Diffraction optical element shaping Gaussian beam into one-dimensional flattened beam or rectangular flattened beam

A diffractive optical element, flat-top beam technology, applied in optical elements, diffraction gratings, optics, etc., can solve the problems of complex preparation process, and achieve the effects of high energy transmittance, flexible use, and simple installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

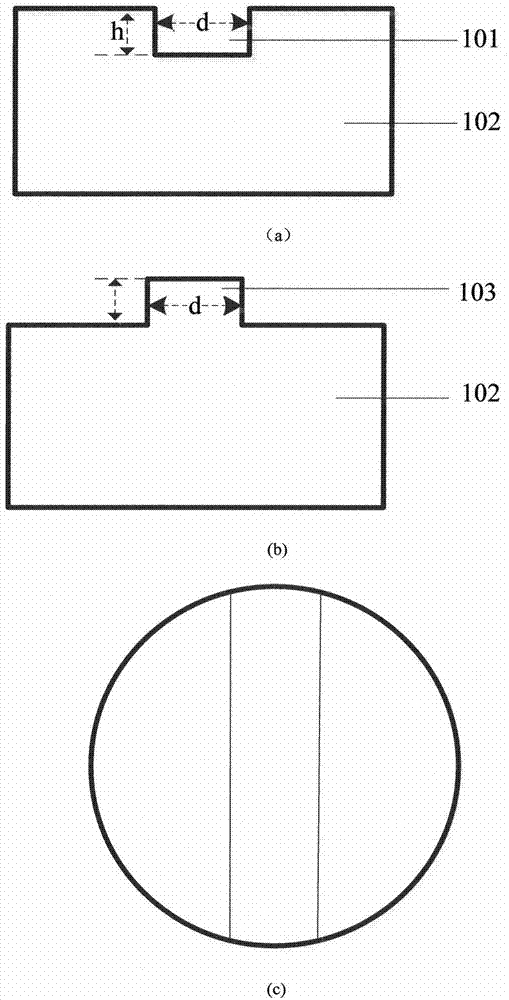

[0035] The DOE of the present invention should cooperate with other optical elements to obtain the final required one-dimensional flat-hat beam or rectangular flat-hat beam. Other optical components refer to: beam expander and collimator, which is used to expand and collimate the original incident beam, and the diameter of the beam waist after collimation should be larger than the size of the active area of the DOE. For example, for a square step or groove sample, the collimated beam waist diameter should completely cover the entire area of the square step or groove. For samples with circular steps or grooves, the diameter of the beam waist after collimation should be at least 2 mm larger than the diameter of the circular steps or grooves. The focusing lens is used to converge the DOE-shaped light spot and generate the final one-dimensional top-hat beam or rectangular top-hat beam.

[0036] Specific implementation methods include:

[0037] 1. According to the parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com