Preparation method of low-magnetism stainless steel medium plate with yield strength being 785MPa

A yield strength and stainless steel technology, which is applied in the field of low-magnetic stainless steel medium and thick plates, can solve the problems of reduced yield strength of steel plates and unreachable yield strength of thick plates, so as to avoid deformation structure, coarse structure, decomposition and aggregation growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

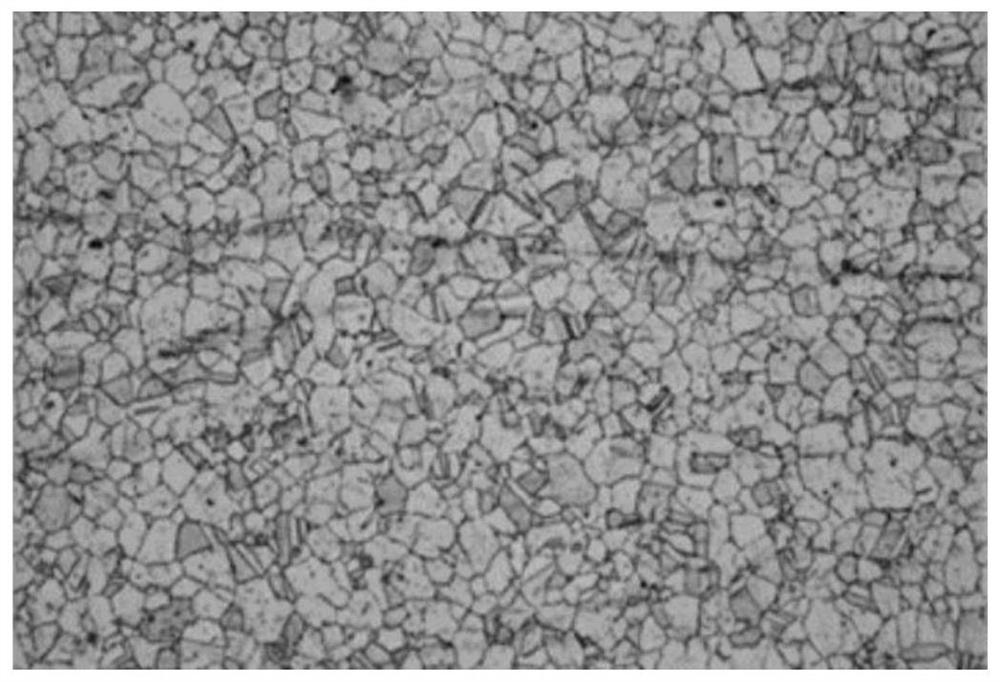

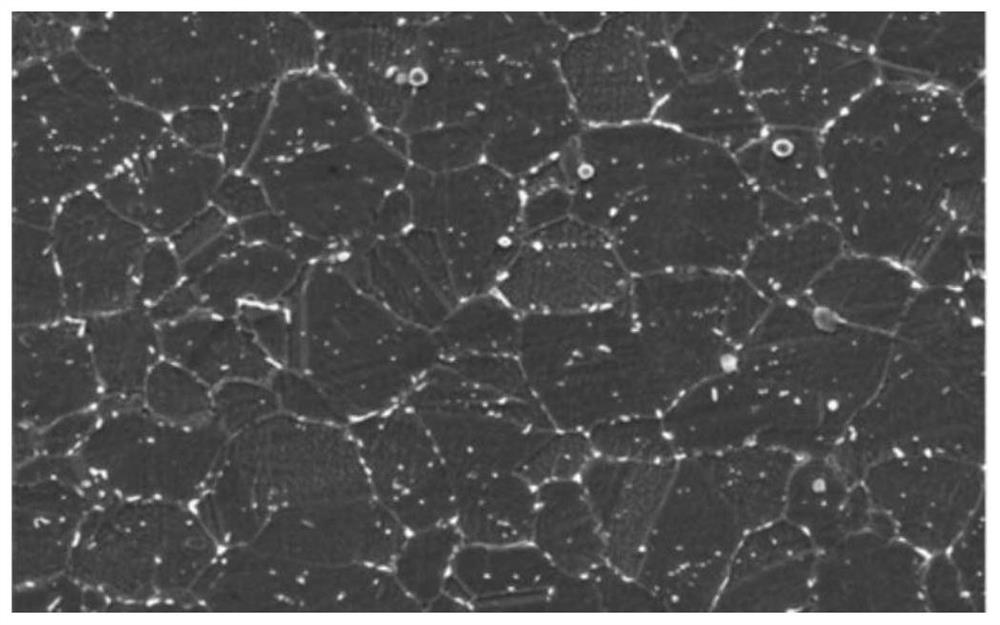

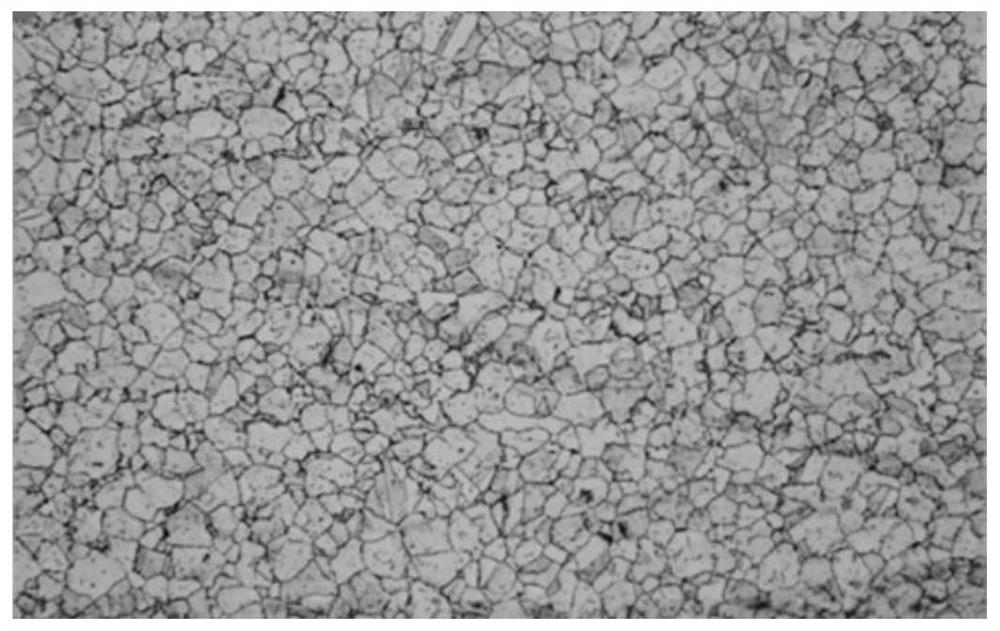

Image

Examples

Embodiment 1

[0035] A preparation method for a low-magnetic stainless steel plate with a yield strength of 785MPa, comprising the steps of:

[0036] 1. Vacuum smelting: batching according to the set chemical composition: weight percentage C: 0.07%, Si: 0.2%, Mn: 1.8%, Mo: 2.1%, Cr: 14%, Ni: 21%, Nb: 0.6%, Ti: 2.2%, Al: 1.1%, P≤0.05%, S≤0.05%, and the balance is Fe. Vacuum induction furnace is used for smelting. First, pure iron and aluminum-containing deoxidizer are added. After vacuuming for 40 minutes, argon gas is poured into the furnace to reach 0.09MPa. , Cr, Ni, Mo, Ti, and Al are added to the melting furnace in sequence, and after electromagnetic stirring, the tapping temperature is 1500-1600°C, and cast into 4 rod-shaped ingots of Φ100*600;

