Patents

Literature

55results about How to "High usage requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

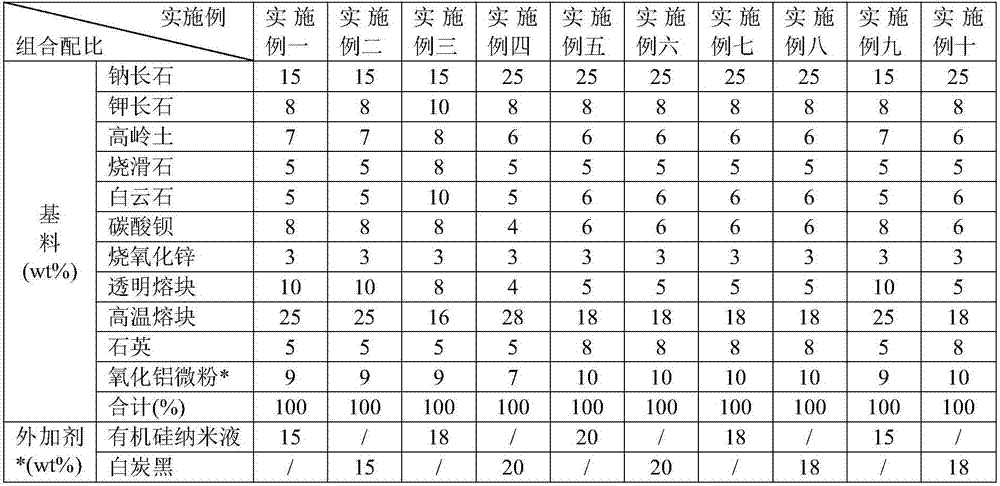

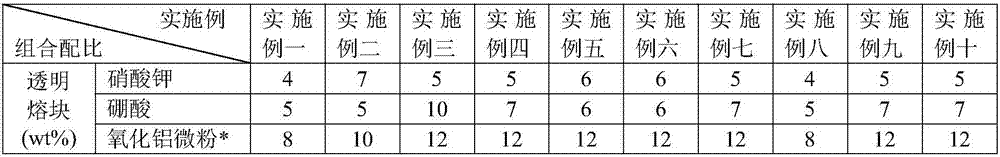

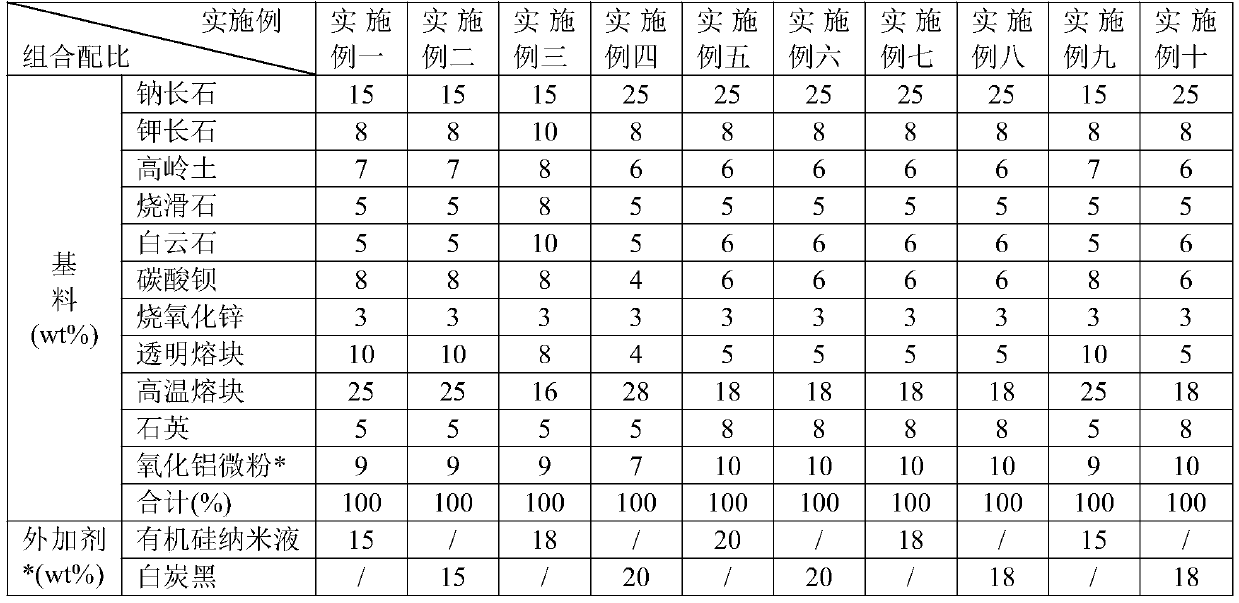

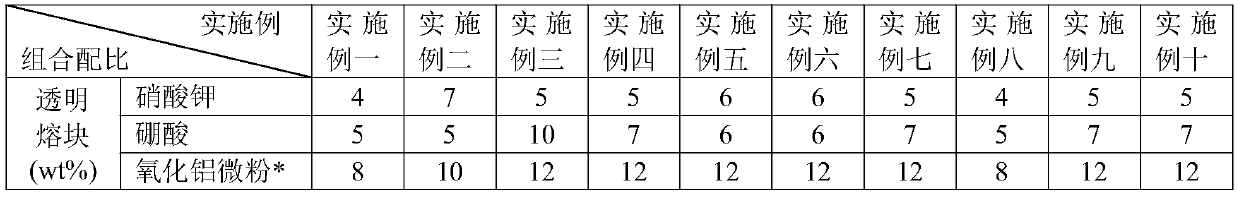

Low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and preparation method thereof

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

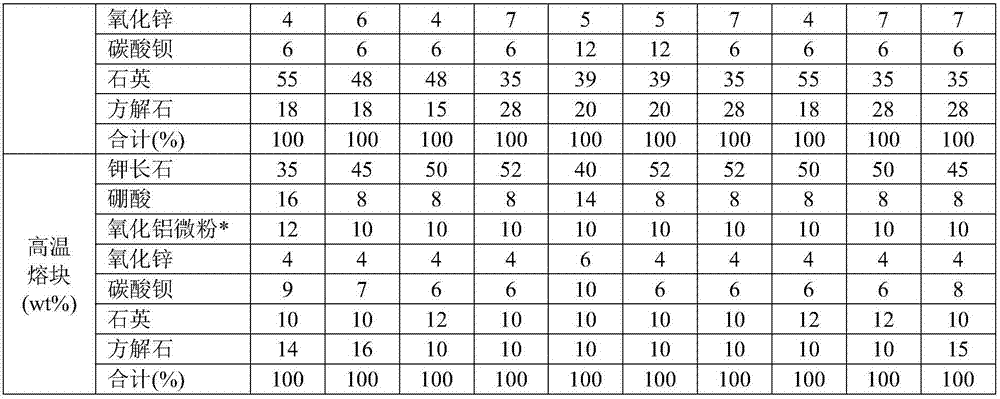

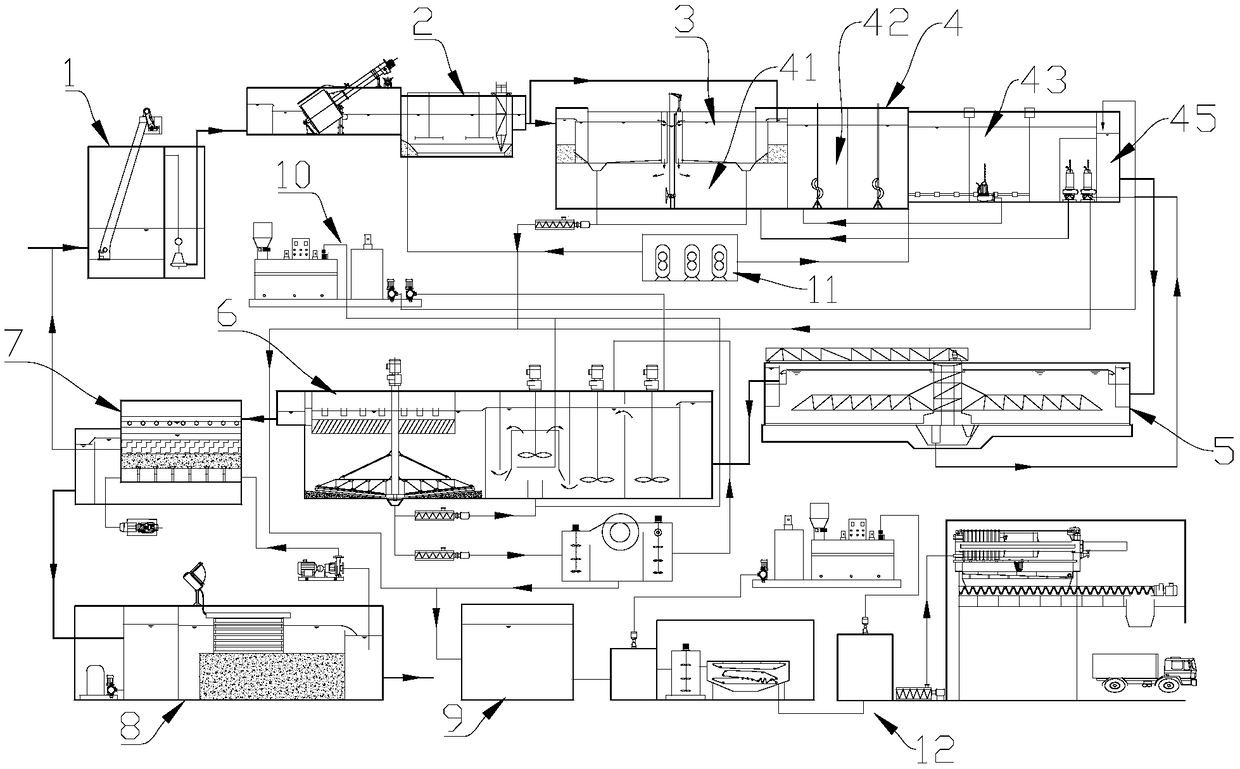

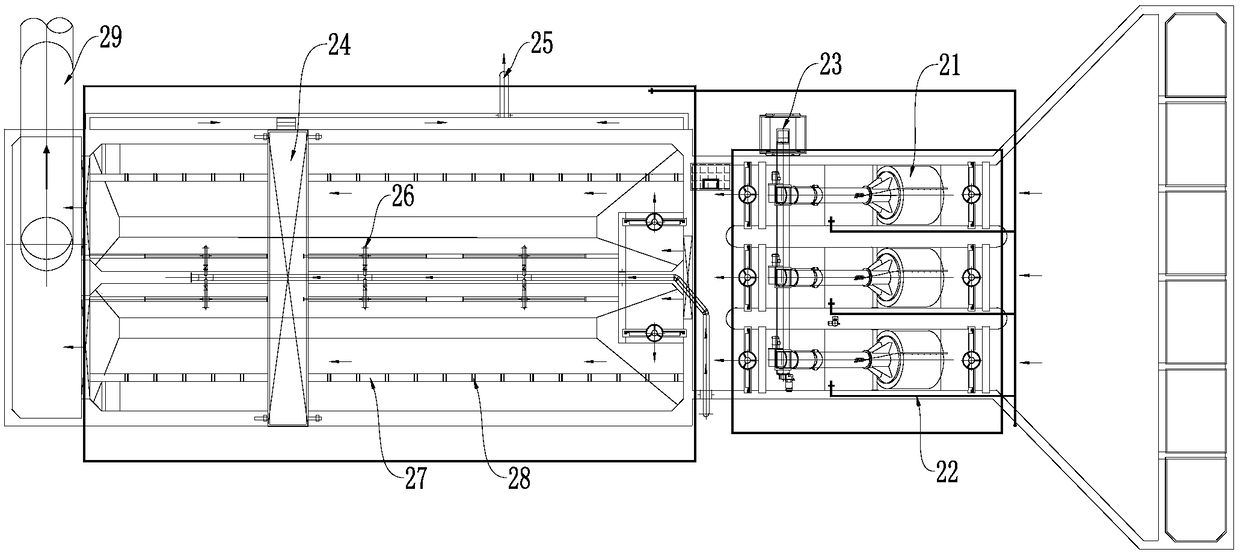

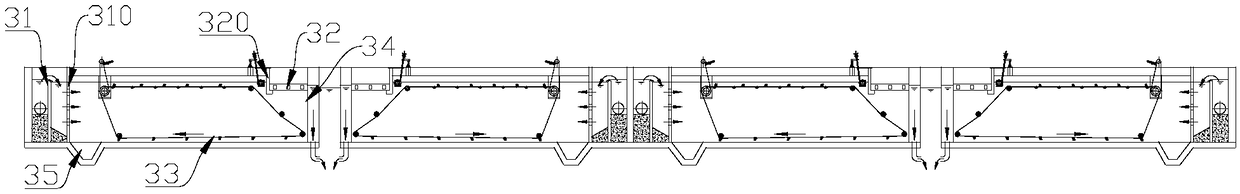

Urban sewage treatment technology for standard surface quasi IV-class water

PendingCN109264932AHigh environmental requirementsHigh usage requirementsWater/sewage treatment by irradiationSpecific water treatment objectivesFlocculationFiber

The invention relates to an urban sewage treatment technology for standard surface quasi IV-class water. A system is included and comprises a water inlet pump room, a grit basin, a primary sedimentation tank, an improved MBBR biochemical pool, a secondary sedimentation tank, an efficient sedimentation tank, a filter tank and a disinfecting tank; the water inlet pump room is provided with a coarsescreen, the grit basin is provided with a fine screen, the biochemical pool comprises an anaerobic pool, an anoxia pool and an aerobic pool, the primary sedimentation tank is arranged above the anoxiapool, the drainage end of the aerobic pool is connected to the secondary sedimentation tank, and the aerobic pool is provided with a nitration solution flow back pipe communicated with the anoxia pool; the efficient sedimentation tank comprises a concrete region, a magnetic powder mixing region, a flocculation region and a sedimentation region; the filter tank is provided with a fiber filter material for filtering purified sewage and a back flushing device for cleaning the fiber filter material; the disinfecting tank is provided with a disinfecting device. The system combines the secondary biochemical technology and the depth treatment technology, the units are elaborately and reasonably designed and combined, and the water outlet water quality in a sewage treatment plant and outflow water in the aspect of black and odorous river way sewage interception and source control can reach the surface quasi IV-class water standard.

Owner:SHENZHEN SHENSHUI WATER RESOURCES CONSULTING CO LTD

Preparations of bicomponent PSU type liquid rubber-based sealant and PSU liquid rubber thereof

InactiveCN101434826AGood comprehensive mechanical propertiesEasy to prepareOther chemical processesPolyureas/polyurethane adhesivesPrepolymerIsocyanate

The invention discloses a dual-component PSU-typed liquid rubber-based sealant and a preparation method of the PSU-typed liquid rubber, wherein, the sealant comprises a component A and a component B; the component A comprises PSU-typed liquid rubber, plasticizer, filling material, tackifier, antioxidant and vulcanization retarder; the component B comprises vulcanizing agent, vulcanization accelerator, plasticizer and filling material; and the component A and the component B are mixed together by normal method so as to prepare the finished product. The PSU-typed liquid rubber uses the mixture of polyether glycol and polyether-tribasic alcohol and polyisocyanate as raw materials to generate isocyanate-terminated polyurethane prepolymer under the action of acidic catalyst; furthermore, the isocyanate-terminated polyurethane prepolymer is terminated by sulfhydryl compounds to synthesize the sulfhydryl-terminated liquid rubber which takes the polyurethanes as main chain and has local crosslinking structure characteristic; the liquid rubber is taken as the basic rubber to prepare the sealant which has excellent mechanic performances and can be widely applied to the fields such as the construction of housing, plazas, roads, airports, bridges, hydraulic engineering, water conveyance project, sewage disposal engineering, and the like, the manufacture of automobiles, trains, containers, and the like, and the electric apparatuses, power, aeronautics and astronautics, and the like.

Owner:HENAN YONGLI CHEM

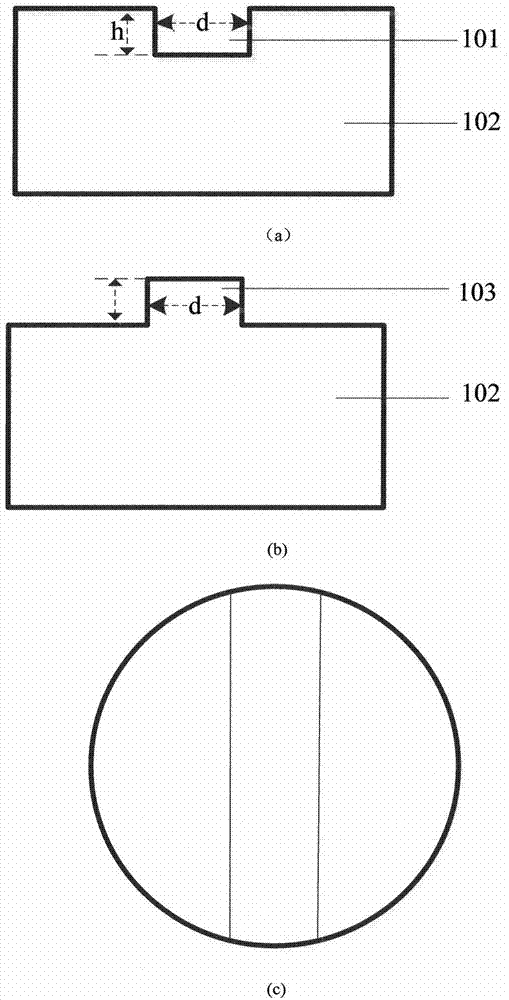

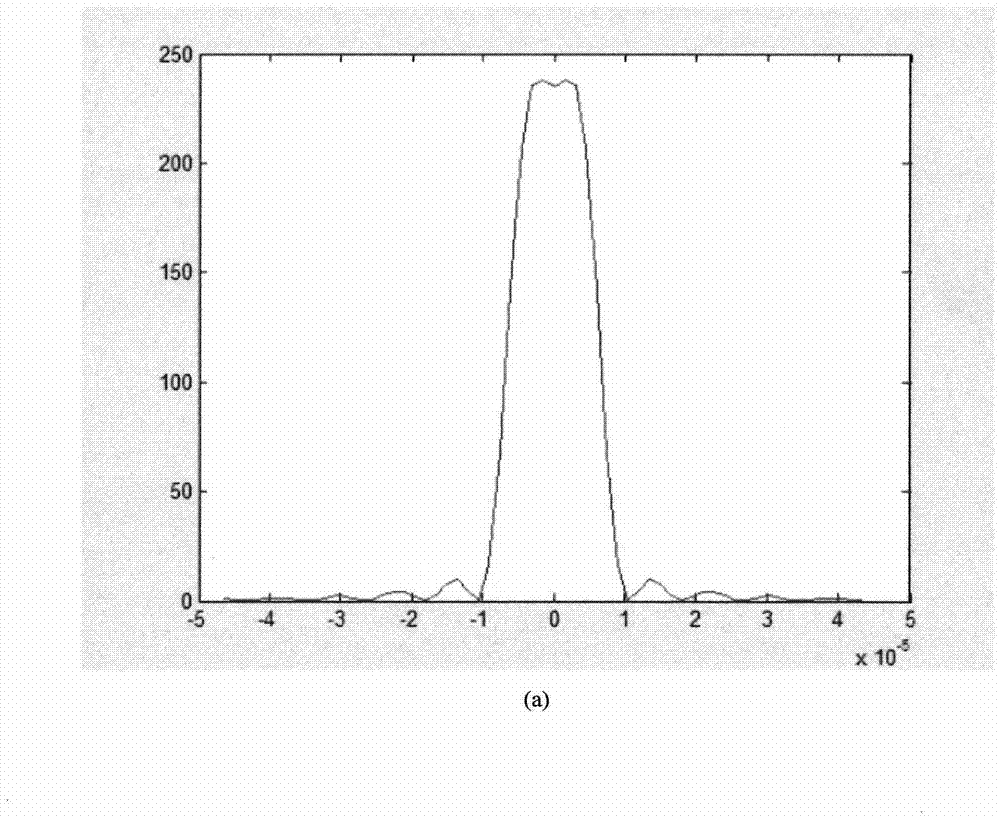

Diffraction optical element shaping Gaussian beam into one-dimensional flattened beam or rectangular flattened beam

InactiveCN104765087AImprove energy transmittanceReduce quality impactDiffraction gratingsPhotomechanical exposure apparatusGaussian beamTransmittance

The invention provides a diffraction optical element shaping Gaussian beam into a one-dimensional flattened beam or a rectangular flattened beam. The diffraction optical element is called DOE for short. A manufacturing method of the DOE is also provided. Grooves or steps which are in different shapes and have different sizes are manufactured at the center of a quartz substrate, the DOE is arranged at different positions in a light path, the DOE is matched with a beam expanding collimating mirror and a focusing lens, and then the one-dimensional flattened beam or the rectangular flattened beam is formed. The DOE has the following prominent advantages of being high in energy transmittance rate, insensitive to the change of a lasing mode and easy and flexible to install and use.

