Patents

Literature

410results about How to "Reduce quality impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

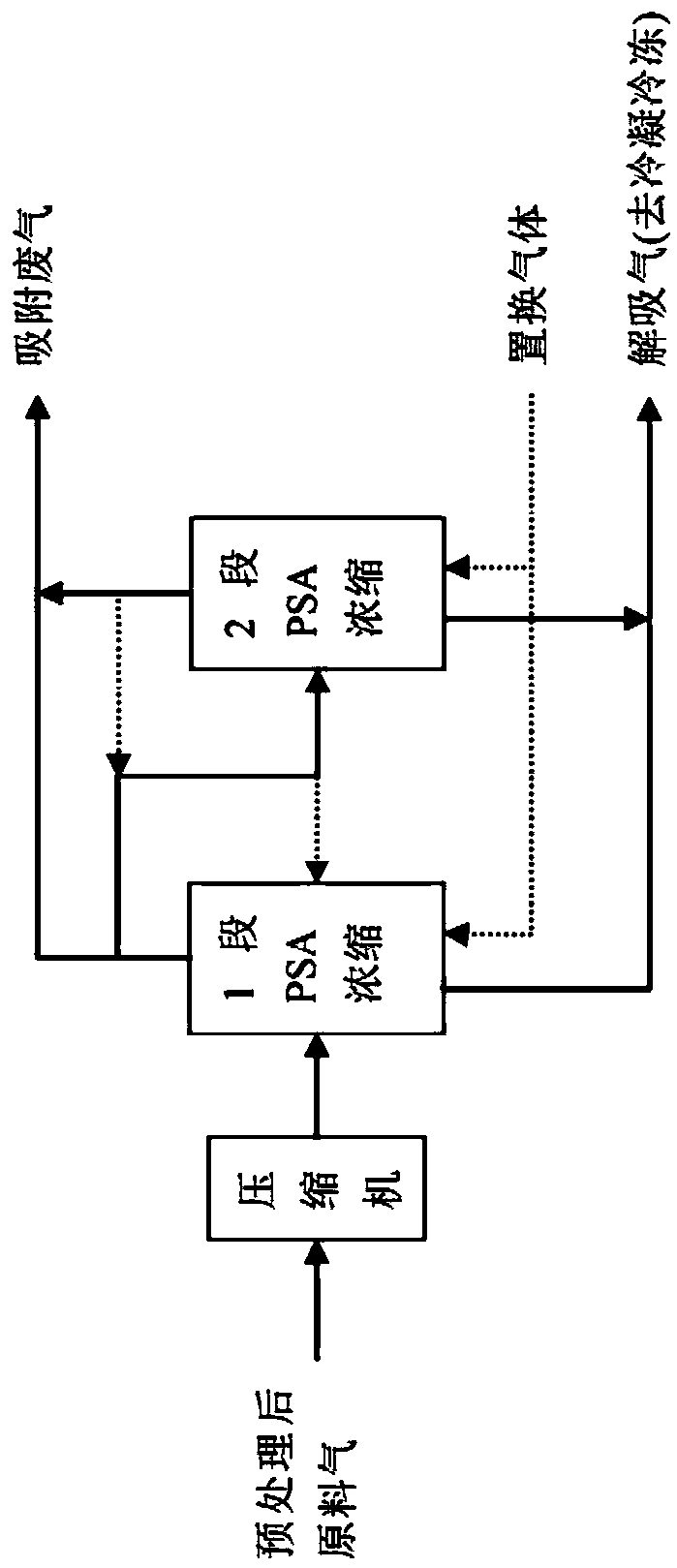

Method for recycling and reusing all components of LED-MOCVD (Light Emitting Diode-Metal Organic Chemical Vapor Deposition) preparation process tail gas through pressure swing adsorption in whole temperature process

ActiveCN108658042ARealize the recycling and reuse of all componentsEmission reductionHydrogen separation using solid contactDispersed particle separationDistillationLight-emitting diode

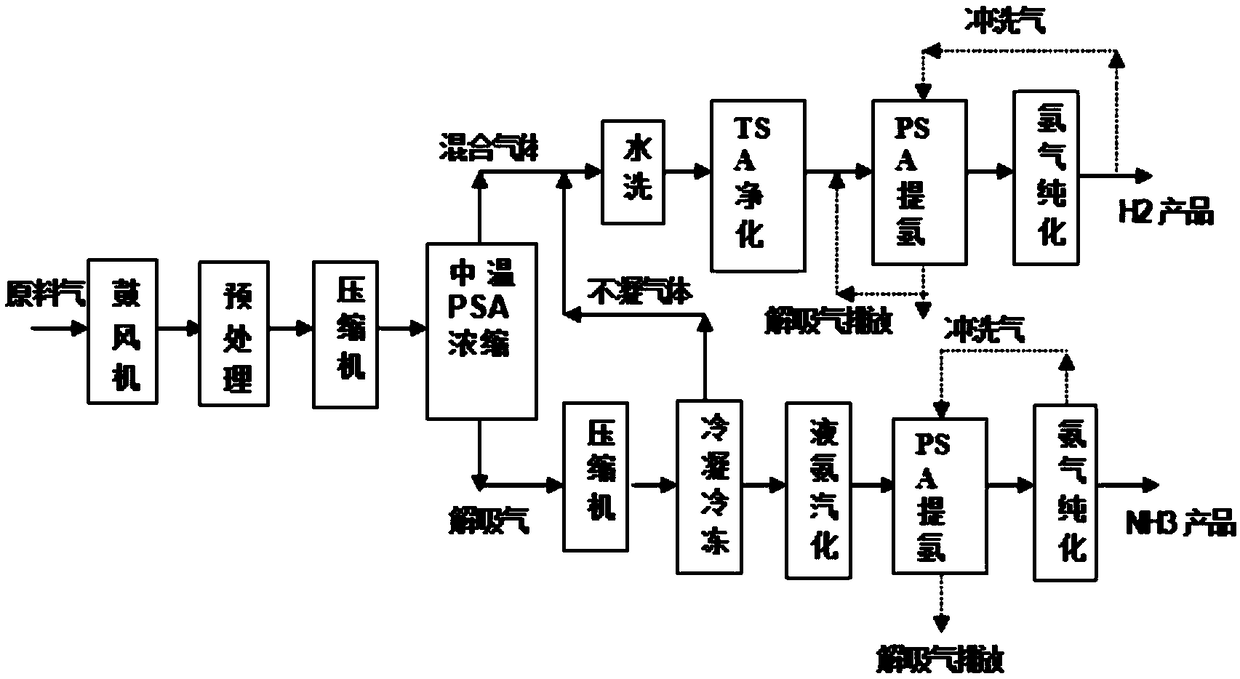

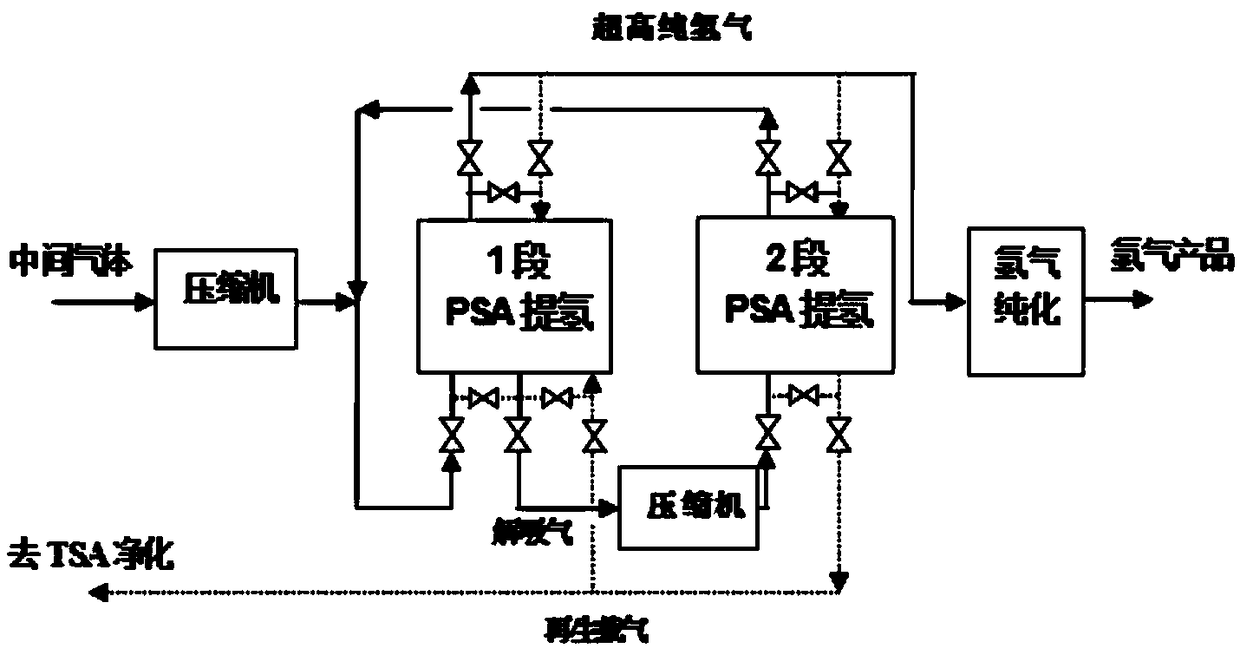

The invention discloses a method for recycling and reusing all components of an LED-MOCVD (Light Emitting Diode-Metal Organic Chemical Vapor Deposition) preparation process tail gas through pressure swing adsorption in a whole temperature process. The method comprises procedures of pretreatment, medium-temperature pressure swing adsorption concentration, variable-temperature adsorption purification, pressure swing adsorption (PSA) hydrogen refining, hydrogen purification, condensation, freezing or ammonia gas distillation, liquid ammonia gasification, pressure swing adsorption ammonia extraction and ammonia gas purification, and hydrogen or ammonia-containing waste gases of the LED-MOCVD preparation process are purified till standards of electron-scale hydrogen (of which the purity is greater than or equal to 99.99999%v / v) and an electron-scale ammonia gas (of which the purity is greater than or equal to 99.99999%v / v) used in the LED-MOCVD preparation process, then recycling and reuseof waste gases are achieved, the hydrogen yield is greater than or equal to 75-86%, and the ammonia gas yield is greater than or equal to 70-85%. By adopting the method, the technical difficulty thata normal-pressure or low-pressure waste gas in the LED-MOCVD preparation process cannot be recycled or reused in the LED-MOCVD preparation process can be solved, and blanks of green and circular economic development of the LED industry can be made up.

Owner:SICHUAN TECHAIRS

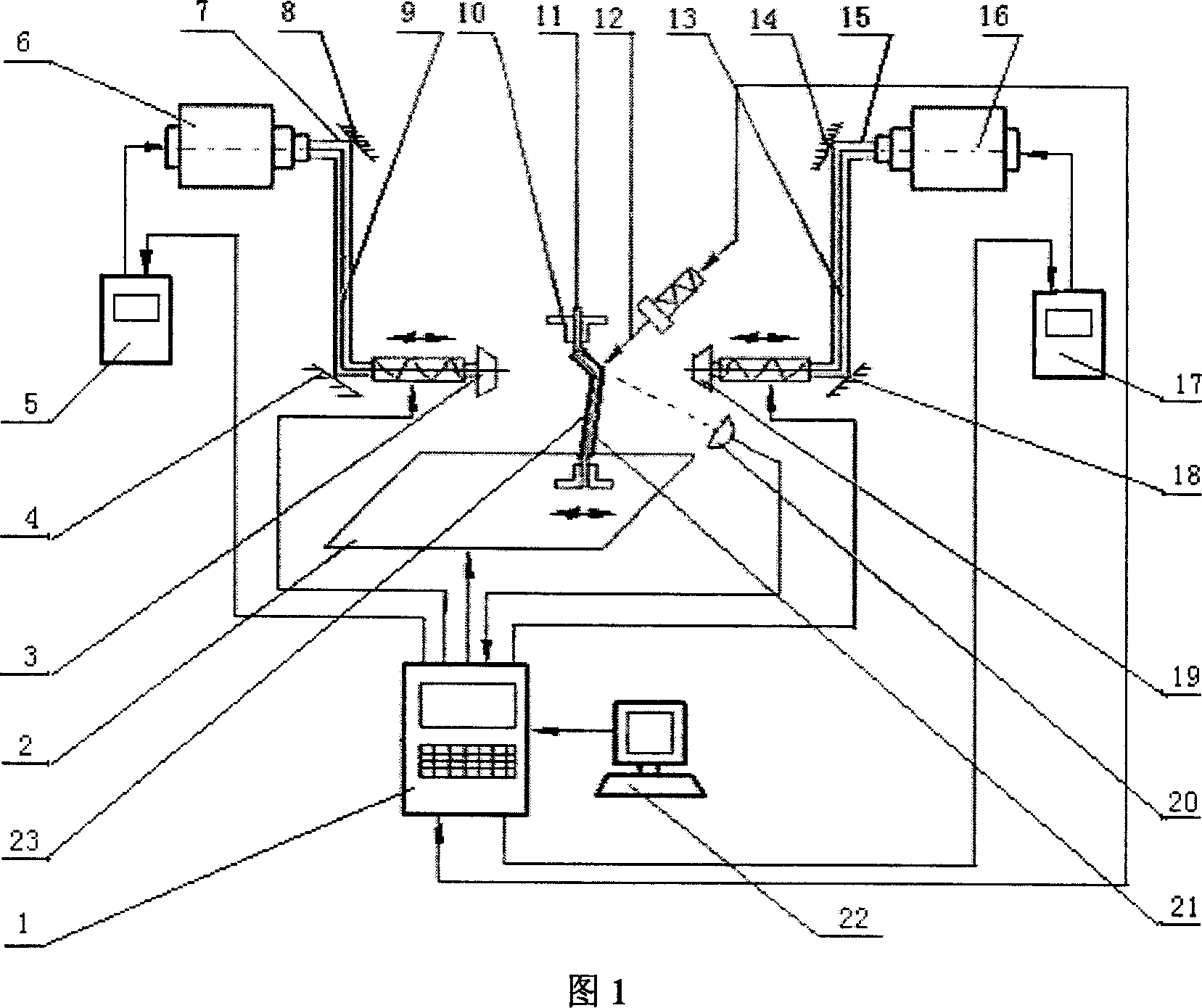

Plate forming process and apparatus

InactiveCN1931467APrecise Local FormingAccurate shapeShaping toolsComputer controlShock waveLaser processing

The plate forming process and apparatus belongs to the field of laser processing technology. The present invention has CO2 laser for pre-heating plate, infrared thermometer for measuring and controlling the plate heating temperature, neodymium glass laser for providing powerful short laser pulse to induce the generation of laser shock wave as the forming force source in processing plate and plate deformation measuring feedback device. The present invention is superior to laser thermal stress forming process, which has inferior formed surface quality, and laser shock forming process, which has small deformation amount, and can form plate directly in relatively great deformation amount, relatively high size precision and relatively high surface quality.

Owner:JIANGSU UNIV

Islanding Detection Method of Photovoltaic Grid-connected Inverter

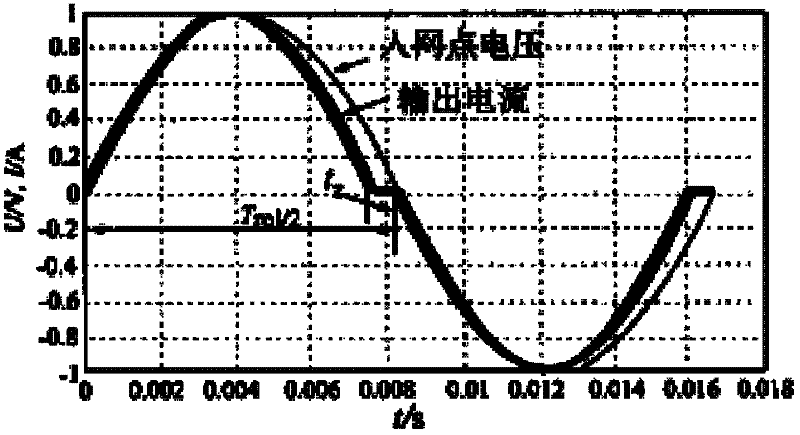

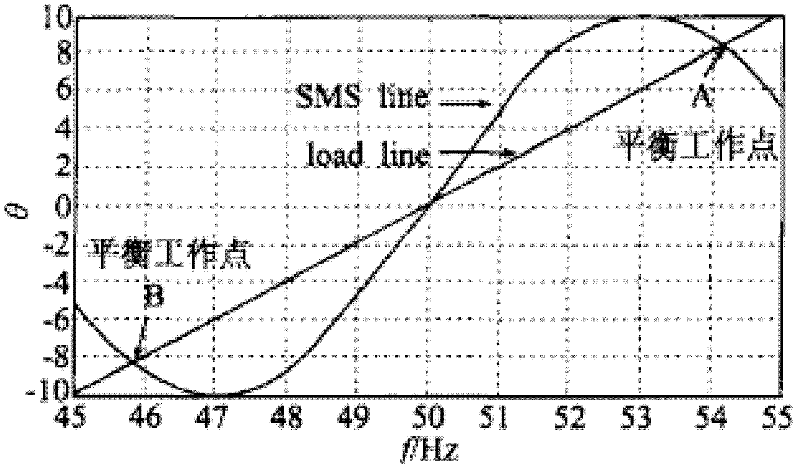

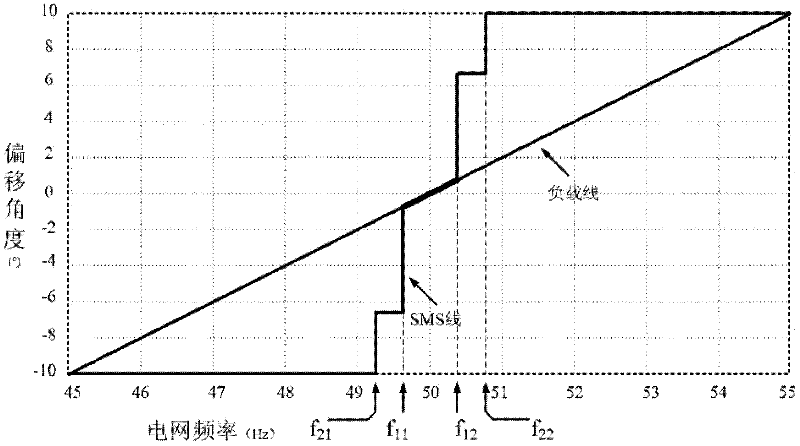

ActiveCN102262182AReduce quality impactSave storage spaceSingle network parallel feeding arrangementsFrequency measurement arrangementIslandingGrid connected inverter

The invention discloses a method for detecting an island of a photovoltaic grid-connected inverter. The method comprises the following steps of: 1), detecting a voltage frequency at a common coupling point of the inverter and a power grid, wherein when the voltage frequency is between f11 and f12, a phase position of output current of the inverter is the same to that of voltage at the coupling point; and, by modifying the phase position between the output current of the inverter and the voltage at the coupling point, compared with the voltage at the coupling point, the output current is ahead of time in theta degrees (when fgrid is more than f12 and less than f22) or lags in theta degrees (when fgrid is more than f21 and less than f11); and 2), to compensate a dead zone appeared in frequency detection, judging whether an island effect exists by modifying an amplitude value of the output current of the inverter within one power frequency period after every four power frequency periods and recovering the amplitude value of the output current into an original value after the period. According to the method, harmonic waves output by the inverter to the power grid can be effectively reduced; the detection time is short; the calculation method is simple; and the computing resource of a control chip can be saved.