[0037] 2. Electroslag remelting: Weld four rod-shaped ingots of Φ100*600 into one long ingot, and obtain an electroslag ingot of Φ166mm*624mm after electroslag remelting;

[0038] 3. Forging: The heating temperature before electroslag ingot ...

Embodiment 2

[0046] A preparation method for a low-magnetic stainless steel plate with a yield strength of 785MPa, comprising the steps of:

[0047] 1. Vacuum smelting: batching according to the set chemical composition: weight percentage C: 0.06%, Si: 0.2%, Mn: 2%, Mo: 2%, Cr: 16%, Ni: 23%, Nb: 0.5%, Ti: 2.4%, Al: 1.1%, P≤0.05%, S≤0.05%, and the balance is Fe. Vacuum induction furnace is used for smelting. First, pure iron and aluminum-containing deoxidizer are added. After vacuuming for 40 minutes, argon gas is poured into the furnace to reach 0.09MPa. , Cr, Ni, Mo, Ti, and Al are added into the melting furnace in sequence, and after electromagnetic stirring, the tapping temperature is 1500-1600°C, and cast into rod-shaped ingots;

[0048] 2. Electroslag remelting: Weld four rod-shaped ingots of Φ100*600 into a long ingot, and obtain an electroslag ingot of Φ174mm*621mm after electroslag remelting;

[0049] 3. Forging: The heating time before electroslag ingot forging is greater than o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com