Patents

Literature

156results about How to "No impurity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

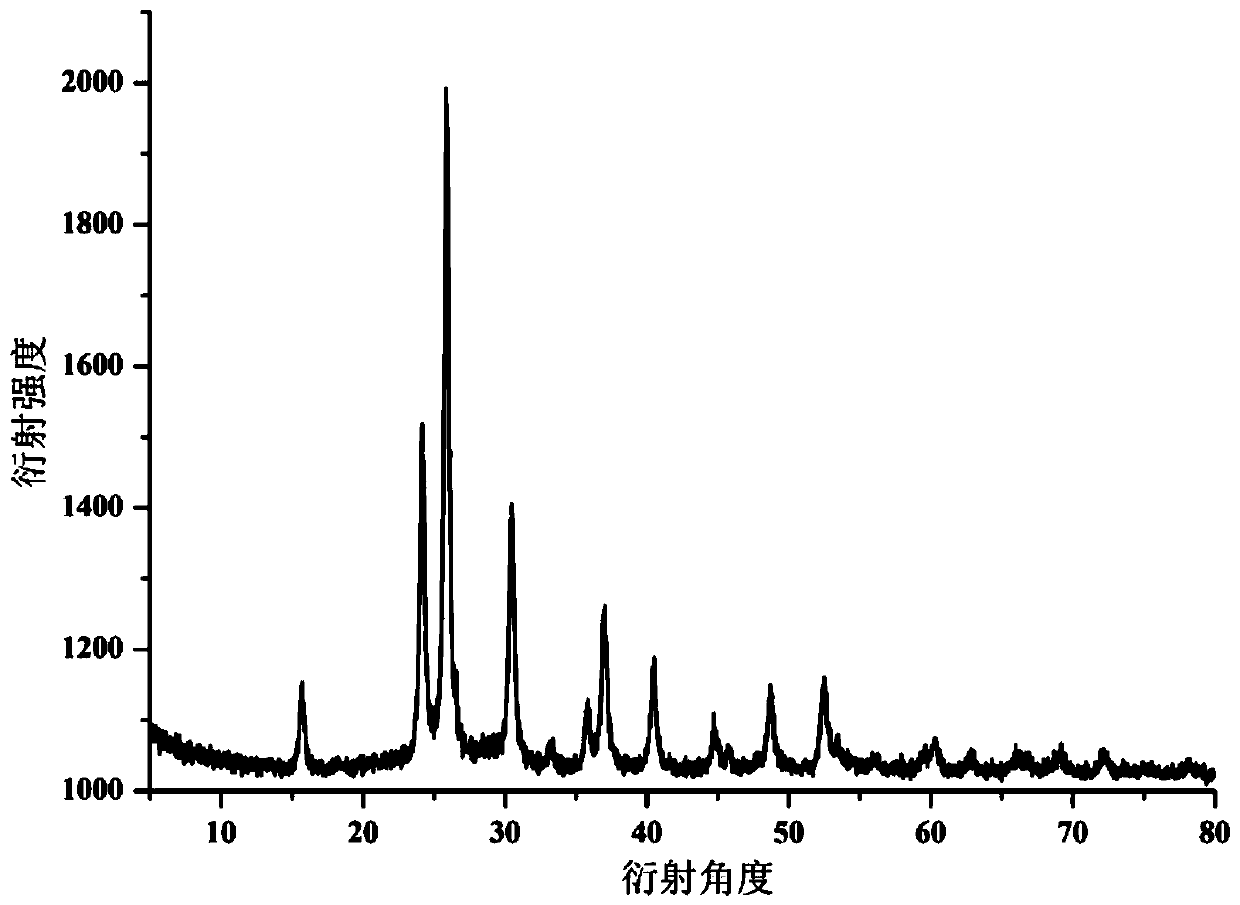

Preparation method of high-compaction density 523-type ternary positive electrode material

InactiveCN107799764AIncrease compaction densityLower pHCell electrodesSecondary cellsManganateSingle crystal