Owner:ALTENERGY POWER SYST

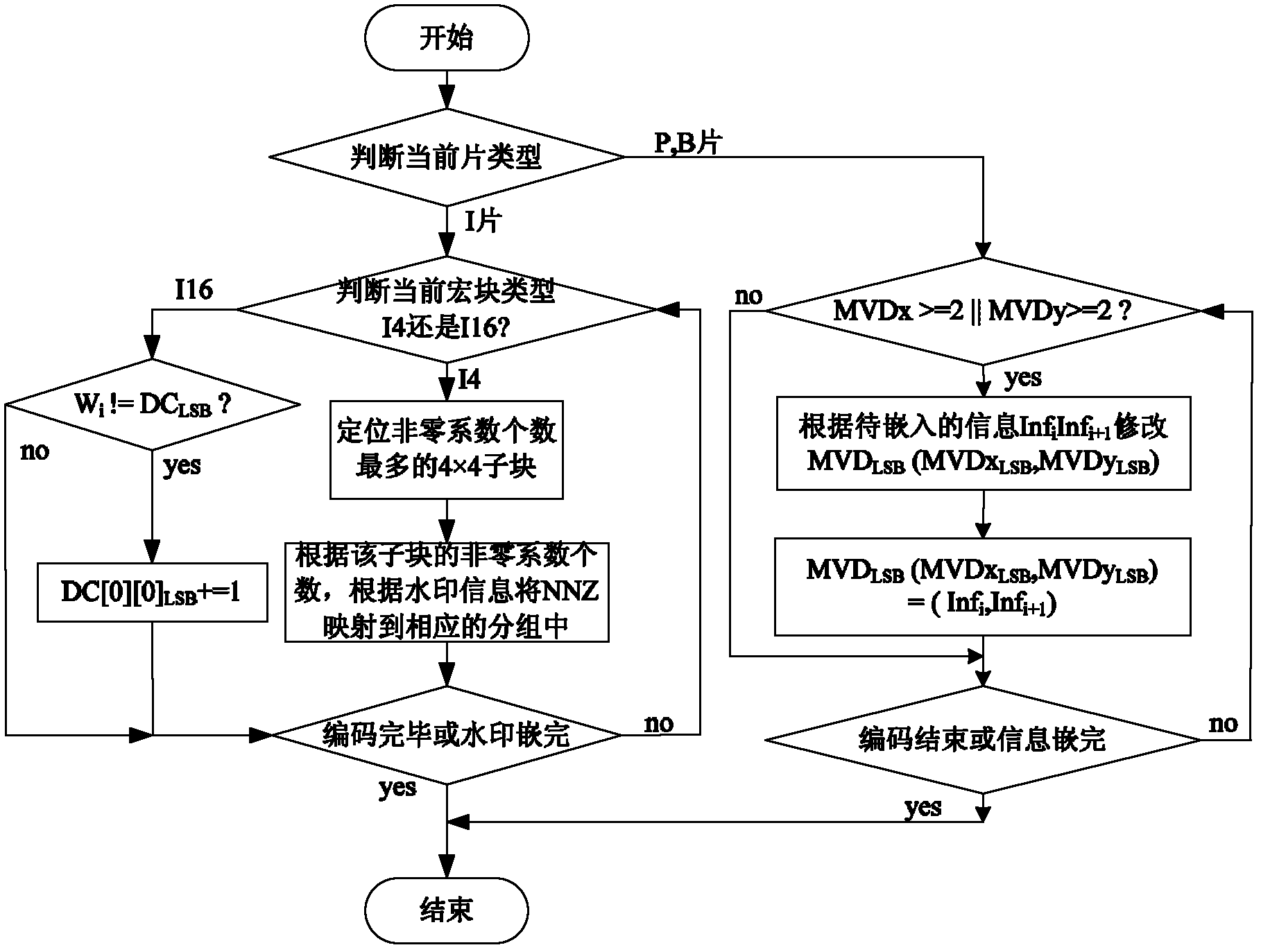

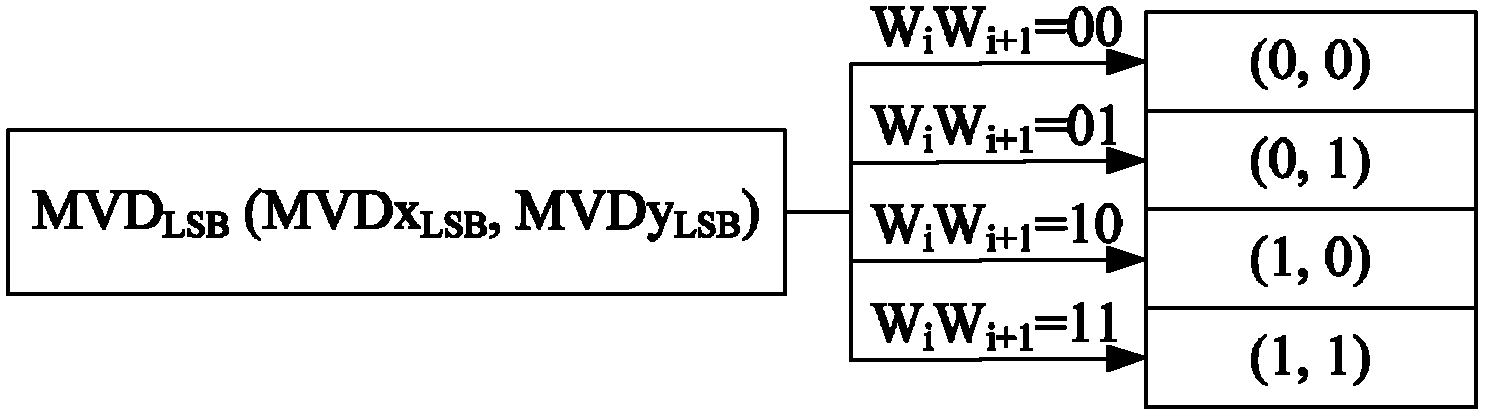

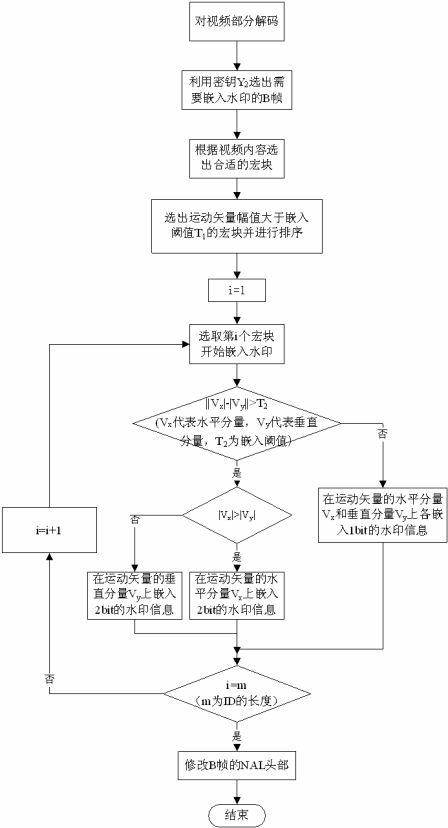

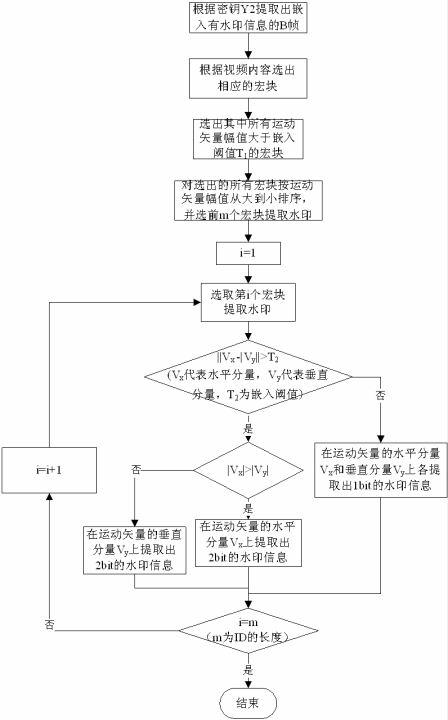

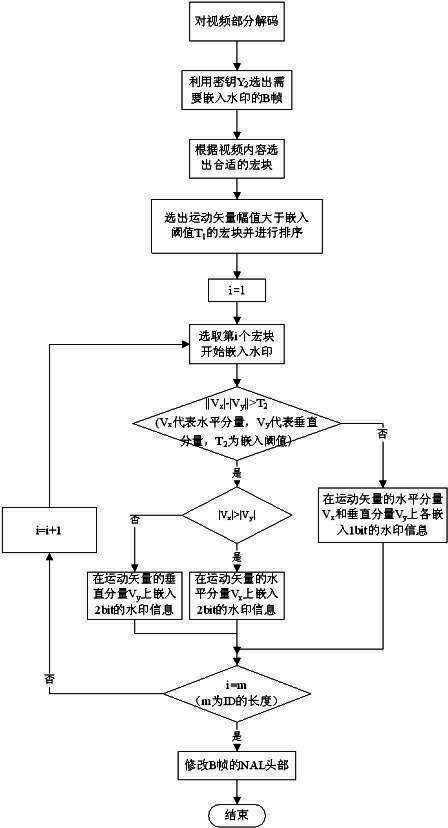

Information hiding method facing to H.264/AVC (automatic volume control) video

InactiveCN102223540AEnsure safetyIncrease hidden capacityTelevision systemsDigital video signal modificationAutomatic controlMotion vector

The invention discloses an information hiding method facing to an H.264 / AVC (automatic volume control) video. The embedding of watermark information is realized through modifying a data communication terminal (DCT) coefficient of a frame I, but for a frame B and a frame P, the embedding of the hiding information is realized through modifying motion vector data (MVD), thus on one hand, the embedded watermark information can be used for authenticating the integrity of the content of the video streaming, and on the other hand, whether the video is attacked is judged, and whether the extracted information is credible and the like at an information detection end according to the integrity of the extracted watermark information, thus ensuring the safety of the private information; as the frame P and frame B in a video sequence are divided into a motion subblocks from the size range of 16*16 to 4*4; the smaller subblock division provides a large amount of MVD data which can provide for hiding the private information, thus the video has larger information hiding capacity; and the process extracting the information is simple and rapid, does not need an original video file for reference, and only needs to decode the DCT coefficient of the frame I and the MVD data of the frame B and frame P, thereby effectively improving the instantaneity and the practicability.

Owner:NINGBO UNIV

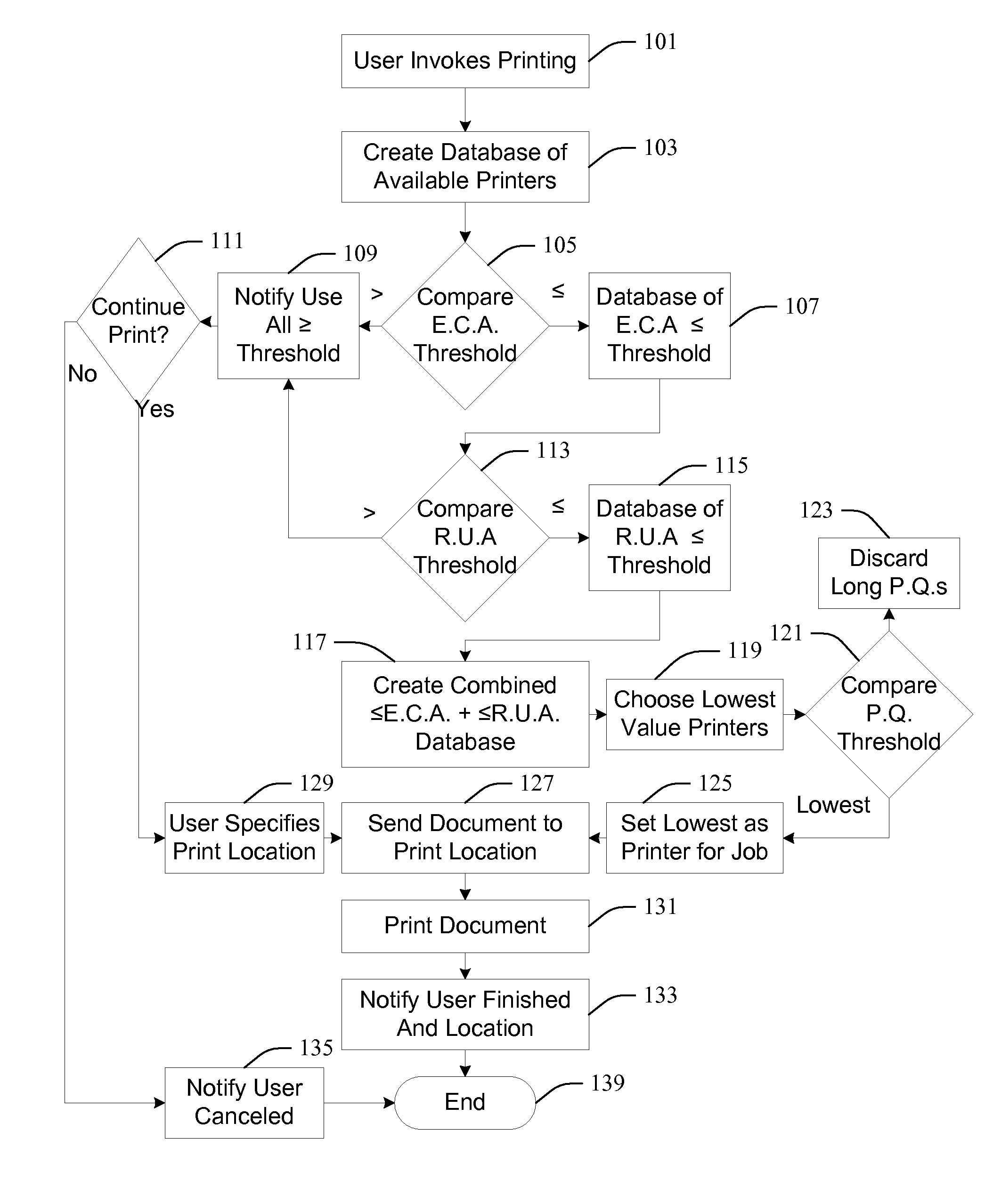

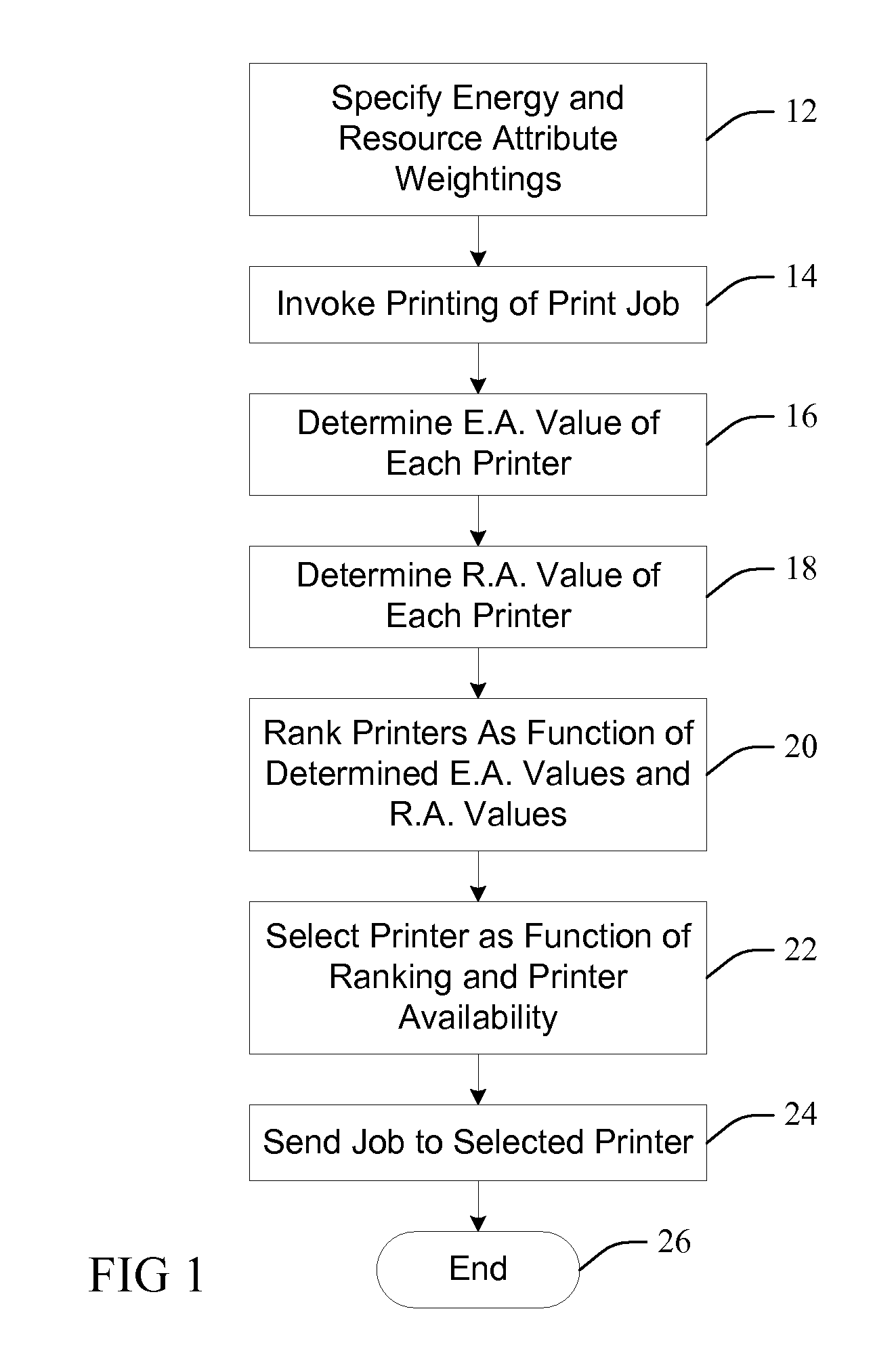

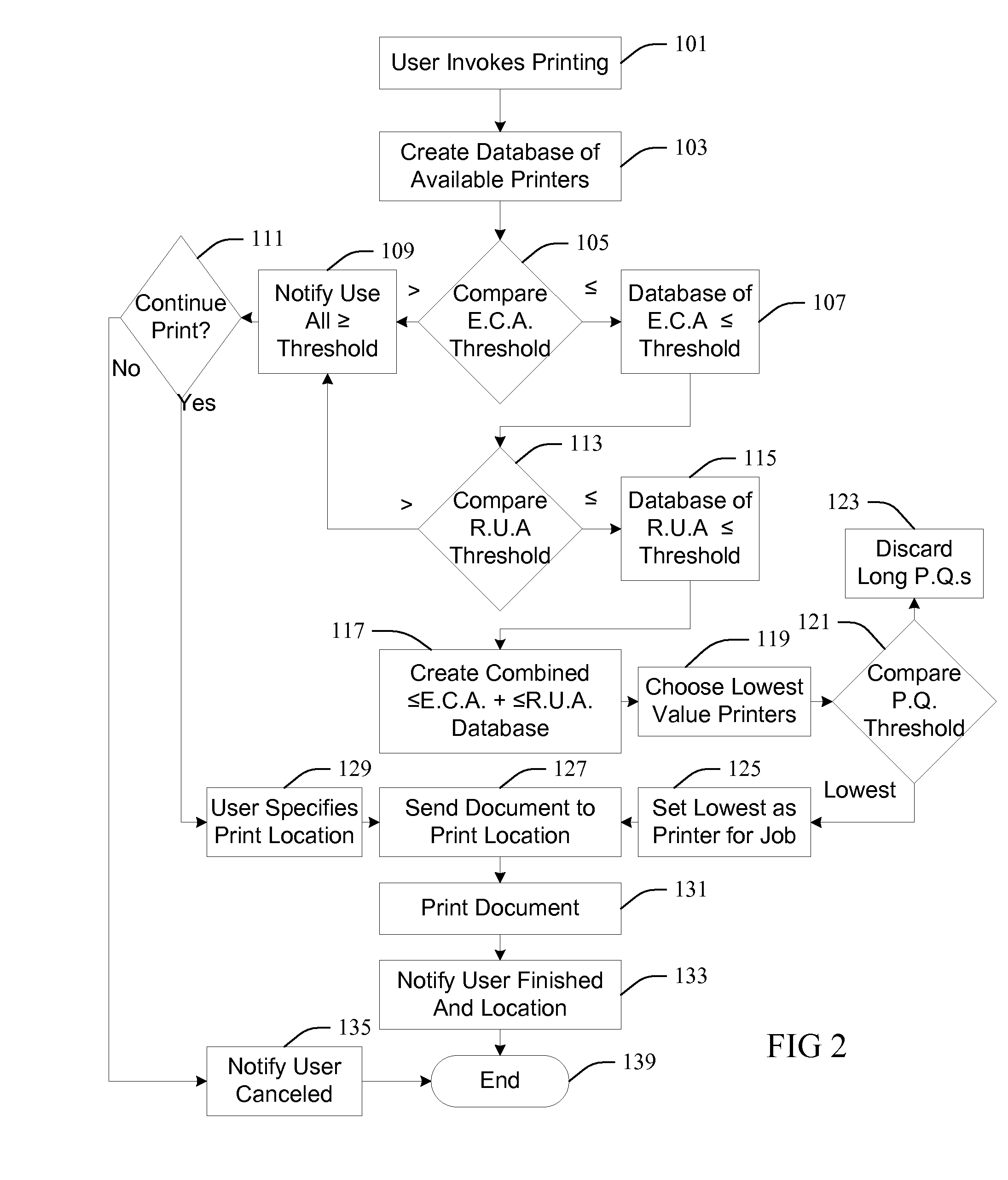

Method, system, and product for comparative efficiency decisions in print operations

InactiveUS20090287806A1Low transition energyReduce quality impactEnergy efficient ICTMultiple digital computer combinationsResource consumptionLow resource

Methods, devices, services and program products are provided for selecting a printer from a plurality of printers as a function of a printer resource consumption attribute where there is a network environment comprising a plurality of printers, each of the plurality of printers having a resource consumption attribute value. A user invokes a print operation through the network environment and a processing means compares weighted resource consumption attribute values for each of the plurality of printers. Processing means automatically select at least one destination printer from the plurality of printers having a lower resource usage requirement for performing a print operation relative to at least one unselected printer of the plurality of printers. Processing means also automatically choose a destination printer as a function of an availability of each of the destination printers.

Owner:IBM CORP

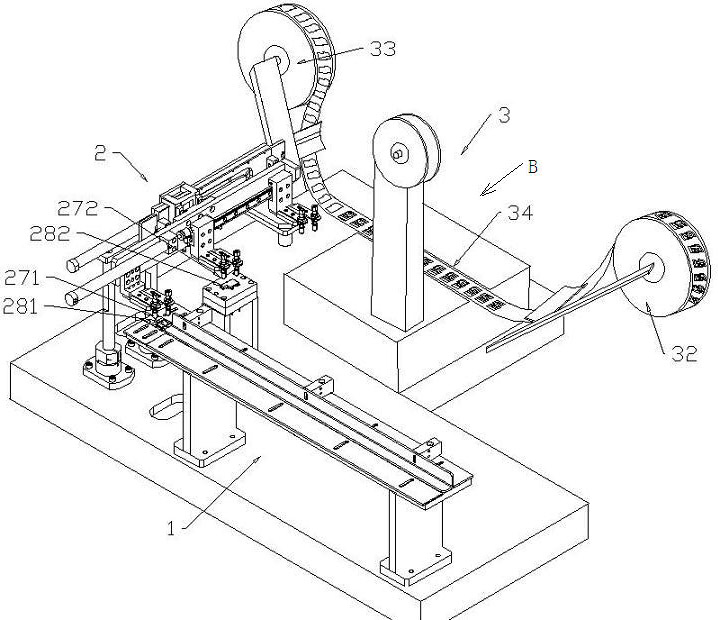

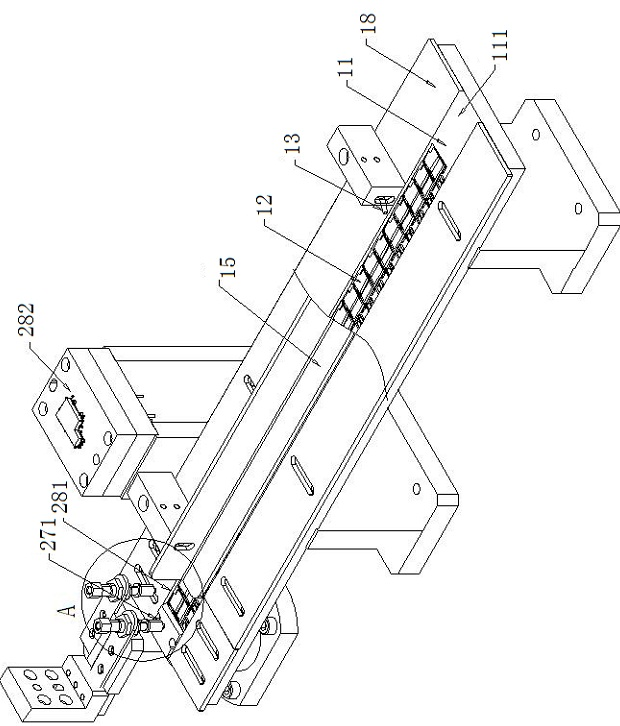

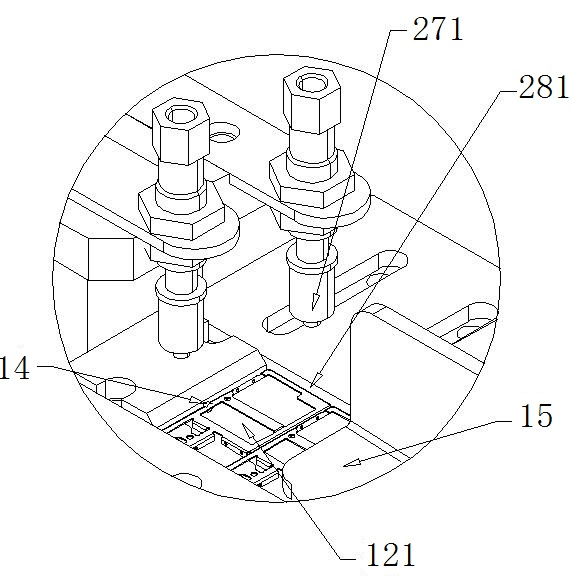

Integrated machine for automatically detecting flatness and packaging carrier belt for shielding case

ActiveCN102673822AFully automatedReduce quality impactPackaging automatic controlEngineeringAutomation

The invention discloses an integrated machine for automatically detecting flatness and packaging a carrier belt for a shielding case. The integrated machine comprises a blowing and feeding mechanism, a double stroke transmission mechanism, an automatic packaging mechanism and a controlling device. Shielding cases to be detected enter into a first work station in the blowing and feeding mechanism orderly, the controlling device controls the double stroke transmission mechanism to execute a first stroke, a first nozzle sucks the shielding cases at the first work station and conveys the shielding cases to a second work station for flatness detection, a second nozzle sucks the qualified shielding cases detected at the second work station and conveys the shielding cases to a third work station to be arranged on the carrier belt, and the carrier belt where the shielding cases are arranged is automatically packaged by an adhesive tape and coiled automatically by a receiving disc. The integrated machine provided by the invention detects and conveys the shielding cases automatically, sorts qualified and unqualified products and arranges the qualified products on the carrier belt automatically. The carrier belt is automatically packaged by the adhesive tape and operators do not contact with the detection and packaging process of the shielding cases, thereby realizing automation of the packaging process of the shielding cases.

