Breakdown-resistant insulating paint

An insulating coating and breakdown-resistant technology, applied in epoxy resin coatings, coatings, etc., can solve problems such as poor mechanical strength and high temperature curing, and achieve the effects of strong adaptability, good breakdown resistance, and simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

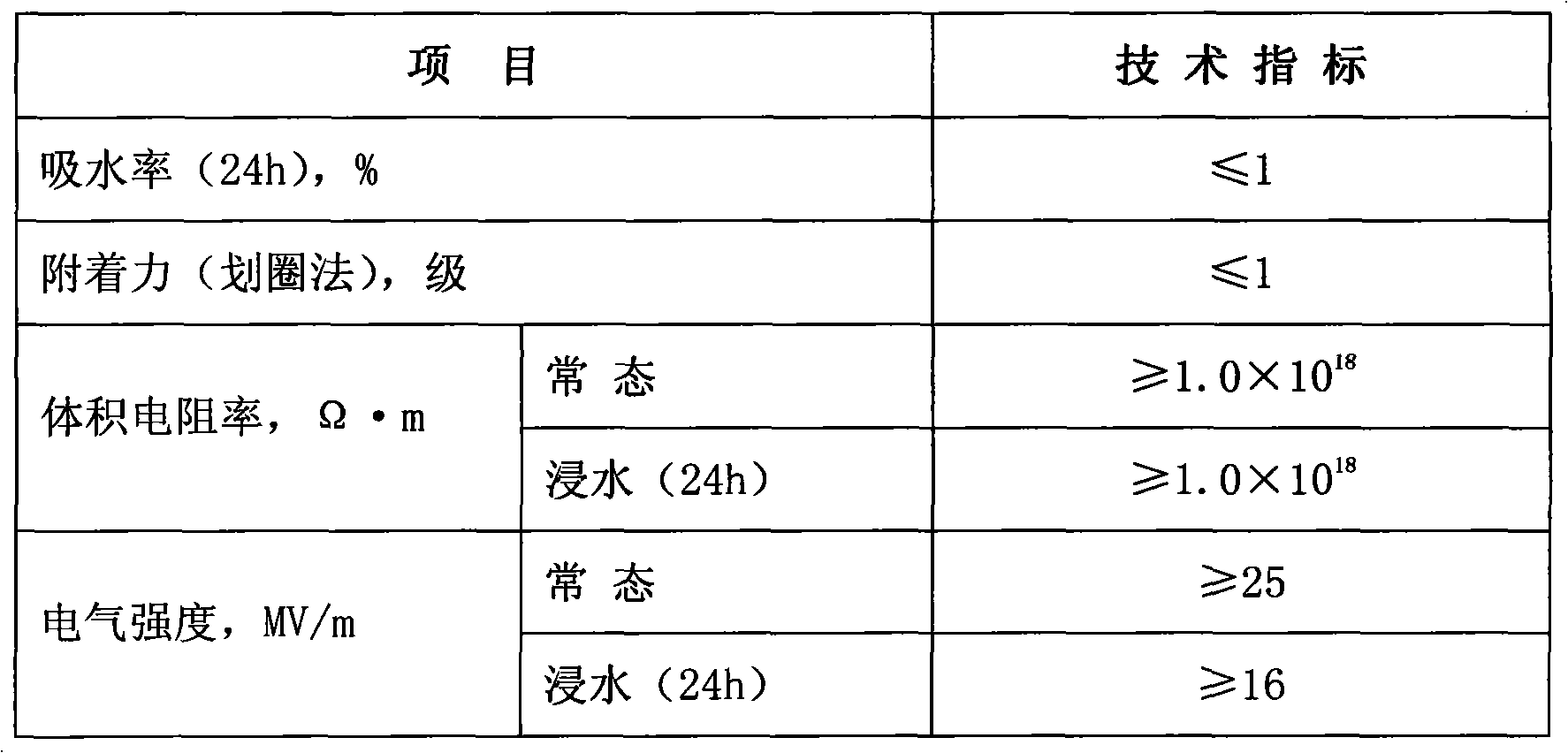

Examples

Embodiment 1

[0016] A breakdown-resistant insulating coating in this embodiment is formed by uniformly mixing two emulsions A and B at a weight ratio of 10:1, wherein:

[0017] A emulsion includes the following components by weight: 30 parts of silicone modified epoxy resin, 25 parts of 325 mesh mica powder, 15 parts of 800 mesh ceramic powder, 15 parts of 400 mesh aluminum hydroxide, 20 parts of mixed solvent, modified bentonite 5 parts, 5 parts of modified polyurethane, 8 parts of halogen-free flame retardant, 5 parts of antimony trioxide, 0.8 part of defoamer, 1.0 part of leveling agent, 1.0 part of wetting and dispersing agent.

[0018] Emulsion B includes the following components in parts by weight: 25 parts of polyamide curing agent and 25 parts of mixed solvent.

[0019] The above mixed solvent has the following components by weight: 3 parts of n-butanol, 6 parts of xylene, and 2 parts of acetone, which are uniformly mixed.

