Bridgeless boost converter with pfc circuit

A technology of control circuit and single-cycle control, which is applied in the direction of control/regulation system, output power conversion device, DC power input conversion to DC power output, etc., can solve problems such as impractical realization, and achieve total cost reduction and elimination Intrinsic loss, effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

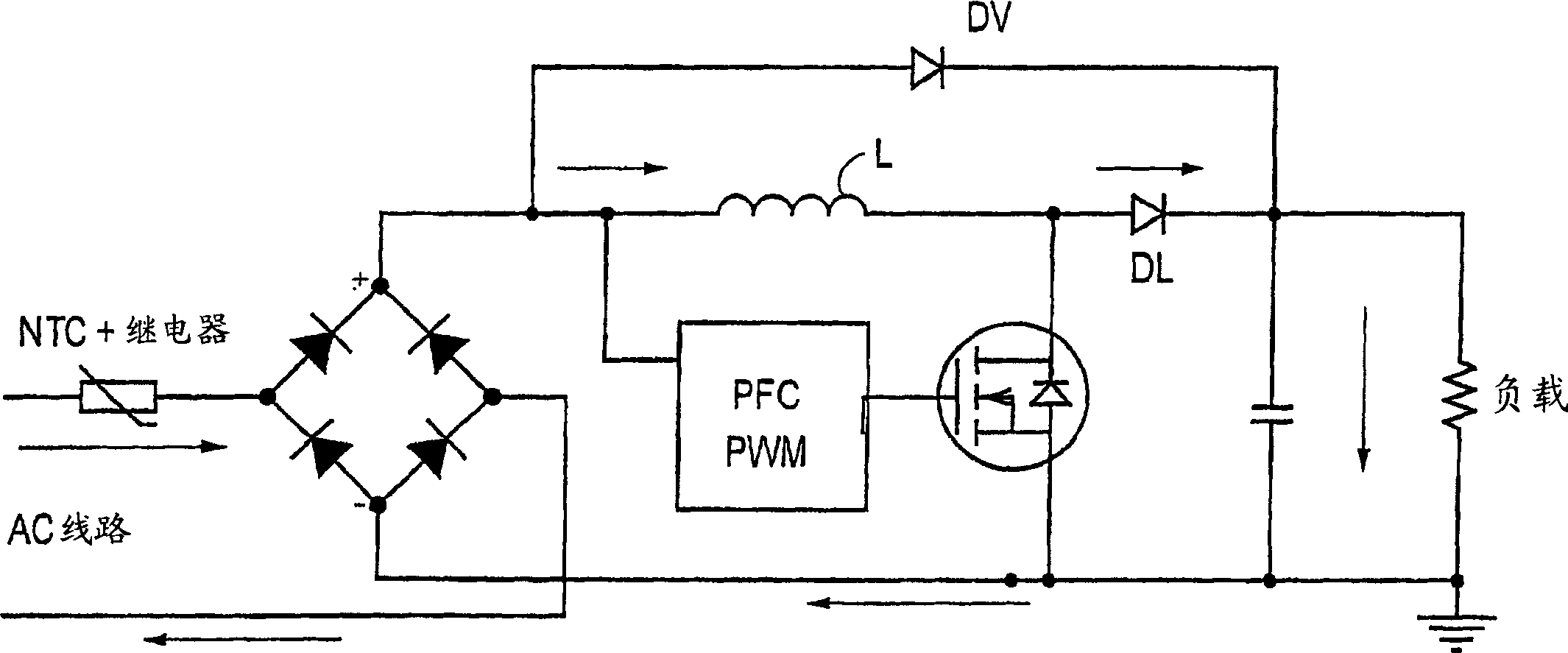

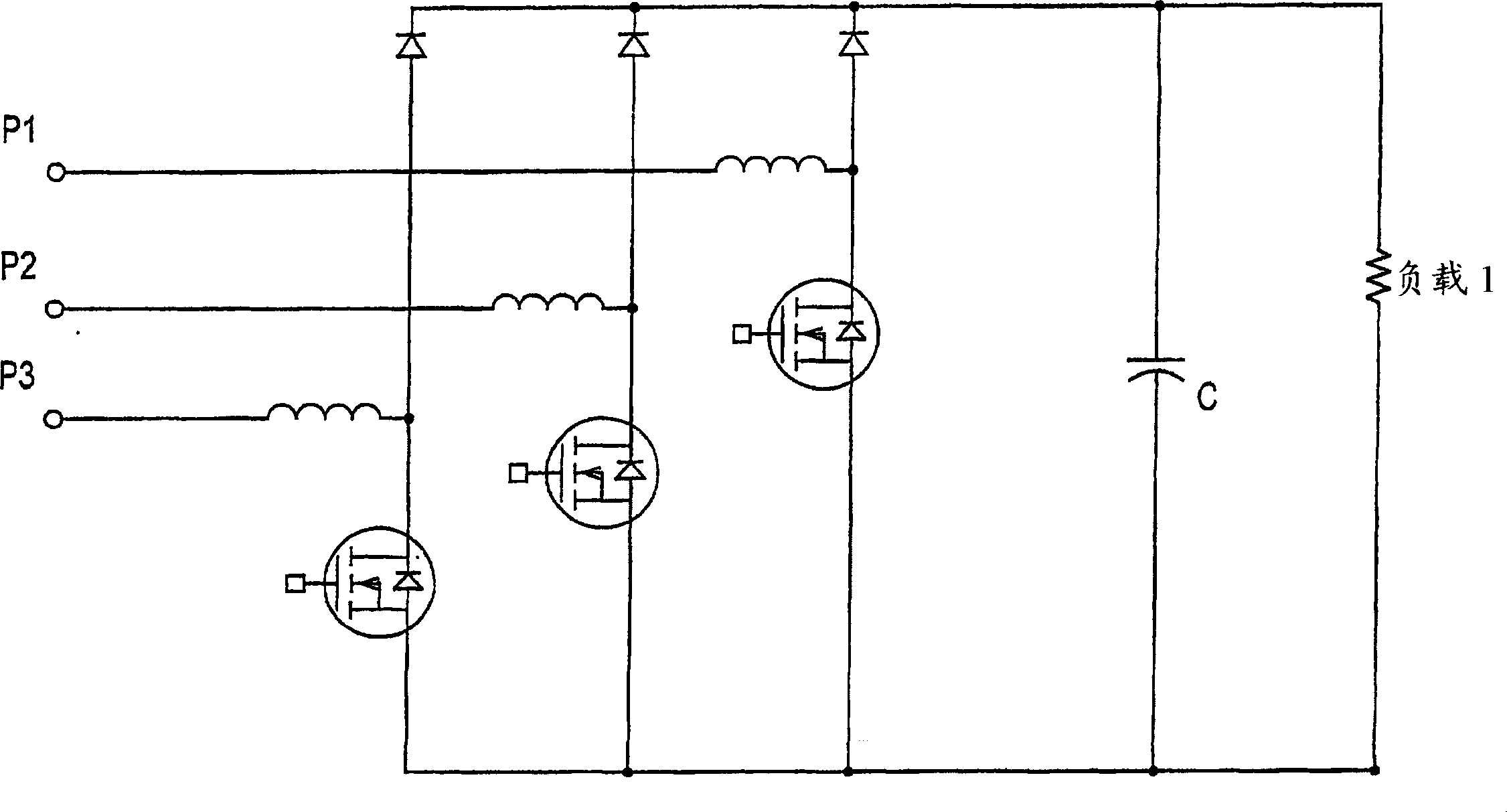

[0048] I. Recommended circuit

