Protective cover based on double-sided explosive welding and charging structure

An explosive welding and protective cover technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high risk factor, low work efficiency, environmental damage, low utilization rate of explosive energy, etc., to reduce noise pollution, Avoid complex process and dust pollution, improve the effect of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] For the double-sided explosive welding of stainless steel and steel, a protective cover and charge structure were invented, in which the size of the base plate is 2000mm×2000mm×20mm; the size of the double plate is 2000mm×2000mm×5mm.

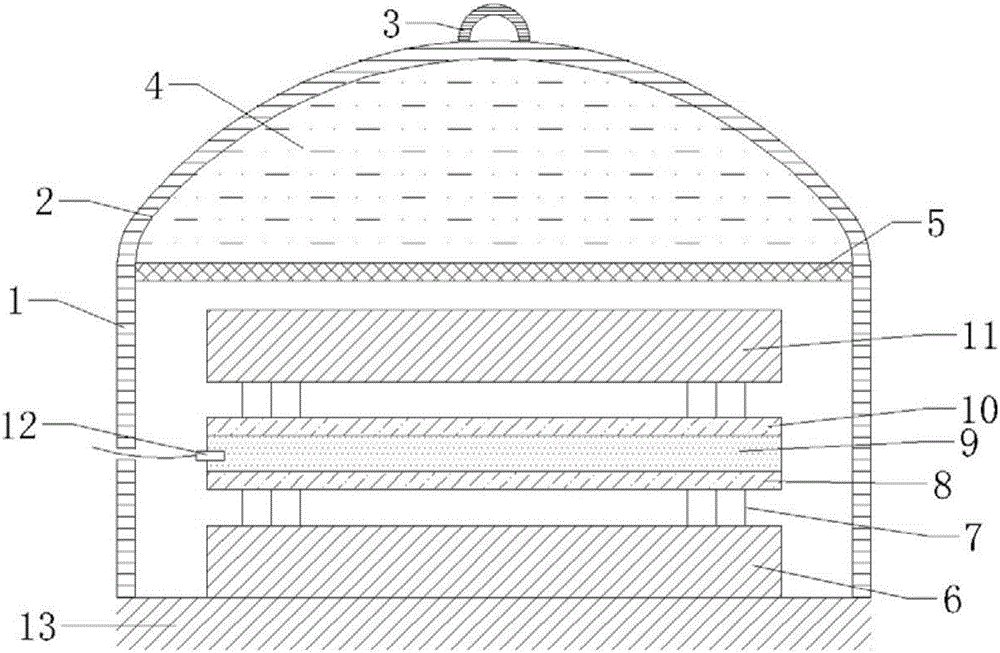

[0028] refer to figure 1 , The double-sided explosive welding restraint cover includes: a shell, a buffer layer and a restraint net. The shell material is iron, its inner diameter is 3000mm, the wall thickness is 20mm, and its shape is a "bow" structure composed of a cylindrical shell and a sub-hemispherical shell. The height of the cylindrical shell is 1000mm, and the height of the sub-hemispherical shell is 500mm; the buffer layer is filled with waste Tires; the restraint net is steel wire mesh.

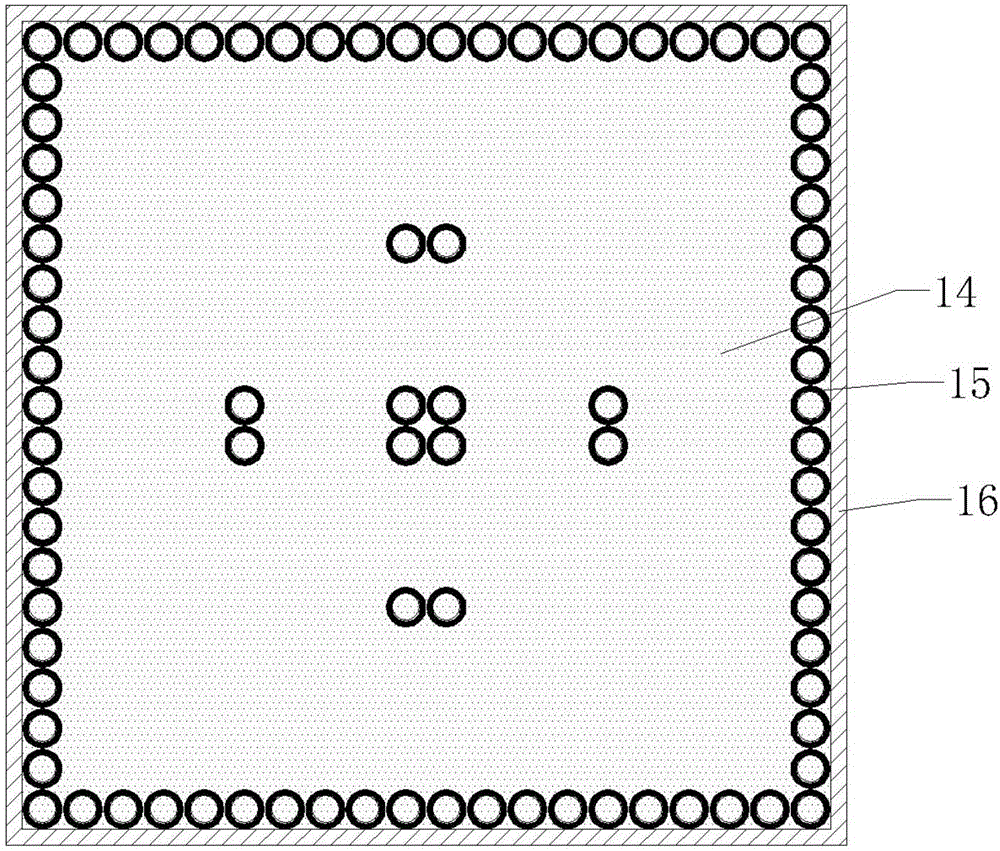

[0029] refer to figure 2 , the double-sided explosive welding charge structure includes: a restraint box, a supporting shell and explosives. Here, the constraining box is selected as a paper box, and its side length is 2000mm for the side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com