Owner:北京润和微光科技有限公司

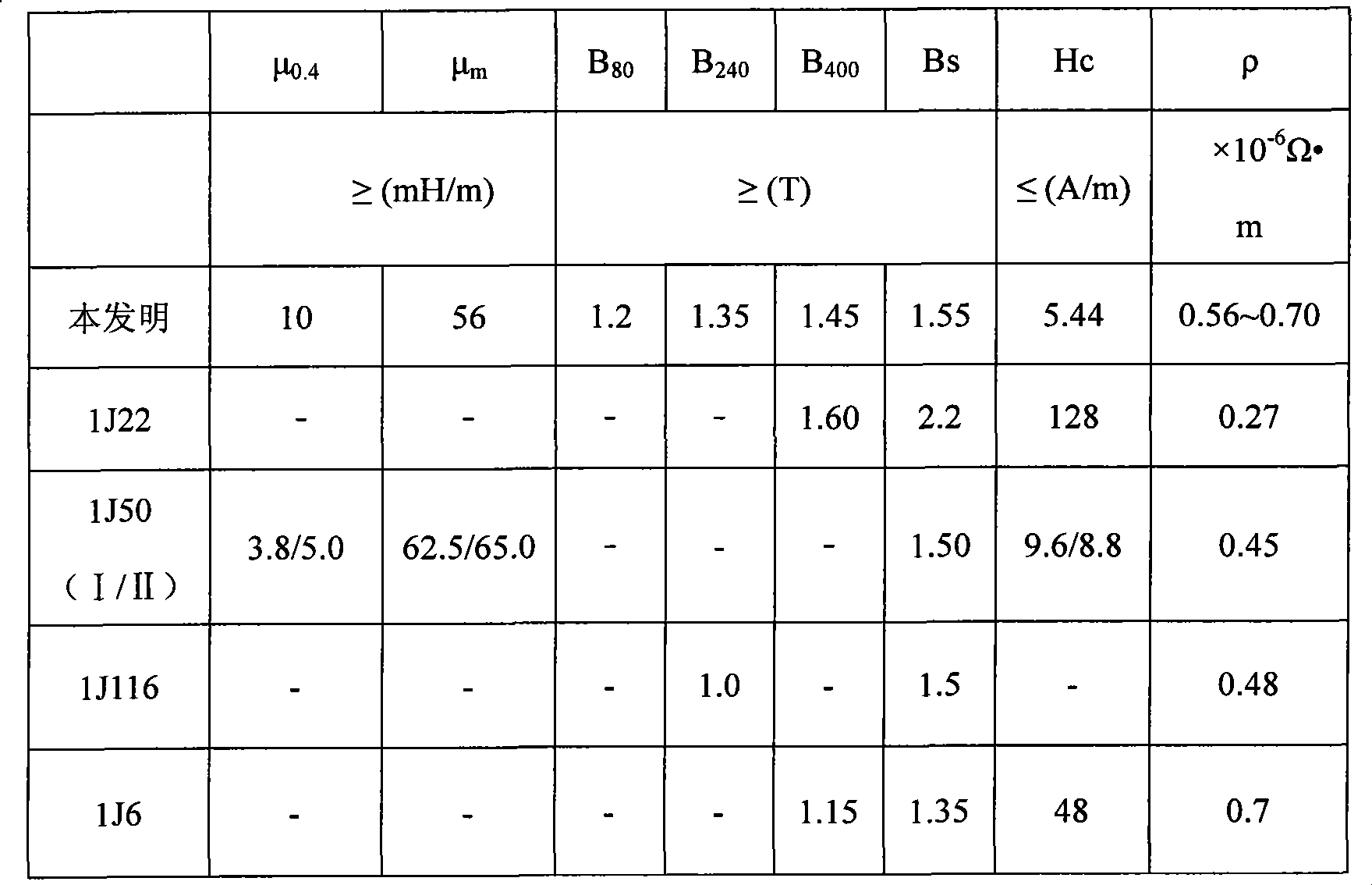

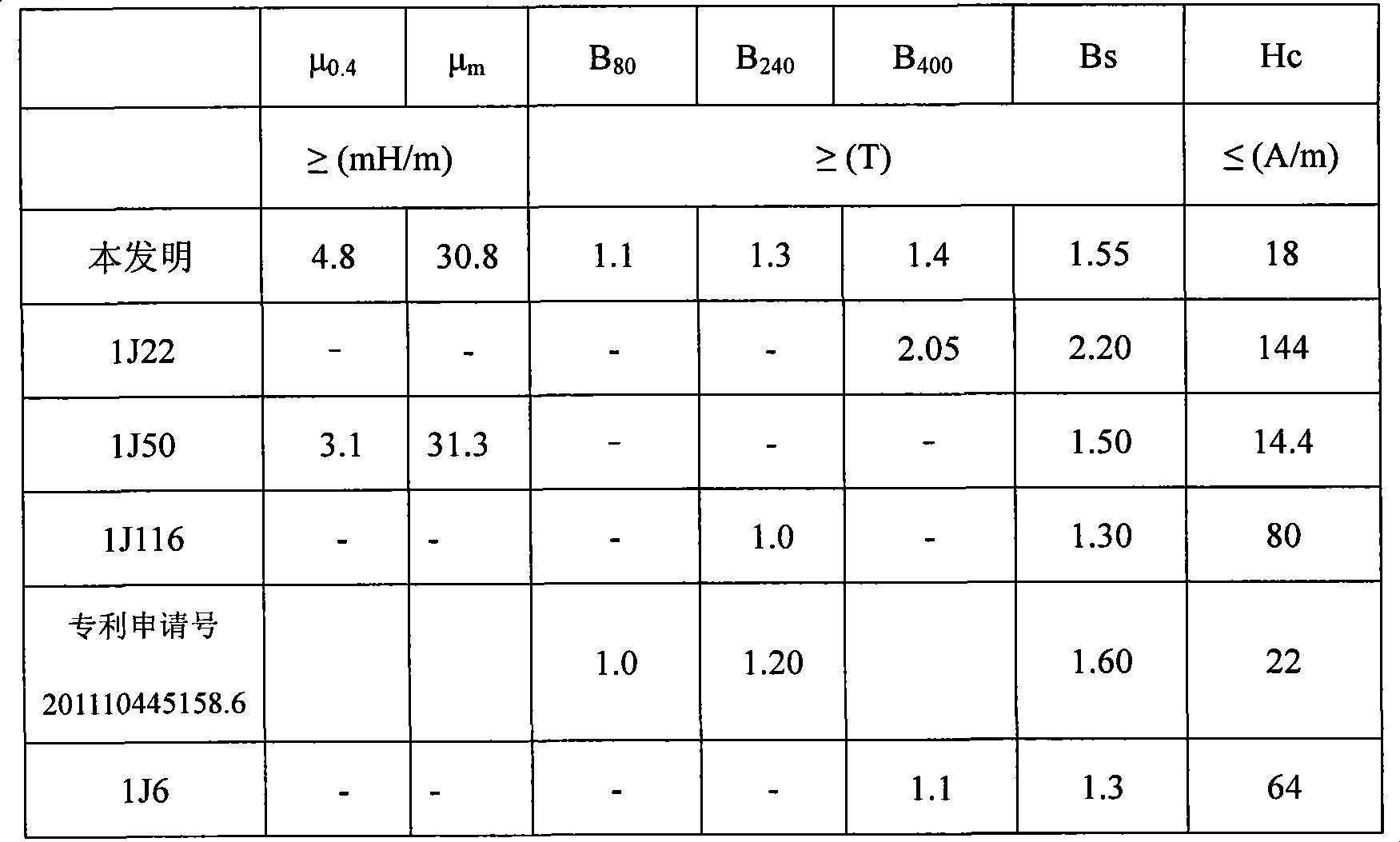

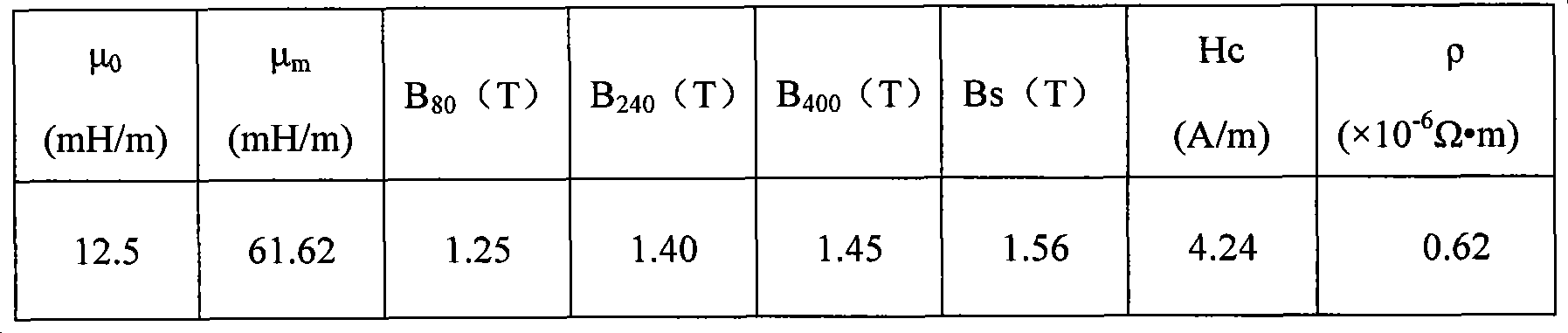

Anti-corrosion FeNiCo magnetically soft alloy with high magnetic induction intensity

The invention includes a FeNiCo magnetically soft alloy and a production method thereof, wherein the FeNiCo magnetically soft alloy has high magnetic induction intensity, high magnetic permeability, low coercive force, high stability and good corrosion resistance in a low magnetic field. The FeNiCo magnetically soft alloy comprises the following components by mass percent: not more than 0.02 percent of C, 0.2-0.80 percent of Si, not more than 0.50 percent of Mn, 29.00-35.00 percent of Ni, 25.00-32.00 percent of Co, not more than 5.00 percent of Mo, not more than 0.50 percent of Cu, 0.01-0.55 percent of microelements including 0.001-0.05 percent of rare earth elements, and the balance of Fe and inevitable impurities. The FeNiCo magnetically soft alloy is processed and manufactured by adopting the methods of vacuum melting, forging, hot rolling and cold rolling, and after heat treatment, the FeNiCo magnetically soft alloy has the characteristics of high magnetic induction intensity, high magnetic permeability, low coercive force, high stability and good corrosion resistance in a low magnetic field, and can be manufactured into the transducer, the filter, the electromagnetic valve, the transformer and the like in the field of aviation, aerospace, navigation, electron, electric power and the like.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Two-component colorful flexible polysulfide ammonia ester sealant and preparation method thereof

InactiveCN105111996AColor stableNot easy to yellowNon-macromolecular adhesive additivesOther chemical processesPolymer scienceVulcanization

The invention discloses a two-component colorful flexible polysulfide ammonia ester sealant and a preparation method thereof. The sealant consists of a component A and a component B; expressed by weight part, the component A is prepared from 15 to 60 parts of PSU type liquid rubber, 10 to 30 parts of a plasticizer, 10 to 60 parts of a filler, 0.1 to 5 parts of a tackifier, 0.1 to 5 parts of an antiager and 0.1 to 5 parts of a premature vulcanization retarder; the component B is prepared from 10 to 40 parts of a vulcanizing agent, 0.1 to 5 parts of a vulcanization accelerator, 10 to 50 parts of a plasticizer, 1 to 20 parts of a colorant and 10 to 50 parts of a filler; the mass ratio of the component A to the component B is 5 to (15 to 1). The component A and the component B are respectively ground to be pasty and then are mixed uniformly, thus obtaining a product. The product is stable in storage, excellent in physical and mechanical properties, and easy to blend into multiple colors, and the defect of color singleness of an existing flexible sealant is overcome.

Owner:HENAN YONGLI CHEM

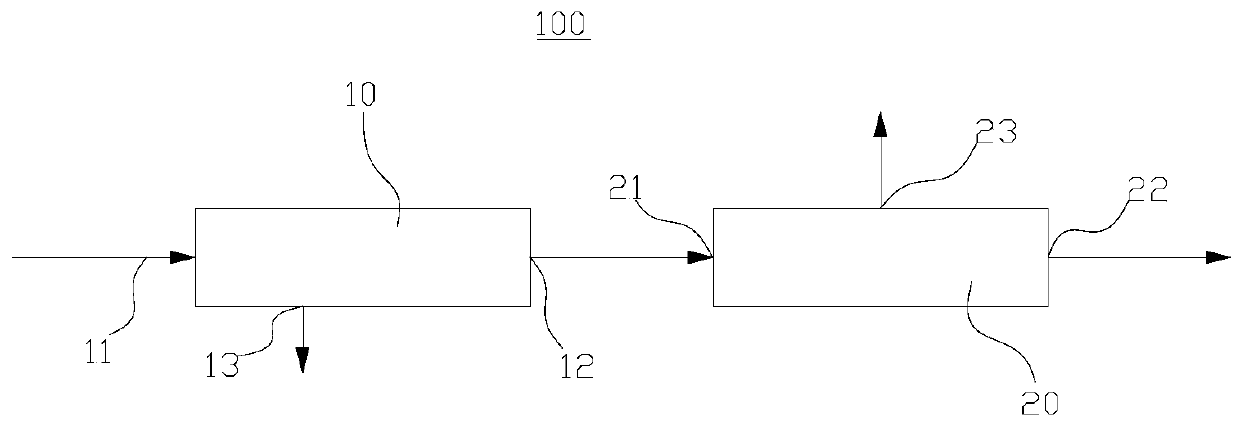

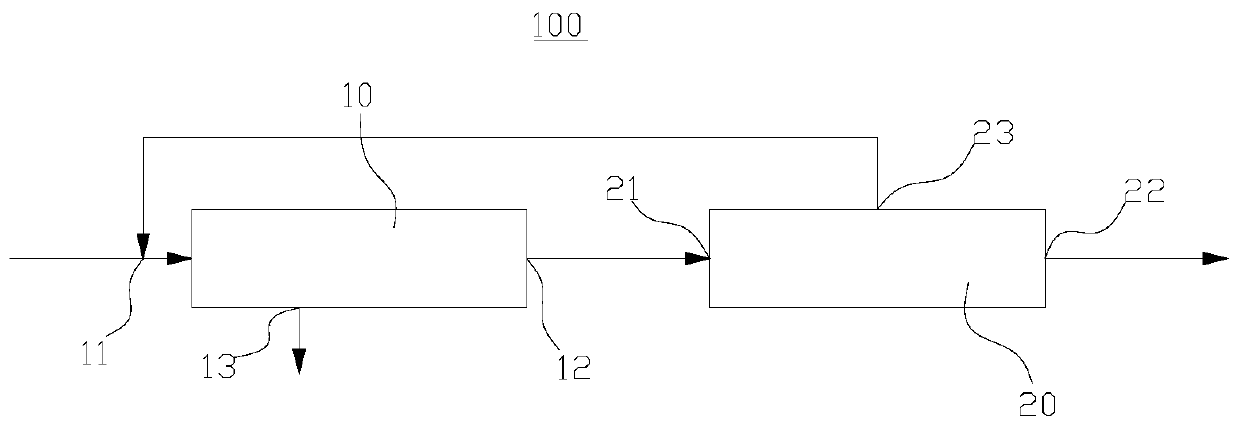

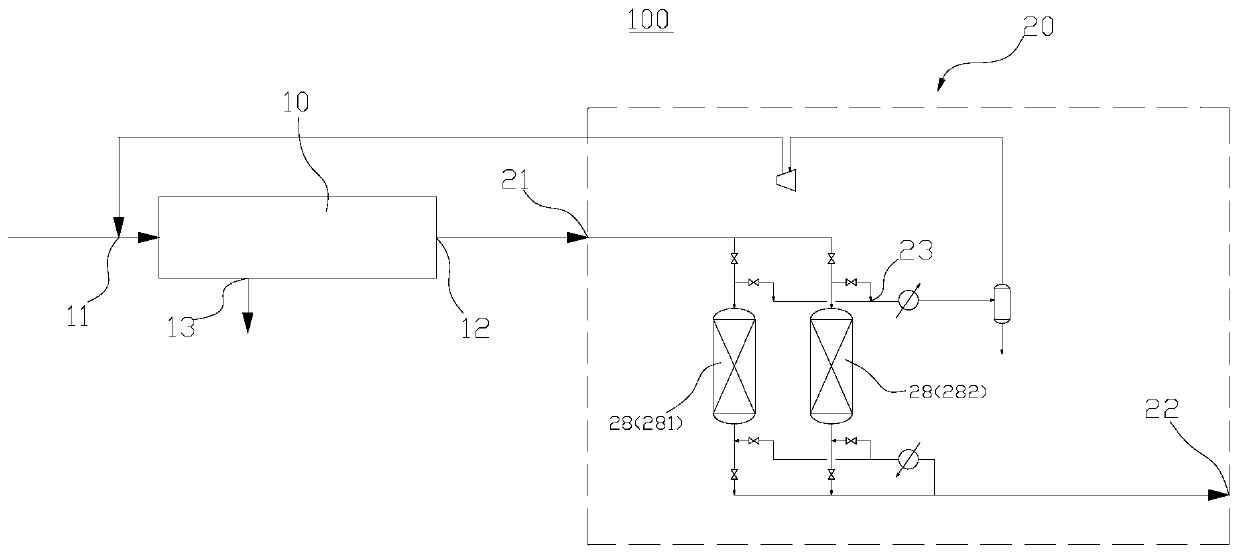

Natural gas desulfurization system and method

The invention provides a natural gas desulfurization system and method, and belongs to the technical field of desulfurization. The natural gas desulfurization system comprises an MDEA deacidificationunit and a TSA desulfurization unit. The MDEA deacidification unit has a delivery inlet and a delivery outlet, and is configured to perform coarse desulfurization treatment on raw natural gas enteringvia the delivery inlet so as to obtain a crude desulfurized natural gas. The TSA desulfurization unit has a first inlet, a first outlet and a second outlet; the delivery outlet is communicated with the first inlet, and the crude desulfurized natural gas can enter the first inlet via the delivery outlet. The TSA desulfurization unit is configured to perform fine desulfurization treatment on the crude desulfurized natural gas to obtain a fine desulfurized natural gas to be discharged via the first outlet and a first regenerated gas to be discharged via the second outlet. The first regenerated gas is capable of removing sulfides adsorbed on the TSA desulfurization unit via the second outlet. The fine desulfurized natural gas treated by the MDEA deacidification unit and the TSA desulfurization unit can meet higher use requirements.