Owner:南通诚业德精密组件有限公司

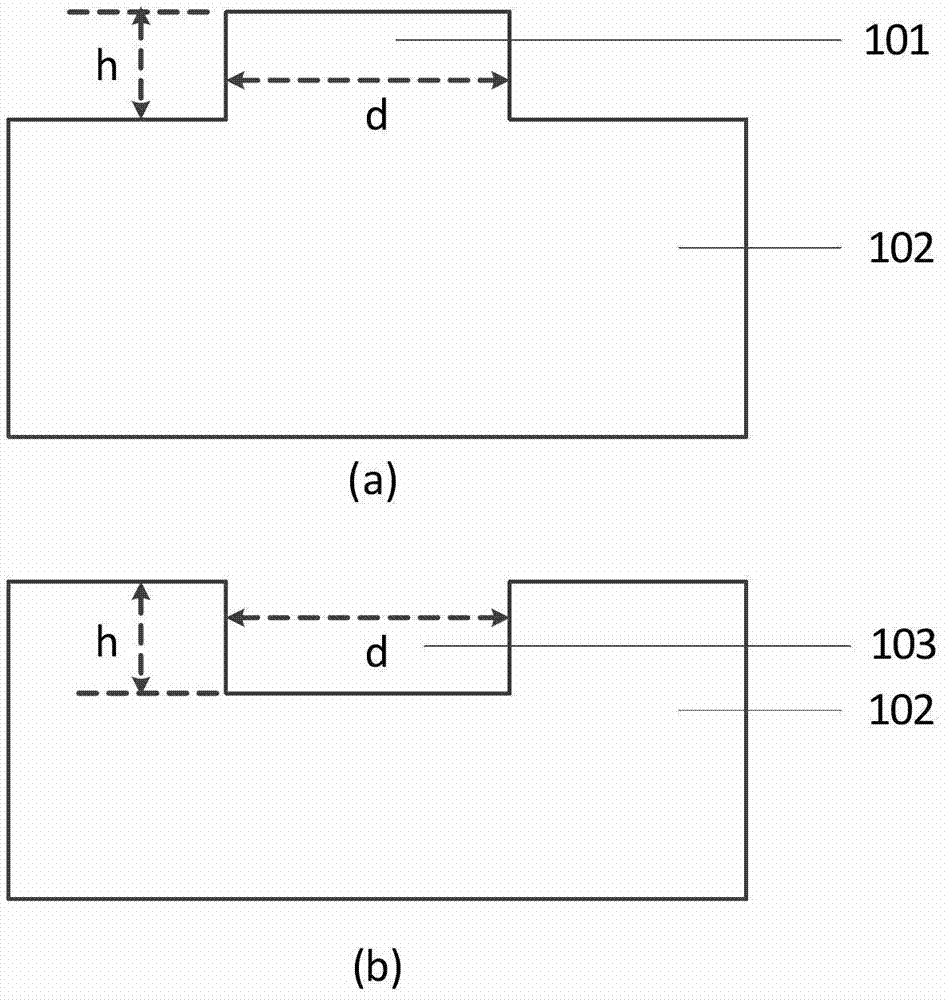

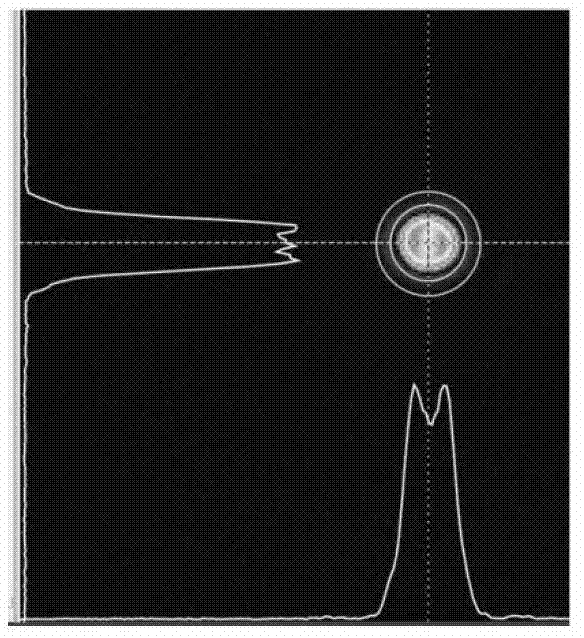

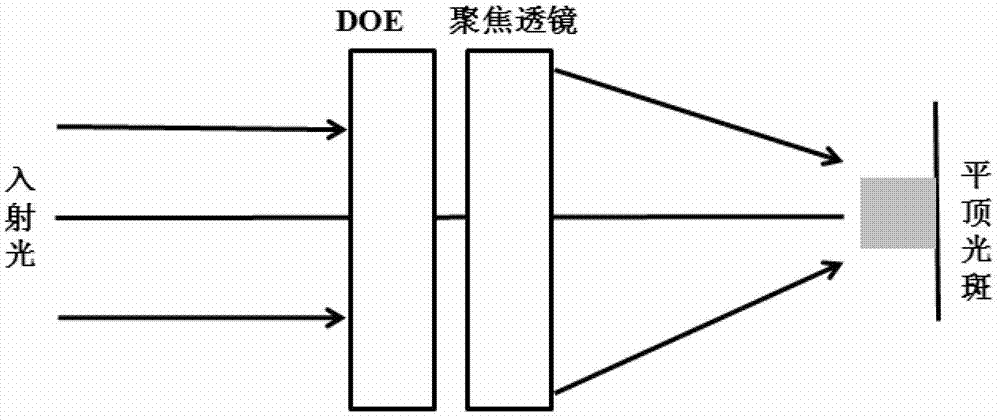

Diffractive optical element for shaping gauss beam into flat-topped beam, and preparation method thereof

ActiveCN103399406AImprove energy transmittanceEasy to usePhotomechanical exposure apparatusMicrolithography exposure apparatusGaussian beamTransmittance

The invention provides a new diffractive optical element for shaping a gauss beam into a flat-topped beam, and the diffractive optical element is called DOE for short; the invention also provides a preparation method of the DOE. Grooves or steps with different shapes and sizes are prepared in the center of a quartz substrate, and the DOE is then arranged at the different positions of a light path and is matched with a beam expanding collimation lens and a focusing lens, so that the flat-topped beam can be realized. The DOE has the outstanding advantages of being high in energy transmittance, less sensitive to the incident laser mode change, and simple and flexible in installation and use.

Owner:北京润和微光科技有限公司

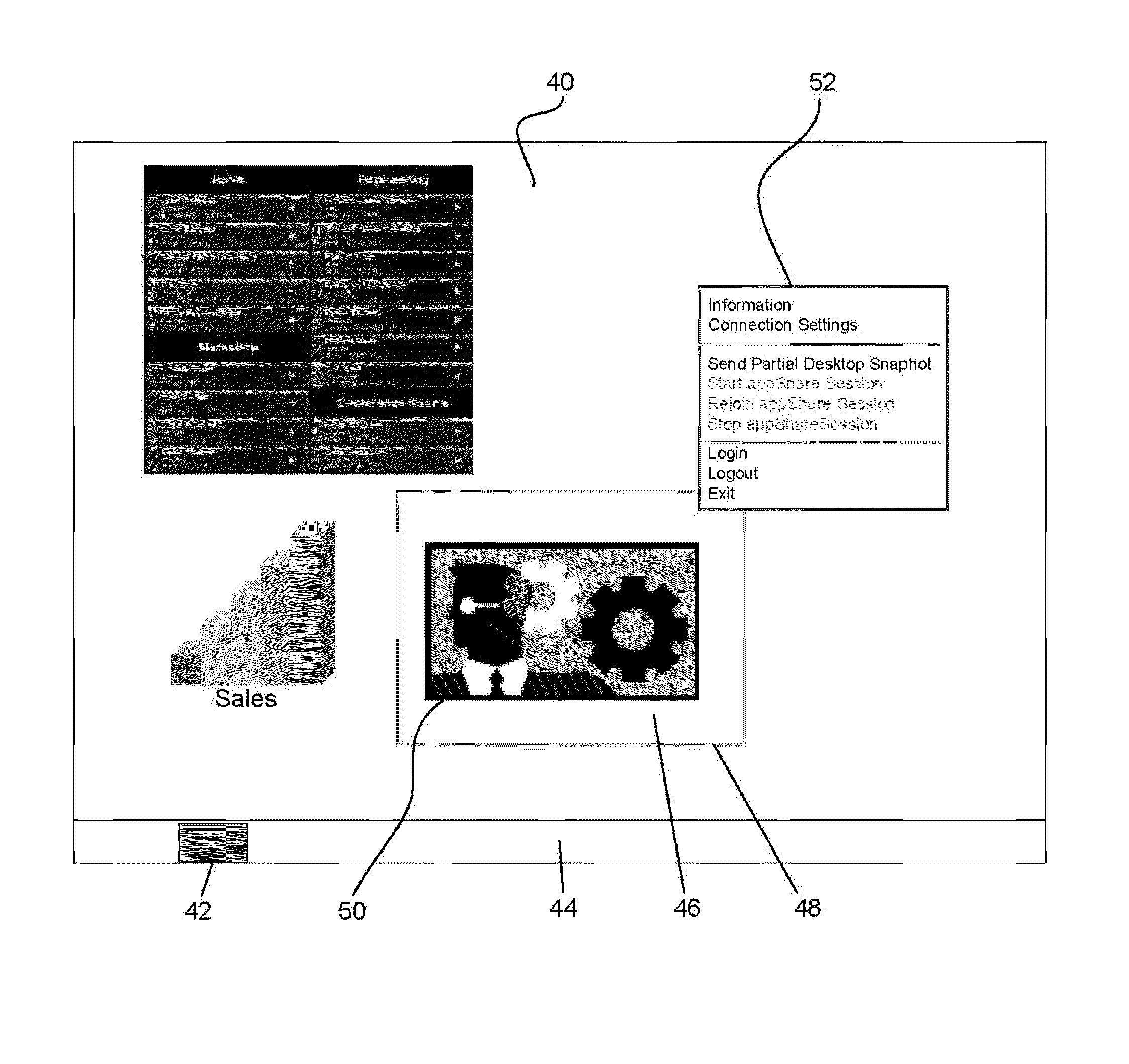

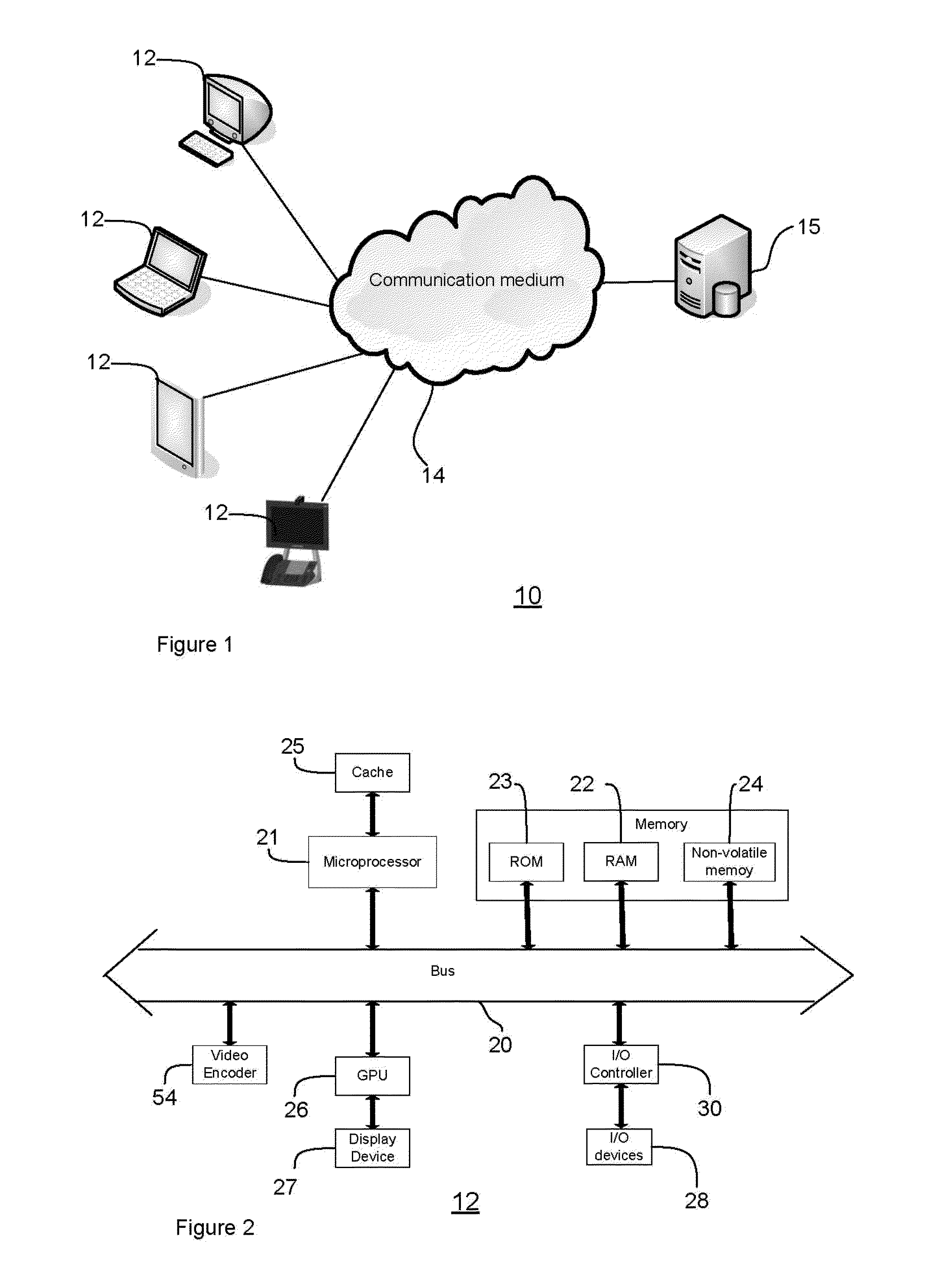

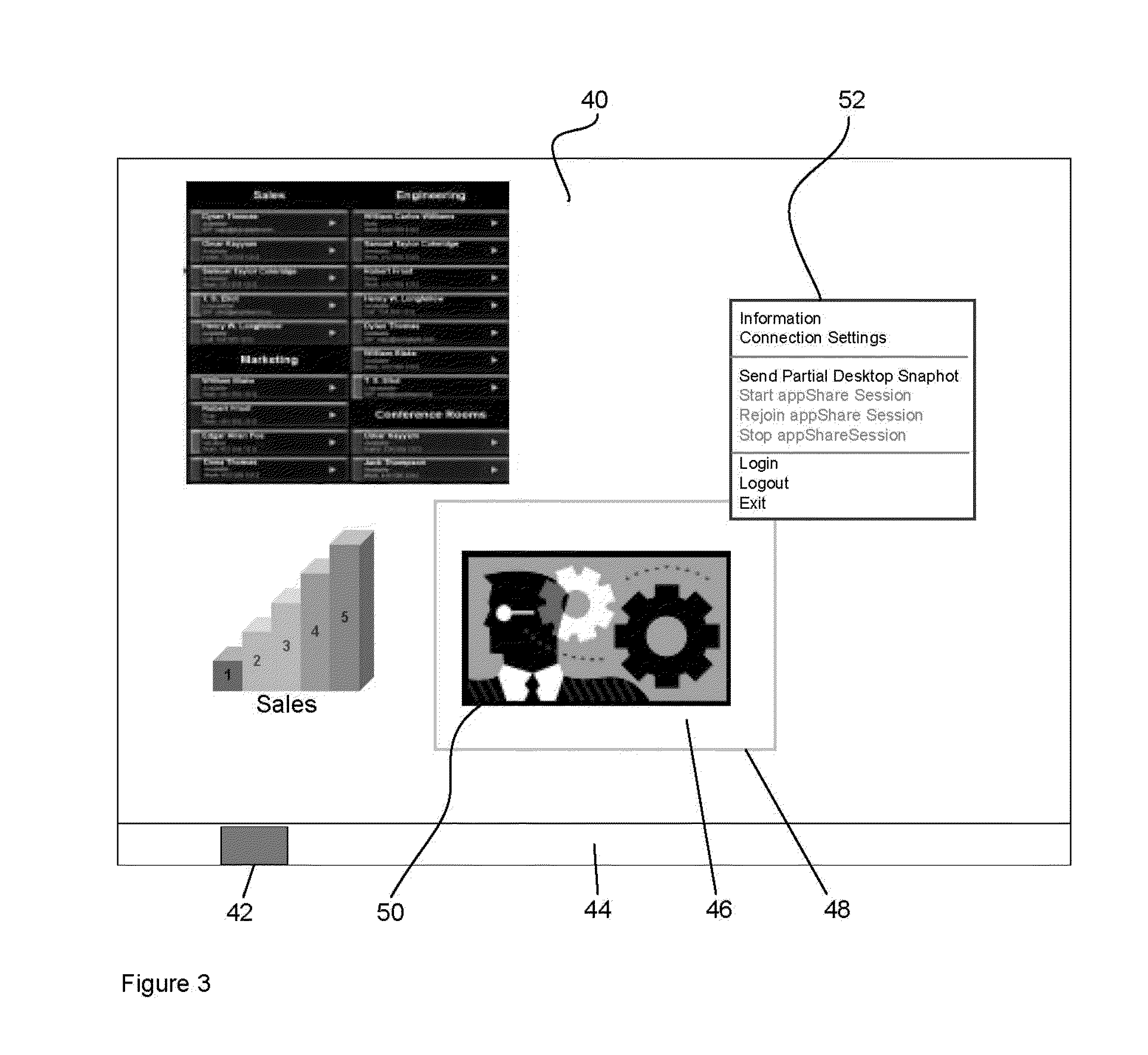

Collaboration system & method

ActiveUS20130141517A1Minimizes encodingMinimizes de-coding resource resourceTelevision conference systemsTwo-way working systemsDisplay deviceNetwork service

A network apparatus in a collaboration system with a plurality of participants, the apparatus comprising: a processing structure; and a memory including computer program code, wherein the memory and the computer program code are configured, with the processing structure, to cause the network apparatus to at least: present content on a display coupled to the processing structure; select a portion of the display for sharing, the portion having the shared content; simultaneously send said shared content to said display and to an encoder for encoding; automatically discover a network server configured to distribute the shared content with the plurality of participants; couple the apparatus to the network server and transmit the shared content to the network server for distribution to at least one of the plurality of participants, such that the shared content is encoded and decoded, and displayed in real-time.