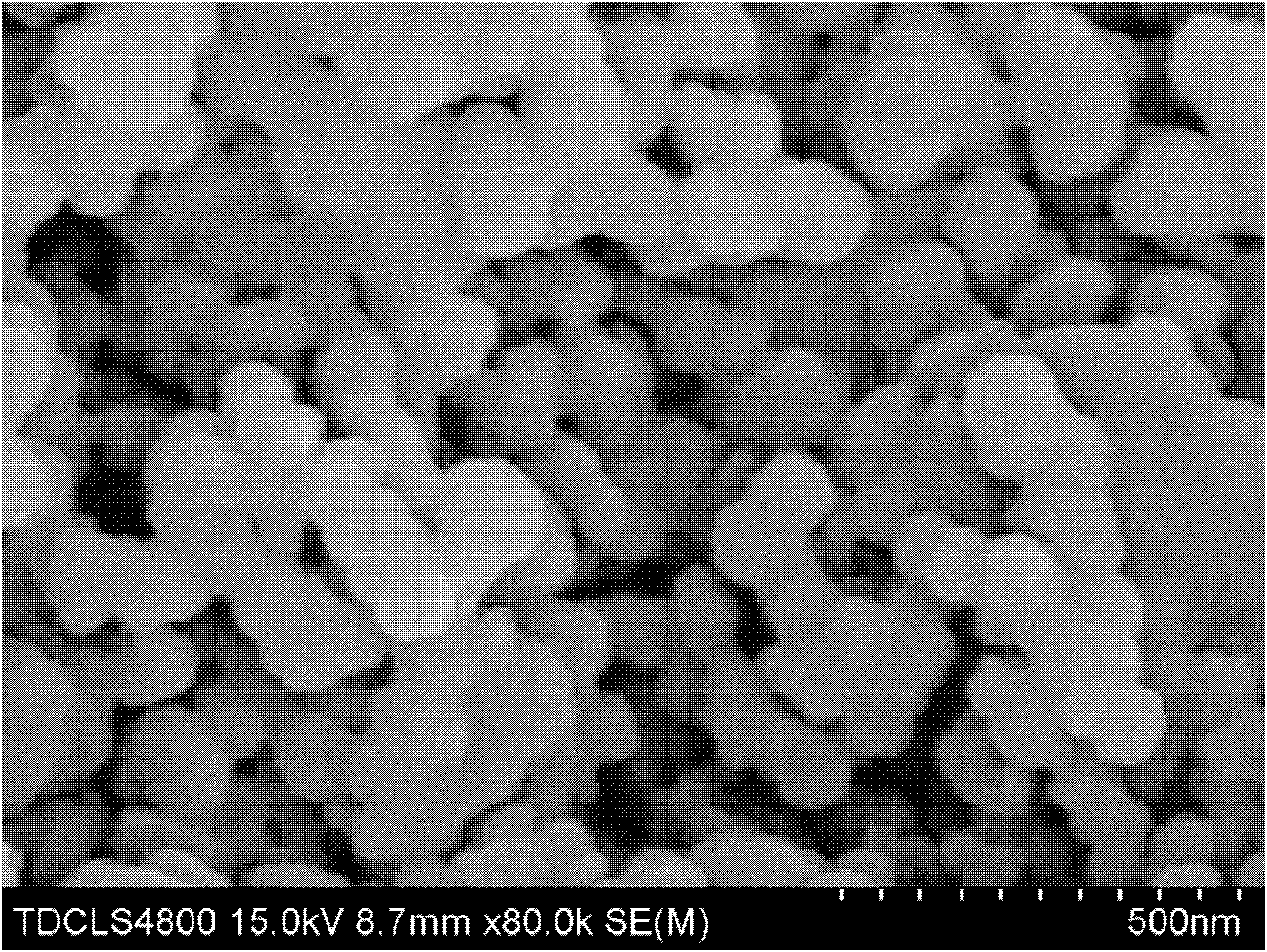

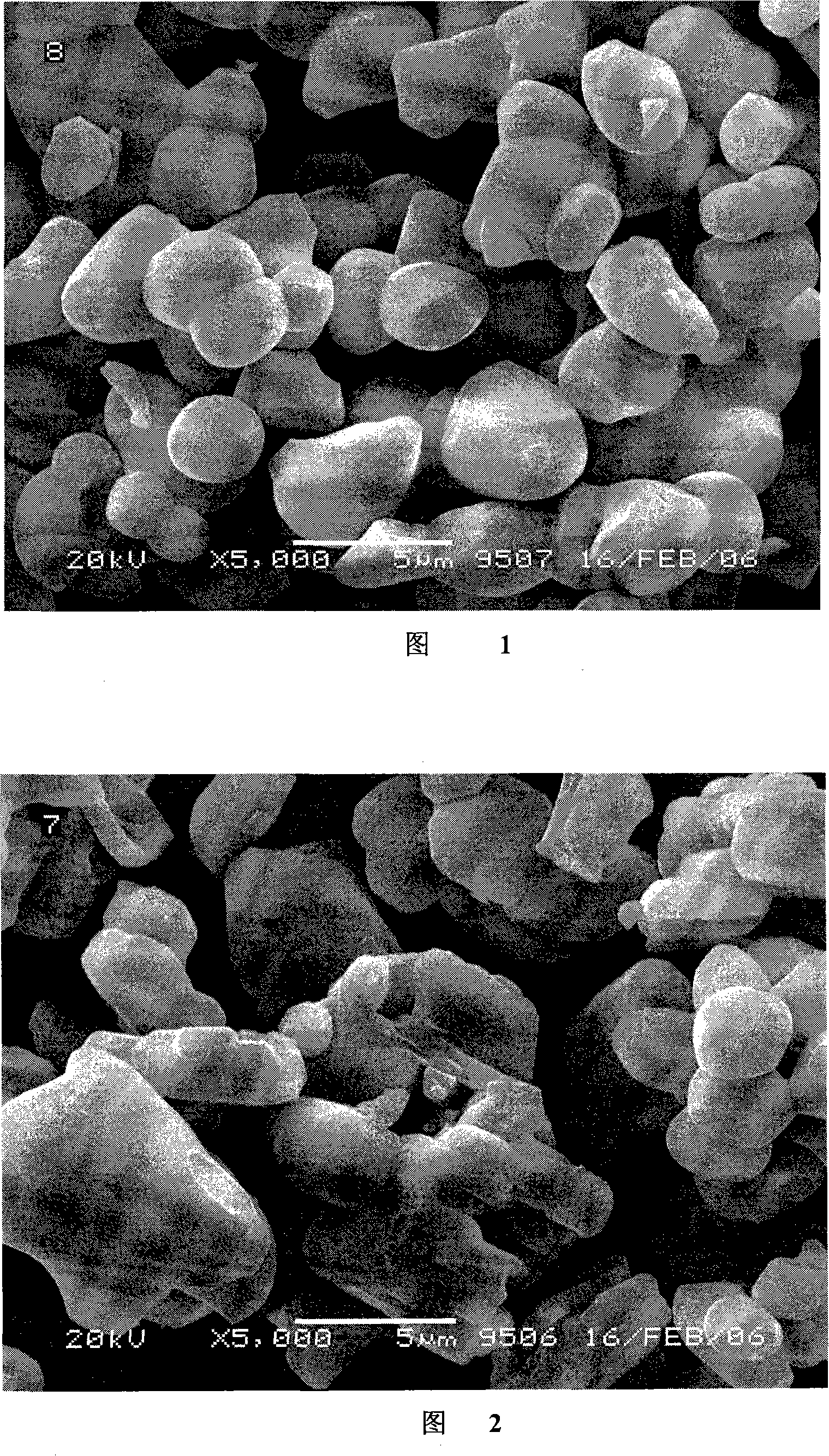

The invention provides a preparation method of a high-compaction density 523-type ternary positive electrode material, and belongs to the technical field of preparation of a lithium ion battery positive electrode material. A high-compaction density and low-pH value lithium nickel cobalt manganate NCM523-type ternary positive electrode is in a spherical shape, grain D50 of secondary agglomeration particle is 10-12 micrometers, and the size of primary single-crystal particle is 1.5-3 micrometers. The preparation method of the high-compaction density 523-type ternary positive electrode material comprises the steps of doping 0.1-1.0% of metal oxide into a mixture of lithium carbonate and a ternary precursor LiNi<0.5>Co<0.2>Mn<0.3>(OH)<2>, performing primary sintering, paste washing, secondarysintering, breakage, iron removal, sieving and mixing, and finally, obtaining an NCM523-type ternary positive electrode material. By the method, the compaction density of the NCM523-type ternary positive electrode material is effectively improved, a pH value is reduced, the compaction density of the prepared NCM523-type ternary positive electrode material is larger than 3.7g / cm<3>, and the pH value is smaller than 10.80.