Owner:CHENGDU SEPMEM SCI & TECH

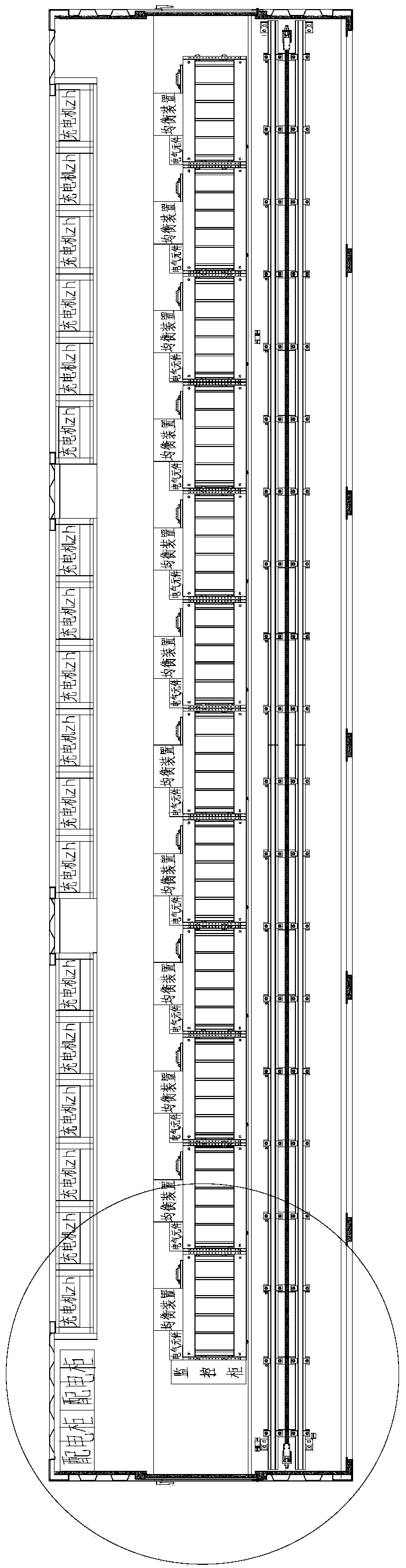

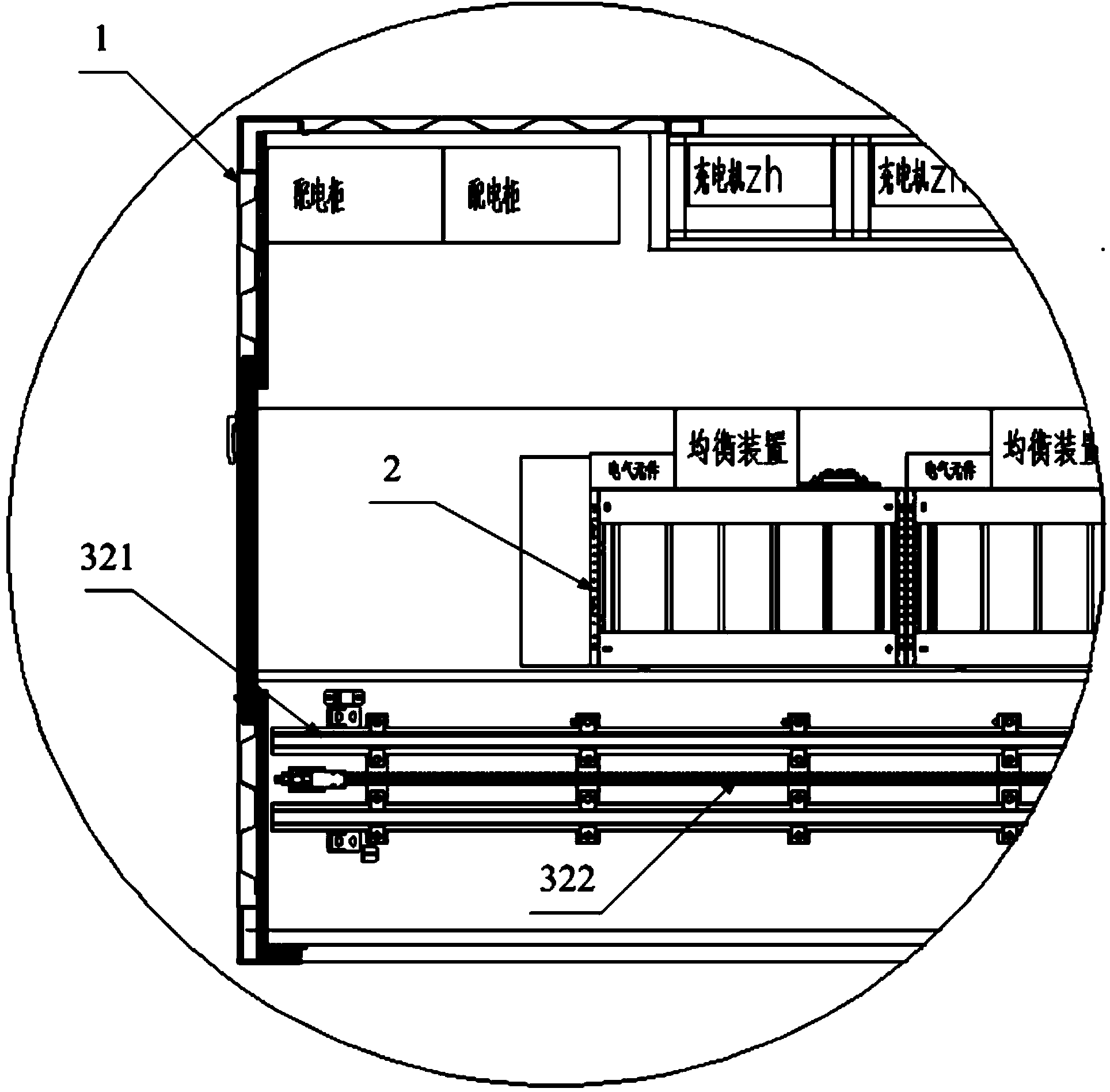

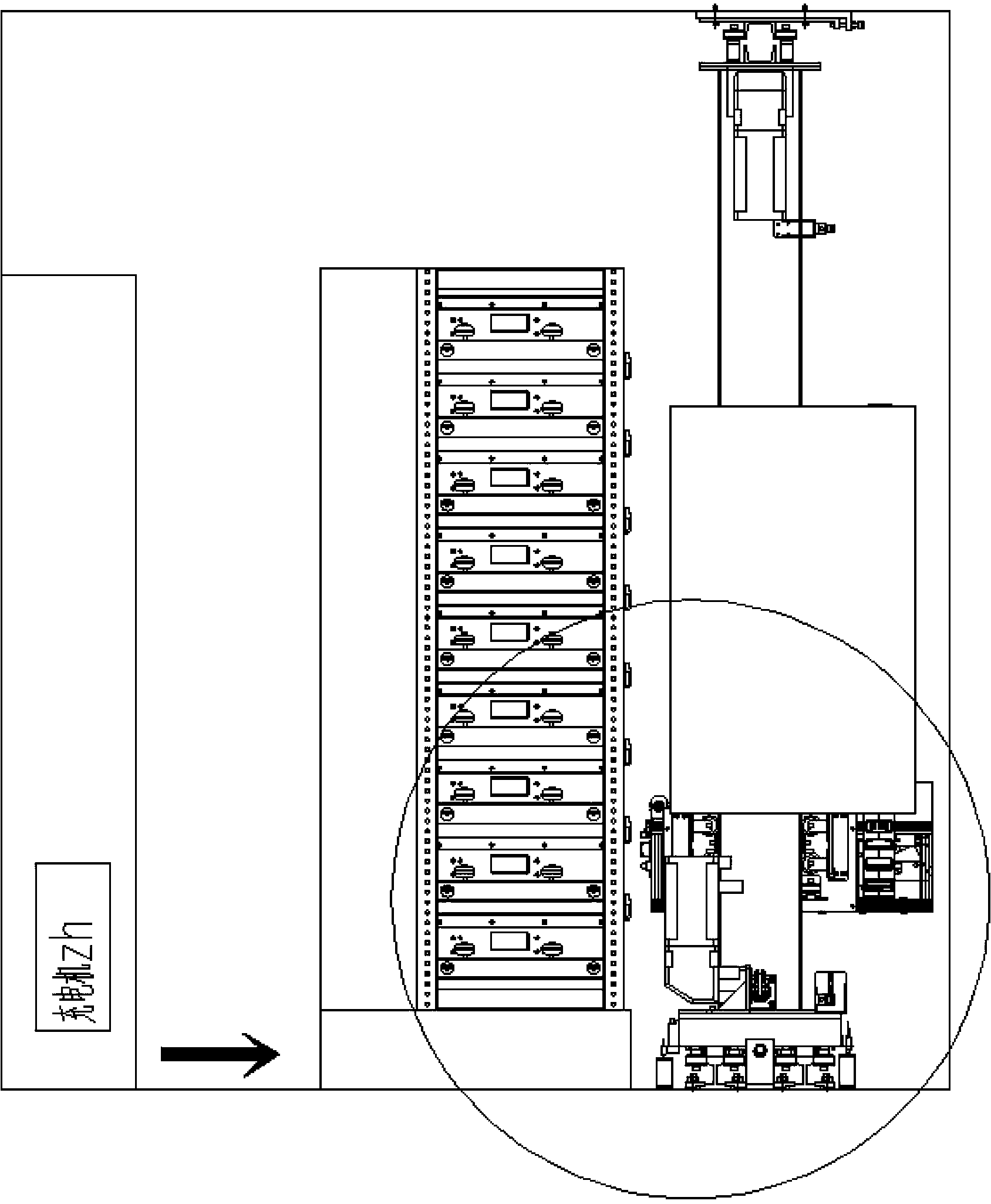

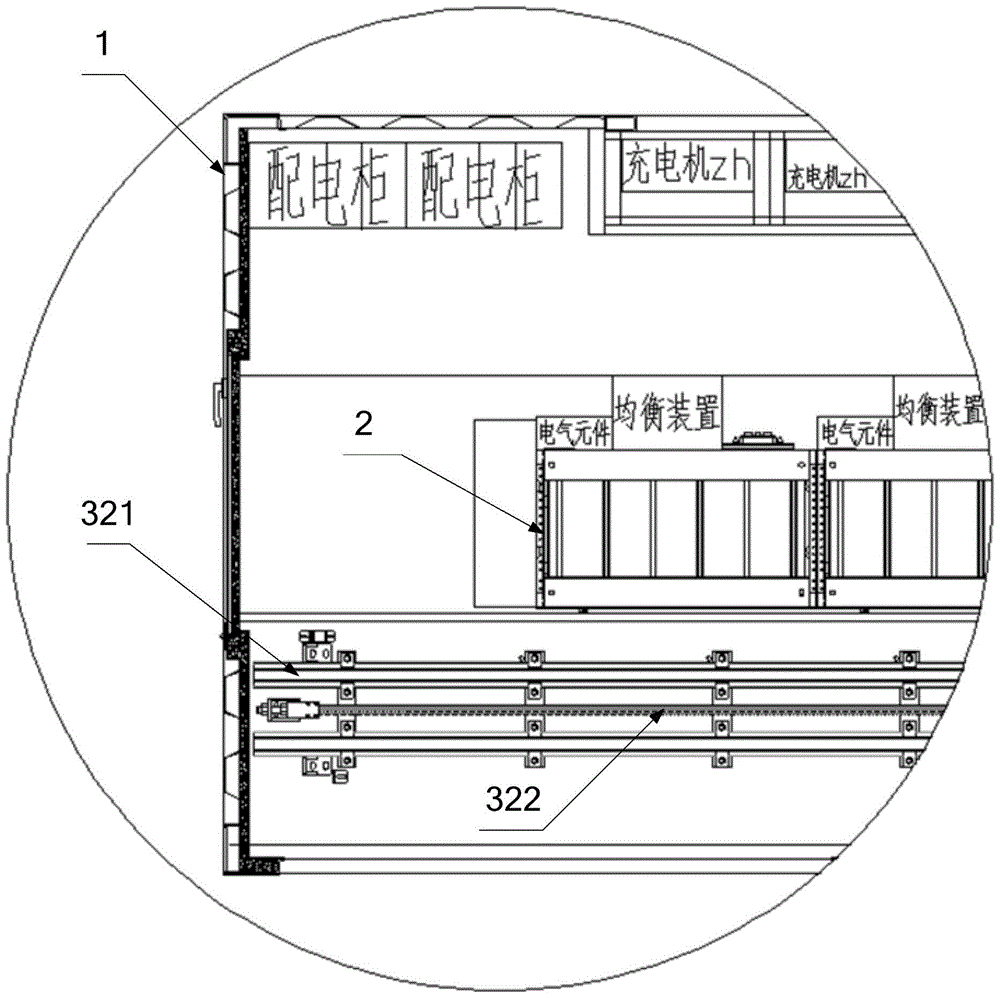

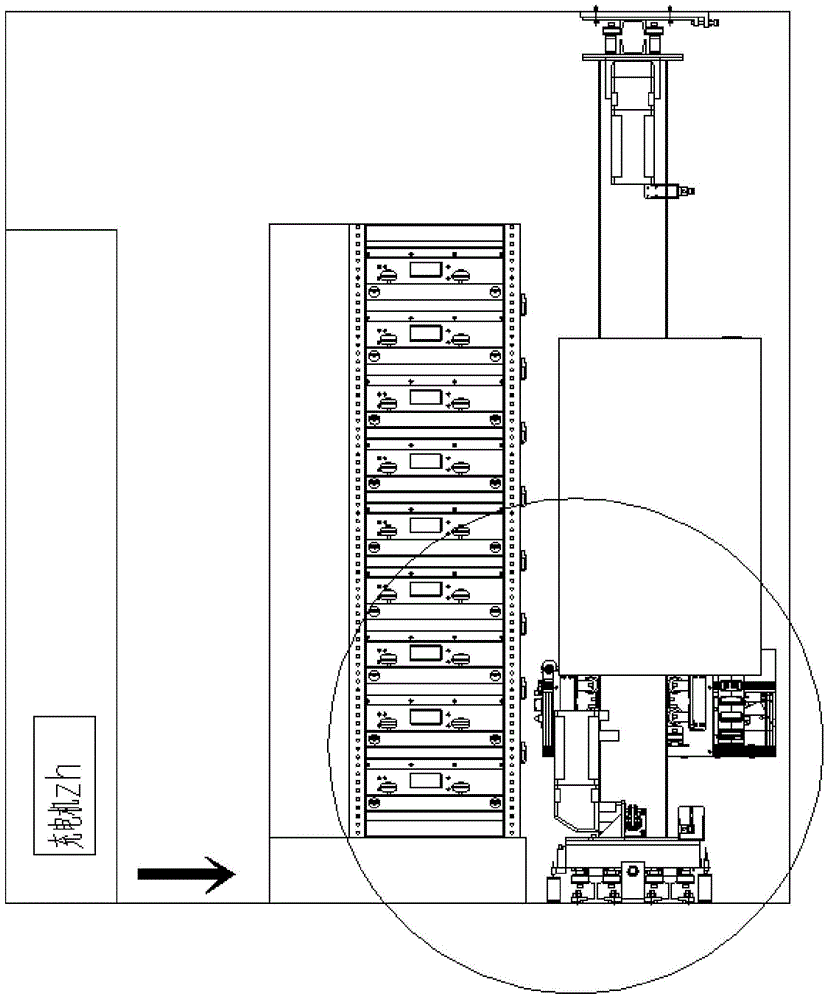

Intensive accumulator charging and replacing station for electric vehicles

ActiveCN104340185ALow infrastructure requirementsReduce usageVehicle servicing/repairingElectrical batteryAutomotive battery

The invention discloses an intensive accumulator charging and replacing station for electric vehicles. By modifying containers, a charging device and an accumulator can be implanted in the station, and spatial utilization rate is increased; meanwhile, referring to the present mode of a mobile charging bin and an accumulator transfer box, an accumulator support and a charging support are integrally mounted, mounting is convenient and reliable, and project construction period is saved; an automatic taking and placing device is additionally mounted and communicated with the accumulator, whether the accumulator is fully charged or not can be automatically identified and recognized and the accumulator can be placed into an accumulator storage area without an electric forklift, and the accumulator of the electric vehicles can be conveniently replaced. Further, a safety protection system is added, a safety guardrail, a safety light curtain and a safety switch can be operated within the range to keep surrounding people safe by the aid of the automatic taking and placing device; the system information can be processed by a PLC (programmable logic controller), and docking of the man-machine exchange control information can be realized via a touch display screen.

Owner:STATE GRID CORP OF CHINA +2

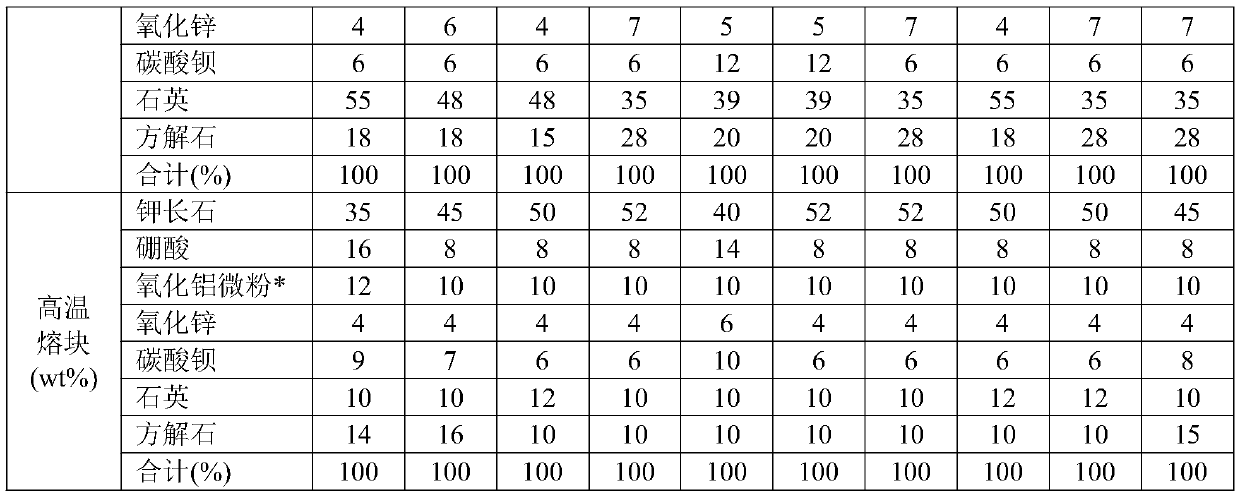

A low-temperature, high-hardness, high-wear-resistant full-polish glaze and its preparation method

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC UNIV

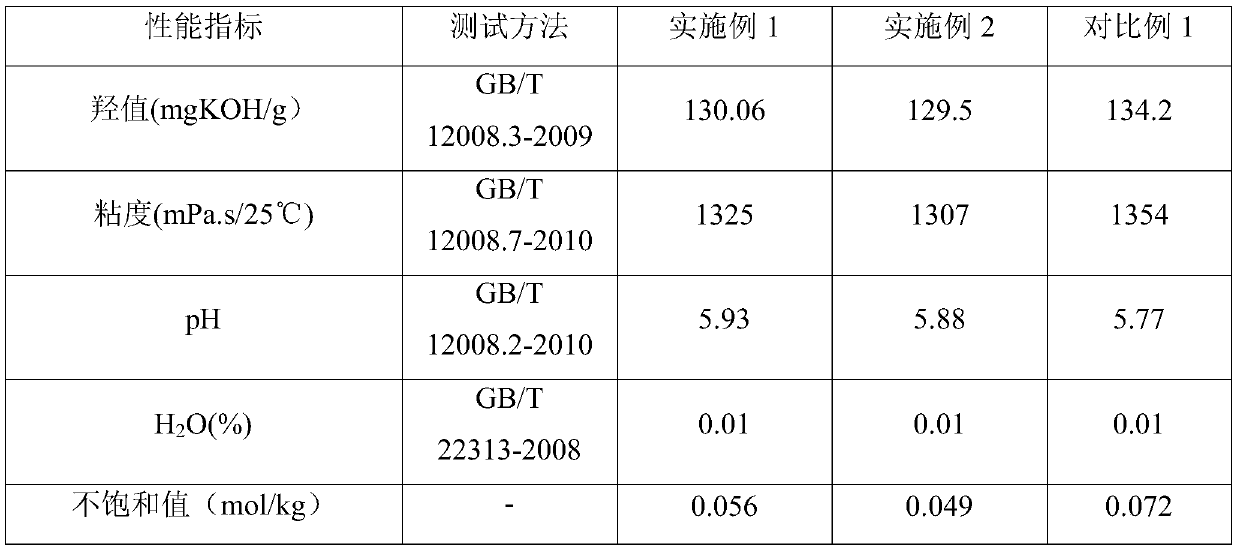

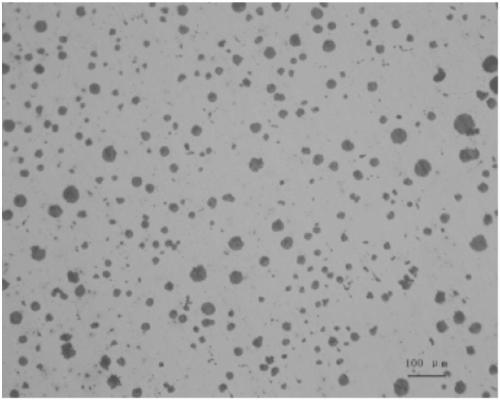

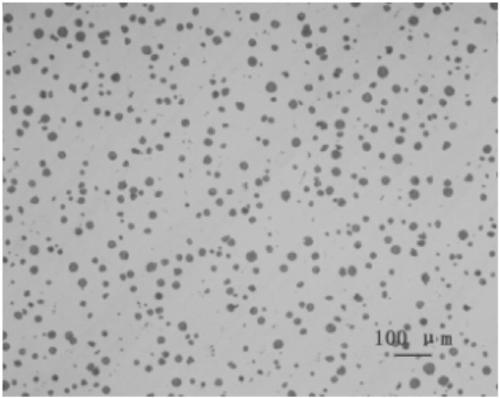

Preparation method of high-functionality polyether polyol

The invention belongs to the technical field of polyether polyol synthesis, and particularly relates to a preparation method of high-functionality polyether polyol, wherein the preparation method comprises the following steps: (1) by using a high-functionality initiator or a mixed initiator containing the high-functionality initiator as an initiator, adding alkylene oxide under the action of a catalyst, and carrying out a polymerization reaction to obtain oligomer polyether polyol; and (2) adding an initiator which is the same as the initiator in the step (1), a catalyst and alkylene oxide into the oligomer polyether polyol obtained in the step (1), and carrying out a polymerization reaction to obtain the high-functionality polyether polyol. According to the invention, a step-by-step secondary feeding mode is adopted, the high-viscosity initiator system is diluted to a certain extent, the olefin oxide addition reaction is easier to start, the problems of long initiation time and non-uniform polymerization are solved, the unsaturated value index of a polyether polyol product is lower, the actual hydroxyl value of the product is closer to the theoretical hydroxyl value, and the product can meet higher use requirements.

Owner:SHANDONG BLUSR DONGDA CHEM

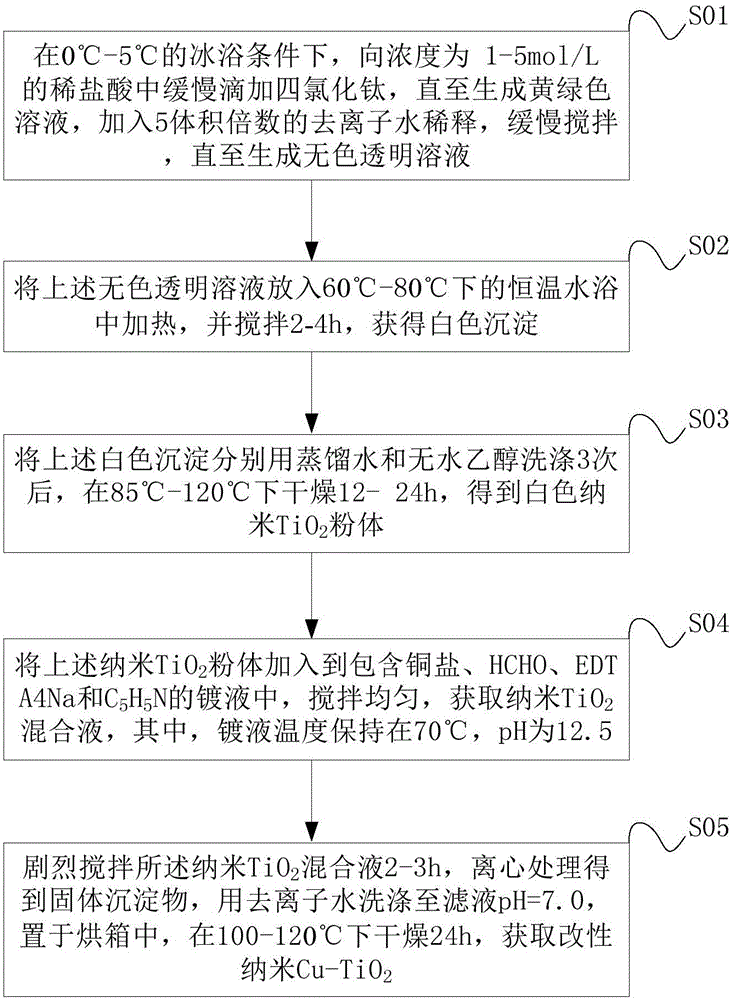

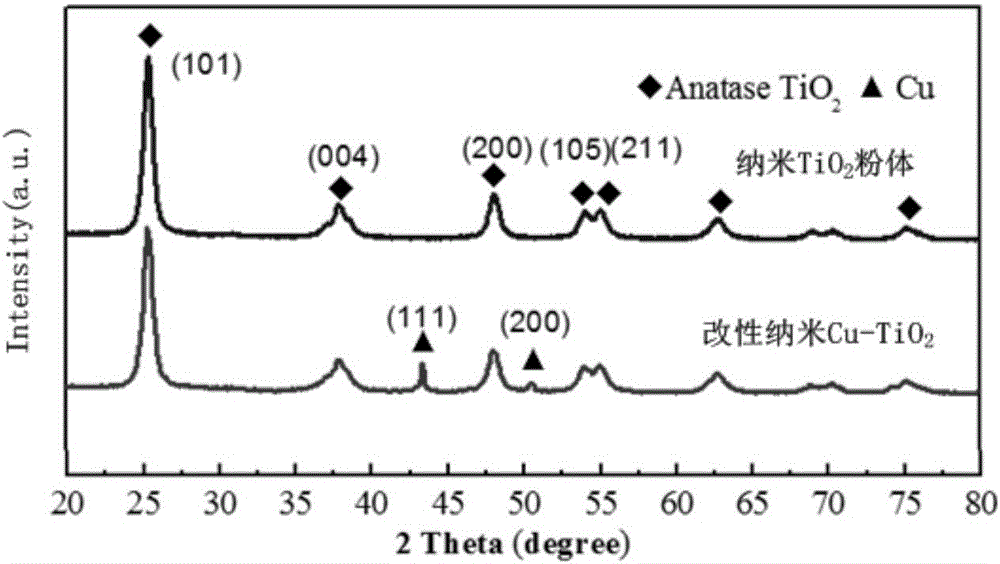

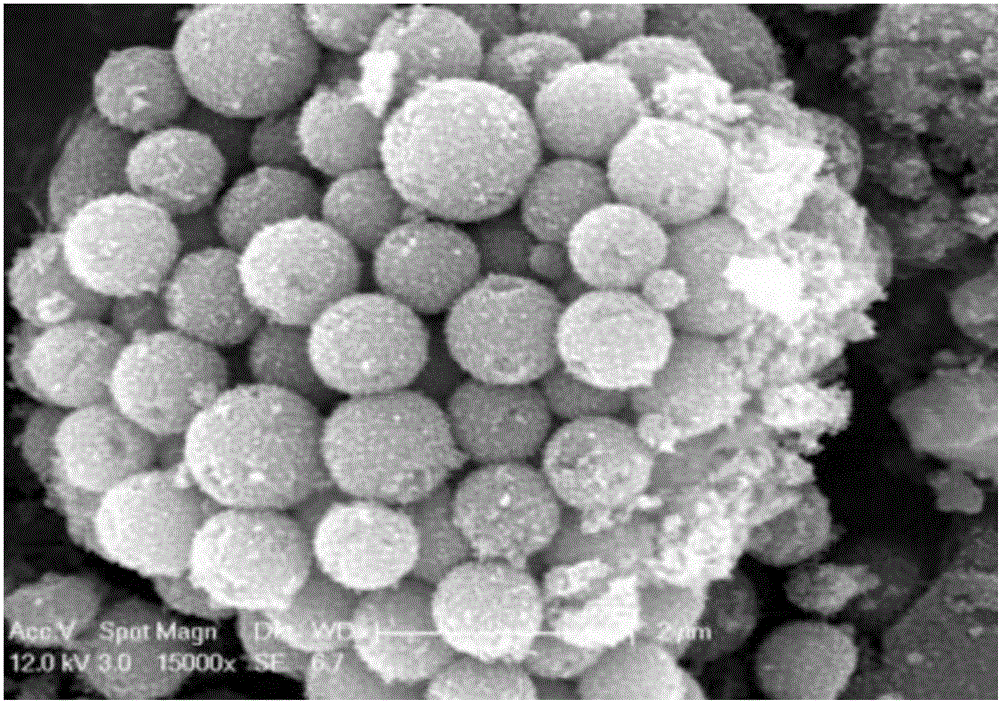

Lubricating type anti-rust oil special for bearing bush

The invention provides lubricating type anti-rust oil special for a bearing bush.The lubricating type anti-rust oil comprises lubricating oil base oil, p-hydroxybenzoic aldehyde, tung oil, diazolidinyl urea, allyl polyethylene glycol 2-3, polyethylene glycol, dithio-borate, salicylate, an anticorrosion additive and a coalescing agent, wherein the lubricating oil base oil contains spherical modified nanometer Cu-TiO2.The lubricating oil base oil contains the spherical modified nanometer Cu-TiO2 component, and copper nanoparticles are loaded on the surface of spherical nanometer TiO2 powder, so that a damaged part is effectively filled, and in-situ remediation is achieved on the damaged surface.Meanwhile, the spherical modified nanometer Cu-TiO2 component enables the nanoparticles between friction antithesis faces to be flattened under heavy loads and high temperature to form a sliding system, and therefore friction and abrasion are lowered more easily.It can be seen that the lubricating type anti-rust oil special for the bearing bush has the good anti-rust effect, and the stable and good lubricating effect can also meet the high using requirement for the bearing bush.

