Patents

Literature

41results about How to "Good moisture absorption and quick drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-layer knitted fabric with functions of moisture absorption, quick drying and antibiosis

InactiveCN102094286AGood moisture absorption and quick dryingGood antibacterial effectWeft knittingYarnWater transferYarn

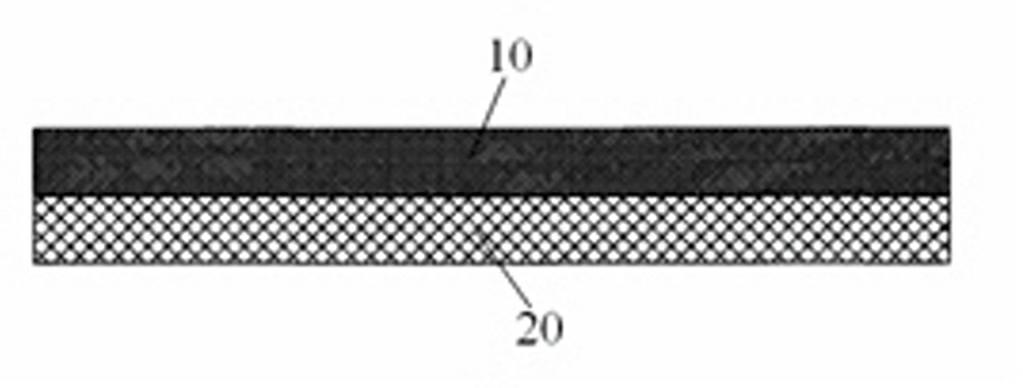

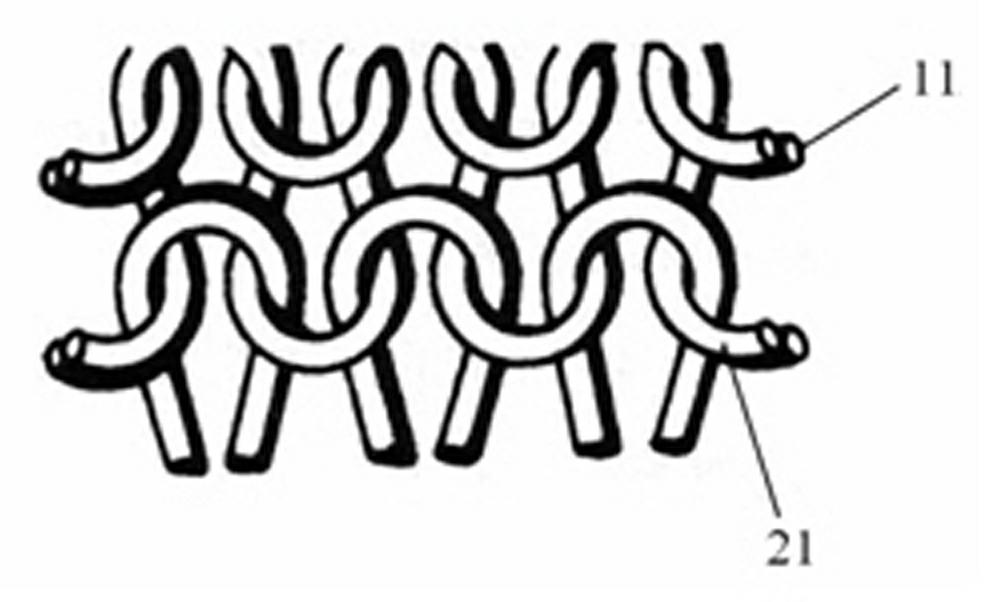

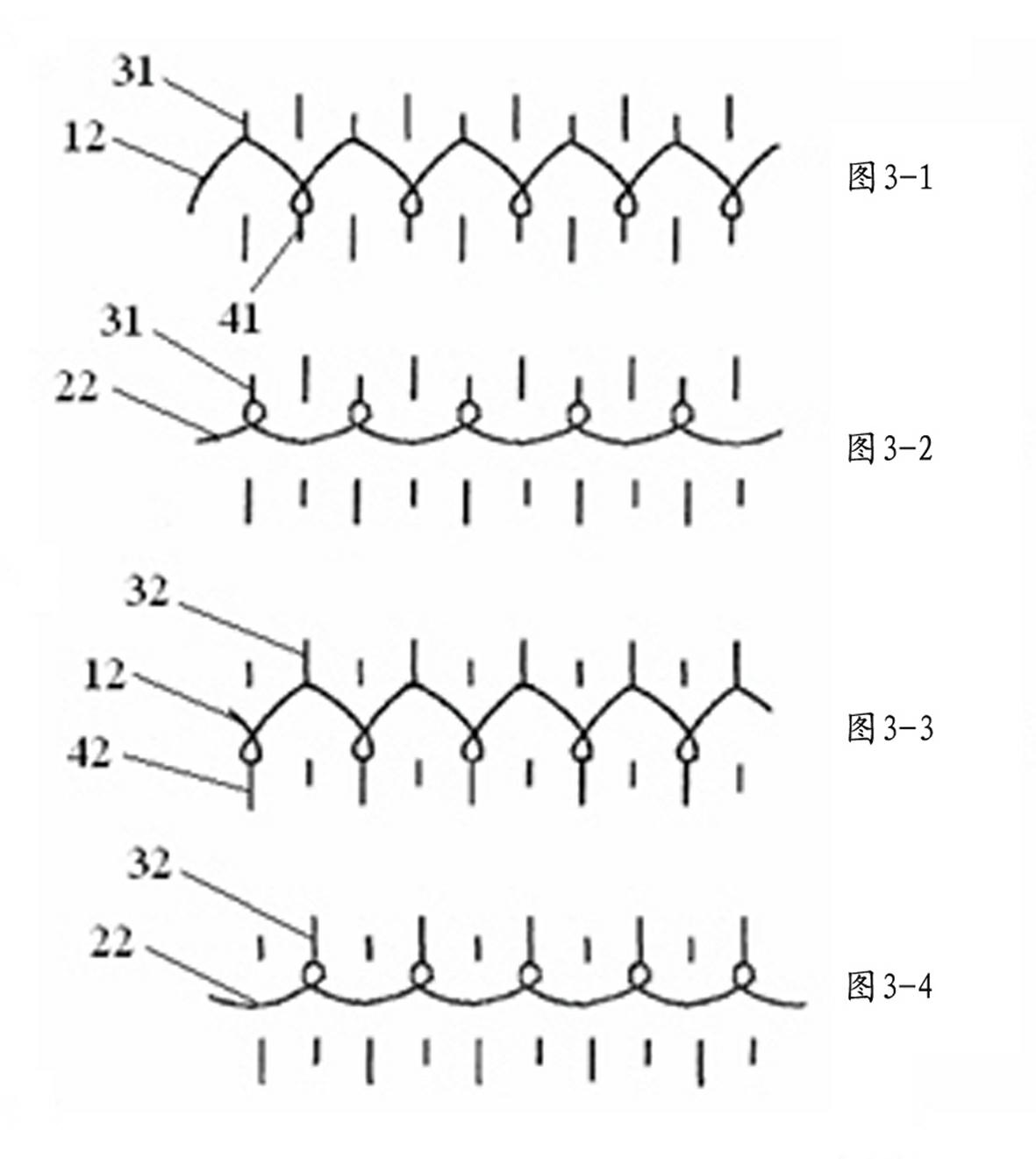

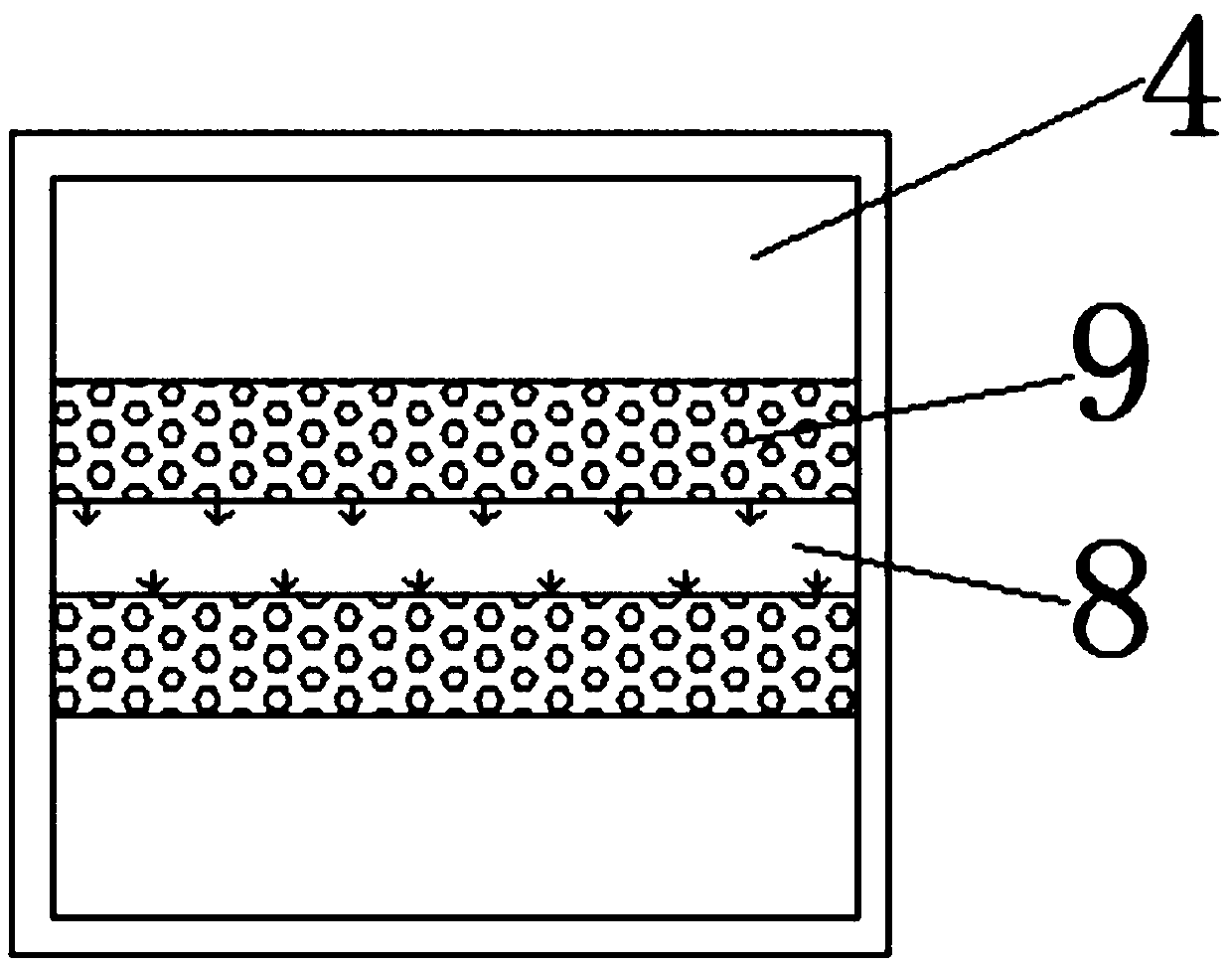

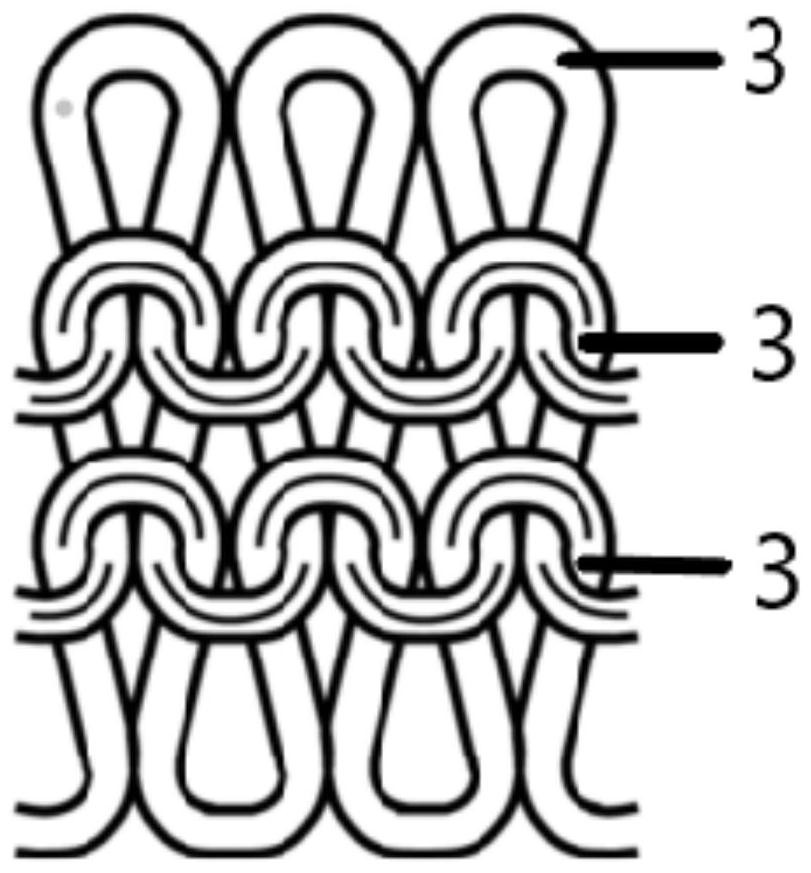

The invention discloses a double-layer knitted fabric with functions of moisture absorption, quick drying and antibiosis, which comprises an outer layer and an inner layer, wherein the outer layer is made of hydrophilic yarns; and the inner layer is made of moisture conducting and sweat exhausting yarns containing an antibiosis substance; and the outer-layer yarns are connected with the inner-layer yarns by knitting structures. In the invention, power for water transfer is provided by virtue of an inner-layer and outer-layer difference between the outer layer made of the hydrophilic yarns and the inner layer made of the moisture conducting and sweat exhausting yarns; and the moisture and sweat of skin can quickly permeate to the outer layer by the inner layer, and the inner layer keeps dry, therefore, the favorable moisture absorbing and quick drying functions can be achieved. Meanwhile, the antibiosis substance in the inner yarn can be in favorable contact with the skin, a good antibiosis effect is ensured, and various skin diseases can be effectively prevented and treated.

Owner:广东名鼠股份有限公司

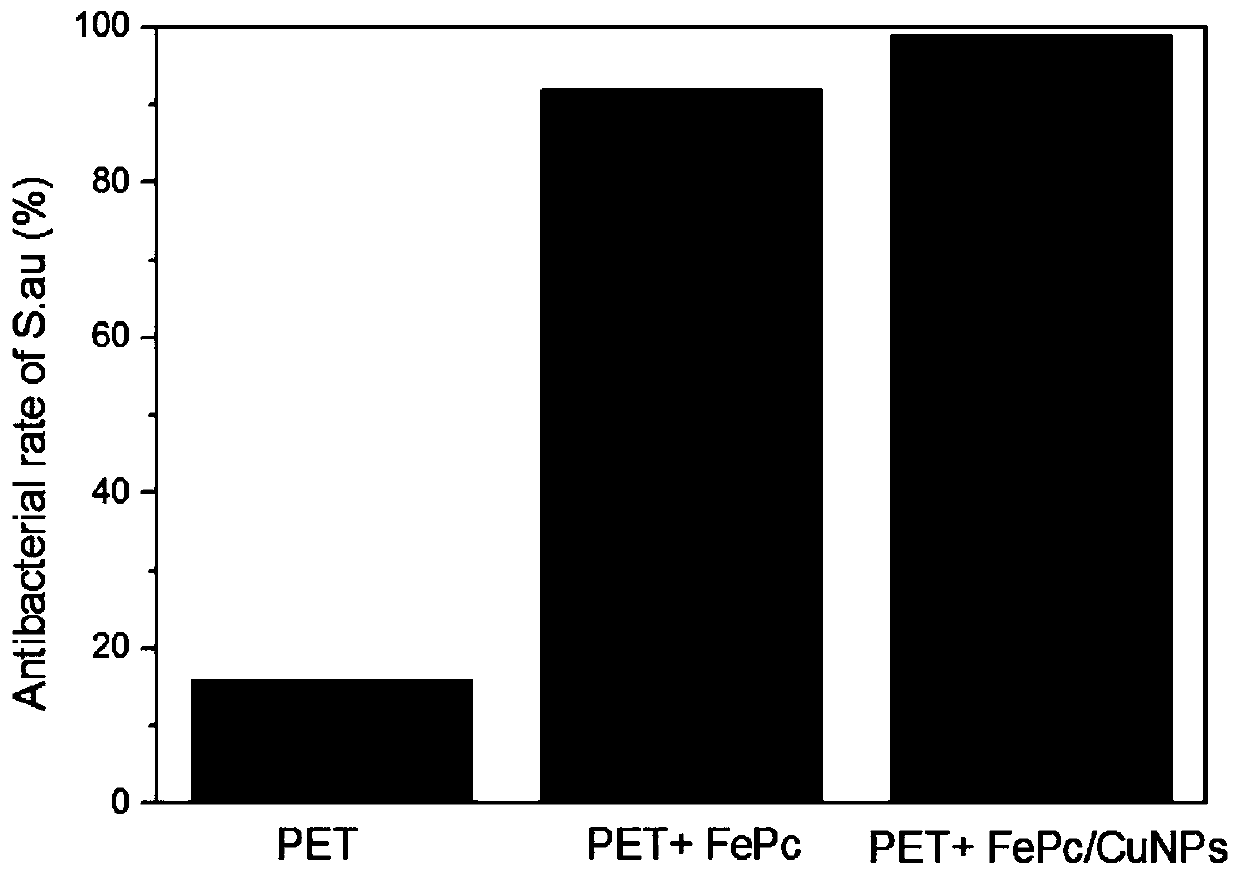

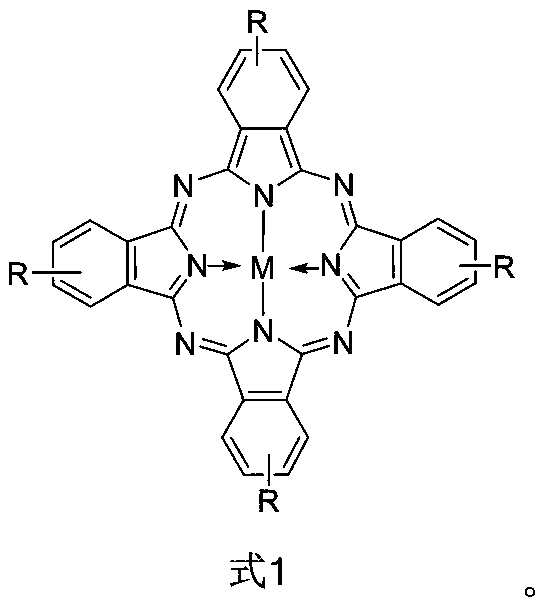

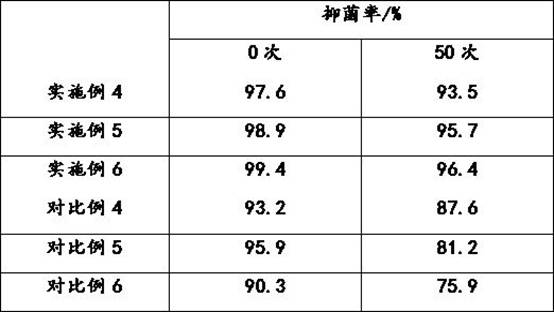

Catalytic composite anti-bacterial fiber and preparation method and application thereof

