Highly-oriented arrangement core-shell structure fiber polyvinylidene fluoride-based composite medium and preparation method thereof

A polyvinylidene fluoride, core-shell structure technology, applied in the field of dielectric capacitors, can solve the problems of low energy storage density, low dielectric breakdown strength, etc., and achieve the effects of reducing breakdown probability, low equipment price, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

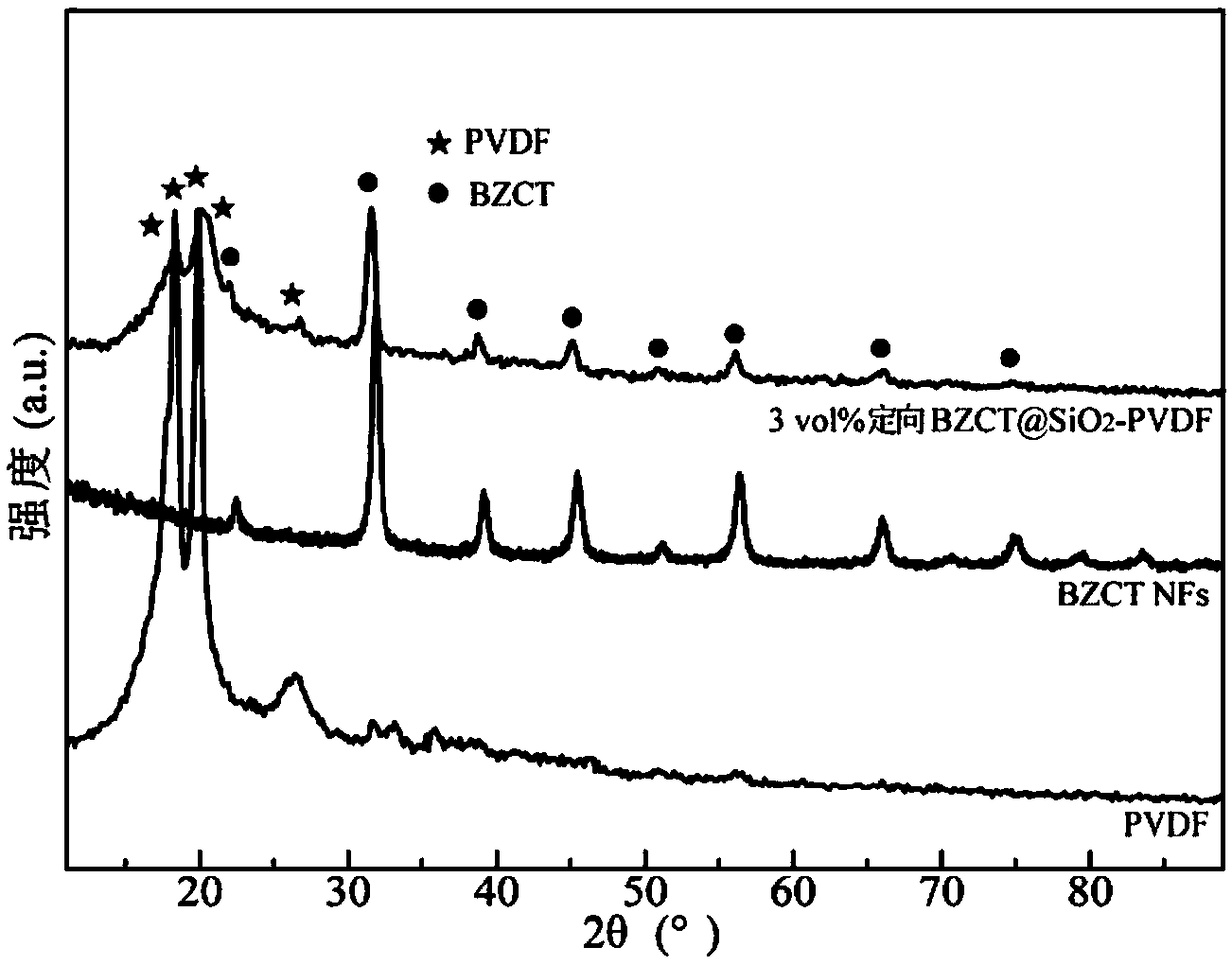

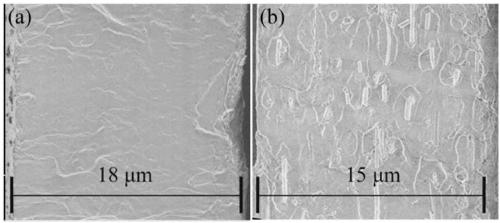

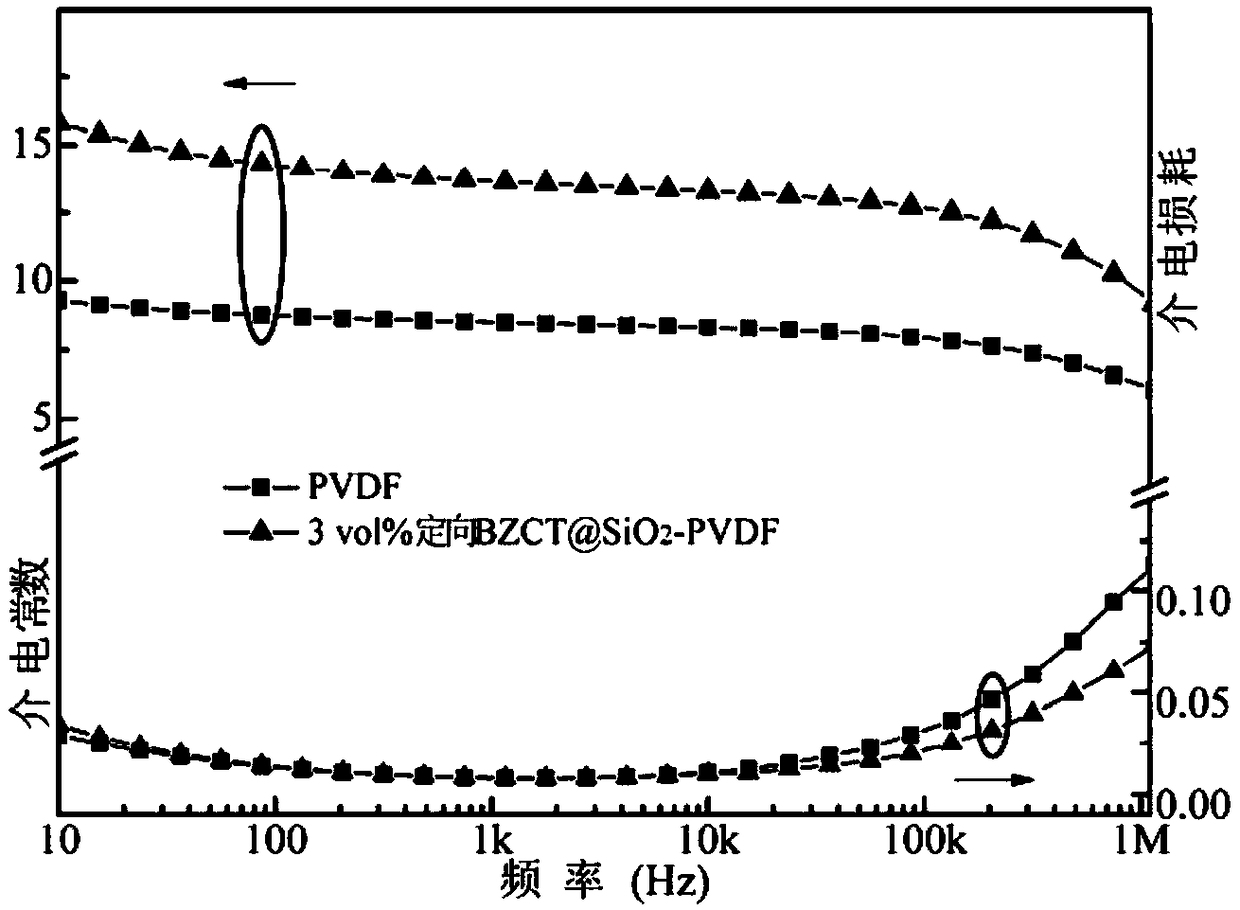

[0042] Specific implementation method 1: The polyvinylidene fluoride-based composite medium with highly oriented arrangement core-shell structure fiber provided by this embodiment is composed of highly oriented anisotropic core-shell structure BZCT@SiO 2NFs filling phase and PVDF composite, the core-shell structure BZCT@SiO 2 Highly oriented arrangement of NFs filling phase in composite media, BZCT@SiO 2 NFs have a core-shell fiber structure, the core layer is barium calcium zirconate titanate, and the shell layer is silicon oxide.