Owner:湖南省卓尔轴瓦科技股份有限公司

-40 DEG C low-temperature high-strength high-toughness nodular cast iron, preparation method thereof and railway locomotive parts

ActiveCN109930058AImprove strength and toughnessGuaranteed purityChemical compositionMaterial requirements

The invention discloses -40 DEG C low-temperature high-strength high-toughness nodular cast iron, a preparation method thereof and railway locomotive parts. The nodular cast iron comprises the following components, by weight, of 3.6% to 3.9% of C, 1.9% to 2.1% of Si, smaller than 0.2% of Mn, smaller than 0.3% of P, 0.003% to 0.012% of S, 0.35% to 0.5% of Cu, 1.1% to 1.5% of Ni, smaller than or equal to 0.03% of Fe, 0.025% to 0.05% of Mg and the balances Fe and inevitable impurities. The constitution of the nodular cast iron disclosed by the invention realizes organic integration of high strength, high toughness and low temperature impact toughness of the nodular cast iron, so the nodular cast iron can meet higher use requirements and has technological perspectiveness. The nodular cast irondisclosed by the invention meets the material requirements of key parts applied to rail traffic.

Owner:CHANGZHOU LANGRUI CASTING +1

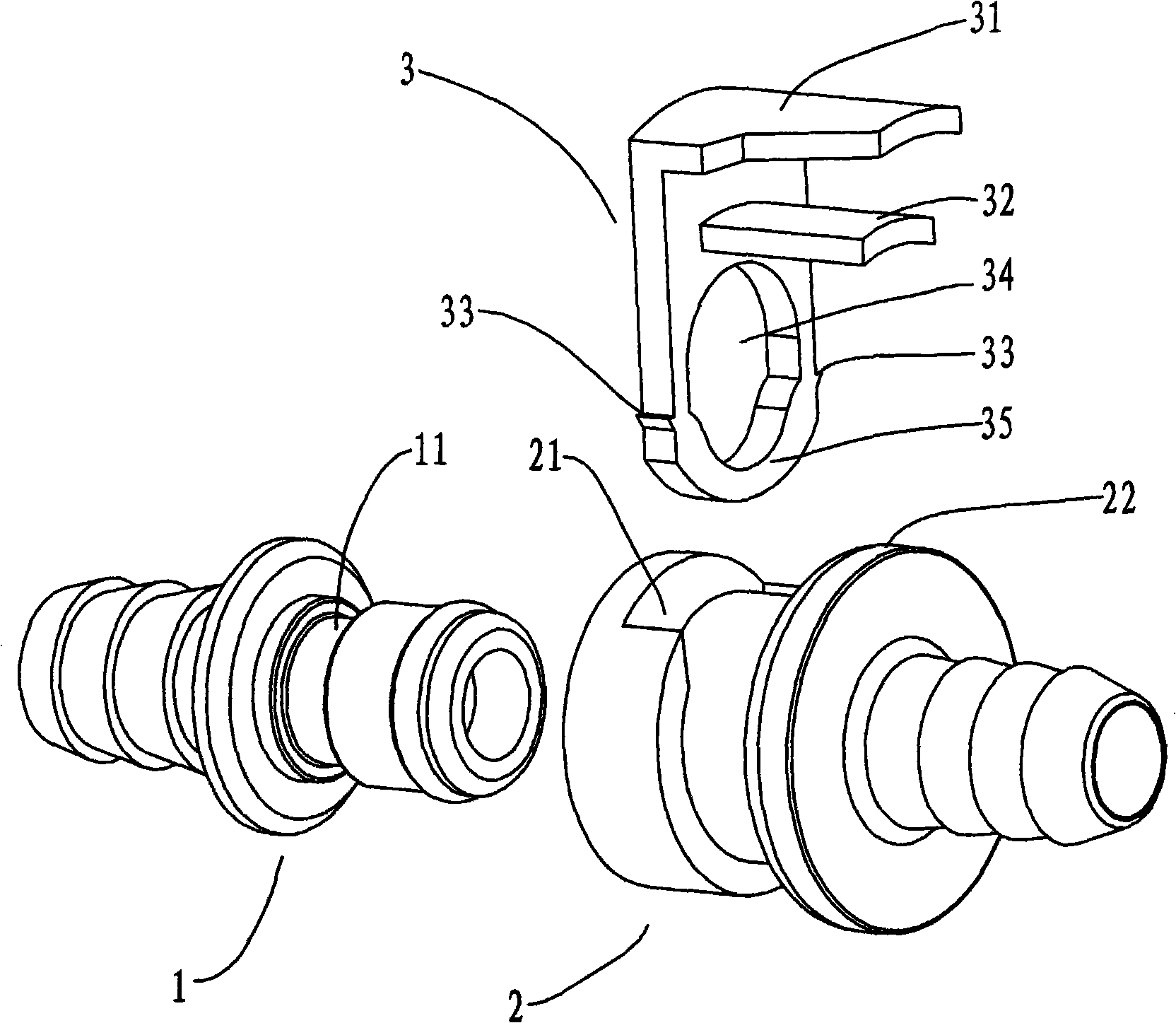

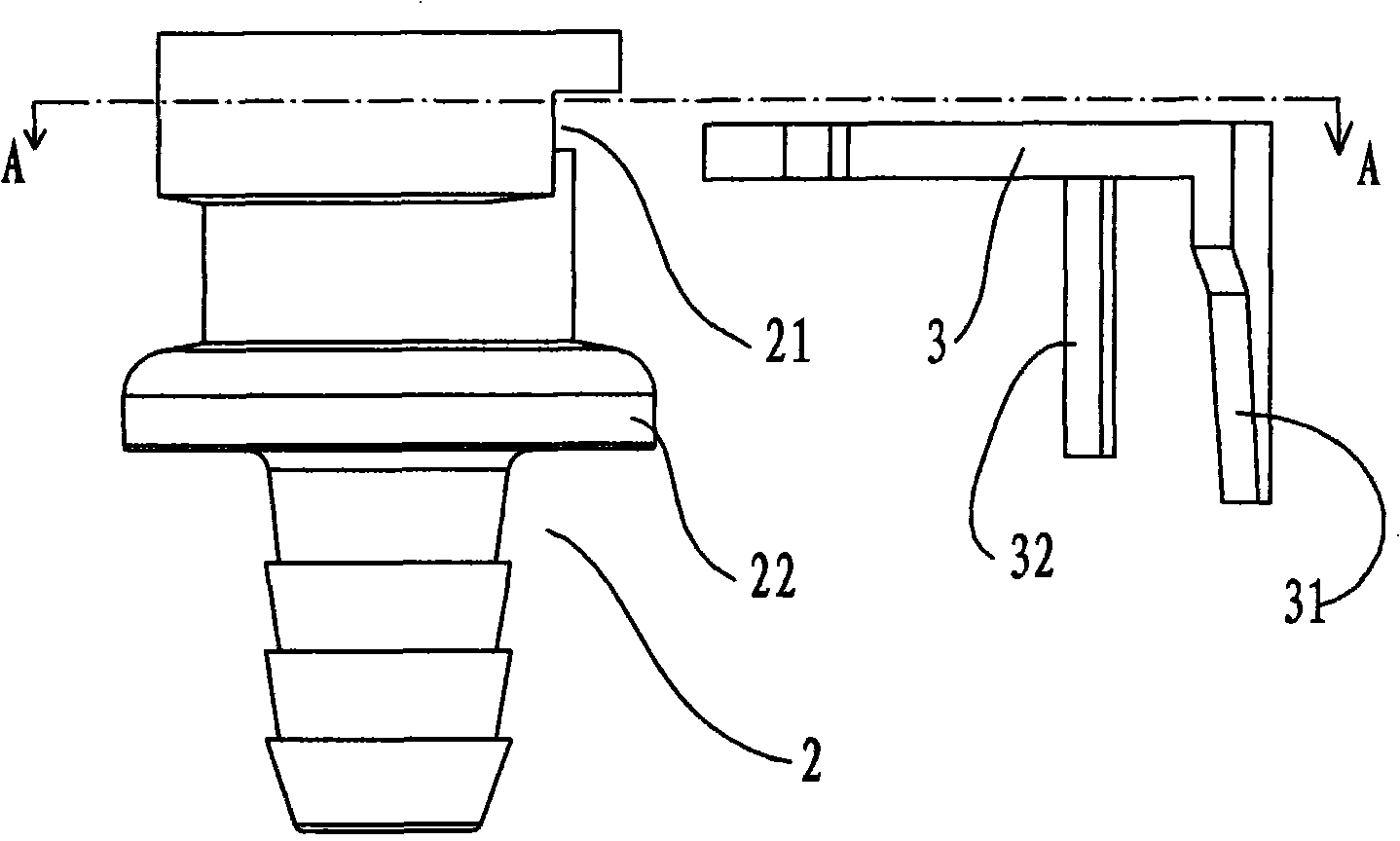

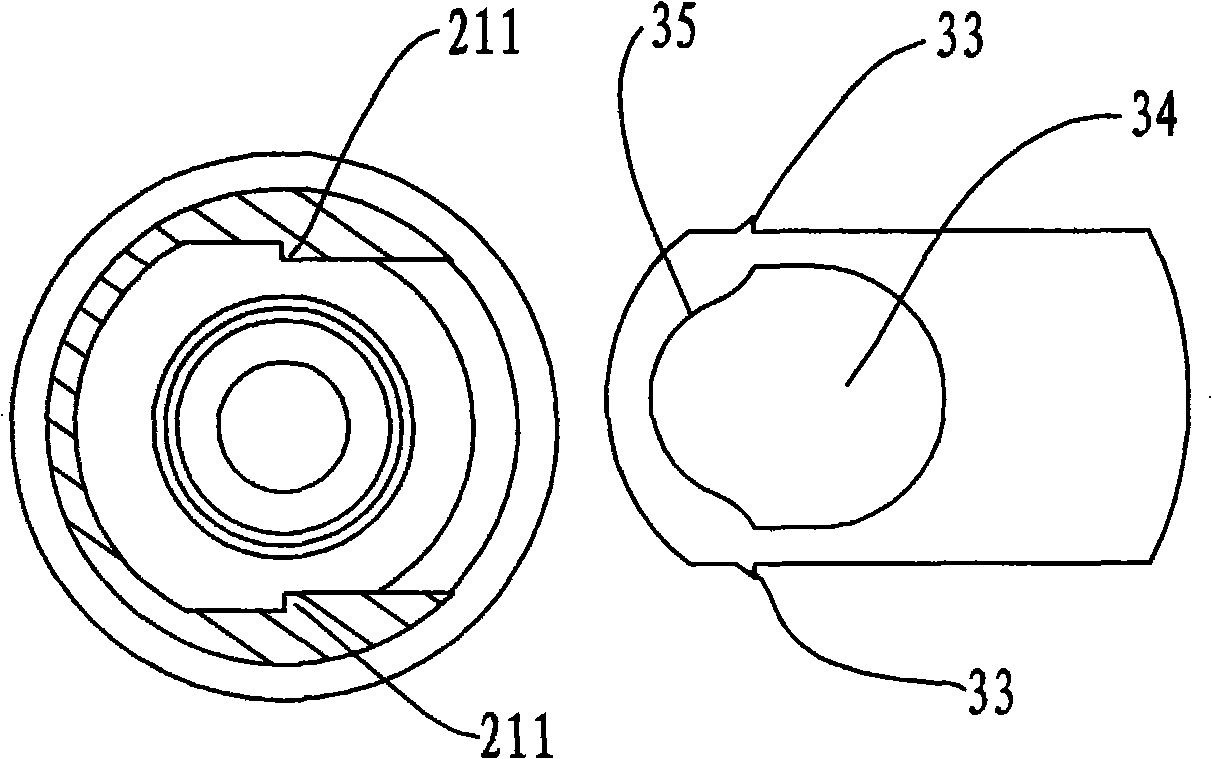

Quick water feeding and purifying system for outdoor drinking water

InactiveCN101269857AEasy to useOutstanding FeaturesTravelling sacksTreatment involving filtrationWater qualityNozzle

The invention provides an outdoor drinking water quick water and purification system, which relates to the outdoor individual drinking water appliance and is invented for providing a quick water system that can water in a water bottle without putting a backpack under various use environments and a water quality purification system that can get quickly the drinking water in various use environments. The water system is provided with the water bottle, one end of which is provided with a soft guide pipe for leading water out, and the water output end of the water bottle is provided with a quickly dismantling female joint. The purification system is provided with a water-seal suction nozzle, a water bottle can filler, a tap can filler, a filter and a water drawing device, which all are provided with quickly dismantling male joints that are respectively matched and connected with the female joint. The state that the female joint is matched and connected with the water-seal suction nozzle is a normal state. The female joint is matched and connected with the water bottle can filler, so bottled water can be added into the water bottle. The female joint is matched and connected with the tap can filler, so the drinking tap water can be directly added. The female joint is matched and connected with the tap can filler and the filter, thereby the non-drinking tap water is purified to be drinking tap water and then is added into the water bottle. The female joint is matched and connected with the water drawing device and the filter, so natural water body can be drawn and purified to be the drinking water and then is added into the water bottle.

Owner:中山喜玛拉雅户外用品有限公司

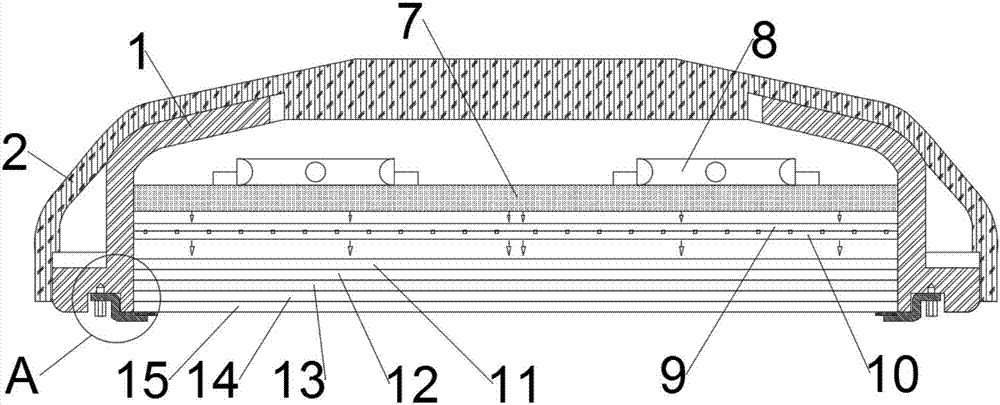

Shock-absorbing TFT-LCD device with stronger simulating stereoscopic feeling

The invention discloses a shock-absorbing TFT-LCD device with a stronger simulating stereoscopic feeling. The device includes an inner polarizing film, a backlight mechanism is arranged above a film sheet of the inner polarizing film and composed of a first transparent brightening film, a second transparent brightening film and a light-emitting transparent light guide plate in sequence from bottom to top, the light-emitting transparent light guide plate is made by mixing polymethyl methacrylate and a rare earth coordination compound, the contact portions of the two ends of the lower surface of an outer polarizing film and screen fixing frames are provided with damping cushion pads, the portions, corresponding to inner concave clamp blocks, of the bottoms of frame bodies of screen supporting frames are provided with rectangular grooves, and the inner concave clamp blocks are arranged in inner cavities of the rectangular grooves through pre-tightening bolts. On the basis of the transparent light guide plate, image displaying is conducted, the simulating stereoscopic feeling of a displayed image is stronger, the user experience is better, a display screen is well protected, damage caused by external impact is avoided, and the safety of the display device is well protected.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

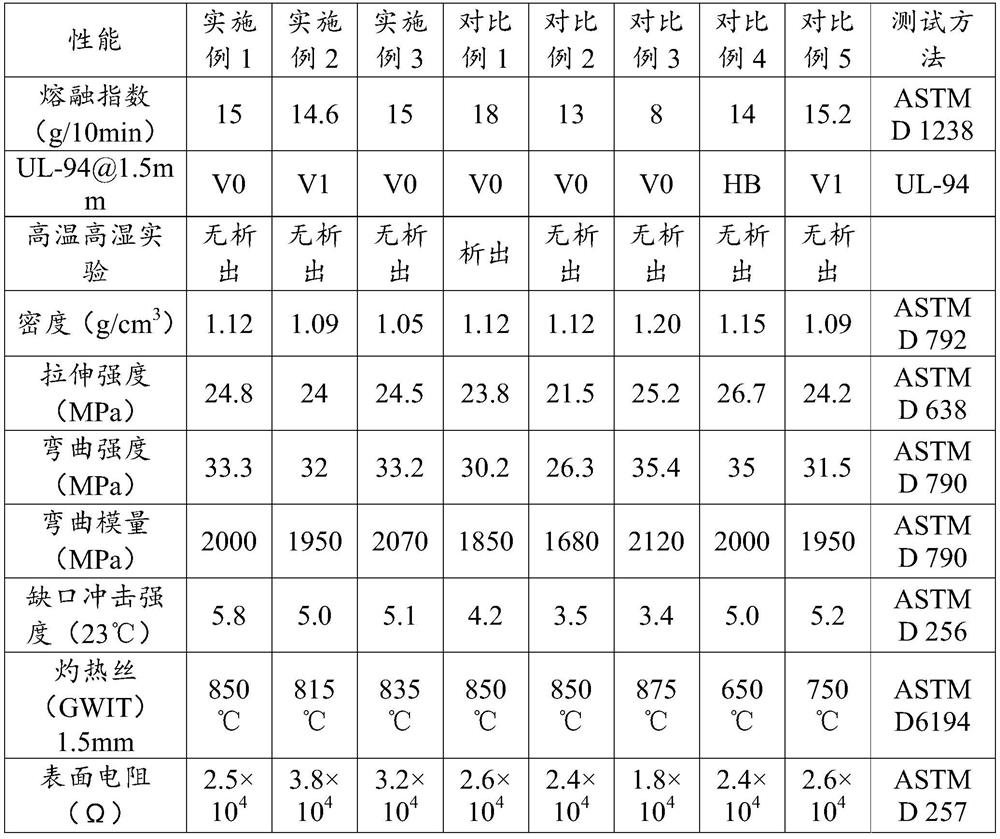

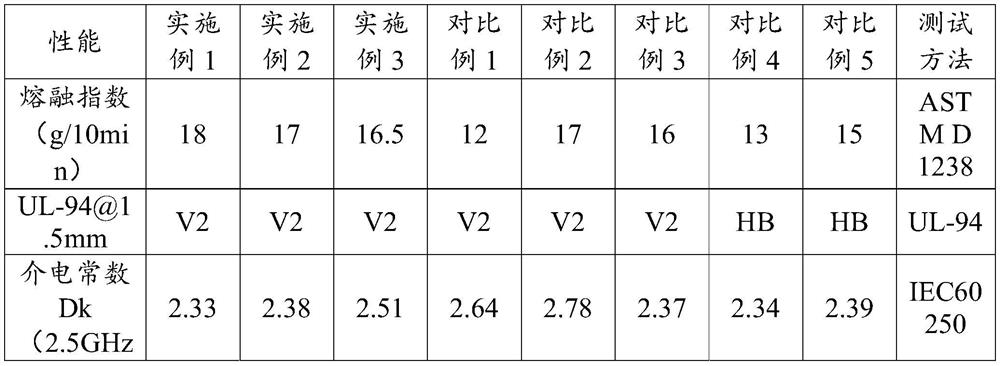

High-temperature-resistant high-humidity-resistant halogen-free flame-retardant antistatic polypropylene material

PendingCN112521681ARetain mechanical and mechanical propertiesHigh heat distortion temperatureHeat deflection temperaturePolymer science

The invention discloses a high-temperature-resistant high-humidity-resistant halogen-free flame-retardant antistatic polypropylene material, and belongs to the technical field of high polymer materials. According to the high-temperature-resistant high-humidity-resistant halogen-free flame-retardant antistatic polypropylene material disclosed by the invention, a halogen-free flame retardant, a coupling agent and expandable graphite with specific contents are added into polypropylene resin, and the expandable graphite is modified by utilizing the coupling agent and then the modified graphite ismatched with other components, so that the original mechanical properties of the polypropylene resin can be effectively retained, the thermal deformation temperature and the flame retardance of the material are remarkably improved, and meanwhile, the material can be prevented from being separated out in a high-temperature and high-humidity environment; the material also meets the GWIT standard ofglowing filaments at 850 DEG C, has excellent antistatic performance, and particularly meets the high use requirements of the glowing filaments in the field of electronic products. The invention further discloses a preparation method of the high-temperature-resistant high-humidity-resistant halogen-free flame-retardant antistatic polypropylene material. The preparation method is simple in operation steps and low in requirements for preparation equipment, and can achieve industrial large-scale production.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD

