Sub wavelength metal construction lens with millimeter wave band high energy transmissivity

A millimeter-wave band, metal structure technology, applied in the direction of lenses, optics, instruments, etc., can solve the problems of low energy transmittance and diffraction efficiency, and achieve the effects of low cost, increased sampling density, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

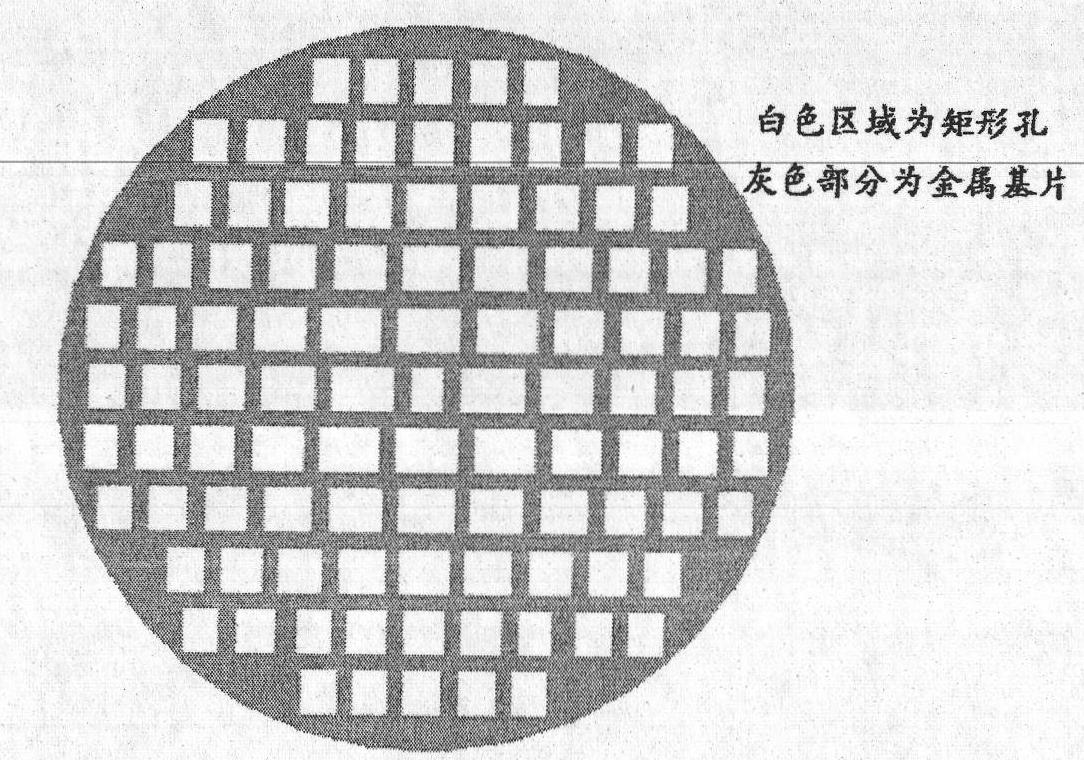

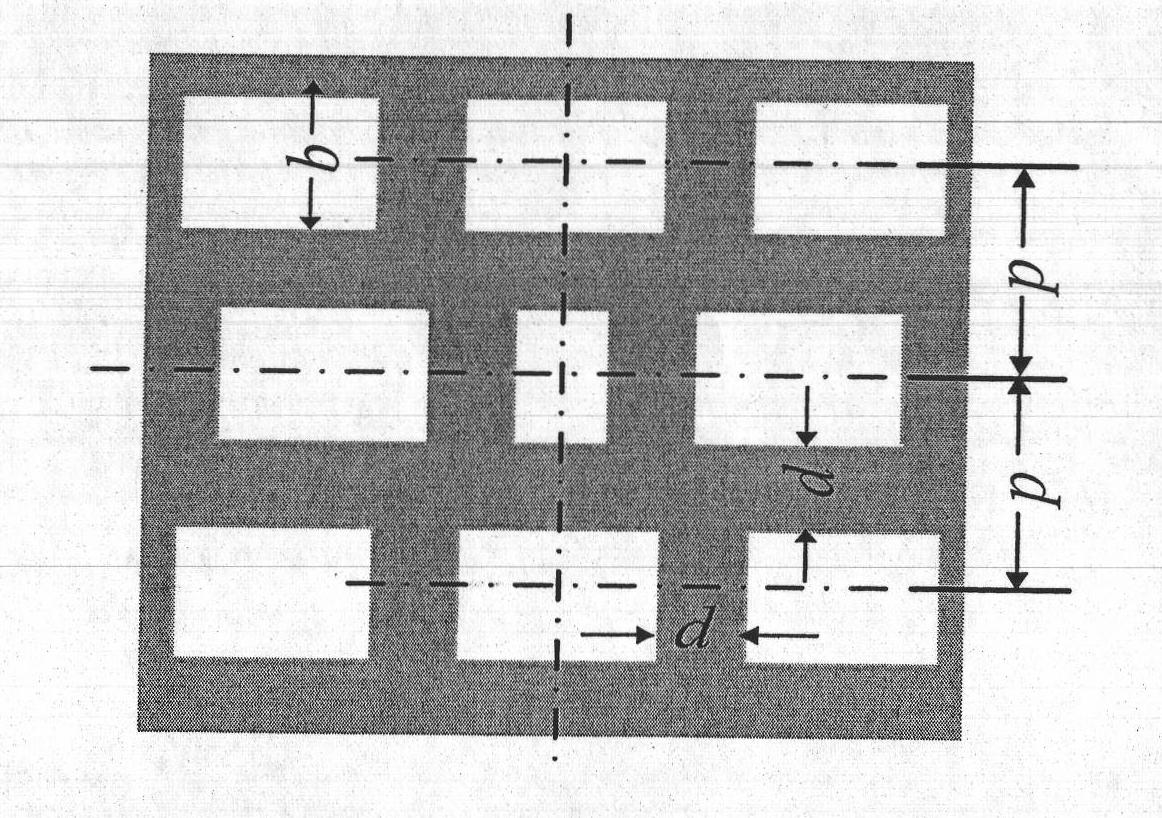

[0029] Embodiment 1, a manufacturing process of a structural lens applied to sub-wavelength metal pinholes in the millimeter wave band is as follows:

