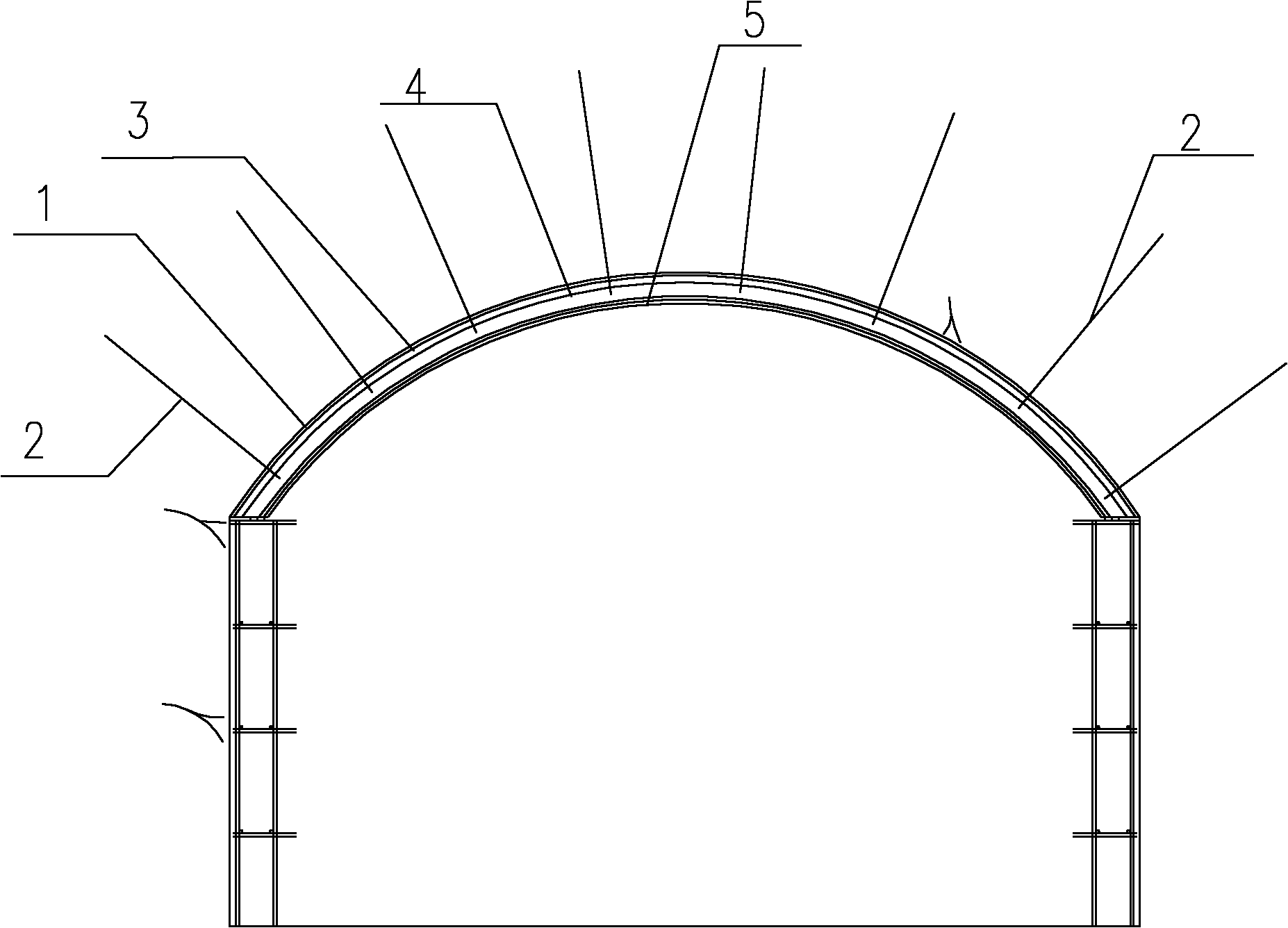

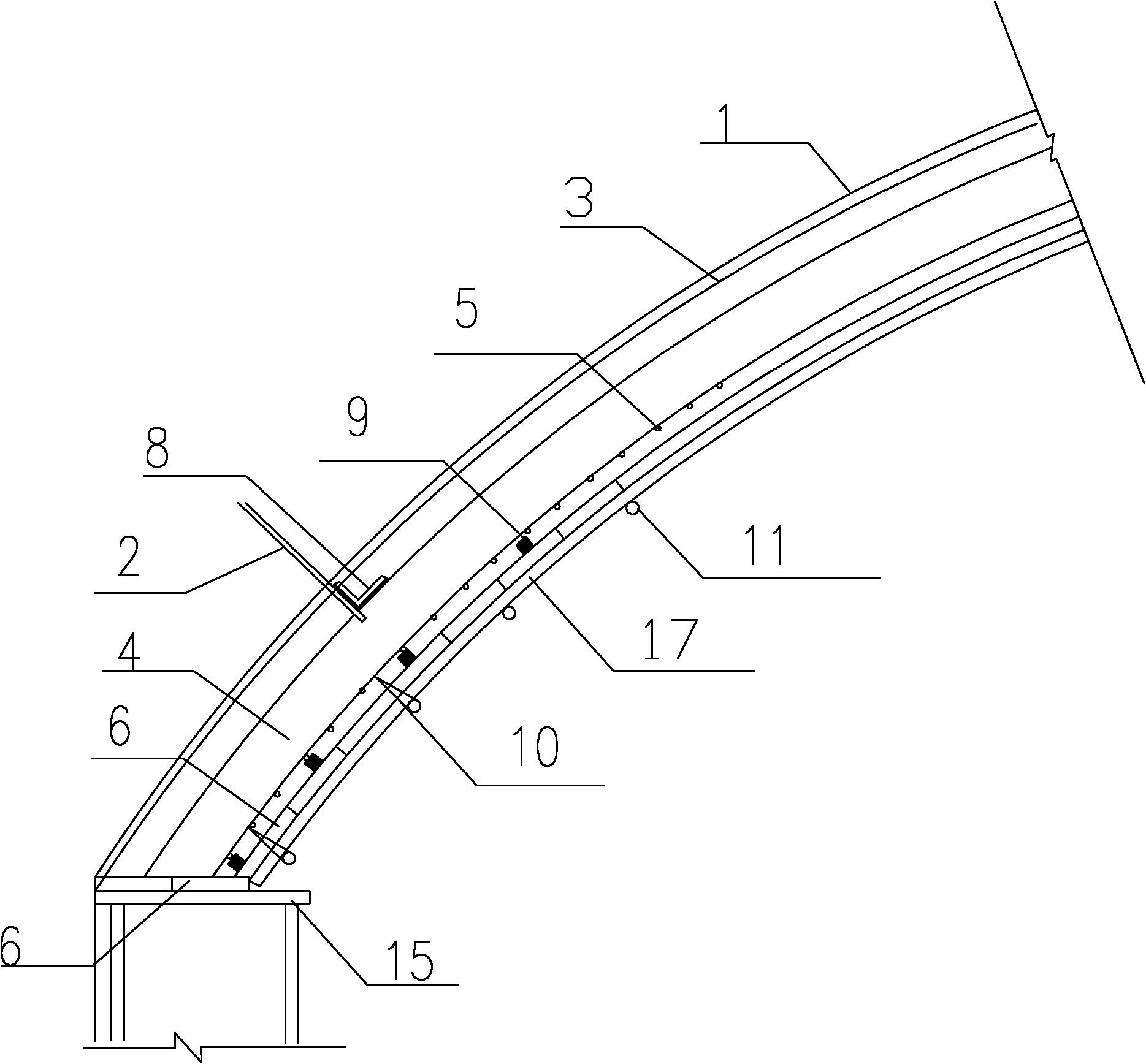

Cavern arch mould spraying concrete construction structure and process

ActiveCN101936170AEffectively closedShort construction periodUnderground chambersBuilding reinforcementsFalseworkUnderground cavern

The invention discloses a cavern arch mould spraying concrete construction structure and a cavern arch mould spraying concrete construction process. The structure comprises an anchor rod, a steel structure, concrete and a template, wherein the anchor rod is fixed in a bed rock; the steel structure is fixed through the anchor rod; the detachable template is suspended and fixed and forms a cavern arch pouring space with the bed rock together; and the concrete is sprayed into the pouring space through the template. The construction process comprises the following steps of: rock bed surface treatment, anchor rod construction, inner steel fabric installation, I iron installation, outer steel fabric installation, template installation, concrete spraying and the like. The construction needs no concrete delivery pump, does not need to build a full bearing scaffold and needs only a few constructors and spraying equipment. Therefore, construction materials are greatly saved; the construction period is short; arch lining concrete can be substituted by the mould spraying concrete of an underground cavern permanent structure; and the arch mould spraying concrete is more convenient to operate and the quality is assured.

Owner:SINOHYDRO BUREAU 7 CO LTD

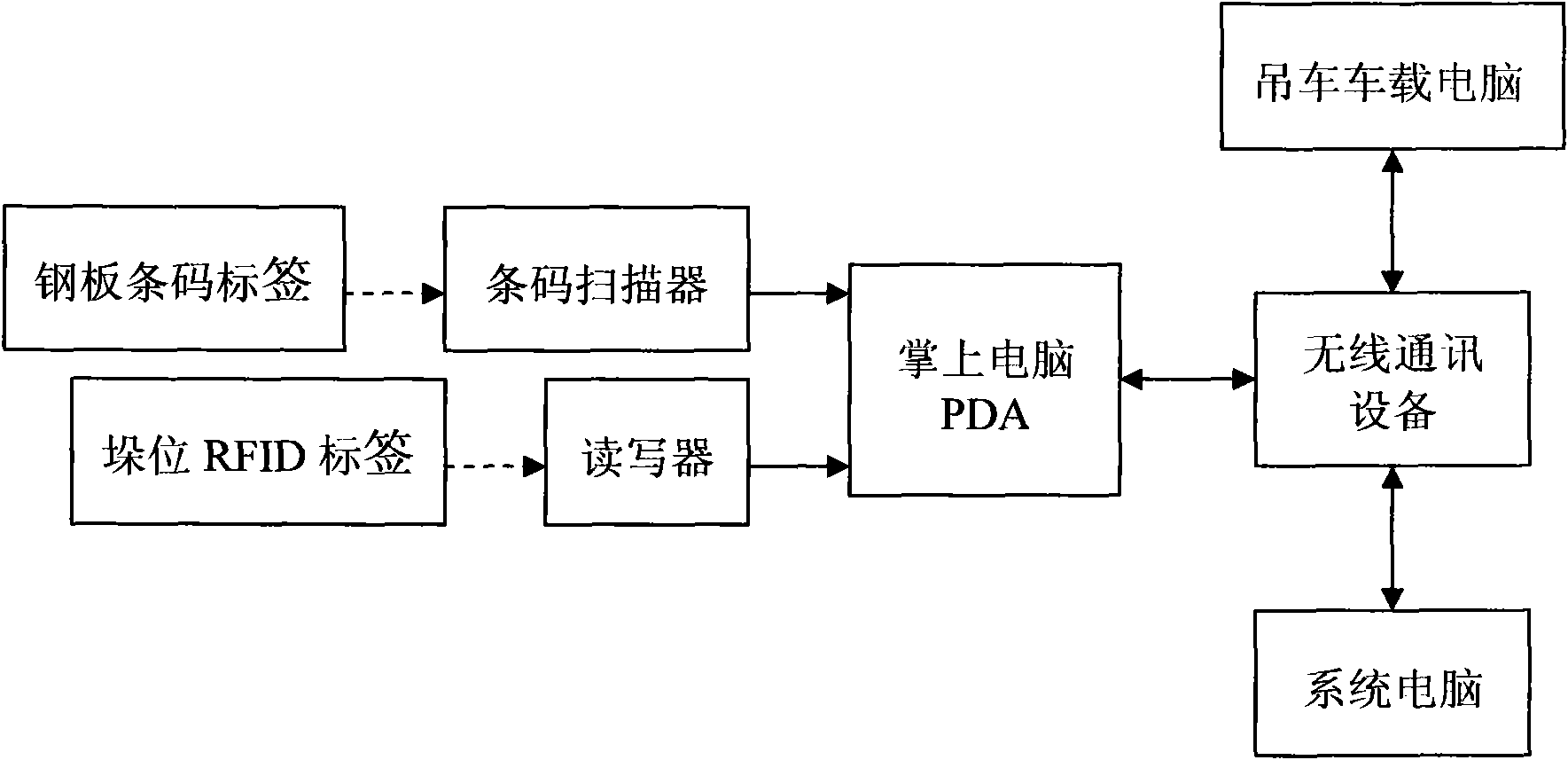

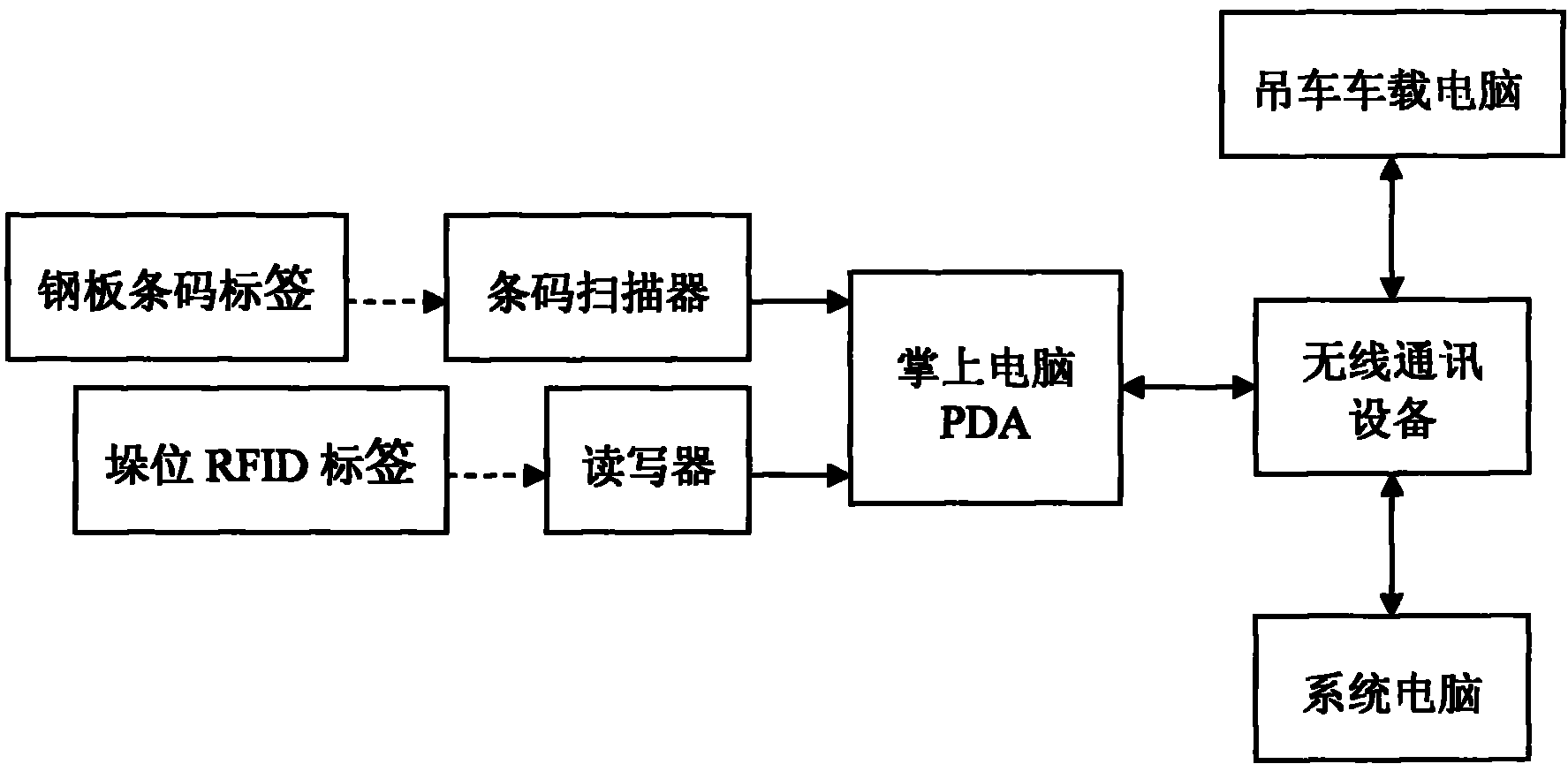

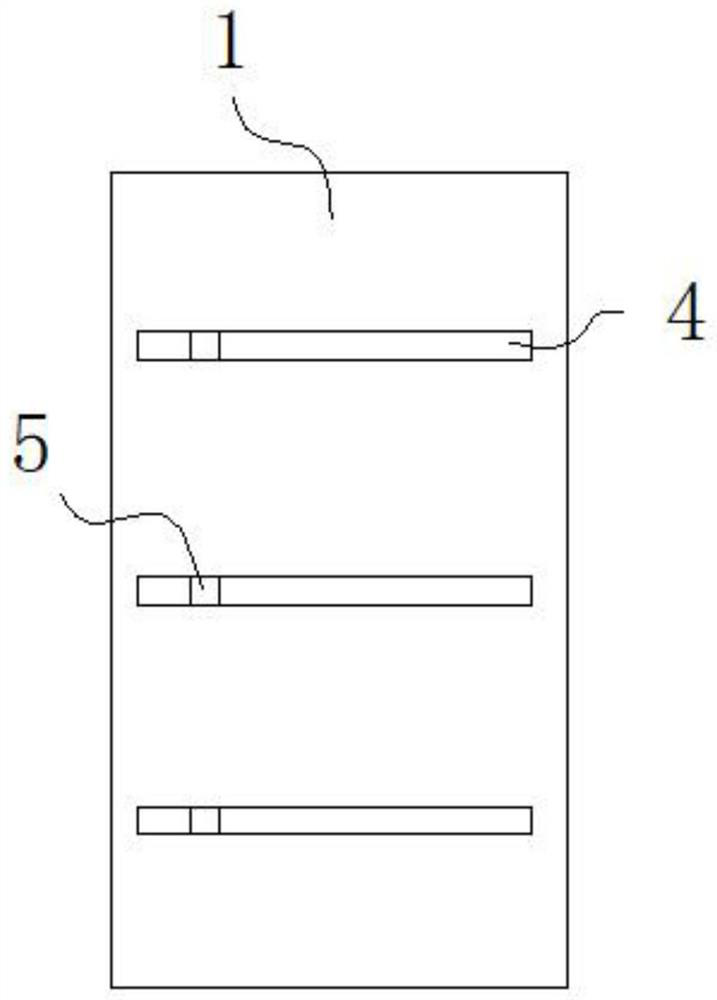

System for controlling in and out of storage of steel plates

InactiveCN101894324AReduce errorsAccurate informationEnergy industryCo-operative working arrangementsIn vehicleSteel plates

The invention discloses a system for controlling in and out of storage of steel plates. The system is characterized in that a steel plate is provided with a bar code label, and a bar code scanner thereof is connected with a palm computer PDA (Personal Digital Assistant); an RFID (Radio Frequency Identification) label is arranged at each stack position in a warehouse, and a reader-writer thereof is connected with the palm computer PDA; and the palm computer PDA is connected with a crane vehicle computer and a system computer through a wireless communication apparatus. The system shortens the time of ERP (Enterprise Resource Planning) information update such that the daily update of the information becomes the update in time, provides timely material information for production management, reduces the working time of workers from 12 h per day at present to 8-9 h, reduces errors of steel plate information and provides more accurate information for management, and decreases the unnecessary material-pouring and return and greatly saves electric power consumption.

