Cavern arch mould spraying concrete construction structure and process

A technology of sprayed concrete and concrete, which is applied to structural elements, building components, underground chambers, etc., can solve the problems of high construction cost, safety and quality improvement, and long construction period, and achieve short construction period, guaranteed quality, and structural integrity. The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

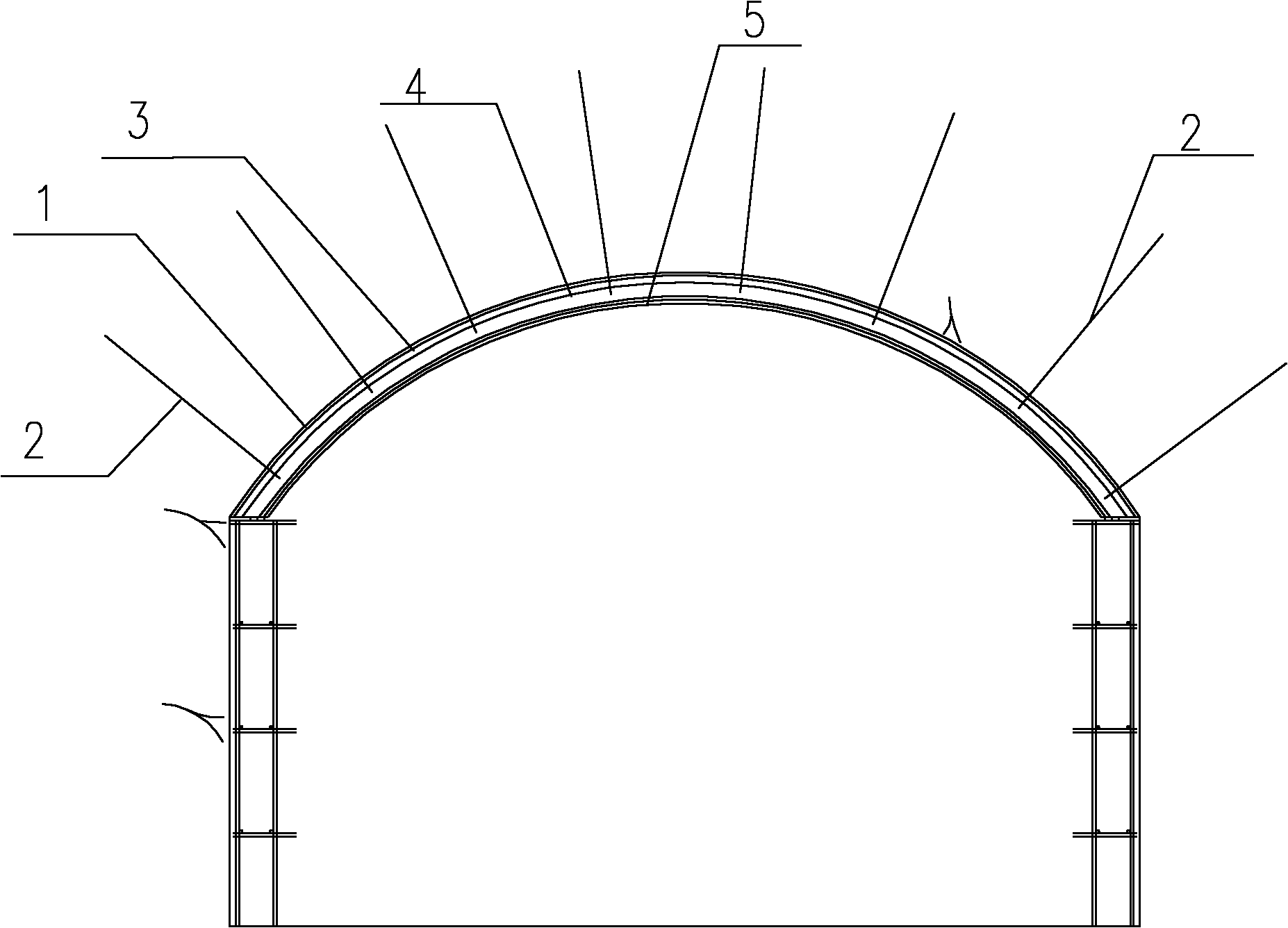

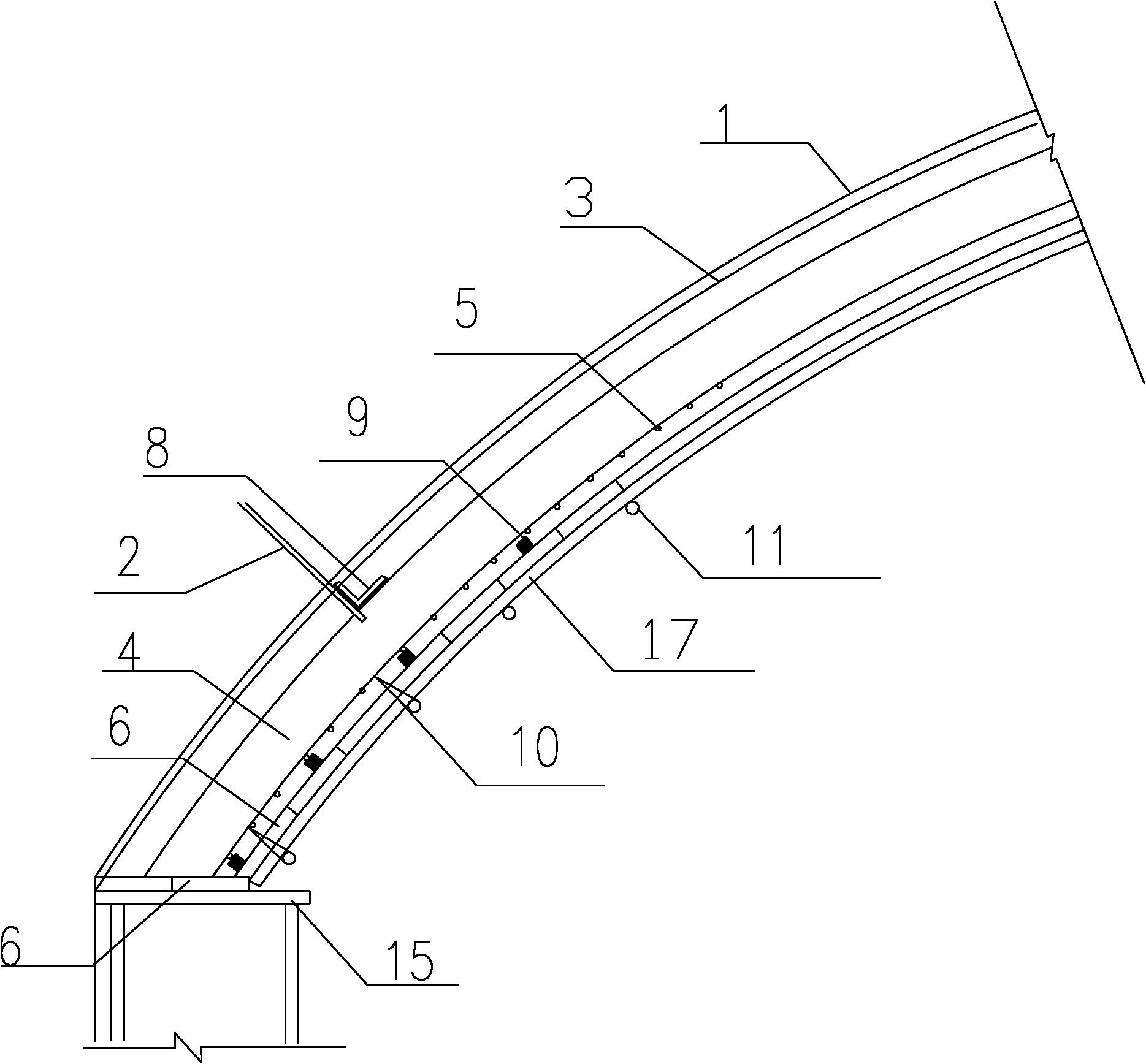

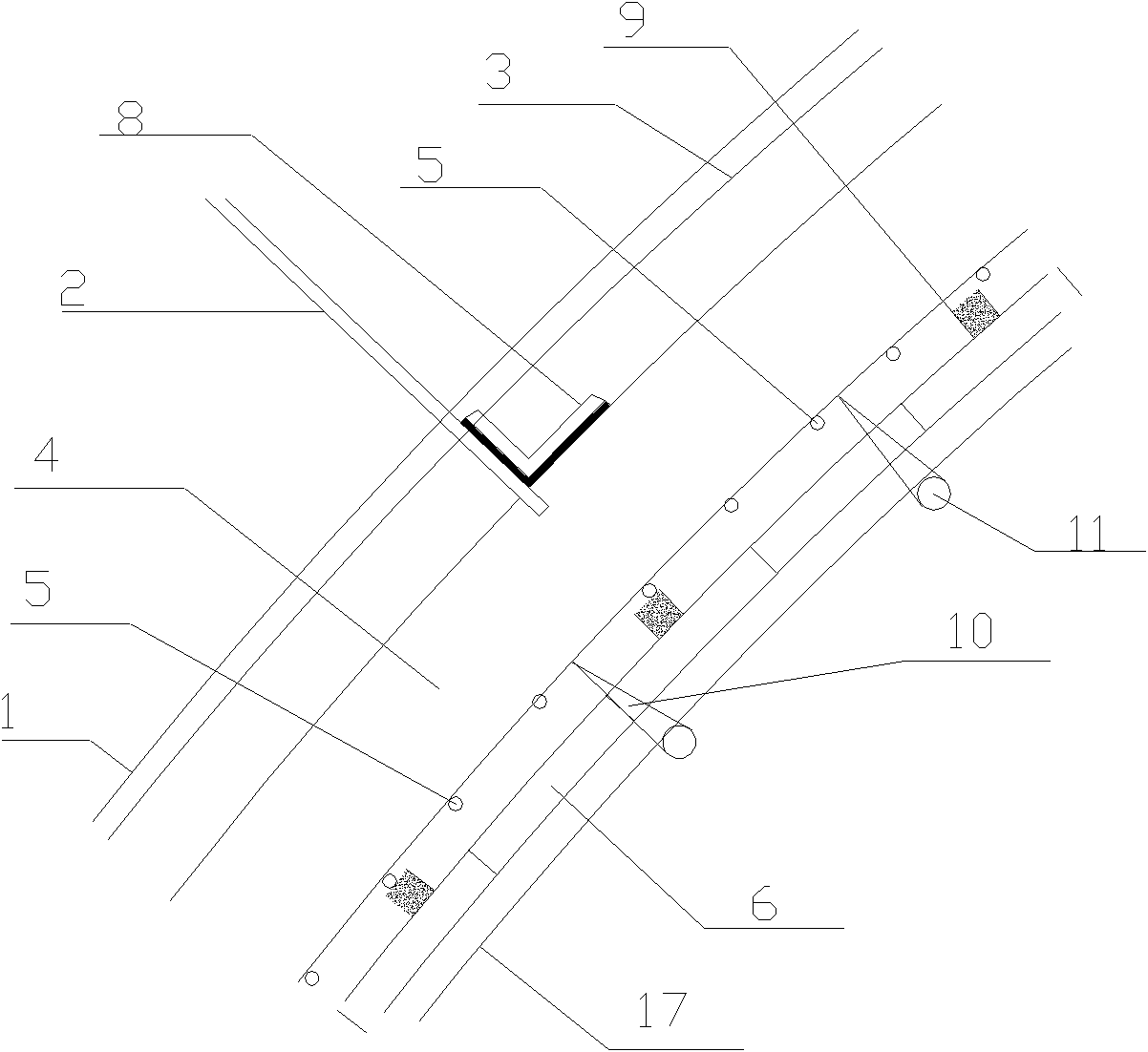

[0138] combine Figure 1 to Figure 3 .

[0139] figure 1 It is a schematic diagram of the sprayed concrete structure of the cave roof arch form of the present invention. The cavern top arch anchor rod 2 and steel structure are schematically shown in the figure, the present invention adopts formwork suspension