A method for preparing moisture-absorbing and quick-drying cotton fabric with internal and external hydrophobic and hydrophilic structure from acrylate

A technology of acrylate and hydrophilic structure, which is applied in plant fibers, textiles and papermaking, and improved hand-feeling fibers. It can solve the problems of affecting the wearing comfort of cotton fabric clothing and reducing the hydrophilicity of cotton fabrics, and achieve good moisture absorption speed. Dry performance, improved wearing comfort, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

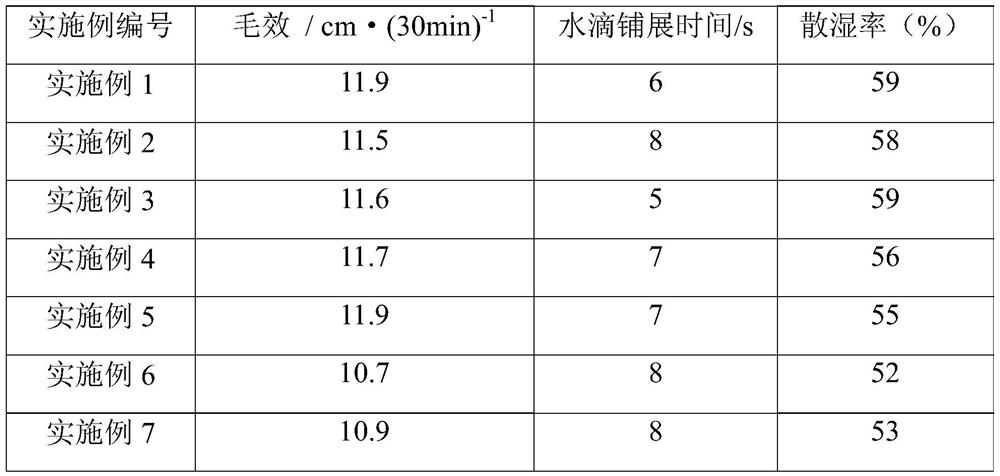

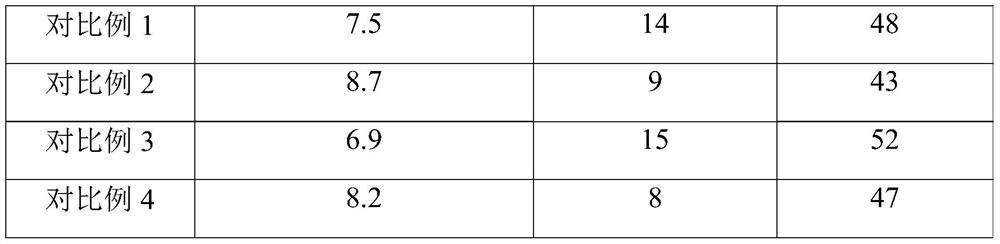

Examples

Embodiment 1

[0042] (1) Mix acrylate, penetrant NR, maleate, ammonium persulfate and water to prepare the first finishing solution, wherein the concentration of acrylate is 50g / L, and acrylate is dimethyl methacrylate A mixture of amino ethyl ester, hydroxyethyl methacrylate and methyl methacrylate, the mass ratio of the three is 1:1:1, the concentration of penetrant NR is 25g / L, and the concentration of maleate is 12g / L L, the concentration of ammonium persulfate is 8g / L. The cotton fabric was soaked twice and rubbed with the first finishing liquid, the squeeze rate was controlled to 65%, coiled, stacked at 50° C. for 24 hours, then washed with water and dried.

[0043] (2) Add the hydrophilic softener SYNICO-6811 into water to prepare the second finishing liquid, wherein the concentration of the hydrophilic softener SYNICO-6811 is 50 g / L. Then, it was dried at 85° C. for 2 minutes, and then baked at 150° C. for 3 minutes to obtain finished cotton fabric A1.

Embodiment 2

[0045](1) Mix acrylate, penetrant NR, fumarate, ammonium persulfate and water to prepare the first finishing solution, wherein the concentration of acrylate is 40g / L, and acrylate is dimethyl methacrylate A mixture of amino ethyl ester, hydroxyethyl methacrylate and methyl methacrylate, the mass ratio of the three is 1:0.8:1.2, the concentration of penetrant NR is 30g / L, and the concentration of fumarate is 8g / L L, the concentration of ammonium persulfate is 6g / L. The cotton fabric was soaked twice and rubbed with the first finishing liquid, the squeeze rate was controlled to 60%, coiled, stacked at 40° C. for 48 hours, then washed with water and dried.

[0046] (2) Add the hydrophilic softener SYNICO-6811 into water to prepare the second finishing liquid, wherein the concentration of the hydrophilic softener SYNICO-6811 is 40 g / L. Then, it was dried at 90° C. for 1 minute, and then baked at 140° C. for 5 minutes to obtain finished cotton fabric A2.

Embodiment 3

[0048] (1) Acrylate, penetrant NR, itaconate, ammonium persulfate and water are mixed to obtain the first finishing solution, wherein the concentration of acrylate is 60g / L, and acrylate is dimethyl methacrylate A mixture of amino ethyl ester, hydroxyethyl methacrylate and methyl methacrylate, the mass ratio of the three is 1:1.2:0.8, the concentration of penetrant NR is 20g / L, and the concentration of itaconate is 15g / L L, the concentration of ammonium persulfate is 10g / L. The cotton fabric was soaked twice and rubbed with the first finishing liquid, the squeeze rate was controlled to 70%, coiled, stacked at 60° C. for 12 hours, then washed with water and dried.

[0049] (2) Add the hydrophilic softener SYNICO-6811 into water to prepare the second finishing liquid, wherein the concentration of the hydrophilic softener SYNICO-6811 is 60 g / L. Then, it was dried at 75° C. for 3 minutes, and then baked at 160° C. for 1 minute to obtain finished cotton fabric A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com