Owner:JINCHUAN GROUP LIMITED +1

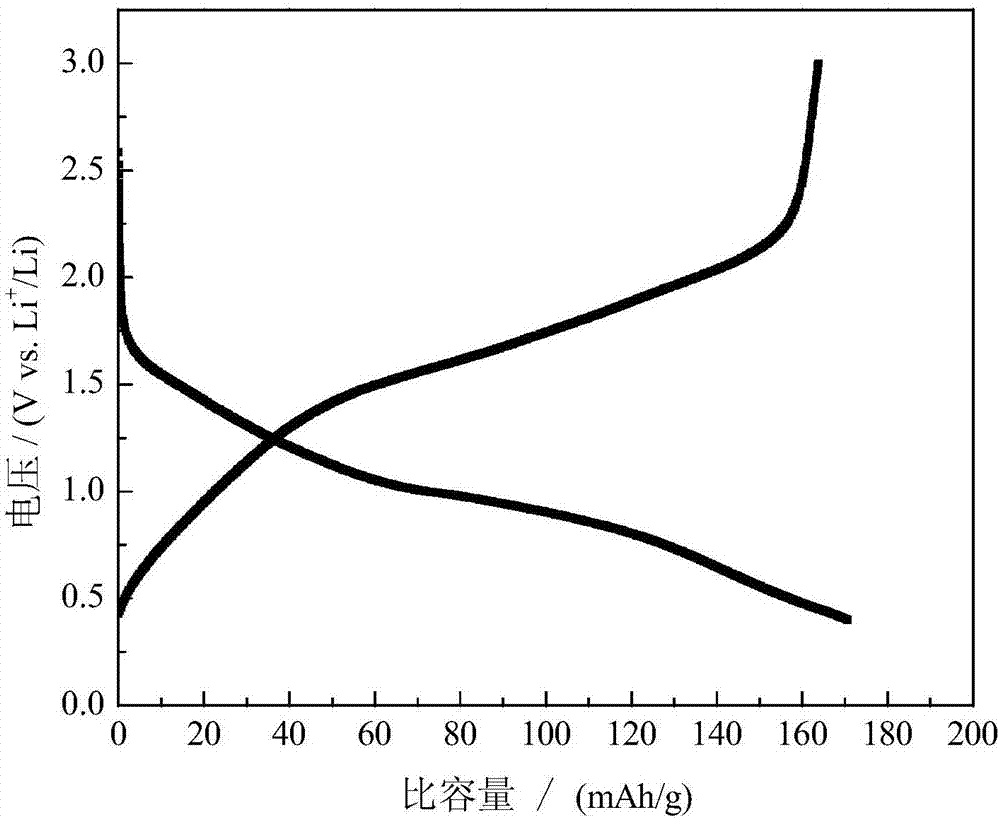

Lithium ferrous silicate anode material coated with crystalline carbon and preparation method thereof

The invention relates to a high-purity lithium ferrous silicate anode material coated with crystalline carbon and a preparation method thereof. In the lithium ferrous silicate anode material coated with the crystalline carbon, the particle diameter of powder is 50-350 nm, and the initial discharge capacity of the anode material at the rate of C / 16 is 125.7-150.3 mAhg<-1>, the weight percent of carbon is 5-15 percent by weight; a Li2FeSiO4 precursor is prepared by using a sol-gel method which comprises the following steps of: with ascorbic acids as reductants and carbon sources, catalyzing by Fe(NO3)3 while reducing ferric ions to form crystalline graphite; and uniformly coating on surfaces of Li2FeSiO4 particles, thus, the electrical property of the Li2FeSiO4 / C anode material is effectively improved. Taking a carbon coating amount of 10.1 percent by weight as an example, the synthesized powder has high purity and is free of impurity phases; the initial discharge capacity at the rate of C / 16 is 150.3 mAhg<-1>; and after circulation forty times, the specific ratio is 137.2 mAhg<-1>, which embodies better rate performance and better circulation performance.