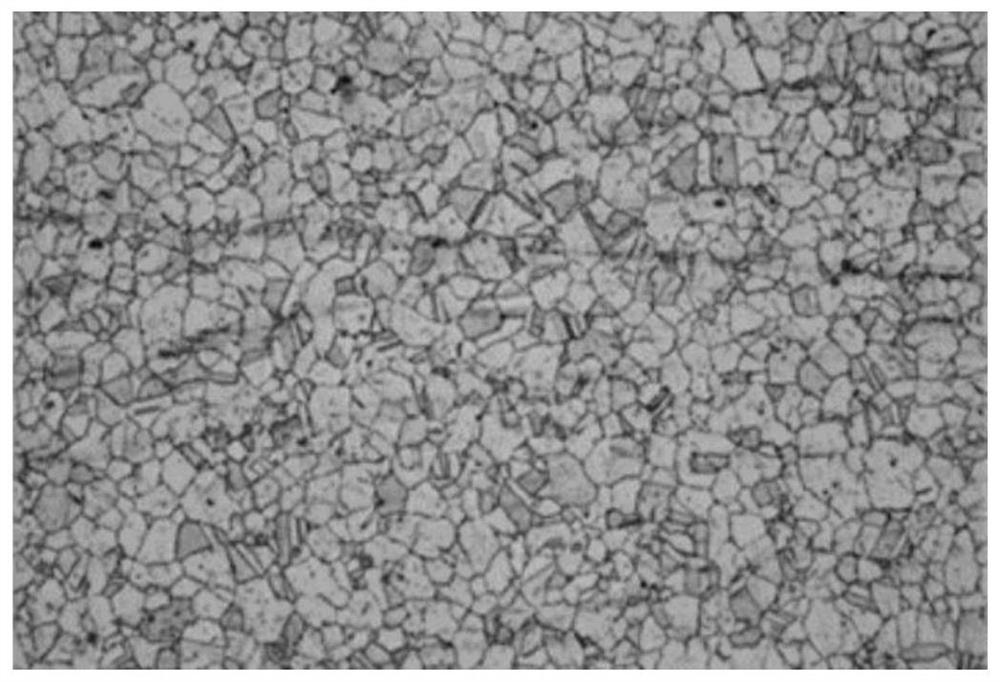

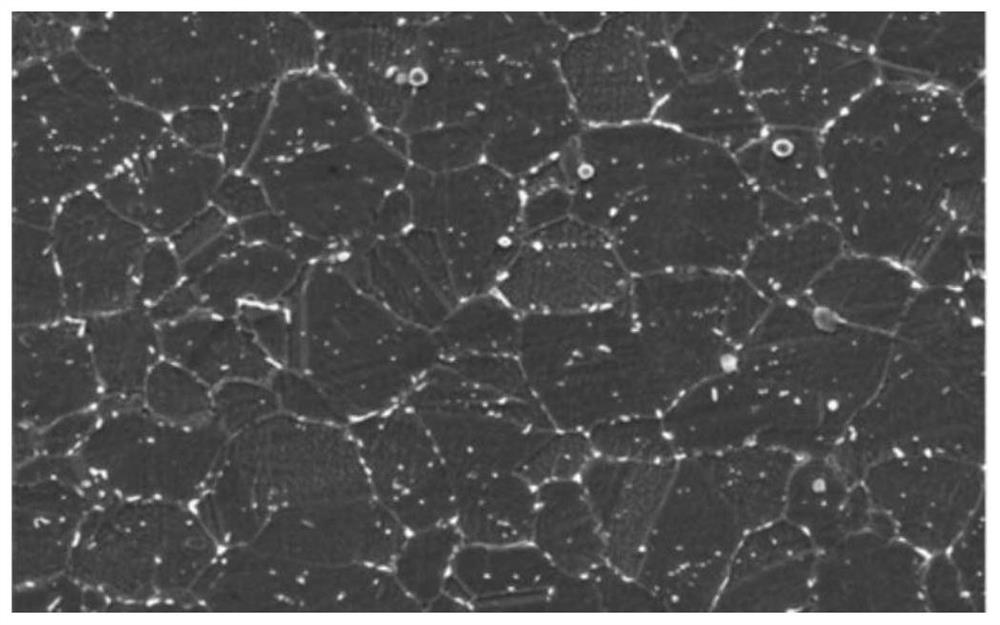

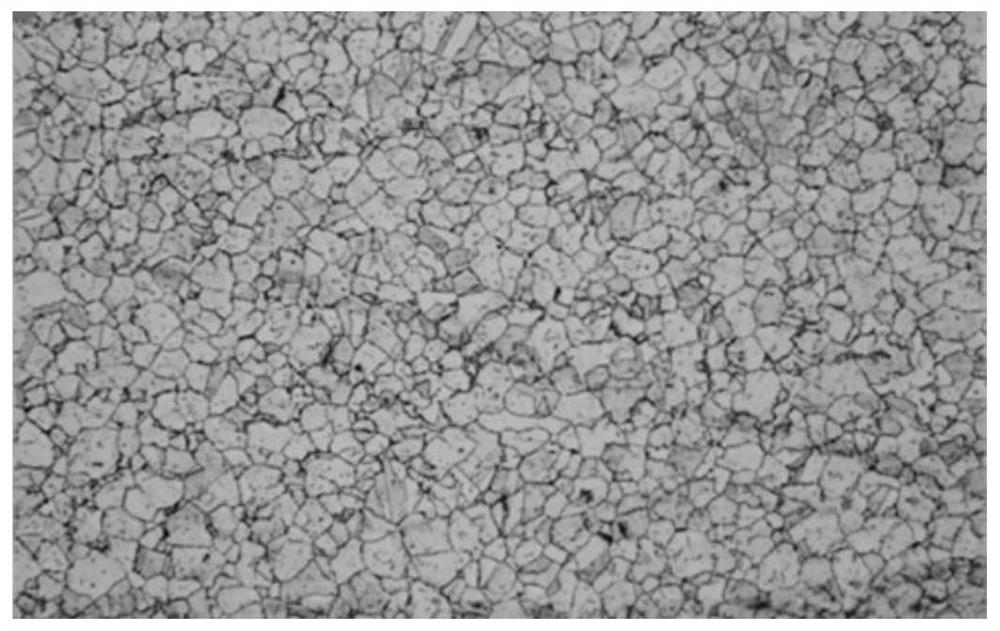

Preparation method of low-magnetism stainless steel medium plate with yield strength being 785MPa

ActiveCN111926260AFine grainSolve the problem of increased rolling force as the thickness increasesSS - Stainless steelUltimate tensile strength

The invention relates to a preparation method of a low-magnetism stainless steel medium plate with the yield strength being 785MPa, and belongs to the metallurgy field. The method comprises the stepsof carrying out vacuum melting, carrying out electroslag remelting, forging, carrying out controlled rolling and carrying out heat treatment. According to the method provided by the invention, a controlled rolling process and a heat treatment process are set according to the target thickness of a low-magnetism stainless steel plate; a preparation method comprising controlled rolling in an unrecrystallized zone, low-temperature solid solution treatment and two-stage aging treatment is adopted for a low-magnetic stainless steel plate with the thickness being larger than or equal to 20mm and smaller than or equal to 40mm; and a preparation method comprising controlled rolling under small pressure in an incompletely recrystallized zone and direct two-stage aging treatment after hot rolling isadopted for a low-magnetic stainless steel plate with the thickness being larger than 40mm and smaller than or equal to 80mm. A low-magnetic stainless steel plate with the thickness ranging from 20mmto 80mm has the performance indexes that the yield strength is larger than or equal to 785MPa, the tensile strength is larger than or equal to 1100MPa, the elongation percentage is larger than or equal to 15 percent, and the relative magnetic permeability is smaller than or equal to 1.005.

Owner:NORTHEASTERN UNIV

Halogen-free flame-retardant low-dielectric-loss glass fiber reinforced polypropylene material

ActiveCN112521688ALow preparation equipment requirementsEasy to operateGlass fiberHeat deflection temperature

The invention discloses a halogen-free flame-retardant low-dielectric-loss glass fiber reinforced polypropylene material, and belongs to the technical field of high polymer materials. The halogen-freeflame-retardant low-dielectric-loss glass fiber reinforced polypropylene material is prepared from the following components in parts by weight: 35 to 80 parts of polypropylene resin, 10 to 40 parts of low-dielectric-loss glass fiber and 1 to 4 parts of halogen-free flame retardant; and the dielectric loss of the low-dielectric-loss glass fiber at the frequency of 4-4.5 GHz is 4*10 <-2>-5*10 <-2>.According to the product, the halogen-free flame retardant with specific content and the glass fiber material with specific dielectric loss coefficient are added into the polypropylene resin, so thatthe original mechanical properties of the polypropylene resin can be effectively retained, the dielectric loss of the material is relatively low, and the thermal deformation temperature and flame retardancy of the material are also improved, and the material meets high use requirements in the field of electronic products. The invention further discloses a preparation method of the product. The preparation method is simple in operation steps and low in requirements for preparation equipment and achieves industrial large-scale production.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD

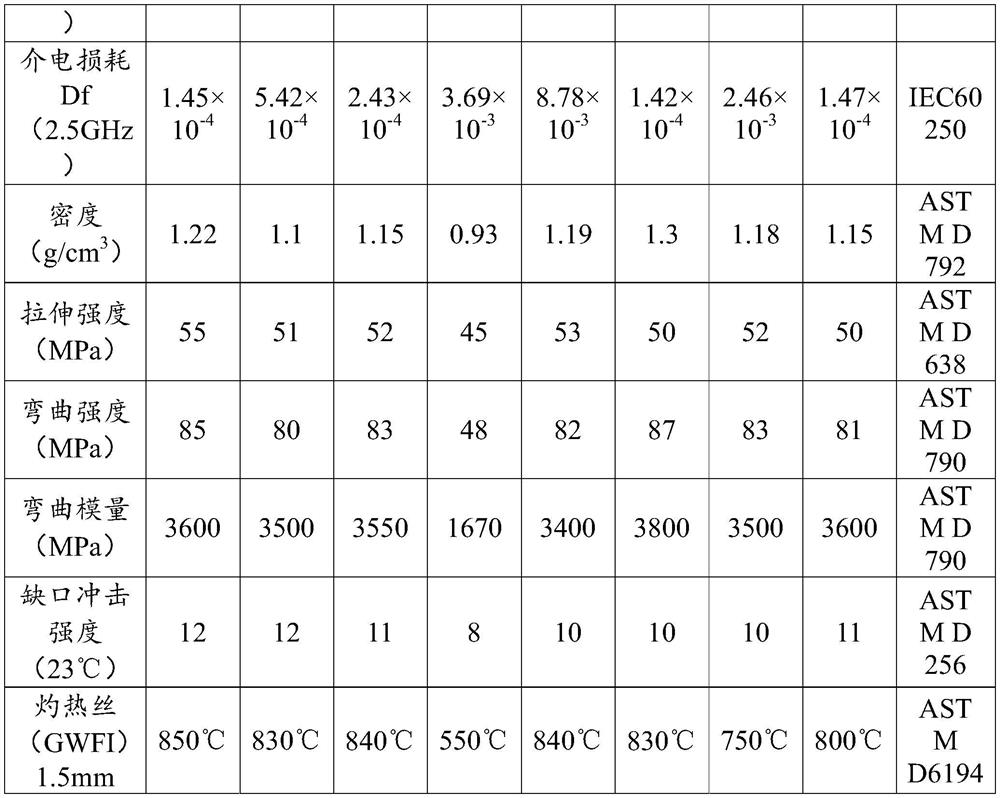

Preparation method of extruded magnesium oxide tube

InactiveCN108516804AHigh purityHigh hardnessCeramic shaping apparatusMagnetic separationCelluloseHigh density

The invention belongs to the technical field of metallurgy, in particular to a preparation method of extruded magnesium oxide tube. Aiming at the problems of long operation and high production cost ofthe magnesium oxide pipe prepared by the prior method, the extruded magnesium oxide tube preparation method provides a preparation method of extruded magnesium oxide tube, which is characterized by comprising the following steps of: grinding the magnesium oxide block ball into a certain fineness; the magnesium oxide powder is subjected to magnetic separation by an electromagnetic magnetic separator; stirring magnesium oxide powder with high-viscosity cellulose, and stirring to obtain dough; mixing the mixed magnesium oxide paste into a material cylinder, and extruding and forming through a die; the magnesium oxide pipe after extruding is naturally air-dried or dried, the extruded magnesium oxide pipe is sintered into a finished product through high-temperature heat insulation. The extruded magnesium oxide tube preparation method has the advantages that the semi-finished product with higher density is obtained through extrusion conditions, and the sintering conditions are controlled to prepare the magnesium oxide pipe with high density, large hardness and good compactness.

Owner:盐城市华康电热绝缘材料厂

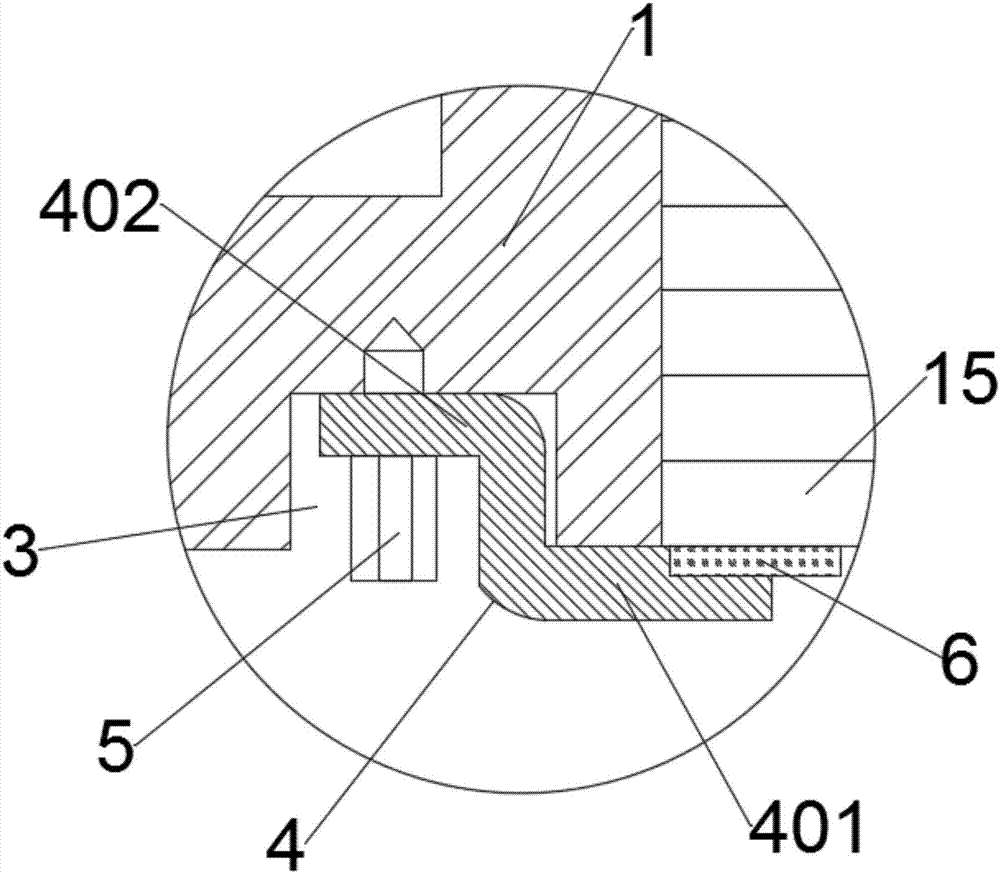

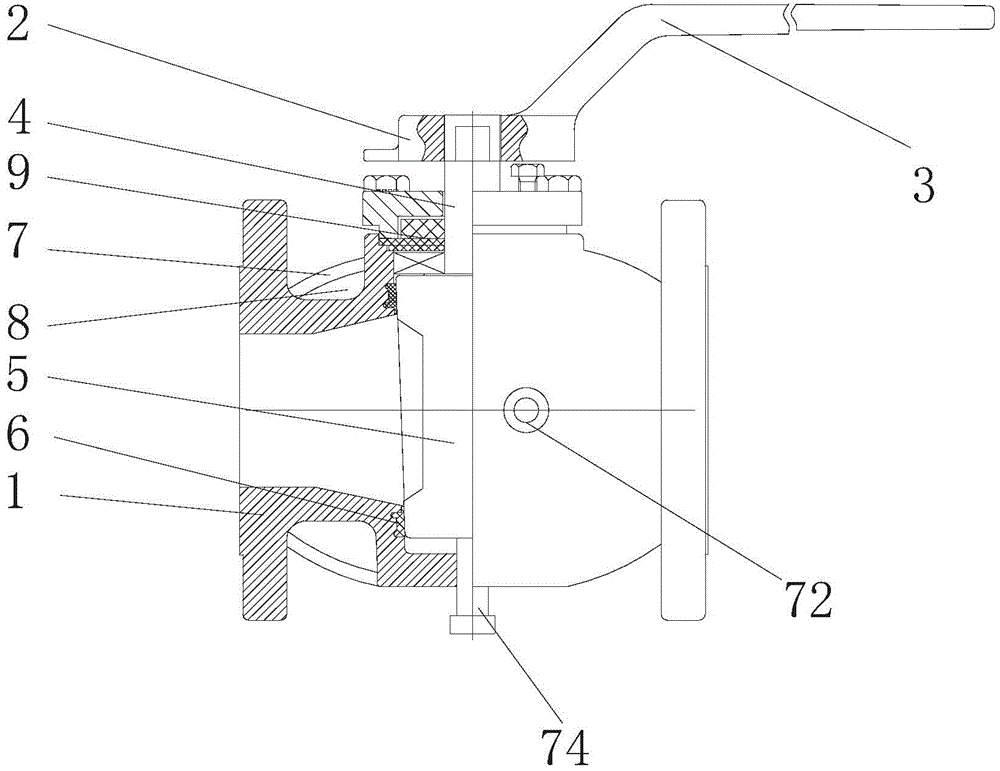

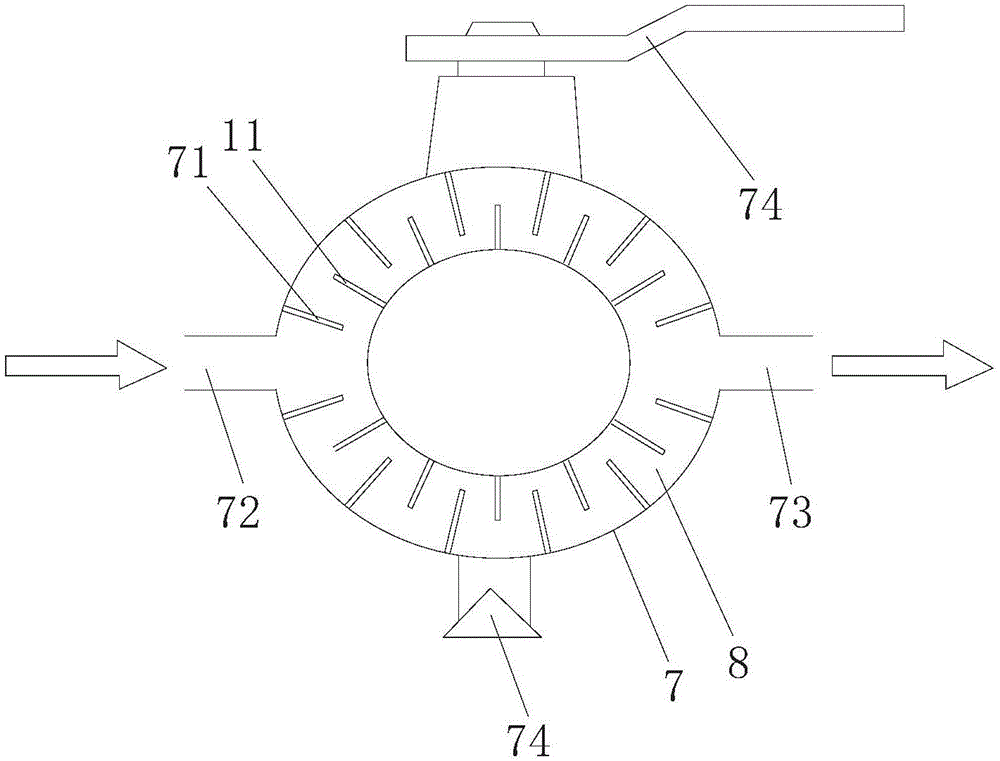

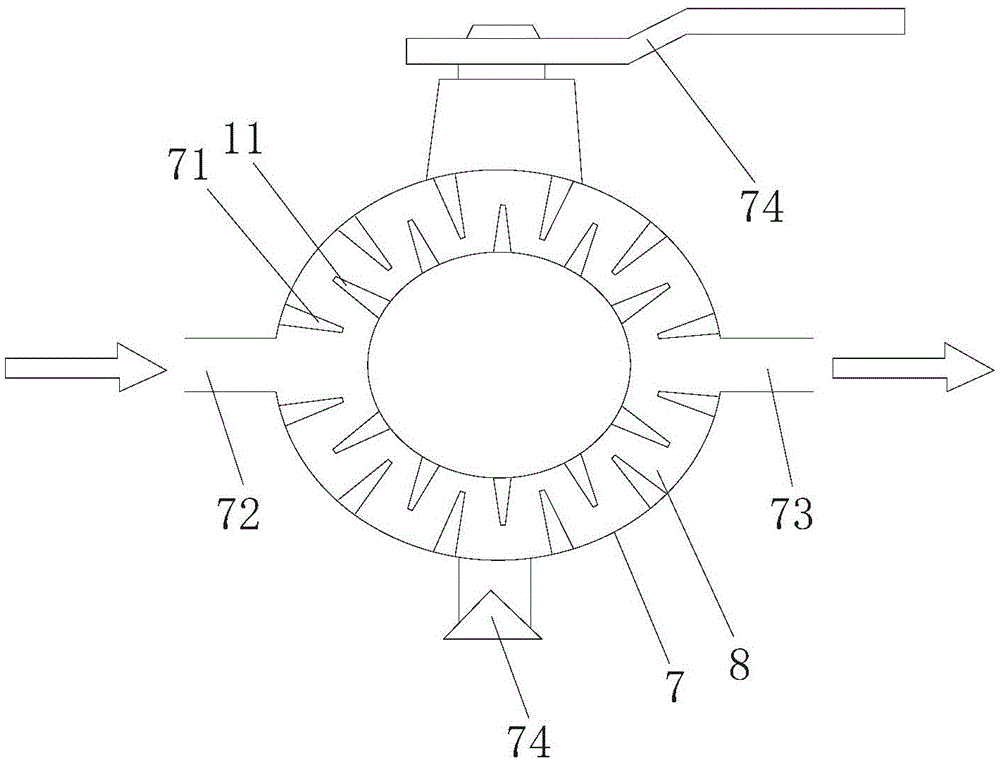

Novel thermal insulation jacket plug valve

ActiveCN105276339AImprove heat preservation functionIncrease flow spacePlug valvesThermal insulationThermal insulationPlug valve

The invention discloses a novel thermal insulation jacket plug valve. The novel thermal insulation jacket plug valve comprises a valve body, a valve cover and a handle; a valve rod, a plug cock and a valve seat are arranged in the valve body; the handle is fixedly connected with the valve cover; the two ends of the valve rod are connected with the valve cover and the plug cock respectively; the valve body is sleeved with a jacket for thermal insulation, and the jacket and the valve body jointly form a thermal insulation cavity; a plurality of first thermal insulation fins are uniformly arranged on the inner wall of the jacket in the circumferential direction of the jacket; second thermal insulation fins are uniformly arranged on the outer wall of the valve body in the circumferential direction of the valve body; fin bodies of the first thermal insulation fins and fin bodies of the second thermal insulation fins are opposite and staggered and enable a flow channel of the thermal insulation cavity to be in an up-and-down shape. By means of the novel thermal insulation jacket plug valve, the thermal insulation performance and effects are better, the thermal insulation time is longer, and higher thermal insulation demands are met.

