A kind of fencing clothing fabric and its processing technology

A processing technology and technology for fencing clothing, applied in clothing, apparel, fabric surface trimming and other directions, can solve the problems of non-standard breakdown resistance and low strength of fabrics, solve the problem of Velcro hooking, improve breakdown resistance, good The effect of moisture absorption and quick-drying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

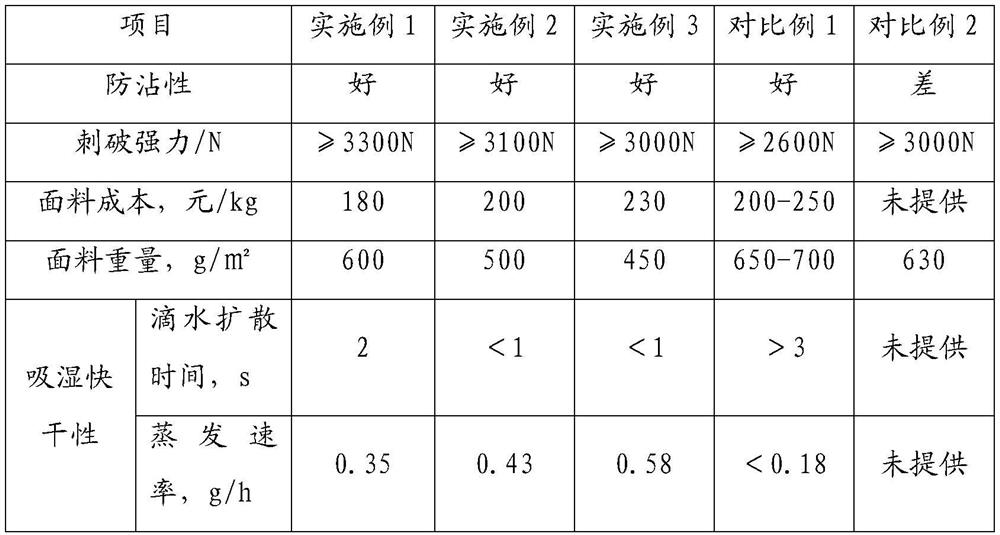

Embodiment 1

[0024] A fencing uniform fabric is composed of ultra-high molecular weight polyethylene filament and composite covering yarn. The ultra-high molecular weight polyethylene specification is 400D, and the strength is 38 g / denier; the composite covered yarn is made of 550D high-strength polyester with a filament strength of 8 g / denier and 30SCoolMax moisture-absorbing and sweat-wicking yarn.

[0025] The composite covered yarn spinning process is as follows: 550D high-strength polyester is used as the core yarn, the pre-tension is 10cN, 30S CoolMax moisture-absorbing and sweat-wicking yarn is used as the outer covering yarn, and the covering degree is 300 turns / m.

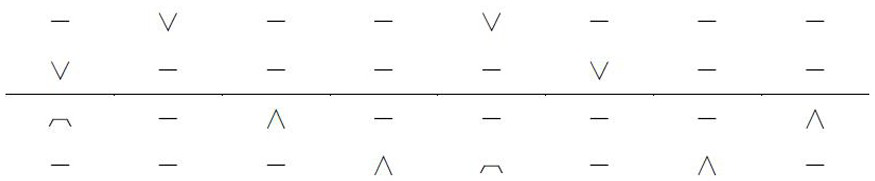

[0026]The weaving process adopts dobby weave and is woven on a 15-needle large circular machine. The upper dial is a combination of knitting and flat stitch (floating thread) knitting, and the lower needle cylinder is a combination of knitting, tuck knitting and flat stitch (floating thread) knitting. When the lower ne...

Embodiment 2

[0032] A fencing uniform fabric is composed of ultra-high molecular weight polyethylene filament and composite covering yarn. The ultra-high molecular weight polyethylene specification is 350D, and the strength is 38 g / denier; the composite covered yarn is made of 500D high-strength polyester with a filament strength of 8.5 g / denier and 30S CoolMax moisture-absorbing and sweat-wicking yarn.

[0033] The composite covered yarn spinning process is as follows: 500D high-strength polyester is used as the core yarn, the pre-tension is 10cN, 30S CoolMax moisture-absorbing and sweat-wicking yarn is used as the outer covering yarn, and the covering degree is 350 turns / m.

[0034] The weaving process adopts dobby weave and is woven on 18-needle circular knitting machine. The upper dial is a combination of knitting and flat stitch (floating thread) knitting, and the lower needle cylinder is a combination of knitting, tuck knitting and flat stitch (floating thread) knitting. When the low...

Embodiment 3

[0040] A fencing uniform fabric is composed of ultra-high molecular weight polyethylene filament and composite covering yarn. The ultra-high molecular weight polyethylene specification is 300D, and the strength is 40 g / denier; the composite covered yarn is made of 400D high-strength polyester with a filament strength of 8.5 g / denier and 40S CoolMax moisture-absorbing and sweat-wicking yarn.

[0041] The composite covered yarn spinning process is as follows: 400D high-strength polyester is used as the core yarn, the pre-tension is 15cN, 30S CoolMax moisture-absorbing and sweat-wicking yarn is used as the outer covering yarn, and the covering degree is 450 turns / m.

[0042] The weaving process adopts dobby weave and is woven on 18-needle circular knitting machine. The upper dial is a combination of knitting and flat stitch (floating thread) knitting, and the lower needle cylinder is a combination of knitting, tuck knitting and flat stitch (floating thread) knitting. When the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com