Owner:大连斯博瑞科技有限公司

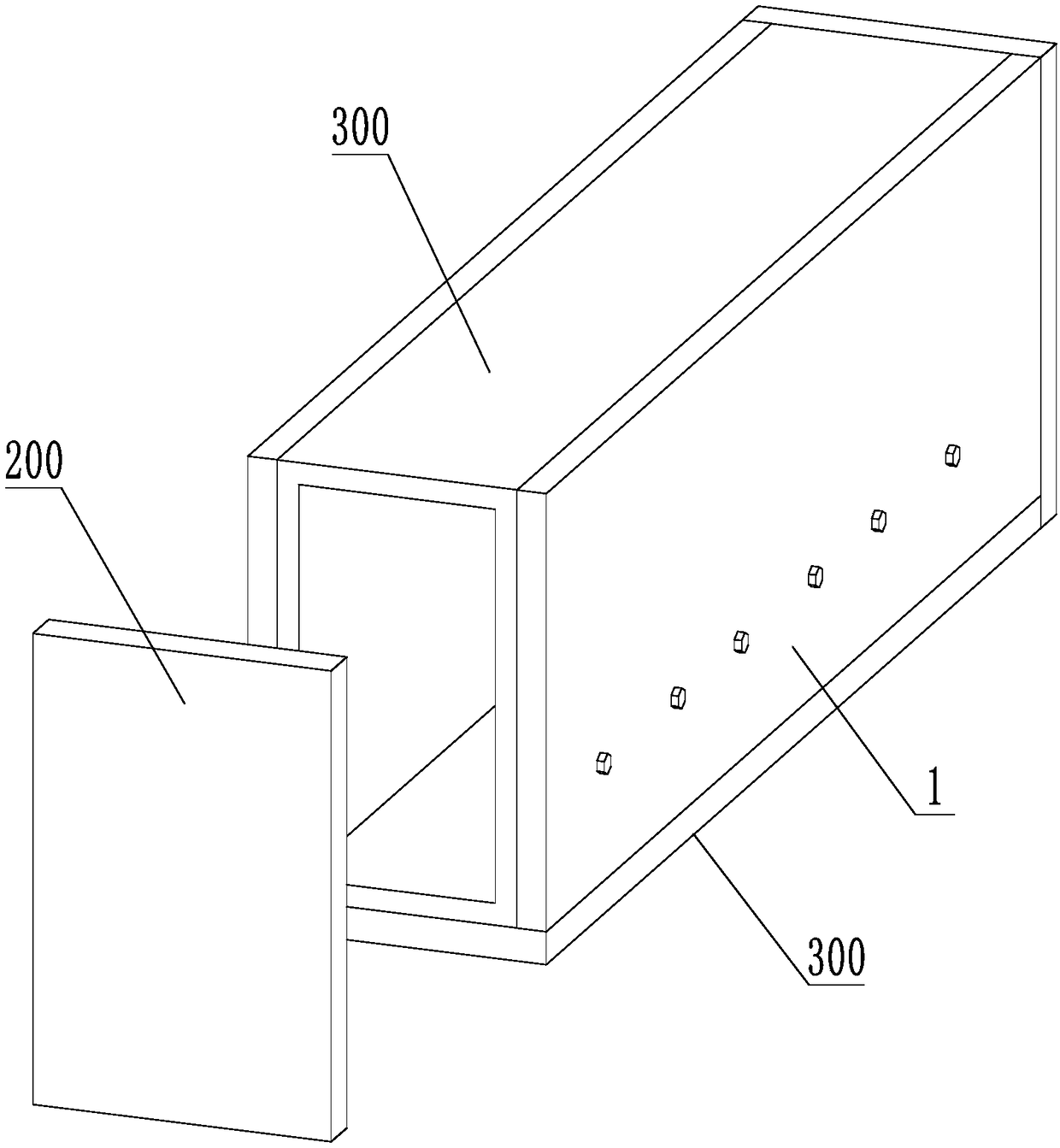

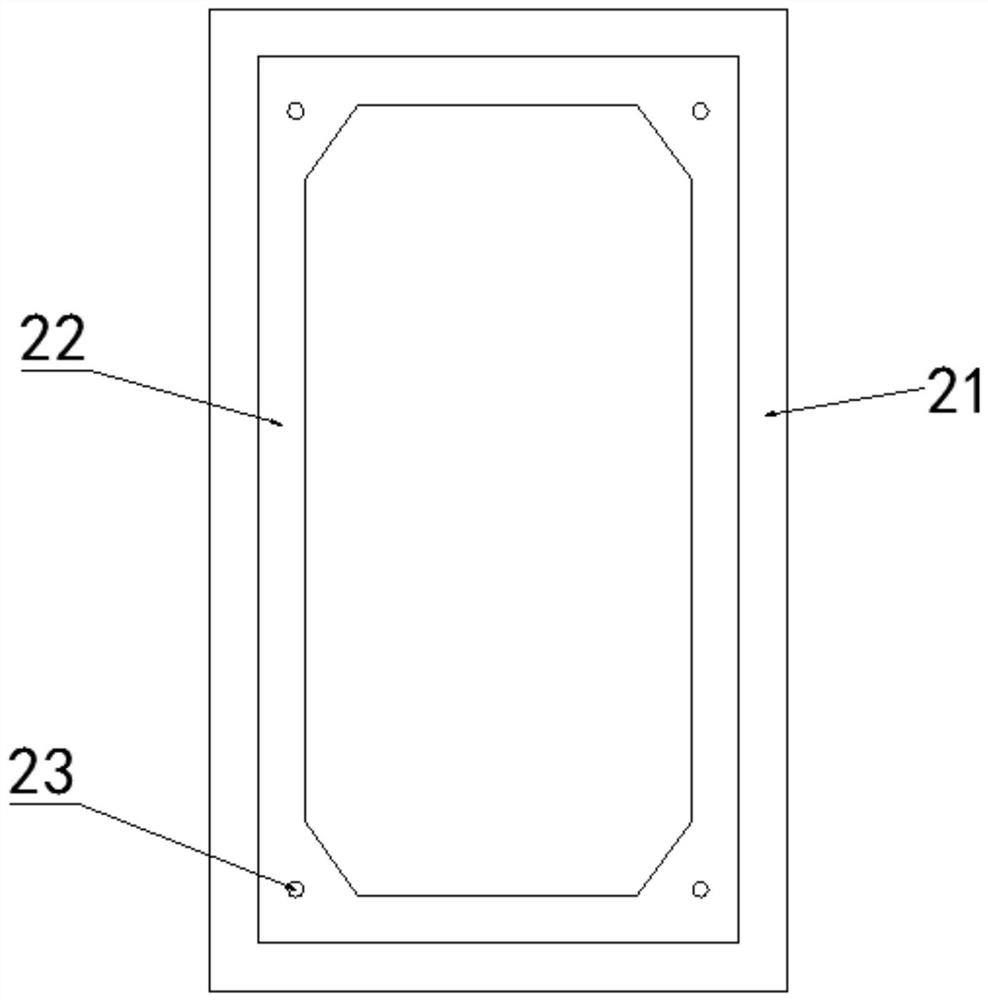

Roughening-free construction method and mould for precast hollow slab girder

ActiveCN108908662AReduce construction difficultyClosely connectedDischarging arrangementMouldsPlate girderBuilding construction

The invention relates to a roughening-free construction method and mould for a precast hollow slab girder, relates to the field of bridge building construction, and solves the problem that the surfaceof the precast hollow slab girder is difficultly roughened. The roughening-free construction mould comprises a bottom formwork of a rectangular groove structure with an opening in the upper end, an end formwork and a lateral formwork, wherein the lateral formwork comprises an external plate and a plurality of inner lining plates which are detachably connected to the inner side of the external plate, a plurality of paralleled protruding ribs which make contact with the surface of the precast hollow slab girder are arranged on the inner surfaces of the inner lining plates, grooves are formed inthe inner side face of the external plate, the inner lining plates are inserted into the grooves and are flush with the surface of the external plate, and locking bolts penetrate through the externalplate from the outer side face to the inner side face and are in threaded connection with the inner lining plates. In the slab girder precasting stage, roughening is conducted, grooved rough surfaceswhich are uniformly distributed are formed, and construction is simple.

Owner:北京中兴恒工程咨询有限公司

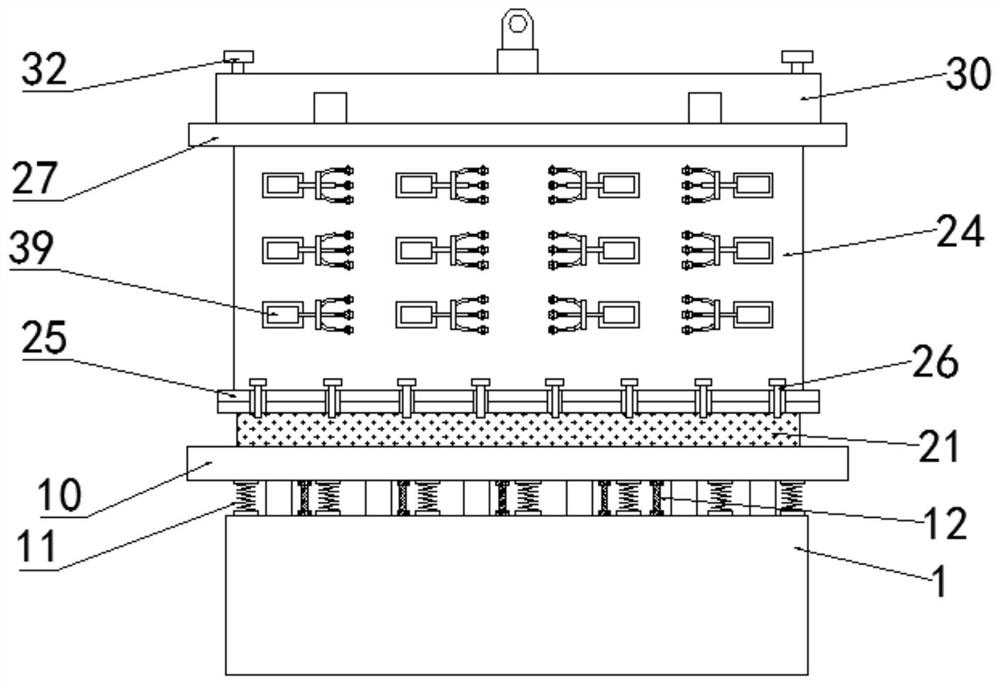

Assembly type prefabricated square culvert forming device and assembly type prefabricated square culvert forming and manufacturing process

ActiveCN112092181AGuaranteed stabilityHit fastDischarging arrangementMouldsElectric machineStructural engineering

The invention discloses an assembly type prefabricated square culvert forming device and an assembly type prefabricated square culvert forming and manufacturing process. The assembly type prefabricated square culvert forming device comprises a base; a plurality of vibration devices are arranged at the bottom of the interior of the base; each vibration device comprises a first motor base; the bottom of each first motor base is fixedly connected with the inner bottom of the base; a first motor is arranged in the center of the top of each first motor base; a first motor shaft is arranged at the output end of the side face of the first motor; a runner is arranged on the side, away from the first motor, of the first motor shaft; a connecting rod is arranged on the outer surface of the other side of the runner; a plurality of sleeves penetrating through the top of the base are arranged at the top of the interior of the base; and bearing columns are arranged in the sleeves. The assembly typeprefabricated square culvert forming device has the beneficial effects that when the first motor drives a supporting plate to ascend and descend in a reciprocating mode, impact force generated by descending of the supporting plate can be absorbed by a plurality of buffer springs, meanwhile, a plurality of limiting columns play a role in limiting the lowest descending height of the supporting plate, and the overall stability of the forming device is guaranteed.

Owner:连云港市成盛混凝土构件有限责任公司

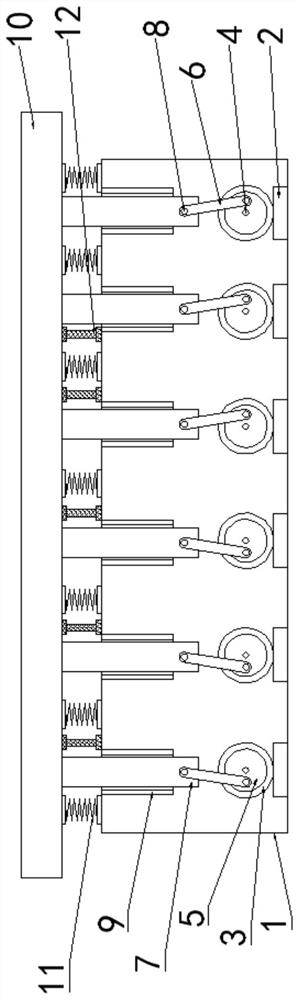

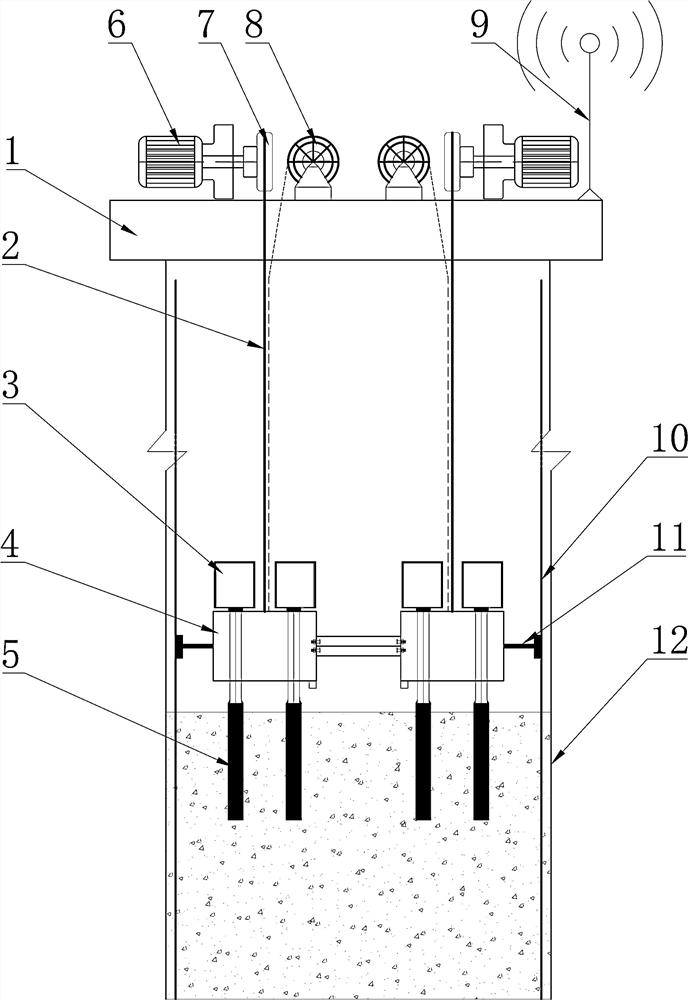

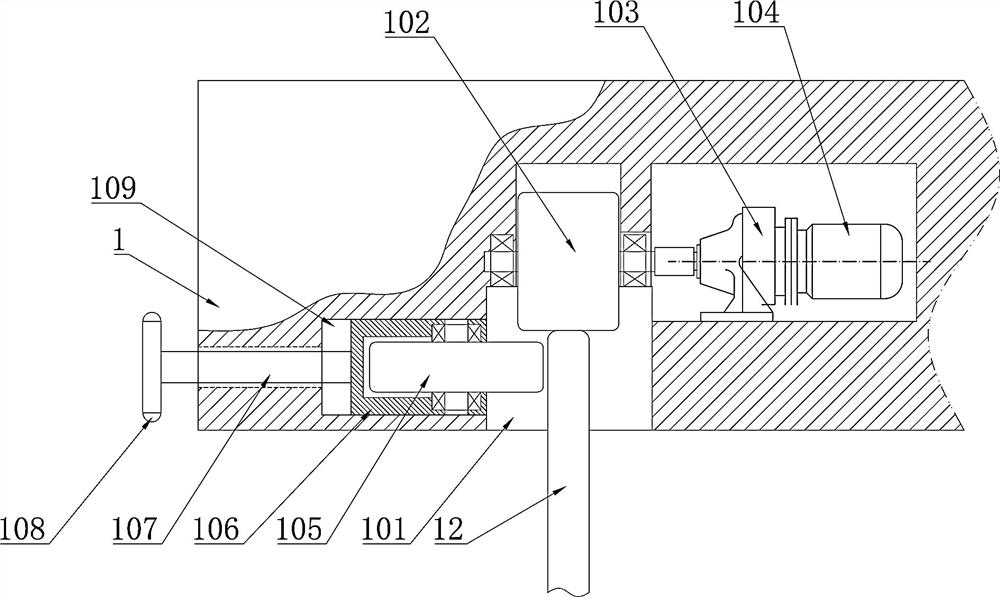

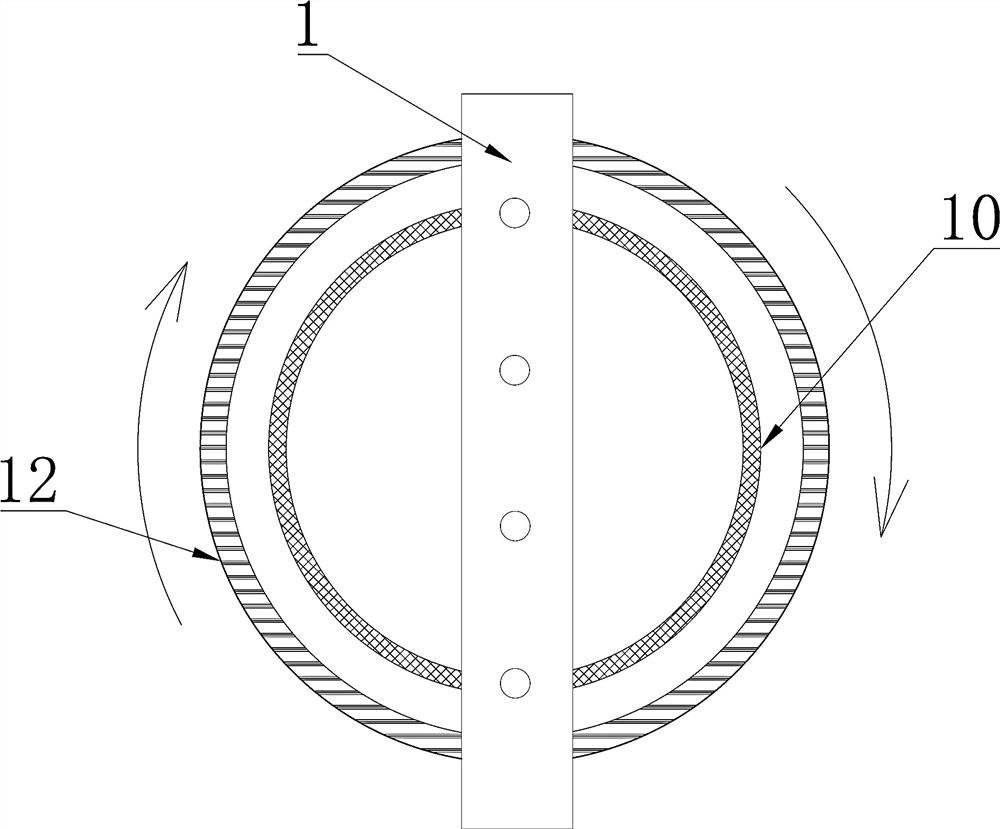

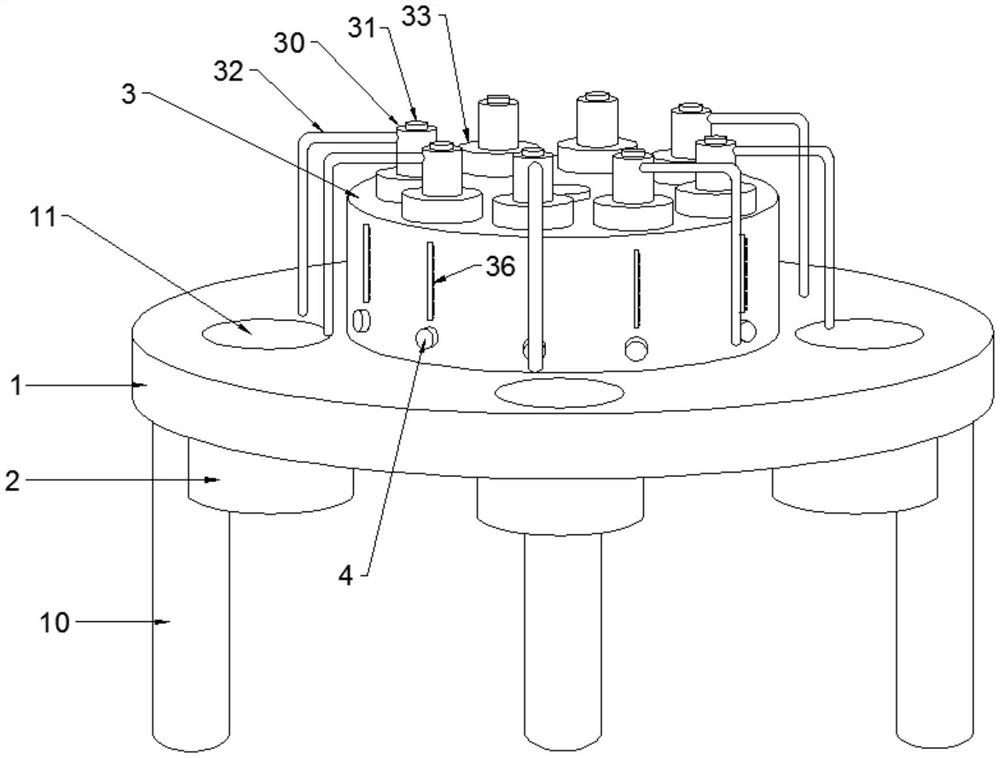

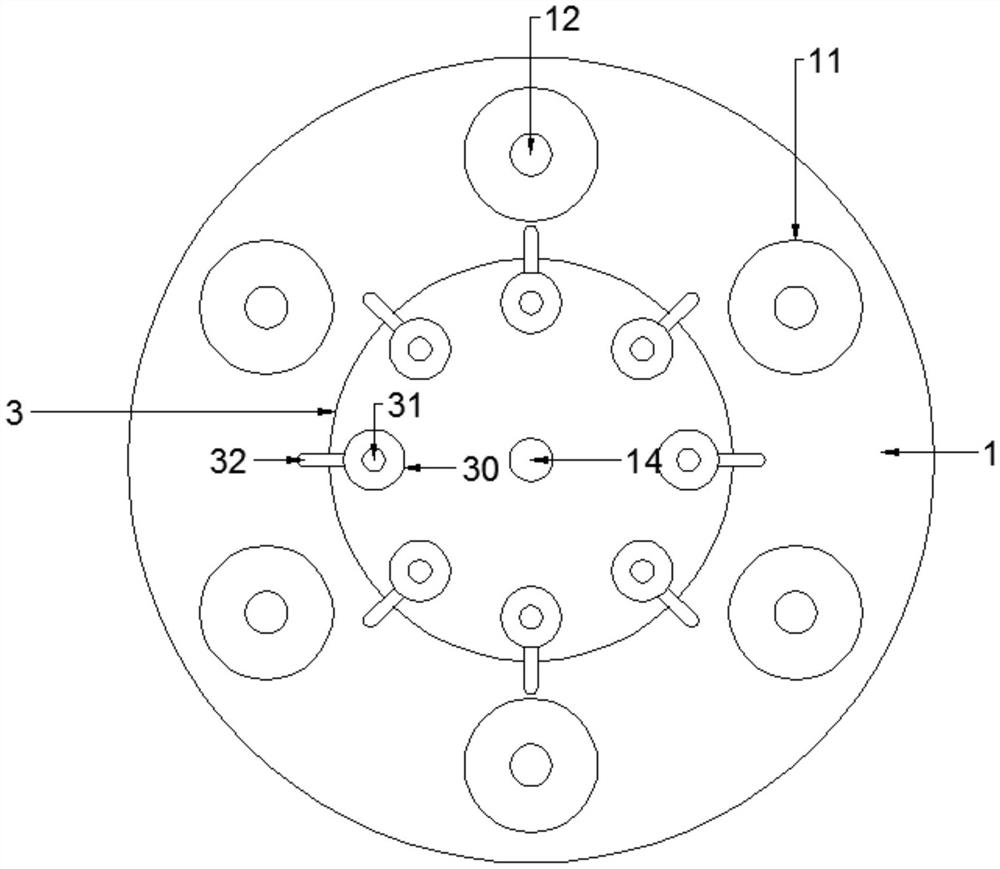

Pile body (or column body) concrete vibrating rod lifting device and construction method thereof

ActiveCN113152439AAvoid security risksAccelerateBridge erection/assemblyBulkheads/pilesElectric machineryArchitectural engineering

The invention provides a pile body (or column body) concrete vibrating rod lifting device and a construction method thereof. A cross beam is used for being placed at the opening position above a formwork frame; a plurality of winches and a plurality of counterweight vibrating platforms are arranged on the cross beam; the winches are connected with the counterweight vibrating platforms through lifting ropes; a plurality of vibrating motors are arranged on the counterweight vibrating platforms; the vibrating motors are connected with vibrating rods; and every two adjacent counterweight vibrating platforms are connected through a connecting rod. By using the device, manual descending for vibrating operation can be avoided, the safety risk of a conventional vibrating process is avoided, and compared with conventional manual descending for vibrating, the concrete pouring and vibrating time is shortened, and the construction efficiency is greatly improved. The vertical and full-section vibrating range of concrete can be effectively controlled by controlling the wellhead winch and changing the position of the wellhead cross beam, the construction quality of pile body or column body concrete is ensured, and the device has high popularization value in terms of safety, quality and efficacy.