Owner:FLUOROSEAL SPECIALTY VALVES SUZHOU

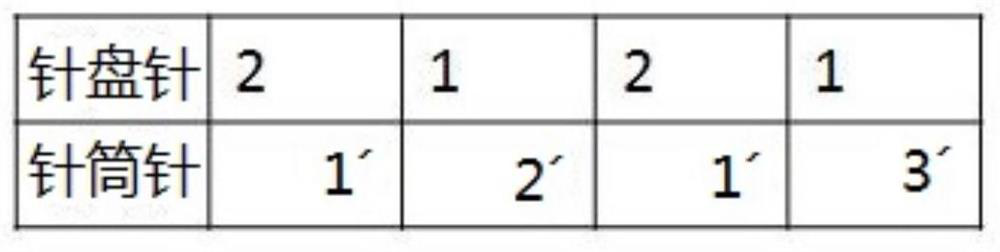

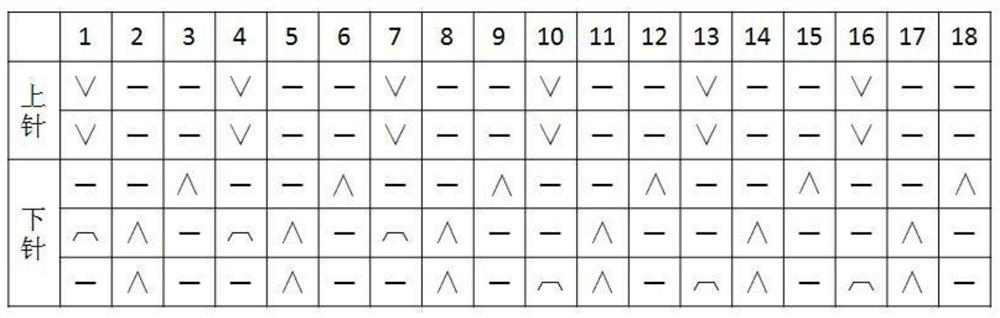

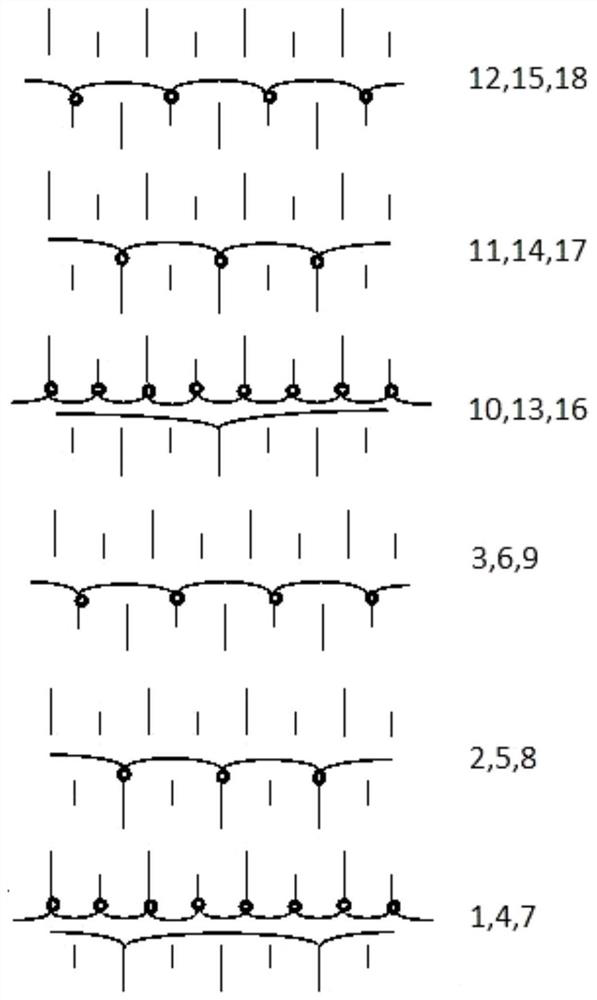

One-way moisture conduction towel fabric and production method thereof

The invention discloses a one-way moisture conduction towel fabric and a production method thereof. The production method comprises the following steps of providing a double-sided machine, and arranging cams and knitting needles according to fabric design requirements, wherein dial needles comprise knitting needles with two needle butts, cylinder needles comprise knitting needles with three needle butts, the two needles of the dial needles are arranged at an interval of 1, the arrangement mode of the cylinder needles adopts four needles as a cycle, and the arrangement mode of the knitting needles in each cycle is the first needle, the second needle, the first needle and the third needle; providing yarns, wherein the yarns comprise common yarns and sea-island yarns; by using the double-sided machine, performing knitting by adopting 18 paths as a cycle; and in a woven gray fabric, enabling the common yarns to form a mesh surface, and enabling the sea-island yarns to form a to-be-napped surface. The one-way moisture conduction towel fabric has relatively good and relatively durable comfort and air permeability, has the characteristics of quick water absorption and quick drying, and can meet high use requirements of consumers.

Owner:JIANGSU JUJIE MICROFIBERS TEXTILE GRP

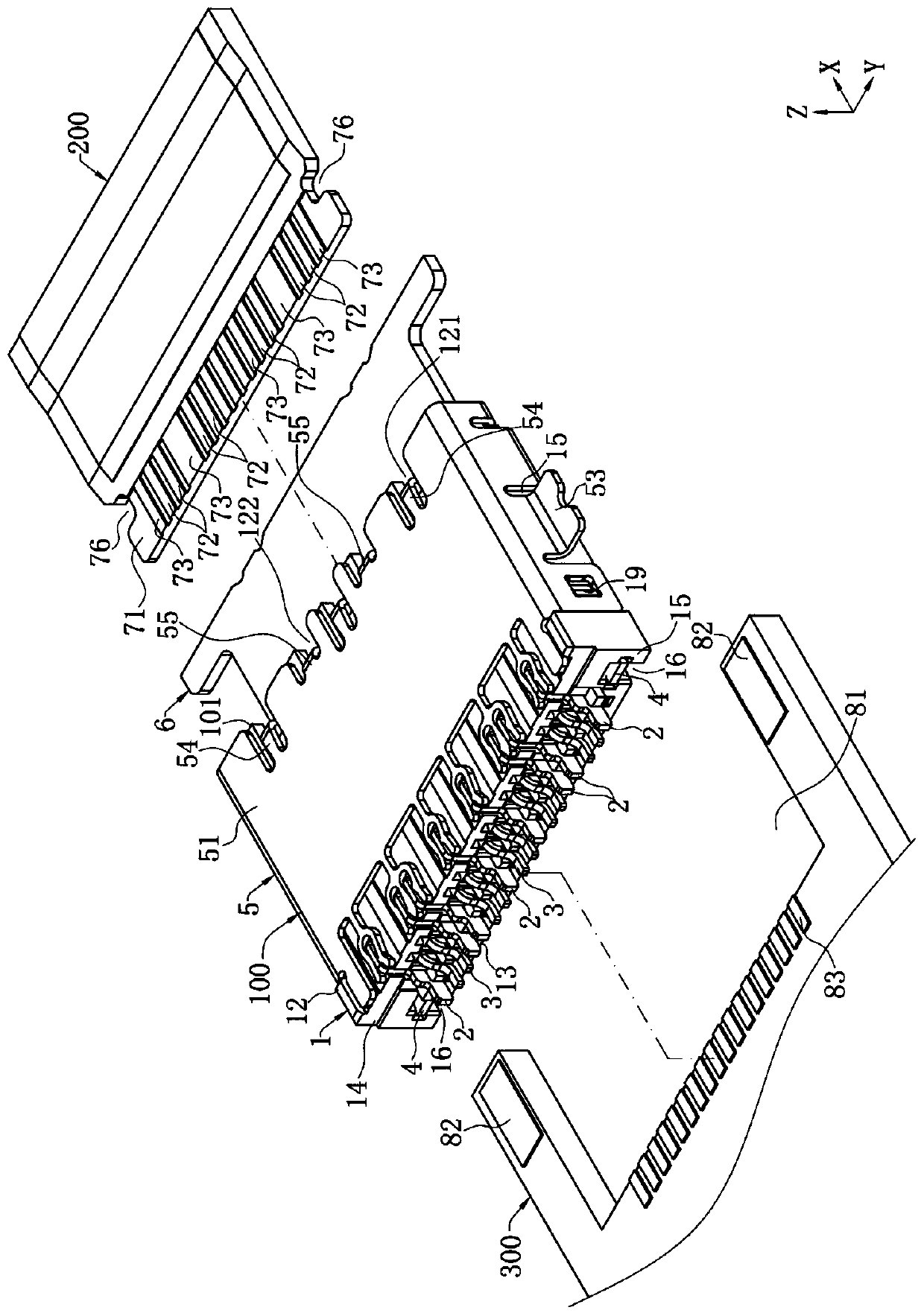

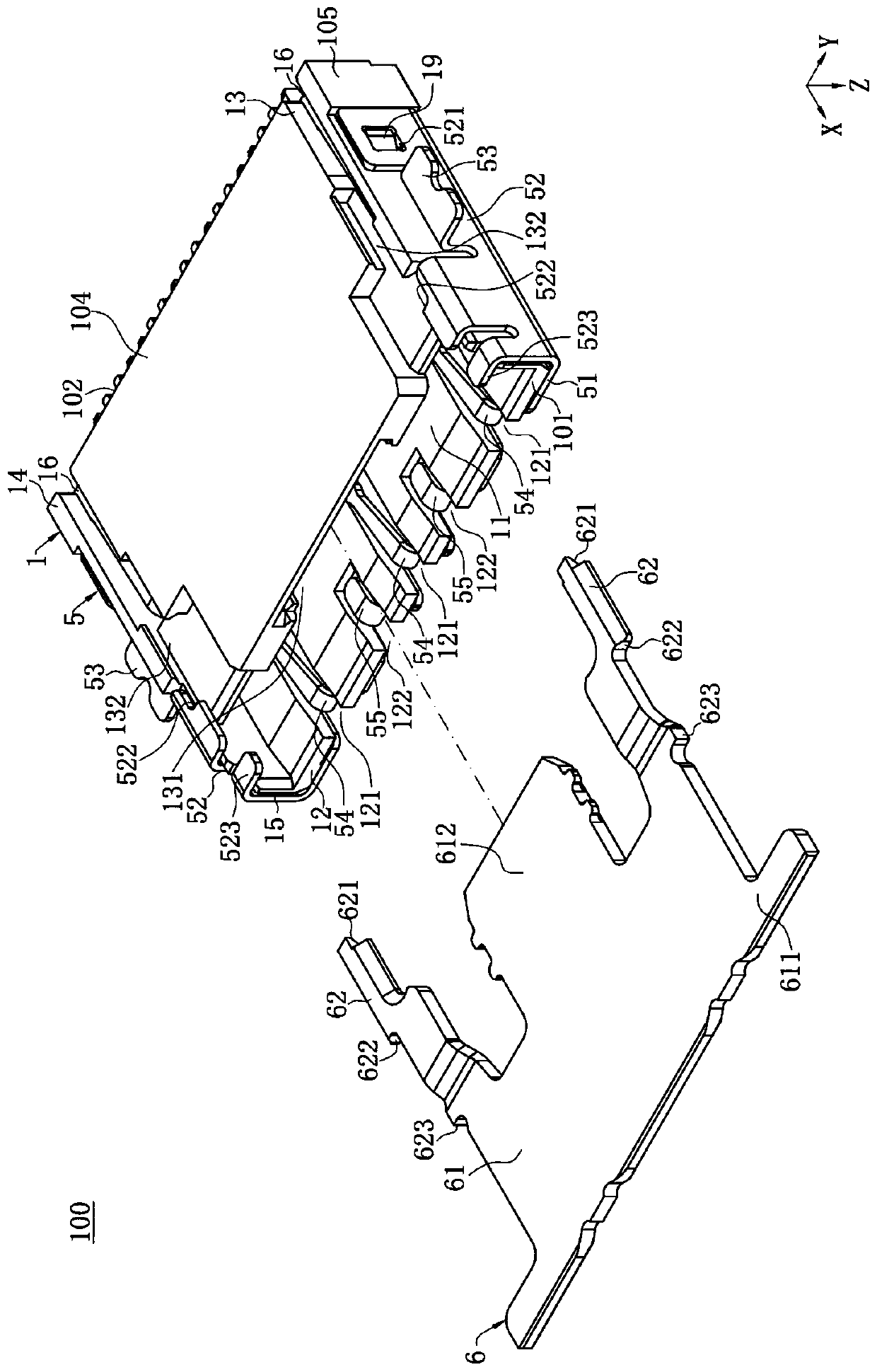

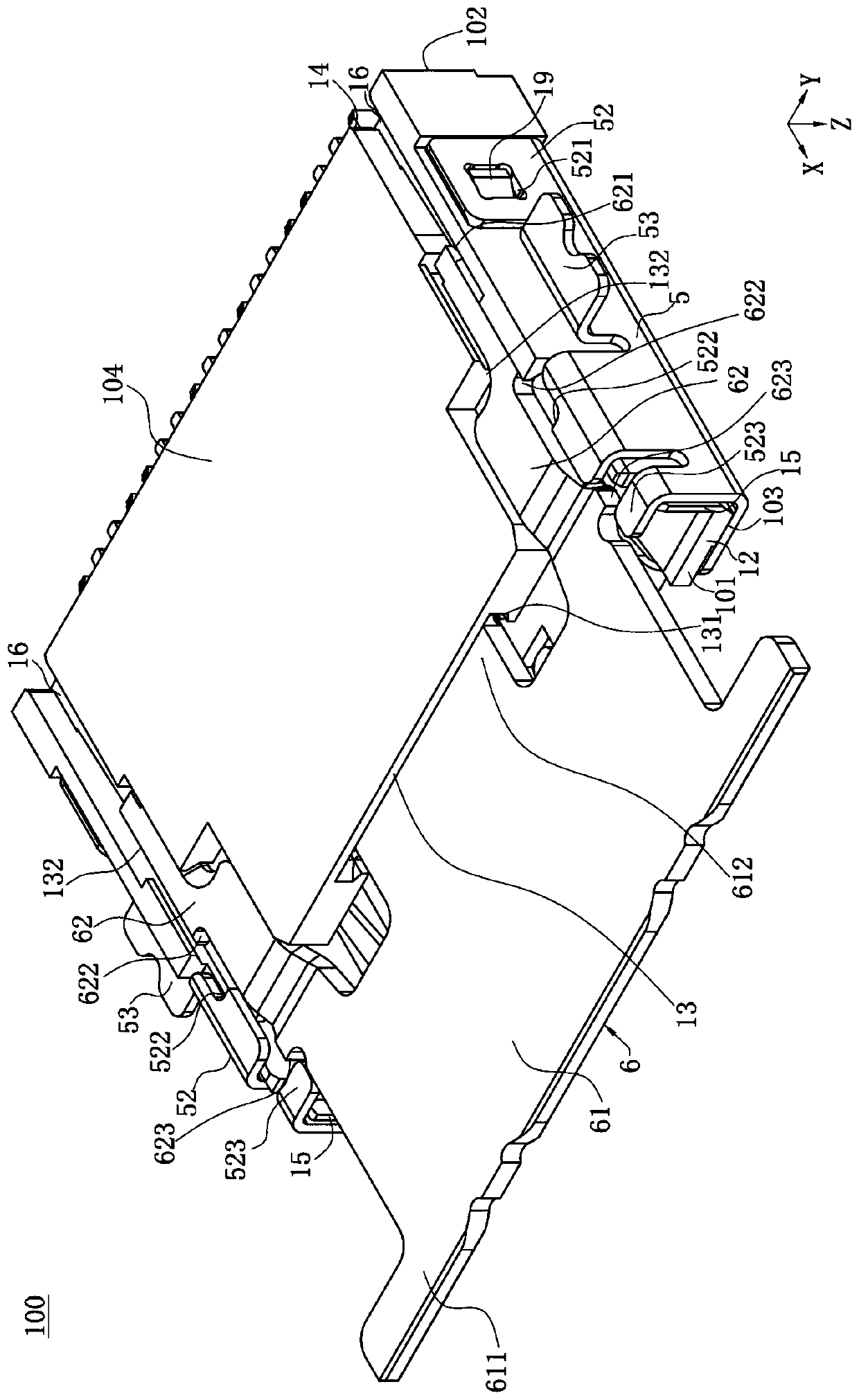

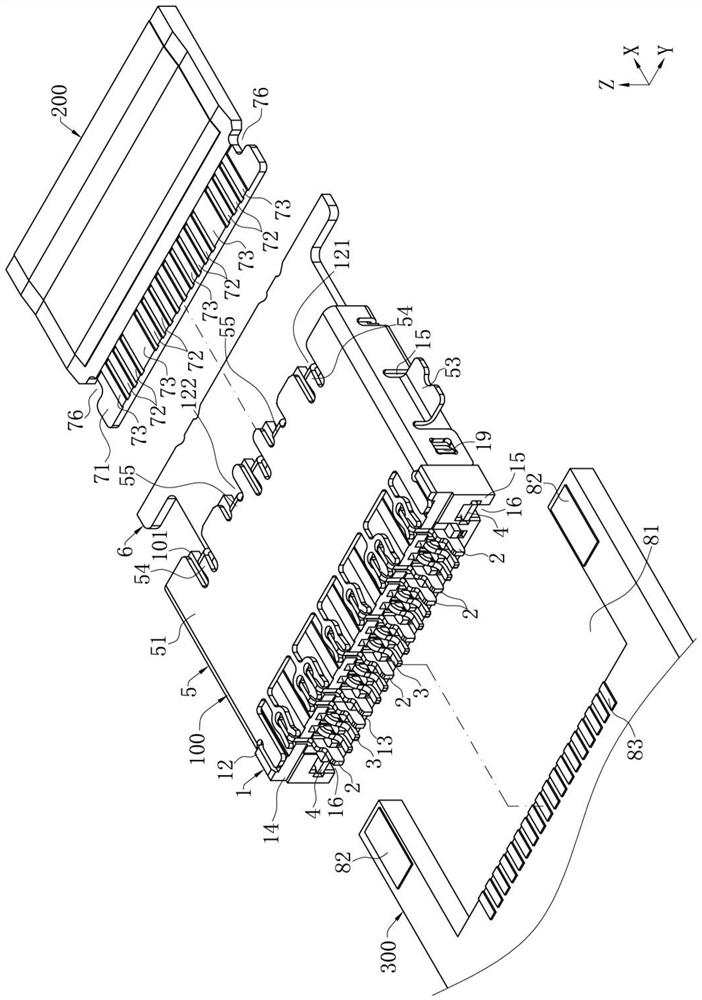

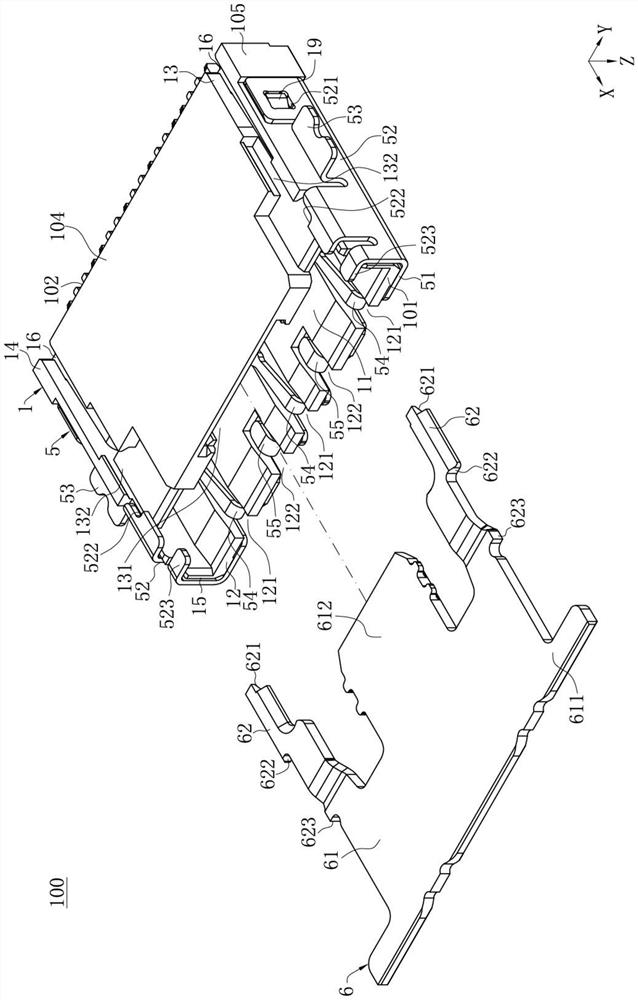

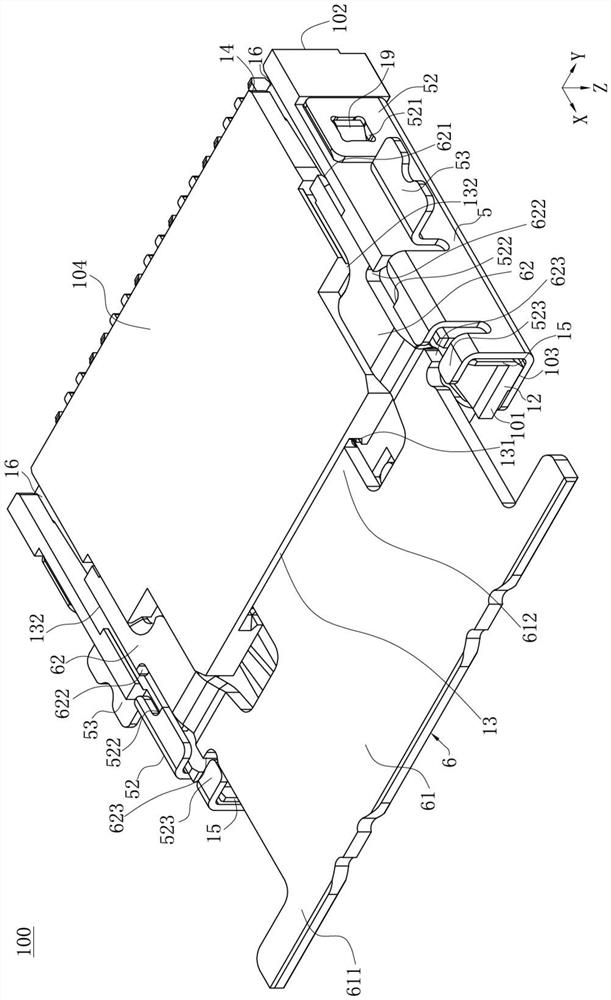

Electric connector

InactiveCN111064026AIncrease distanceAvoid breakingCoupling contact membersCouplings bases/casesMechanical engineeringPhysics

