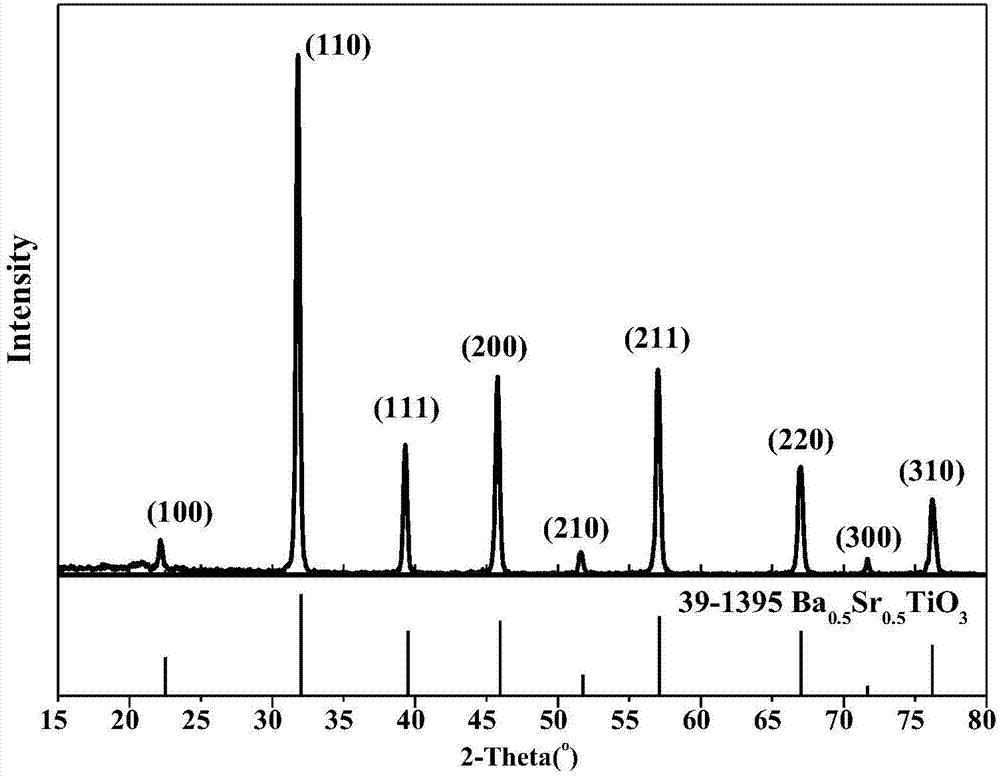

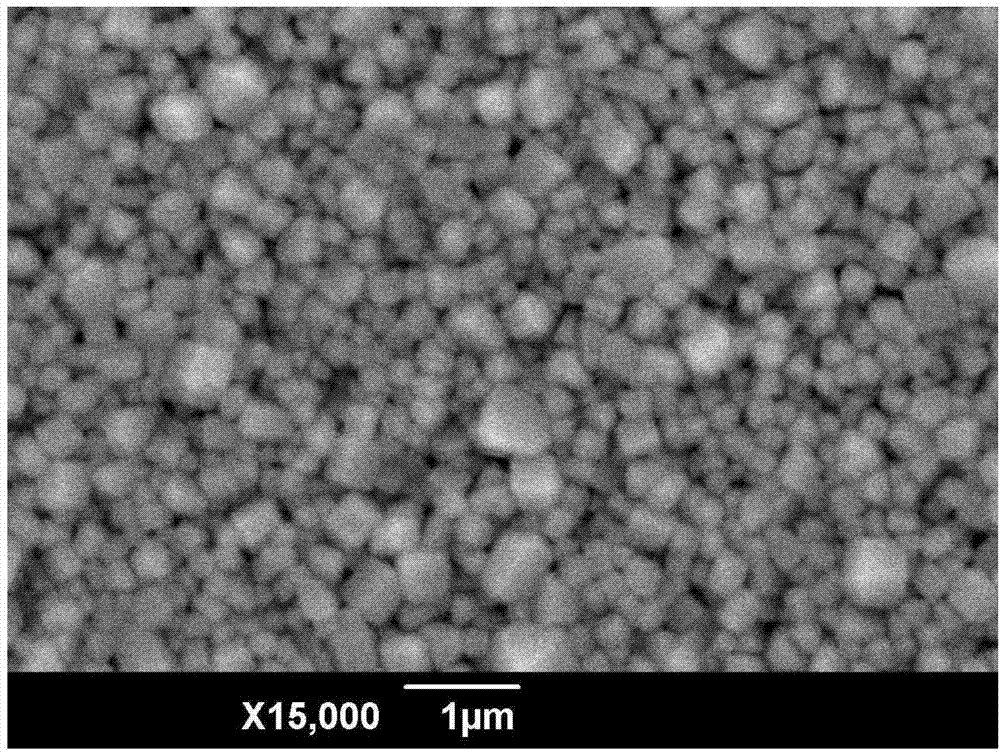

Method for preparing (Ba, Sr) TiO3 nano powder by virtue of Mg<2+> doped hydro-thermal method

A technology of nano-powder and hydrothermal method, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., which can solve problems such as hindering the application of alcohol energy and being easily broken down, so as to ensure solid solution and improve energy storage Characteristics and the ability to resist breakdown, the effect of powder phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Add the first KOH solution with a concentration of 4.5-5.5mol / L to Sr(NO 3 ) 2 Mix well in the solution, where Sr(NO 3 ) 2 The molar ratio of KOH and KOH is 1:1 to obtain mixed solution A; while TiCl 4 Add dropwise to the second KOH solution with a concentration of 3-4.5mol / L and mix evenly, in which TiCl 4 The molar ratio of KOH and KOH is 1:3.8 to obtain mixed solution B; then press Sr(NO 3 ) 2 and TiCl 4 The molar ratio is 1:0.5, take the mixed solution A and the mixed solution B and mix evenly to obtain the SrTiO containing SrTiO 3 complexes; the presence of SrTiO in an alkaline environment 3 Put the complex into a hydrothermal kettle to fully react, the filling rate is 75%, the condition of hydrothermal reaction is 190 ℃, keep warm for 8h, and obtain SrTiO in alkaline environment 3 powder; the synthesized SrTiO in an alkaline environment 3 After the powder was washed with deionized water until the pH value was 5, it was dried at 70°C for 12 hours t...

Embodiment 2