Owner:MITEL

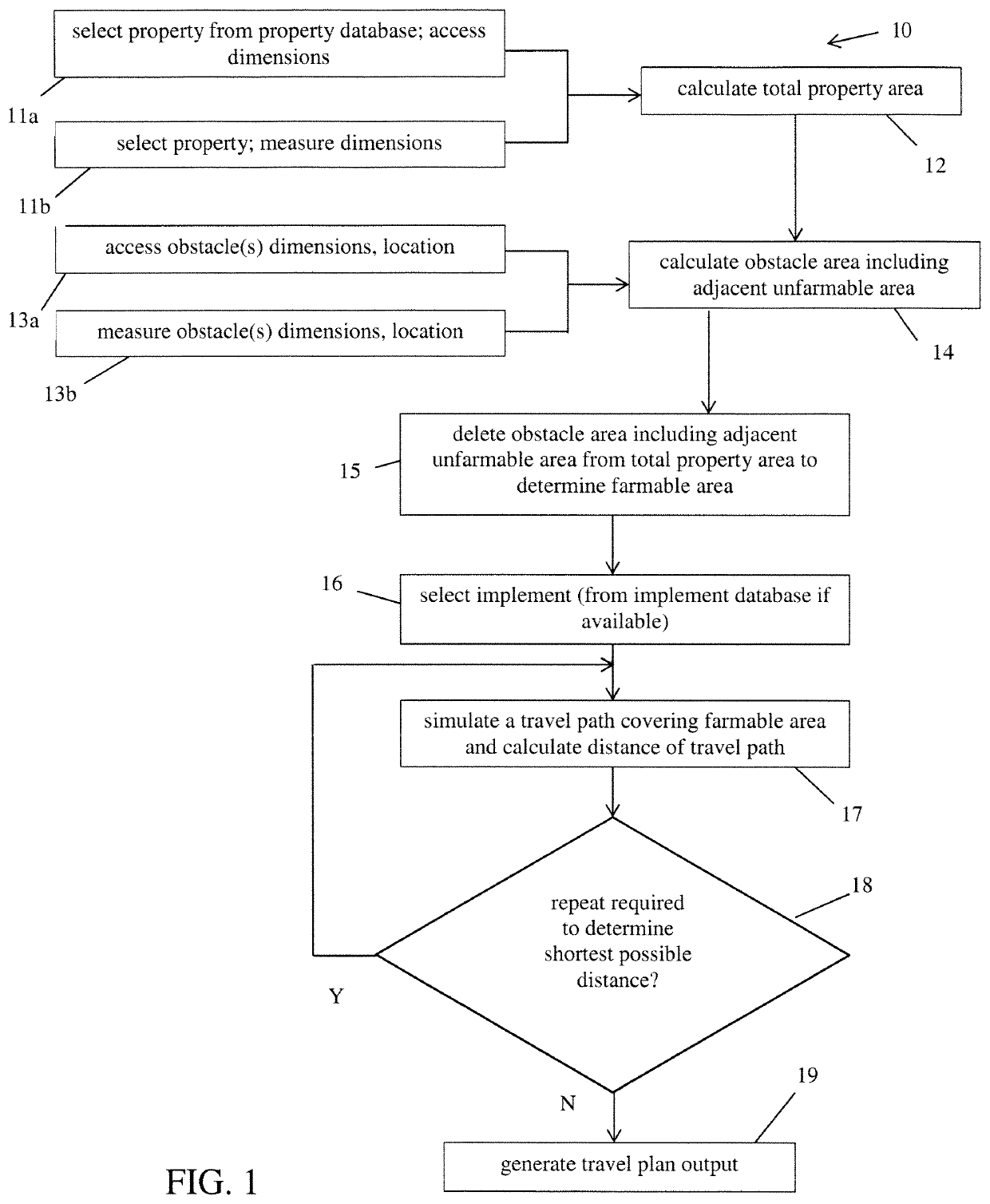

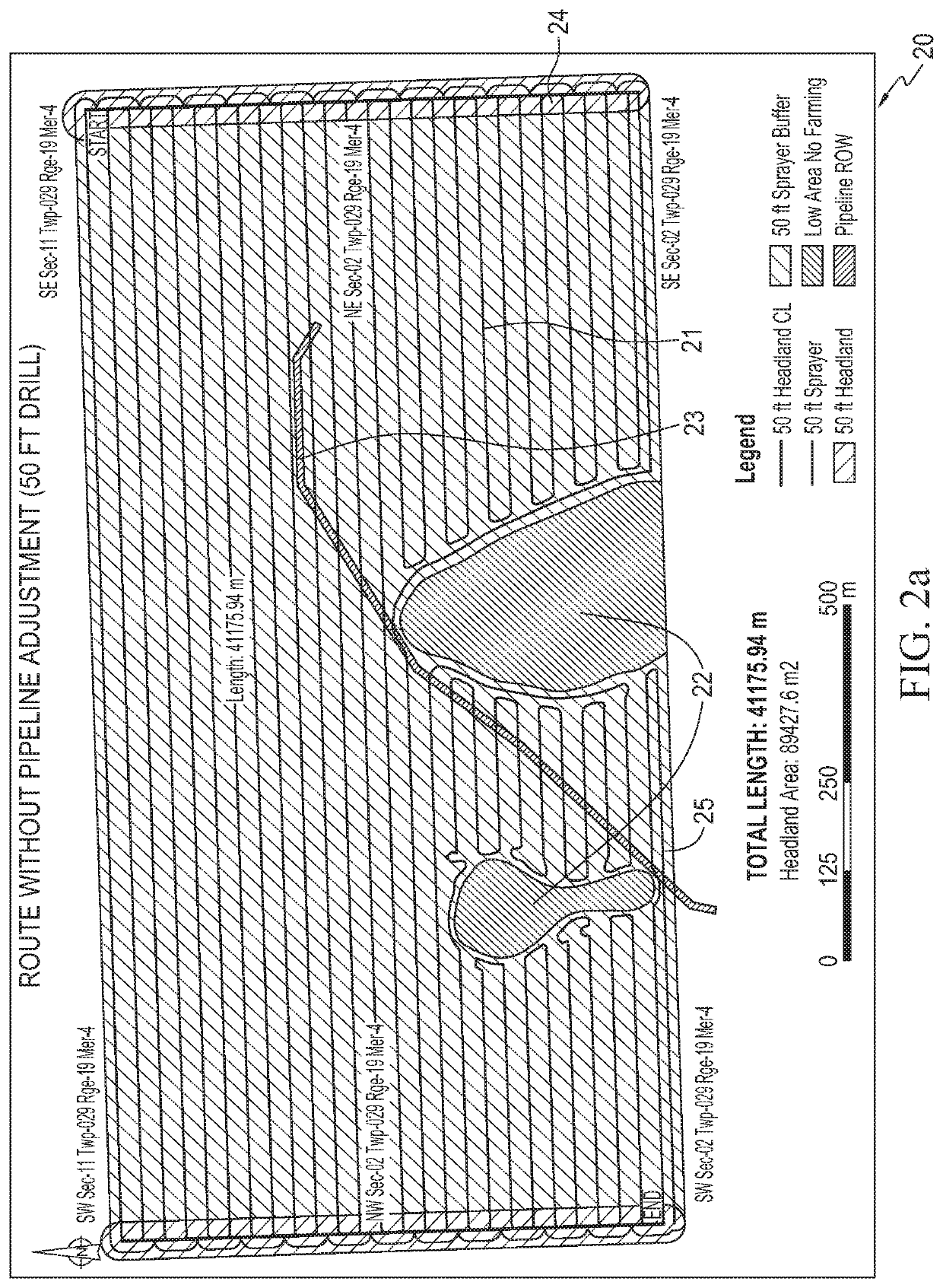

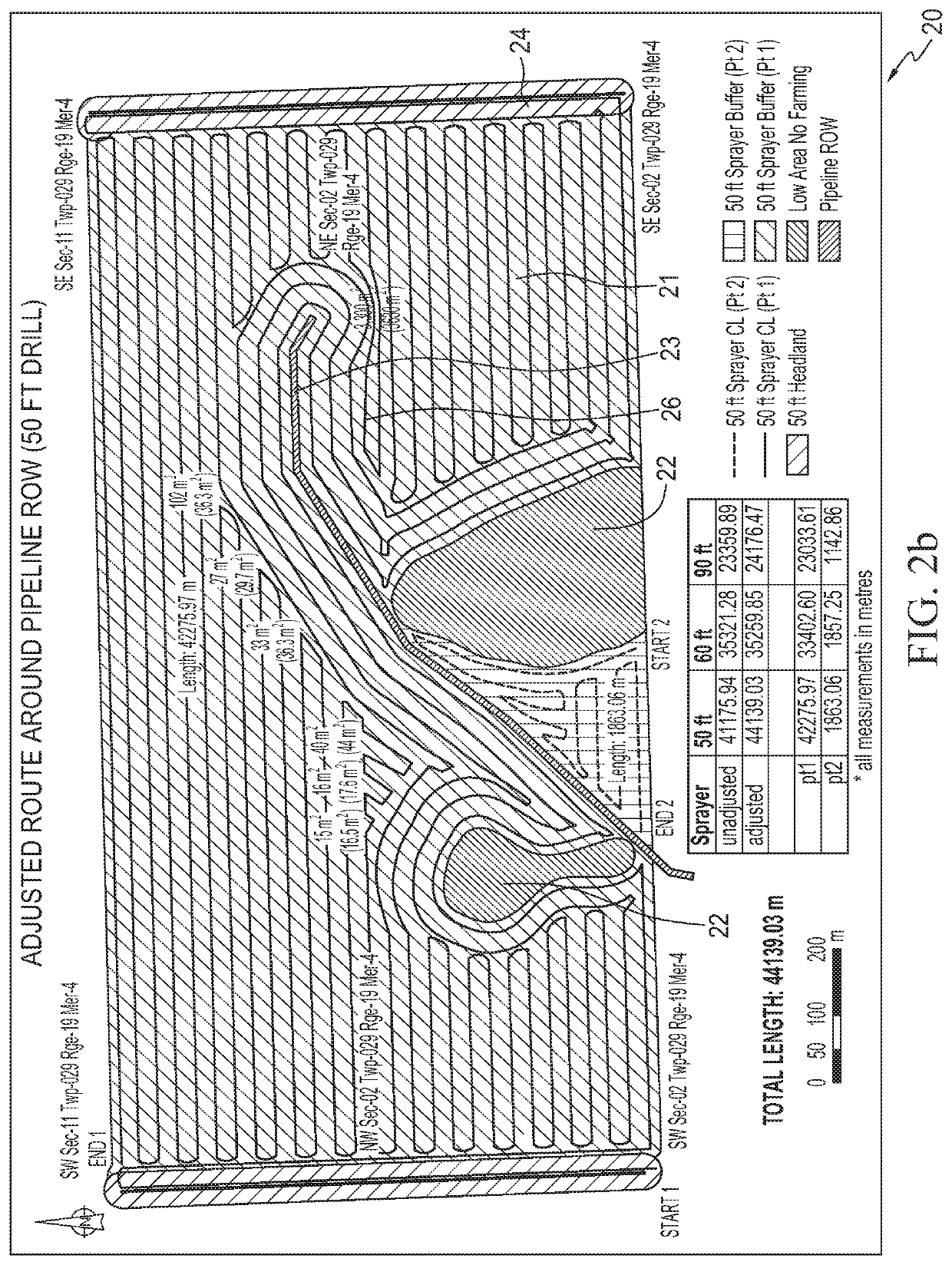

Method and system for determining optimized travel path for agricultural implement on land with obstacle

ActiveUS10740703B2Low efficiencyShorten the timeForecastingAgricultural landEnvironmental resource management

Owner:VERGE TECH INC

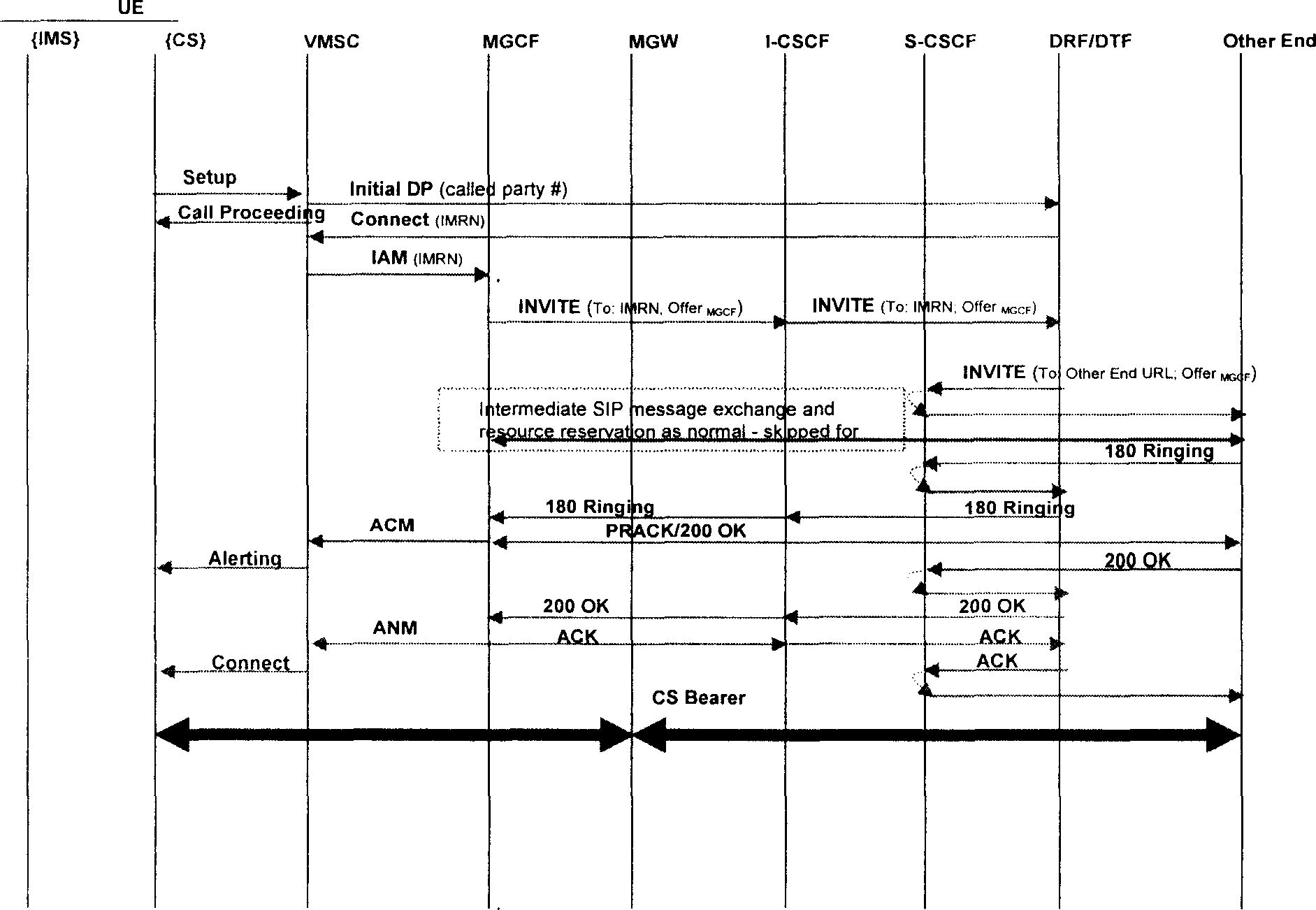

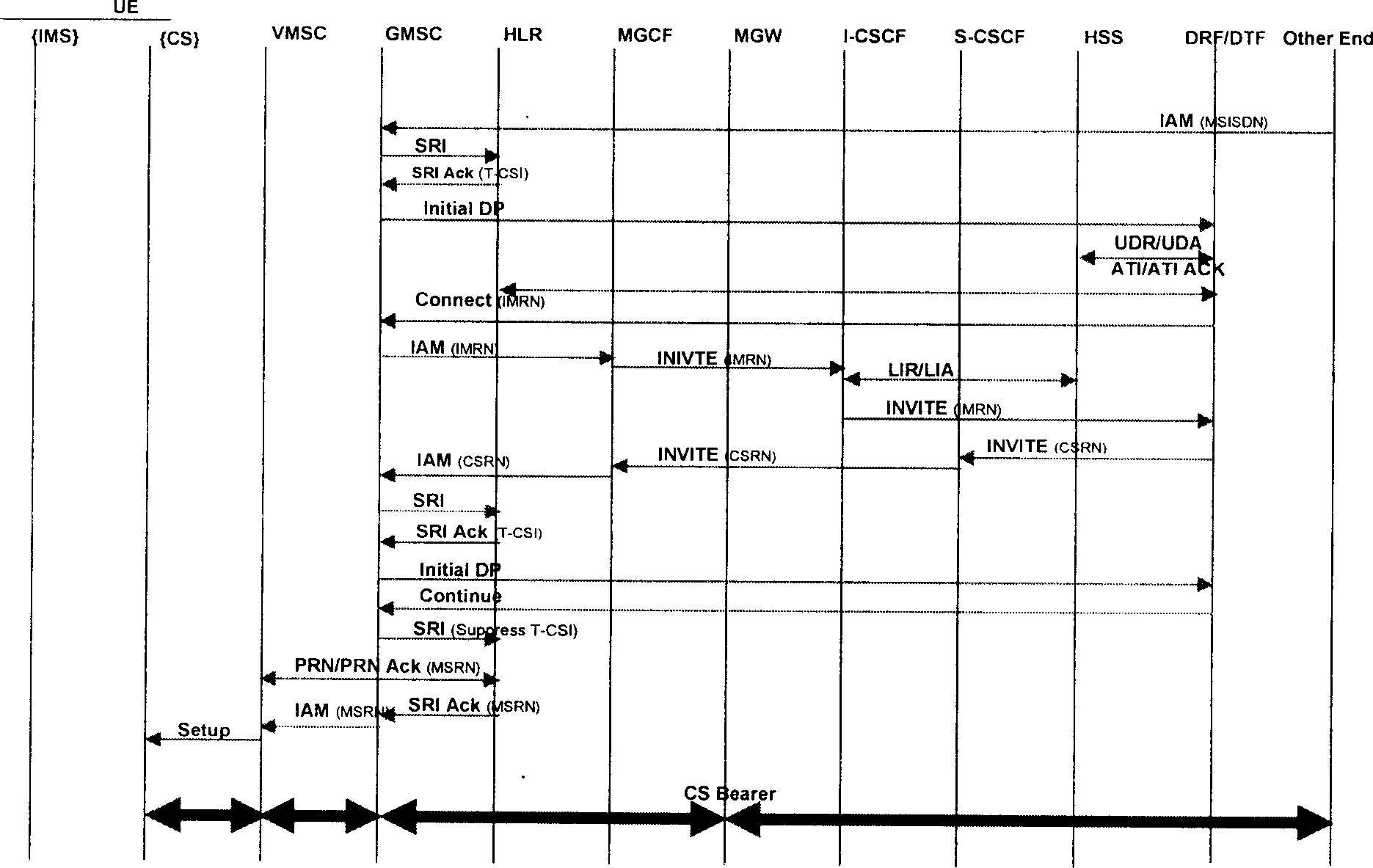

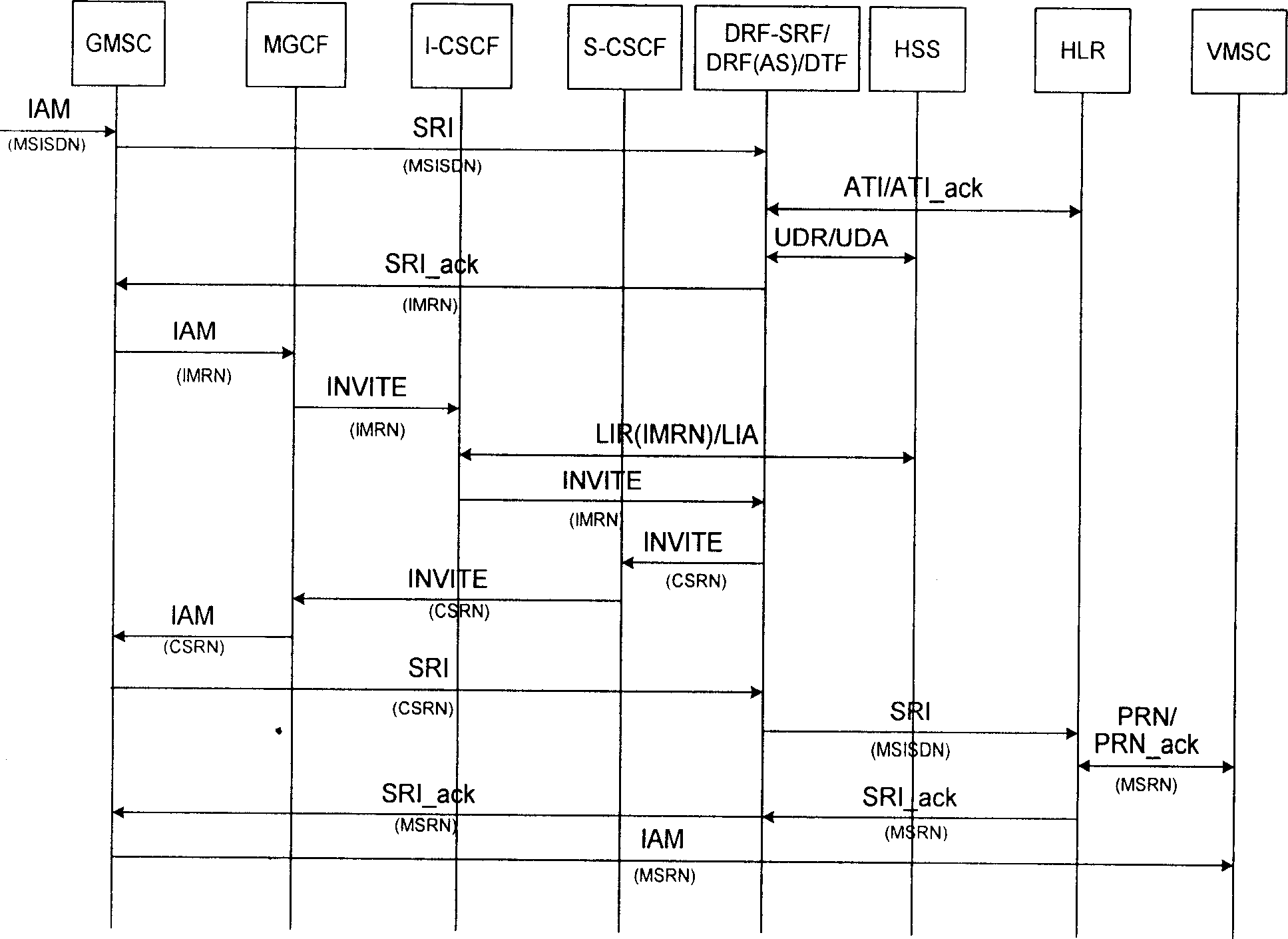

Control method and system of session route path

ActiveCN1913503AReduce the number of speech codec conversionsAvoid voice service quality degradationHybrid switching systemsSpeech soundTransmission time

This invention provides a method for controlling session route paths and a system, in which, an appied server determines a metwork entity in the IMS domain corresponding to the session and provides it to S-CSCF, which routes the session to the network entity in the IMS and the network entity in it routes it to the network entity in the circuit exchange domain. This invention does not make sound coding and decoding conversion between DTM and IP loads to two sections of entry and outlet calls of a same session so as to reduce the transmission times of the sound coding and decoding to avoid the reduction of phone service. This invention prolongs the IP load path in the IMS domain and reduces the DTM load path to increase the usability of IP load.

Owner:HUAWEI TECH CO LTD

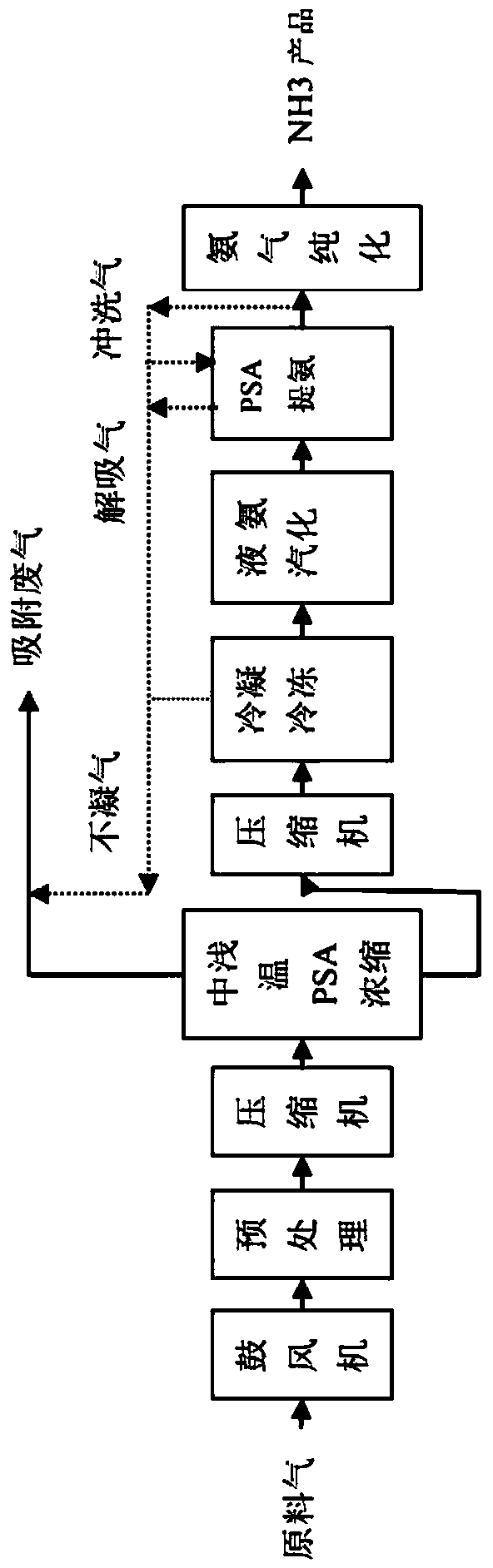

Method for full temperature range PSA (pressure swing adsorption) ammonia purification and recycling of waste gas from LED-MOCVD (metal-organic chemical vapor deposition) process

ActiveCN108744882ARealize the recycling and reuse of all componentsEmission reductionGas treatmentAuxillary pretreatmentVaporizationCircular economy

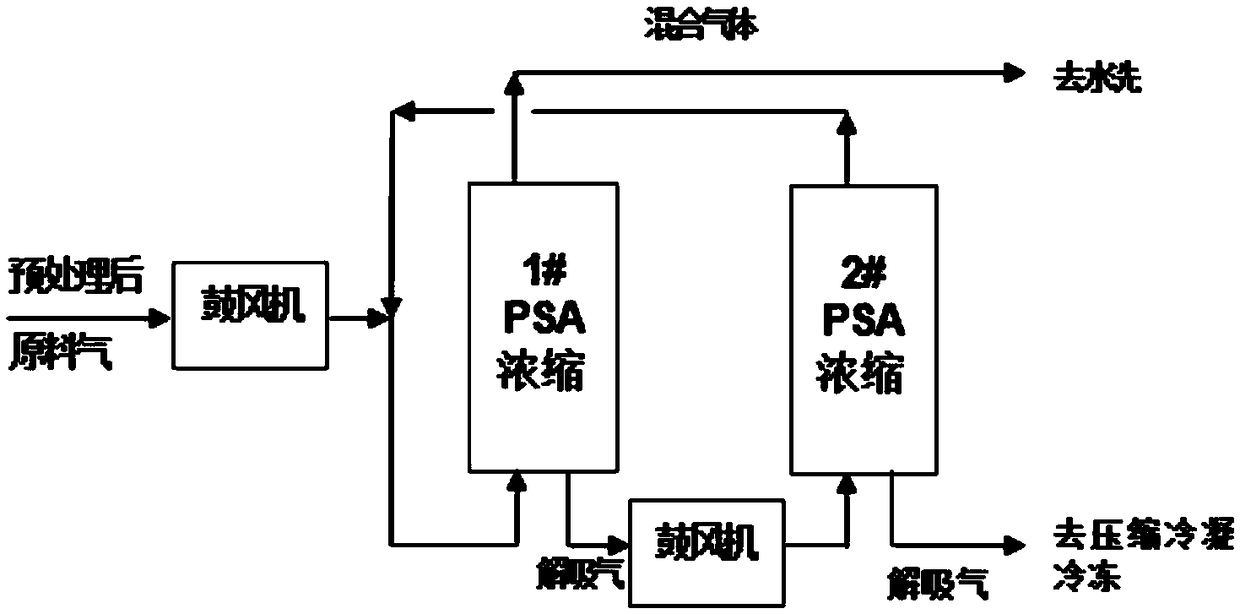

The invention discloses a method for full temperature range PSA (pressure swing adsorption) ammonia purification and recycling of waste gas from LED-MOCVD (metal-organic chemical vapor deposition) process. By procedure of pretreatment, medium and shallow temperature PSA concentration, condensation and freezing, liquid ammonia vaporization, PSA ammonia extraction and ammonia purification, the ammonia-containing waste gas from the LED-MOCVD process is purified to conform to the standard of electronic grade ammonia gas required by the LED-MOCVD process, and the waste gas is recycled; the ammoniagas yield is higher than or equal to 70%-85%. The technical problem that atmospheric or low pressure ammonia-containing waste gas from the LED-MOCVD process cannot be returned to the LED-MOCVD processfor use is solved, and the gap in green LED industry and circular economy development is filled in.

