Barium titanate@boron nitride composite with one-dimensional core-shell structure and preparation method

A composite material and core-shell structure technology, applied in the direction of nitrogen compounds, titanium compounds, chemical instruments and methods, etc., can solve the problems of low breakdown field strength, limited energy storage capacity, difficult diffusion, etc., and achieve good breakdown resistance The effect of performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

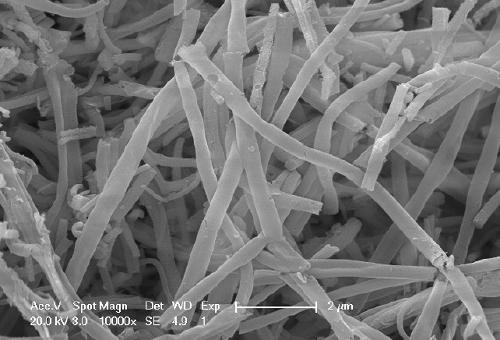

Image

Examples

Embodiment 1

[0019] A barium titanate@boron nitride composite material with a one-dimensional core-shell structure and its preparation method:

[0020] (1) One-dimensional barium titanate nanomaterials were prepared by hydrothermal method, and barium hydroxide, sodium hydroxide, potassium hydroxide, sodium citrate, one-dimensional titanium dioxide materials and other materials were added to the mixture of alcohol and water, Among them, the mass ratio of barium hydroxide, sodium hydroxide, potassium hydroxide, sodium citrate, and one-dimensional titanium dioxide material is 1:1:1:1:2, and the ratio of alcohol to water is 1:2, and then add and mix the above Liquid was added into the polytetrafluoroethylene lining, followed by microwave hydrothermal reaction, the reaction temperature was 100°C, and the reaction time was 40 minutes. After the reaction, the sample was taken out, and then the obtained sample was washed twice with deionized water and alcohol. , dried at 70°C for 9 hours;

[0021...

Embodiment 2

[0024] A barium titanate@boron nitride composite material with a one-dimensional core-shell structure and its preparation method:

[0025] (1) One-dimensional barium titanate nanomaterials were prepared by hydrothermal method, and barium hydroxide, sodium hydroxide, potassium hydroxide, sodium citrate, one-dimensional titanium dioxide materials and other materials were added to the mixture of alcohol and water, Among them, the mass ratio of barium hydroxide, sodium hydroxide, potassium hydroxide, sodium citrate, and one-dimensional titanium dioxide material is 1: 1.5: 1.5: 2:-3, and the ratio of alcohol to water is 1: 3, and then add the above The mixed solution was added to the polytetrafluoroethylene lining, and then microwave hydrothermal reaction was carried out. The reaction temperature was 150°C, and the reaction time was 40 minutes. After the reaction, the sample was taken out, and then the obtained sample was cleaned with deionized water and alcohol for 3 times, dry at...

Embodiment 3

[0028] A barium titanate@boron nitride composite material with a one-dimensional core-shell structure and its preparation method:

[0029] (1) One-dimensional barium titanate nanomaterials were prepared by hydrothermal method, and barium hydroxide, sodium hydroxide, potassium hydroxide, sodium citrate, one-dimensional titanium dioxide materials and other materials were added to the mixture of alcohol and water, Among them, the mass ratio of barium hydroxide, sodium hydroxide, potassium hydroxide, sodium citrate, and one-dimensional titanium dioxide material is 1:1.2: 1.2:1.5:2.5, and the ratio of alcohol to water is 1:2.5, and then add and mix the above Liquid was added into the polytetrafluoroethylene lining, followed by microwave hydrothermal reaction, the reaction temperature was 120°C, and the reaction time was 80minh. After the reaction, the sample was taken out, and then the obtained sample was washed with deionized water and alcohol for 3 times , dried at 80°C for 8 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com