Seabed communication complex cable and preparation method thereof

An integrated cable and submarine communication technology, applied in communication cables, cable/conductor manufacturing, insulated cables, etc., can solve the problems of submarine control cables' water resistance and breakdown resistance that are difficult to meet actual needs, and achieve easy promotion and excellent water resistance Sex, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

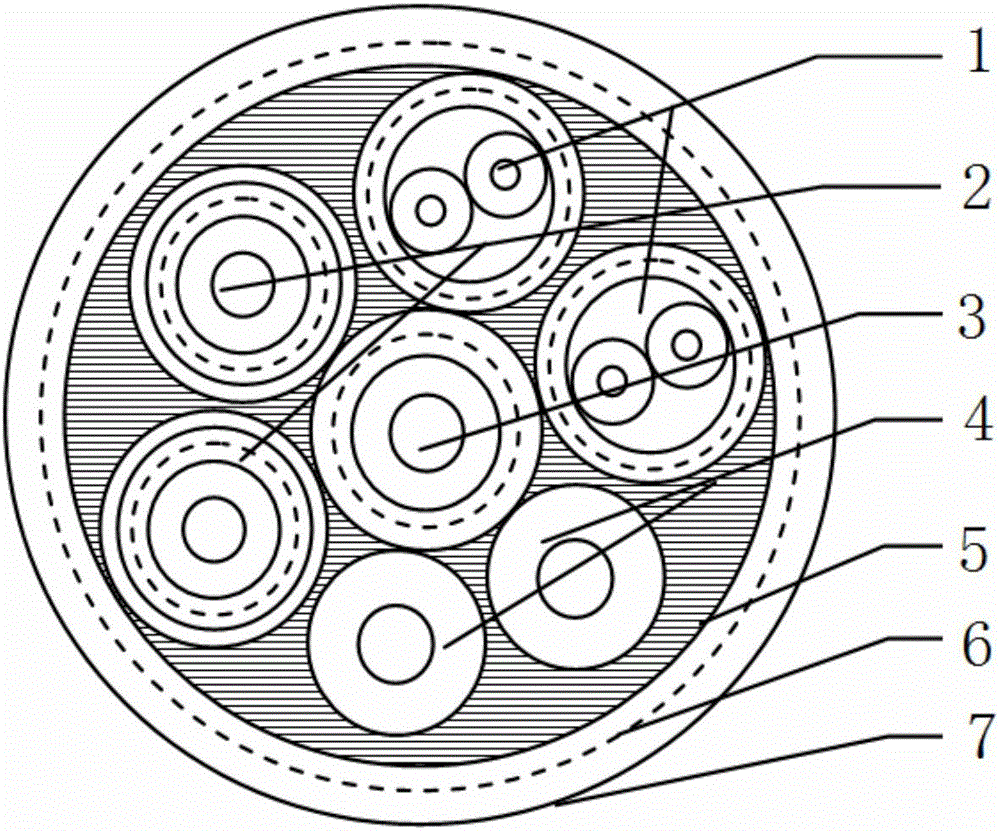

[0023] The present invention provides a submarine communication integrated cable, such as figure 1 As shown, including the wire core, the wire core is successively sheathed with a PVC water-blocking tape coating layer 5, a galvanized steel wire braided shielding sleeve 6, and a cross-linked polyolefin sheath 7 from the inside to the outside; the wire core and the PVC barrier Silicone gel is filled between the hose coating layer 5, and silicone gel is filled between the galvanized steel wire braided shielding sleeve 6 and the cross-linked polyolefin sheath 7; the core includes a first wire 1, a single-mode optical fiber 2, Coaxial radio frequency cable 3 and second wire 4;

[0024] Wherein, the first wire 1 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com