Owner:CCCC SECOND HARBOR ENG

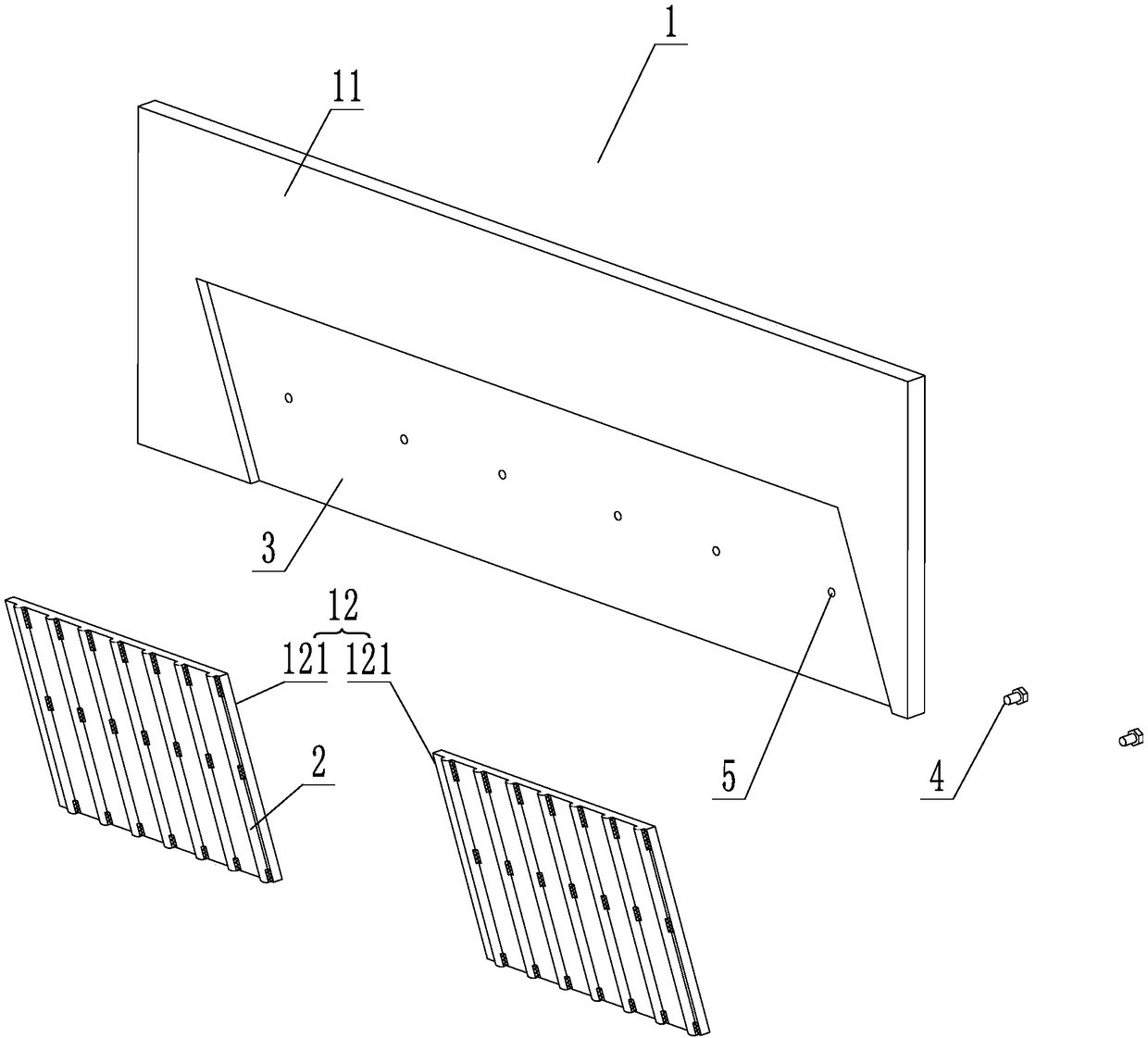

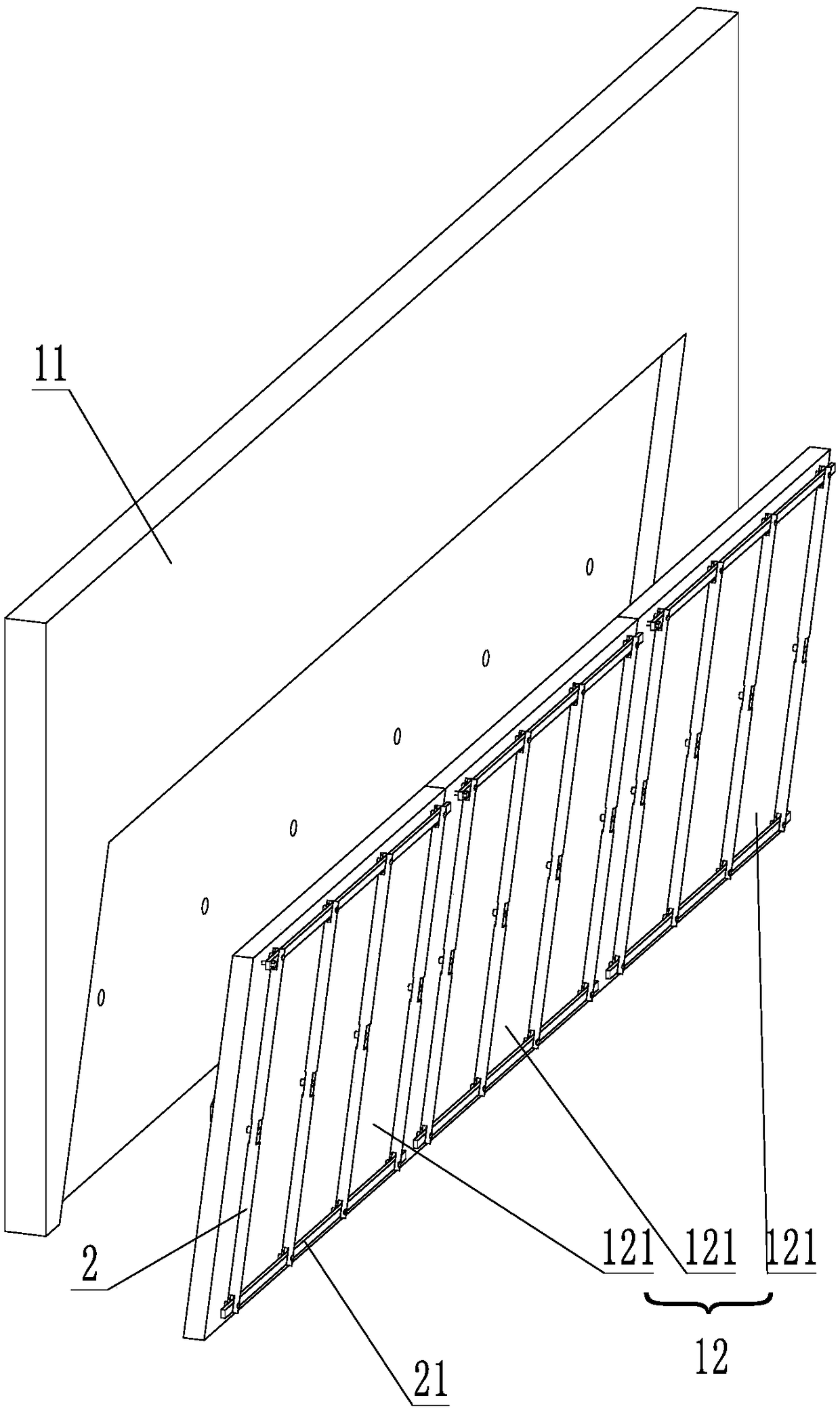

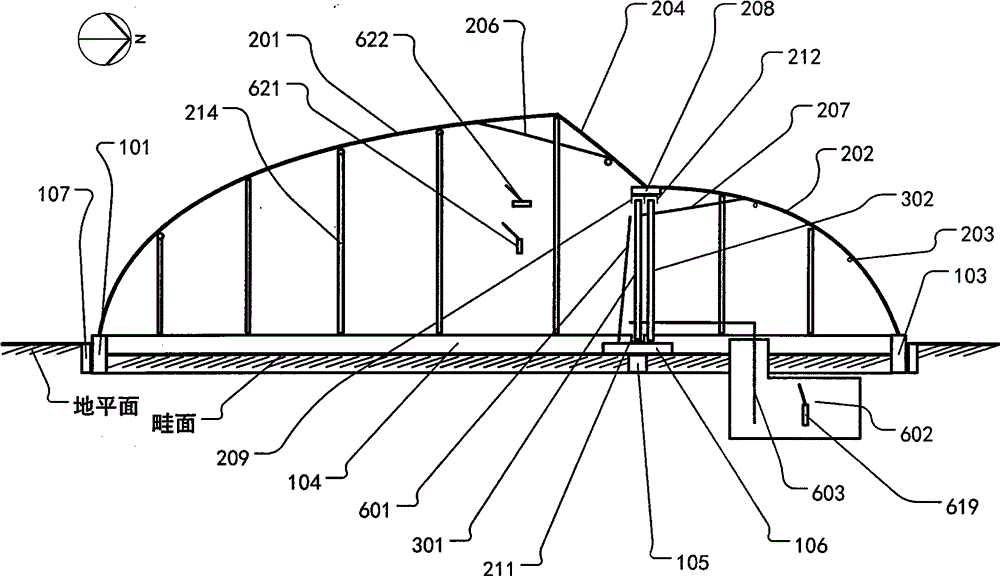

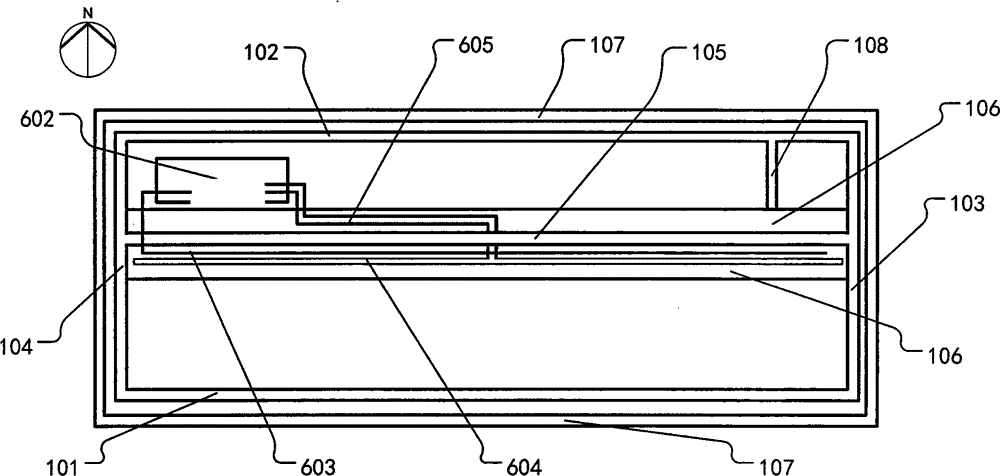

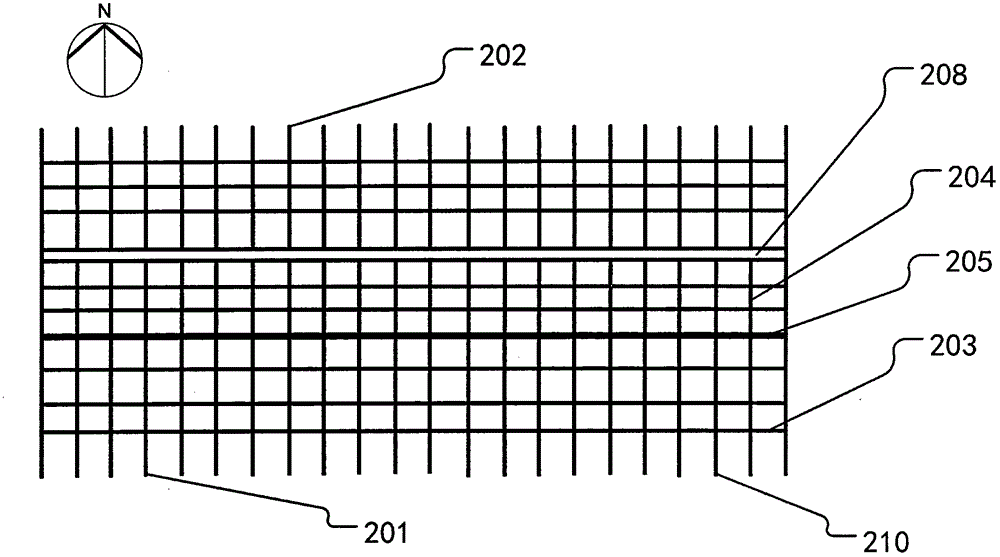

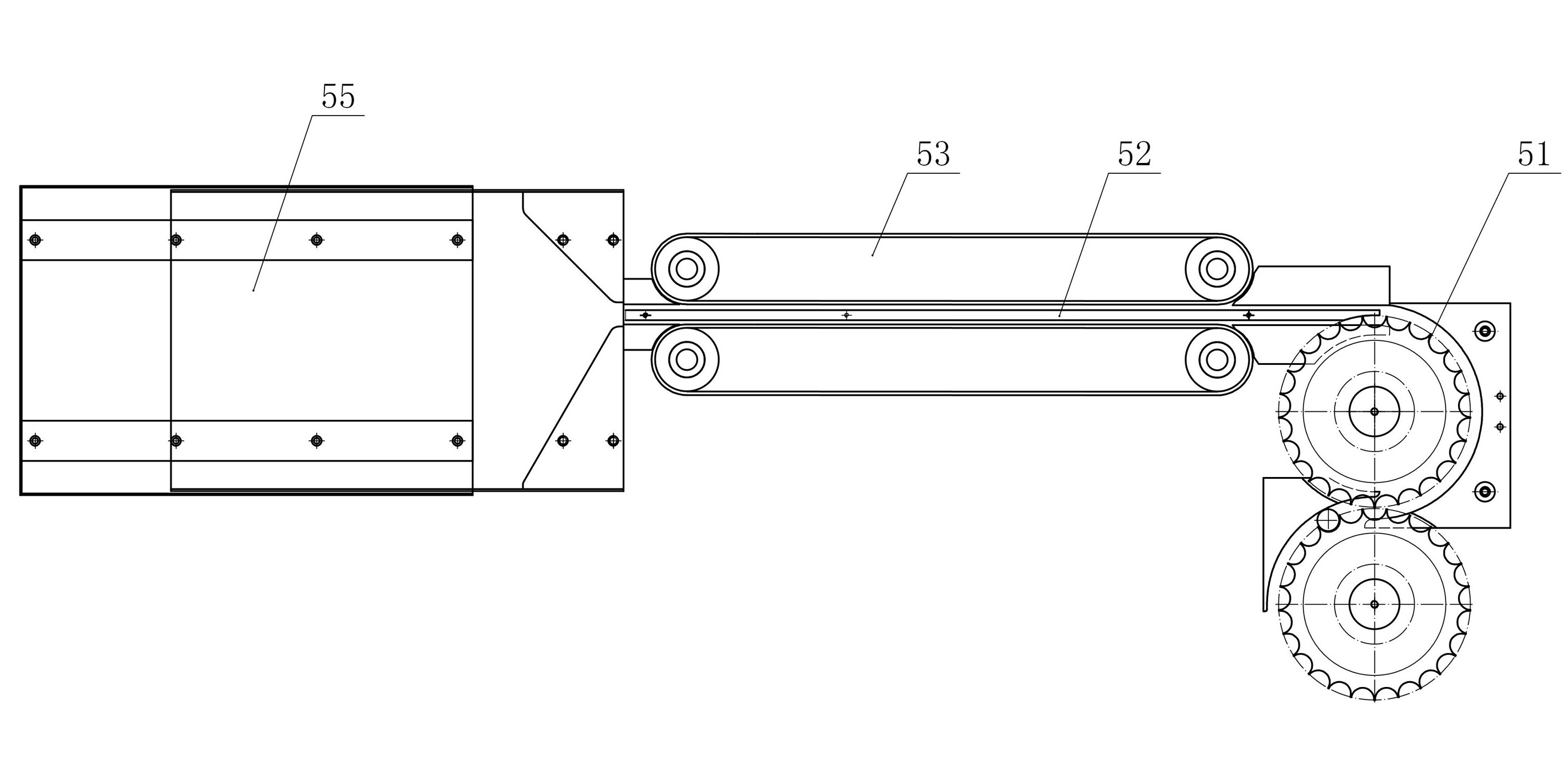

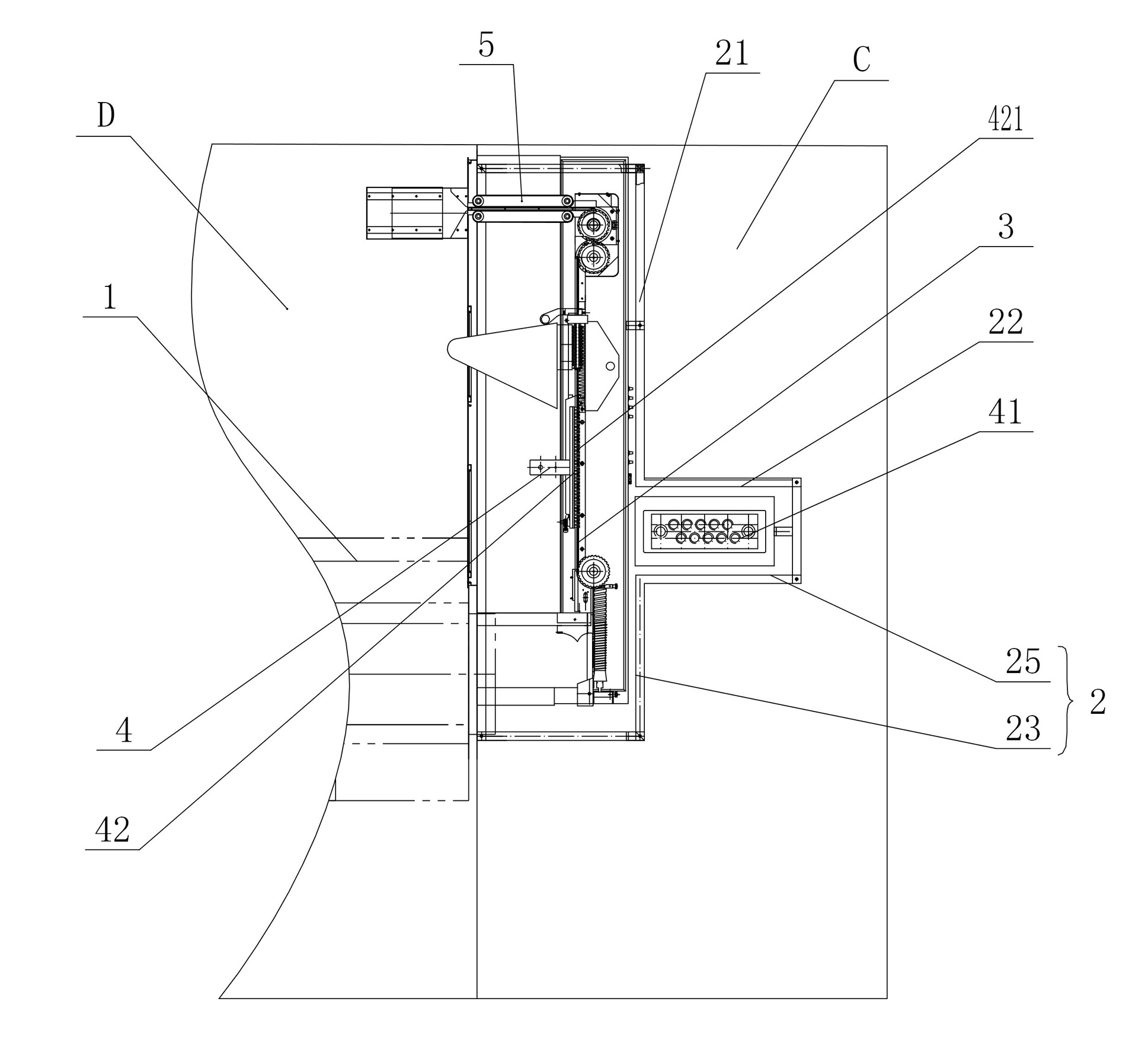

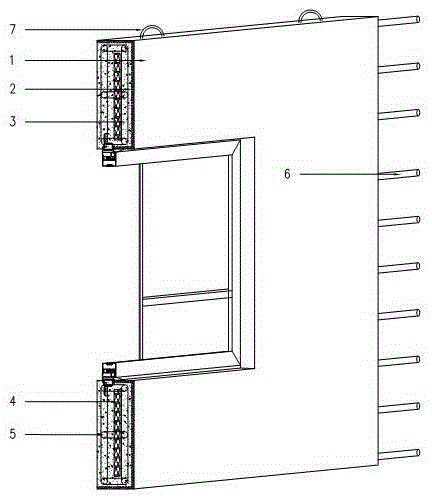

Novel south and north dual-shed sunlight greenhouse and operating method

InactiveCN104823756AImprove land utilizationIncrease indoor arable landClimate change adaptationGreenhouse cultivationAutomatic controlAgricultural engineering