ActiveCN109797450AImprove liquidityImprove surface activityFilament/thread formingMonocomponent polyesters artificial filamentPolyesterFiber

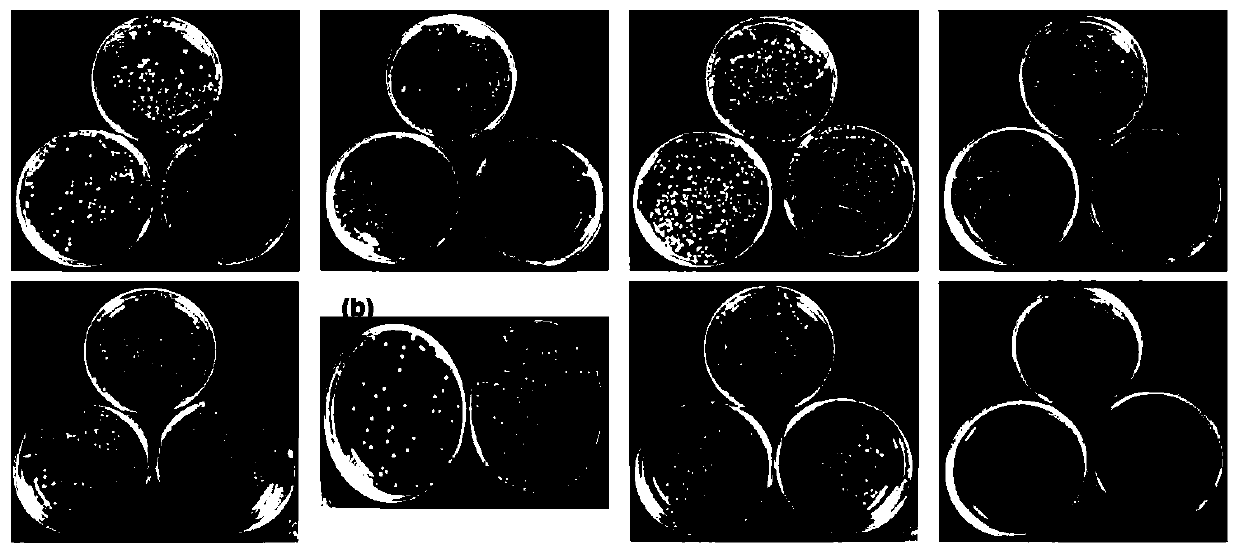

The invention provides a preparation method for a catalytic composite anti-bacterial fiber, and belongs to the field of fiber materials. The catalytic composite anti-bacterial fiber is prepared by performing profiled spinning treatment on a functional master batch and a polymer matrix. The functional master batch comprises a composite anti-bacterial catalyst, an additive and a high polymer. The composite anti-bacterial catalyst comprises nano metal particles and a photocatalyst. The high polymer and the polymer matrix independently comprise polyester or polyamide. The catalytic composite anti-bacterial fiber is capable of selecting the nano metal particles and the photocatalyst as the composite anti-bacterial catalyst, so the catalytic composite anti-bacterial fiber has the better anti-bacterial effect compared with the anti-bacterial fiber with a single anti-bacterial catalyst, and through using the additive, flowability and surface activity of the anti-bacterial catalyst are increased, so the anti-bacterial catalyst is uniformly distributed in the polymer matrix, and the composite anti-bacterial catalyst is prevented from being aggregated while mixed.

Owner:ZHEJIANG SCI-TECH UNIV

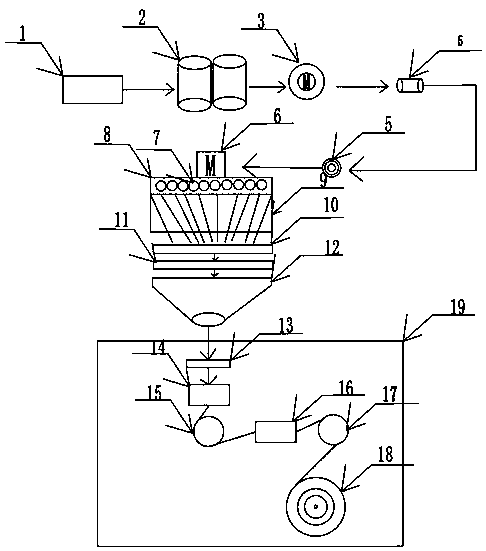

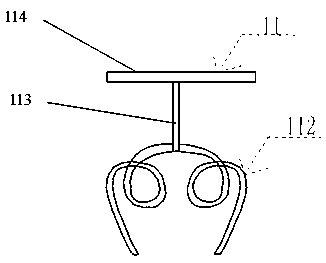

Production equipment of hydrophilic moisture-conducting secondary plied porous fibers and production method of porous fibers

InactiveCN110616469AStrengthen bondageUniform tensionNew-spun product collectionArtificial thread manufacturing machinesPorous fiberMoisture

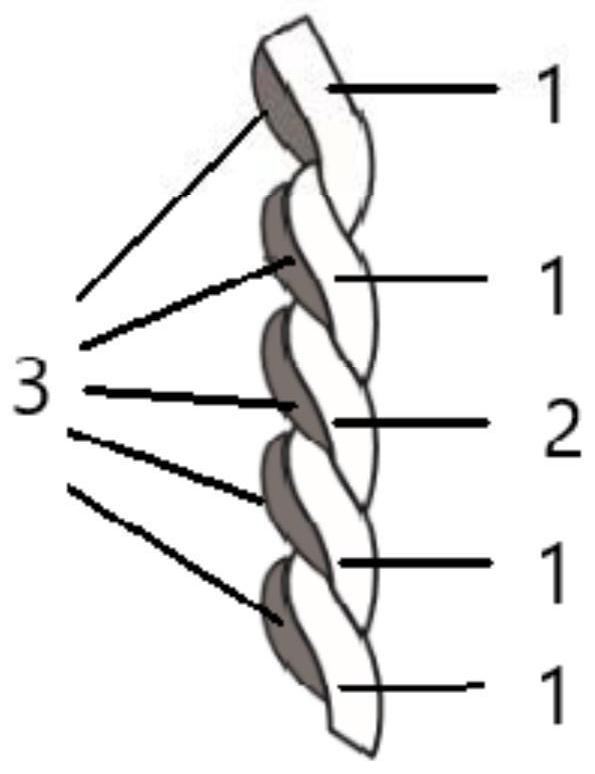

The invention provides production equipment of hydrophilic moisture-conducting secondary plied porous fibers and a production method of porous fibers. In the production equipment of the hydrophilic moisture-conducting secondary plied porous fibers, a single-rod double-end two-way guider mainly features two-way guidance, so that the binding of the guider to tows is strengthened; the two tows, before being plied, are symmetrically deviated from the angular direction of the guider, the uniform tension of the two tows is ensured, the friction between the two tows before and after plying is reduced, fiber branching and breaking are avoided, and yarn drifting and broken ends are avoided, yarn skipping during winding switching is avoided, the problems, such as hairy fiber falling during cake winding, are avoided, and product quality is improved.

Owner:JIANGSU DELI CHEM FIBER CO LTD

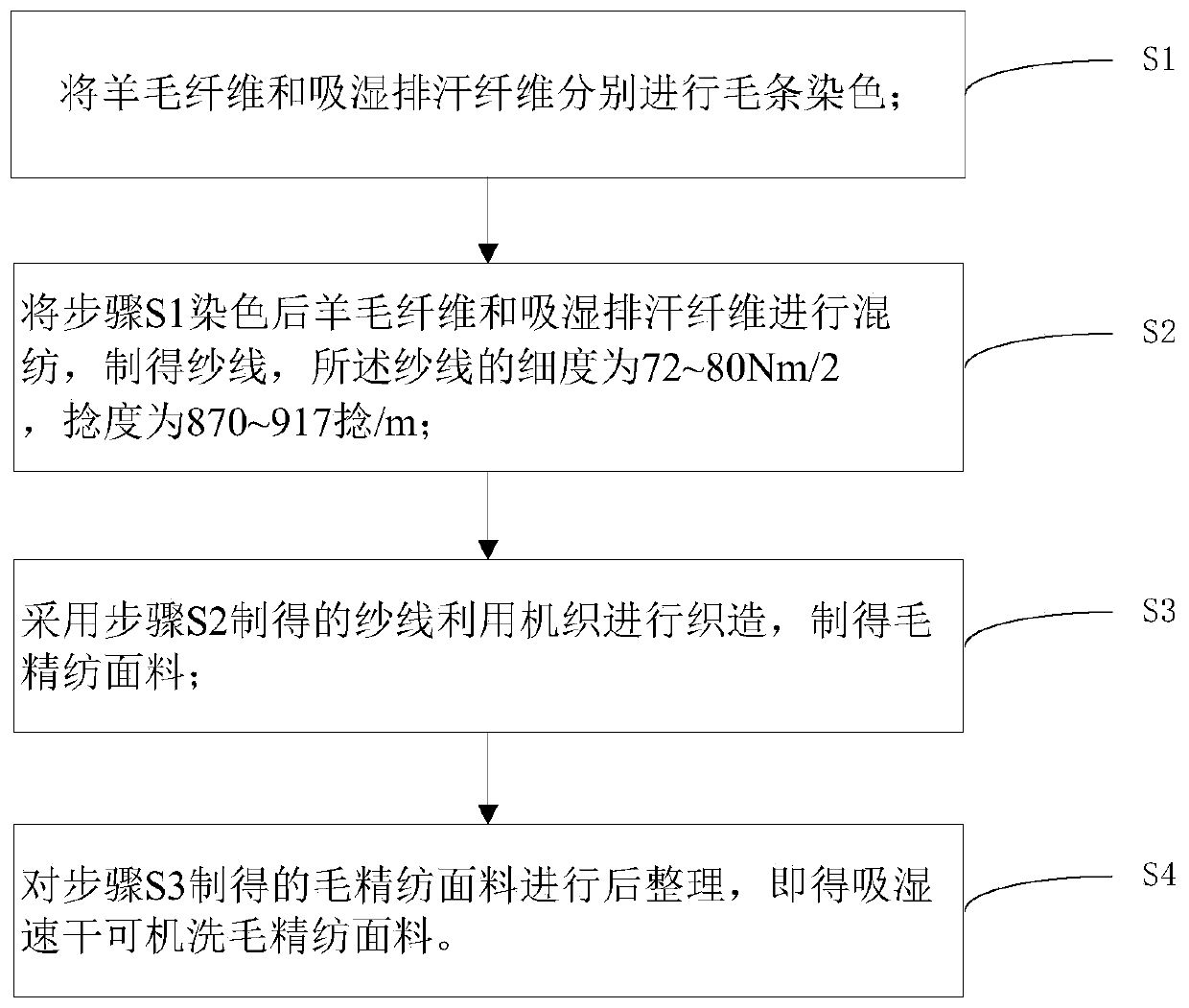

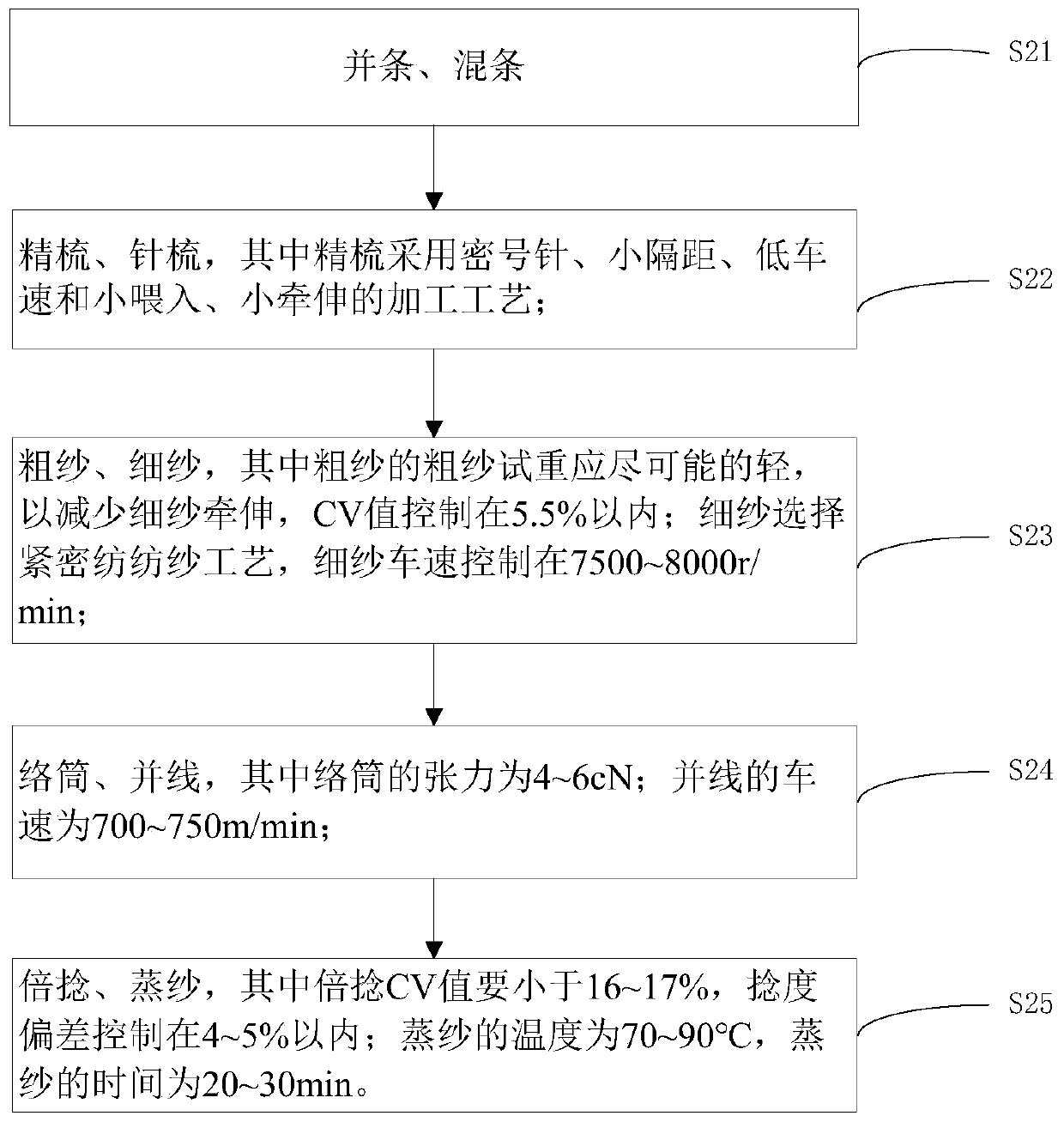

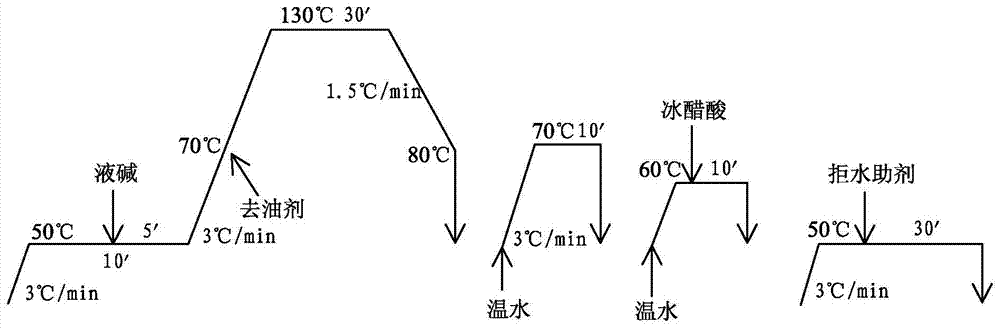

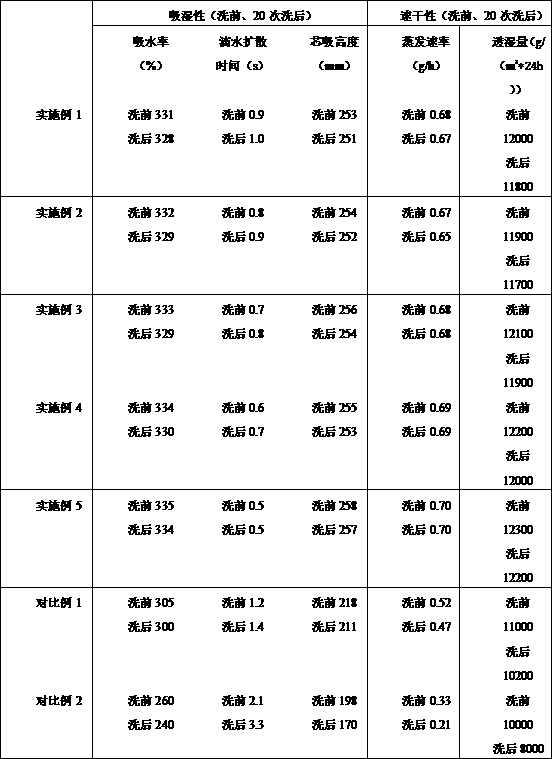

Moisture absorbing and quick-dry machine washable wool worsted fabric and production method thereof