Owner:TIANJIN UNIV

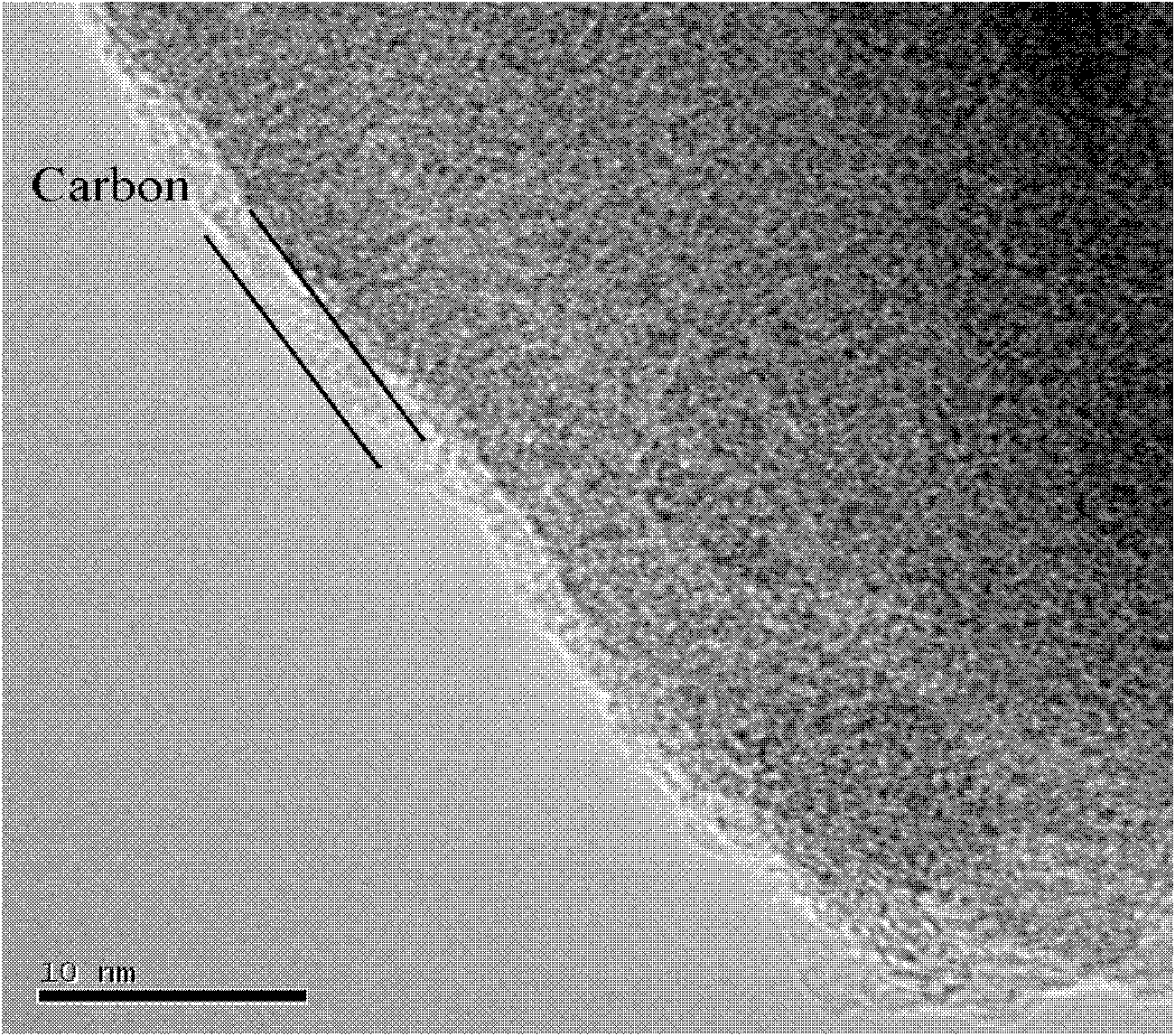

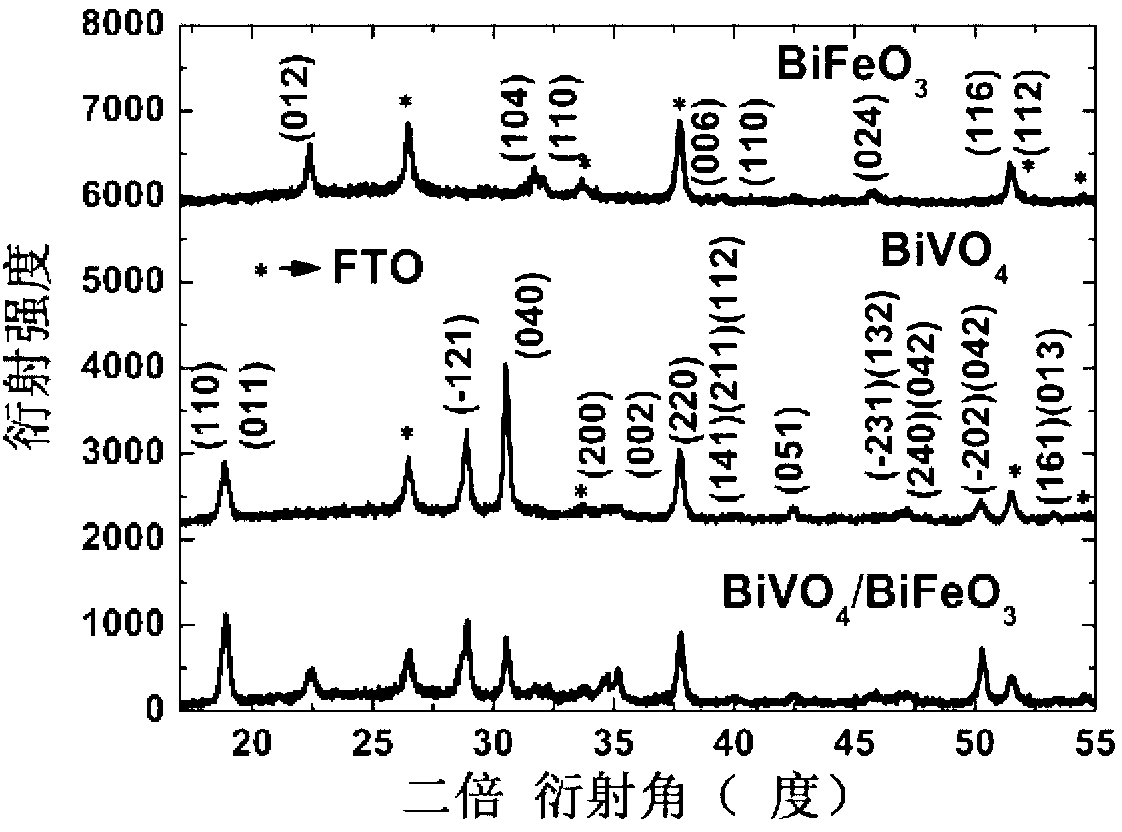

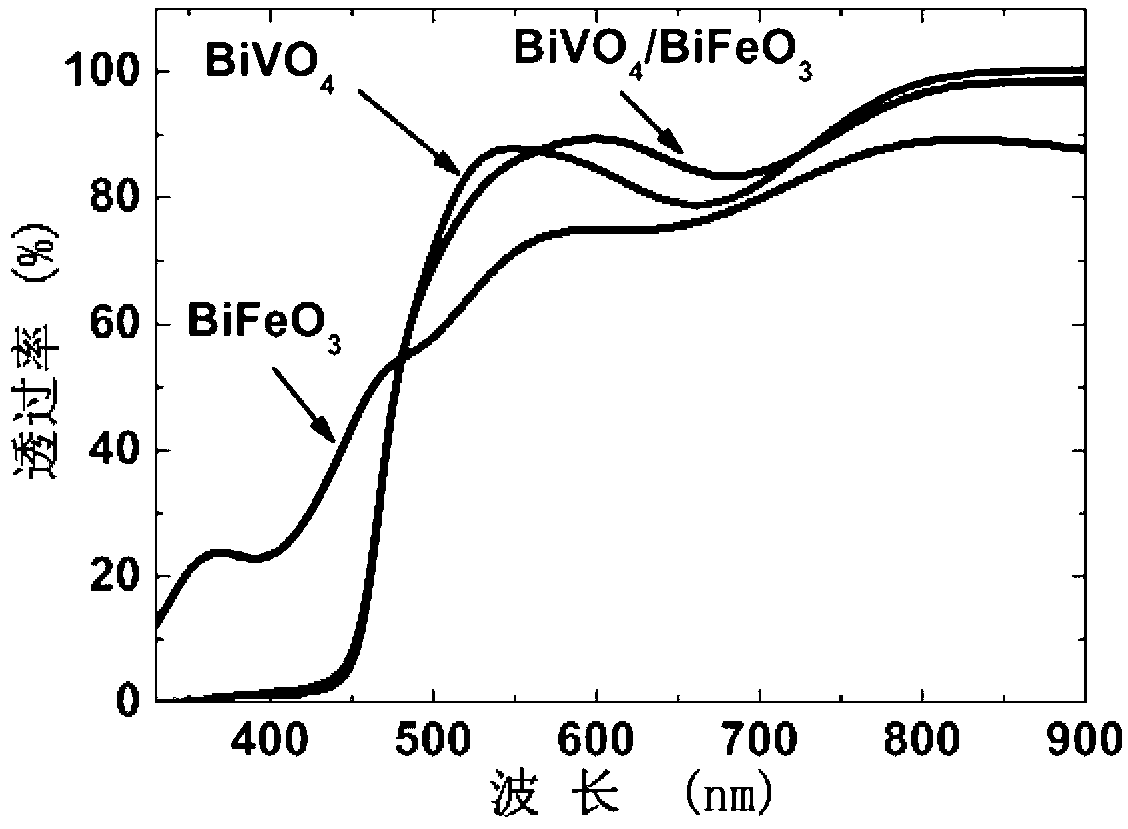

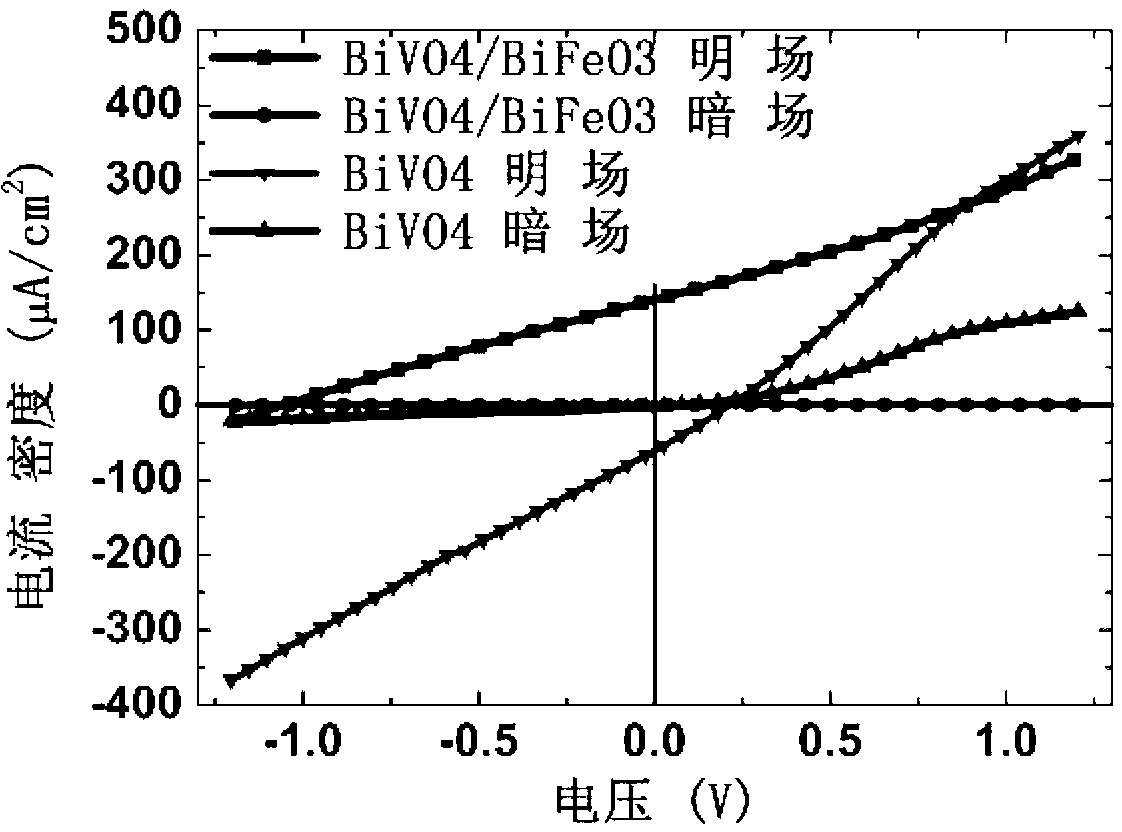

Method for preparing bismuth vanadate/bismuth ferrite heterojunction film solar cells

InactiveCN103078013ANo impurityReduce manufacturing costRenewable energy productsSemiconductor devicesHeterojunctionBismuth vanadate

The invention relates to a method for preparing bismuth vanadate / bismuth ferrite heterojunction film solar cells on a glass substrate. The method comprises the following steps: selecting FTO (Fluorinedoped Tin Oxide) conductive glass as a base, preparing a perovskite-structure bismuth vanadate / bismuth ferrite heterojunction film with a chemical solution deposition method, and then preparing a top electrode on the film with a physical sputtering method to obtain the solar cells. The photovoltaic effect of the bismuth vanadate film can be increased and is reversed by utilizing an ultra-thin bismuth ferrite layer. The method can prepare the bismuth vanadate / bismuth ferrite heterojunction film with high consistency and good repeatability on the glass substrate with a low cost. The prepared heterojunction film has good photovoltaic properties, the diode direction of the heterojunction film is opposite to the diode direction of a pure bismuth vanadate film, and ultra-thin bismuth ferrite ferroelectric films and similar bismuth vanadate / bismuth ferrite heterojunction films have a wide application prospect in the fields of solar cells and photoelectric devices due to the good properties.