[0020] The preparation method of the breakdown-resistant...

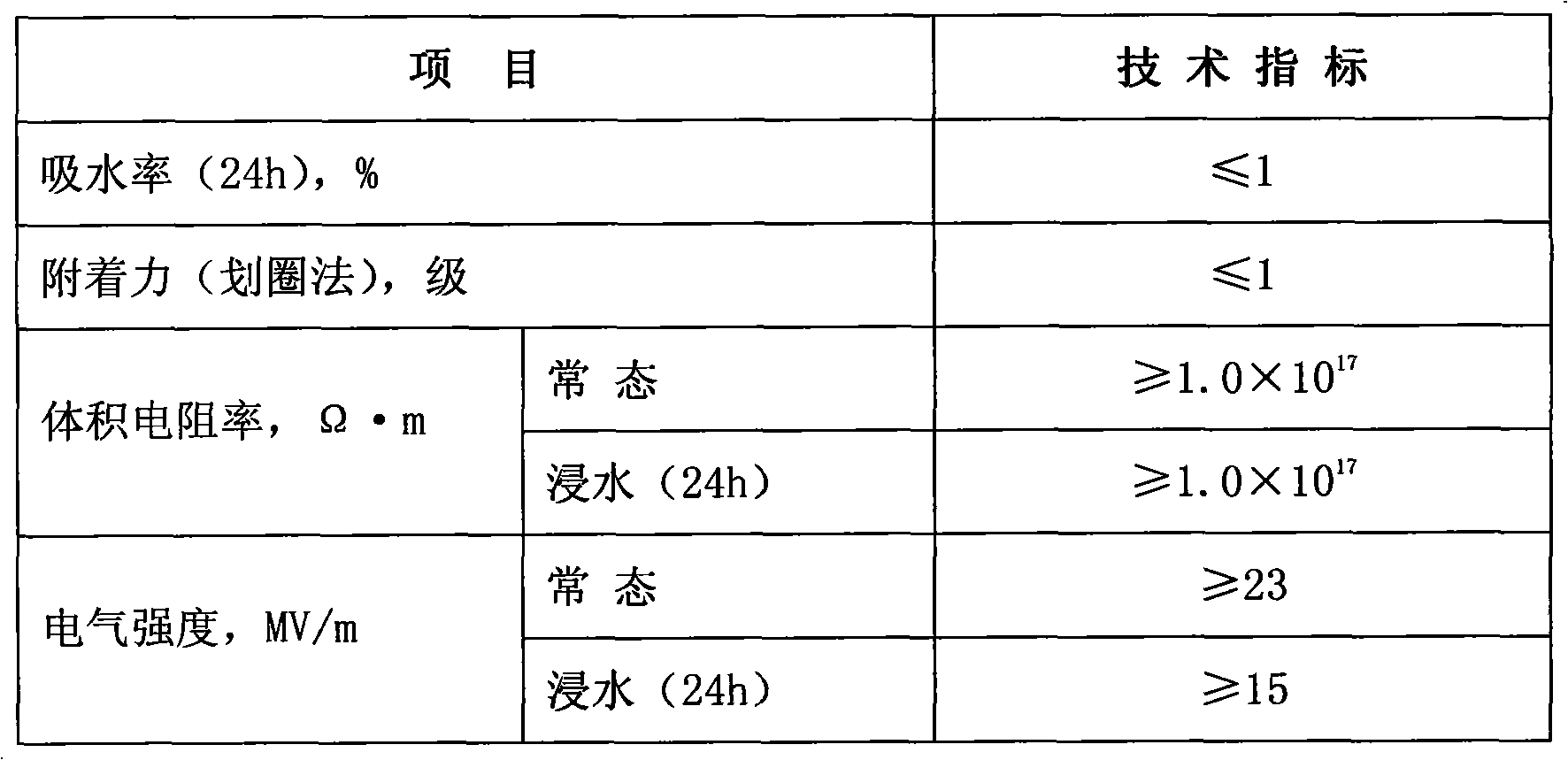

Embodiment 2

[0026] A breakdown-resistant insulating coating in this embodiment is formed by uniformly mixing two emulsions A and B at a weight ratio of 10:1, wherein:

[0027] A emulsion includes the following components by weight: 60 parts of silicone modified epoxy resin, 40 parts of 200 mesh mica powder, 10 parts of 325 mesh and 1000 mesh ceramic powder, 15 parts of 300 mesh aluminum hydroxide, 10 parts of quartz sand, mixed 25 parts of solvent, 6 parts of modified bentonite, 6 parts of modified polyurethane, 12 parts of halogen-free flame retardant, 8 parts of antimony trioxide, 1.0 part of defoamer, 1.0 part of leveling agent, 1.5 parts of wetting and dispersing agent.

[0028] Emulsion B includes the following components in parts by weight: 30 parts of polyamide curing agent and 20 parts of mixed solvent.

