Fencing clothes fabric and processing technology thereof

A processing technology and fencing clothing technology, which is applied in the direction of clothing, clothing, fabric surface trimming, etc., can solve the problems of low strength and substandard penetration resistance of fabrics, improve the penetration resistance, solve the problem of Velcro snagging, reduce The effect of locking displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

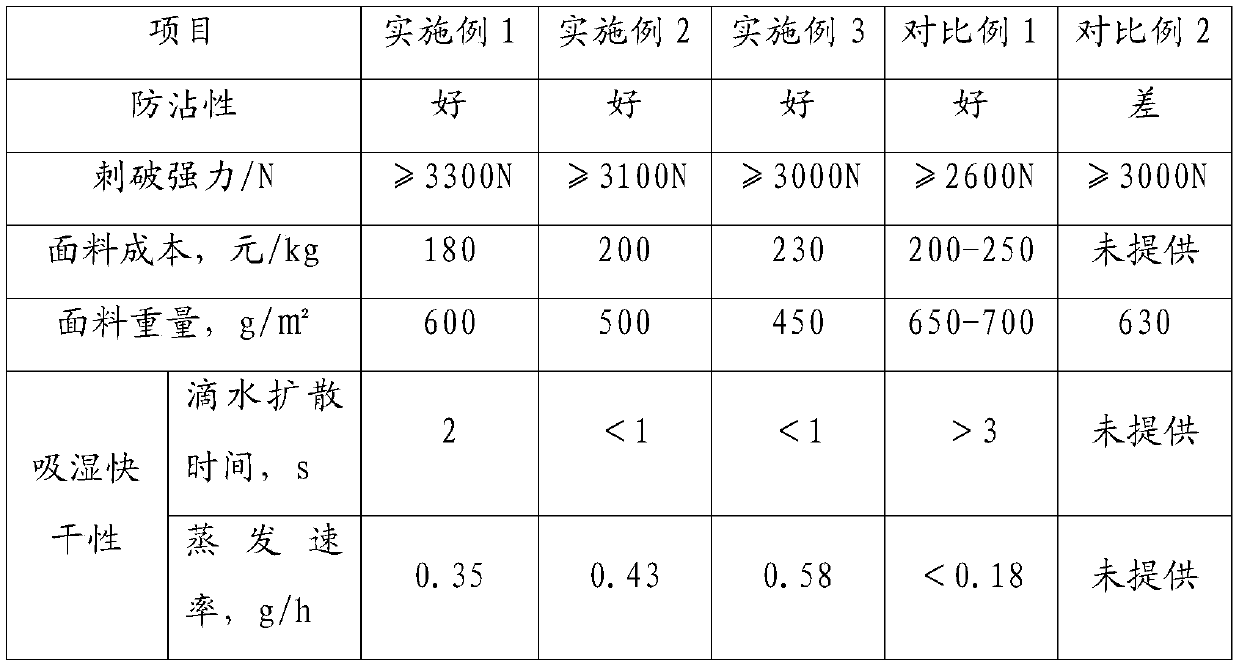

Embodiment 1

[0024] A fencing uniform fabric is composed of ultra-high molecular weight polyethylene filament and composite covering yarn. The ultra-high molecular weight polyethylene specification is 400D, and the strength is 38 g / denier; the composite covered yarn is made of 550D high-strength polyester with a filament strength of 8 g / denier and 30SCoolMax moisture-absorbing and sweat-wicking yarn.

[0025] The composite covered yarn spinning process is as follows: 550D high-strength polyester is used as the core yarn, the pre-tension is 10cN, 30S CoolMax moisture-absorbing and sweat-wicking yarn is used as the outer covering yarn, and the covering degree is 300 turns / m.

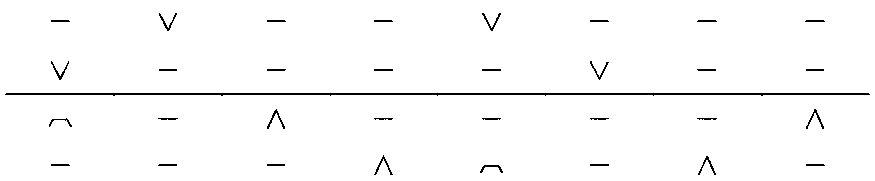

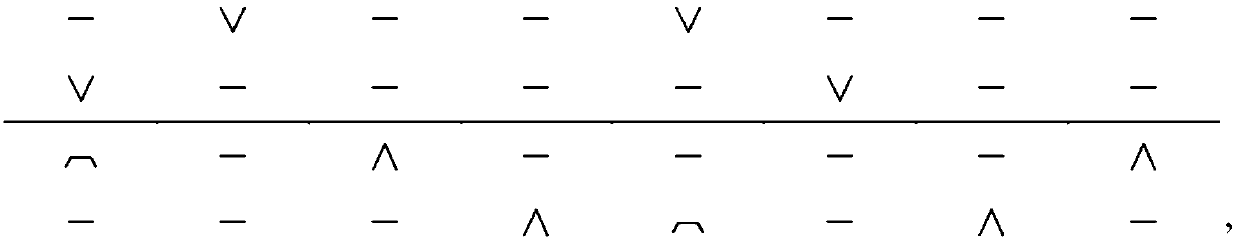

[0026]The weaving process adopts dobby weave and is woven on a 15-needle large circular machine. The upper dial is a combination of knitting and flat stitch (floating thread) knitting, and the lower needle cylinder is a combination of knitting, tuck knitting and flat stitch (floating thread) knitting. When the lower ne...

Embodiment 2

[0032] A fencing uniform fabric is composed of ultra-high molecular weight polyethylene filament and composite covering yarn. The ultra-high molecular weight polyethylene specification is 350D, and the strength is 38 g / denier; the composite covered yarn is made of 500D high-strength polyester with a filament strength of 8.5 g / denier and 30S CoolMax moisture-absorbing and sweat-wicking yarn.

[0033] The composite covered yarn spinning process is as follows: 500D high-strength polyester is used as the core yarn, the pre-tension is 10cN, 30S CoolMax moisture-absorbing and sweat-wicking yarn is used as the outer covering yarn, and the covering degree is 350 turns / m.

[0034] The weaving process adopts dobby weave and is woven on 18-needle circular knitting machine. The upper dial is a combination of knitting and flat stitch (floating thread) knitting, and the lower needle cylinder is a combination of knitting, tuck knitting and flat stitch (floating thread) knitting. When the low...

Embodiment 3

[0040] A fencing uniform fabric is composed of ultra-high molecular weight polyethylene filament and composite covering yarn. The ultra-high molecular weight polyethylene specification is 300D, and the strength is 40 g / denier; the composite covered yarn is made of 400D high-strength polyester with a filament strength of 8.5 g / denier and 40S CoolMax moisture-absorbing and sweat-wicking yarn.

[0041] The composite covered yarn spinning process is as follows: 400D high-strength polyester is used as the core yarn, the pre-tension is 15cN, 30S CoolMax moisture-absorbing and sweat-wicking yarn is used as the outer covering yarn, and the covering degree is 450 turns / m.

[0042] The weaving process adopts dobby weave and is woven on 18-needle circular knitting machine. The upper dial is a combination of knitting and flat stitch (floating thread) knitting, and the lower needle cylinder is a combination of knitting, tuck knitting and flat stitch (floating thread) knitting. When the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com