Owner:SHANGHAI JIAO TONG UNIV

Silicon carbide powder and preparation method thereof

InactiveCN102491333AControl reaction processLow reaction temperatureNanotechnologySilicon carbideCarbide siliconReaction temperature

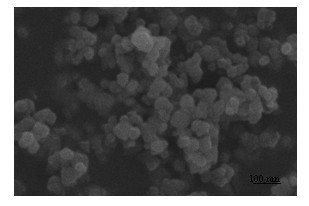

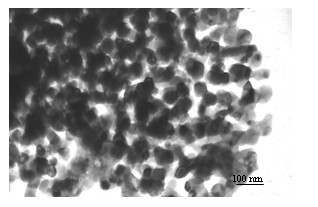

The invention specifically relates to silicon carbide powder and a preparation method thereof. According to a technical scheme, the preparation method comprises the following steps of: uniformly mixing 5-20 percent by weight of nano-silicon dioxide or silica micro-powder, 0.5-2.5 percent by weight of carbon black or amorphous graphite powder, 70-88 percent by weight of an alkali metal chloride and 5-15 percent by weight of aluminum powder serving as raw materials; putting the uniformly-mixed raw materials into a tubular electric furnace, raising the temperature to 800-1,000 DEG C at the temperature raising rate of 4-10 DEG C per minute under the atmosphere of argon, and preserving heat for 2-10 hours; and putting an obtained product into nitric acid of which the concentration is 2-5 mol / L for soaking for 3-8 hours, filtering, cleaning with deionized water till the pH value of a cleaning solution is 7.0, and drying at the temperature of 110 DEG C for 8-24 hours to obtain silicon carbide powder. The method has the characteristics of low reaction temperature, simple process, controllable synthesis process, low production cost, and the like; and the prepared silicon carbide powder has the characteristics of high crystallization, high product purity, freeness from an impure phase and powder particle size of 50-200 nanometers.

