Spraying sandwiched concrete shear wall structure of clamp die fixing machinery and construction method

A concrete shear wall and mechanical spraying technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of large on-site construction volume, long construction period, waste of resources, etc., and improve the overall bending strength and impact resistance. , High injection pressure and injection volume, the effect of avoiding fire damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

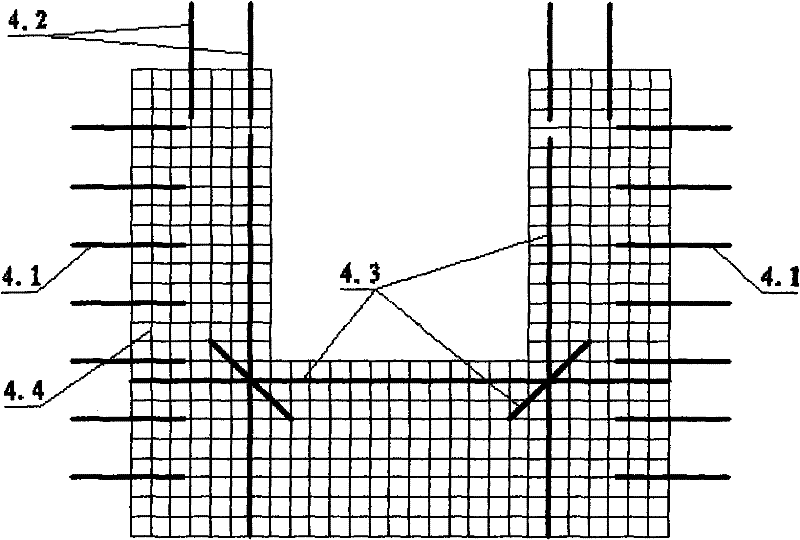

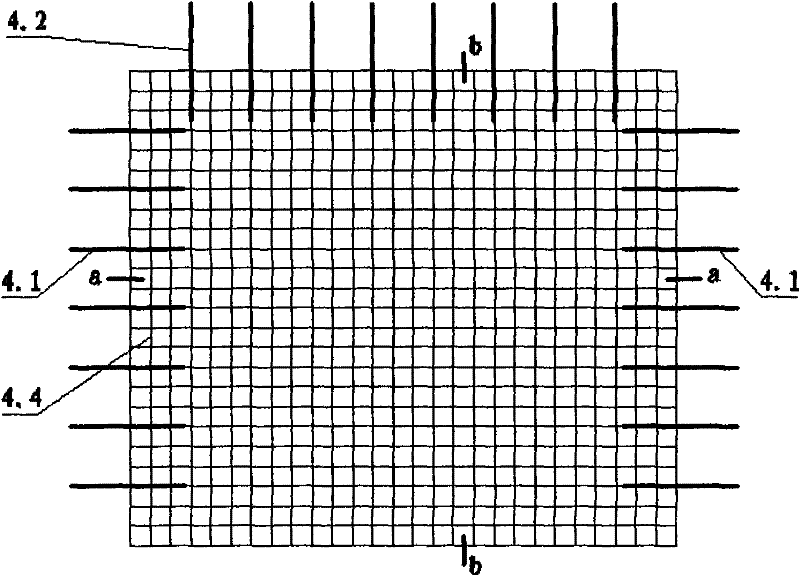

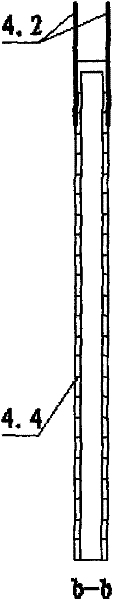

[0062] The invention provides a construction method for clamping and fixing mechanical spraying sandwich concrete shear walls and a clamping and fixing mechanical spraying sandwich concrete shear wall structure prepared by the method. The main features of the construction method are: after the prefabricated steel mesh core board is installed on the lower beam / foundation cast on site, the clamping formwork of the clamping column and the clamping beam is installed, and then the steel mesh core board is installed The two sides of the steel mesh core board are fixed with clamping columns and clamping beams, and the concrete layer is mechanically sprayed on the light material board surface of the steel mesh core board, and the steel mesh of the steel mesh core board is consolidated in the concrete layer, Then carry out the on-site pouring of the clamped formwork columns and clamped formwork beams, and vibrate during the pouring, so that the poured concrete is densely consolidated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com