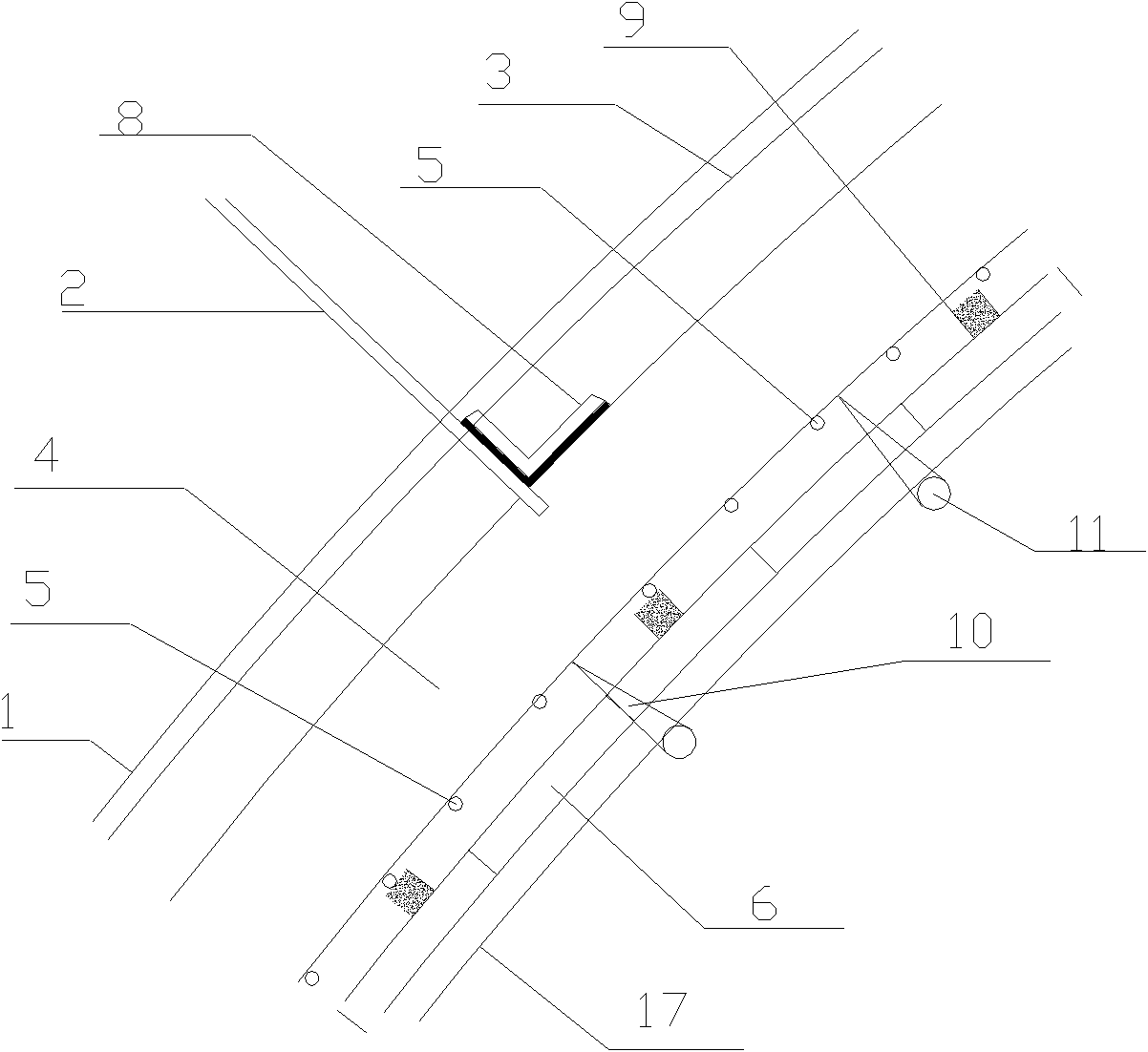

The present invention discloses a structure of a novel south and north dual-shed sunlight greenhouse with a middle wall and an operating method. Structurally, the sunlight greenhouse mainly comprises a sunlight greenhouse foundation (1), a south and north shed steel frame prefabricated part connector (2), the middle wall (3), a side wall (4), a cushion working room (5) and a heat exchange control system (6). A sliding door type movable structure of the middle wall (3) plays an important role of regulating the illumination distribution, temperature conditioning and ventilation of a south shed and a north shed. A vertical splitter plate water heat exchange automatic control structure of the heat exchange system (6) is combined with the movable middle wall (3), so that the heat exchange ability of the sunlight greenhouse is improved. The operating method of the sunlight greenhouse mainly comprises the following steps: insulating heat, storing heat, releasing heat and lowering humidity in winter; and ventilating, shading, radiating and cooling in summer, and has the advantages of saving cultivated land, producing all the year, being low in construction cost and the like.

Owner:廊坊市大华夏神农信息技术有限公司

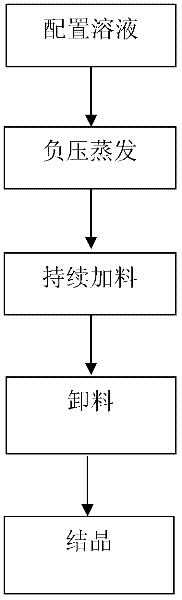

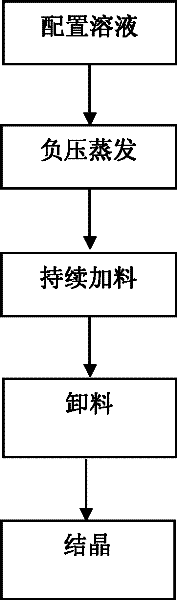

Negative pressure evaporation and step-by-step feeding method of nickel sulfate solution

The invention discloses a negative pressure evaporation and step-by-step feeding method of a nickel sulfate solution. The method comprises the following steps: preparing the nickel sulfate solution to be produced; performing vacuum pumping on a negative pressure evaporator; performing continuous heating on the solution in the negative pressure evaporator; performing cooling and crystallization on the concentrated solution; and further performing step-by-step feeding. The method is characterized in that the step-by-step feeding and the vacuum pumping operation are simultaneously performed. Therefore, the volume of the evaporation device can be fully utilized, the number of times of operation can be reduced, and the purpose of improving working efficiency can be further achieved. The method disclosed by the invention has the characteristics of fast evaporation speed, high production efficiency and simple operation, the number of equipment used by the method is small, and the equipment occupies small area, and is environment-friendly and pollution-free.

Owner:广东芳源新材料集团股份有限公司

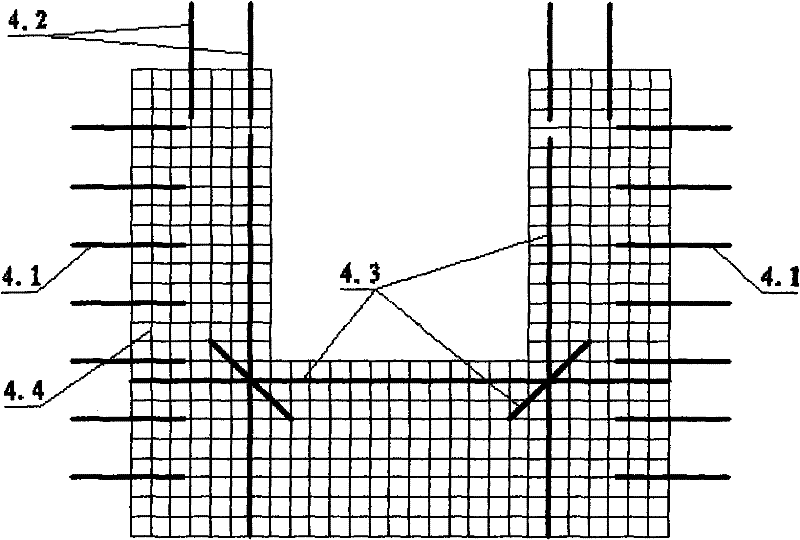

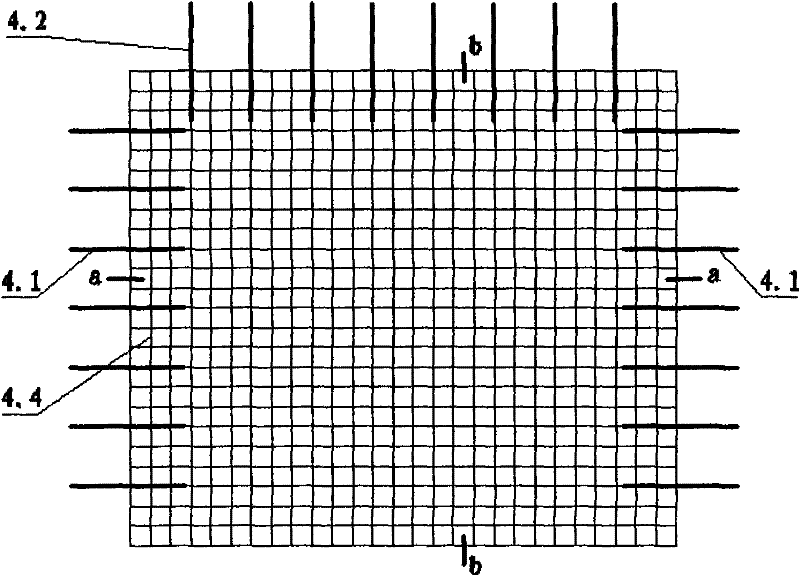

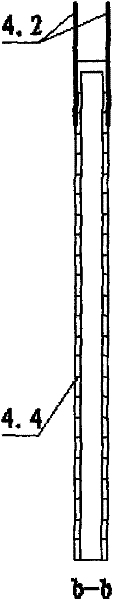

Spraying sandwiched concrete shear wall structure of clamp die fixing machinery and construction method

InactiveCN102220809AImprove flexural strengthImprove impact resistanceWallsBuilding material handlingShock resistanceUltimate tensile strength

The invention relates to a spraying sandwiched concrete shear wall structure of a clamp die fixing machinery and a construction method; the method comprises the following steps: a precast steel mesh core plate is installed on a poured-in-place underbeam / foundation correspondingly, then a clamp die column and a clamp die of a clamp die beam are installed, two side surfaces of the steel mesh core plate are fixed by the clamp die, a concrete layer is sprayed mechanically on the surface of the steel mesh core plate, a steel mesh of the steel mesh core plate is solidified in the concrete layer, then the clamp die column and the clamp die beam are poured in place, vibrating is conducted in the pouring process, and the poured concrete is densely solidified with the corresponding edge of the concrete layer, so that a frame light sandwiched concrete beating wall body can be formed. By adopting the method, the effects of integrity, strength, impact resistance, shock resistance, heat insulation, energy conversation and the like of the wall body can be greatly improved, the self weight of the wall body can be reduced, the pouring formwork can be saved by 60%, the working can be reduced, the construction period can be accelerated, the engineering manufacturing cost is lowered, and the invention is particularly suitable for shear walls of multi-layer and high-rise buildings and construction.

Owner:BEIJING HUAMEIKEBO TECH DEV +1

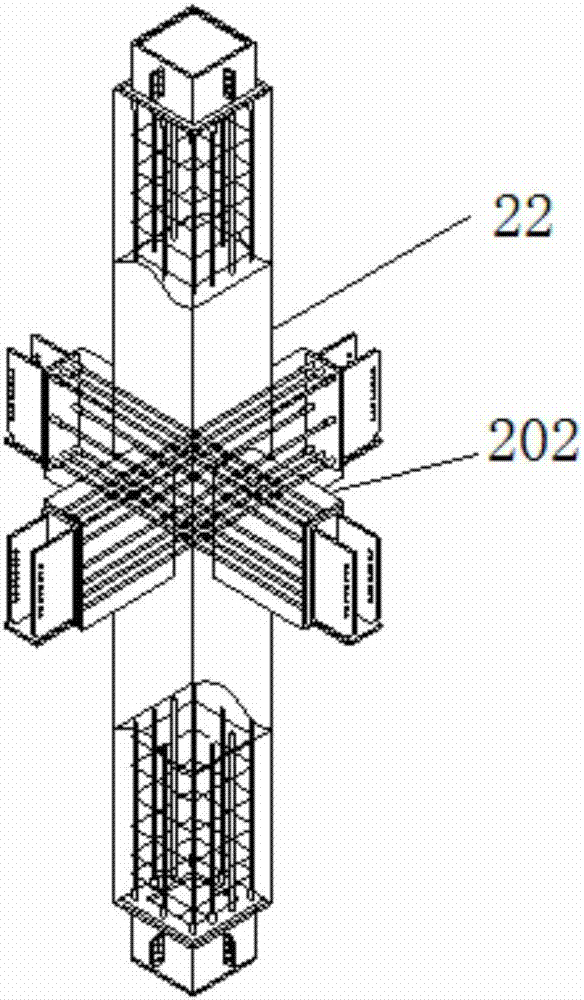

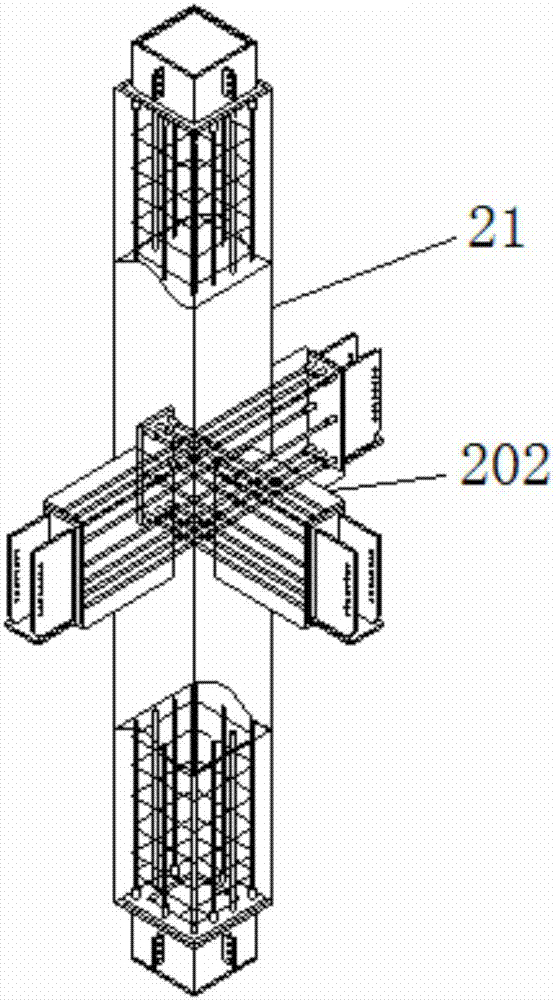

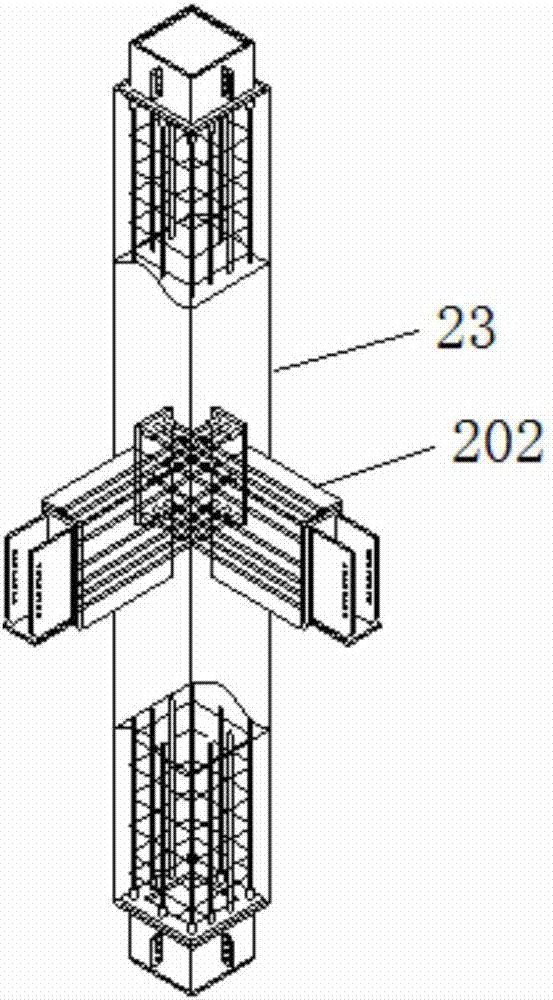

Member of prefabricated concrete framework used for steel joint connection and construction method

PendingCN107574924ASimple structureReliable power transmissionBuilding constructionsEngineeringBuilding construction

Owner:CHONGQING UNIV

Pour point depressant for lubricant

ActiveUS8163683B2Reduce pointsHigh indexLiquid carbonaceous fuelsBase-materialsCarbon numberPolymer science

There is provided a pour point depressant for lubricants that has an effect of lowering pour points of both solvent refined base oils and high viscosity index base oils. A pour point depressant for lubricants comprising: a mixture of an alkyl (meth)acrylate polymer (A) that is composed of an alkyl(meth)acrylate containing alkyl groups having an average carbon number (CA) of 12.5 to 13.8, and an alkyl(meth)acrylate polymer (B) that is composed of an alkyl(meth)acrylate containing alkyl groups having an average carbon number (CB) of 13.9 to 15.5.

Owner:TOHO CHEM IND

Process for producing oligomers

InactiveUS20060003903A1Easy to usePour point and cloud pointOrganic chemistryFatty acid esterificationOligomerCloud point