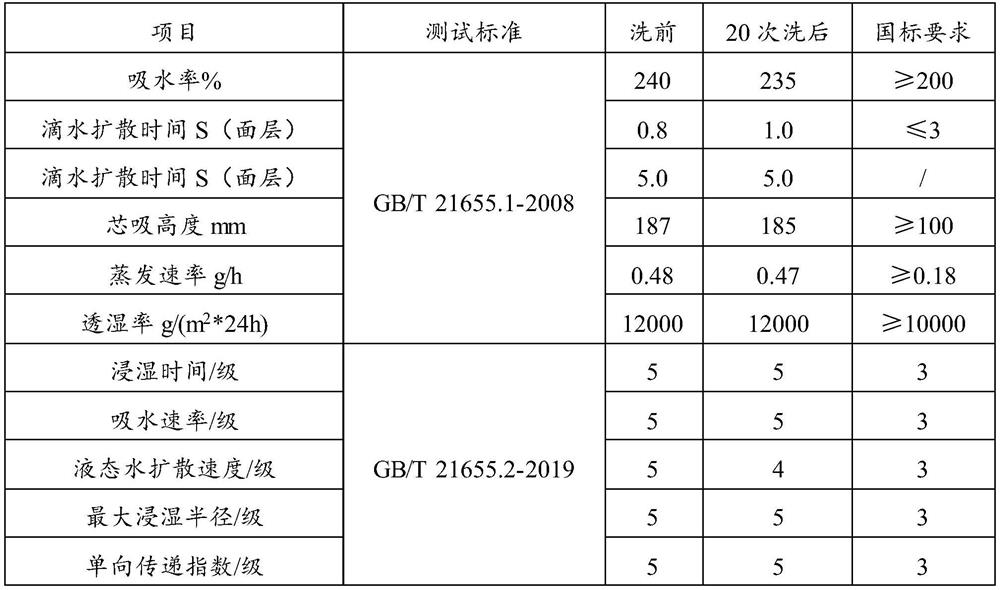

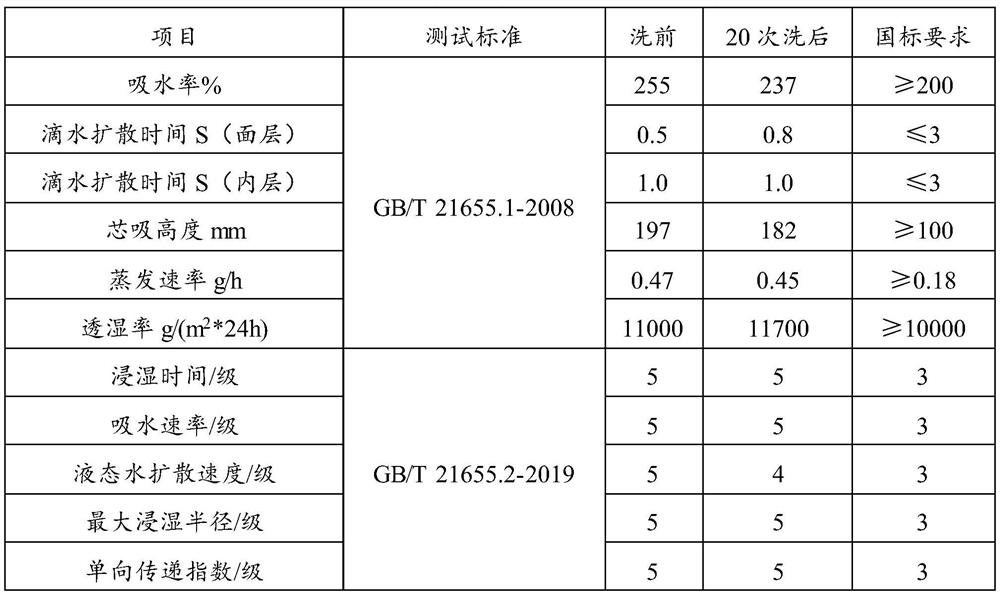

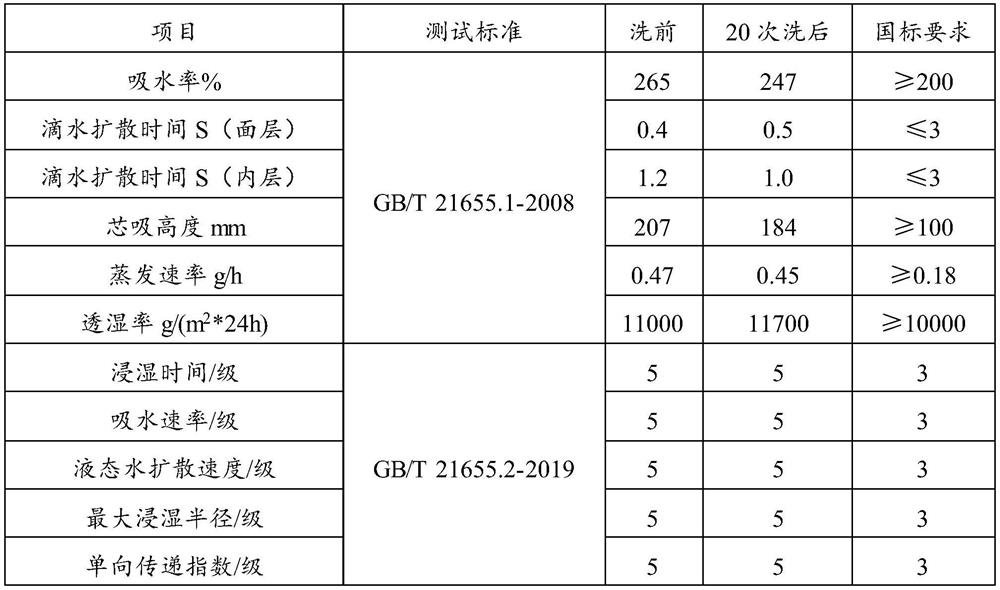

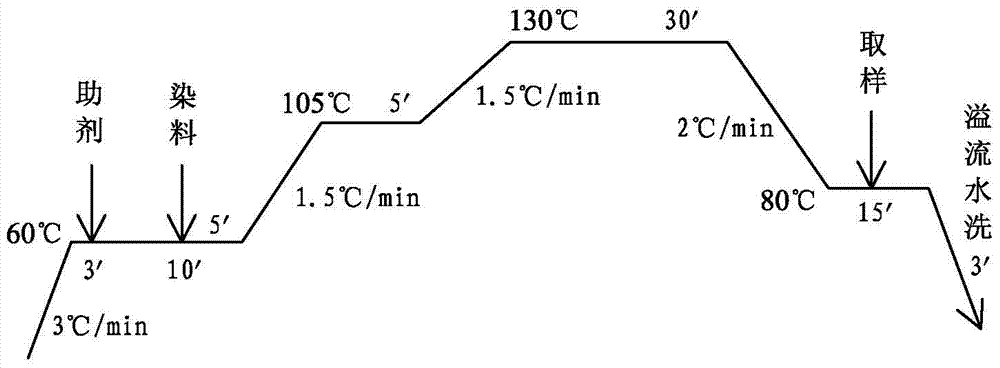

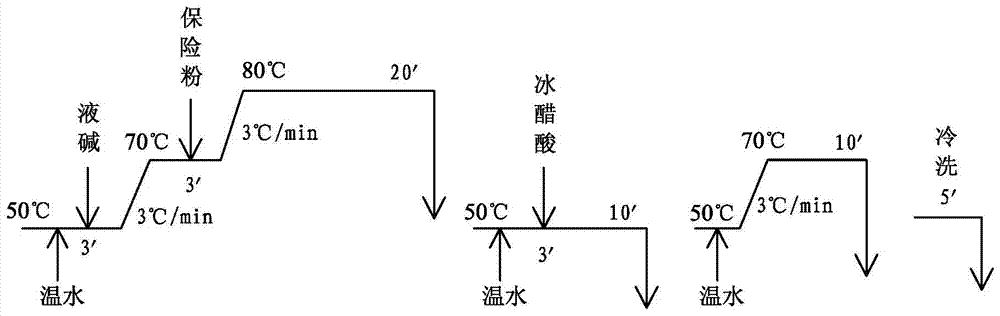

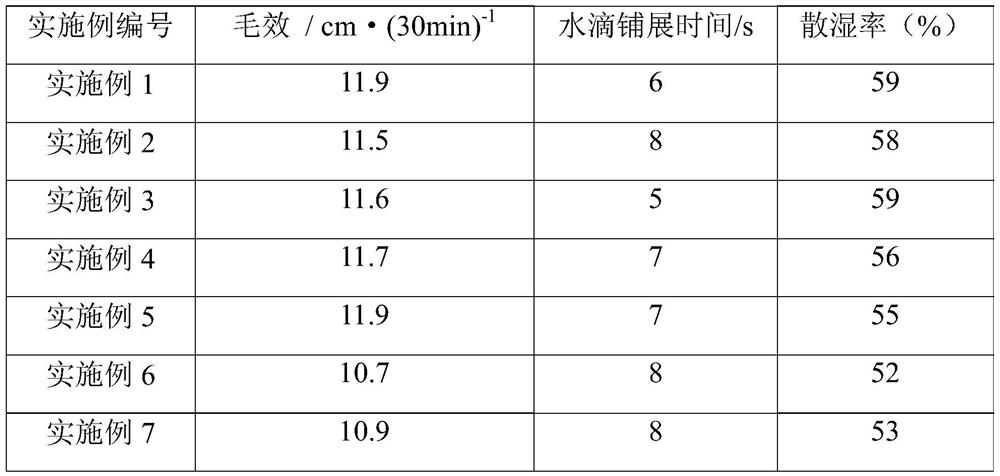

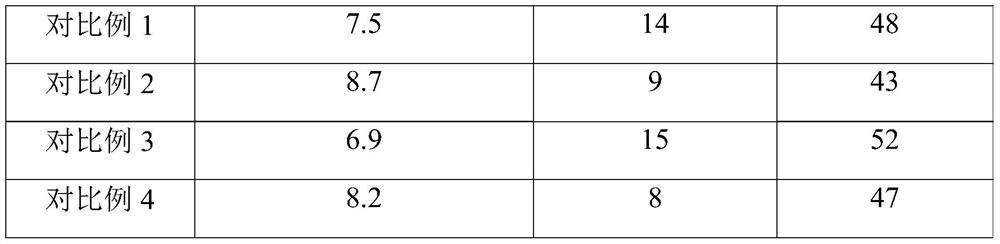

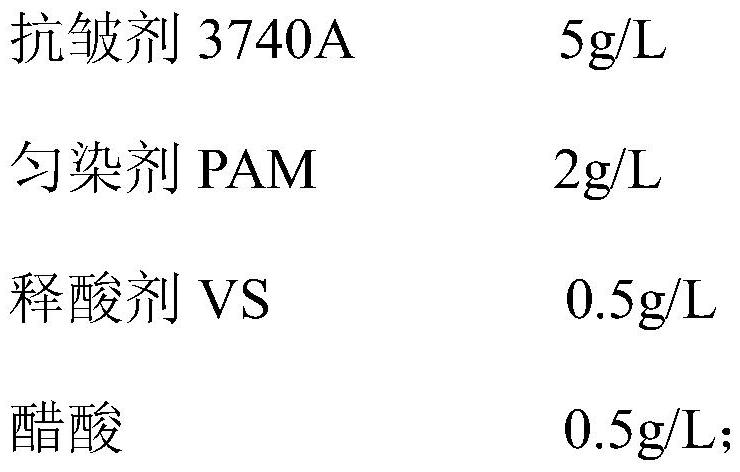

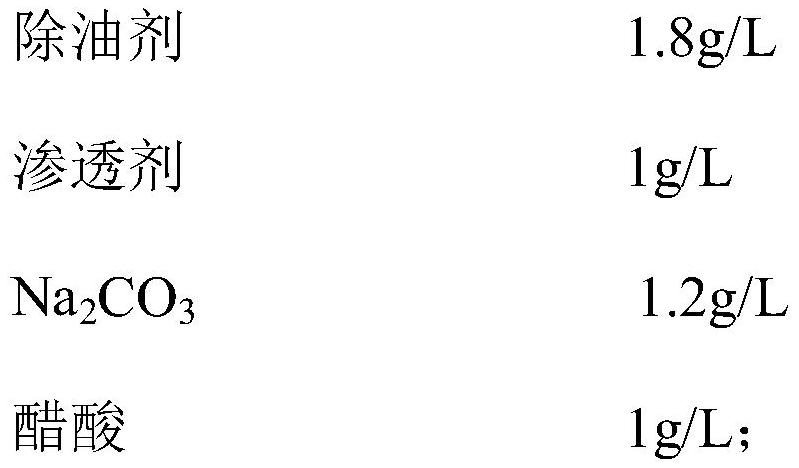

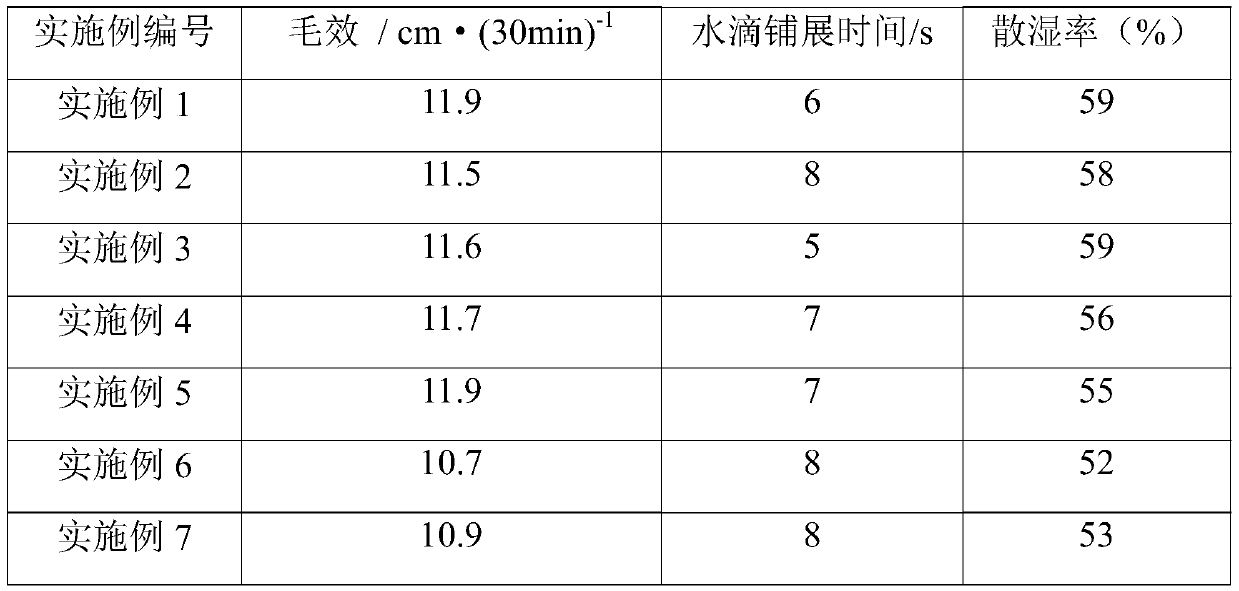

ActiveCN109825925ASolve stuffySolve the shortcomings of poor moisture absorption and perspirationFilament/thread formingDyeing processYarnAfter treatment

The invention relates to a moisture absorbing and quick-dry machine washable wool worsted fabric and a production method thereof. The fabric is formed by blending wool fiber and moisture absorbing andperspiring fiber through wool top dyeing, spinning, weaving and after-treatment; the production method comprises the steps that wool fiber and the moisture absorbing and perspiring fiber are dyed separately, then, the dyed wool fiber and the moisture absorbing and perspiring fiber are blended to obtain blended yarn with the fineness being 72-80 Nm / 2 and the twist degree being 870-917 twist / m, theblended yarn is woven by means of a weaving machine to obtain the wool worsted fabric, and finally after-treatment is performed to obtain the moisture absorbing and quick-dry machine washable wool worsted fabric. The problems that in the prior art, a pure wool fabric is stuffy in summer and poor in moisture absorbing and perspiring performance are solved, and the wool worsted fabric is thin in texture, good in touch, good in breathability, good in moisture absorbing and quick-dry performance, stable and lasting in function and environmentally friendly and saves energy, and has the machine washable function; the application limit of wool fiber as the summer fabric is broken through, the various requirement for modern society is met, and the good application and popularization value is achieved.