Owner:WUHAN UNIV OF SCI & TECH

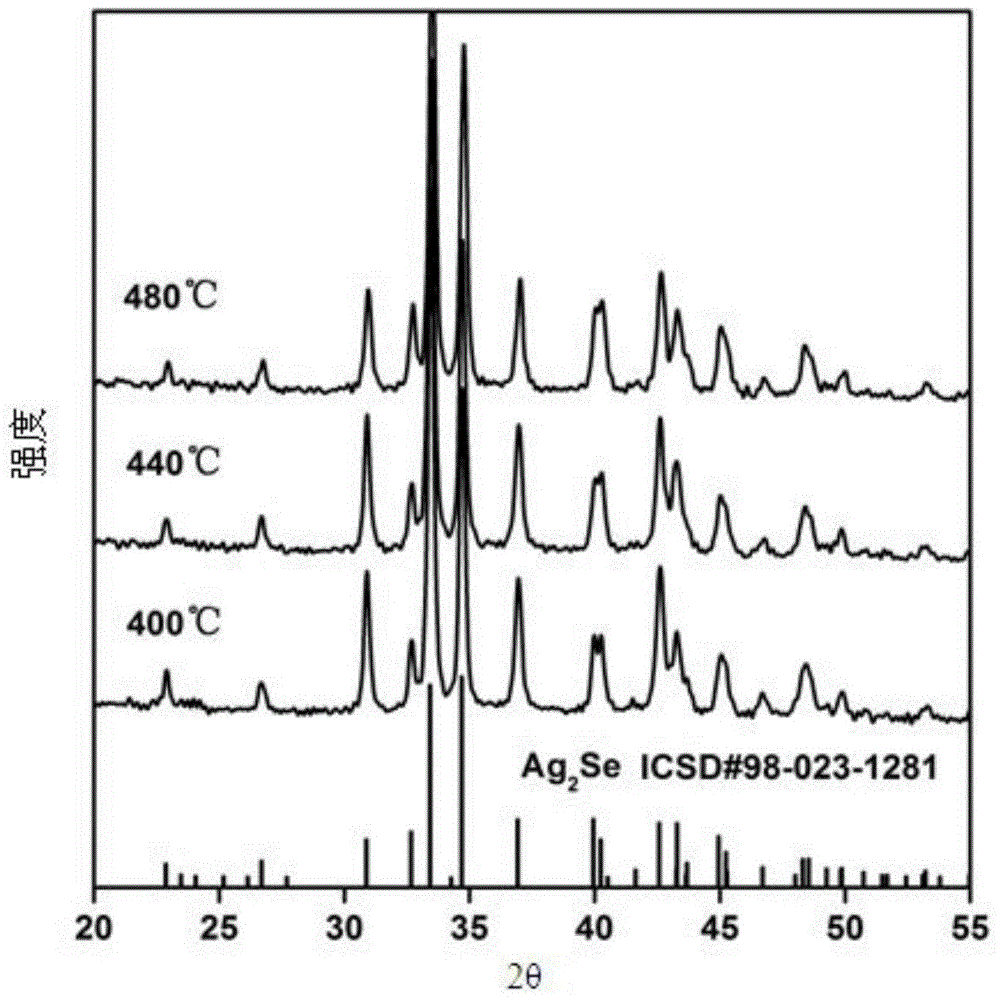

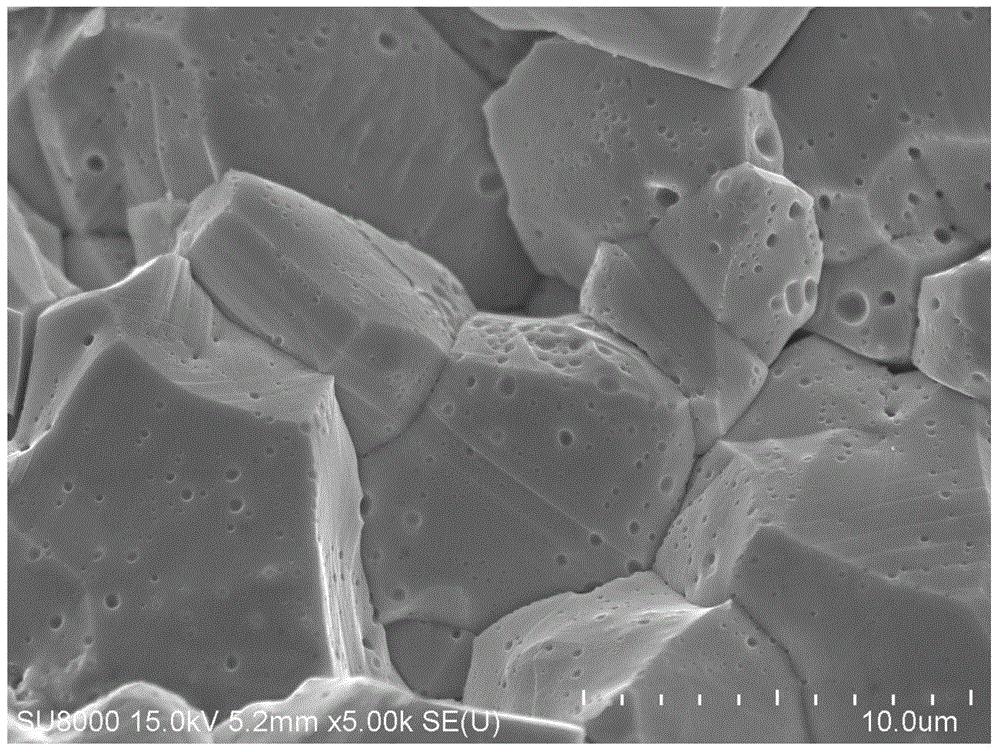

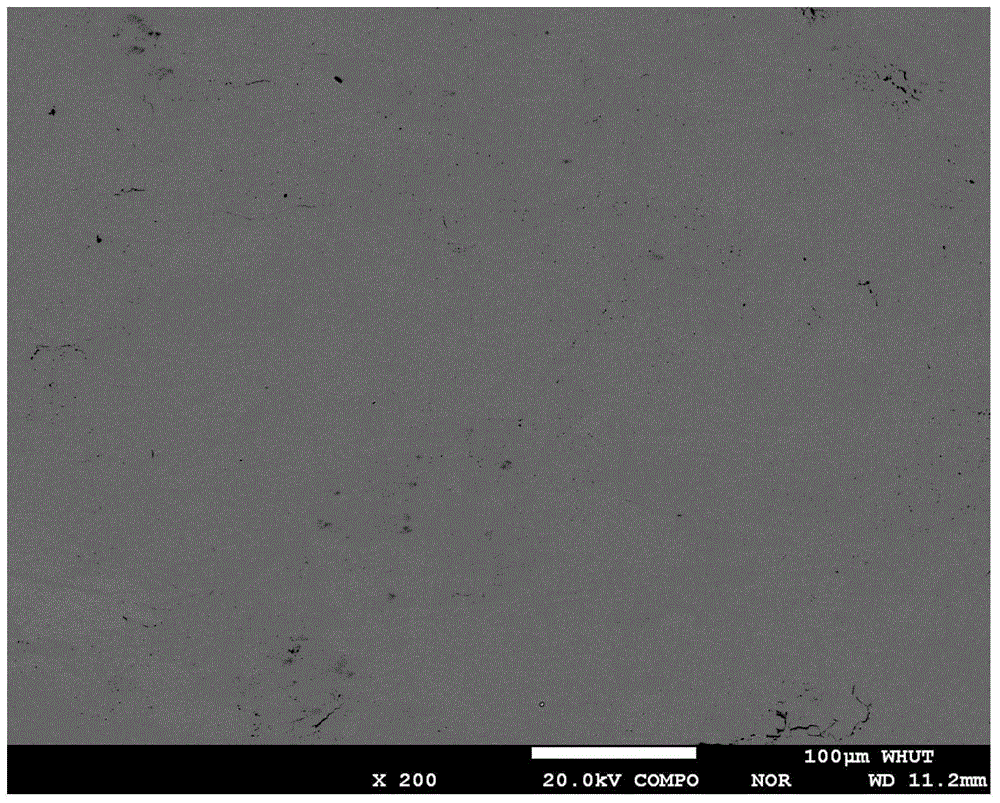

Method for quickly preparing Ag2Se block thermoelectric material through self-homogenization

ActiveCN104878234AAchieve densificationSignificant self-homogenizing effectThermoelectric device manufacture/treatmentThermoelectric materialsRoom temperature

The invention discloses a method for quickly preparing an Ag2Se block thermoelectric material through self-homogenization for the first time. Ag powder and Se powder are used as raw materials; firstly the raw materials are easily mixed, and then the mixed raw materials are directly subjected to plasma activated sintering (PAS), so compact Ag2Se block thermoelectric material can be prepared in several minutes. The process dissolved by the method is super easy, the preparation time is super short, the obtained product is uniform in component distribution, and an obvious effect of self-homogenization is shown. The prepared Ag2Se block thermoelectric material is superior in performance, the room temperature ZT exceeds 0.6, and a good foundation is laid for large-scale preparation and large-scale application of the Ag2Se compound.

