System for controlling in and out of storage of steel plates

A control system, storage and in-out technology, applied in the field of control systems, can solve the problems of material dumping and homing, time waste, economic waste, etc., and achieve the effects of reducing material dumping and homing, saving power consumption, and accurate information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

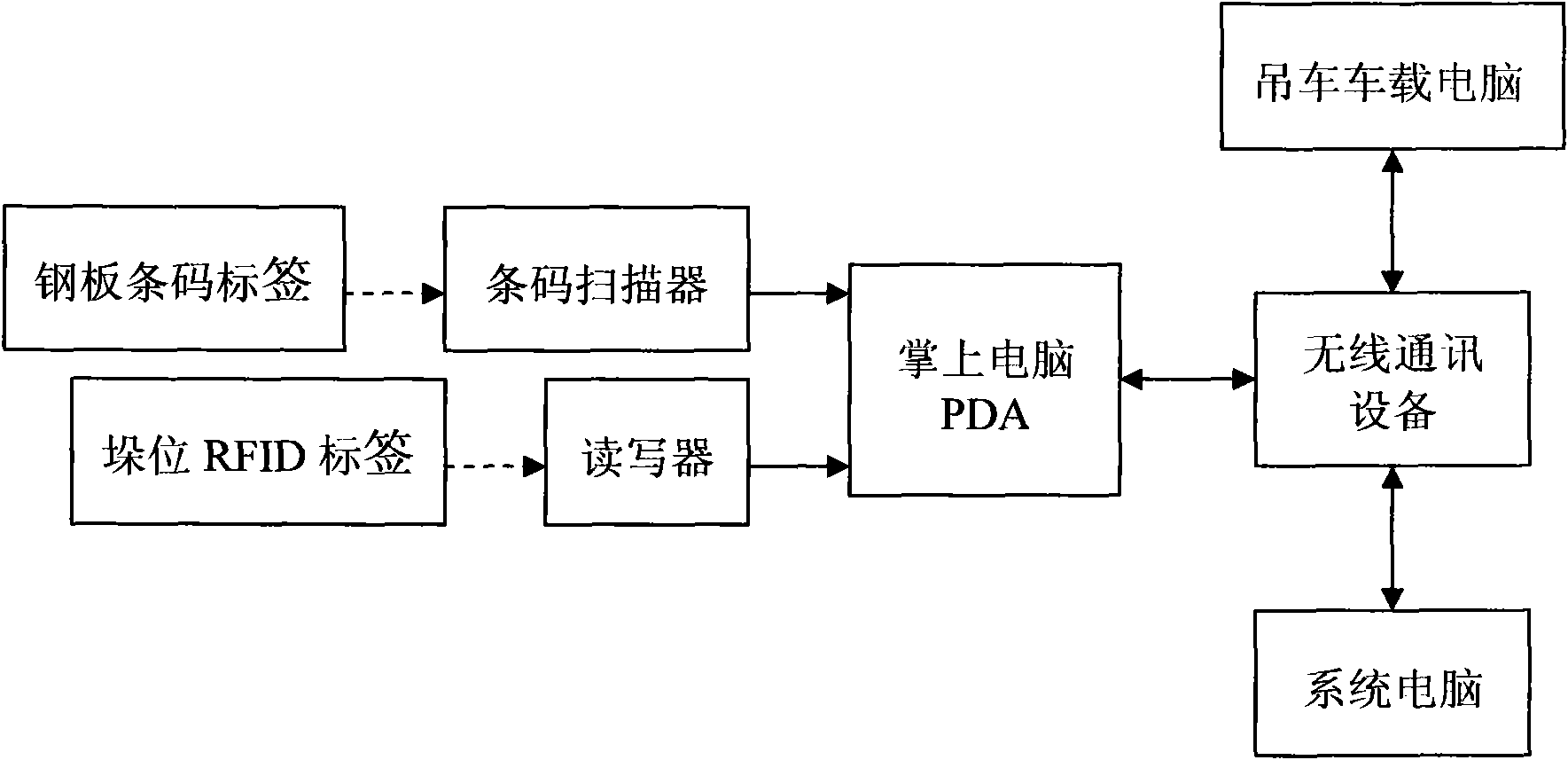

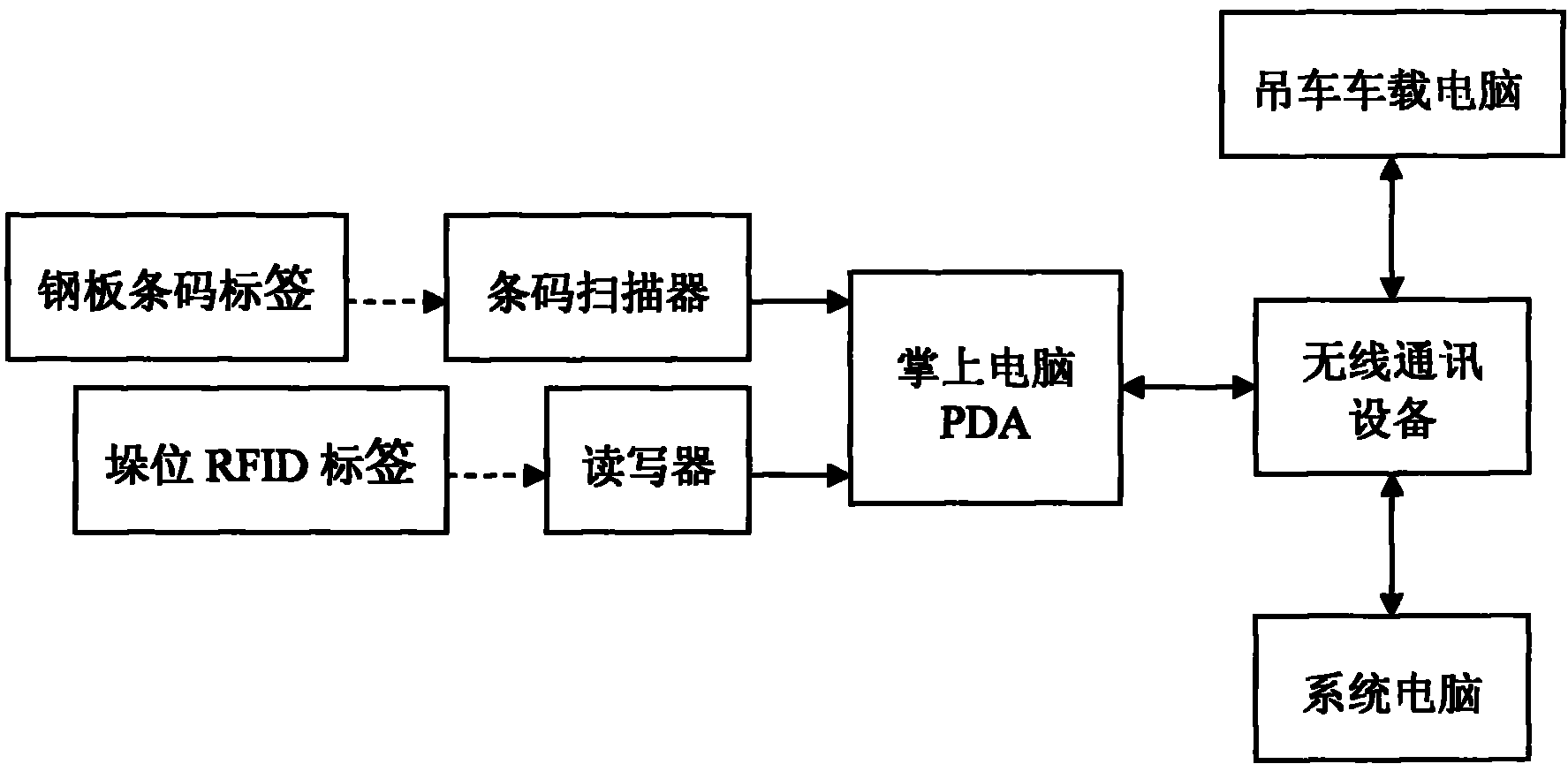

[0015] Such as figure 1 As shown, a steel plate entry and exit control system is equipped with a barcode label on the steel plate, and its barcode scanner is connected with a handheld computer PDA. The handheld computer PDA uses a 7527S handheld computer terminal; The model is EPC Gen2, and the RFID reader is connected to the PDA; the PDA is connected to the computer on the crane and the system computer through the 9160 high-power wireless AP. The model of the wireless AP is Intel IXP420, and the computer on the crane is 8515. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com