Owner:山东如意毛纺服装集团股份有限公司 +1

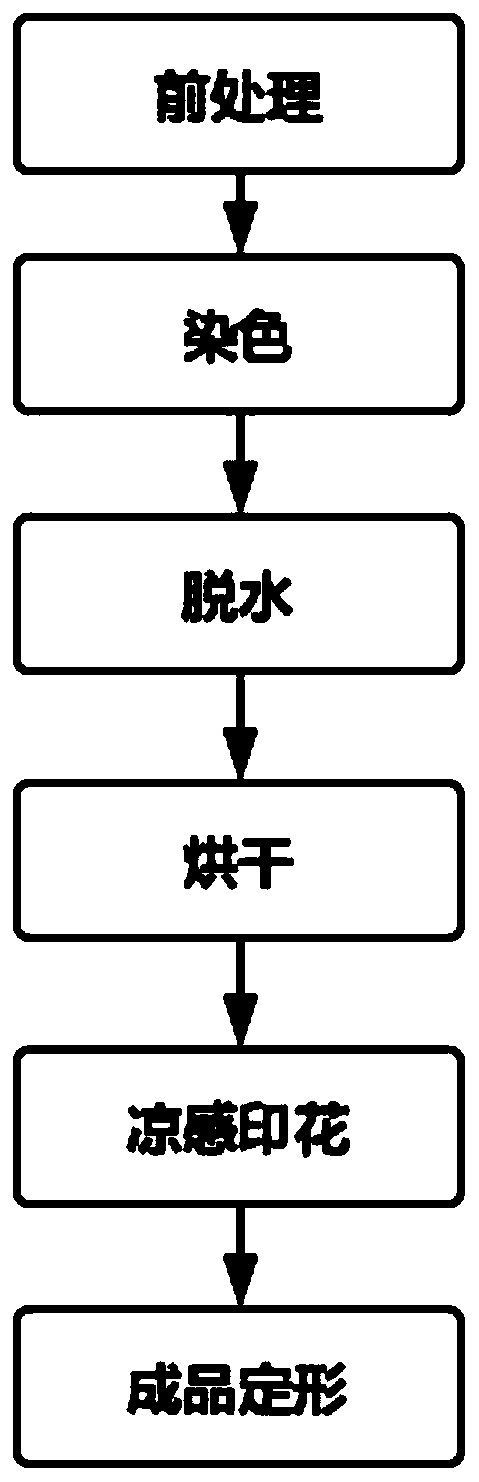

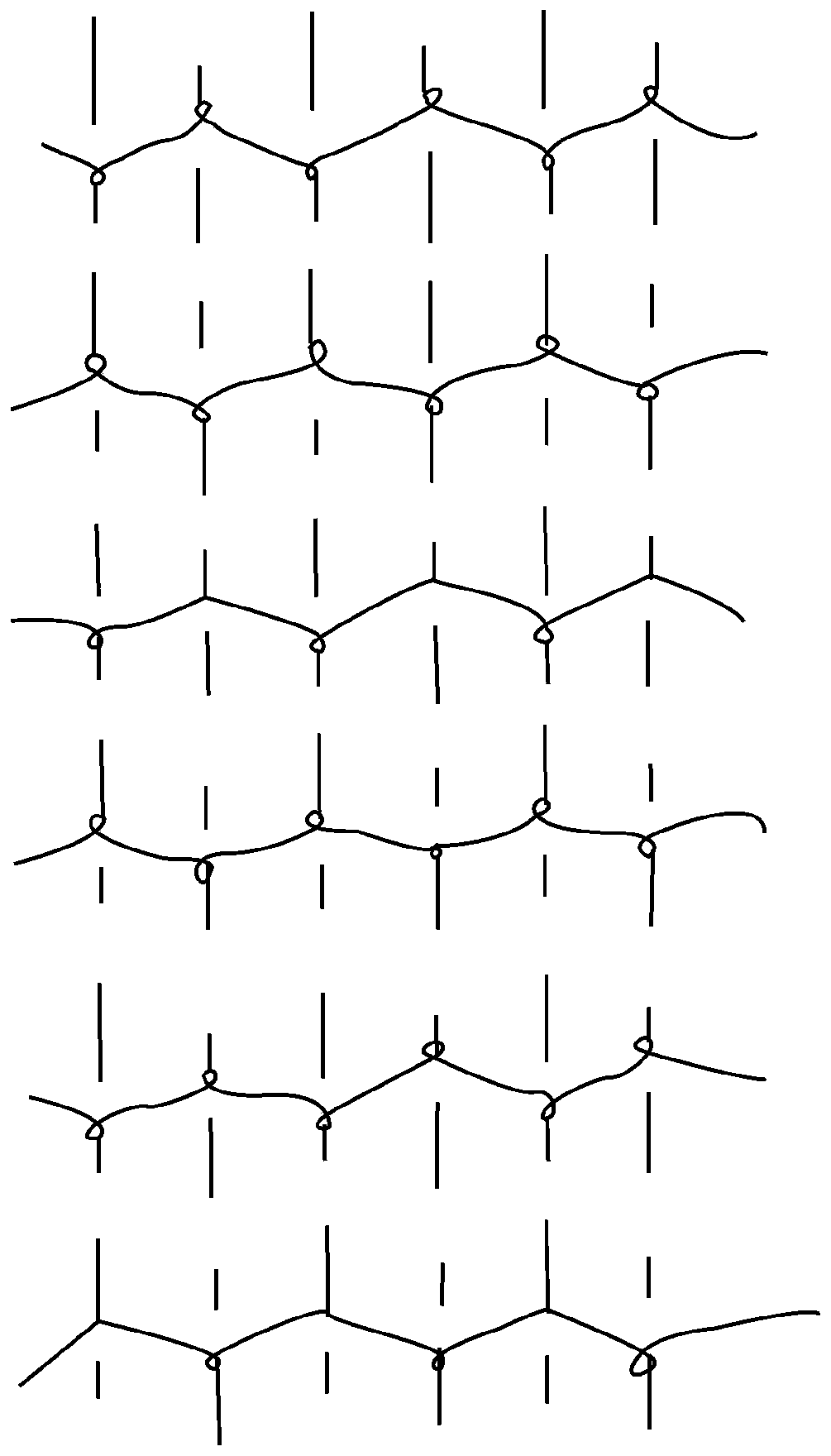

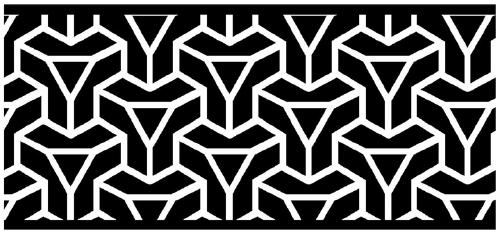

Preparation method of knitted fabric with moisture absorption and sweat releasing and continuous cool feeling functions

InactiveCN111058168AGood moisture absorptionFunction increaseWeft knittingDyeing processPolyesterColour fastness

The invention discloses a preparation method of a knitted fabric with moisture absorption and sweat releasing and continuous cool feeling functions. According to the preparation method, chemically andphysically modified polyester filaments are taken as raw materials, a weaving process and a dyeing and finishing process are adopted, and the knitted fabric is designed into a honeycomb or mesh double-sided tissue structure; and a printing paste is prepared by adopting a cool feeling finishing agent with strong cooling effect and water washing resistance, and the printing paste is transferred tothe fabric in a printing mode. The preparation method has the beneficial effects that by testing the basic performance, the burst strength, the color fastness, the moisture absorption quick-drying performance and the moisture absorption and cool feeling performance of the knitted fabric, the result shows that the knitted fabric has excellent moisture absorption and quick-drying performance, and iscapable of effectively relieving discomfort and wet cold feeling of people caused by damp sweat; and moreover, the knitted fabric also has excellent moisture absorption and cooling performance, and all performances meet standard values.

Owner:JIANGSU JINCHENZHEN TEXTILE

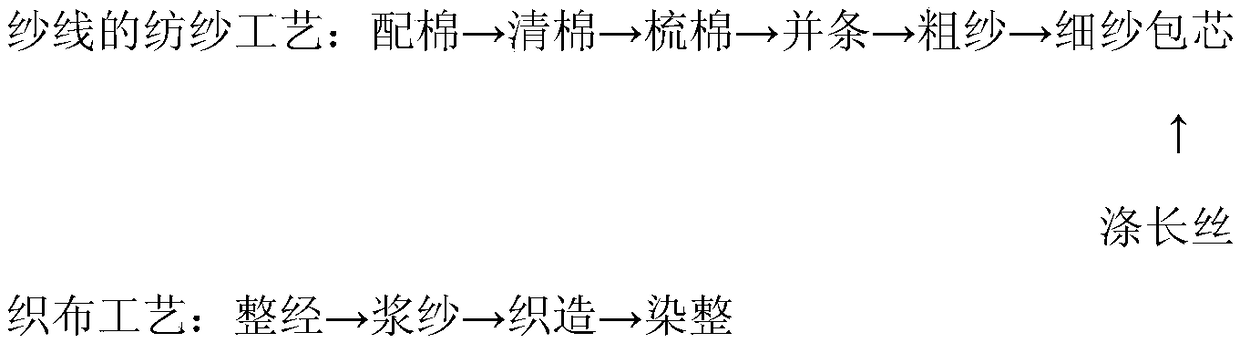

Staple-fiber corn-spun filament yarn containing natural plant antibacterial components, shirt fabric, and production method of shirt fabric

InactiveCN108866719AExtensive antibacterialImprove efficacyWoven fabricsYarnEngineeringWear resistance

The invention relates to the technical field of textiles, in particular to a staple-fiber corn-spun filament yarn containing natural plant antibacterial components, shirt fabric, and a production method of the shirt fabric. The staple-fiber corn-spun filament yarn is an Aiwei antibacterial fiber core-spun filament containing herbal natural antibacterial components, wherein wormwood extract accounts for 10% by weight of Aiwei antibacterial fiber which is bamboo fiber matrix. Core spinning is carried out in order to ensure that strength, wear resistance, wrinkle resistance, breathability, and quick drying property of the yarn are improved at the premise of ensuring that excellent functionality of bamboo fiber containing natural plant antibacterial components; shirt fabric cool, and stylish and having body texture is attained; the application limits of bamoo fiber material in shirt fabrics are broken through.

Owner:WEIQIAO TEXTILE

Weaving method of nano antibacterial cool fiber knitted fabric, nano antibacterial cool fiber knitted fabric woven via weaving method and application of nano antibacterial cool fiber knitted fabric wove

The invention discloses a weaving method of nano antibacterial cool fiber knitted fabric, nano antibacterial cool fiber knitted fabric woven via the weaving method and application of the nano antibacterial cool fiber knitted fabric. The weaving method of the novel nano antibacterial cool fiber knitted fabric subjects antibacterial cool modified mica polyester filament yarns, modal / polyester blended yarns and spandex to weaving in eyelet weave and plain weave form; the eyelet weave is made with antibacterial cool modified mica polyester filament yarns and spandex filament yarns; the plain weaveis made with modal / polyester blended yarns and spandex filament yarns; the two weaves are made into variable eyelet jacquard weave. The nano antibacterial cool fiber knitted fabric prepared herein via the weaving method has good fabric effect and smooth and cool handle, presents cross stripes, has bright color, can inhibit bacteria, and has a good application prospect.

Owner:QINGDAO XUEDA GRP

Moisture-absorbing and sweat-releasing yarn and fabric and garment thereof

InactiveCN112695394AGood moisture absorption and quick dryingExcellent unidirectional moisture transfer performanceWeft knittingWarp knittingYarnPolymer science

The invention provides a moisture-absorbing and sweat-releasing yarn and fabric and clothing thereof. The moisture-absorbing and sweat-releasing yarn is provided with a multilayer structure formed by composite melt spinning or composite spinning, the outer layer fiber of the multilayer structure is exposed to the environment, the hydrophilicity of the outer layer fiber is superior to that of the inner layer fiber of the multilayer structure, the fineness of the outer layer fiber is smaller than that of the inner layer fiber, the outer layer fiber has a circular cross section, and the inner layer fiber has a special-shaped cross section. According to the embodiment of the moisture-absorbing and sweat-releasing yarn, the yarn is ingeniously designed and combined, so that sweat absorbed by the yarn is distributed to the outer layer fiber as much as possible and is quickly evaporated in an external environment, and the inner layer fiber retains moisture as little as possible through moisture transfer. The moisture-absorbing and sweat-releasing yarn is better in moisture absorption, quick drying and one-way moisture conduction performance. Moisture-absorbing and sweat-releasing fabric is woven from the moisture-absorbing and sweat-releasing yarn, sweat management is achieved on the fiber and yarn layer, and sports clothes with the sweat management function can be further manufactured.

Owner:ANTA CHINA

A functional one-way moisture-absorbing and sweat-wicking super-dry fabric and its production process

ActiveCN104928833BExcellent water repellencyQuickly absorbs moisture and spreadsWeft knittingFibre typesPolyesterSocial benefits

A functional one-way moisture-absorbing and sweat-wicking ultra-dry fabric, which is formed by weaving moisture-absorbing and sweat-wicking polyester filaments and ordinary polyester filaments into a double-sided structure. , post-treatment, shaping and hydrophilic softness and other production processes, anti-ultraviolet additives are added in the dyeing process, and moisture-absorbing and sweat-wicking additives are added in the shaping process. The functional one-way moisture-absorbing and sweat-wicking ultra-dry fabric of the present invention adopts a double-sided structure, the inner layer has excellent water repellency and can quickly guide sweat to the outer layer, and the outer layer can quickly absorb moisture and diffuse, realizing one-way from inside to outside Moisture-wicking and quick-drying function, good one-way moisture guide, quick-drying, anti-ultraviolet and washing resistance, good reproducibility, one-way moisture guide is uniform and stable, dry and comfortable to wear, non-sticky, good overall performance. It can meet people's needs for wearing comfort, functionality and practicability, has a wide range of applications, and has good market prospects and economic and social benefits.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

A method for preparing moisture-absorbing and quick-drying cotton fabric with internal and external hydrophobic and hydrophilic structure from acrylate

ActiveCN110924155BGood moisture absorption and quick dryingImprove hydrophilicityGrip property fibresVegetal fibresTextile printerPolymer science

The invention relates to the technical field of textile printing and dyeing, and discloses a method for preparing moisture-absorbing and quick-drying cotton fabrics with internal and external hydrophobic and hydrophilic structures from acrylate. The method comprises the following steps: (1) mixing acrylate, penetrating agent, unsaturated acid salt, persulfate and water to prepare the first finishing solution; (2) padding the cotton fabric with the first finishing solution , rolled up, stacked at 40-60°C for 5-48 hours, then washed and dried; (3) mixing the hydrophilic softener with water to prepare the second finishing solution; (4) mixing the step (2 ) padding the second finishing liquid obtained by padding, then drying and baking. The cotton fabric obtained after finishing according to the method of the invention has better moisture absorption and quick-drying performance and hydrophilicity.