[0033] Step 1: Add the first KOH solution with a concentration of 4.5-5.5mol / L to Sr(NO 3 ) 2 Mix well in the solution, where Sr(NO 3 ) 2 The molar ratio of KOH and KOH is 1:1.5 to obtain mixed solution A; while TiCl 4 Add dropwise to the second KOH solution with a concentration of 3-4.5mol / L and mix evenly, in which TiCl 4 The molar ratio of KOH and KOH is 1:4.1 to obtain mixed solution B; then press Sr(NO 3 ) 2 and TiCl 4 The molar ratio is 1:0.8, take the mixed solution A and the mixed solution B and mix evenly to obtain the presence of SrTiO in the alkaline environment 3 complexes; the presence of SrTiO in an alkaline environment 3 Put the complex into a hydrothermal kettle to fully react, the filling rate is 80%, the condition of hydrothermal reaction is 195 ℃, keep warm for 9h, get the SrTiO in the alkali environment 3 powder; the synthesized SrTiO in an alkaline environment 3 After the powder was washed with deionized water until the pH value was 6, it was drie...

Embodiment 3

[0037] Step 1: Add the first KOH solution with a concentration of 4.5-5.5mol / L to Sr(NO 3 ) 2 Mix well in the solution, where Sr(NO 3 ) 2 The molar ratio of KOH and KOH is 1:1.2 to obtain mixed solution A; while TiCl 4Add dropwise to the second KOH solution with a concentration of 3-4.5mol / L and mix evenly, in which TiCl 4 The molar ratio of KOH and KOH is 1:4.5 to obtain mixed solution B; then press Sr(NO 3 ) 2 and TiCl 4 The molar ratio is 1:0.6, take the mixed solution A and the mixed solution B and mix evenly to obtain the presence of SrTiO in the alkaline environment 3 complexes; the presence of SrTiO in an alkaline environment 3 The complex of the compound is put into a hydrothermal kettle to fully react, and the filling rate is 85%. 3 powder; the synthesized SrTiO in an alkaline environment 3 After the powder was washed with deionized water until the pH value was 7, it was dried at 60°C for 8 hours to obtain SrTiO 3 Powder.

[0038] Step 2: TiCl 4 Add BaCl w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com