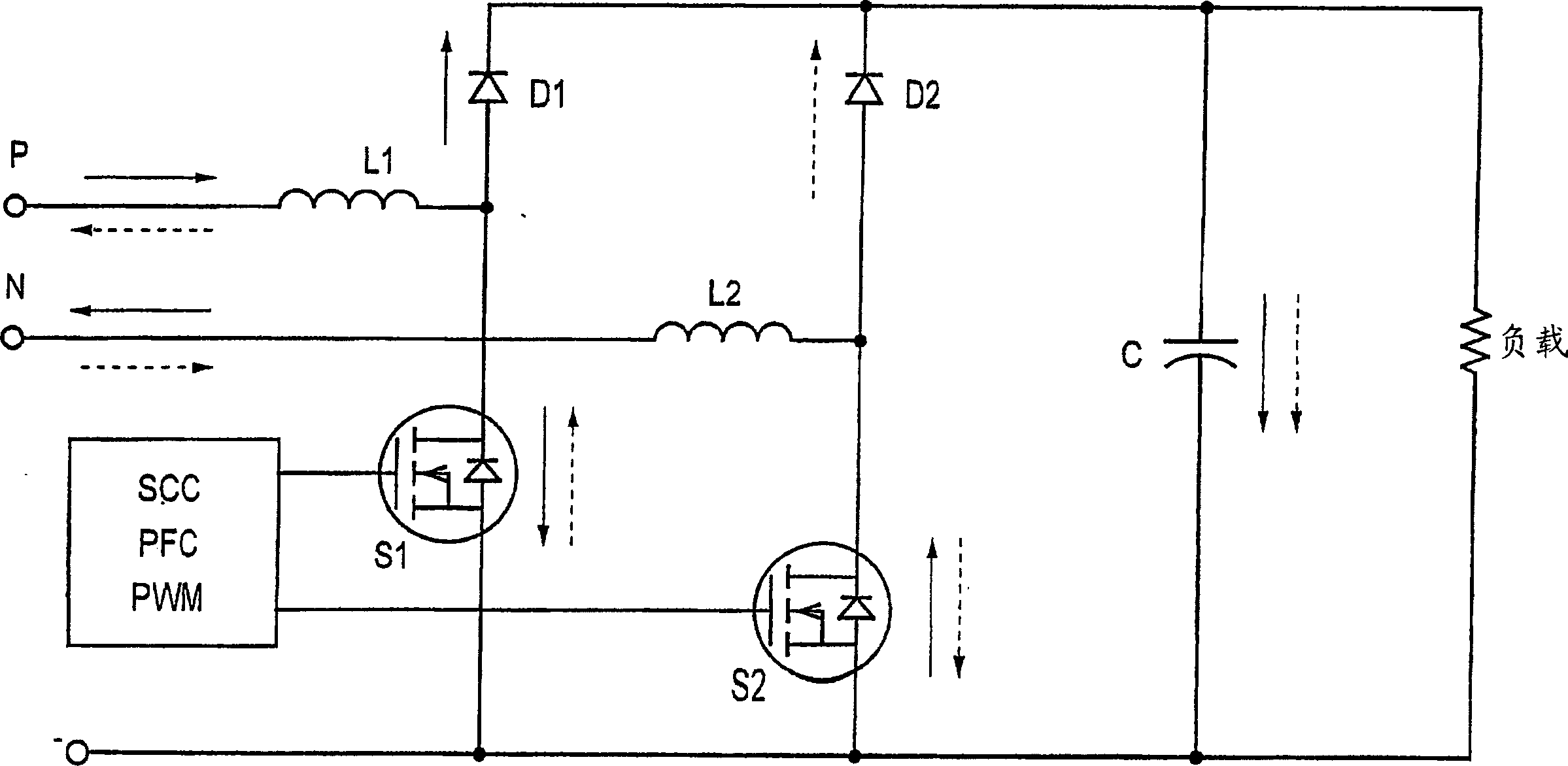

[0049] The proposed circuit does not use the input bridge at all, but replaces the function of the input bridge with two boost diodes and two boost switches. The two boost switches are controlled by a closed loop using One Cycle Control (OCC) a / k / a Single Cycle Control (SCC) techniques.

[0050] The boost inductor in the existing circuit is moved in front of where it performs the rectifier function, and it can be a single inductor, or it can be split into two inductors (as shown), one on each of the two input lines .

[0051] figure 2A simplified circuit diagram is shown in . The circuit consists of two boost inductors L1 and L2 working in parallel. There may be a common core (not shown). Only one inductor can be actively active (boosted) at a time. During the positive portion of the input sine wave (indicated by the solid arrow), the gate of MOSFET S1 is driven high and current flows through the boost inductor L1, thereby charging the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com