Owner:WUHAN TEXTILE UNIV

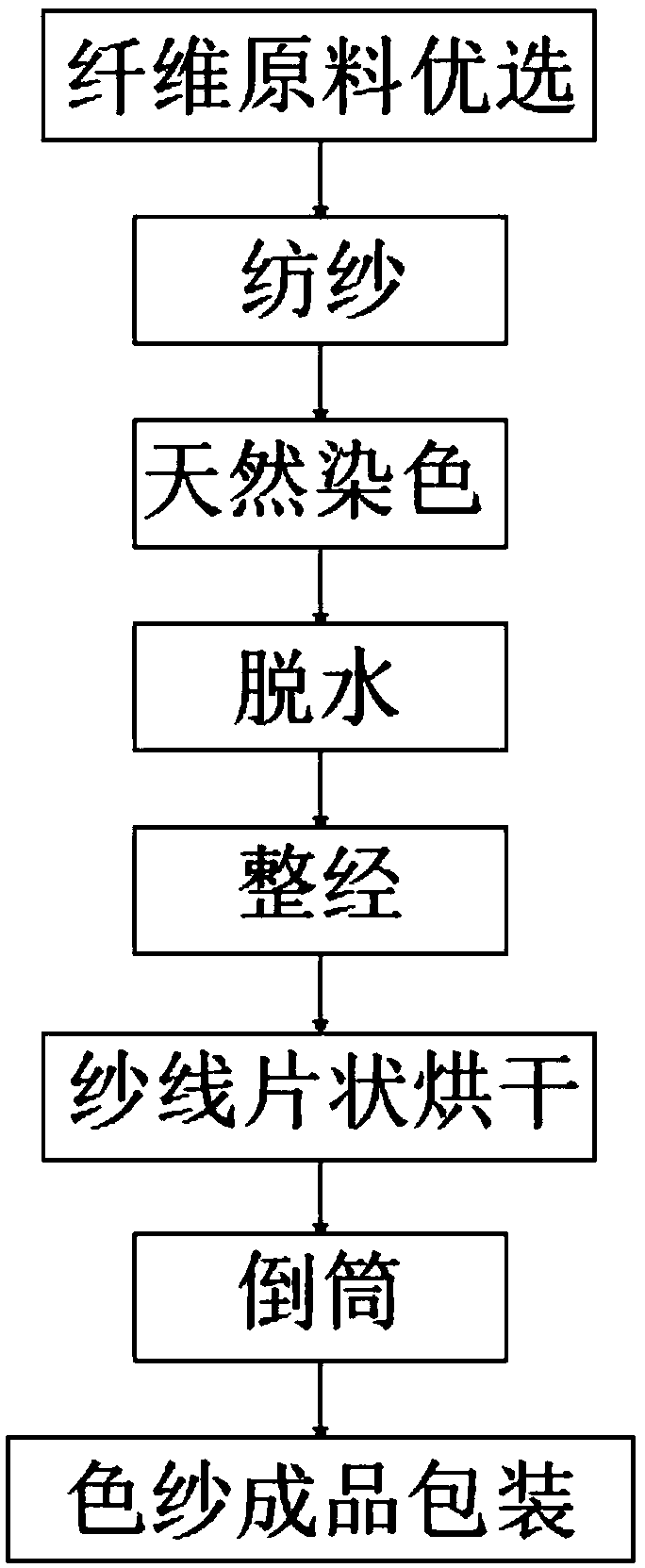

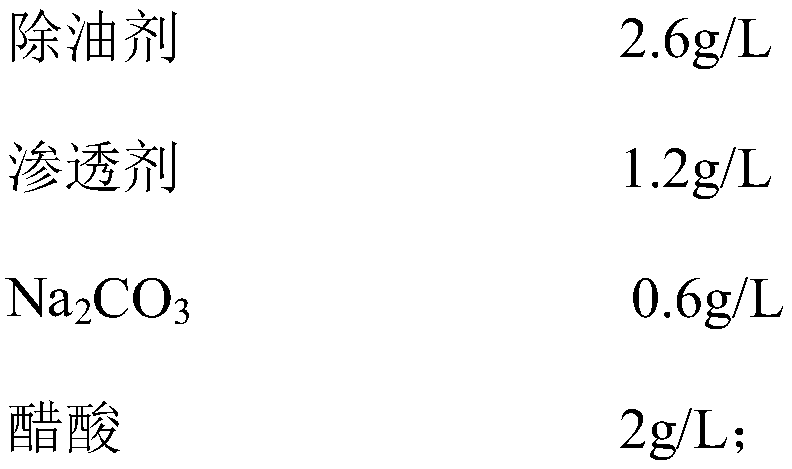

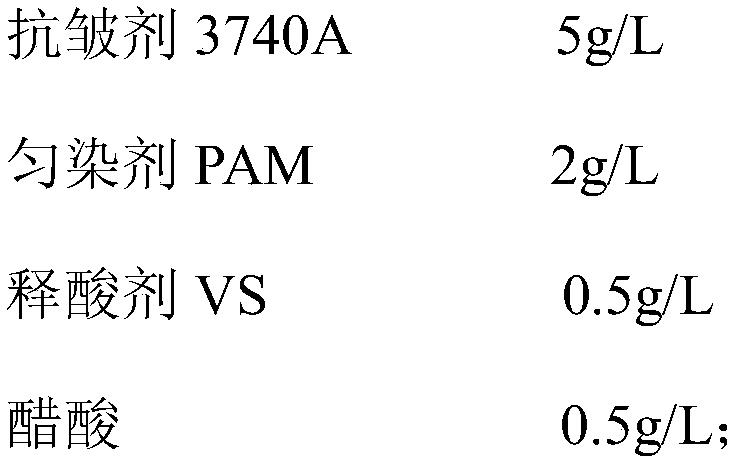

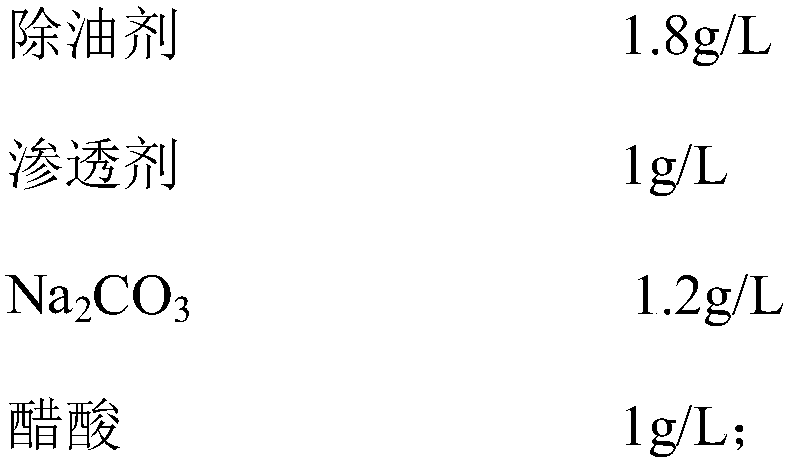

Production method of enVironment-friendly hydroscopic and fast dry natural dyeing yarn

InactiveCN108677300AGood moisture absorption and quick dryingNovel methodWarping machinesWrinkle resistant fibresYarnBobbin

The inVention discloses a production method of an enVironment-friendly hydroscopic and fast dry natural dyeing yarn, and belongs to the field of spinning. The production method of the enVironment-friendly hydroscopic and fast dry natural dyeing yarn has the adVantages that the yarn is blended with a certain proportion of cross section Viscose, the content of an enVironment-friendly polylactic acidfiber in the fiber whole content of the yarn is controlled at 60% or aboVe, the content of the cross section Viscose is controlled at 40% or below, a yarn dyeing method comprises the steps that a natural dyestuff is adopted to dye and dehydrate the blended yarn, then dyed wet-state bobbin color yarns pass through a warping machine, a certain number of strips of bobbin color yarns are warped intoflaky warp beams, then a drying deVice on a slasher is utilized to dry the wet-state bobbin color yarns in a flaky mode, then a rewinding machine producing knitted jean yarns is utilized to rewind strips of color yarns on a flaky color yarn axis into the bobbin color yarns, and it can be achieVed that the produced colored yarn has the adVantages of dyeing naturally, being enVironmentally friendly,absorbing moisture and drying quickly.

Owner:北京宇宙沙盘太空科技有限公司

Underwear fabric and processing technique thereof

ActiveCN109023686ASoft touchGood shape retentionWeft knittingHeating/cooling textile fabricsHigh densityEngineering

The invention provides an underwear fabric and a processing technique thereof. The underwear fabric is made by circularly weaving upper unilateral weaves, needle-containing double-sided weaves and lower unilateral weaves, and air layers are arranged between the upper unilateral weaves and the needle-containing double-sided weaves and between the needle-containing double-sided weaves and the lowerunilateral weaves. The underwear fabric is smooth in hand feeling, close-fitting, capable of keeping warm, dry and cool, comfortable, breathable and good in shape keeping capability, and has the advantages of high density, good drooping performance and good color fastness. The processing technique is simple, the energy is saved, the consumption is reduced, the prepared fabric is used for processing of integrated seamless underwear, the molding of mold cloth is more stereoscopic and comfortable, the situation that traditional underwear sponge mold cloth is thick and easy to deform is avoided, the excellent washability and fastness can be provided, and a new wearing experience is brought.

Owner:PACIFIC (PANYU) TEXTILES LTD

Copper ammonia fiber fabric and preparation method thereof

ActiveCN111350007AGood moisture absorption and quick dryingImprove mechanical propertiesArtificial filaments from cellulose solutionsFibre typesCuprammonium rayonPolymer science

The present invention provides a copper ammonia fiber fabric and a preparation method thereof. The method comprises the steps of firstly preparing cotton linter natural cellulose, a copper compound concentrated ammonia solution, gamma-aminopropyltriethoxy silane modified nano alumina as raw materials into modified copper ammonia fibers, then forming mixed filaments I by the modified copper ammoniafibers, methyl acryloxypropyl trimethoxy silane modified superfine polyamide fibers and a water-soluble vinylon fiber network, then forming mixed filaments II by the modified copper ammonia fibers and a superfine polyester fiber network, and finally weaving the mixed filaments I and the mixed filaments II into warps and wefts by using a loom to obtain a grey fabric, and performing vacuum heatingand finishing to remove water-soluble vinylon fibers so as to obtain the copper ammonia fiber fabric. The copper ammonia fiber fabric has excellent moisture-absorbing and quick-drying performance andgood mechanical performance.

Owner:汕头市现代服饰有限公司

A method for preparing moisture-absorbing and quick-drying cotton fabric

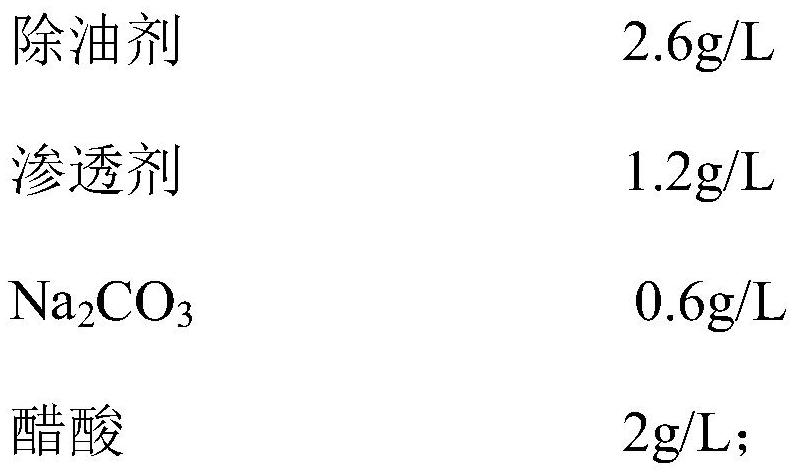

ActiveCN110952314BGood moisture absorption and quick dryingImprove hydrophilicityLiquid repellent fibresVegetal fibresSodium bicarbonateTextile printer

The invention relates to the technical field of textile printing and dyeing processing, and discloses a method for preparing moisture-absorbing and quick-drying cotton fabrics. The method comprises the following steps: (1) mixing glyoxal, silane coupling agent, penetrating agent, sodium bicarbonate, magnesium chloride and water to obtain a first finishing solution, padding the cotton fabric with the first finishing solution, Roll up, stack at 60-80°C for 5-48 hours, then wash and dry; (2) Mix the hydrophilic softener and water to obtain the second finishing solution, which will be obtained after the treatment in step (1) padding the second finishing solution on the cotton fabric, then drying and baking. The cotton fabric obtained after finishing according to the method of the invention has better moisture absorption and quick-drying performance and hydrophilicity.

Owner:WUHAN TEXTILE UNIV

Continuous dyeing and finishing process for bamboo-cotton-polyester blended antibacterial anti-ultraviolet anti-static woven fabric

PendingCN114150519AGuaranteed qualityGuaranteed whiteness effectMercerising of indefinite length fabricsSingeingDisperse dyeColour fastness

The invention discloses a continuous dyeing and finishing process for bamboo-cotton-polyester blended antibacterial anti-ultraviolet anti-static woven fabric. The woven fabric is sequentially subjected to the steps of strengthened singeing, high-temperature enzyme desizing, scouring, bleaching, mercerizing, sizing, dyeing and finishing. In the step of dyeing, polyester fiber components are dyed by disperse dye, the disperse dye is padded, then two groups are pre-dried by infrared rays, then hot air drying is carried out by adopting a three-section pre-drying room, the temperature of a first box is 50-60 DEG C, the temperature of a second box is 70-90 DEG C, the temperature of a third box is more than 100 DEG C, and finally the polyester fiber components are baked at 210 DEG C for 3.5 minutes; according to the color fastness requirement, the reactive dye or the vat dye is determined to be used for dyeing the bamboo / cotton fibers. The scouring and bleaching auxiliary agent with the environment-friendly low-alkaline property is adopted, the environment-friendly enzyme desizing process is combined, dyeing and finishing are conducted, and meanwhile the cloth cover quality and the whiteness effect of the bamboo-cotton-polyester blended fabric are guaranteed, and the excellent anti-ultraviolet, antibacterial, deodorant, moisture-absorbing and quick-drying performance is achieved.

Owner:SHAANXI GILDLAND SCI & TECH CO LTD

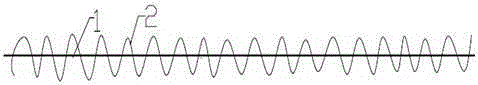

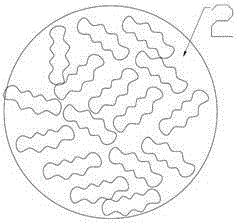

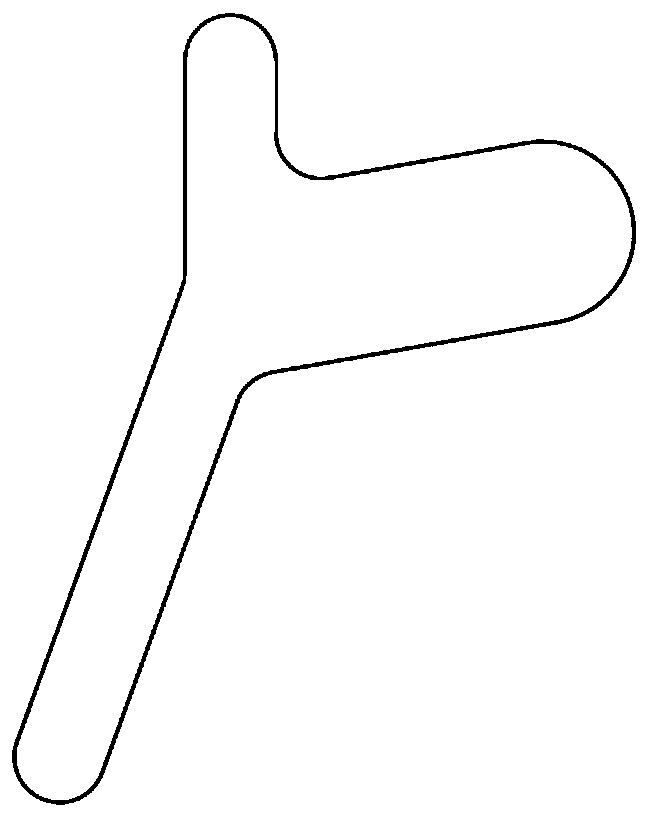

Novel multifunctional cladding yarn and preparation method

The invention discloses a novel multifunctional cladding yarn and a preparation method, wherein the multifunctional cladding yarn comprises a core wire and an external cladding wire covering the core wire; the external layer cladding wire is made of a kind of super fine denier nylon 6 yarn with the cross section in a double 8 structure; and the core wire is spandex filament. The yarn is made by the steps of (1) preparing the super fine denier nylon yarn that has a special double 8 structure on the cross section; (2) winding nylon wire, wherein the nylon wire is wound with n on-line tension apparatus with a tension controller; (3) drawing-off and twisting the spandex filament with the nylon yarn that has a double 8 cross section; (4) using a rewinder of the on-line tension to roll the finished product, so as to manufacture a multifunctional cladding yarn. The novel multifunctional cladding yarn prepared by the invention has the advantages of good moisture absorption and rapid drying by reconstructing the yarn surface structure and increasing yarn permeability; increased contact area with skin; soft feeling; tight fabrics; and greatly improved enjoy performance; and it's cool on wearing and the yarn is smooth like the silk.

Owner:JIANGSU JIADE FIBER TECH

Preparation method of bi-directional moisture absorption quick-dry cotton fabric

ActiveCN110846897AGood moisture absorption and quick drying performanceGood hydrophilicityGrip property fibresVegetal fibresChemistryPolymer chemistry

The invention relates to the technical field of textile printing and dyeing, and discloses a preparation method of a bi-directional moisture absorption quick-dry cotton fabric. The method includes thesteps: (1) mixing polyethylene emulsion, penetrating agents, sulfuric acid and water to obtain first finishing liquor, soaking the cotton fabric into the first finishing liquor, rolling the cotton fabric, stacking the cotton fabric for 5-48 hours at the temperature of 40-60 DEG C, and washing and drying the cotton fabric; (2) mixing hydrophilic softeners and water to obtain second finishing liquor, soaking the cotton fabric treated in the step (1) into the second finishing liquor, and drying and baking the cotton fabric. The cotton fabric finished by the method has good moisture absorption quick-dry performance and hydrophilicity.