[0030] (1) The incident light wavelength is selected as =6mm, the metal material is aluminum, and the incident direction is perpendicular to the metal disc.

[0031] (2) Determine that the aperture of the lens is D=120mm, and the film thickness is 7mm, which is greater than

[0032] (3) Select the focal length of the lens as 100mm, and the phase at each point (x, y) on the surface of the component It can be calculated by the following formula:

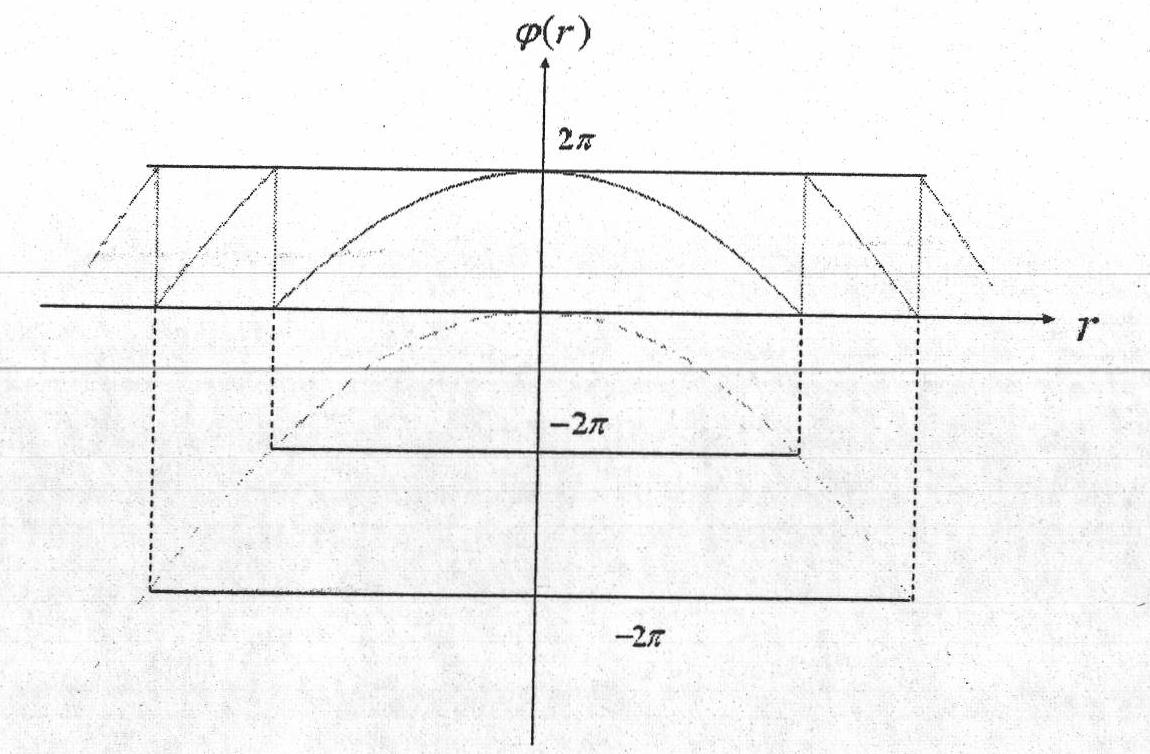

[0033] φ ( x , y ) = 2 mπ - 2 π λ ( x 2 + y 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com