One-way moisture conduction towel fabric and production method thereof

A production method and unidirectional wet-guiding technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of poor quick-drying, inability to meet consumer needs, reduced fabric feel and comfort, and achieve good hand feel , good heat retention, and the effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A method for producing a unidirectional wet guide towel fabric, comprising the following steps:

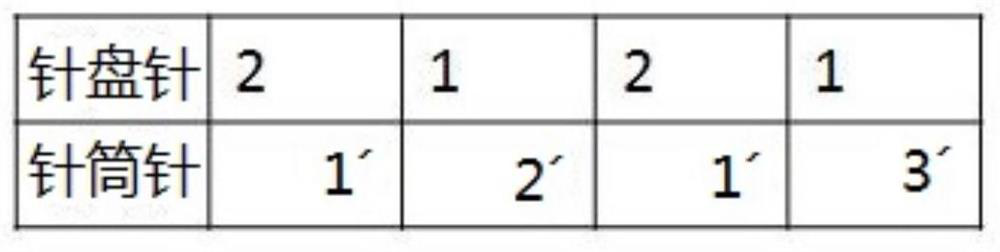

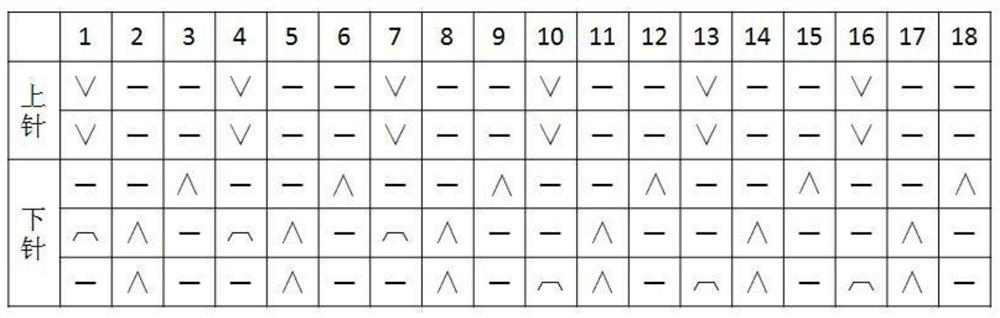

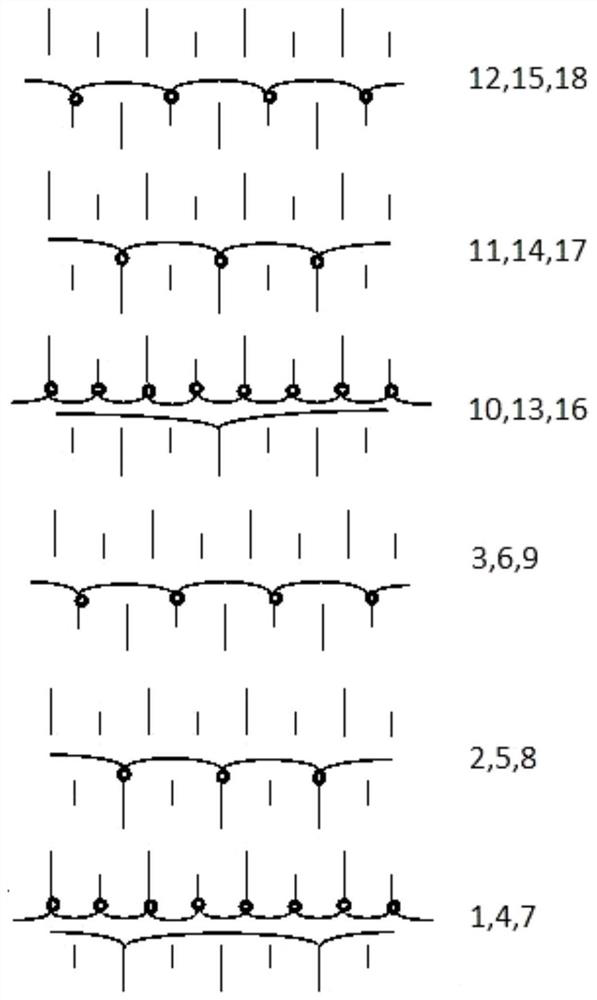

[0027] Provide a double-sided machine, arrange the triangles and knitting needles according to the fabric design requirements; the dial needles in the knitting needles include two kinds of knitting needles with butts ( figure 1 Marked as 1, 2), cylinder needles include three types of butt knitting needles ( figure 1 marked as 1', 2', 3'); such as figure 1 As shown in the arrangement of knitting needles, the two needles of the dial needle are arranged one by one, and the arrangement of the cylinder needles adopts a cycle of four needles. The second stitch, the first stitch, and the third stitch; the triangular arrangement method is as follows figure 2 shown; among them, figure 2 "∨∧" in the formula means circled triangle; "─" means floating line triangle; "︹" means tucked triangle;

[0028] Yarns are provided, and the yarns include ordinary yarns and sea-island yarns; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com