Owner:WUHAN TEXTILE UNIV

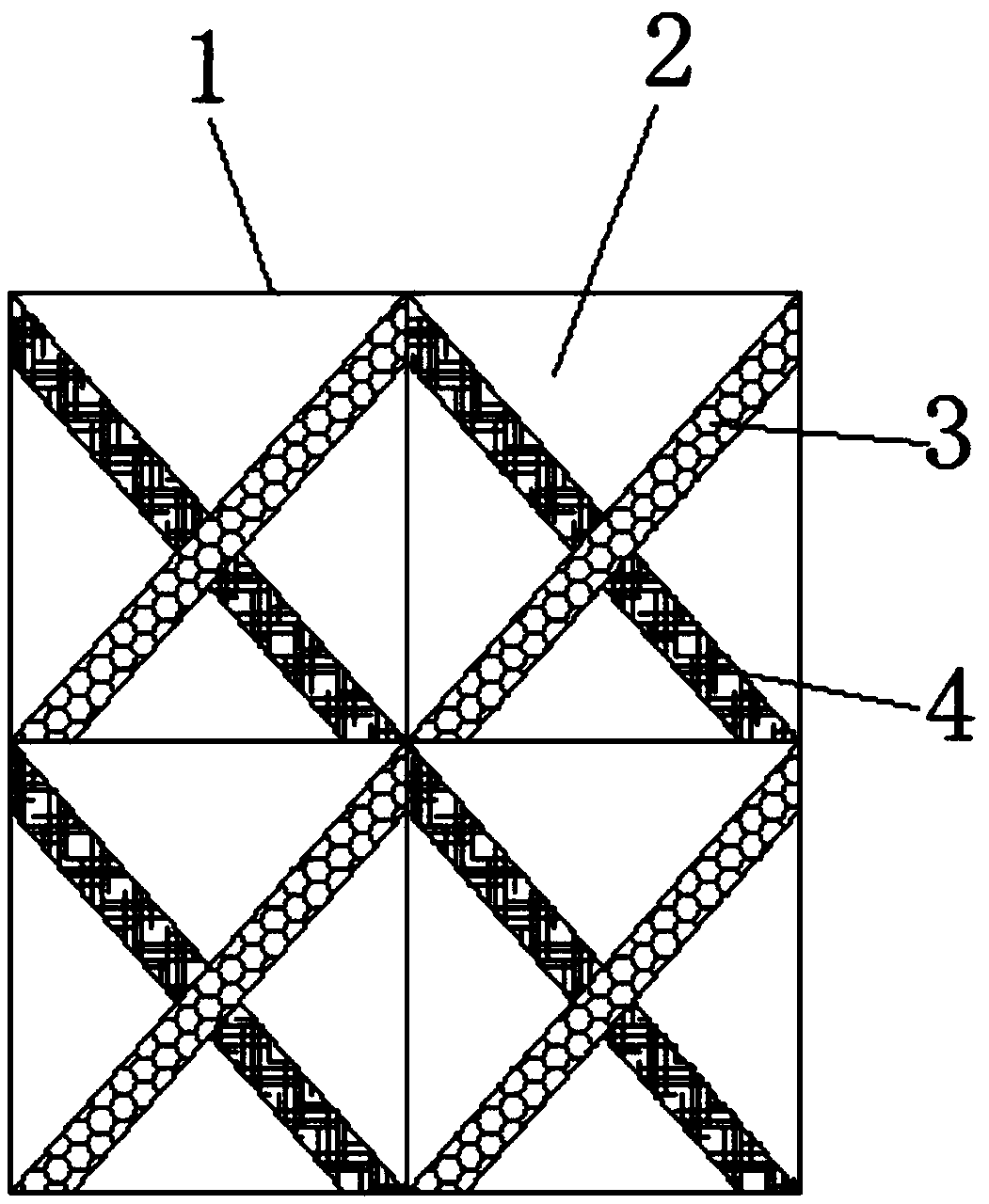

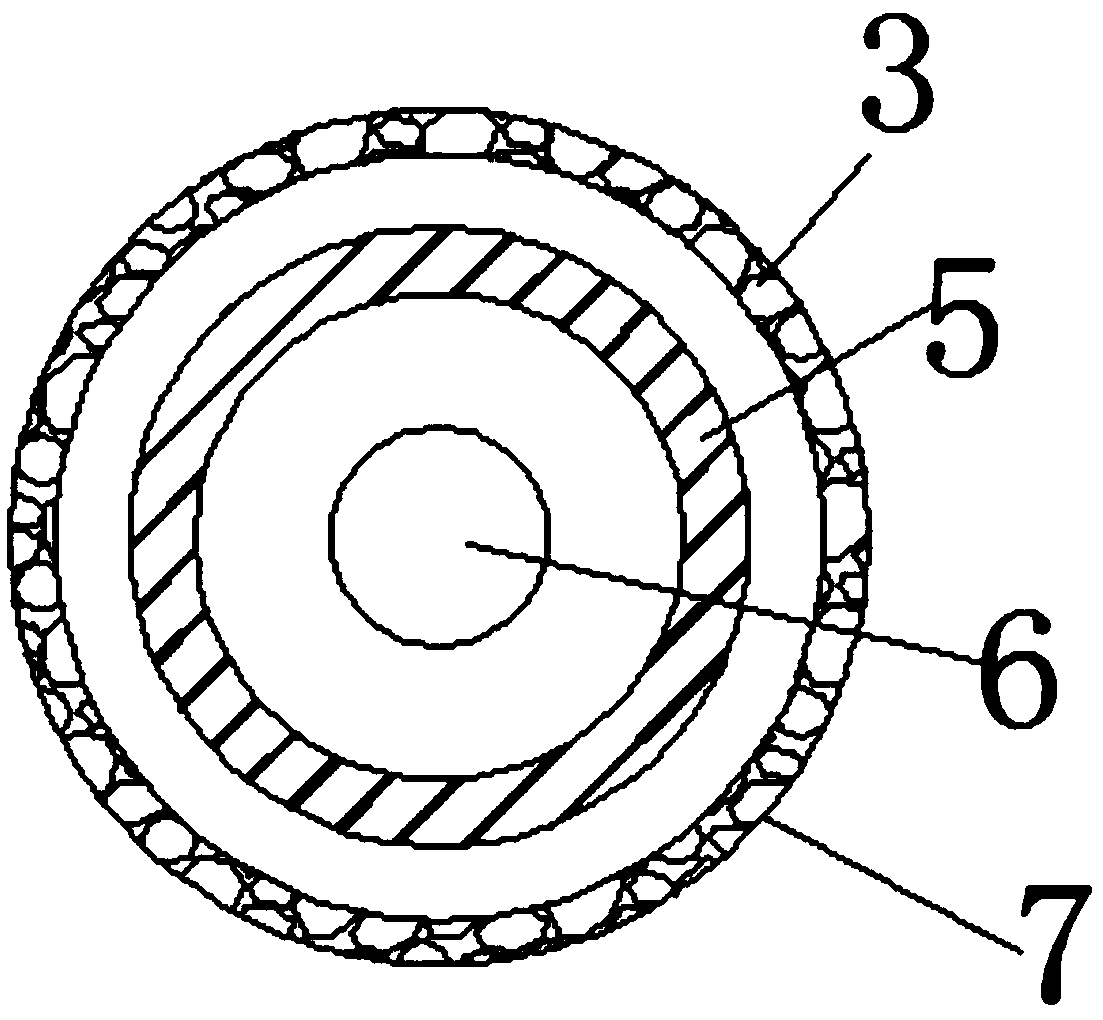

Waterproof and environment-friendly sportswear fabric with high wear resistance

InactiveCN109094155AHigh moisture absorption and quick dryingEnhanced moisture absorption and quick dryingSynthetic resin layered productsMelt spinning methodsYarnPolyester

The invention relates to waterproof and environment-friendly sportswear fabric with high wear resistance. The waterproof and environment-friendly sportswear fabric with high wear resistance comprisessportswear fabric (1), wherein the sportswear fabric (1) comprises a wear-resistant breathable layer (2), polyester fibers (3) and polyimide fibers (4), the polyester fibers (3) and the polyimide fibers (4) are arranged in the wear-resistant breathable layer (2), the polyester fibers (3) are located on the polyimide fibers (4), polyester yarn (6) is arranged in the polyester fibers (3), a bamboo fiber layer (7) is connected with the inner wall of the polyester fibers (3), and an organic cotton synthetic fiber layer (5) is arranged between the polyester yarn (6) and the bamboo fiber layer (7);furthermore, the polyester fibers are prepared from polyester as a substrate and water-absorbing compound powder as filler by melt spinning; the water-absorbing compound powder is prepared from a sodium polyacrylate and carbon nano tube mixture by vacuum dewatering.

Owner:广州巨枫科技有限公司

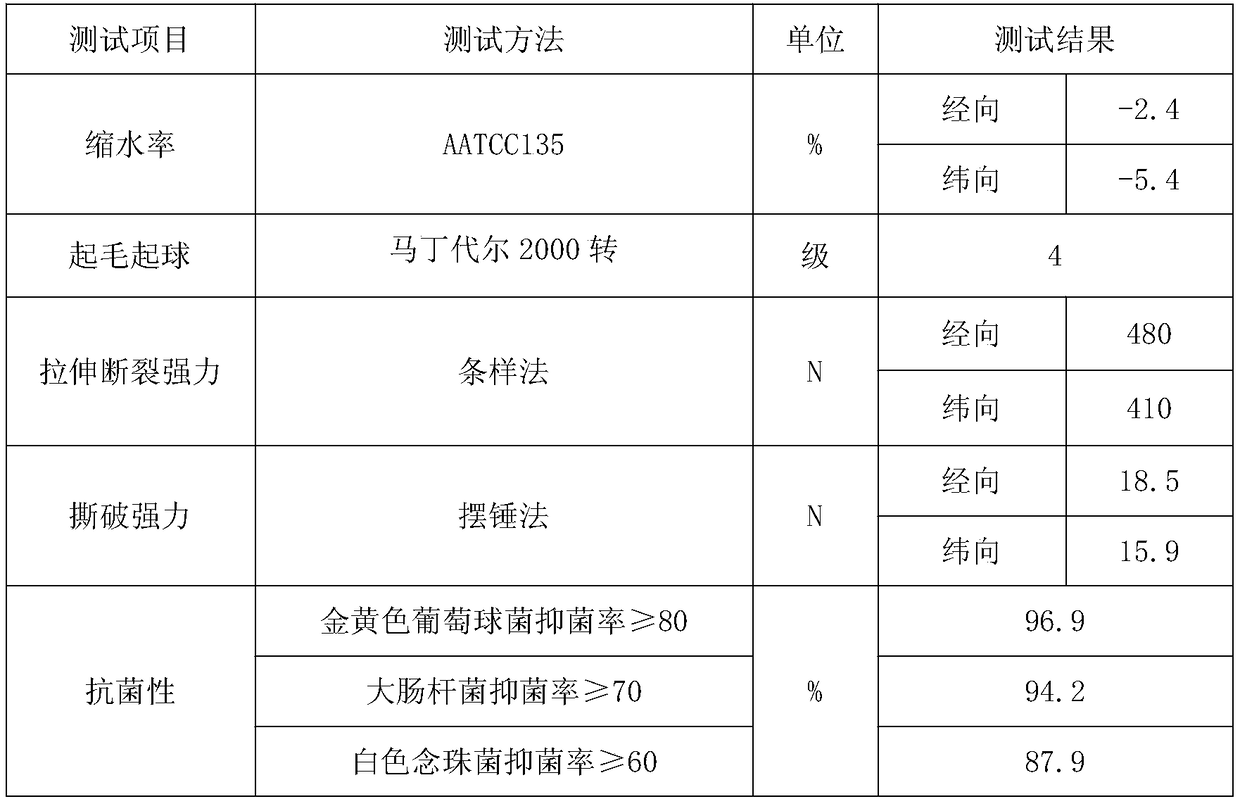

Moisture-absorption quick-dry antibacterial fabric and preparation method thereof

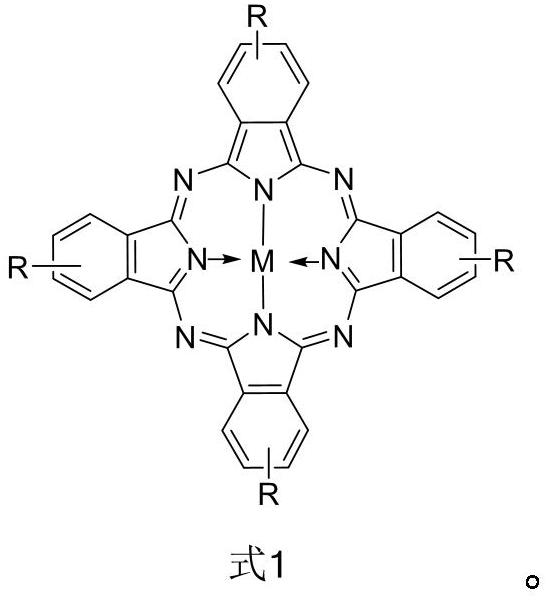

ActiveCN114250541ALarge specific surface areaImprove hydrophilicityMulti-ply fabricsMonocomponent polyesters artificial filamentPolyesterYarn

The invention discloses a moisture-absorption quick-dry antibacterial fabric and a preparation method thereof, and relates to the technical field of textiles. The preparation method comprises the following steps: firstly, preparing porous nano titanium dioxide, crosslinking the porous nano titanium dioxide and polyester by using 1, 2, 3, 4-butanetetracarboxylic acid as a crosslinking agent to obtain TiO2 modified polyester, performing electrostatic spinning on the TiO2 modified polyester to obtain TiO2 modified polyester fibers, and performing double-layer weaving on the TiO2 modified polyester fibers and natural fiber blended yarns to obtain the moisture-absorbing quick-drying antibacterial fabric. According to the invention, porous nano titanium dioxide is grafted with hydroxyl-terminated polyester, so that the fabric has the characteristics of excellent moisture absorption, quick drying and antibacterial property.