Owner:MALASIAN PALM OIL BOARD

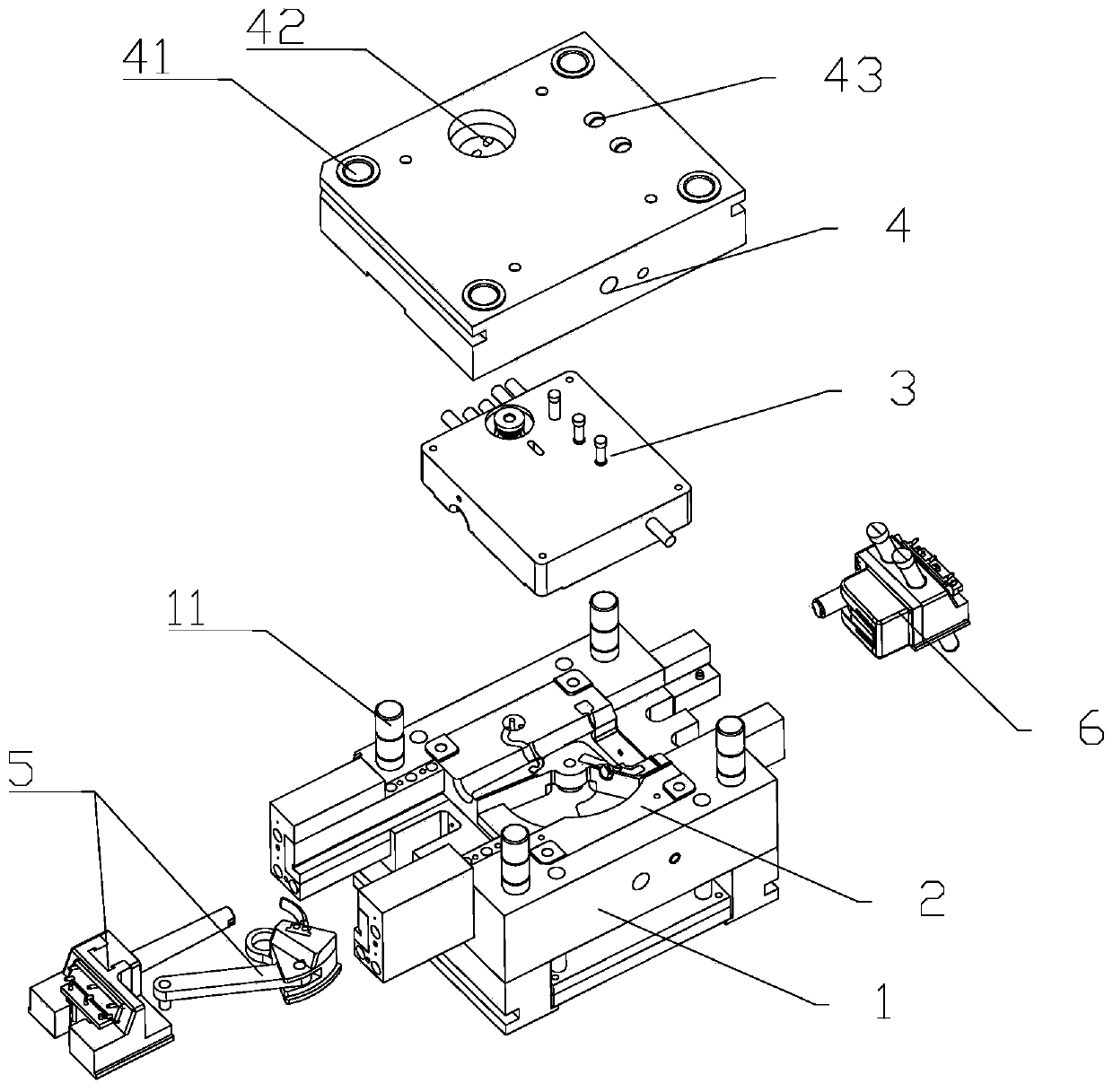

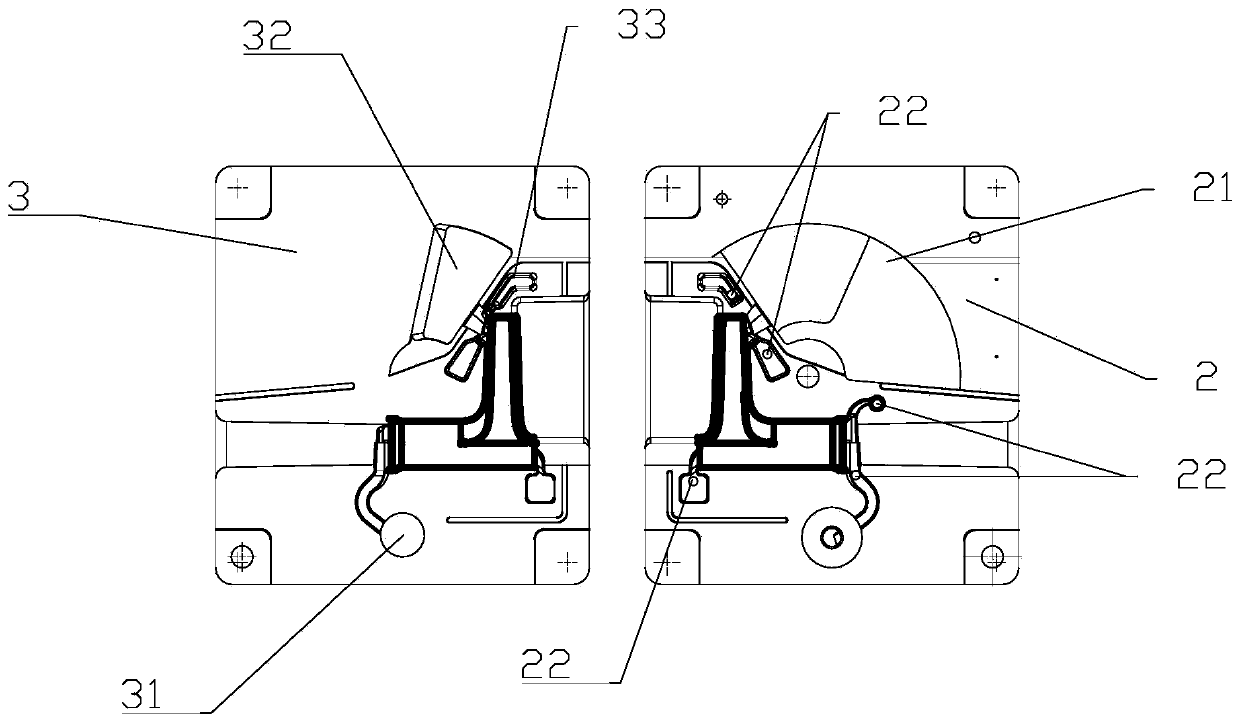

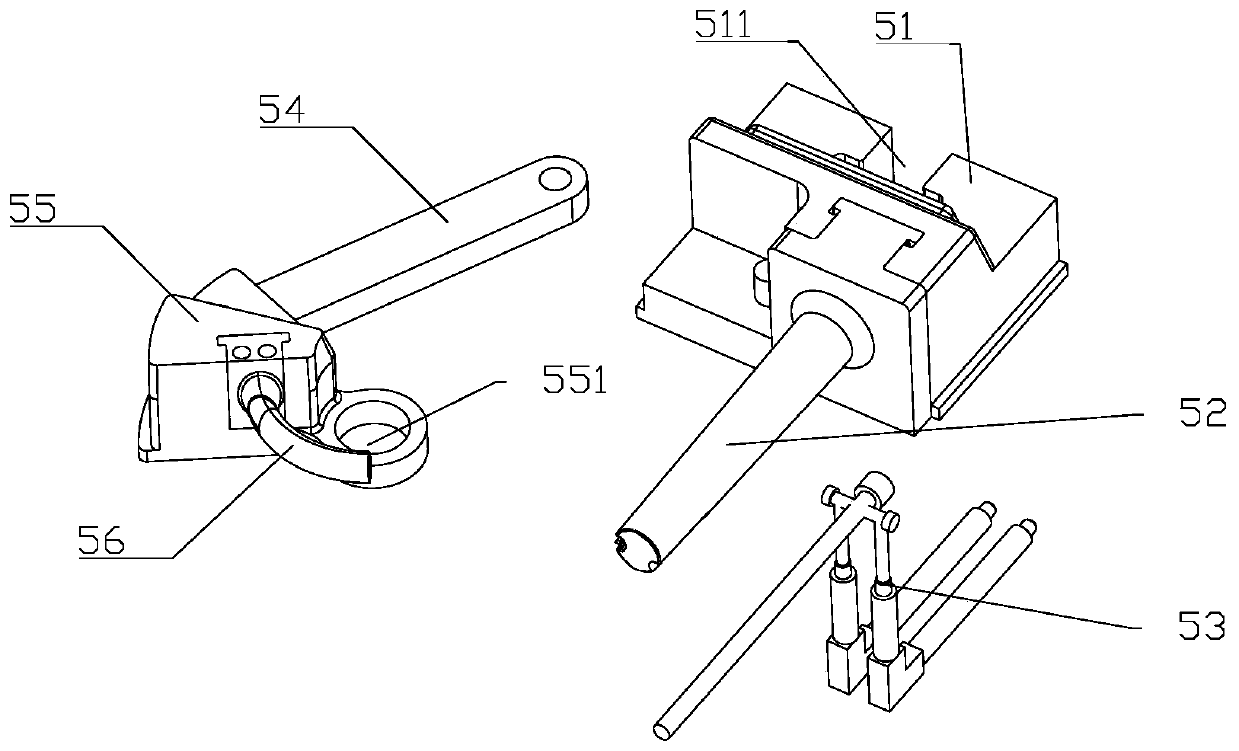

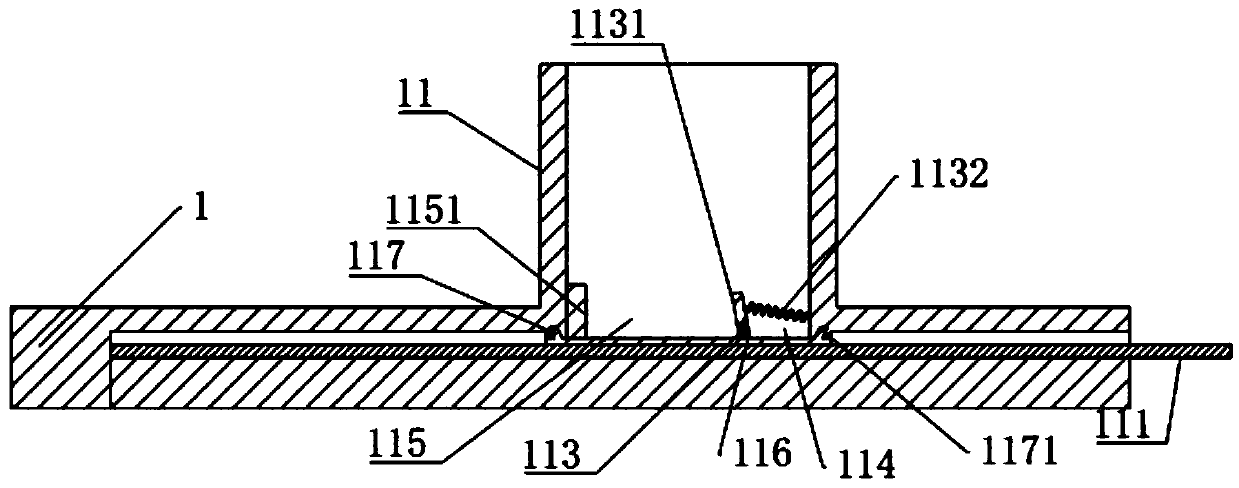

Water faucet forming mould

The invention relates to the technical field of water faucet manufacturing equipment. A water faucet forming mould comprises a lower mould frame, a lower mould core, an upper mould core and an upper mould frame, wherein the lower mould core is fixedly arranged on the lower mould frame; the upper mould core is fixedly arranged on the upper mould frame; a side core-pulling mechanism is arranged on one side of the lower mould frame; an oblique guide pin sliding block mechanism is arranged on the other side of the lower mould frame; the side core-pulling mechanism comprises a direct pushing part and a rotating part; the rotating part and the direct pushing part are hinged; the rotating part is hinged into the lower mould core; the oblique guide pin sliding block mechanism is movably connectedto the other side of the lower mould frame; and the oblique guide pin sliding block mechanism and the lower mould frame form movable connection through an oblique guide pin. According to the water faucet forming mould provided by the invention, the casting dosage is less, so that the waste is reduced; the mould is simple in overall structure and low in cost; through arranging a cooling system, thecooling speed is improved; and the side core-pulling mechanism is driven through a connecting rod, and one movement action and one rotation action are produced at the same time and are associated, sothat the precision for processing every time is high.

Owner:杨立夸

Encapsulating device

ActiveCN102079393ACompact structureBottle safetyConveyorsPackaging under vacuum/special atmosphereEngineeringBottle

The invention discloses an encapsulating device, which comprises an isolating cover, and an encapsulating machine, a sealing machine and a bottle outlet mechanism which are arranged in the isolating cover and connected with one another; the bottle outlet mechanism comprises a shifting wheel bottle-conveying component and a bottle-packaging disc; the shifting wheel bottle-conveying component is arranged at the bottle outlet end of the sealing machine; and the bottle outlet end of the shifting wheel bottle-conveying component is connected with the bottle inlet end of the bottle-packaging disc through a friction conveying belt component. The encapsulating device has the advantages of simple structure, steady and stable bottle conveying, safety and high efficiency.

Owner:TRUKING TECH LTD

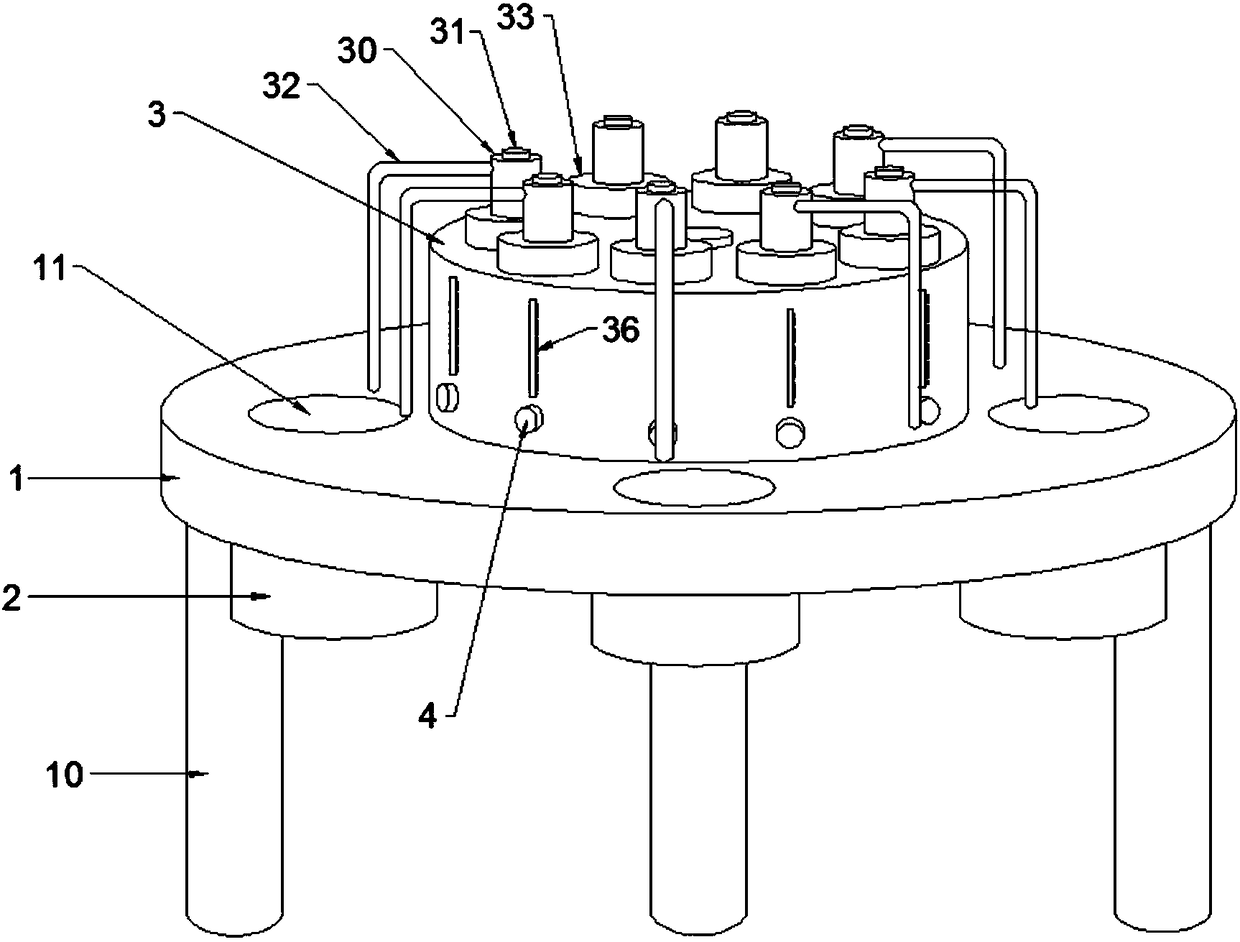

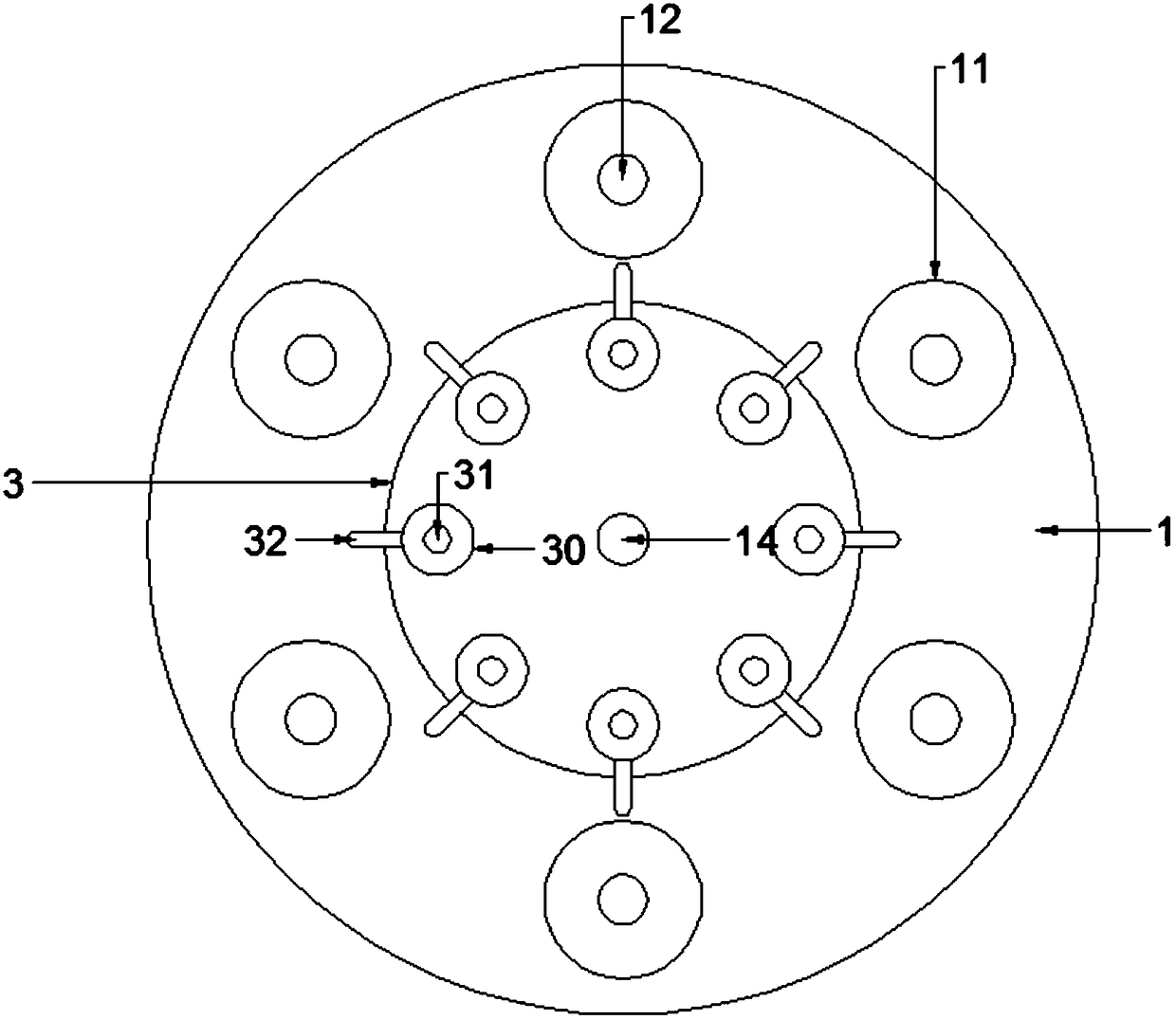

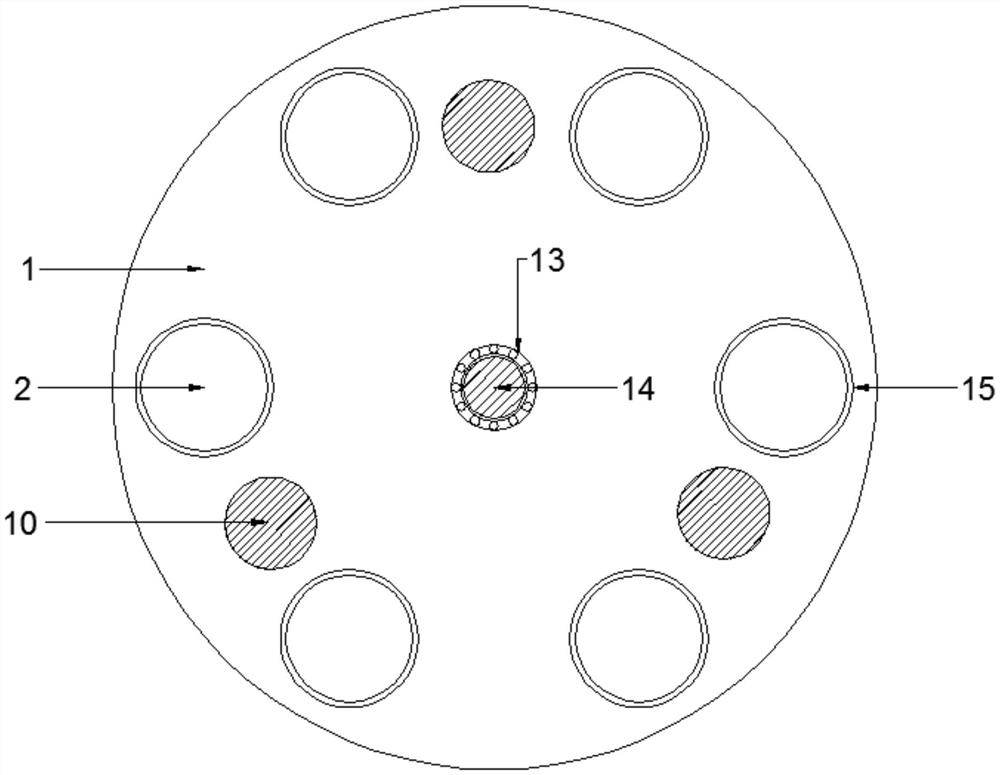

Environment-friendly type chemical reagent containing device for chemical engineering

ActiveCN108855261AImprove utilization efficiencyFlexible transferLaboratory glasswaresHazardous material storageLiquid wasteExhaust pipe

The invention discloses an environment-friendly type chemical reagent containing device for chemical engineering. The environment-friendly type chemical reagent containing device comprises an operation platform, a recycling box, a containing transfer box and an extruding rod, wherein a plurality of placing grooves are arranged around the top surface of the operation platform; a liquid leaking holeis formed in the inner bottom surface of each placing groove; the containing transfer box is rotationally and fixedly arranged at the top surface of the operation platform; the interior of the surrounding part of the containing transfer box is provided with a plurality of liquid storage cavities; the top part of each liquid storage cavity is rotationally and fixedly connected with a rotary box; an overflow pipe penetrates into each rotary box; a liquid drain cylinder is fixedly arranged at the top surface of each rotary box; the side surface of each liquid drain cylinder is connected with a liquid drain pipe; an extruding rod penetrates through the side wall of the containing transfer box; the right end of the extruding rod extends into a sealing air chamber, and a compression sealing gasket is fixedly arranged at the right end of the extruding rod; the top opening of an air exhaust pipe at the top surface of the sealing air chamber is positioned at the inner top part of the liquid storage cavity. The environment-friendly type chemical reagent containing device has the advantages that the handling of chemical reagents by an operator is reduced, the overflow waste of the reagent isreduced, the damage to the environment due to free dumping of the waste liquid is reduced, the operation time is shortened, and the utilization efficiency of the containing transfer box is greatly improved.

Owner:SHANGHAI LINKCHEM TECH CO LTD

Pour point depressant for lubricant

ActiveUS20100120641A1Reduce pointsHigh indexLiquid carbonaceous fuelsBase-materialsCarbon numberMeth-

There is provided a pour point depressant for lubricants that has an effect of lowering pour points of both solvent refined base oils and high viscosity index base oils. A pour point depressant for lubricants comprising: a mixture of an alkyl(meth)acrylate polymer (A) that is composed of an alkyl(meth)acrylate containing alkyl groups having an average carbon number (CA) of 12.5 to 13.8, and an alkyl(meth)acrylate polymer (B) that is composed of an alkyl(meth)acrylate containing alkyl groups having an average carbon number (CB) of 13.9 to 15.5.

