Heterojunction bipolar transistor and manufacturing method thereof

一种异质结双极、制造方法的技术,应用在半导体/固态器件制造、半导体器件、电气元件等方向,能够解决集电极电阻增大、结晶性恶化、缺陷能级增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0075] Fig. 6 is a cross-sectional view showing the structure of the HBT in the first embodiment of the present invention.

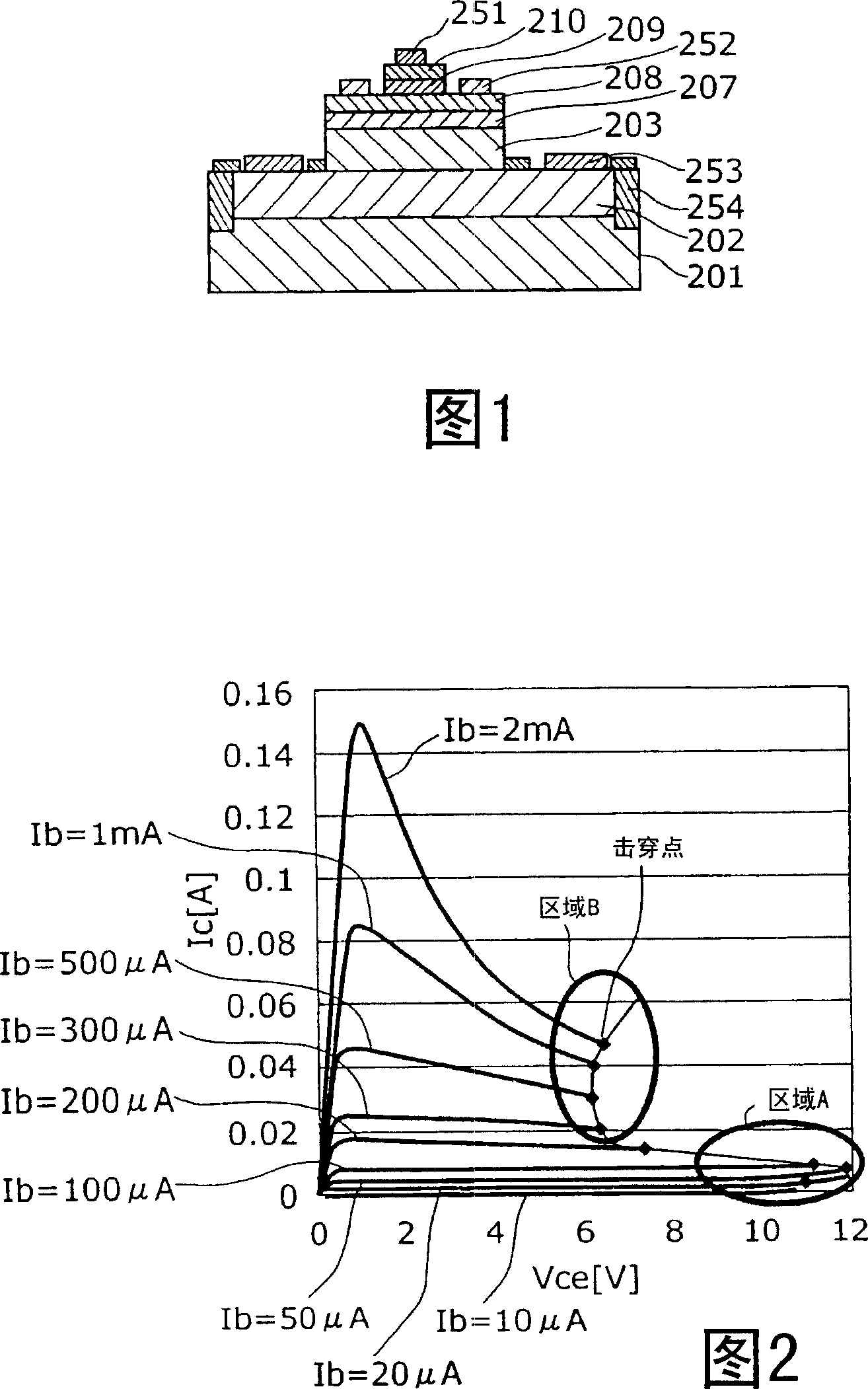

[0076] As shown in FIG. 6, in this HBT, on a substrate 101 made of semi-insulating GaAs, a 5×10 18 cm -3 A high concentration of doped n-type impurities n + Auxiliary collector layer 102 made of GaAs. On the auxiliary collector layer 102, an n-type doped collector layer 110 is formed, and on the collector layer 110, a 4×10 19 cm -3 The base layer 106 is made of p-type GaAs with a film thickness of 100 nm doped with impurities at a high concentration. On the base layer 106, a 3×10 17 cm -3 The impurity concentration is doped into the emitter layer 107 made of n-type InGaP and having a larger energy band gap than the base layer 106 . The collector layer 110, the base layer 106, and the emitter layer 107 are processed into a convex shape such that the base region is isolated, thereby forming a base island region. On the emitter layer 107, stacked in...