The invention discloses an electric connector. The electric connector comprises an insulating body. A number of terminals are arranged on the insulating body and comprise two signal terminal pairs andtwo grounding terminals positioned between the two signal terminal pairs. A metal shell covers the insulating body, and comprises a neck part extending backwards from the top plate, a first elastic arm, a second elastic arm and a third elastic arm, wherein the first elastic arm, the second elastic arm and the third elastic arm respectively extend backwards from the neck part. The first elastic arm and the second elastic arm are respectively provided with a rightward first contact part. The second elastic arm and the third elastic arm are respectively provided with a leftward second contact part. The first contact part of the first elastic arm and the second contact part of the second elastic arm are staggered. The first contact part of the second elastic arm and the second contact part ofthe third elastic arm are staggered. When the neck part deviates rightwards, the first contact part of the first elastic arm abuts against one grounding terminal rightwards, and the first contact part of the second elastic arm abuts against the other grounding terminal rightwards. When the neck part deviates leftwards, the second contact part of the second elastic arm abuts against one groundingterminal leftwards, and the second contact part of the third elastic arm abuts against the other grounding terminal leftwards.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

Electric connector

ActiveCN112038803AIncrease distanceAvoid breakingCoupling contact membersCouplings bases/casesEngineeringMechanical engineering

The invention discloses an electric connector. The electric connector comprises an insulating body; a plurality of terminals are arranged on the insulating body and comprise two signal terminal pairsand two grounding terminals positioned between the two signal terminal pairs; the metal shell covers the insulation body and comprises a neck portion extending backwards from the top plate, a first elastic arm, a second elastic arm and a third elastic arm; the first elastic arm, the second elastic arm and the third elastic arm extend backwards from the neck portion; the first elastic arm and the second elastic arm are respectively provided with a rightward first contact portion, and the second elastic arm and the third elastic arm are respectively provided with a leftward second contact portion. The first contact portion of the first elastic arm and the second contact portion of the second elastic arm are staggered, the first contact portion of the second elastic arm and the second contactportion of the third elastic arm are staggered, when the neck portion deviates rightwards, the first contact portion of the first elastic arm abuts against one grounding terminal rightwards, and thefirst contact portion of the second elastic arm abuts against the other grounding terminal rightwards. When the neck portion deviates leftwards, the second contact portion of the second elastic arm abuts against one grounding terminal leftwards, and the second contact portion of the third elastic arm abuts against the other grounding terminal leftwards.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

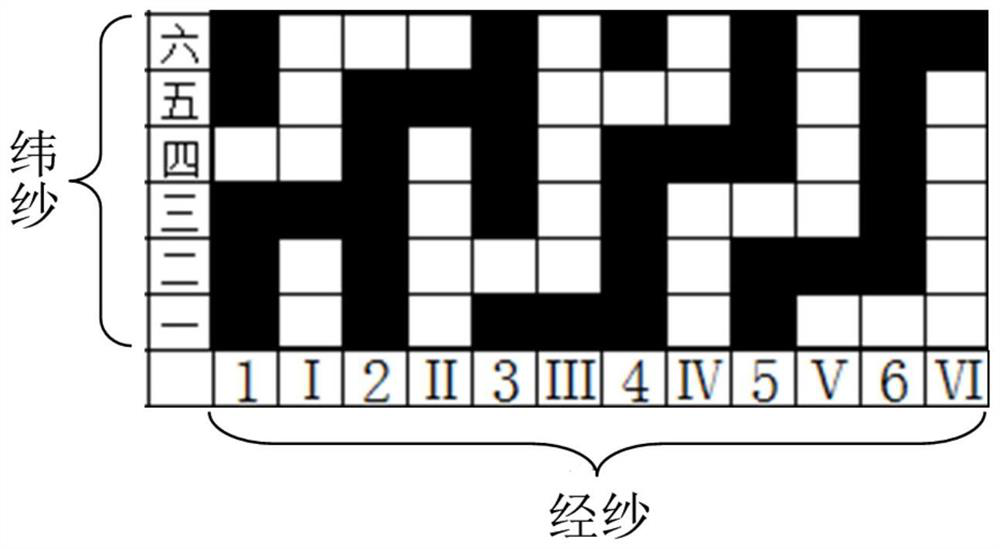

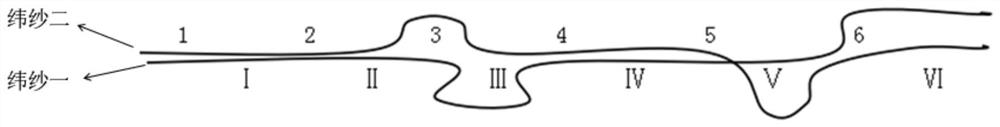

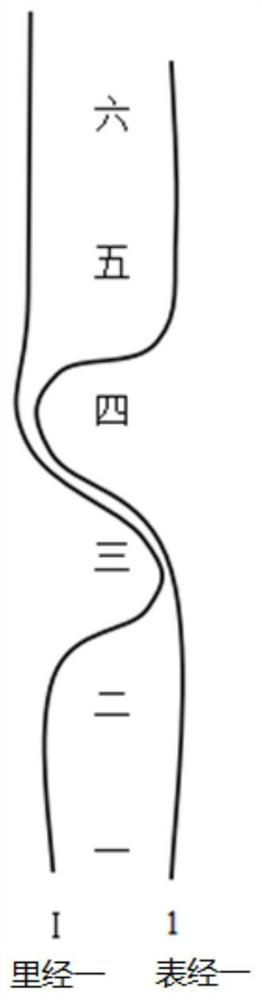

Super imitation leather suede fabric with particle appearance and production method thereof

PendingCN113445176ASoft touchUniform and fine velvetFibre typesDyeing processPolyesterChamois leather

The invention discloses a super imitation leather suede fabric with a particle appearance and a production method thereof. The super imitation leather suede fabric is formed by interweaving surface warps, inner warps and weft yarns, wherein the surface warps and the inner warps are made of sea-island low stretch yarns, and the weft yarns are made of polyester elastic yarns; the fabric is composed of a plurality of circulation texture patterns; one circulation texture pattern comprises six surface warps, six inner warps and six weft yarns; the row ratio of the surface warps to the inner warps is 1: 1; and the fabric is subjected to slurry impregnation treatment and sanding treatment, and convex particles are uniformly distributed on the surface of the fabric. The super imitation leather suede fabric has the advantages of soft hand feeling and fine suede feeling, and has super leather texture and the particle appearance.

Owner:JIANGSU JUJIE MICROFIBERS TEXTILE GRP

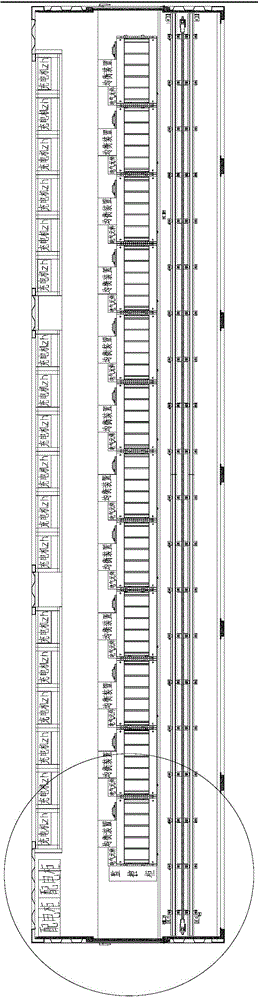

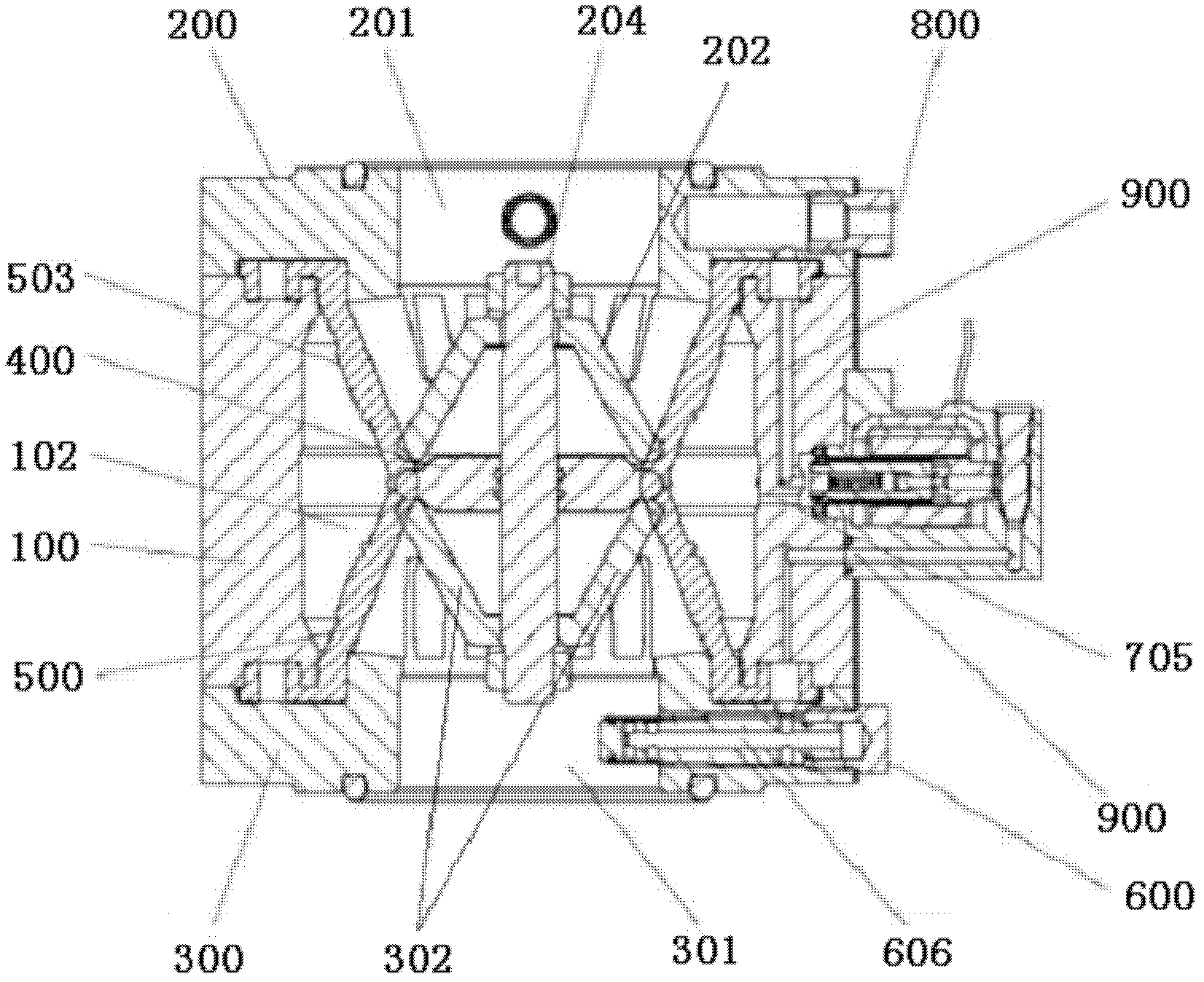

An electric vehicle intensive charging and swapping station

ActiveCN104340185BLow infrastructure requirementsReduce usageVehicle servicing/repairingElectrical batteryAutomotive battery

The invention discloses an intensive accumulator charging and replacing station for electric vehicles. By modifying containers, a charging device and an accumulator can be implanted in the station, and spatial utilization rate is increased; meanwhile, referring to the present mode of a mobile charging bin and an accumulator transfer box, an accumulator support and a charging support are integrally mounted, mounting is convenient and reliable, and project construction period is saved; an automatic taking and placing device is additionally mounted and communicated with the accumulator, whether the accumulator is fully charged or not can be automatically identified and recognized and the accumulator can be placed into an accumulator storage area without an electric forklift, and the accumulator of the electric vehicles can be conveniently replaced. Further, a safety protection system is added, a safety guardrail, a safety light curtain and a safety switch can be operated within the range to keep surrounding people safe by the aid of the automatic taking and placing device; the system information can be processed by a PLC (programmable logic controller), and docking of the man-machine exchange control information can be realized via a touch display screen.

Owner:STATE GRID CORP OF CHINA +2

Method for preparing high-purity dipping asphalt

InactiveCN102492452AHigh purityReduce manufacturing costWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionManufacturing technologyQuinoline

The invention, relating to the preparation technique of asphalt materials, particularly discloses a method for preparing high-purity dipping asphalt. The method comprises the following steps: step 1, preparing an extracting agent by mixing 57-63 wt% of washing oil and 37-43 wt% of diesel oil; step 2, putting middle-temperature liquid asphalt and the extracting agent in a mixing kettle according to the weight ratio of 1:1, stirring for 1.5-2 h at a kettle temperature of 148-152 DEG C, then pumping into a standing settler, standing for more than 24 h at a temperature of 140-150 DEG C, and pumping into the asphalt liquid having a required purity in a distilling still; step 3, steaming out distillates of the extracting agent by using an underpressure distillation method, and finally carrying out cooling forming by a forming machine. A product obtained by the invention has high purity, wherein the content of quinoline insolubles is generally less than 0.5 %, and the minimum content can be less than 0.1 %, and the product can satisfy the high request for utilization, and the steps are simple, and the preparation cost is low.

Owner:韩国清

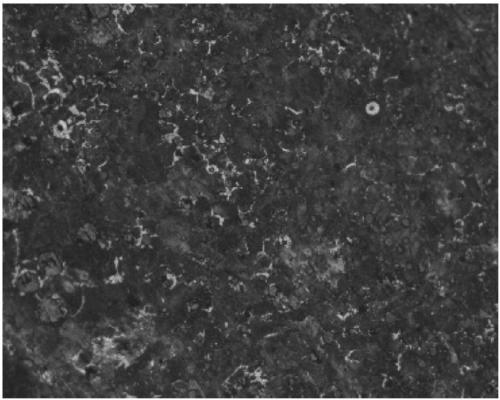

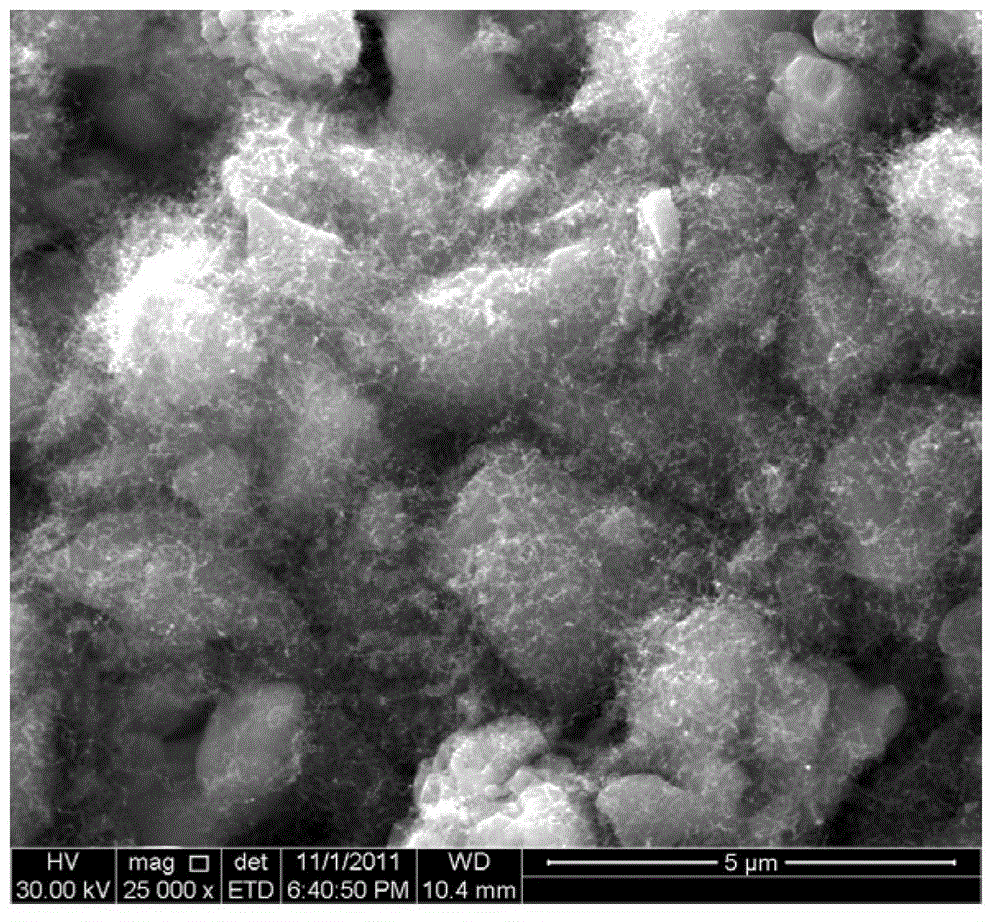

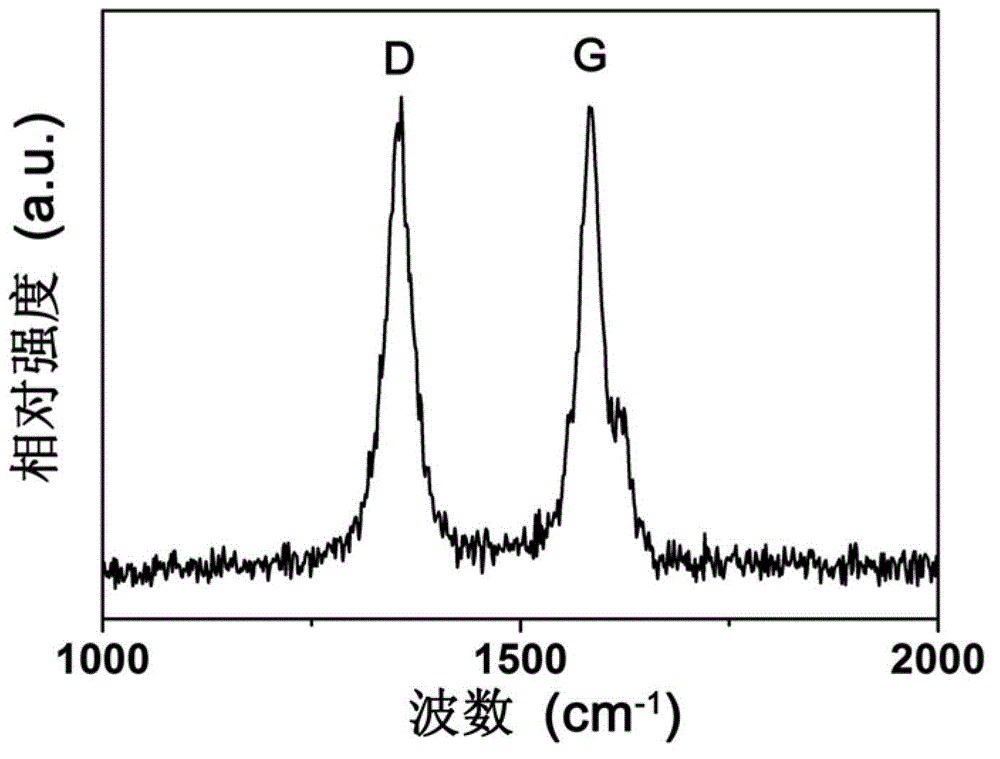

A kind of preparation method of in-situ growth carbon nanotube reinforced aluminum-based solder

ActiveCN103276322BHigh usage requirementsAddress stressWelding/cutting media/materialsSoldering mediaNitrateCarbon nanotube

Owner:HARBIN INST OF TECH

Aluminum strip material for capacitor shell and manufacturing method for aluminum strip material

The invention relates to manufacturing of an aluminum alloy material, in particular to an aluminum strip material for a capacitor shell and a manufacturing method for the aluminum strip material. The material comprises the following alloy components in percentage by weight: 0.2 to 0.3 percent of Si, 0.45 to 0.55 percent of Fe, 0.08 to 0.12 percent of Cu, 0.01 percent of Mn, 0.03 percent of Zn, 0.03 percent of Ti and the balance of Al. By optimizing the proportion of the alloy components and matching a low sub-cooling casting and rolling technology, an optimized cold rolling process and two annealing processes, the produced aluminum strip material for the capacitor shell has high precision, low aeolotropy, low earring rate and high forming rate, and meets relatively high using requirements; and compared with the conventional aluminum strip material produced by using 1100 alloy and used for the capacitor shell, the aluminum strip material has the advantages that: an annealing process isreduced, the production efficiency is improved, the energy is saved, and exhaust of waste gas is reduced.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