Owner:TOHO CHEM IND

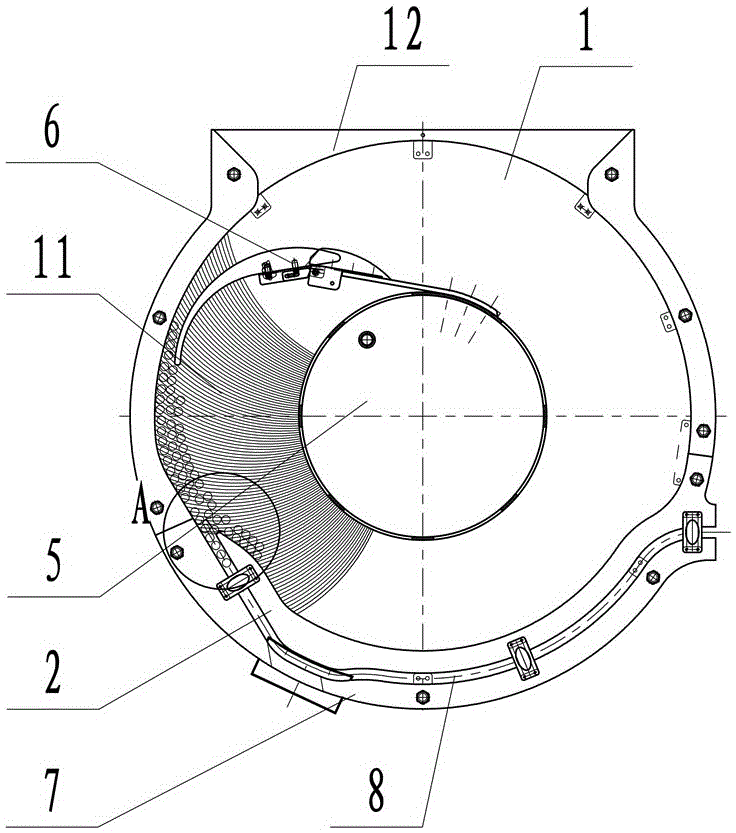

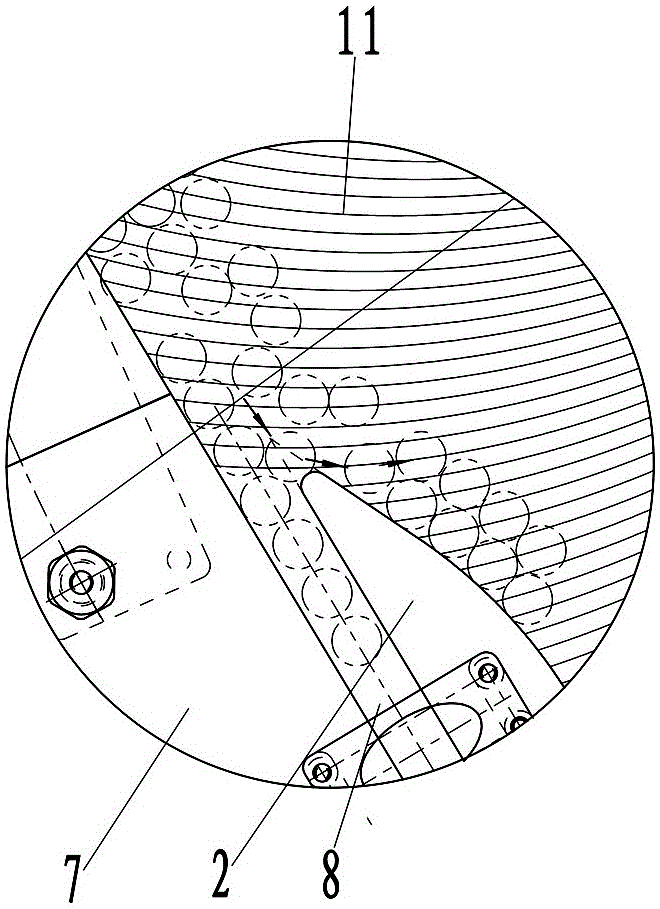

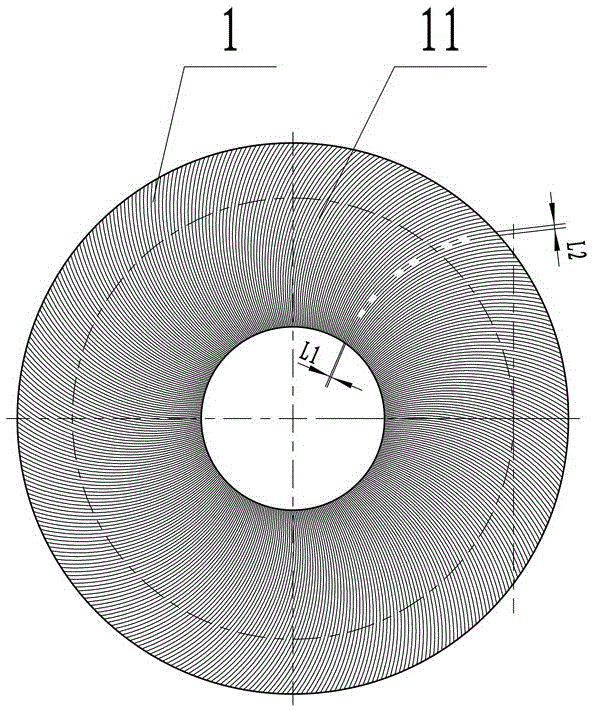

A bottle unscrambler

The invention provides a bottle arranging mechanism. The bottle arranging mechanism comprises a bottle arranging disc and a bottle separating barrier fixedly arranged on the bottle arranging disc, wherein the bottle arranging disc comprises a bottle arranging area for arranging bottle bodies, the bottle arranging area is provided with bottle arranging textures, and each bottle arranging texture comprises a texture section stretching from the middle part of the bottle arranging disc to the outside of the bottle arranging disc. The bottle arranging mechanism provided by the invention has the advantages that the resistance is reduced, and a bottle falling phenomenon is prevented from happening.

Owner:TRUKING TECH LTD

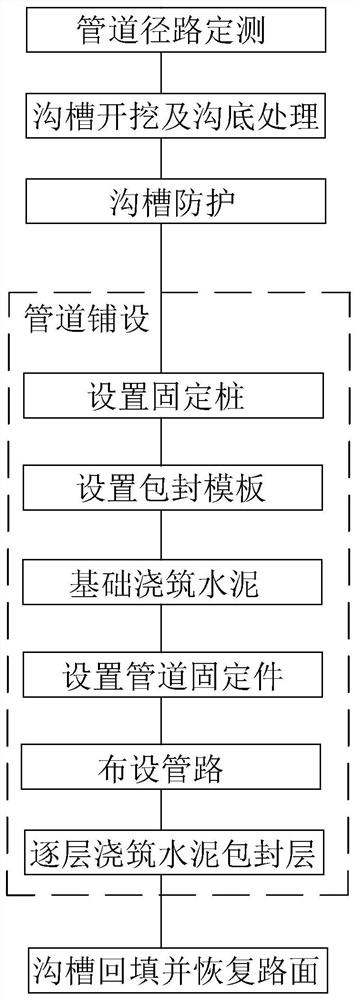

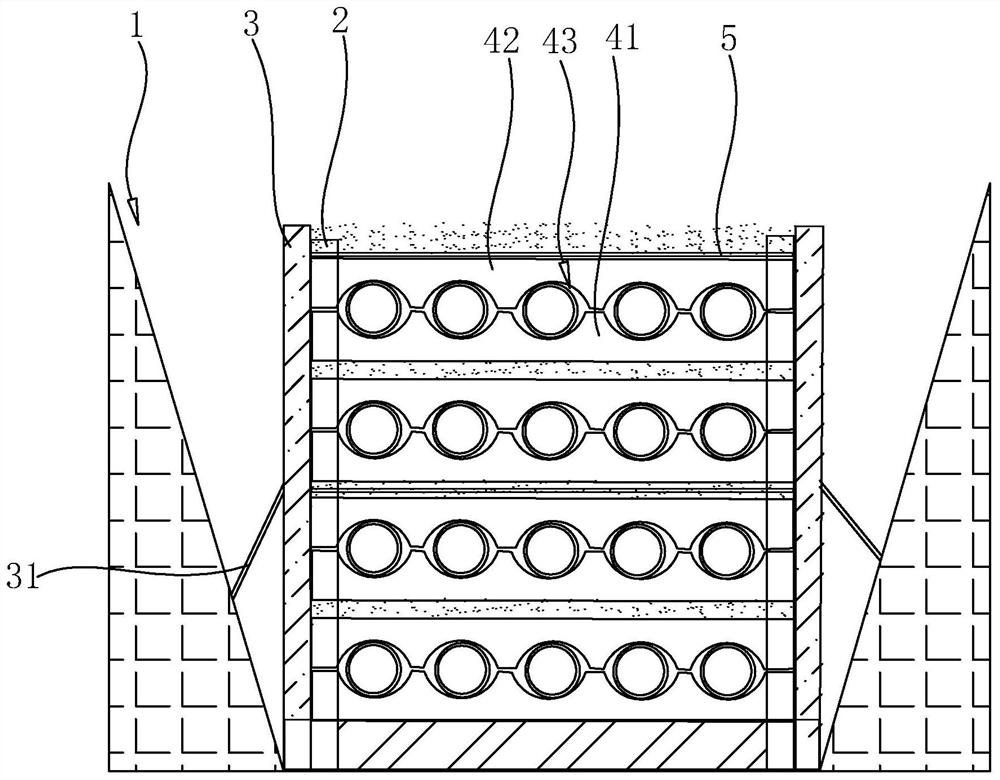

Pipeline laying method

PendingCN112878403AConditions affecting construction qualityReduce quality impactSoil-shifting machines/dredgersApparatus for laying cablesStructural engineeringCement Material

The invention relates to the field of communication pipeline construction, and discloses a pipeline laying method. The method comprises the steps of pipeline diameter measurement, trench excavation as well as trench bottom treatment, trench protection, pipeline laying, trench backfilling and pavement recovery; pipeline laying specifically comprises the step that two rows of fixing piles are arranged on the two sides in a trench and are parallel to the side walls of the trench; an encapsulation templates are arranged on the sides, close to the side walls of the trench, of the fixing piles, and the encapsulation templates are parallel to the side walls of the trench; cement is poured to a foundation; pipeline fixing pieces are arranged, the pipelines are fixedly arranged layer by layer through the pipeline fixing pieces, and the arranged pipelines are connected through pipeline connectors; and cement encapsulation layers are poured layer by layer, one cement encapsulation layer is poured every time when one layer of pipeline is arranged, and a waist line is transversely connected between every two opposite fixing piles on the two sides of the trench every time when two layers of pipelines are arranged. The arrangement positions of the pipelines are fixed through the pipeline fixing pieces, and the situation that the construction quality of the pipelines is affected by deviation or floating of the pipelines during cement pouring is effectively reduced.

Owner:陕西中怡信息技术有限公司

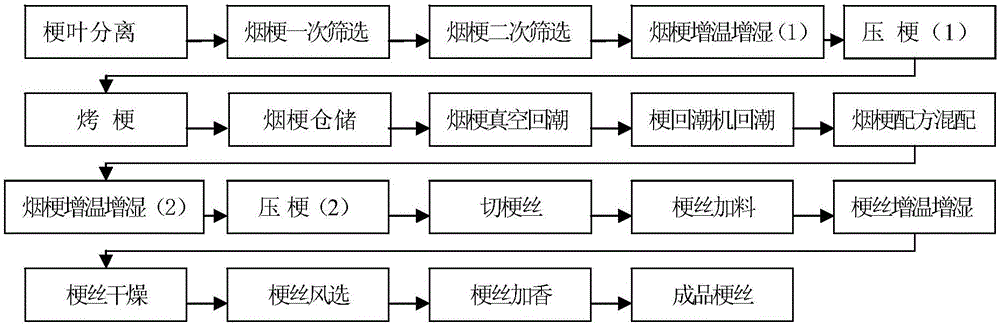

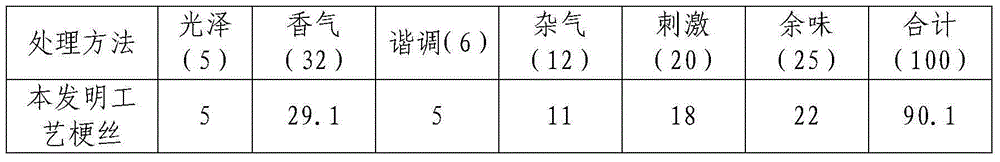

Method for processing tobacco stems into shredded stems

The invention discloses a method for manufacturing stem shreds by processing tobacco stems. The method includes the steps of stem and leaf separating, tobacco stem screening, tobacco stem warming and humidifying, stem pressing, stem roasting, tobacco stem storing, tobacco stem dampening, tobacco stem formula mixing, secondary tobacco stem warming and humidifying, second stem pressing, stem shred cutting, stem shred adding, stem shred warming and humidifying, stem shred drying, stem shred winnowing, perfuming and the like. A whole set of complete new stem shred processing method from leaf hitting tobacco stem re-roasting processing to stem shred manufacturing from the tobacco stems is formed. According to the method, the stem shred production environment is improved; the production cost is reduced; the stem shred quality is improved. The method is easy and convenient, and strong in maneuverability; and large-scale production and application can be conveniently achieved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

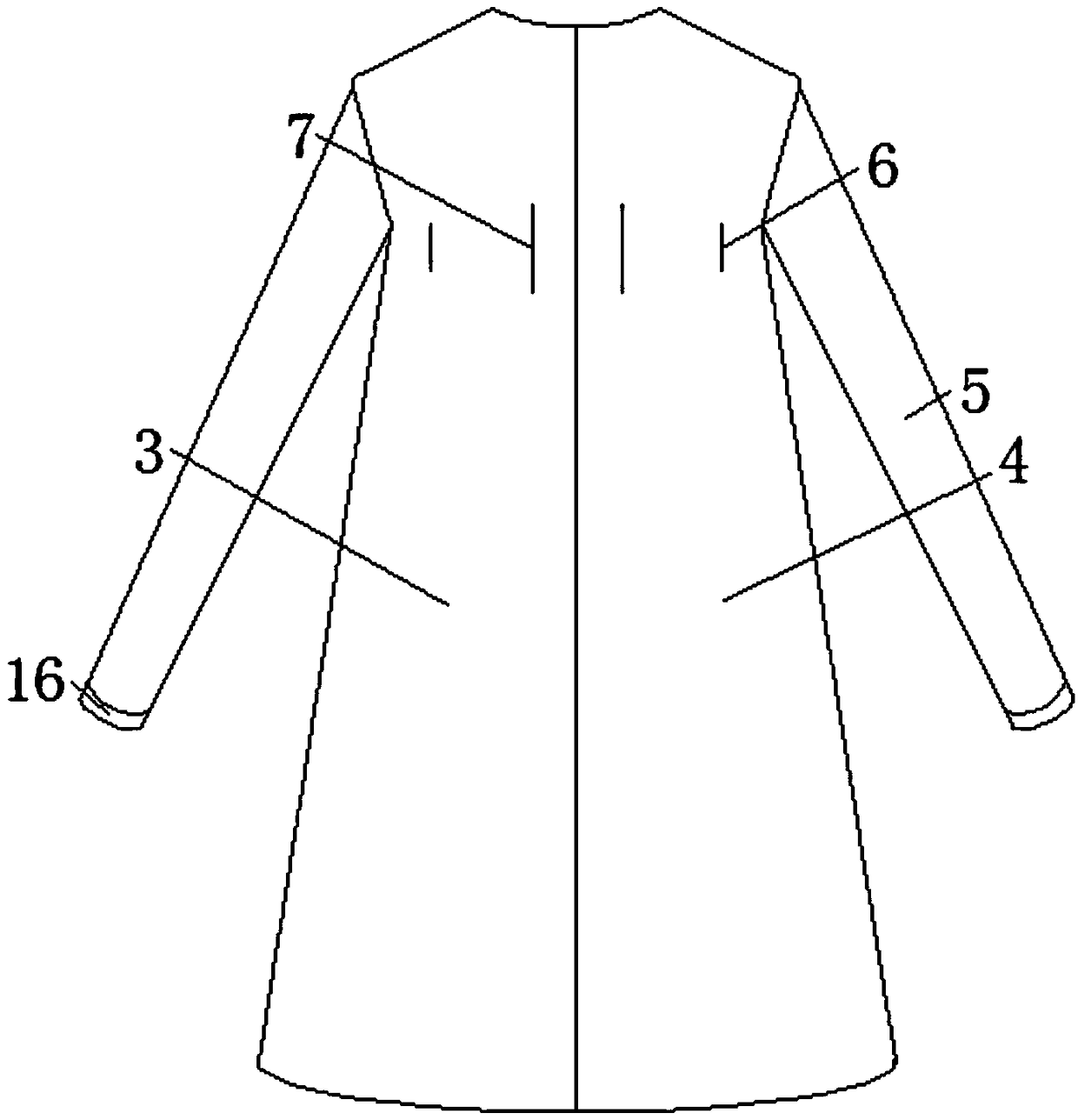

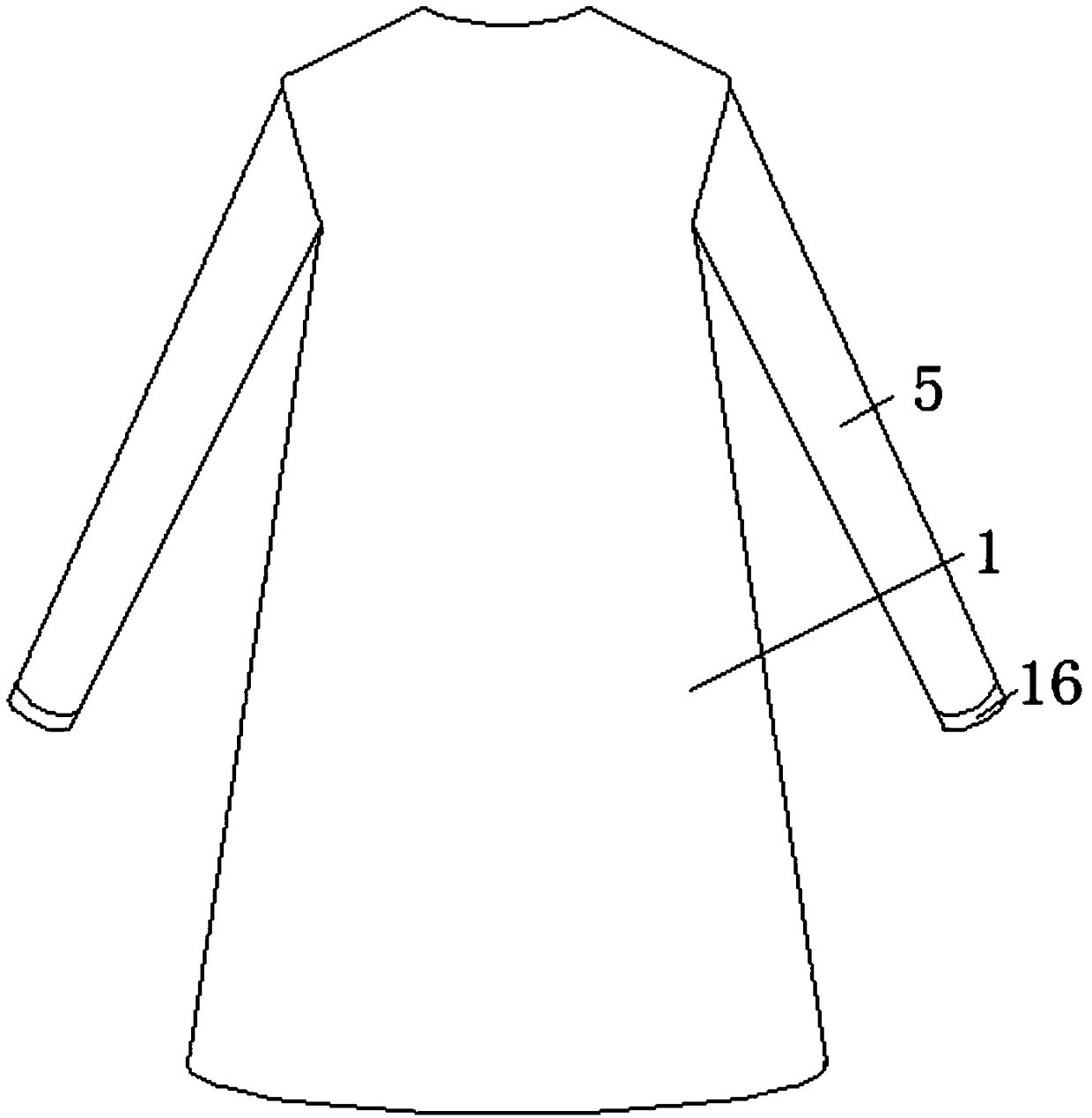

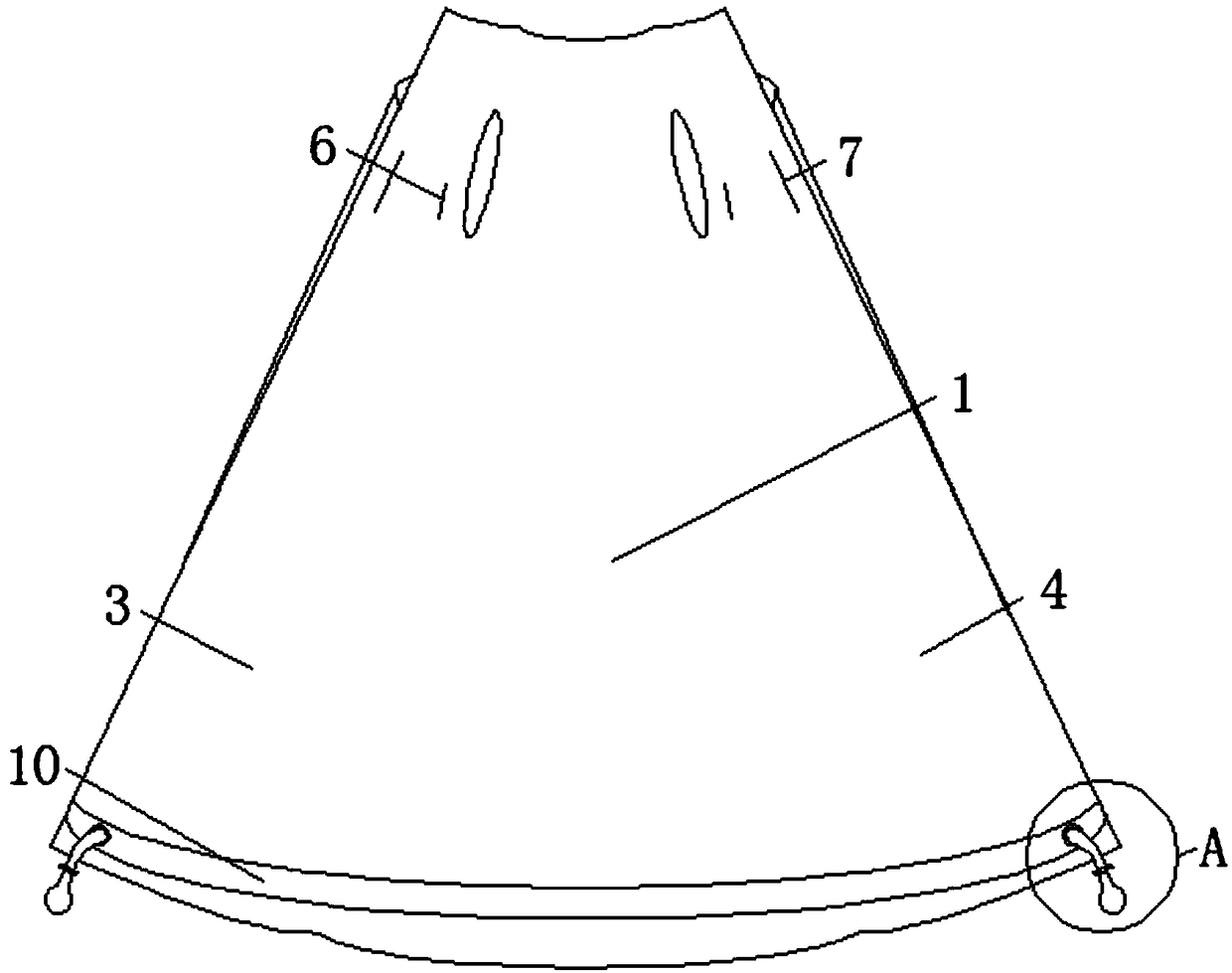

Medical garment for after-delivery lactation

The invention discloses a medical garment for after-delivery lactation. The medical garment comprises a rear garment piece and a first wearing cylinder, a left garment piece and a right garment pieceare fixedly connected to the surface of the rear garment piece separately, and sleeves are fixedly communicated with the surfaces of the left garment piece and the right garment piece; operation portsare formed in the surfaces of the left garment piece and the right garment piece, lactation ports are formed in the surfaces of the left garment piece and the right garment piece, the inner walls ofthe two sides of the two operation ports are fixedly connected through zippers, and the inner walls of the two sides of the two lactation ports are fixedly connected through zippers. According to themedical garment for after-delivery lactation, during actual use, if a puerpera needs lactation after delivery, one hand stably supports an infant, the other hand pulls out the zipper of the lactationport and the operation port of the side, the hand extends in the garment from the corresponding operation port, the breast is supported, the position is adjusted, and lactation for the infant is conducted at the corresponding lactation port; since the lactation ports and the operation ports are vertically formed, the zippers are pulled when the garment is not used and can be posed at vertical bags, and that is to say, breast-shaped check pieces are arranged so that the psychological burden of the puerpera can be avoided.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