Owner:ZHEJIANG TIANCAIYUNJI TECH CO LTD

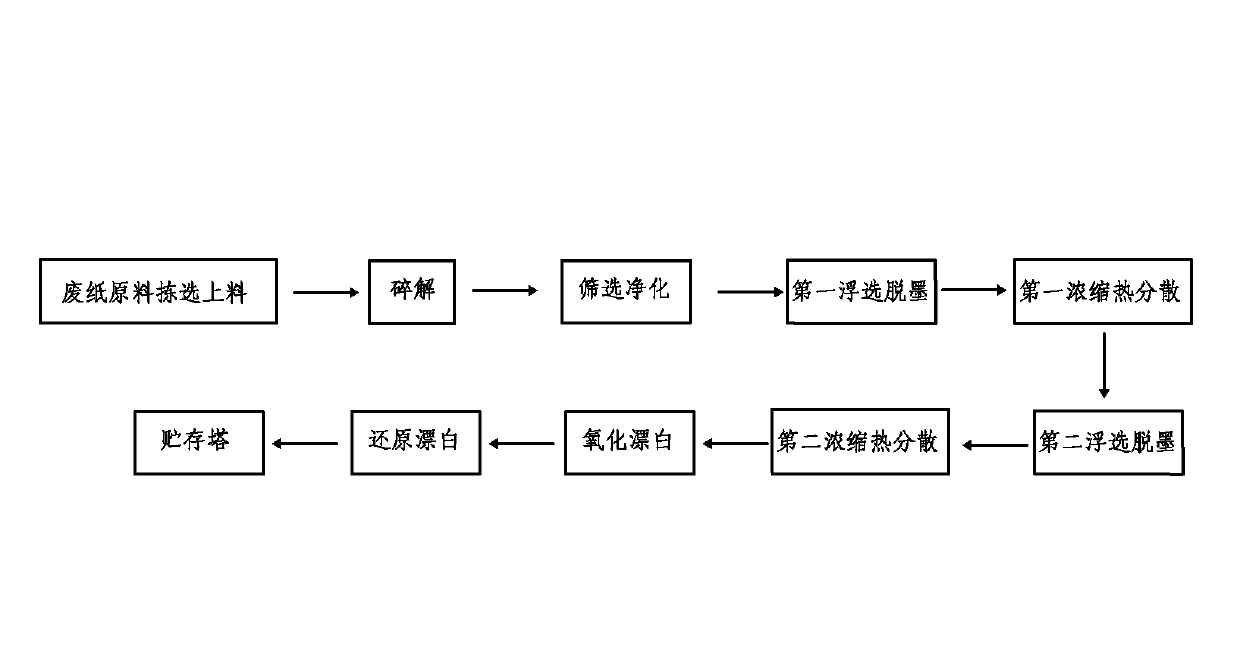

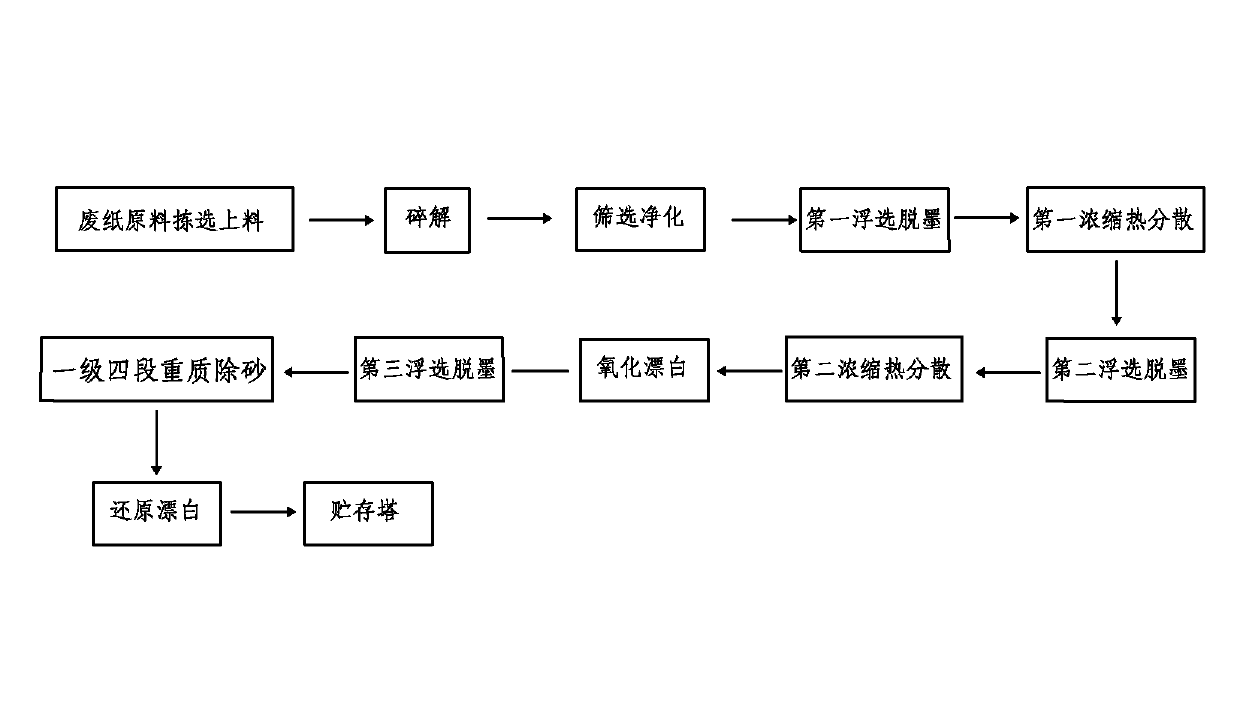

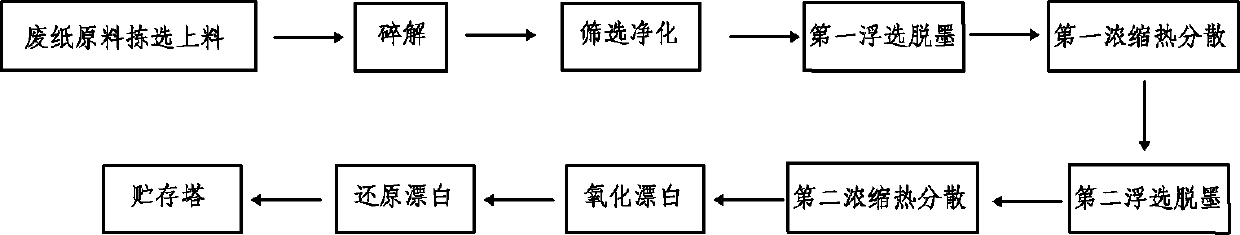

Process for preparing recovered pulp with high whiteness and high cleanliness

InactiveCN102677515ALow costHigh whitenessCellulosic pulp after-treatmentPaper recyclingDeinkingProduction line

The invention relates to the technical field of papermaking raw material processing, in particular to a process for preparing recovered pulp with high whiteness and high cleanliness in a papermaking industry. The process comprises the following steps of: selecting and feeding of waste paper raw materials; disintegration; screening purification; first flotation deinking; first concentrated heat dispersion; second flotation deinking; second concentrated heat dispersion; oxidation bleaching; reduction bleaching; and storage in a storage tower. According to the process, 20-30 percent of high-quality office waste paper and 70-80 percent of other low-quality waste paper raw materials are matched, so that the cost of the waste paper raw materials is effectively reduced, and the corporate profit is increased. An advanced rotary drum pulper, a pulping machine and a production line of office waste paper screening purification, flotation deinking, concentrated heat dispersion and pulp bleaching are introduced, and the recovered pulp is prepared through the efficient use of chemicals and an effective production control process. The whiteness of the recovered secondary pulp achieves 90 percent ISO, and the cleanliness is high. The whiteness and the cleanliness of finished culture paper are increased.

Owner:DONGGUAN NINE DRAGONS PAPER IND

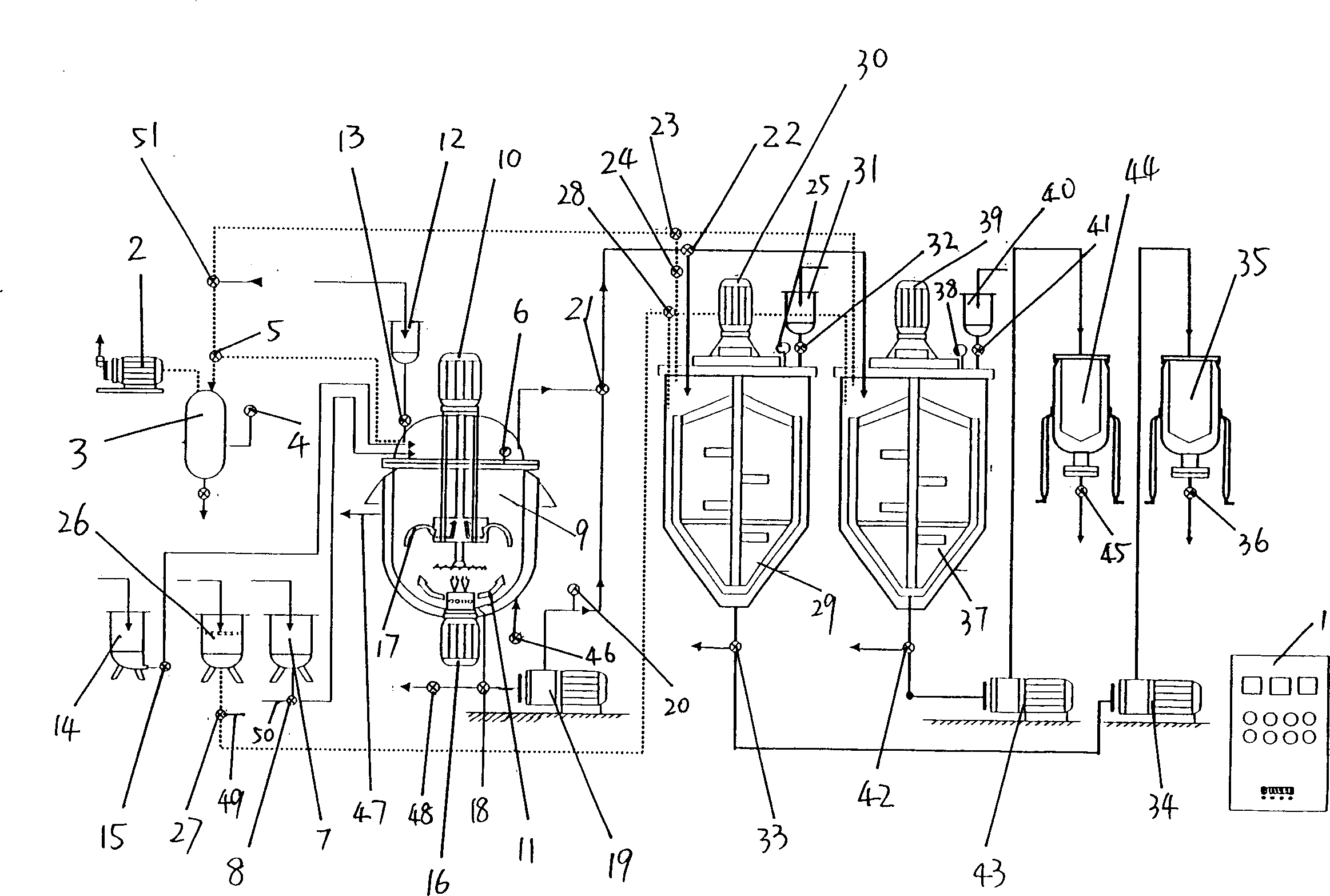

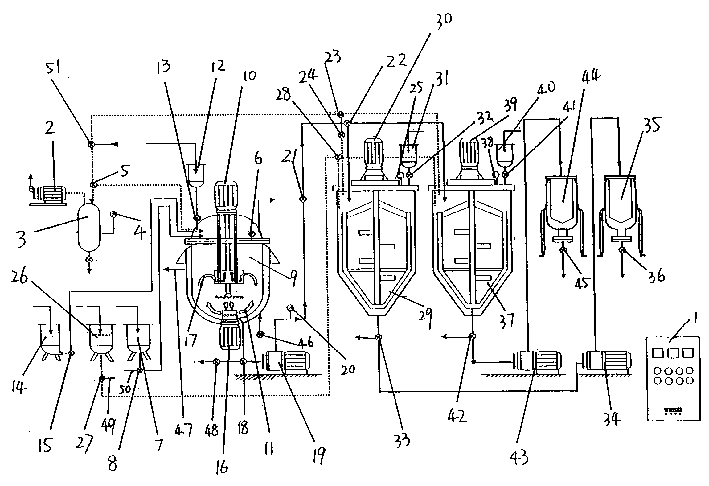

Method for producing coating

The production method of coating compound includes the following steps: placing the liquid material into a liquid material buffer feeding cylinder, opening vacuum pump to evacuate the dispersion emulsifying grinding still to negative pressure, opening liquid material feeding valve and feeding the liquid material into the dispersion emulsifying grinding still, the closing the liquid material feeding valve, adding adjuvant, opening powder material feeding valve and adding pigment anjd filling material, then closing valve and vacuum pump, dispersing for 20 min., starting basket sand mill and pipeline multi-stage wet grinder for about 20 min., stopping basket sand mill, dispersing machine and high shear emulsifying machine, closing reflux valve, opening vacuum pump to negative pressure and opening emulsion feeding valve, adding pigment and adjuvant, regulating pH value, filtering and barrelling to obtain the invented product.

Owner:上海索维机电设备有限公司

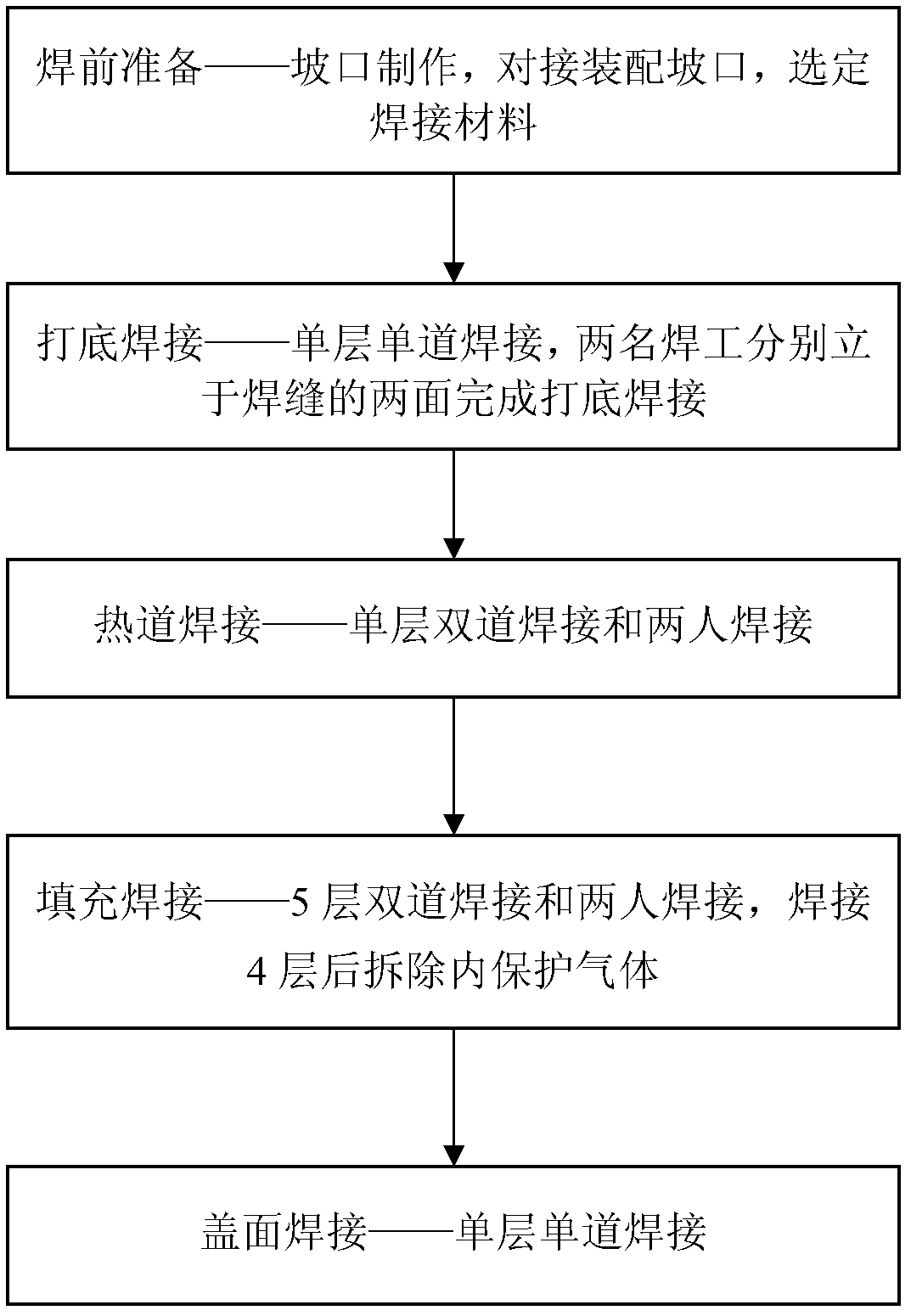

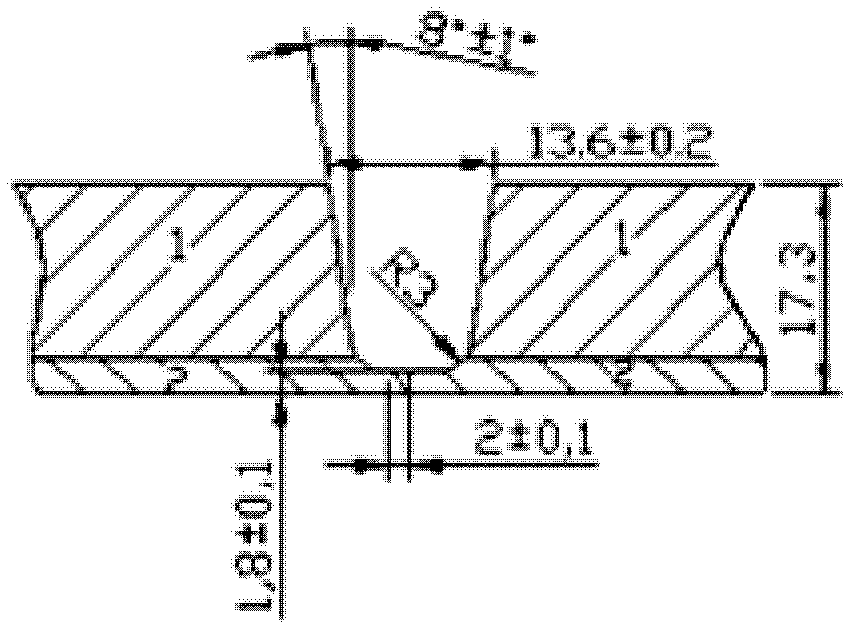

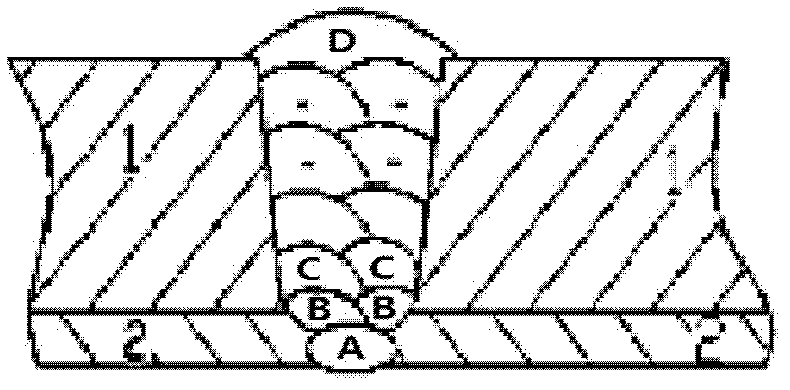

Semiautomatic argon tungsten-arc welding technological process of bimetal compounding sea pipe

The invention relates to a semiautomatic argon tungsten-arc welding technological process of a bimetal compounding sea pipe, a labour hand-held semi-automatic welding gun welding is adopted, a wire feeder continuously feeds wires, and argon gas is utilized as protective gas. The technological process comprises the following operation steps of: firstly, procedure preparation before welding: manufacturing a groove, picking up fitting the groove, and selecting a welding material; secondly, backing welding process: adopting single layer one-pass welding, wherein two welders respectively stand thetwo sides of a welding seam so as to finish the backing welding; thirdly, hot-runner welding procedure: adopting single layer two-way welding and two-person welding; fourthly, filling welding procedure: adopting five-layer two-way welding and the two-person welding, and dismantling the protective gas after welding four layers; and fifthly, a cover surface welding process: adopting the single layer one-pass welding. The technological process provided by the invention has the advantages of high welding quality, small labour intensity, low construction cost, and high production efficiency; and the technological process is suitable for a compounding submarine pipeline and welding procedure of a subsidiary vertical pipe of the compounding submarine pipeline, and is suitable for the welding of a deep water composite material pressure container and deep water pipe manifold nickel base alloy and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +2