Owner:PEAK CHINA CO LTD

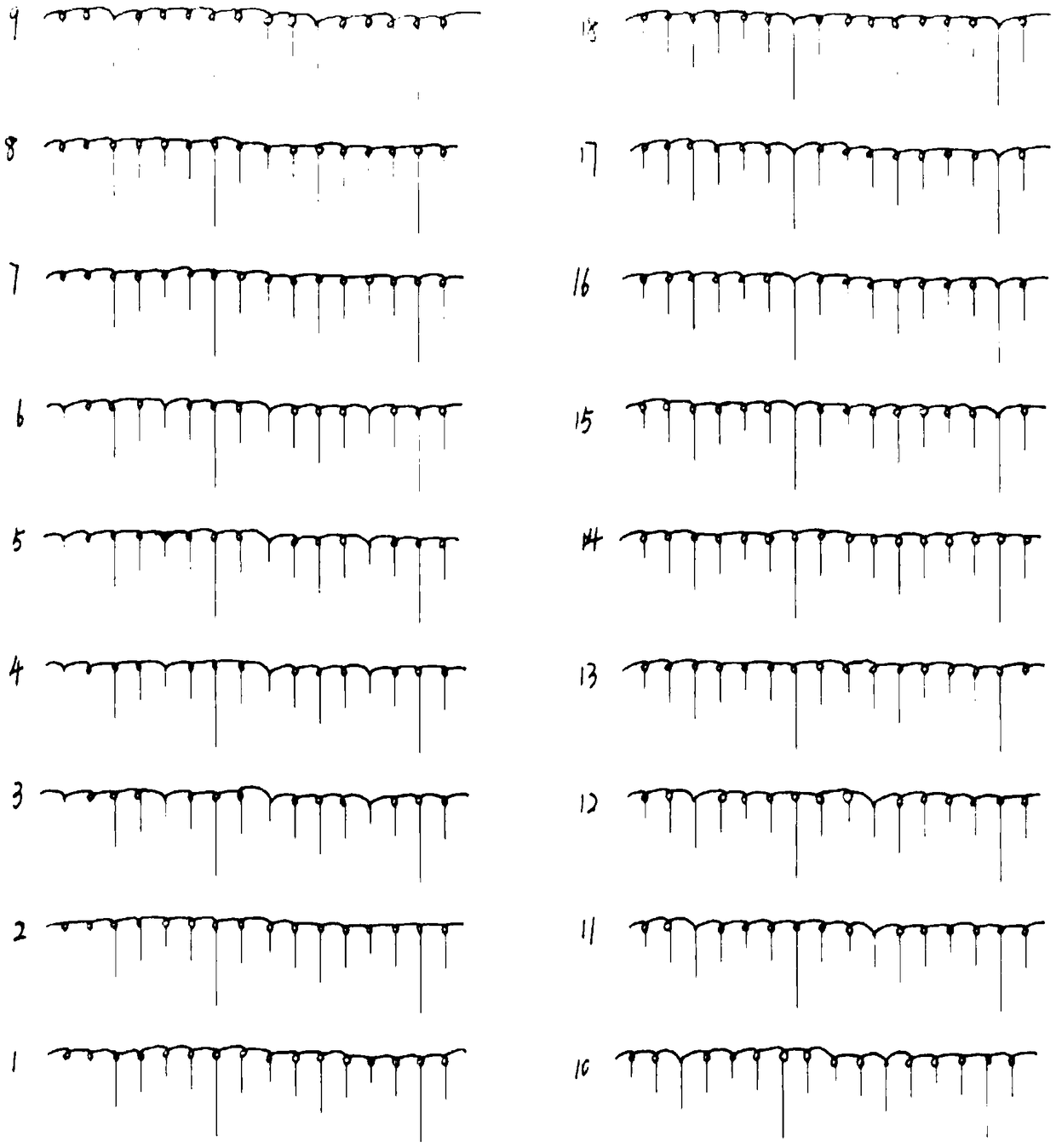

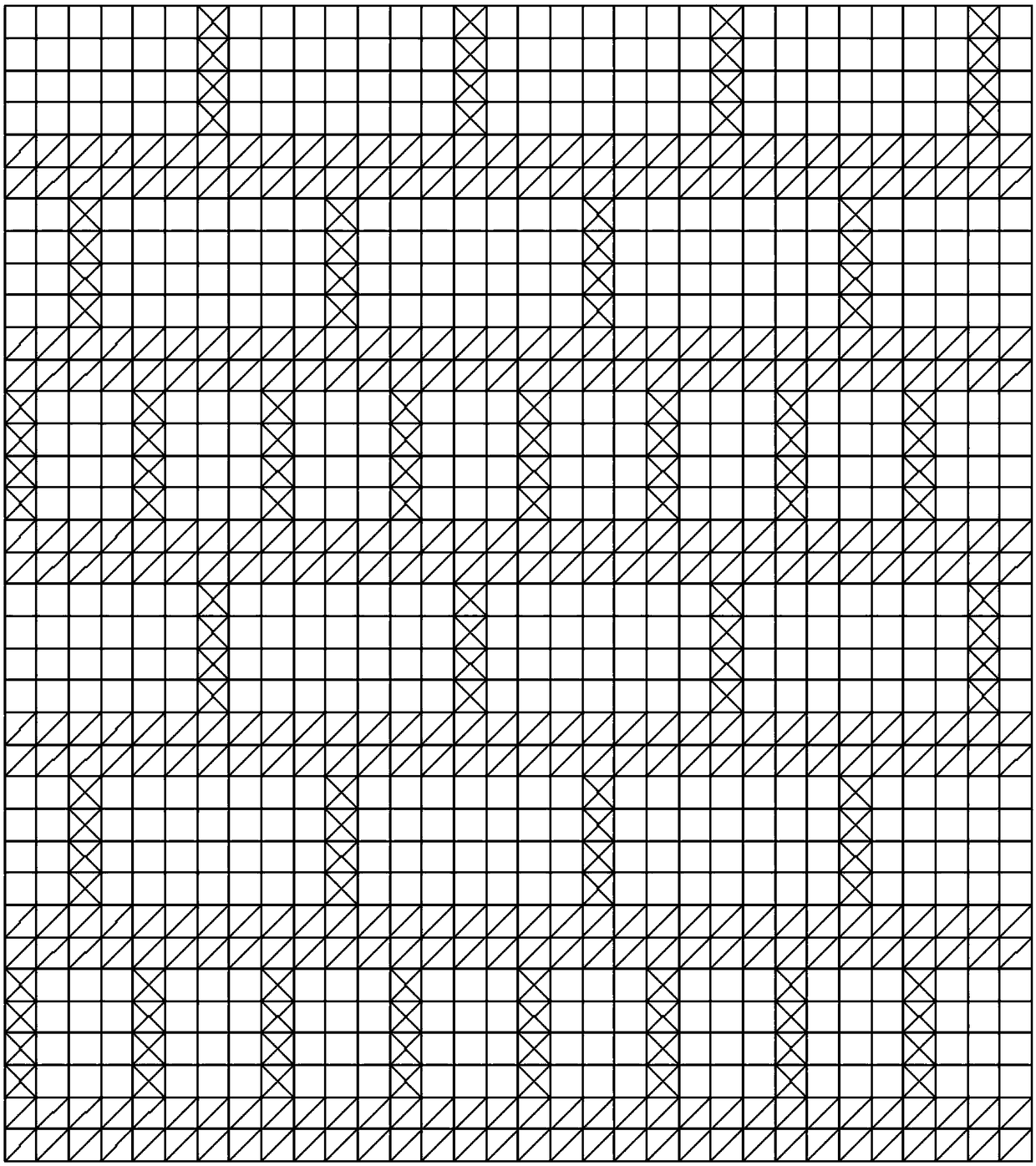

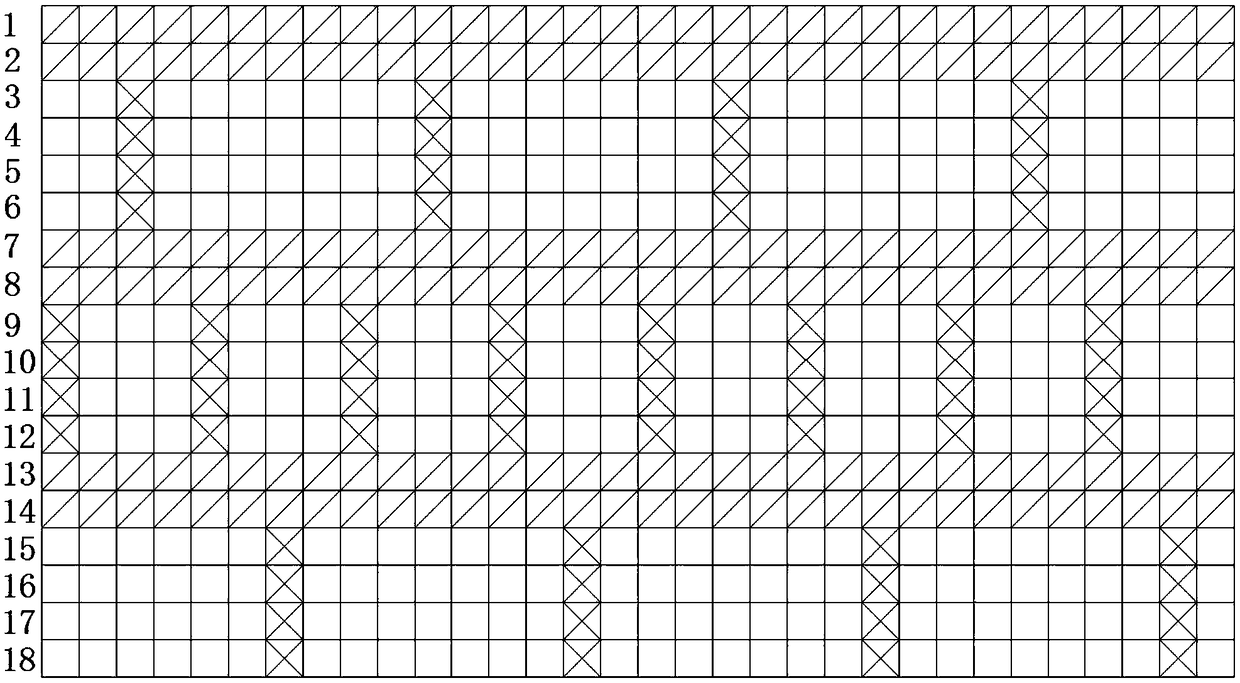

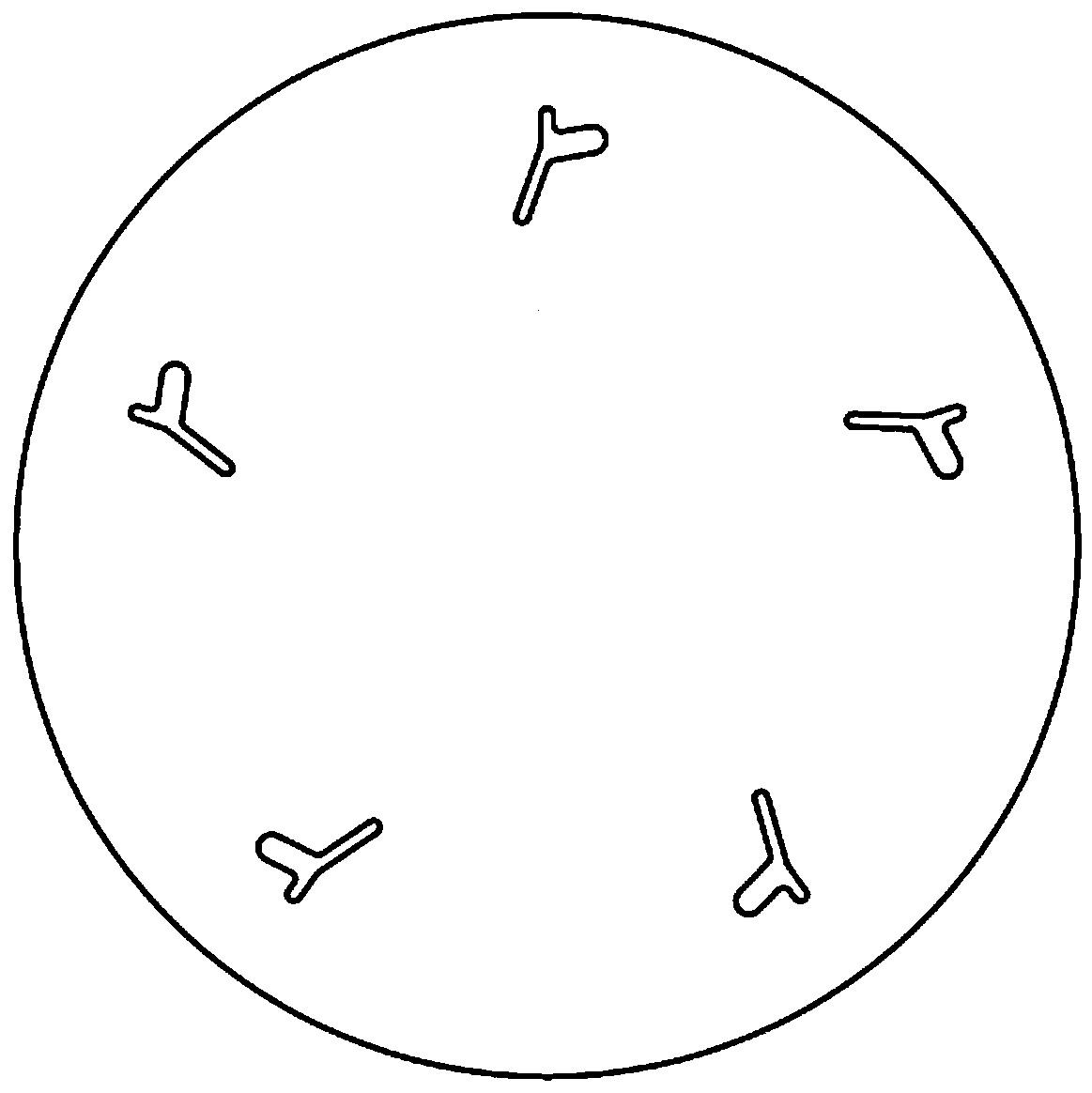

One-way moisture conduction towel fabric and production method thereof

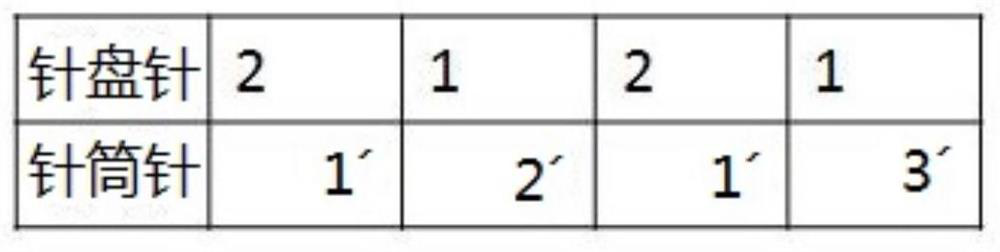

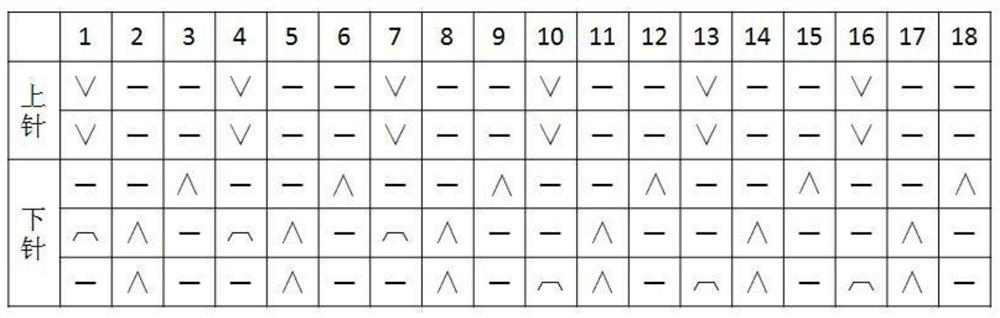

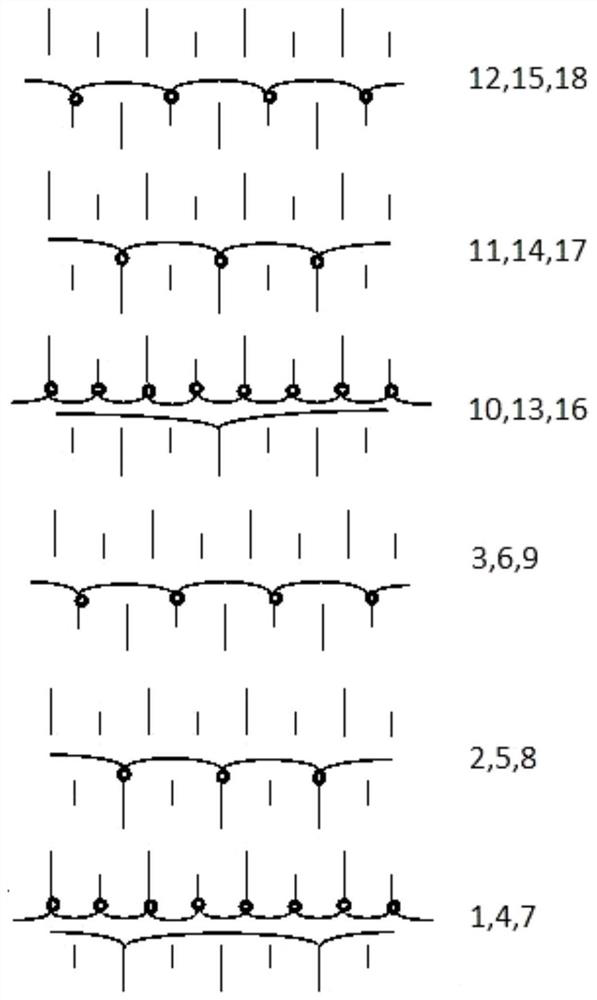

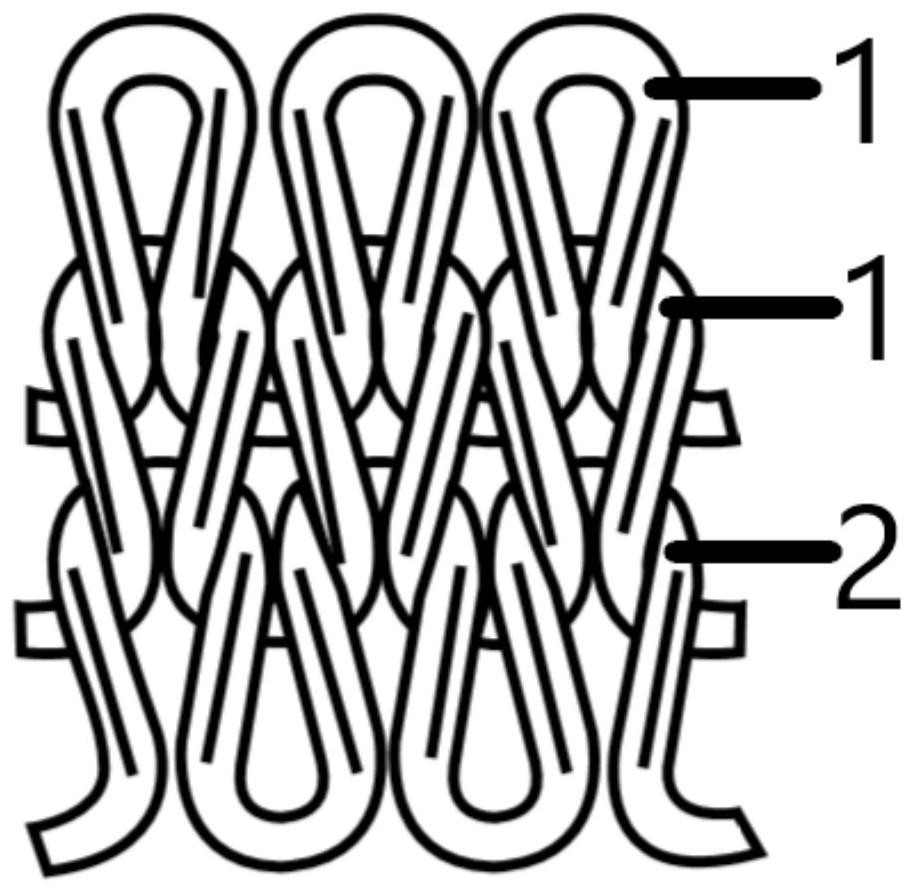

The invention discloses a one-way moisture conduction towel fabric and a production method thereof. The production method comprises the following steps of providing a double-sided machine, and arranging cams and knitting needles according to fabric design requirements, wherein dial needles comprise knitting needles with two needle butts, cylinder needles comprise knitting needles with three needle butts, the two needles of the dial needles are arranged at an interval of 1, the arrangement mode of the cylinder needles adopts four needles as a cycle, and the arrangement mode of the knitting needles in each cycle is the first needle, the second needle, the first needle and the third needle; providing yarns, wherein the yarns comprise common yarns and sea-island yarns; by using the double-sided machine, performing knitting by adopting 18 paths as a cycle; and in a woven gray fabric, enabling the common yarns to form a mesh surface, and enabling the sea-island yarns to form a to-be-napped surface. The one-way moisture conduction towel fabric has relatively good and relatively durable comfort and air permeability, has the characteristics of quick water absorption and quick drying, and can meet high use requirements of consumers.