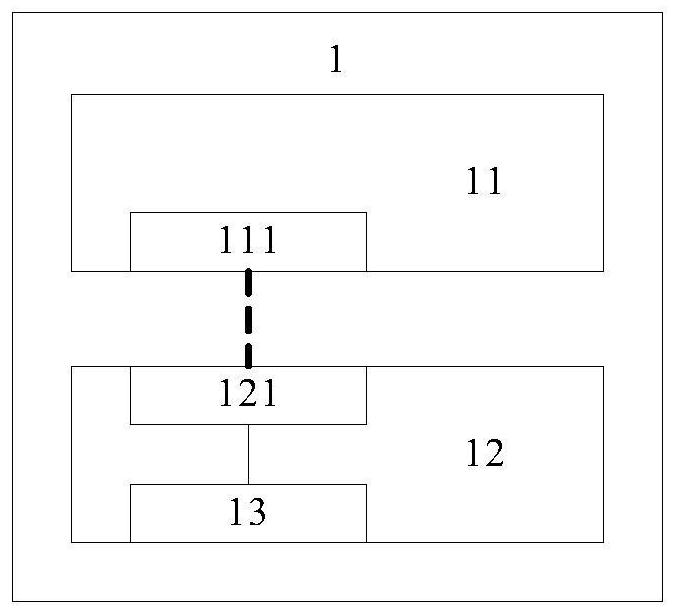

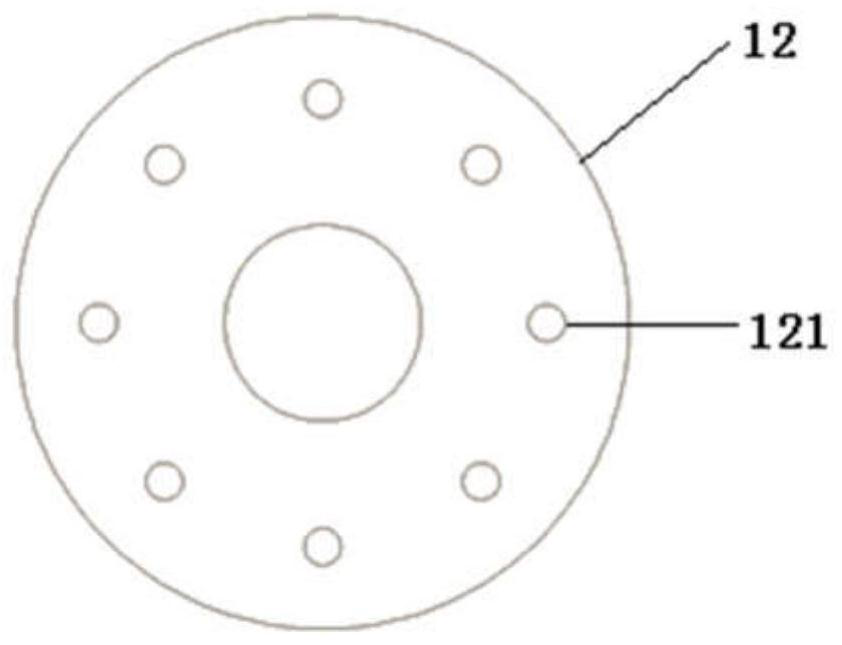

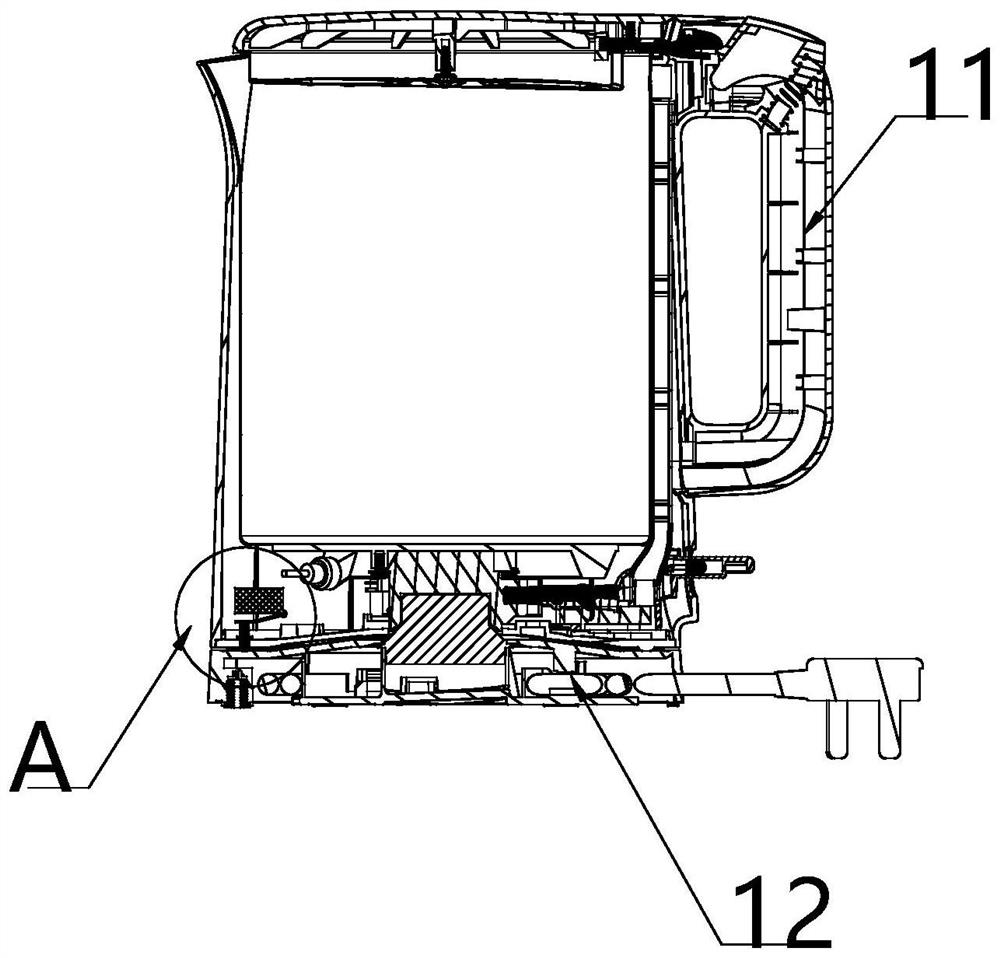

Operation method of household electrical appliance

ActiveCN113040601AHigh usage requirementsImprove user experienceWater-boiling vesselsBeverage vesselsPhysical medicine and rehabilitationControl cell

The invention relates to an operation method of a household electrical appliance, the household electrical appliance comprises a machine body and a machine body base matched with the machine body, and the method comprises the following steps: whether the machine body rotates relative to the machine body base is acquired through a detection unit; according to whether the machine body rotates relative to the machine base or not, a control unit generates a program control instruction and controls the execution unit to work; and a display unit displays the current working state of the household appliance according to the program control instruction of the control unit.

Owner:JOYOUNG CO LTD

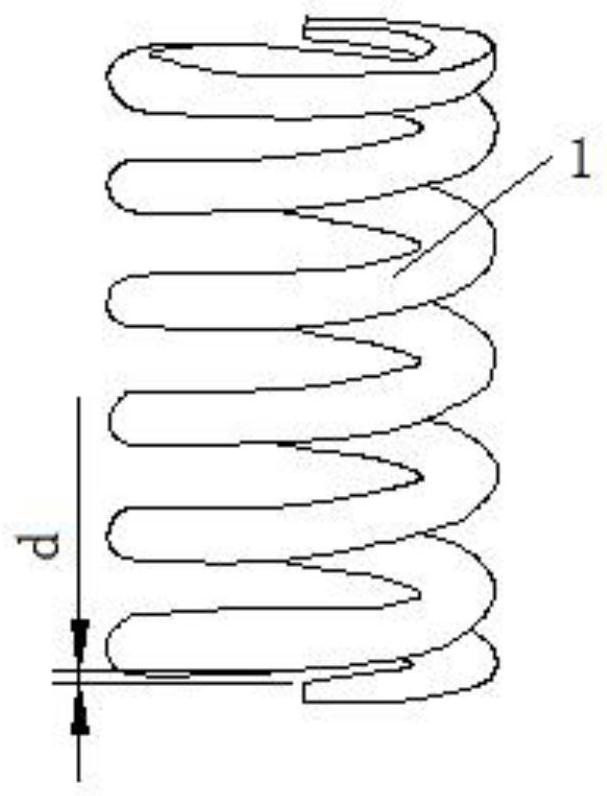

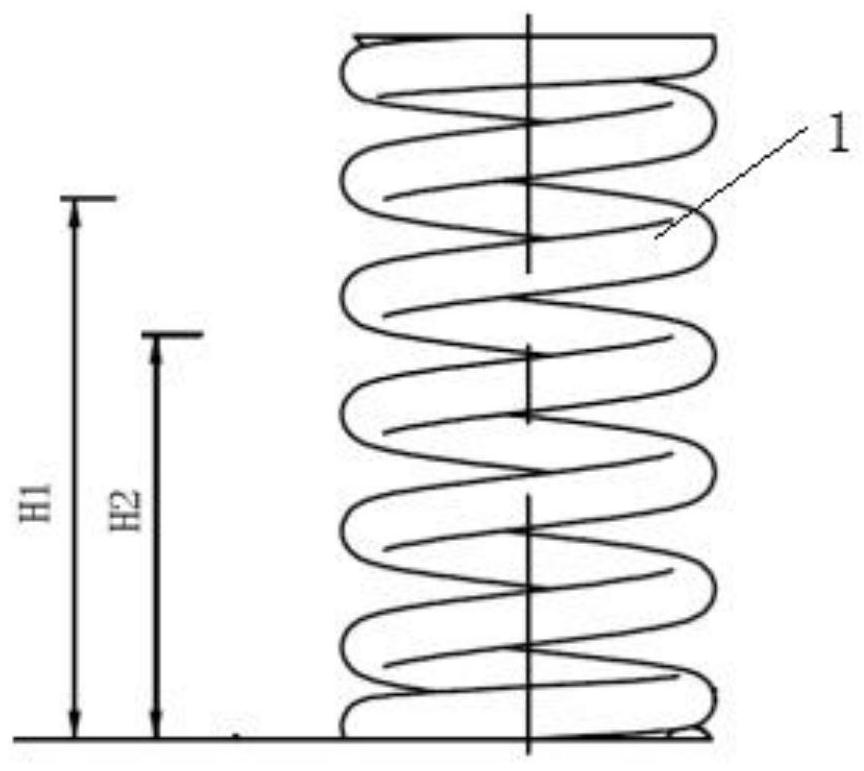

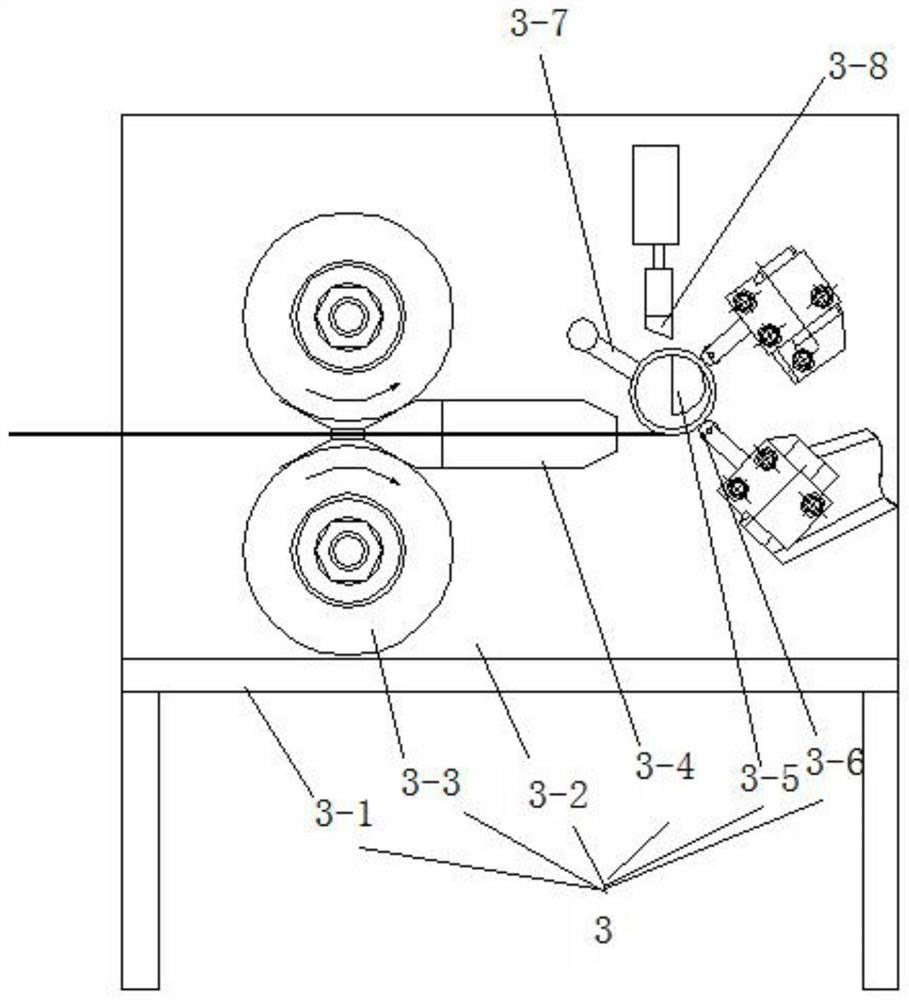

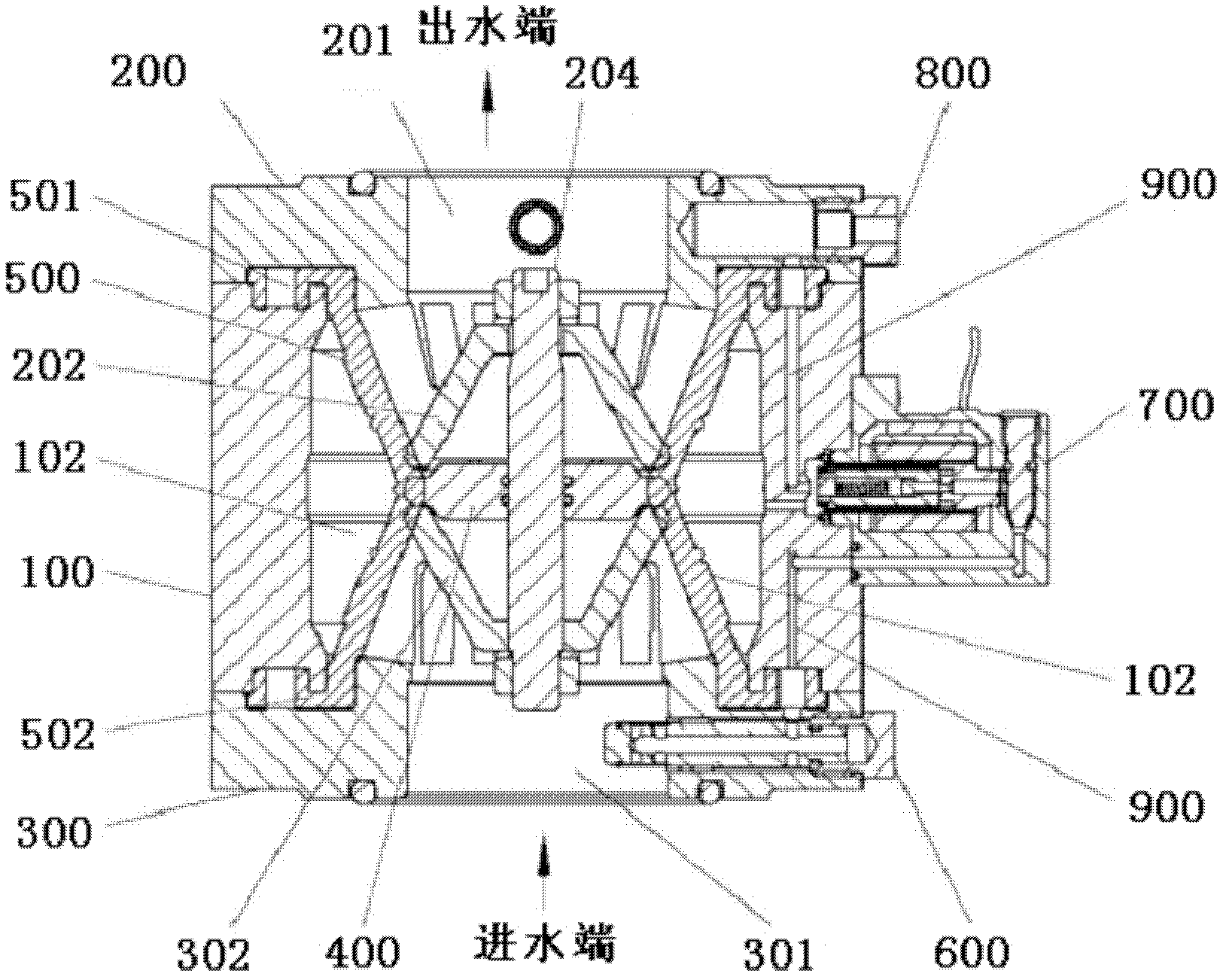

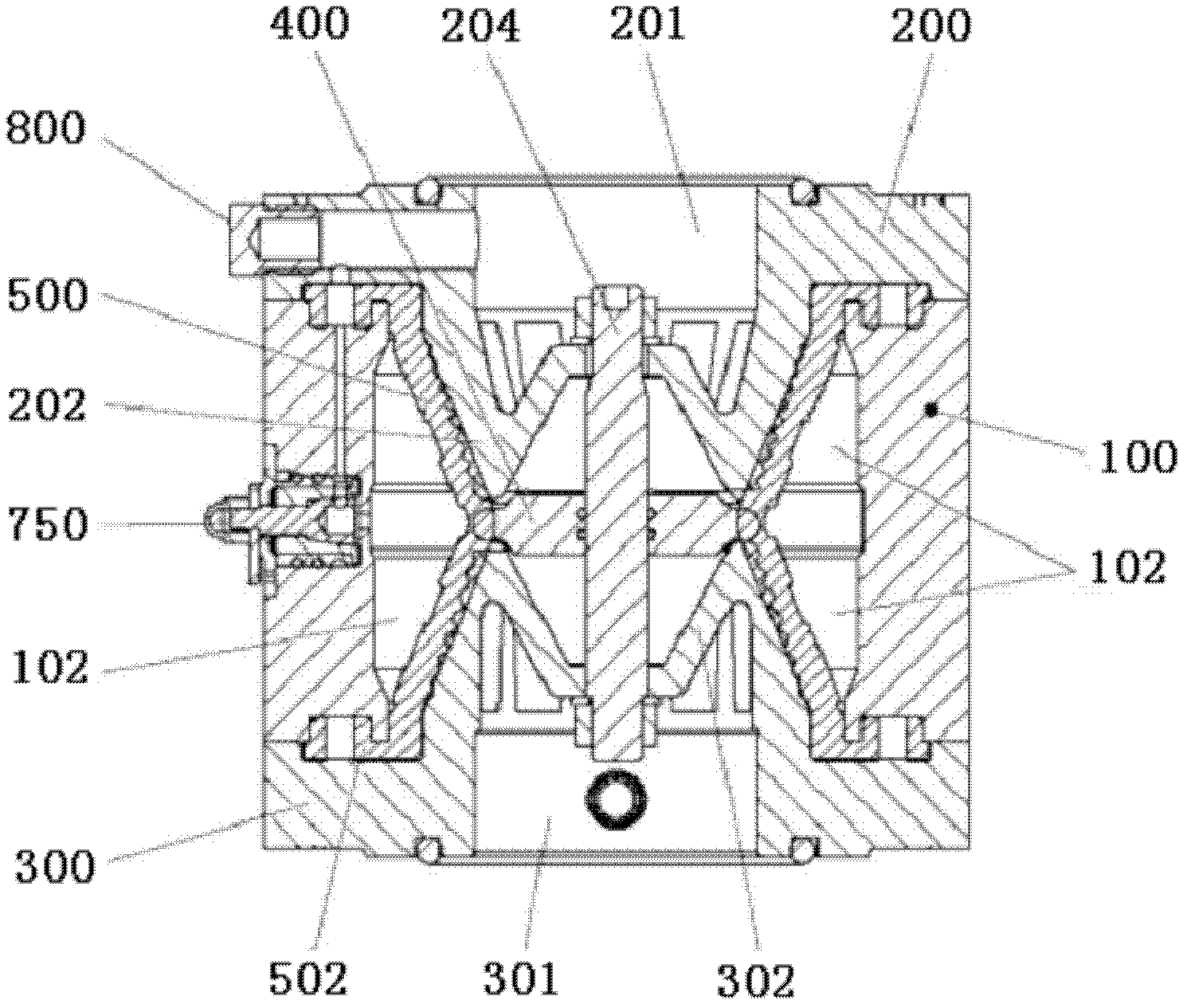

Compression spring with pre-pressed end and winding and detecting method of compression spring

ActiveCN113669396AImprove quality and usage requirementsAvoid situations where the end ring breaksMachine part testingAngles/taper measurementsStructural engineeringContact position

The invention discloses a compression spring with a pre-pressed end and a winding and detecting method of THE compression spring. The compression spring comprises a spring body, wherein gaps between the two ends of the spring body and a corresponding adjacent rings are d, and the size of a contact area of the ends and the adjacent rings is a pressing angle theta when the spring body is compressed to the designated position under stress; the pressing angle theta is an included angle formed by an indentation curve generated at the contact position of the spring end and the adjacent ring and the center position of the radian when sensing paper is used for measurement; in the winding process, a pitch of the spring body in the winding process is adjusted in time, so that the end of the spring is guaranteed to make full contact with an adjacent ring and exist after the two ends of the spring are ground; during detection, whether the end gap meets the requirement or not is judged firstly, if the end gap meets the requirement, then a pre-pressing angle is detected, so that the end and the adjacent ring are guaranteed to be tightly combined only when the end gap and the pre-pressing angle both meet the requirements. By changing the structure of the spring, the situation that a tail ring is prone to breakage after the spring is compressed due to stress is avoided.

Owner:安庆谢德尔汽车零部件有限公司

Energy-saving multifunctional clamping pipe control valve

InactiveCN102425683AEasy to passLow powerDiaphragm valvesOperating means/releasing devices for valvesControl valvesElectromagnetic coil

The invention discloses an energy-saving multifunctional clamping pipe control valve, which comprises a valve body, an upper end cover with a through hole, a lower end cover with a through hole, a middle ring, an elastic clamping pipe, a filter assembly, an electromagnetic coil and a quick joint; the upper end of the valve body is fixedly connected with the upper end cover, and the lower end of the valve body is fixedly connected with the lower end cover; the elastic clamping pipe is arranged in the cavity of the valve body; a buffering cavity is formed between the outer side of the elastic clamping pipe and the valve body; the upper end cover is provided with a fixed seat protruding into the inner cavity of the valve body; the middle ring is sleeved on the middle part of a bolt; and the filter assembly passes through the side wall of a lower valve cover, the electromagnetic coil assembly is arranged on the side wall of the valve body, and the quick joint passes through the side wall of an upper valve cover. The control valve is suitable for impurity-containing water or weak corrosive liquid; the power of the electromagnetic coil is only about 10W, so the velocity of opening and closing the valve can be automatically adjusted, the pressure is automatically stabilized, and the filter is automatically flushed; and when the electromagnetic coil cannot work, the control valve has manual opening and closing function.

Owner:BEIJING LIBOMING TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com