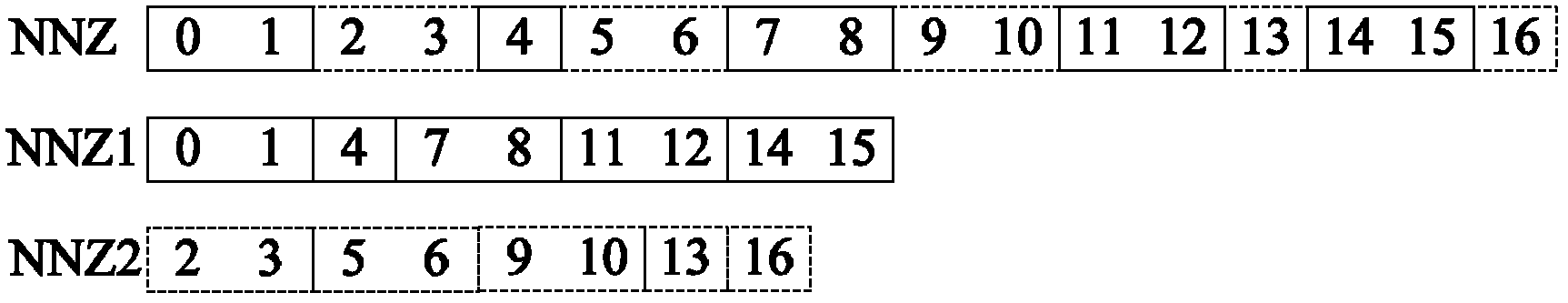

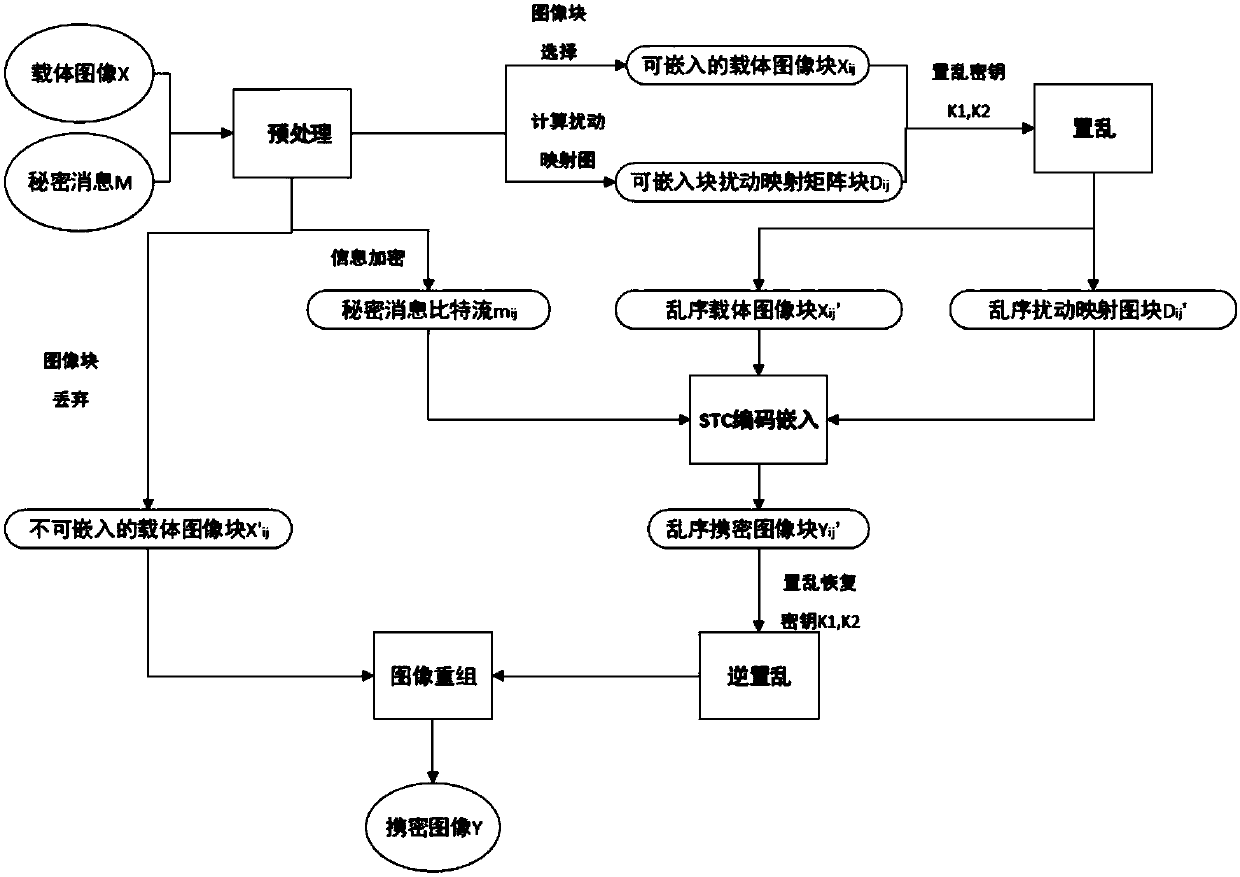

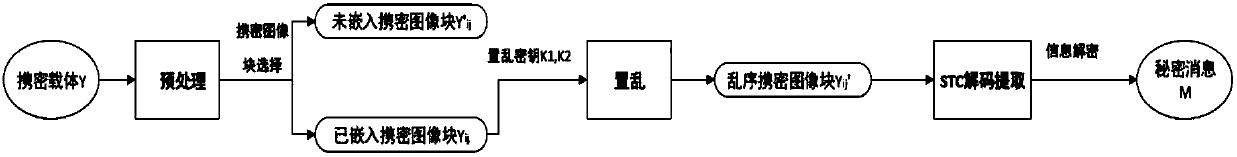

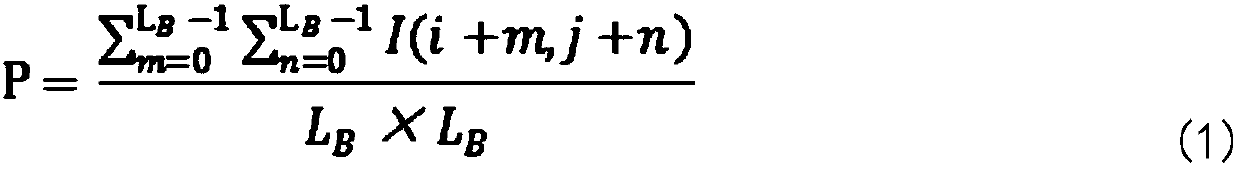

Adaptive steganography algorithm based on binary image

ActiveCN108537049AReduce quality impactHigh resistance to detectionImage analysisDigital data protectionPattern recognitionCovert communication

The invention discloses an adaptive steganography algorithm based on a binary image. The adaptive steganography algorithm based on the binary image comprises the following steps: calculating perturbation of a carrier image according to image texture features, dividing the carrier image into blocks, scrambling image blocks, encrypting secret information, performing STC encoding embedding, reverselyscrambling the encrypted image blocks, and restoring the encrypted image to obtain the encrypted image having the complete texture and the embedded secret information. According to the invention, a novel carrier scrambling algorithm having high security performance and capable of effectively resisting exhaustion cracking is used; through combination of a high-detection resistance measurement method and STC encoding, a designed binary image information hiding method has very high security performance and detection resistance and plays a very important role in secure covert communication.

Owner:SUN YAT SEN UNIV

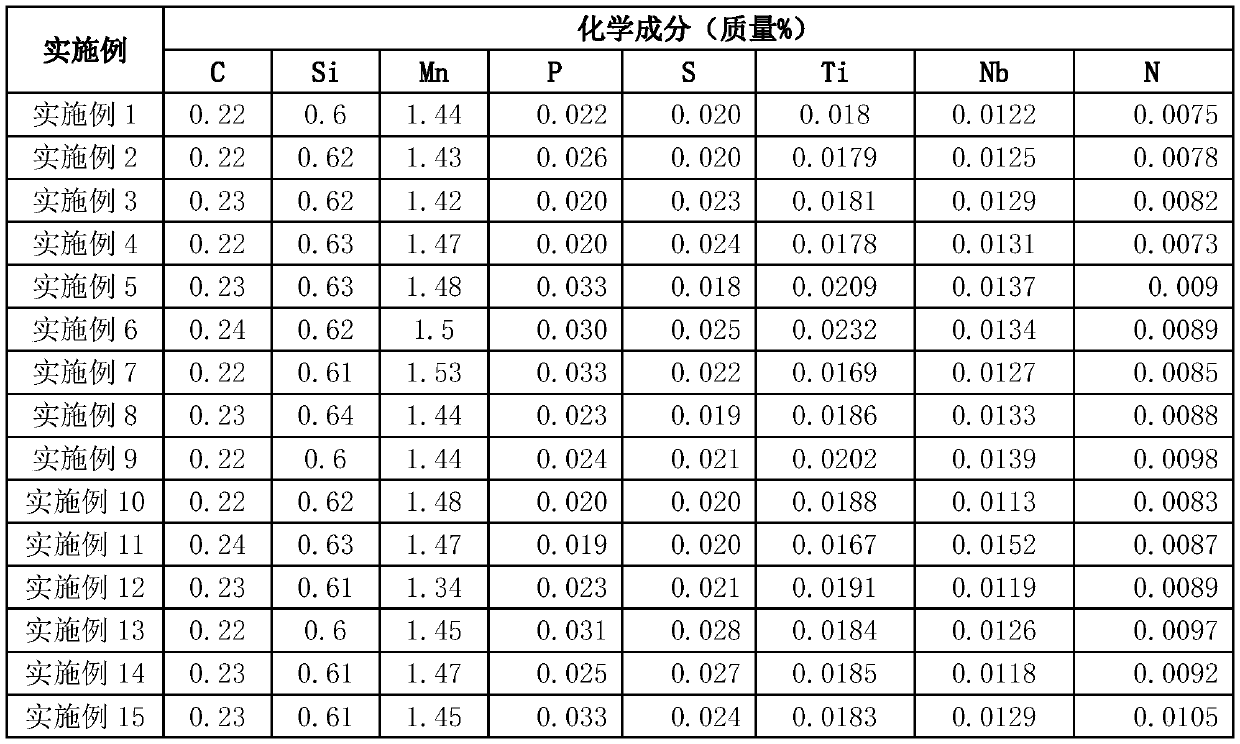

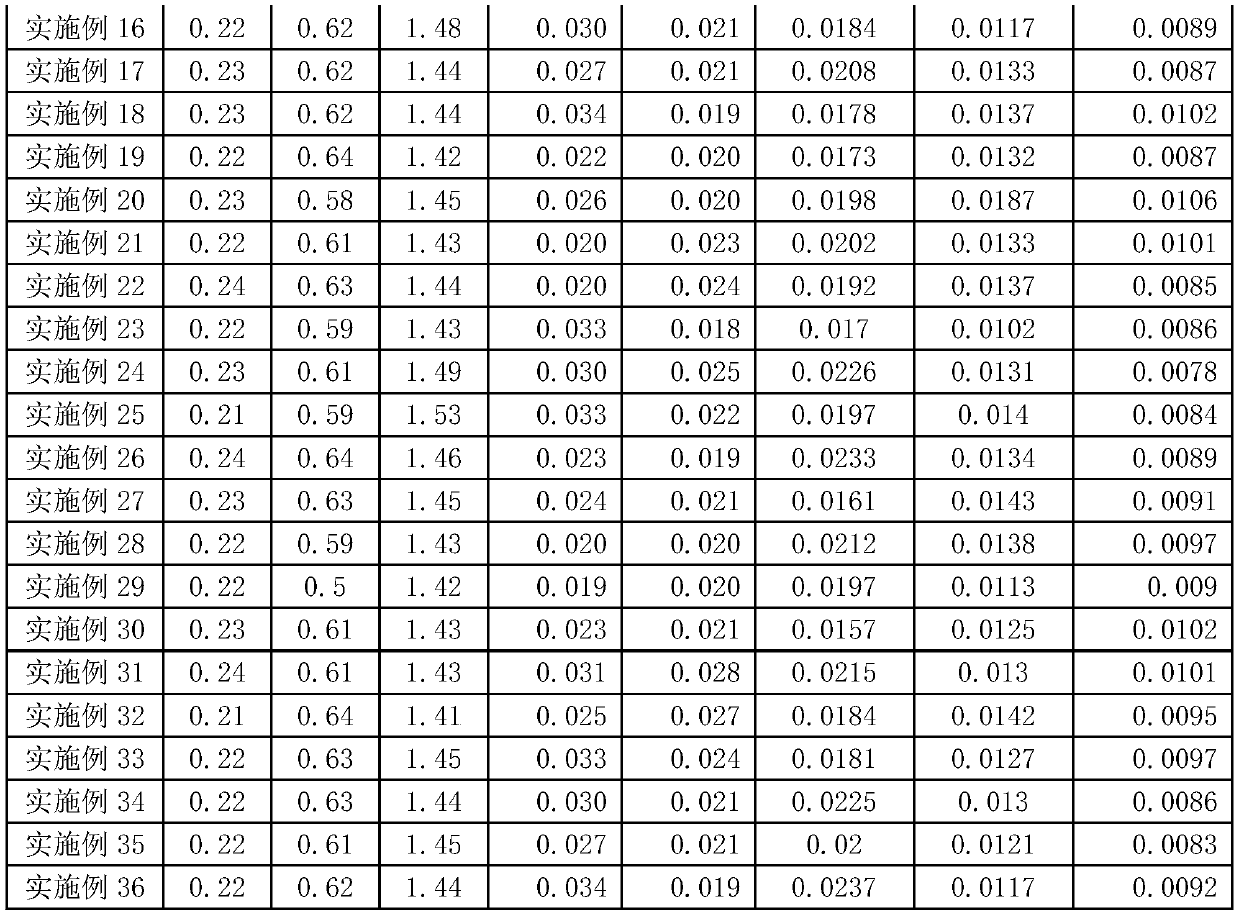

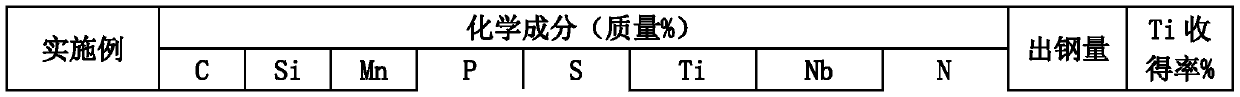

Niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and production method thereof

The invention provides a niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and a production method thereof, and belongs to the technical field of iron and steelsmelting. The niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar comprises, by mass, 0.21-0.25% of C, 0.50-0.65% of Si, 1.40-1.55% of Mn, not greater than 0.045% of P, not greater than 0.045% of S, 0.015-0.025% of Ti, 0.010-0.020% of Nb, 0.0070-0.0110% of N, and the balance Fe and other impurities. In the production method, ferrosilicon, silicomanganese anda carburant are added at the time of 1 / 4 tapping, and all alloys are added at the time of 3 / 4 tapping; the titanium-nitrogen alloy is added at an argon blowing station, and the argon blowing time is greater than or equal to 6 minutes; and high-casting-speed casting powder is adopted for continuous casting, a billet is heated, rolled and fed onto a cooling bed, and finally, the finished product isobtained. According to the niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and the production method thereof, by adding the titanium-nitrogen alloy at the molten steel exposure positon of the argon blowing station, the titanium yield is increased; by reducing the influence of the niobium and titanium content on the quality of the high-casting-speed continuous casting billet, the titanium inclusion in steel is reduced, and the castability of molten steel meets requirements; and by adopting the high-casting-speed continuous casting powder, the cast billet quality is improved.

Owner:YANGCHUN NEW STEEL CO LTD

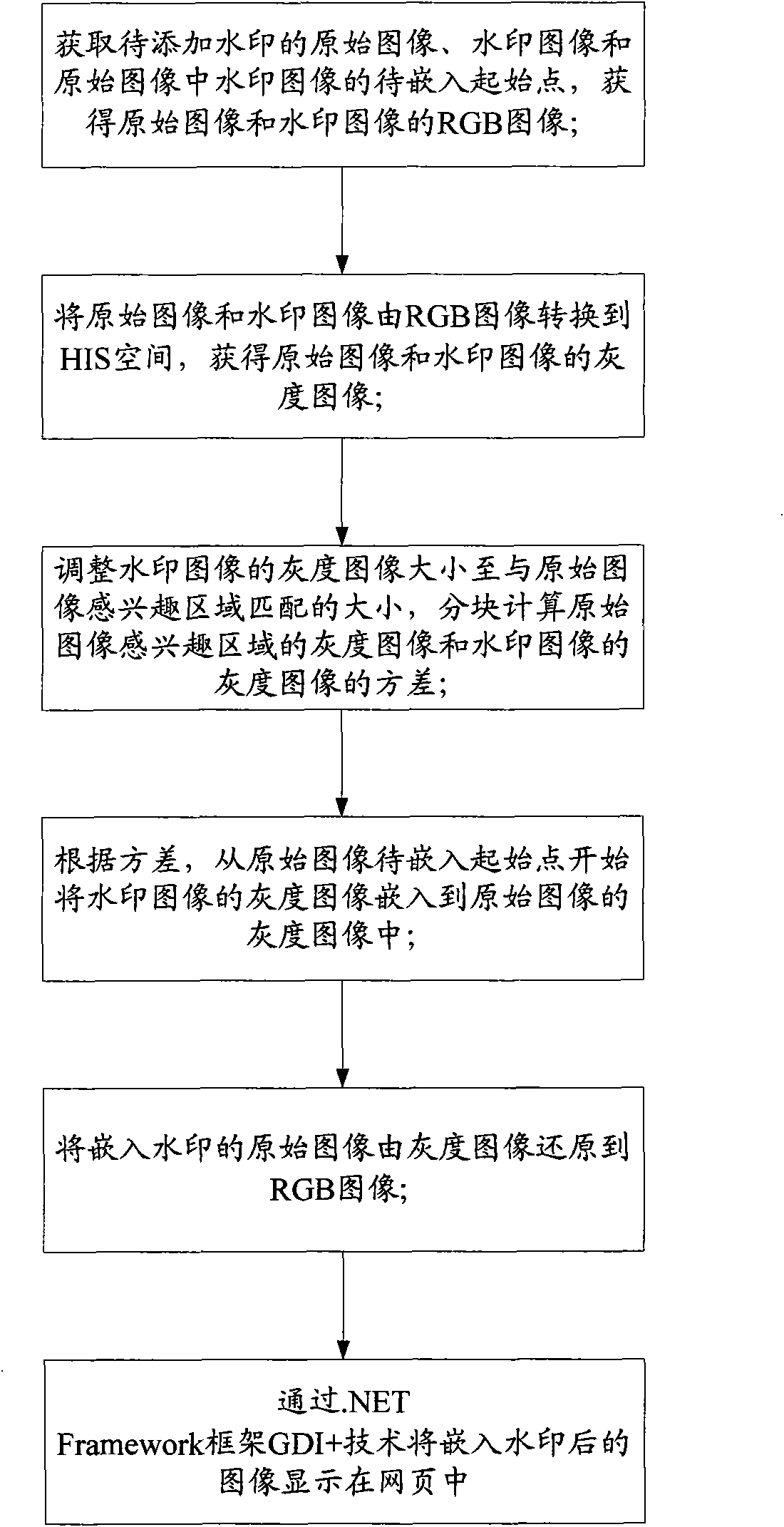

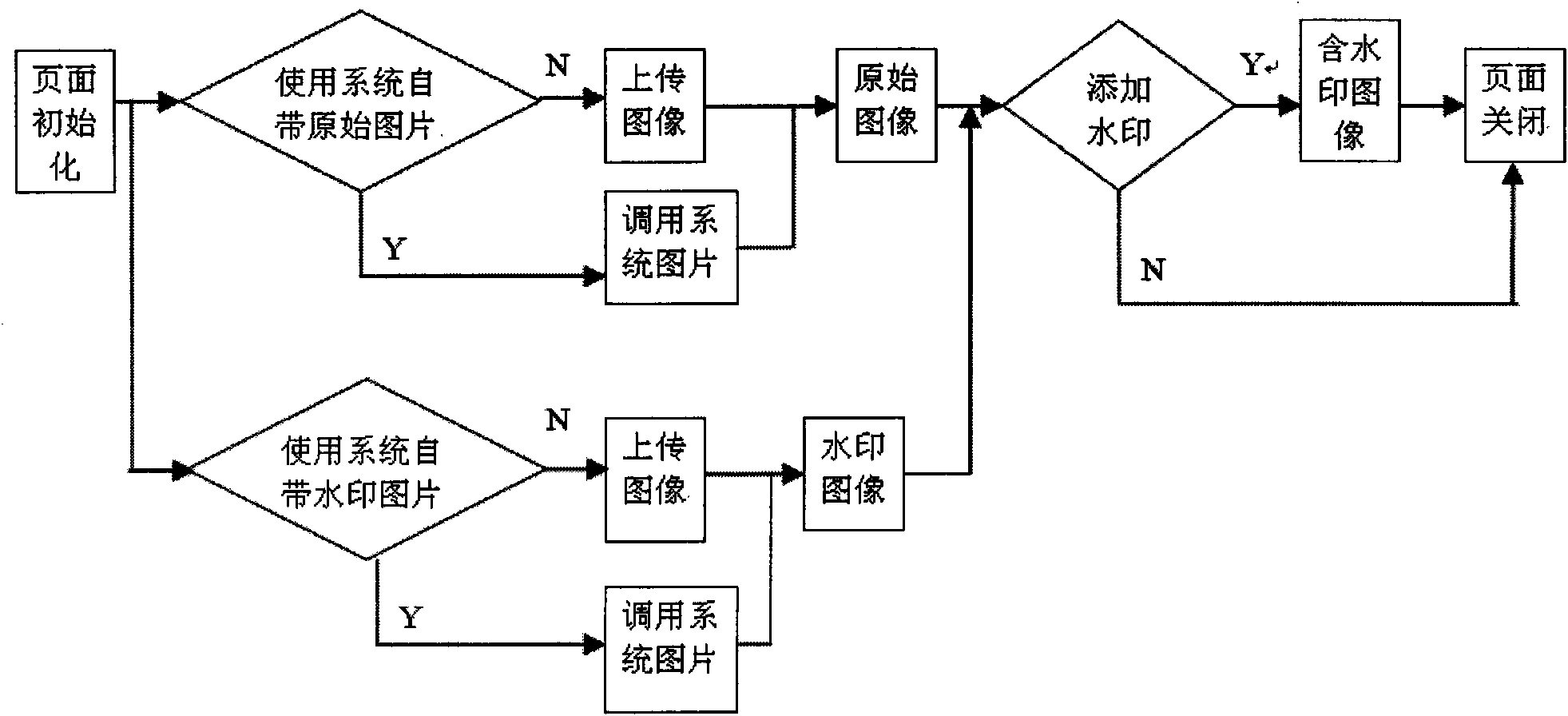

Digital image interesting region visible watermarik adding method suitable for internet

The invention provides a digital image interesting region visible watermarik adding method suitable for internet, which comprises the steps of: acquiring the original image of a watermark to be added,a watermark image and the initial point to be embeded of the watermark image in the original image, and acquiring the RGB images of the original imalge and the watermark image; converting the original image and the watermark image form the RGB images to an HIS space, and acquiring the grayscale images of the original image and the watermark image; adjusting the size of the watermark image to thesize matched with the interesting region of the original image, and calculating the variance between the grayscale image of the interesting region of the original image and the grayscale image of thewatermark image by blocking; embedding the grayscale image of the watermark image into the grayscale image of the original image starting from the initial point to be embedded of the original image according to the variance; and restoring the original image embedded into the watermark from the grayscale image to the RGH image. The method can add watermark at the interesting region of the originalimage (such as the face and eyebrow of people), and has small influence on color image quality, and the added watermark is clear and visible.