no. 2 Embodiment approach

[0091] Fig. 8 is a cross-sectional view showing the structure of the HBT in the second embodiment of the present invention.

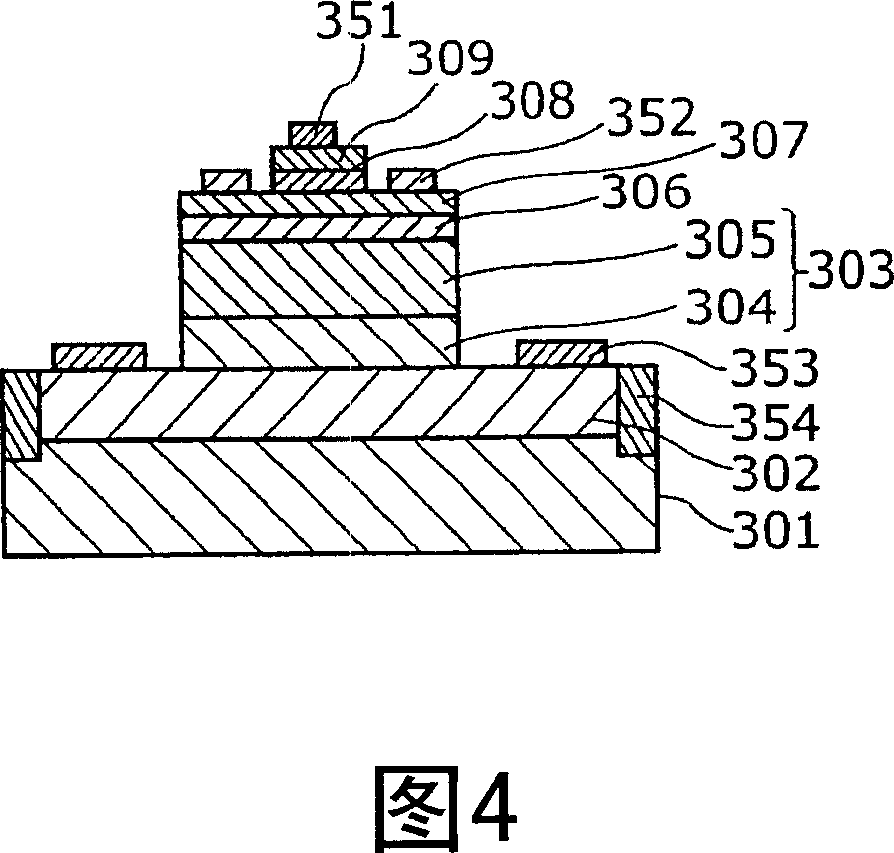

[0092] As shown in FIG. 8, in this HBT, an auxiliary collector layer 102, a collector layer 410, a base layer 106, an emitter layer 107, and an emitter capping layer 108 are sequentially stacked on a substrate 101 made of semi-insulating GaAs. , and the emitter contact layer 109 . At this time, the collector layer 410, the base layer 106, and the emitter layer 107 are processed into a convex shape isolating the base region to form a base island region. In addition, the emitter capping layer 108 and the emitter contact layer 109 are stacked in a convex shape to form an emitter island region.

[0093] On the collector window formed on the exposed portion of the first collector layer 403, AuGe / Ni / Au or the like is formed as the collector electrode 153 by vapor deposition. In addition, on the emitter contact layer 109, an emitter electrode 151 such as Pt / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com