Production method of fiber reinforced cement composite concrete prefabricated building elements

InactiveCN102561584BRealize industrialized prefabrication productionImprove product qualityMouldsClimate change adaptationInsulation layerCement composites

The invention relates to a fiber-reinforced cement composite concrete prefabricated building component (PC-FRC) and its production method, which is suitable for building exterior wall decoration, building structure enclosure, energy-saving and thermal insulation projects, and is especially suitable for prefabricated housing industrialization projects. It is suitable for people's livelihood fields such as natural disaster emergency response and post-disaster reconstruction. Including decorative surface layer, fiber-reinforced cement layer, concrete structure layer, insulation layer and steel skeleton; fiber-reinforced cement layer is compounded on the decorative surface layer, and fiber-reinforced cement layer is connected with concrete structure layer; insulation layer is laid in the concrete structure layer , the insulation layer is completely wrapped by the concrete structure layer; a steel skeleton is also laid in the concrete structure layer. Fiber-reinforced cement layer, thermal insulation layer and concrete structure layer are compositely molded in molds with shapes. There are exposed steel bars on the surface connection parts of the prefabricated building components, which are used for the connection between the prefabricated parts and the building structure during building assembly; the hoisting embedded parts are laid on the concrete structure layer.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

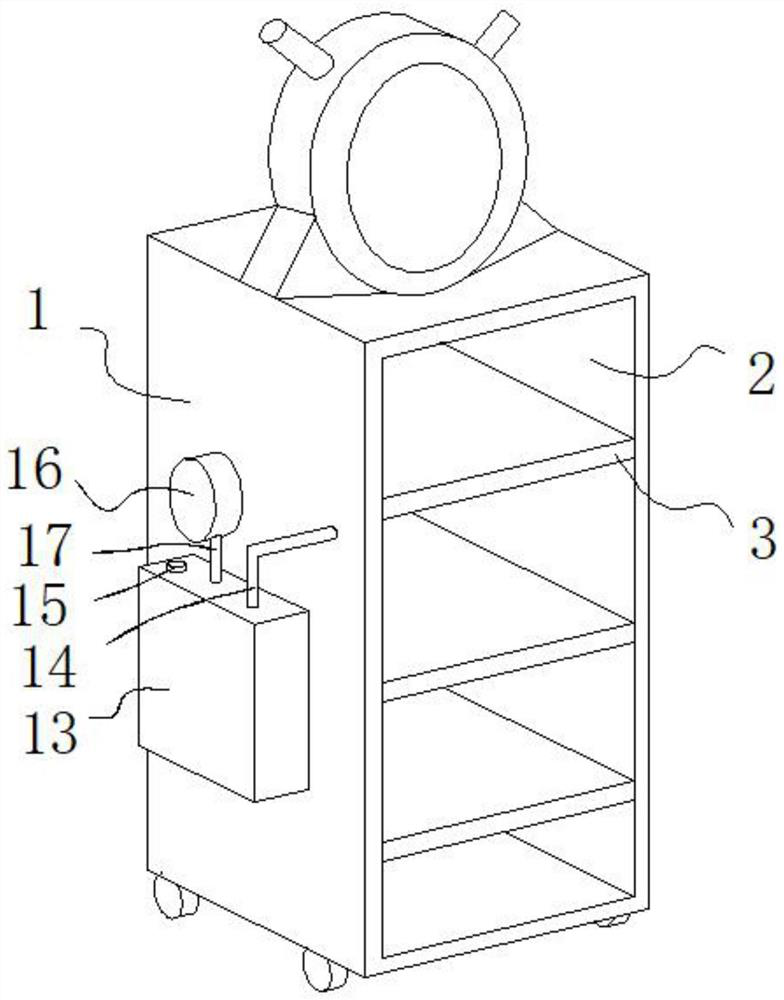

Intelligent cart meal delivery robot

The invention relates to the field of robots, in particular to an intelligent cart meal delivery robot. The intelligent cart meal delivery robot comprises a robot body, wherein a groove is formed in the surface of the robot body, a movable plate is installed in an inner cavity of the groove, guide grooves are formed in the two side walls of the inner cavity of the groove, guide blocks are inserted into inner cavities of the guide grooves, and the two sets of symmetrical guide blocks are fixedly connected with the two side walls of a movable plate correspondingly. According to the intelligent cart meal delivery robot, when the robot body is braked, a bearing plate can drive a limiting sliding block to slide on the inner side and the outer side of a limiting sliding groove, at the moment, the robot body can automatically adjust the current of an electromagnet so that the current can be gradually reduced, and therefore the limiting sliding block and the bearing plate can gradually and slowly slide towards the outer side, impact of inertia is effectively weakened, therefore, pouring of cooking liquor can be greatly reduced, the quality of dishes can be guaranteed, pollution is reduced, and the device is practical and suitable for being widely popularized and used.

Owner:YANGZHOU POLYTECHNIC INST

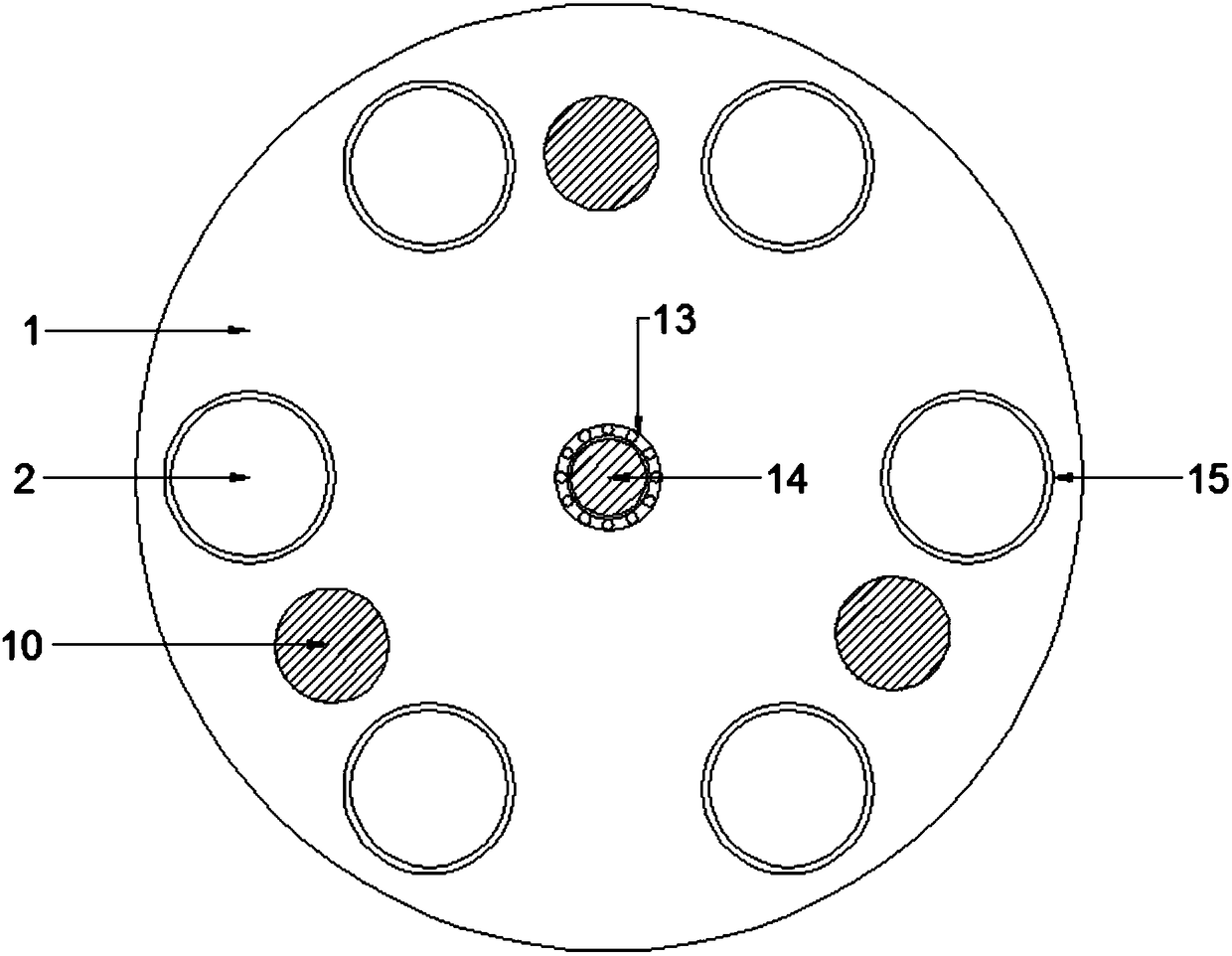

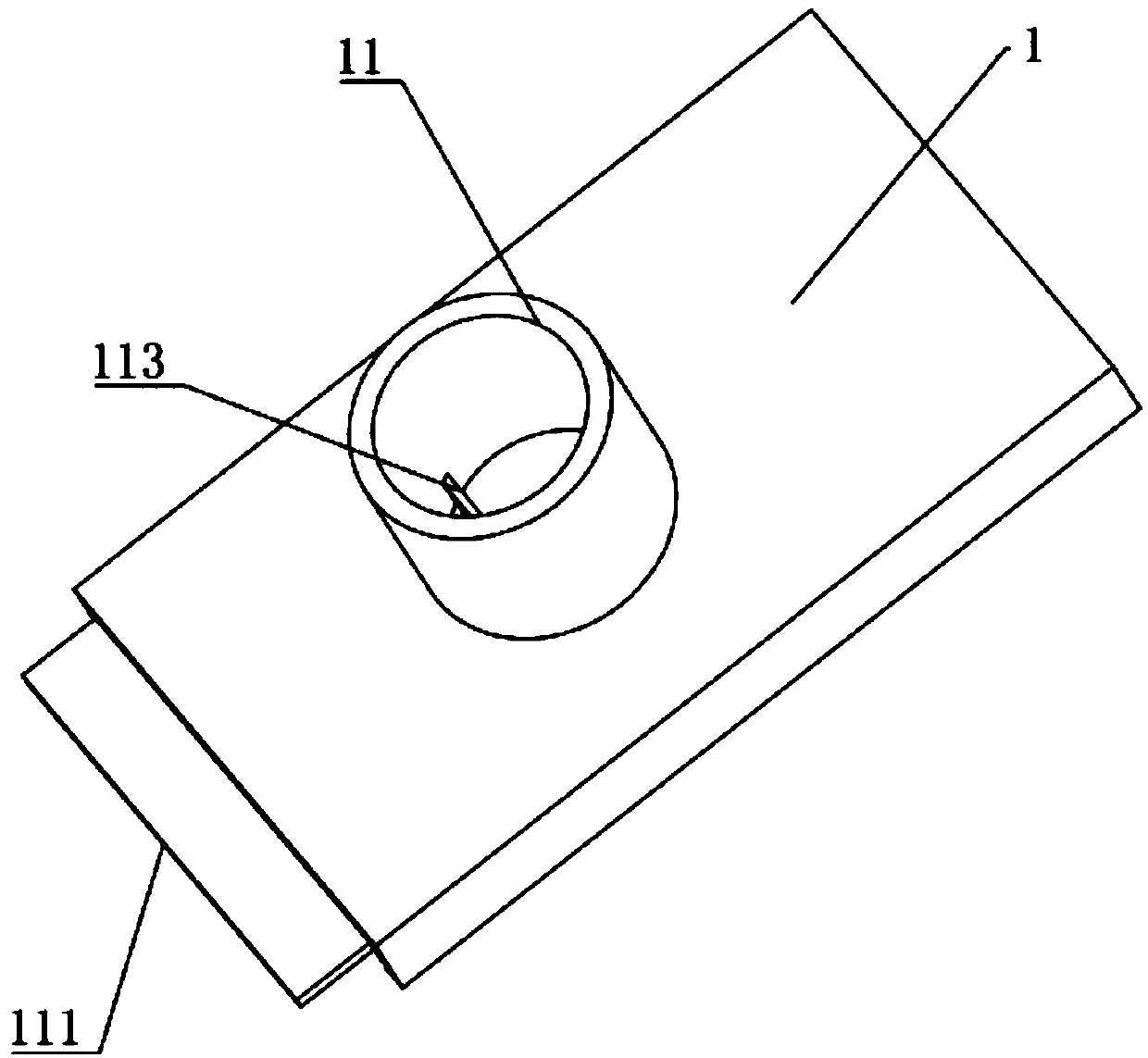

Liquid-based thin-layer cell sheet production clamp

ActiveCN109520800AAvoid absorptionAvoid pushing awayPreparing sample for investigationCENBOLThin layer

The invention discloses a liquid-based thin-layer cell sheet production clamp, belongs to a vertical sheet production clamp for a centrifugal liquid-based thin-layer cell sheet production machine andaims at providing the liquid-based thin-layer cell sheet production clamp capable of reducing outflow of cells on a glass slide with water and furthermore ensuring that the cells on the glass slide are collected. A technical scheme of the liquid-based thin-layer cell sheet production clamp has the key points that a baffle is arranged between inner walls of lower ends of sedimentation tubes; the lower end of the baffle is in contact with the glass slide; the baffle is arranged to be close to the center position of the sheet production machine, and the length of the baffle is smaller than the diameter of the sedimentation tube; a space formed by the sedimentation tube and the glass slide is divided into a cell sedimentation region and a water absorption region by the baffle; the cell sedimentation region is arranged to be close to the center position of the sheet production machine; the upper end of the baffle is provided with a moving plate located on the same plane with the baffle; oneend of the moving plate is hinged with the inner wall of the sedimentation tube, and the other end of the moving plate is in contact with the inner wall of the sedimentation tube; the moving plate isprovided with a tension spring above the cell sedimentation region; and the inner wall, located in the water absorption region, of the sedimentation tube is provided with water absorption cotton.

Owner:YONGKANG JIUJIU TECH

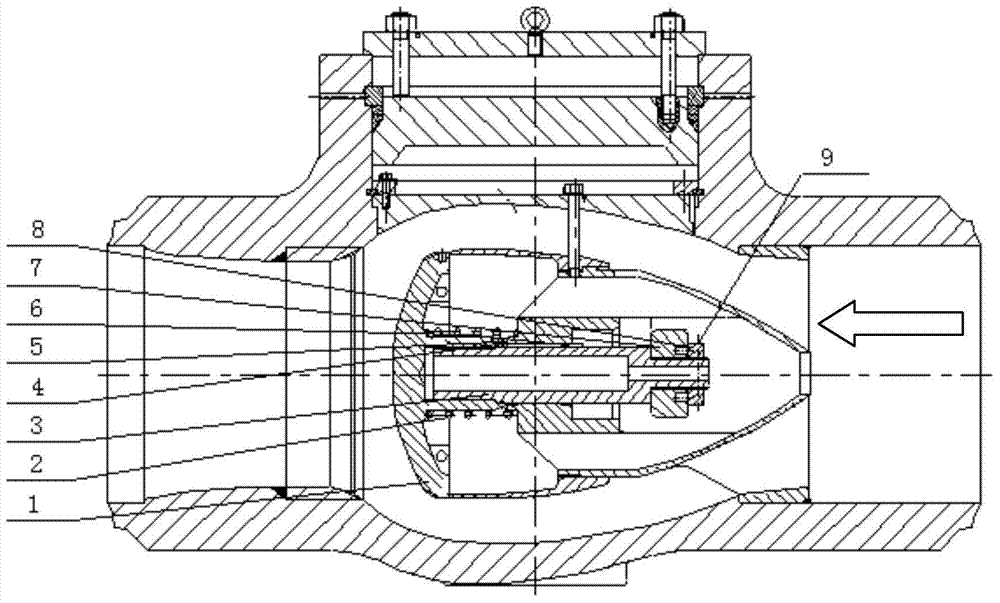

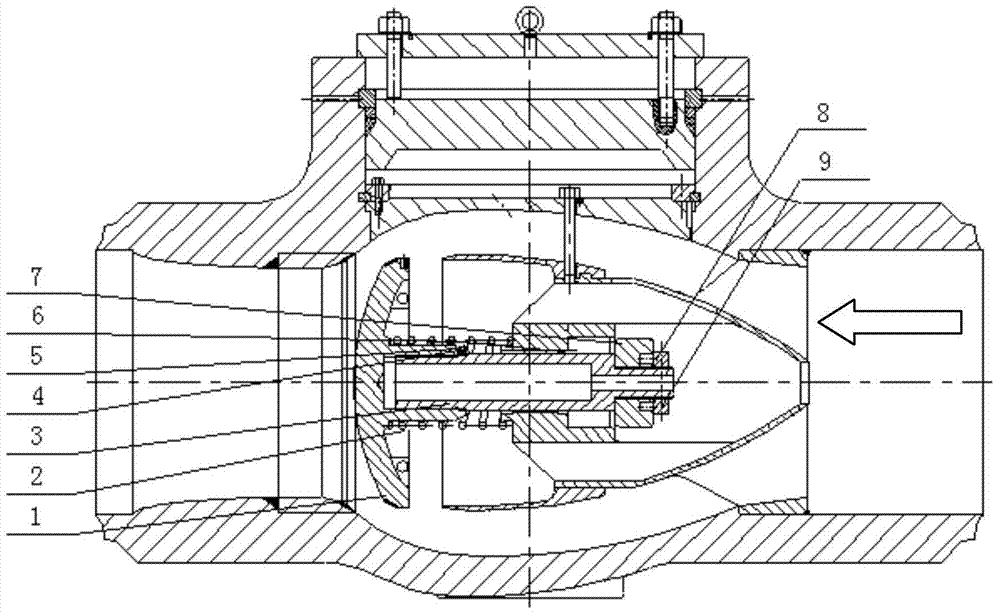

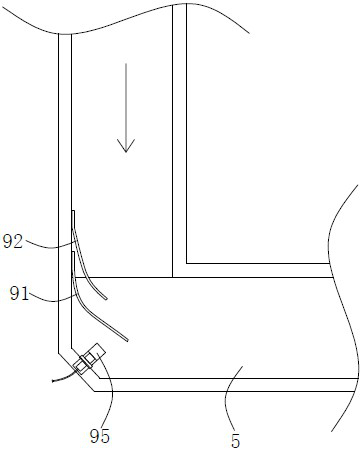

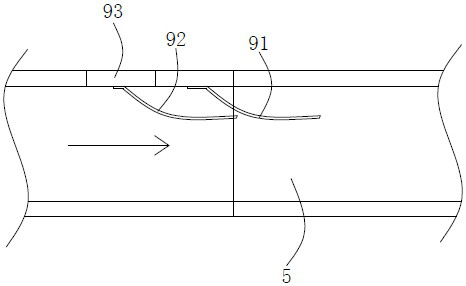

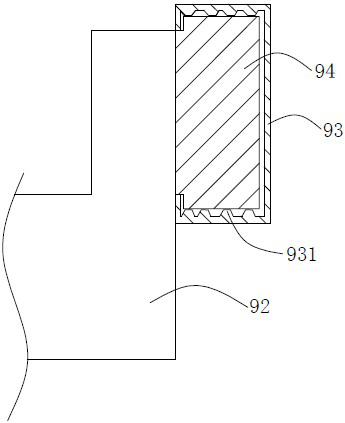

Quick-closing slow closure structure of axle-flow type check valve

InactiveCN104747761AEliminate water hammer effectShort closing timeCheck valvesValve members for absorbing fluid energyEngineeringWater hammer

The invention provides a quick-closing slow closure structure of an axle-flow type check valve. The quick-closing slow closure structure comprises a valve clack, a spring, a guide rod and a piston. The valve clack is connected with the guide rod. The spring is connected with the valve clack. The piston is arranged at the right end of the guide rod. According to the quick-closing slow closure structure of the axle-flow type check valve, on the condition that strokes of the valve clack of the check valve are identical, the valve closing time of the quick-closing slow closure structure is shorter; within the same valve closing time, the amount of media flowing backward in the check value is less; the water hammer effect of the check valve in the valve closing process is effectively reduced; the requirement of the check valve of the quick-closing slow closure structure for space of a valve cavity is lower than that of a check valve with a full-stroke piston mechanism.

Owner:SHANGHAI VALVE FACTORY +1

Batch automatic production line for small-dose bottled liquid preparations

ActiveCN113682585AContinuous processing efficiencyStable processing efficiencyArticle unpackingFlanged caps applicationProcess engineeringBottle fed

The invention discloses a batch automatic production line for small-dose bottled liquid preparations, and belongs to the technical field of pharmaceutical production equipment. The batch automatic production line comprises a bottle body feeding section, a washing, drying, filling and sealing section, a sterilizing and lamp inspection section and a labeling and packaging section which are sequentially connected, a conveying device used for transferring materials is arranged among the sections, and a bottle falling prevention assembly is arranged on the conveying device. The bottle body feeding section comprises an unboxing station and a plurality of unpacking stations, the washing, drying, filling and sealing section comprises a washing and drying station and a filling and sealing station, the sterilizing and lamp inspecting section comprises a sterilizing station and a lamp inspecting station, and the labeling and packaging section comprises a labeling station and a packaging station. The batch automatic production line has the advantages that the automation degree is high, the production process is continuous and stable, and bottle bodies are stable and not prone to toppling over in the conveying process.