Owner:CHONGQING UNIV

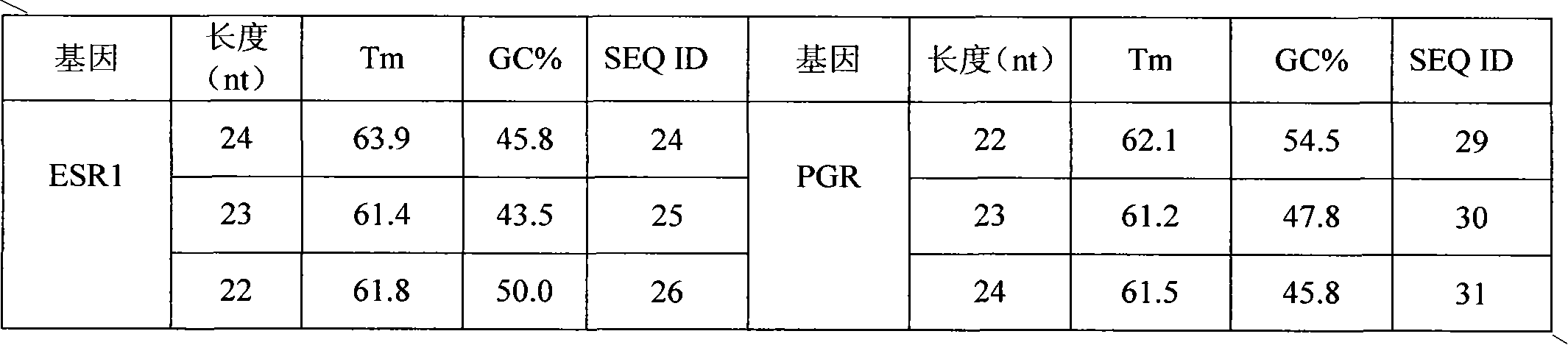

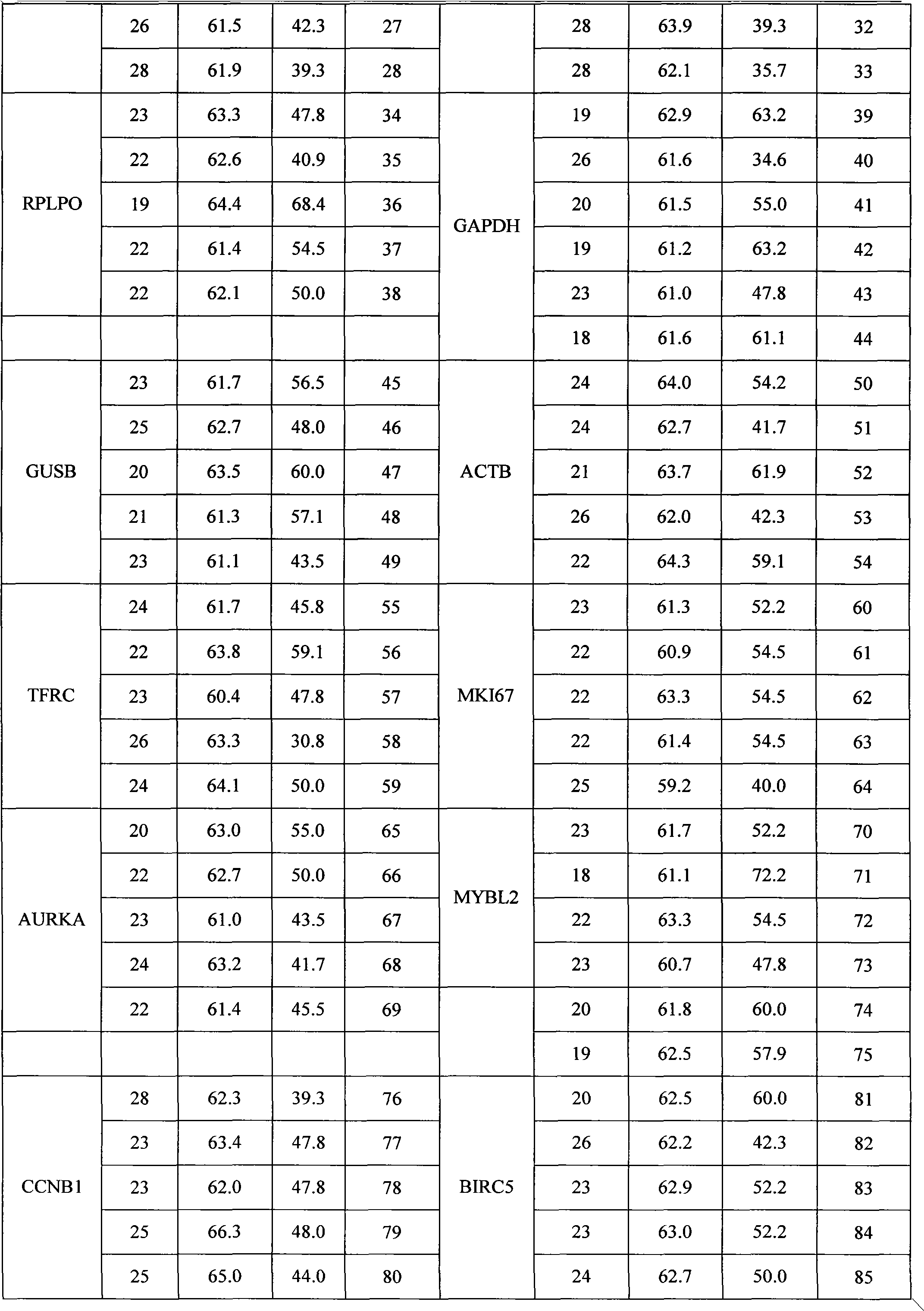

Liquid phase chip for detecting breast cancer prognosis-related gene mRNA expression level

ActiveCN101921858AStrong specificityImprove signal-to-noise ratioMicrobiological testing/measurementSignal-to-noise ratio (imaging)Microsphere

The invention discloses a liquid phase chip for detecting breast cancer prognosis-related gene mRNA expression level, which mainly comprises a microsphere which aims at different target genes and is coupled to amido modified supporting probes, supporting extended probes connecting the supporting probes and target gene mRNA and amplification extended probes. Each supporting probe mainly comprises a 5' end spacer arm sequence and a 3' end specific sequence P1 which is in complementary pairing with a supporting extended probe; the supporting probe comprises SEQ. ID NO.1 specific to ESR1gene and SEQ. ID NO.2 specific to PGR gene; each supporting extended probe mainly comprises a 5' end specific sequence P2 which can be correspondingly combined with the target genes, a spacer arm sequence and a 3' end specific sequence P3 which is in complementary pairing with the specific sequence P1 of a corresponding supporting probe; and the supporting extended probes comprise amplification extended probes, wherein each amplification extension probe comprises a 5' end specific sequence P4 which can be combined with the target genes, a spacer arm sequence and a 3' end sequence P5; or the liquid phase chip also comprises a labeling probe in complementary pairing with the sequence P5. The liquid phase chip can perform hybridization reaction under the homogeneous reaction condition, and the designed probes have the advantages of high specificity and high signal to noise ratio during detection.

Owner:SUREXAM BIO TECH

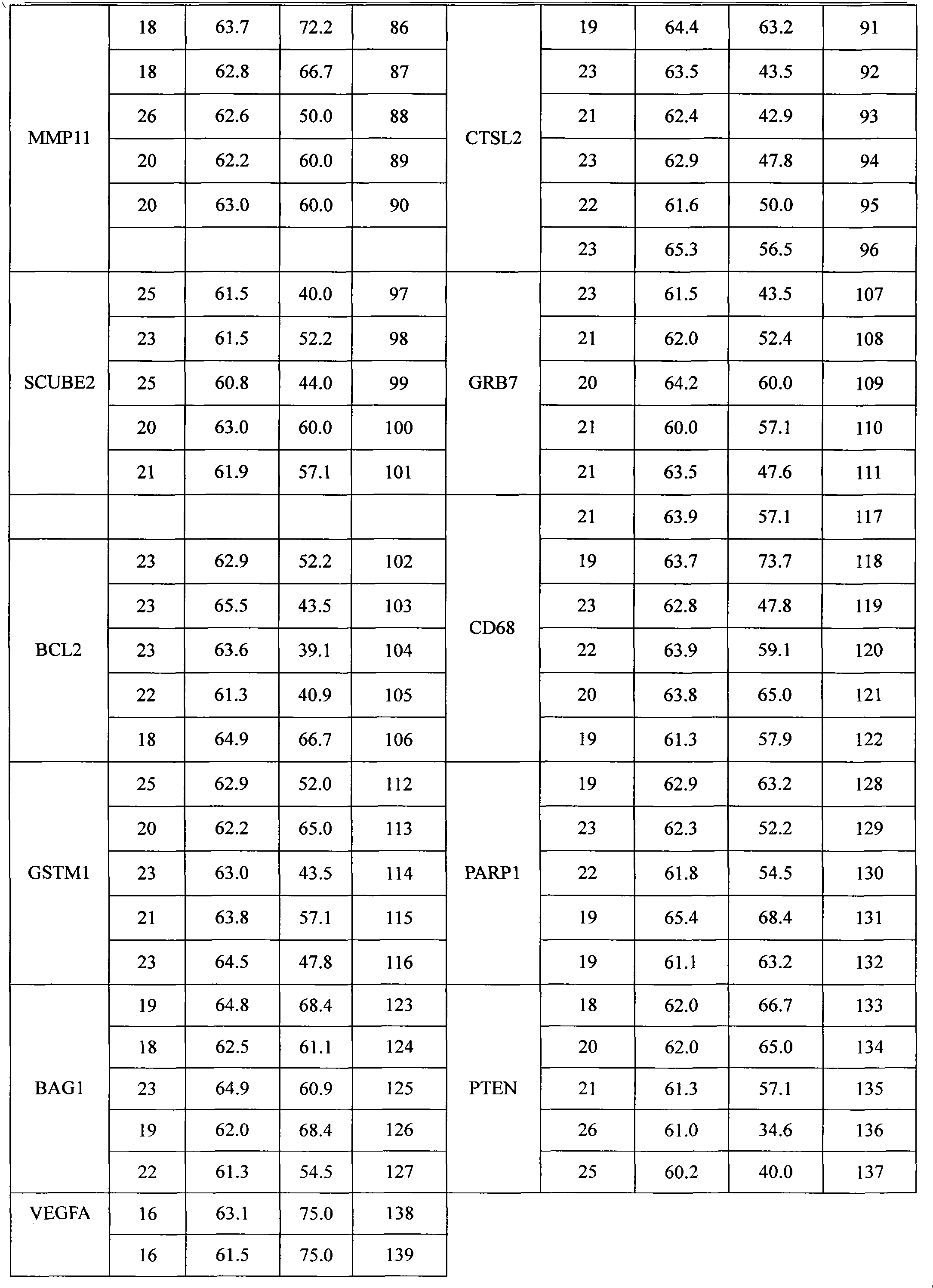

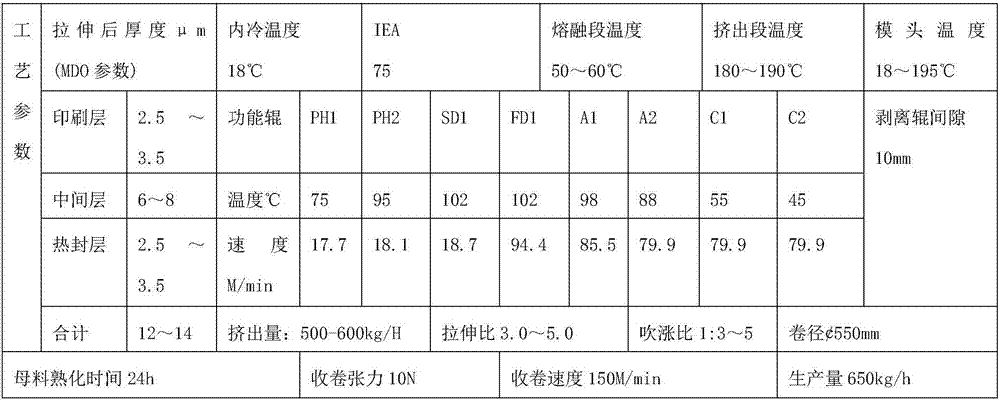

Microporous polyethylene breathable film and preparation method thereof

ActiveCN107283976AFeel comfortableReduce usageSynthetic resin layered productsFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a microporous polyethylene breathable film and a preparation method thereof. The film is obtained by a coextrusion blow molding method, and comprises a printing layer, a middle layer and a heat-sealing layer, wherein each of the printing layer, the middle layer and the heat-sealing layer is prepared from calcium carbonate, metallocene linear low density polyethylene and a fluorine-containing processing agent with a mass ratio of (65 to 75):(25 to 35):(0.5 to 1.5), and the particle size of the calcium carbonate is 1 to 2 mu m. The microporous polyethylene breathable film has obvious advantages in indexes such as pulling strength, hydrostatic pressure and water vapor permeability, thus providing excellent technical guarantee for positioning, cutting and multi-colour printing chromatography of corresponding products; the gram weight of per unit area of the microporous polyethylene breathable film is light, thus plastic resin can be used less, energy consumption is greatly reduced, and carbon emission is reduced, thus providing guarantee for realizing lightness and emission reduction of one-off living sanitary articles.

Owner:永新股份(黄山)包装有限公司

Continuous casting crystallizer casting powder special for bar plate stainless steel containing titanium and manufacturing technique thereof

The invention relates to an auxiliary product for metallurgy used for continuous casting of titanium-containing stainless steel in the metallurgy field, which is mainly applied in the mould powder technique of pre-melted crystallization mould of continuous casting for high titanium containing stainless steel. The materials of the invention comprise: specific used pre-melted base materials containing boron, flux materials, carbonaceous materials and additives; wherein, the flux materials comprise Li2CO3, Na2CO3, NaF, etc. The invention is characterized by good performance of accommodating and adsorbing titanium inclusion under the condition of meeting requirements for adding no carbon and reducing regrinding of traditional stainless steel; besides, after absorption of inclusion, the viscosity properties and solidification properties of the mould powder can be kept relatively stable, and compared with the import slag, the invention has the advantages of lower caking bleeding rate, casting billet with less surface defect, high anterograde of processing. Besides, the production of the invention has little slag strip; reaction in the crystallization mould is active; spreading property is good.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

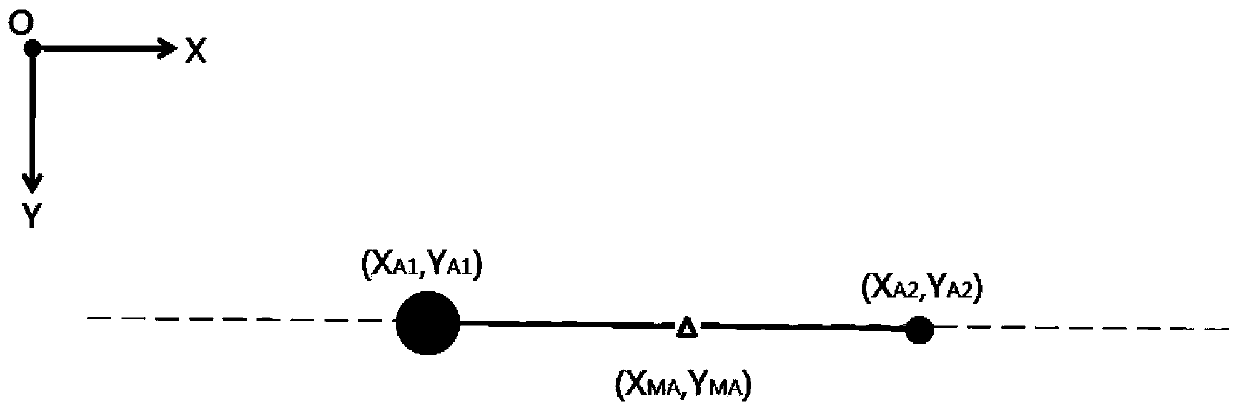

Accurate alignment method for large aperture mirror machine tool

ActiveCN103386640AImprove alignment accuracyOptimize resource allocationOptical surface grinding machinesGrinding feed controlCoordinate changeOptical processing

The invention discloses an accurate alignment method for a large aperture mirror machine tool, belongs to the technical field of optical machining and detection, and aims to solve the problem of low alignment accuracy in the prior art. The method comprises the following steps of fixedly connecting two sets of image acquisition systems to a machining grinding head and a detection probe of the machine tool respectively; calibrating the distortion of the image acquisition systems; and shooting large and small dot pair targets which are adhered to a non-working area of a mirror body to be machined, comparing large and small dot coordinate change of target images at the current position and the initial reference position, calculating the relative rotation angle and translation quantity of the two positions, repeating the steps, and obtaining surface shape detection distribution of the mirror body after the mirror body is traversed to guide the accurate alignment of the machine tool. The high alignment accuracy between the machining grinding head and the detection probe of the machine tool and the mirror body to be machined provides guarantee for high consistency of the traversing track of the machining grinding head and a machining track planned according to the detection surface shape, and the surface shape with higher machining accuracy can be obtained.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Piracy tracing watermarking method applicable to streaming media environment

ActiveCN102307320AImprove real-time performanceReduce complexityTelevision systemsDigital video signal modificationWatermark methodMotion vector

The invention relates to a piracy tracing watermarking method applicable to streaming media environment, and belongs to the multimedia information safety field. The method comprises the following steps: firstly segmenting video before the watermark embedding procedure; according to content of streaming video, selecting macroblocks meeting the conditions to be embedded with watermarks during the watermark embedding process; and determining the macroblock which is best suited for being embedding with watermark information by adopting a quicksort algorithm. In the piracy tracing watermarking method, based on difference between horizontal direction and vertical direction of motion vector of the macroblock, appropriate motion components are adaptively selected to be embedded with 2-bit watermark information, and the NAL (network abstraction layer) head of a B-frame is modified after the watermark embedding procedure so that the watermark can cope with the situations such as frame loss and the like resulting from network transmission. By adopting the piracy tracing watermarking method, the watermark information can be embedded into the streaming video in real time so as to achieve the purpose of piracy tracing.

Owner:JIANGSU YITONG HIGH TECH

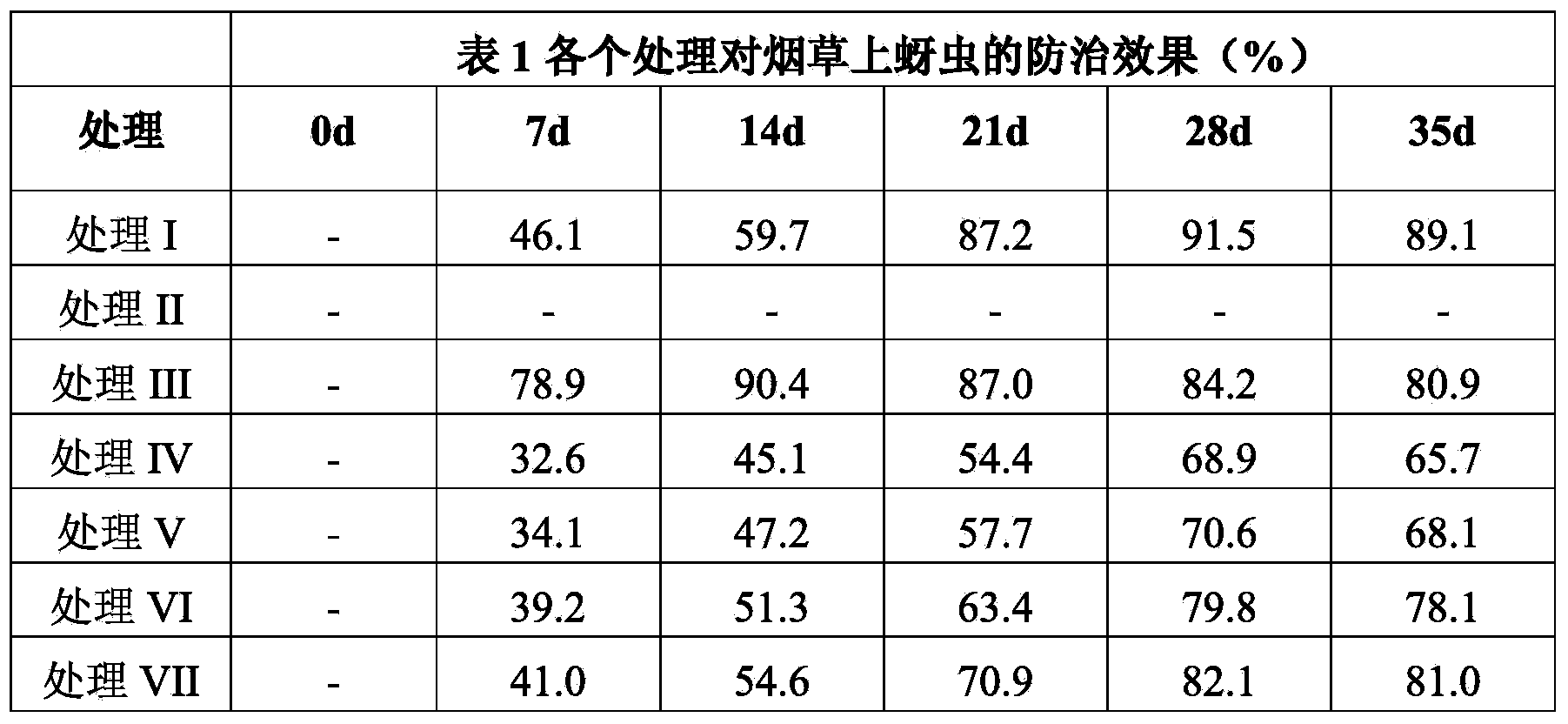

Biological control method of crop-rotation tobacco field myzus persicae

InactiveCN103749139AReduce insect population baseGood control effectPlant protectionNicotiana tabacumChemical control

The invention discloses a biological control method of crop-rotation tobacco field myzus persicae. The method has the following advantages that aphids are prevented through releasing aphidius gifuensis ashmead on oilseed rape of a preceding crop, the initial number of the aphids is obviously reduced in the growing period of tobaccos, meanwhile, the population quantity of the aphidius gifuensis ashmead is maintained in a tobacco field, the myzus persicae on the tobaccos is beneficially controlled during planting of following tobaccos, and the effect is better than a myzus persicae chemical control effect; a releasing mode that non-mummified alates where parasite aphidius gifuensis ashmead lives are combined with adult ashmead of the aphidius gifuensis ashmead is adopted, and the prevention effect is better than the effect that the non-mummified alates or the adult ashmead of the aphidius gifuensis ashmead is separately released; according to the biological control method, myzus persicae prevention does not need pesticides, use amount of chemical drugs is greatly reduced, influences of the chemical drugs on tobacco leaves are reduced and pollution to the environment is reduced.

Owner:YUXI TABACOO COMPANY OF YUNNAN PROVINCE

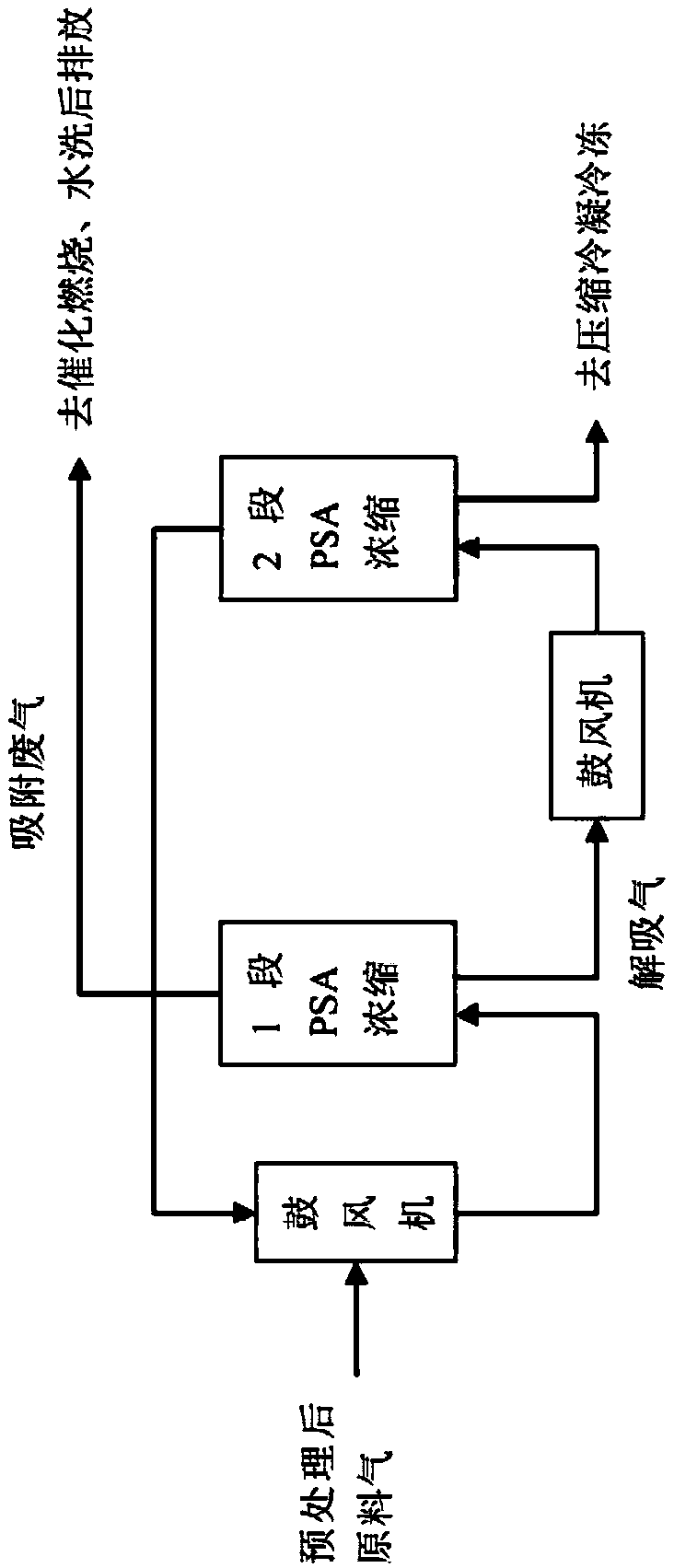

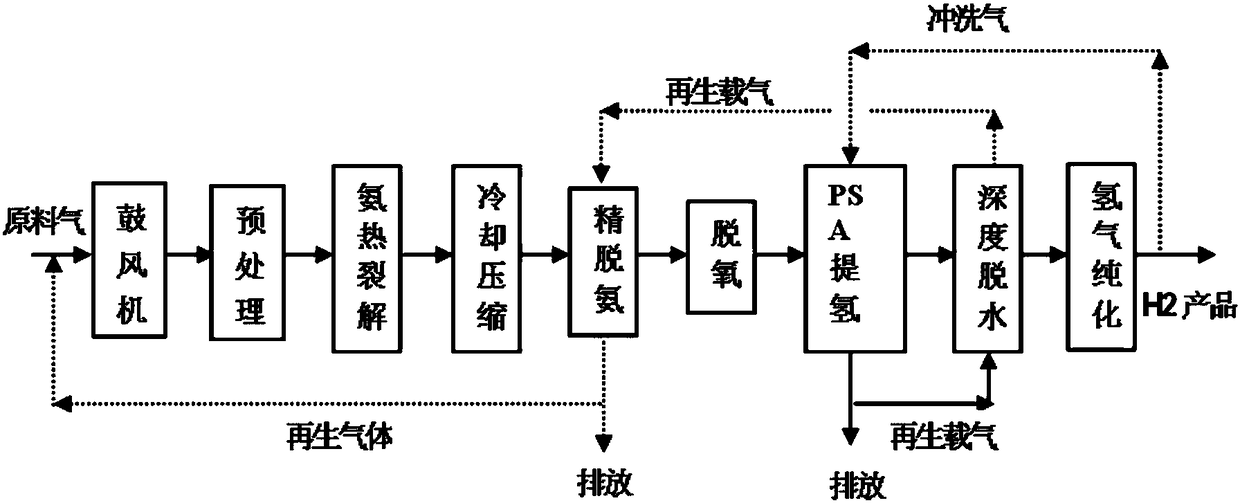

Method for FTrPSA (full temperature range-pressure swing adsorption) hydrogen production recycling of high-concentration ammonia-containing tail gas from LED-MOCVD (light emitting diode-metal oxide chemical vapor deposition) processing

ActiveCN108609583AAchieve reuseEmission reductionHydrogen separation using solid contactDispersed particle separationHigh concentrationChemical vapor deposition

The invention discloses a method for FTrPSA (full temperature range-pressure swing adsorption) hydrogen production recycling of high-concentration ammonia-containing tail gas from LED-MOCVD (light emitting diode-metal oxide chemical vapor deposition) processing. By the process of pretreatment, ammonia thermal cracking, fine deamination, pressure swing adsorption based hydrogen extraction and hydrogen purification, high-concentration ammonia-containing waste gas from the LED-MOCVD processing is subjected to thermal cracking and purification to meet the electronic grade hydrogen standard required by the LED-MOCVD processing, the waste gas is recycled, and the hydrogen yield is higher than or equal to 80%-90%. The technical problem that recycled normal-pressure or low-pressure high-concentration ammonia-containing waste gas from the LED-MOCVD processing cannot return to the LED-MOCVD processing to be used is solved, and the blank in green and circular economy development of the LED industry is filled up.