Owner:JIANGSU JUJIE MICROFIBERS TEXTILE GRP

Method for preparing moisture-absorbing and quick-drying cotton fabric

ActiveCN110952314AGood moisture absorption and quick dryingImprove hydrophilicityLiquid repellent fibresVegetal fibresSilane couplingSodium bicarbonate

Owner:WUHAN TEXTILE UNIV

Copper ammonia silk-like elastic knitted fabric as well as preparation method and application thereof

The invention provides a copper ammonia silk-like elastic knitted fabric as well as a preparation method and application thereof. The fabric is formed by interweaving non-elastic yarns and elastic yarns, and each path of non-elastic yarns of the fabric covers each path of elastic yarns; and the non-elastic yarns comprise composite filaments containing copper ammonia fibers and cold sense filaments. The copper ammonia silk-like elastic knitted fabric disclosed by the invention has the advantages of draping feeling like real silk, smooth hand feeling, cool feeling in contact, sweat absorption, quick drying and ultraviolet resistance, and meanwhile, the problems that the copper ammonia fibers are poor in strength and difficult to weave and chemical fibers generate static electricity are solved.

Owner:QINGDAO IMEI FASHION INT TRADE CO LTD

Raw liquid coloring heavy oxford fabric and production method thereof

InactiveCN108677317AUnique styleSoft touchGrip property fibresWoven fabricsTextile technologyHigh volume manufacturing

The invention belongs to the technical field of textiles, and particularly relates to a raw liquid coloring heavy oxford fabric and a production method thereof. The number of warp is 40-50, the numberof weft is 10-20, the warp density is 90-120 / inch, the weft density is 45-60 / inch, the warp direction weaving shrinkage is 4-6%, and the weft direction weaving shrinkage is 15-18%. Compared with an existing heavy oxford fabric, the raw liquid coloring heavy oxford fabric has a unique style, fabric surface granulation is plump, the hand feeling is smooth and soft, the air permeability is good, theweft direction elastic elongation is 12-15%, and the humidity absorbing and quick drying functions are good. Investment is not needed to improve looms by means of the production method, the raw liquid coloring heavy oxford fabric can be woven on an existing Bigano air-jet loom, the cost is low, and the demand of production in large batches can be met.

Owner:鲁丰织染有限公司

Preparation method of comfortable seersucker

ActiveCN111334917AStable twist performanceEffect of heat shrinkageFilament/thread formingHeating/cooling textile fabricsPolymer scienceCotton fibre

The invention relates to a preparation method of comfortable seersucker. The preparation method comprises the steps of weaving 28-32s warp yarns (cotton fibers) and 50-60s weft yarns (polyamide yarns)to obtain gray fabric, and carrying out relaxation heat treatment to obtain the comfortable seersucker; preparation of polyamide yarns: in the process of preparing the round sheath-core composite fiber from two kinds of polyamide 6 with different viscosities according to the FDY technology, changing spinneret holes in a spinneret plate into trefoil shapes from round shapes, adopting circular airblowing cooling, and controlling the arrangement of the trefoil spinneret holes in the spinneret plate to meet certain conditions so as to prepare the polyamide yarn; the gram weight of the prepared comfortable seersucker ranges from 100 g / m<2> to 130 g / m<2>, the seersucker width ranges from 1.30 cm to 1.50 cm, the seersucker density ranges from 38 pieces / 10 cm to 42 pieces / 10 cm, and the fullnessranges from 6.6 to 7.5; hygroscopicity: the water absorption rate is greater than or equal to 280%, the drip diffusion time is less than or equal to 2.0 seconds, and the wicking height is greater than or equal to 138 mm; and quick dryness: the evaporation rate is more than or equal to 0.32 g / h.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of underwear fabric and its processing technology

ActiveCN109023686BSoft touchGood shape retentionWeft knittingHeating/cooling textile fabricsHigh densityEngineering

The invention provides an underwear fabric and a processing technology thereof. The underwear fabric of the present invention is made of the upper unilateral weave, the needle-containing double-sided weave, and the lower unilateral weave by weft knitting. Between the upper unilateral weave and the needle-containing double-sided weave, An air layer is formed between the needle-containing double-sided tissue and the lower single-sided tissue. The underwear fabric of the invention has smooth hand feeling, close-fitting warmth, dryness, comfort and breathability, good shape retention, and has the advantages of high density, good sag and good color fastness. The processing technology of the present invention is simple, saves energy and reduces consumption, and the prepared fabric is used for the processing of one-piece seamless underwear, which makes the molding of the mold cup more three-dimensional and comfortable, avoids the situation that the traditional underwear sponge mold cloth is thick and easy to deform, and is more durable. Provides excellent wash resistance and fastness, bringing a new wearing experience.

Owner:PACIFIC (PANYU) TEXTILES LTD

A kind of colored catalytic composite antibacterial fiber and its preparation method and application

ActiveCN109706544BRealize industrial productionEvenly distributedPhysical/chemical process catalystsMonocomponent polyesters artificial filamentFiberPolyester

The invention provides a method for preparing a colored catalytic composite antibacterial fiber, which belongs to the field of fiber materials. The composite antibacterial catalyst includes a composite antibacterial catalyst, additives, color pigments and polyester, and the composite antibacterial catalyst includes nanometer metal particles and a photocatalyst. The present invention selects nanometer metal particles and photocatalysts as the composite antibacterial catalyst, which can make the colored catalytic composite antibacterial fiber of the present invention have a better antibacterial effect than the antibacterial fiber with only a single antibacterial catalyst, and through the use of additives, the flow of the antibacterial catalyst is increased properties and surface activity, so that it can be evenly distributed in the polymer matrix to prevent the composite antibacterial catalyst from agglomerating when mixed.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing inner and outer hydrophobic and hydrophilic structure moisture absorption quick-drying cotton fabric from acrylate

ActiveCN110924155AGood moisture absorption and quick drying performanceGood hydrophilicityGrip property fibresVegetal fibresPolymer chemistryTextile printer

The invention relates to the technical field of textile printing and dyeing processing, and discloses a method for preparing an inner and outer hydrophobic and hydrophilic structure moisture absorption quick-drying cotton fabric from acrylate. The method comprises the following steps of (1) carrying out mixing on acrylate, a penetrant, unsaturated acid salt, persulfate and water to prepare a firstfinishing liquid; (2) carrying out padding on cotton fabric in the first finishing liquid, then performing winding, and carrying out placement at a temperature of 40-60 DEG C for 5-48h, and next, performing water washing and drying; (3) mixing a hydrophilic softener and water to prepare a second finishing liquid; and (4) carrying out padding on the cotton fabric obtained in the step (2) in the second finishing liquid, and then carrying out drying and baking. The cotton fabric obtained after being finished according to the method disclosed by the invention has relatively high moisture absorption quick-drying performance and hydrophilicity.

Owner:WUHAN TEXTILE UNIV

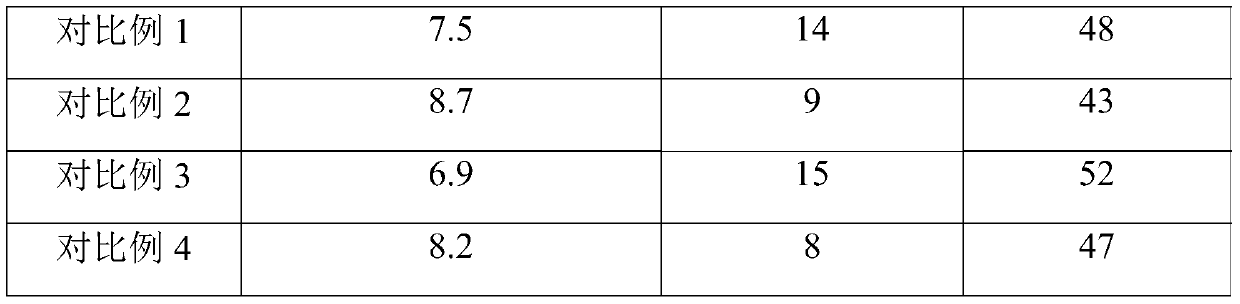

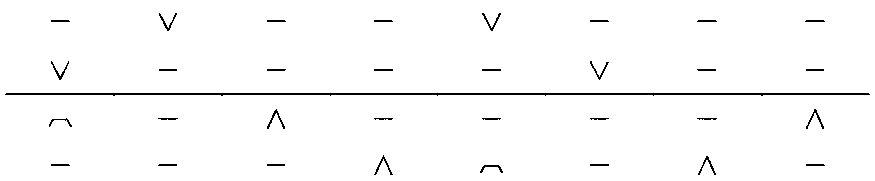

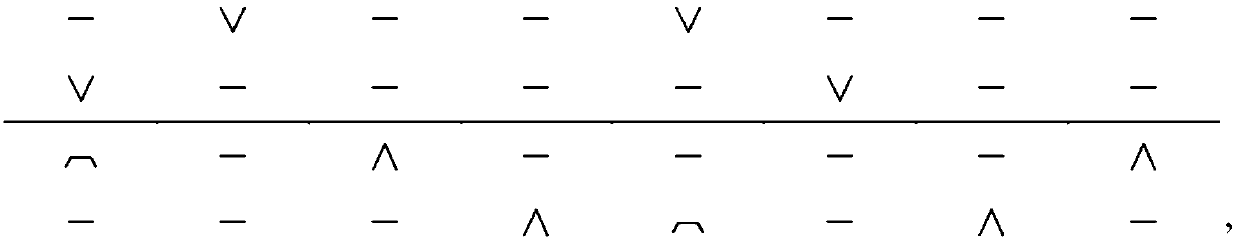

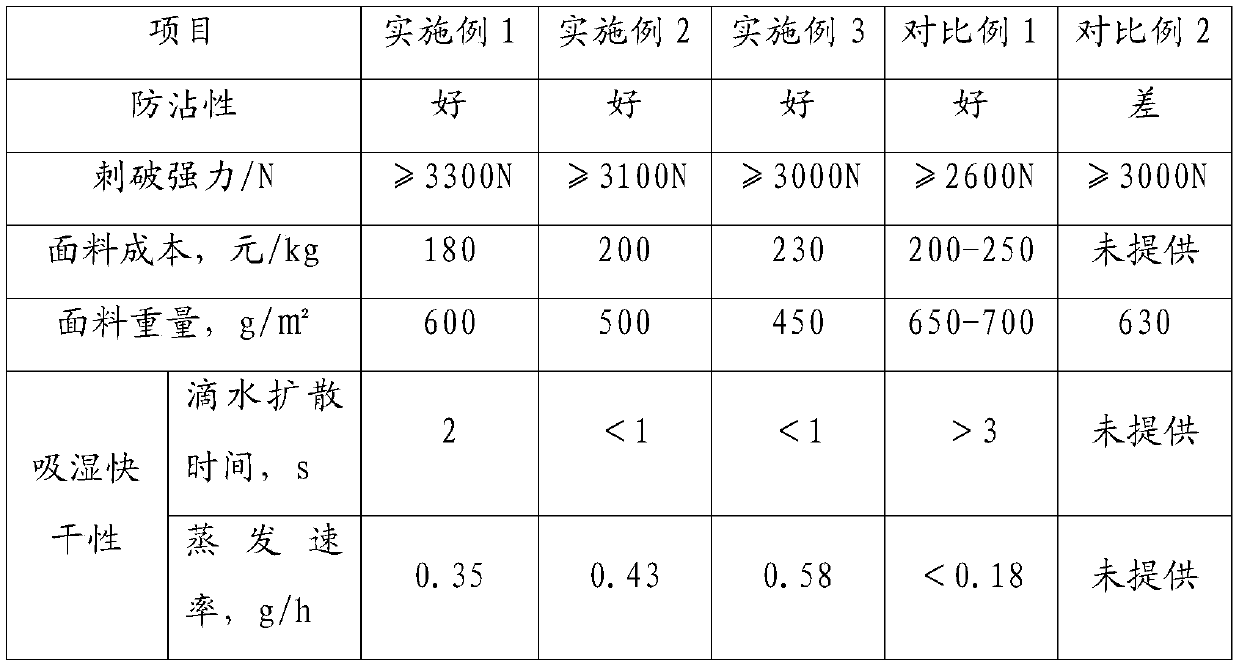

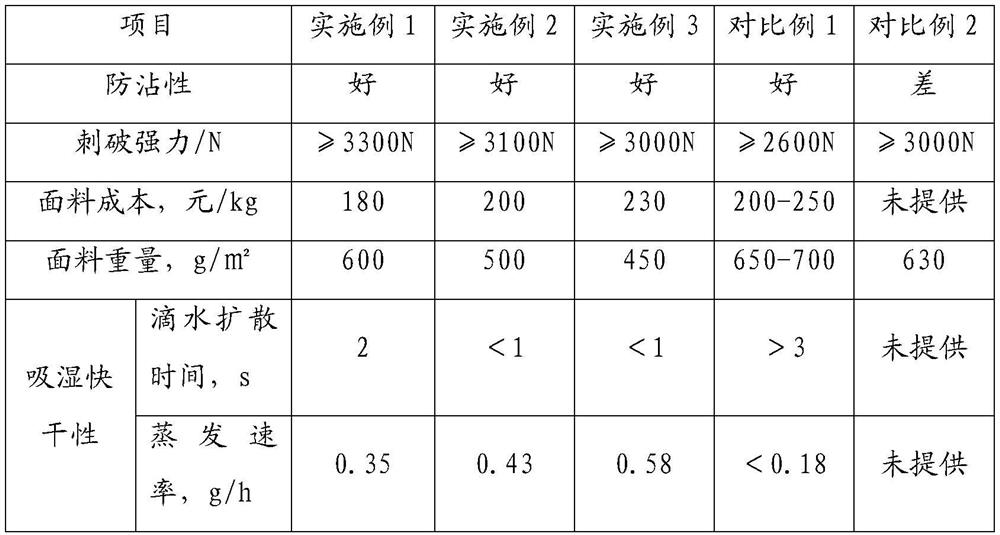

Fencing clothes fabric and processing technology thereof

ActiveCN110438641AReduce locking displacementLarge gap on the reverse sideWeft knittingHeating/cooling textile fabricsEngineeringUHMWPE polyethylene

The invention relates to a fencing clothes fabric and a processing technology thereof, and belongs to the technical field of clothes woven by special materials. Ultra-high molecular weight polyethylene filaments and dobby stitches serving as compound covered yarns are woven to form the fencing clothes fabric. In the dobby stitches, an upper dial combines loop knitting and plain knitting, a lower dial combines loop knitting, ring knitting and plain knitting, loop knitting of the upper dial is implemented by compound covered yarns, loop knitting of the lower dial is implemented by ultra-high molecular weight polyethylene filaments, the ultra-high molecular weight polyethylene filaments are woven to form the front of the fabric, and the compound covered yarns are woven to form the back of thefabric. By the aid of the fabric, dripping water diffusion time is smaller than or equal to 3S, wicking height is larger than or equal to 120mm, an average value of the puncturing strength of the front of the fabric is larger than or equal to 2600N, and the outer surface of the fabric cannot be easily snagged.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Preparation method of knitted underwear fabric

ActiveCN110983597ASimple processLow costWeft knittingLiquid/gas/vapor article treatmentYarnMoisture absorption

The invention relates to a preparation method of knitted underwear fabric. Taken as raw materials, 50 -60 Ne of cotton yarns and 75 -100 D of elastic filaments are knitted and then are sequentially subjected to pretreatment, dyeing, enzyme treatment, first softening treatment, drying, stacking, shaping, second softening treatment and drying and shaping to obtain the knitted underwear fabric. The preparation process of the elastic filaments comprises the following steps of extruding PTT melt from trilobal spinneret orifices with unequal lengths of three leaves, unequal widths thereof and unequal included angles between any two leaves in a spinneret plate (all the trilobal spinneret orifices are distributed in concentric circles, the leaves I of the trilobal spinneret orifices point to rotate for a certain angle at every other position on the same circle, and the rotation change of 360 degrees is completed in one circle), cooling the PTT melt by circular blowing, preparing FDY filamentsaccording to an FDY process, and then carrying out relaxation heat treatment to prepare stretch yarns. The preparation method of the knitted underwear fabric in the invention avoids the problem that the moisture absorption and quick drying performance and the dimensional stability of the knitted underwear fabric in the prior art are reduced due to containing of spandex.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of fencing clothing fabric and its processing technology

ActiveCN110438641BLarge gap on the reverse sideImprove breakdown resistanceWeft knittingHeating/cooling textile fabricsYarnEngineering

The application relates to a fencing clothing fabric and a processing technology thereof, belonging to the technical field of special material woven clothing. It is woven from ultra-high molecular weight polyethylene filament and composite covered yarn dobby weave. In the dobby weave, the upper needle plate is a combination of loop knitting and flat knitting, and the lower needle cylinder is loop knitting, tuck knitting and flat knitting. Needle knitting combination, the loop knitting of the upper dial is made of composite covered yarn, the loop knitting of the lower dial is made of UHMWPE filament, the UHMWPE filament is woven into the front side, and the composite covered yarn is woven into reverse side. Using the fabric obtained by the solution of the application, the drip diffusion time is ≤3S, the wicking height is ≥120mm, the average puncture strength on the front of the fabric is ≥2600N, and the outside is not easy to snag.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com