[0043] The preparation method of the above-mentioned polyvinylidene fluoride-based composite medium with highly oriented arrangement of core-shell structure fibers first adopts the sol-gel method and electrospinning technology to prepare the inorganic fiber filling phase with a large aspect ratio, and then conducts the carbon dioxide Silicon wrapping, followed by compounding with polyvinylidene fluoride (PVDF), and quenching treatment, to obtai...

specific Embodiment approach 2

[0049] Specific implementation mode 2: The polyvinylidene fluoride-based composite medium with highly directional arrangement core-shell structure fiber provided by this embodiment is composed of highly directional arrangement anisotropic core-shell structure BZCT@SiO 2 NFs filling phase and PVDF composite, the core-shell structure BZCT@SiO 2 Highly oriented arrangement of NFs filling phase in composite media, BZCT@SiO 2 NFs has a core-shell fiber structure, the core layer is barium calcium zirconate titanate, the shell layer is silicon oxide, and the core-shell structure is BZCT@SiO 2 The content of NFs filling phase in the composite medium is 3vol%.

[0050] The preparation steps of the above-mentioned polyvinylidene fluoride-based composite medium with core-shell structure fibers in highly oriented arrangement are as follows:

[0051] Step 1: 4.7g barium hydroxide octahydrate [Ba(OH) 2 ·8H 2 O] and 0.2 g calcium hydroxide [Ca(OH) 2 ] dissolved in 16mL acetic acid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com