Owner:QIONGLAI TIANYIN PHARM CO LTD

An environment-friendly chemical reagent containing device for chemical engineering

ActiveCN108855261BImprove utilization efficiencyFlexible transferLaboratory glasswaresHazardous material storageEngineeringExhaust pipe

The invention discloses an environment-friendly type chemical reagent containing device for chemical engineering. The environment-friendly type chemical reagent containing device comprises an operation platform, a recycling box, a containing transfer box and an extruding rod, wherein a plurality of placing grooves are arranged around the top surface of the operation platform; a liquid leaking holeis formed in the inner bottom surface of each placing groove; the containing transfer box is rotationally and fixedly arranged at the top surface of the operation platform; the interior of the surrounding part of the containing transfer box is provided with a plurality of liquid storage cavities; the top part of each liquid storage cavity is rotationally and fixedly connected with a rotary box; an overflow pipe penetrates into each rotary box; a liquid drain cylinder is fixedly arranged at the top surface of each rotary box; the side surface of each liquid drain cylinder is connected with a liquid drain pipe; an extruding rod penetrates through the side wall of the containing transfer box; the right end of the extruding rod extends into a sealing air chamber, and a compression sealing gasket is fixedly arranged at the right end of the extruding rod; the top opening of an air exhaust pipe at the top surface of the sealing air chamber is positioned at the inner top part of the liquid storage cavity. The environment-friendly type chemical reagent containing device has the advantages that the handling of chemical reagents by an operator is reduced, the overflow waste of the reagent isreduced, the damage to the environment due to free dumping of the waste liquid is reduced, the operation time is shortened, and the utilization efficiency of the containing transfer box is greatly improved.

Owner:SHANGHAI LINKCHEM TECH CO LTD

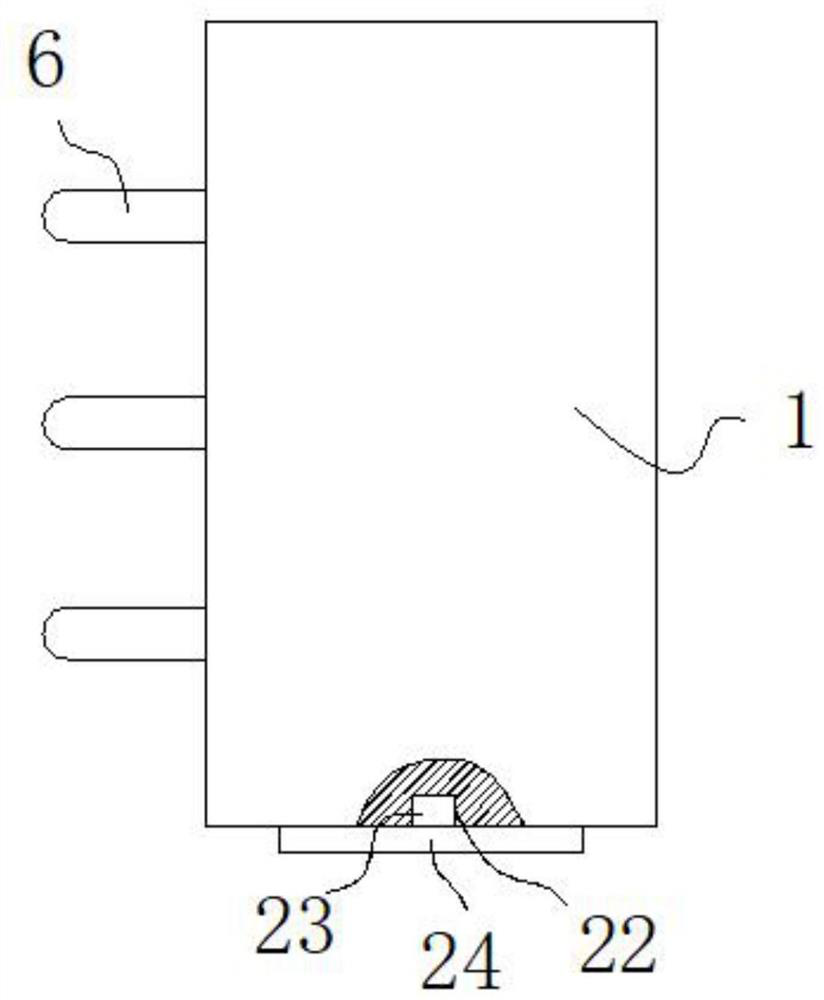

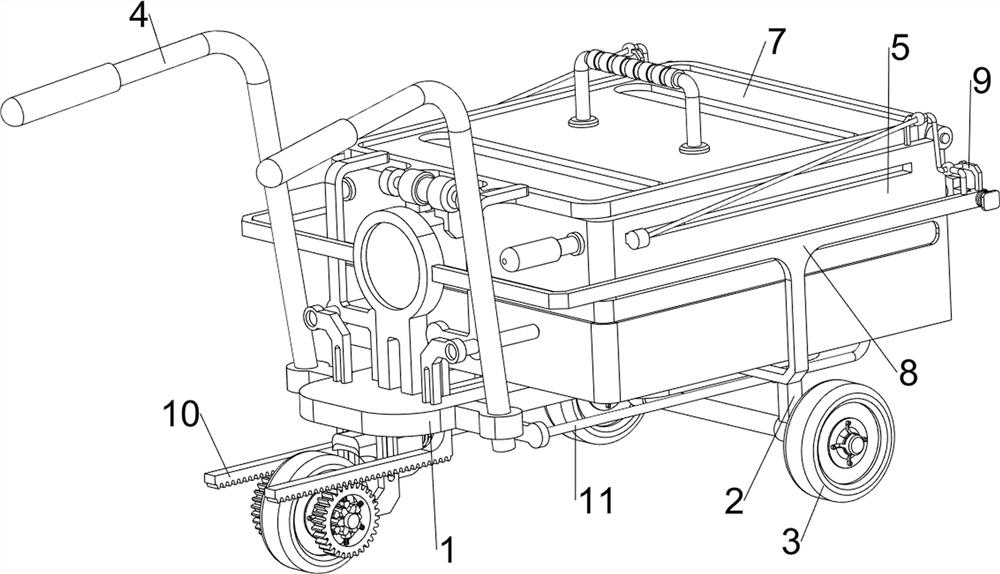

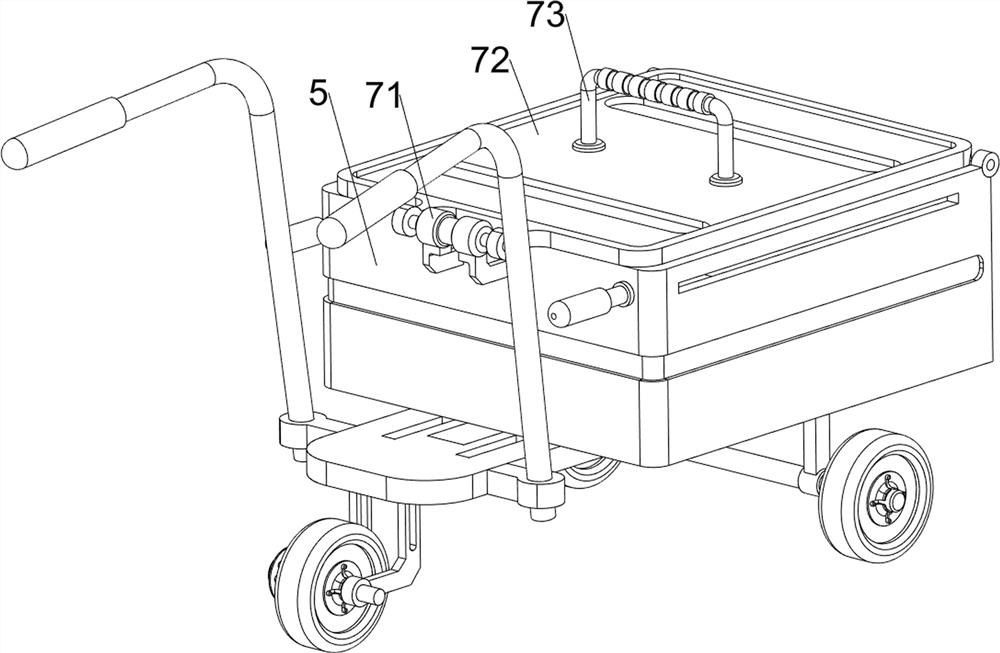

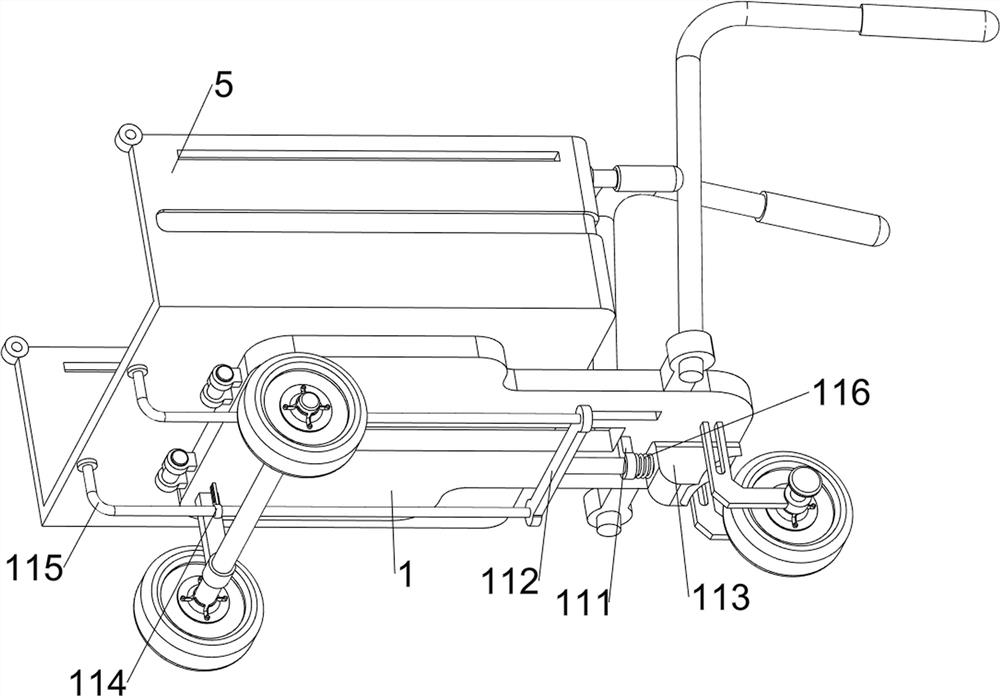

Trolley convenient for unloading in building construction

PendingCN114348088APour automationReduce pouringHand carts with multiple axesHand cart accessoriesArchitectural engineeringUtility trolley

The invention relates to a trolley, in particular to a trolley facilitating unloading in building construction. According to the trolley facilitating unloading in building construction, in the transportation process of building materials, the main body can be blocked, and the building materials are prevented from shaking out. A trolley facilitating unloading in building construction comprises a placing plate, first connecting blocks, wheels, a first handle and a loading frame, the first connecting blocks are arranged on the front side and the rear side of the right end of the bottom of the placing plate, the two wheels are rotationally arranged between the lower portions of the two first connecting blocks through rotating shafts, and the wheels are rotationally arranged at the left end of the bottom of the placing plate through rotating shafts. The telescopic rod of the air cylinder extends to drive the first fixing block to move towards the upper side, the first fixing block drives the loading frame to rotate, and the loading frame pours out the building materials, so that the building materials are automatically poured out, manual pouring out of the building materials is reduced, and the working efficiency can be improved.

Owner:蔡政丽

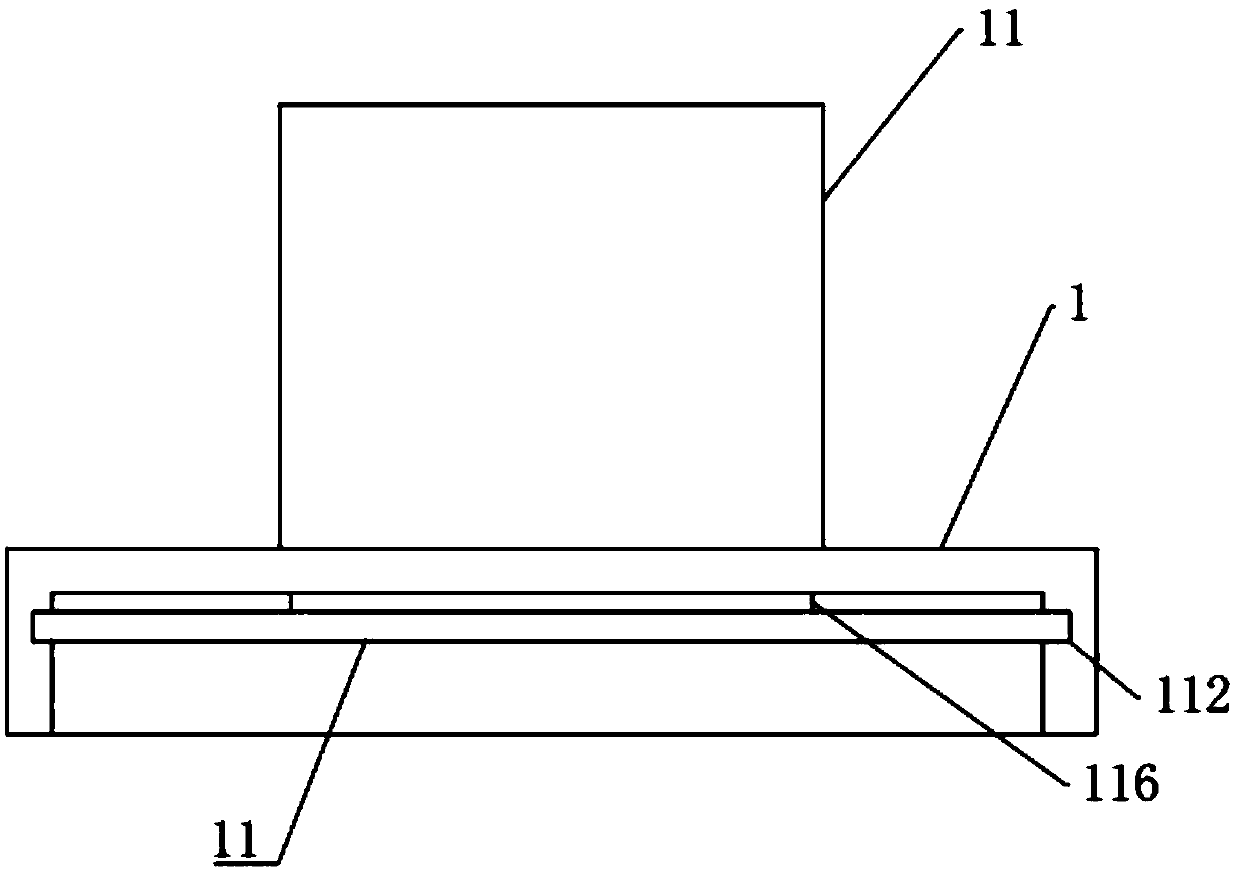

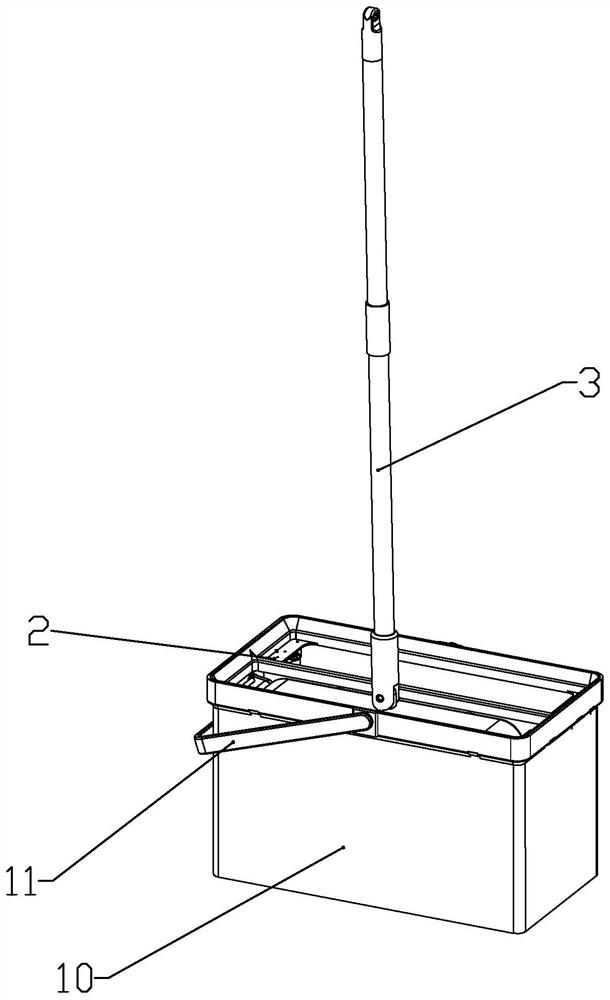

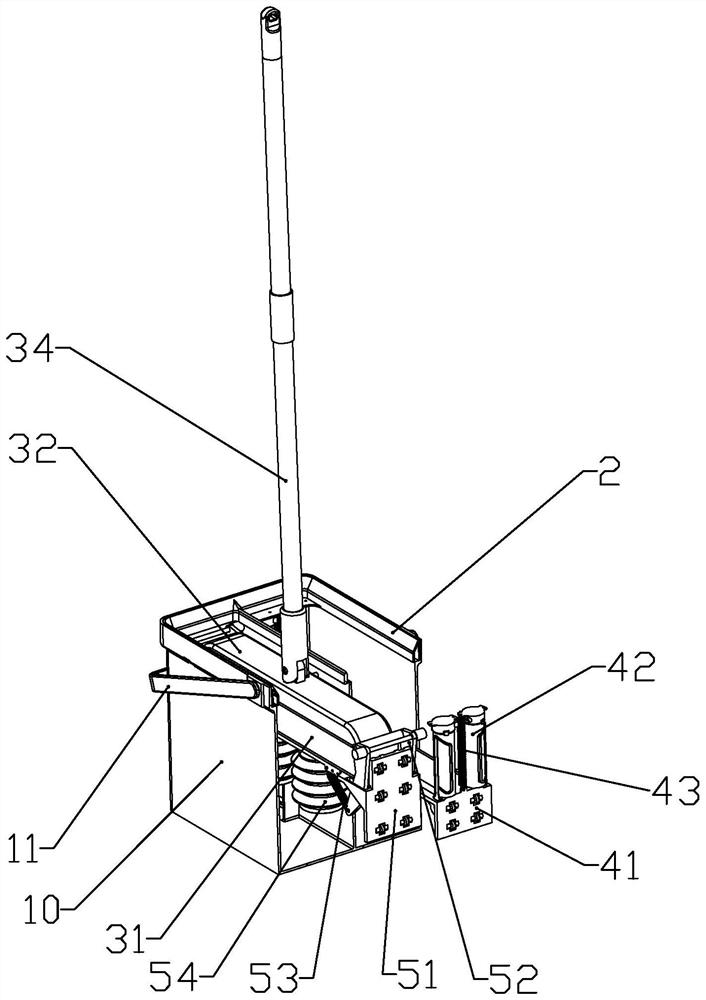

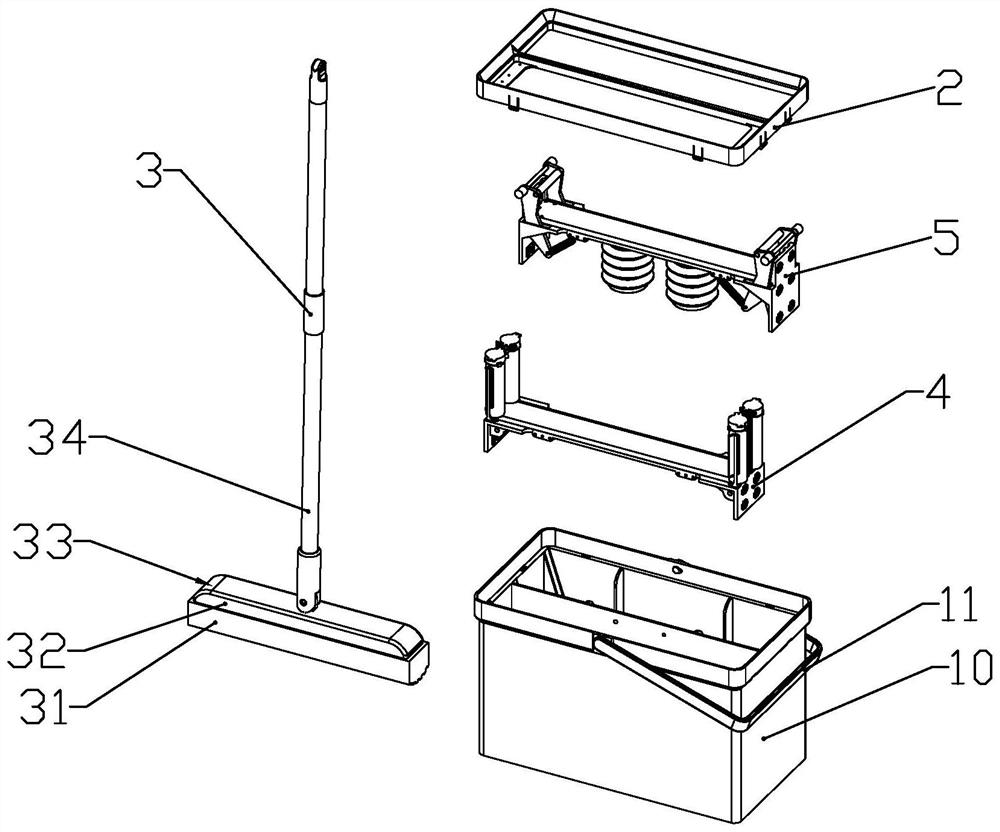

Cleaning and wringing mop bucket kit

ActiveCN111990940AReduce pouringReduce the number of steps to pour out the water in the squeeze bucketCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention belongs to the technical field of cleaning tools and discloses a mop cleaning and wringing bucket kit. The mop cleaning and wringing bucket kit comprises a bucket body and a sponge mop,wherein a water squeezing assembly is slidably connected into the bucket body, the bucket body comprises a cleaning bucket and a water squeezing bucket, a plurality of guide slopes are formed in the water squeezing bucket, the water squeezing assembly comprises a water squeezing frame and a squeezing part, the sponge mop comprises a mop head and cleaning sponge. When the water squeezing frame moves downwards, the squeezing part rotates towards the middle part of the water squeezing bucket along the guide slope, compressing and dehydrating the cleaning sponge, and a lower end of the water squeezing frame is fixedly connected with a plurality of drainage air bags used for draining the water in the water squeezing bucket into the cleaning bucket. The mop cleaning and wringing bucket kit is provided with the mop cleaning bucket and the mop squeezing bucket, the cleaning sponge is compressed and dewatered through a squeezing roller, the water in the water squeezing bucket can be dischargedinto the cleaning bucket in the using process, the water in the water squeezing bucket is always located at a low height, then the height of the bucket body can be reduced, and the cleaning device iscompact in design structure, low in cost and convenient to use and store.

Owner:邳州市景鹏创业投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com