[0029] The above mixed solvent has the following components by weight: 3 parts of n-butanol, 6 parts of xylene, and 2 parts of acetone, which are uniformly mixed.

[0030] The p...

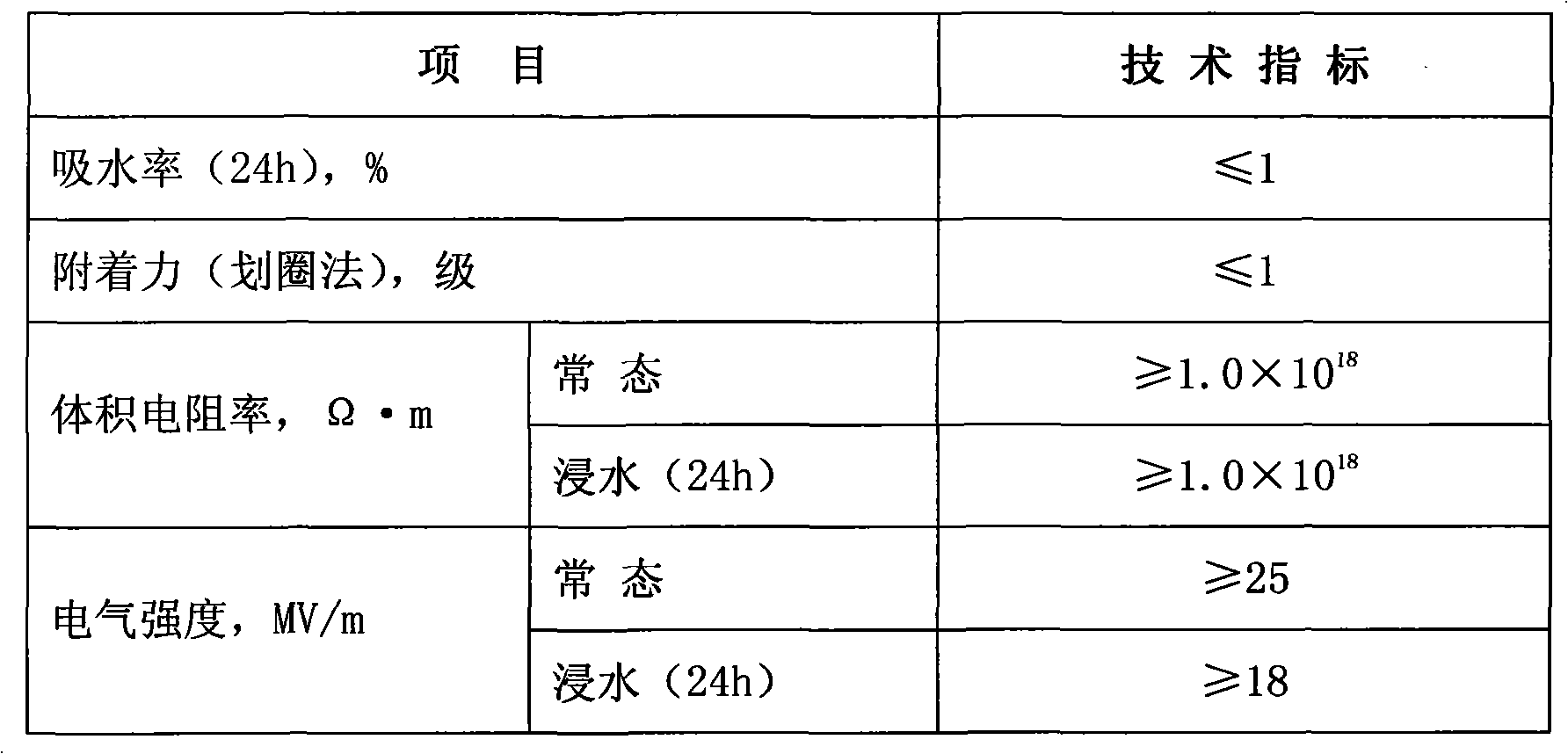

Embodiment 3

[0035] A breakdown-resistant insulating coating in this embodiment is formed by uniformly mixing two emulsions A and B at a weight ratio of 10:1, wherein:

[0036] A emulsion includes the following components by weight: 40 parts of silicone modified epoxy resin, 15 parts of 400 mesh mica powder, 10 parts of 200 mesh aluminum hydroxide, 20 parts of 400 mesh quartz sand, 10 parts of 325 mesh glass powder, mixed 25 parts of solvent, 8 parts of modified bentonite, 10 parts of modified polyurethane, 10 parts of halogen-free flame retardant, 6 parts of antimony trioxide, 0.8 part of defoamer, 1.0 part of leveling agent, 1.2 parts of wetting and dispersing agent.

[0037] Emulsion B includes the following components in parts by weight: 20 parts of polyamide curing agent and 30 parts of mixed solvent.

[0038] The above mixed solvent has the following components by weight: 3 parts of n-butanol, 6 parts of xylene, and 2 parts of acetone, which are uniformly mixed.

[0039] The prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com