technology, the weight of steel structure and formwork suspension structure utilizes anchor rod 2 to support in the concrete construction process, the quantity of anchor rod 2 and the drilling depth According to on-site design needs, this is a conventional mechanical calculation design, no matter how many anchor rods 2 and how to fix them all belong to the protection scope of the present invention. The steel structure is a necessary structural feature of concrete pouring. The steel structure in the concrete structure is to strengthen the toughness of the overall concrete structure and increase the tensile strength. No matter what concrete and steel structure is used, it...

Embodiment 2

[0146] combine Figure 1 to Figure 4 , Figure 4 It is a schematic diagram of the construction state of the sprayed concrete in this example.

[0147] Adopt the specific structure of this example to carry out construction through the following steps:

[0148] A. Treatment of the bedrock surface. After excavation, carry out underexcavation treatment on the rock surface 1 and removal of loose rock blocks; underexcavation treatment ensures that the size of the building structure meets the design requirements and ensures the stability of the structure.

[0149] B, anchor rod construction, set up construction platform 13, carry out anchor rod 2 drilling and pouring; Carry out anchor rod construction after excavation, increase tendons and bones in rock mass, strengthen the intensity of anchorage area surrounding rock;

[0150] C. Install the inner layer of steel mesh, weld the supporting steel bars of the inner layer of steel mesh through the anchor rod 2, and then bind and instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| q value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com