Owner:SICHUAN TECHAIRS

Cocoon cooking method for preparing high-quality grade-6A raw silk

InactiveCN102517644ASolve bottlenecksUniform penetrationAnimal materialSilk filament obtainingMolecular clusterCooking methods

The invention discloses a cocoon cooking method for preparing high-quality grade-6A raw silk, which comprises the following steps: firstly carrying out vacuum infiltration on a silkworm cocoon by utilizing alkaline ionized water with a pH value of 7.5-8.5, then impregnating the silkworm cocoon subjected to the vacuum infiltration by utilizing acidic ionized water with a pH value of 4.5-6.5, cooking the impregnated silkworm cocoon in a machine and adding a certain amount of acidic ionized water at the low-temperature infiltration part. Compared with the background art, the cocoon cooking method has the advantages that a water molecular cluster of the alkaline ionized water is small, the surface tension is small, the infiltration is strong, the water is easy to enter an adhesive part of silk glue, so that the infiltration on a cocoon shell is uniform to be beneficial to improving the clean index of the raw silk; and as the silkworm cocoon subjected to the vacuum infiltration is impregnated by utilizing the acidic ionized water, the surface of the silkworm cocoon subjected to the vacuum infiltration is converted from alkalescence to neutrality or weak acidity so as to be beneficial to reducing the silk glue melting loss on the outer layer of the silkworm cocoon, thereby the cohesion indicator of the raw silk is improved. The cocoon cooking method has the advantages of simplicity, environment friendliness and no pollution.

Owner:ZHEJIANG JIAXIN JINSANTA SILK KNITTING +1

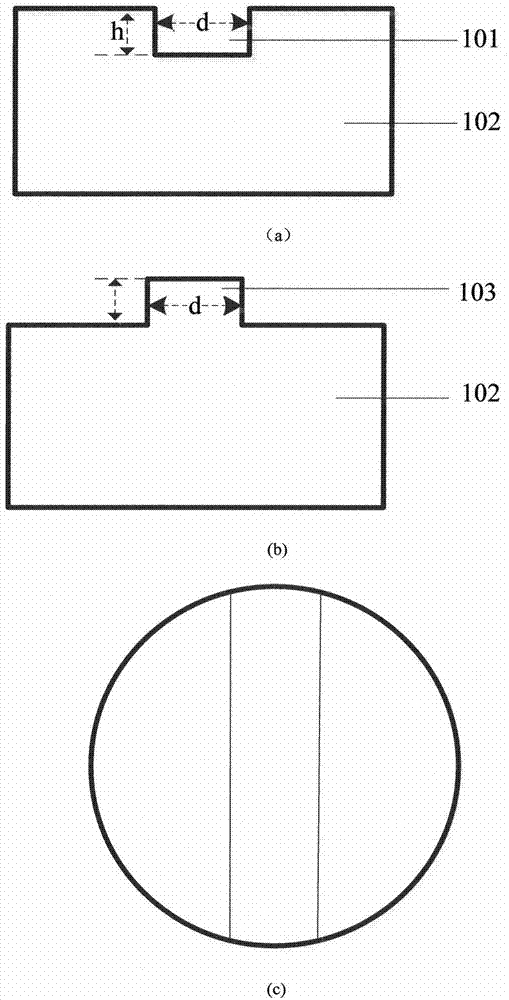

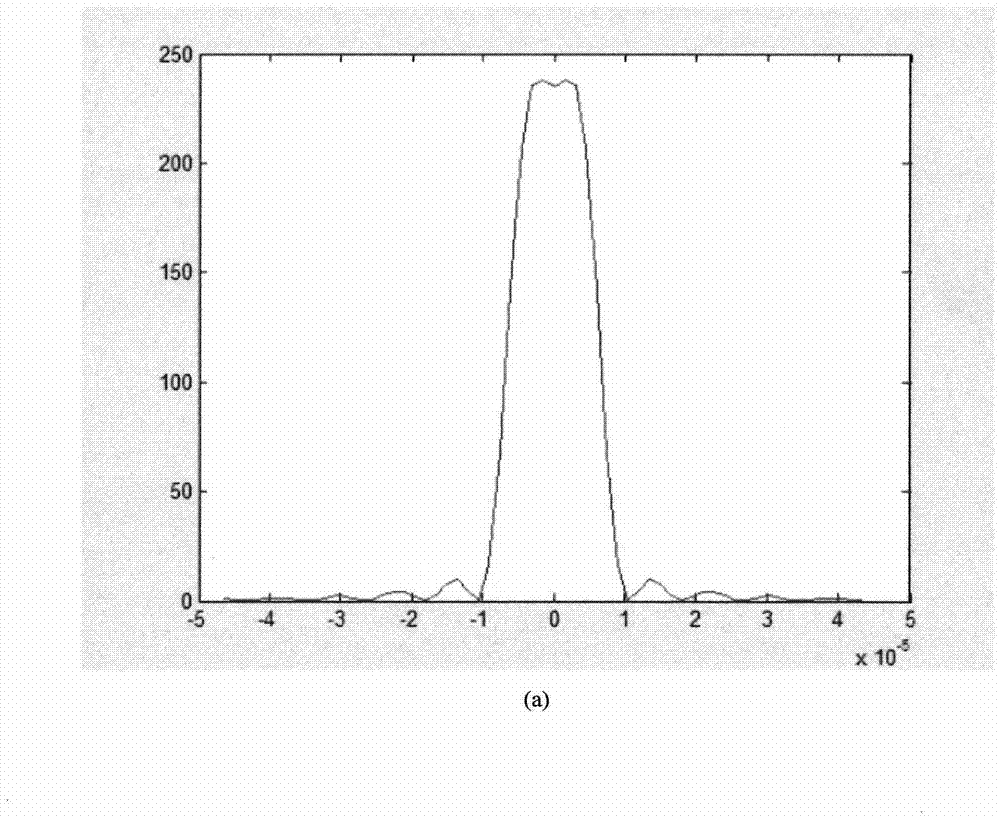

Diffraction optical element shaping Gaussian beam into one-dimensional flattened beam or rectangular flattened beam

InactiveCN104765087AImprove energy transmittanceReduce quality impactDiffraction gratingsPhotomechanical exposure apparatusGaussian beamTransmittance

The invention provides a diffraction optical element shaping Gaussian beam into a one-dimensional flattened beam or a rectangular flattened beam. The diffraction optical element is called DOE for short. A manufacturing method of the DOE is also provided. Grooves or steps which are in different shapes and have different sizes are manufactured at the center of a quartz substrate, the DOE is arranged at different positions in a light path, the DOE is matched with a beam expanding collimating mirror and a focusing lens, and then the one-dimensional flattened beam or the rectangular flattened beam is formed. The DOE has the following prominent advantages of being high in energy transmittance rate, insensitive to the change of a lasing mode and easy and flexible to install and use.

Owner:北京润和微光科技有限公司

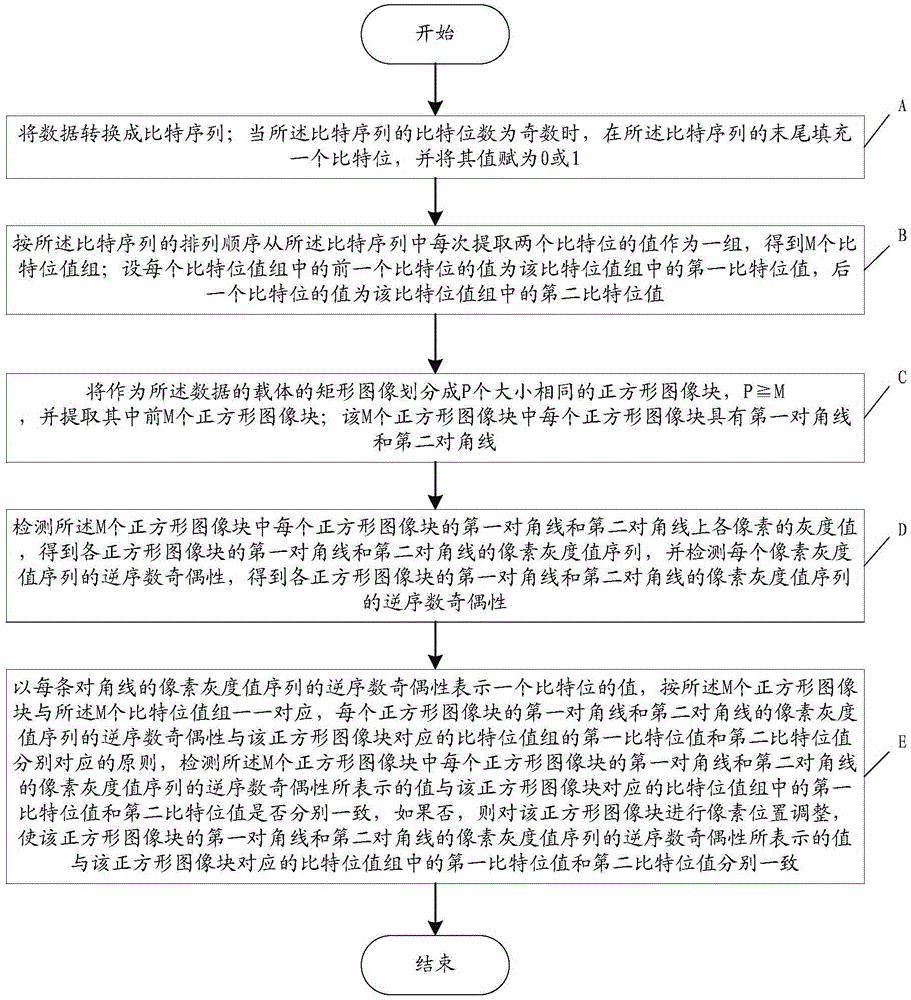

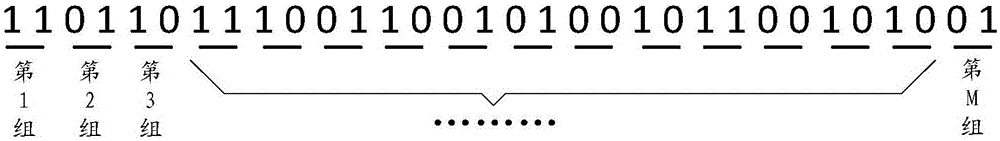

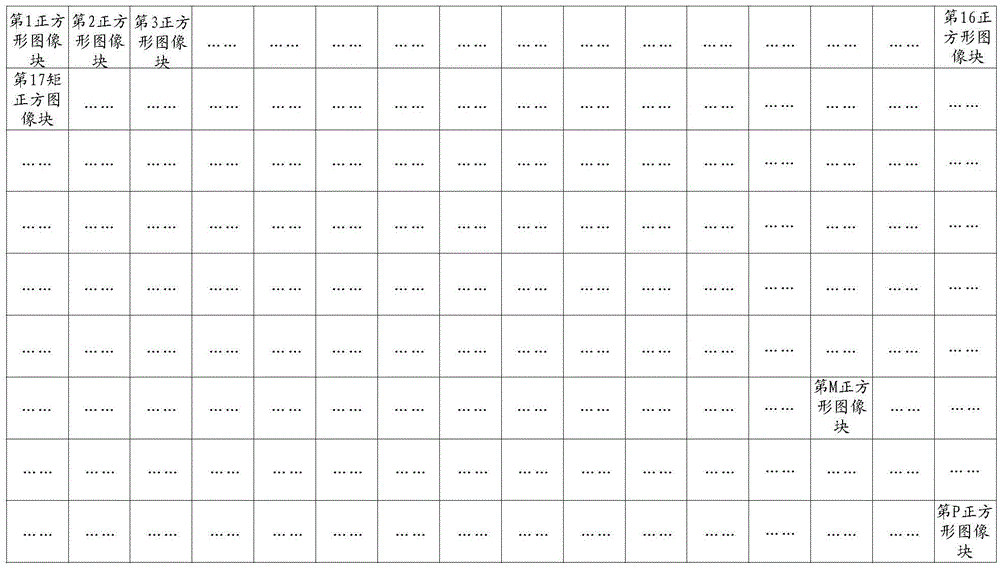

Data hiding method and data hiding system

InactiveCN105160694AReduce quality impactGuaranteed image qualityImage codingCoding/ciphering apparatusPattern recognitionImaging quality

The invention relates to the technical field of data hiding, in particular to a data hiding method and a data hiding system. An image is used as a data carrier; after secret data is converted into a bit sequence by a sending end, the values of each bit in the bit sequence are hidden in the image; the image hidden with the secret data is obtained and is sent to a receiving end; and the receiving end can extract the hidden secret data from the image according to a corresponding secret key. During data hiding, each square image block can hide two-bit data through inverse number odd-even properties of a pixel gray value sequence of two diagonal lines of each square image block, so that the volume of data hidden in the image is twice of the number of the image blocks split by the image. During pixel position regulation on each square image block, only the gray values of at most two pixels on the first diagonal line and the second diagonal line of the square image block need to be regulated, so that the influence on the image quality is little; and the image quality is ensured.

Owner:SHENZHEN UNIV

Method for preparing amorphous atorvastatin calcium

The invention discloses a method for preparing amorphous Atorvastatin calcium. The current method uses more solvent, so the cost is over high; and the residual quantity of the solvent in a product is large, thereby causing big influence on the quality of the product and causing serious environmental pollution. In the method, alcohol solvent and water are combined into mixed alcohol-water solvent which dissolves Atorvastatin calcium containing one or more crystal forms completely; proper temperature is kept for ensuring that the Atorvastatin calcium is not precipitated; and the amorphous Atorvastatin calcium is precipitated by a spray drying method. The method uses the mixed alcohol-water solvent which is removed from the product easily, has little organic residue and causes less influence on drug quality; the usage amount of the solvent is reduced greatly; the concentration of the Atorvastatin calcium in the solution is high; and the purity of the prepared product of the amorphous Atorvastatin calcium is high.

Owner:ZHEJIANG JINGXIN PHARMA

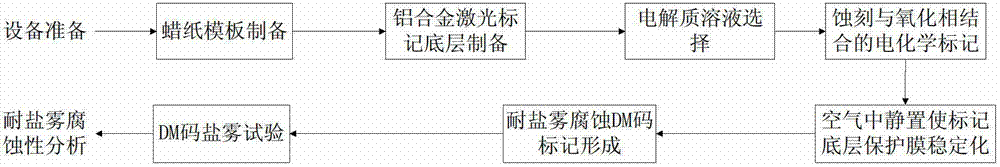

Laser marking method for increasing salt spray corrosion resistance of two-dimension codes on surface of aluminum alloy

InactiveCN102776541AStrong resistance to salt spray corrosionStable structureAnodisationWaxElectrochemistry

The invention provides a laser marking method for increasing salt spray corrosion resistance of two-dimension codes on a surface of an aluminum alloy. A DM code bottom layer is formed by directly marking with laser on an aluminum plate substrate; a square pattern is made on wax paper by using a thermo-sensitive method; the square pattern is larger than specification of existing DM codes on the surface of an aluminum plate; electrochemical etching is carried out in a DM code area of the aluminum plate by using an electrochemical etching method with the wax paper as a template to form a layer of oxidation film having protection function, so that a DM code mark with salt spray corrosion resistance is formed. Compared with the DM code mark directly marked on the surface of the aluminum alloy with laser, salt spray corrosion resistance of the DM code mark generated by the method can be increased greatly, and the oxidation film in a marking area is controllable; the influence of the mark for part matrix out of the marking area is poor; the operation is simple; and the efficiency is higher.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

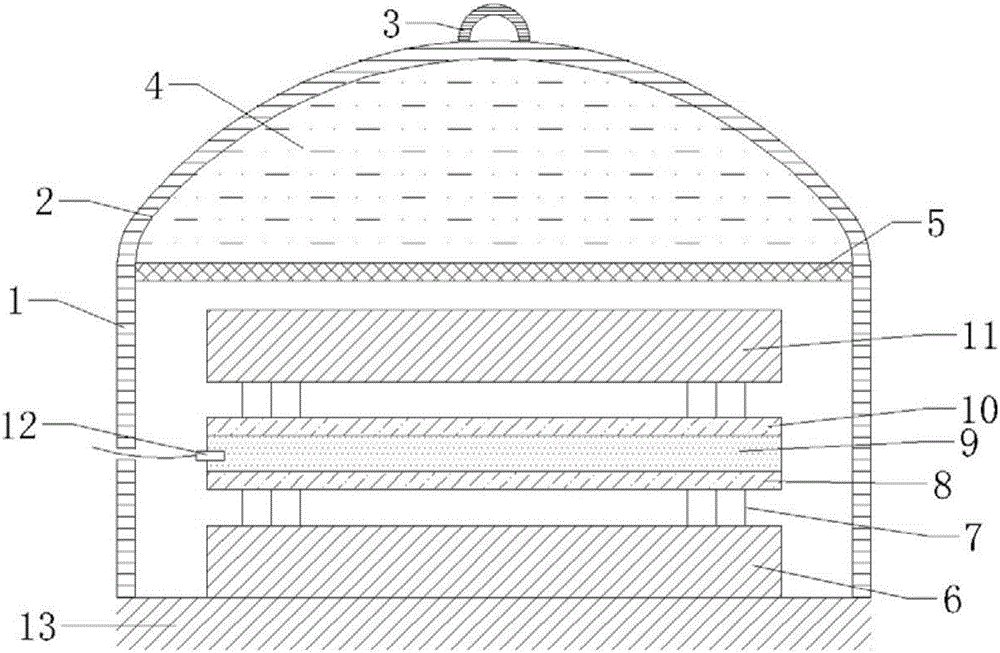

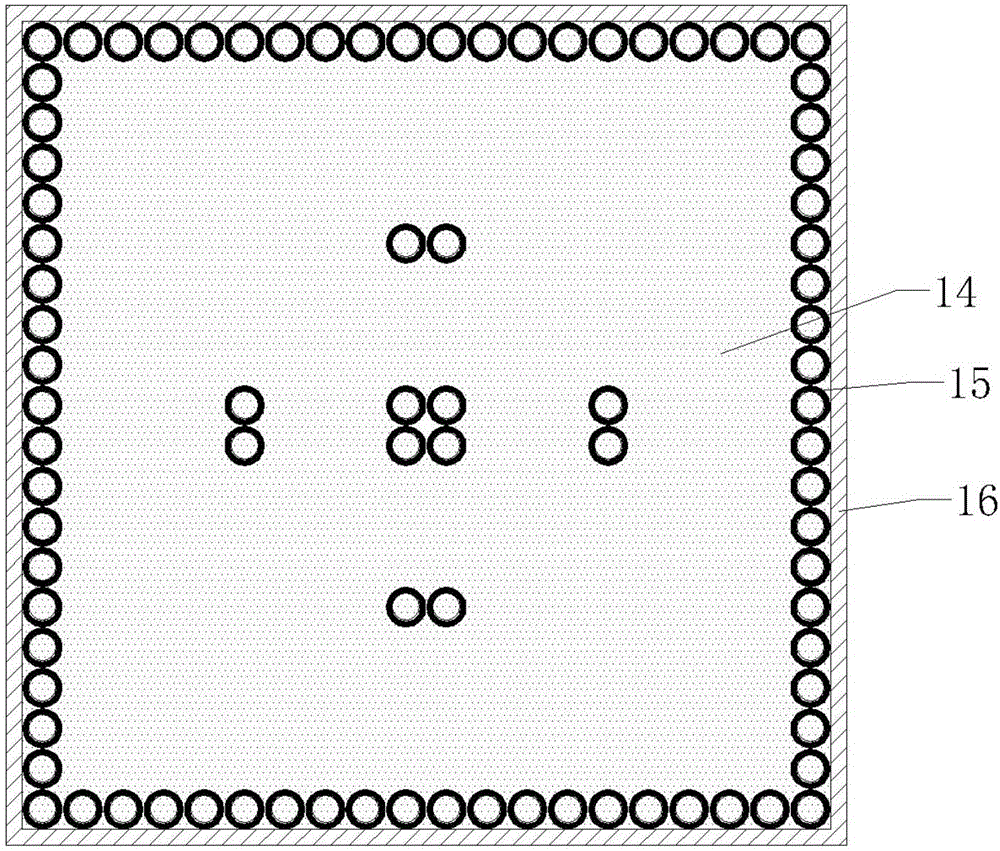

Protective cover based on double-sided explosive welding and charging structure

ActiveCN106735862AAvoid restrictionsImprove securityWelding/cutting auxillary devicesAuxillary welding devicesDetonationBoundary effects

The invention discloses a protective cover based on double-sided explosive welding and a charging structure. The protective cover can be repeatedly used and mainly comprises an outer shell, a buffer layer and a constraint net. The protective cover provides a closed environment for explosive welding, can effectively prevent an upper-layer composite plate and fragments from flying apart, reduces noise pollution and dust pollution and provides a safe and comfortable working environment for explosive machining. The charging structure comprises a constraint box, supporting shells and an explosive. The supporting shells are columnar shells shaped like the Arabic number '8' and evenly distributed along the inner surface of the constraint box, achieve a supporting effect, and enhance detonation at the boundary, thereby reducing the boundary effect. The upper surface and the lower surface of the charging structure are in fit with the upper-layer composite plate and a lower-layer composite plate, and the explosive is in a constraint state in any direction. Accordingly, the explosive detonation critical thickness is reduced, and the energy utilization rate is improved.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com