Owner:WUHAN UNIV OF TECH

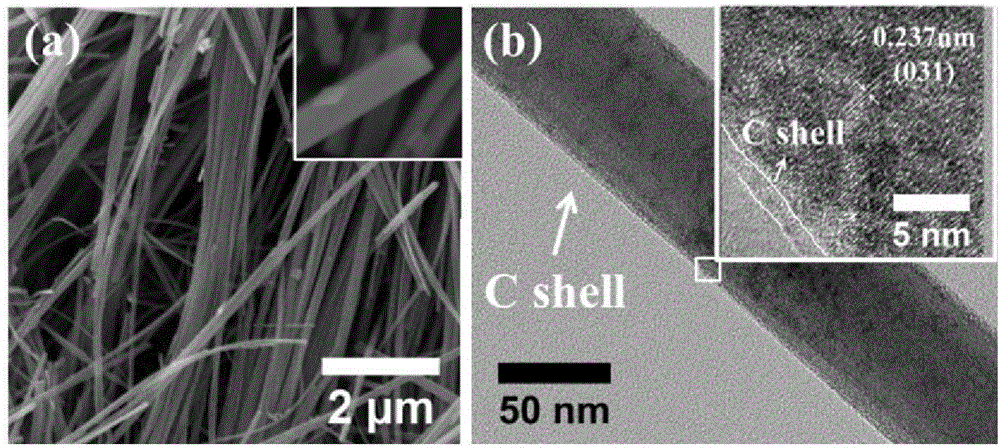

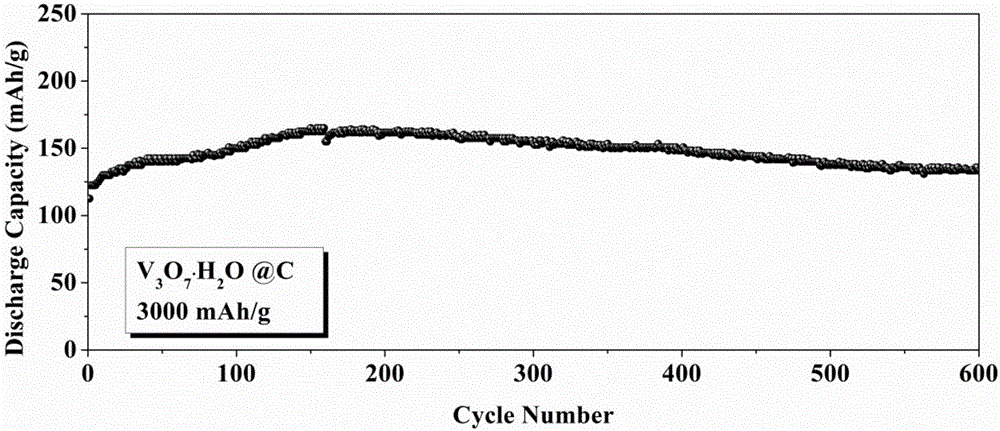

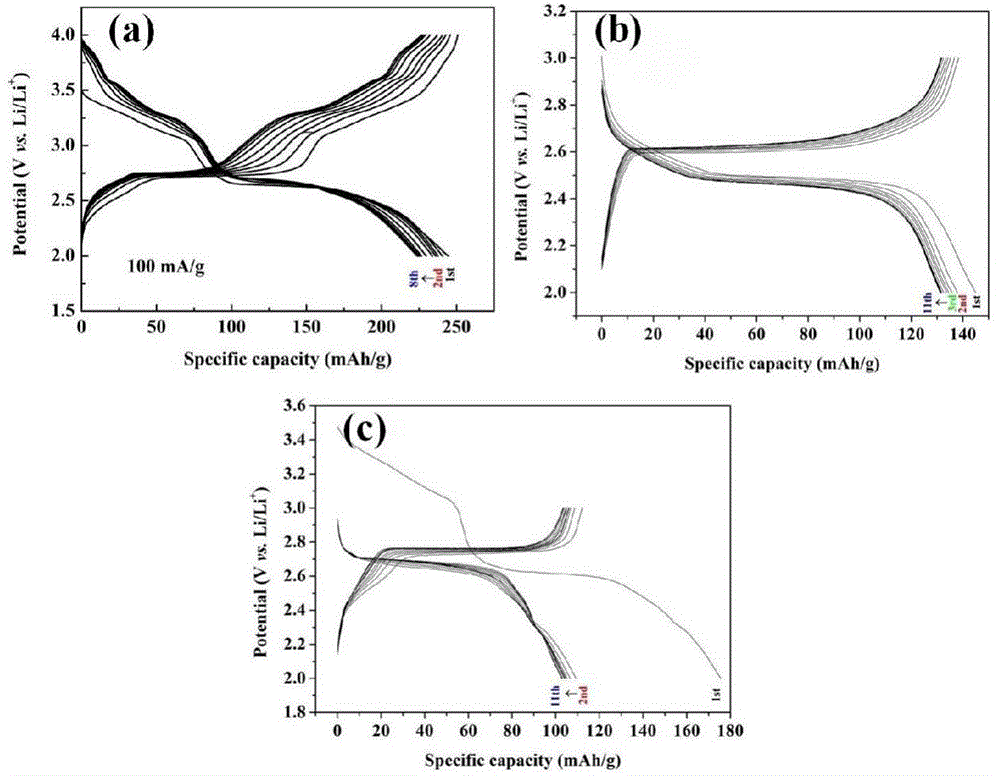

Method for in-situ synthesis of carbon coated-hydrated V3O7 nanobelt and lithium ion battery

InactiveCN105742601AThe product has good crystallinityUniform shapeSecondary cellsPositive electrodesLithium electrodeCarbon coated

The invention relates to a method for in-situ synthesis of a carbon coated-hydrated V3O7 nanobelt and a lithium ion battery, and discloses a method for in-situ synthesis of the carbon coated-hydrated V3O7 nanobelt. The method comprises the following steps of respectively heating reaction raw materials to a certain temperature by a high-temperature hybrid hydrothermal method, mixing the reaction raw materials, cooling the reaction raw materials to a room temperature after completion of the hydrothermal reaction, and carrying out heat preservation and drying processing to obtain the in-situ carbon coated V3O7H2O (V3O7H2O@C) nanobelt. The in-situ synthesis of the carbon coated-hydrated V3O7H2O nanobelt with high crystallinity and high structural strength is achieved by the novel high-temperature hybrid hydrothermal method; the material obtained through preparation can be used for an electrode material of the lithium ion battery; and moreover, the carbon coated-hydrated V3O7H2O nanobelt is endowed with very excellent electrochemical performance and can be applied to the field of the lithium ion battery.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of pyrochlore-type A2B2O7 transparent ceramics

The invention discloses a preparation method of pyrochlore-type A2B2O7 transparent ceramics, relating to A2B2O7-series nano powder preparation by a sol-gel process and belonging to the field of ceramic material preparation. The preparation method comprises the following steps: at room temperature, weighing RE2O3 and ZrOCl2.8H2O or TiCl4 according to the stoichiometric proportion, dissolving the rare earth oxide in nitric acid, adding the ZrOCl2.8H2O or TiCl4 to be dissolved, adding a mixed solution containing a dispersing agent (NH4)2SO4 and PAA (polyacrylic acid), slowly and dropwisely adding into an ammonium bicarbonate solution to obtain a precursor, and drying; adding a certain amount of sintering assistant ethyl orthosilicate or silicon dioxide sol into the precursor, carrying out ball milling, drying, screening and calcining to obtain nano powder; and carrying out compression molding, isostatic cool pressing, vacuum sintering, annealing and polishing treatment to finally obtain the transparent A2B2O7-series ceramics. By adopting the self-made high-activity nano powder to prepare the transparent A2B2O7-series ceramics at low temperature, the technique is simple and feasible.

Owner:FUJIAN CASTECH CRYSTALS

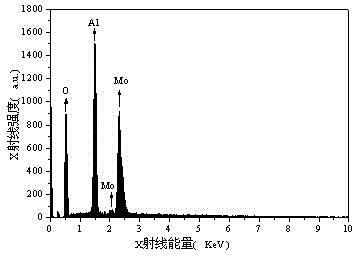

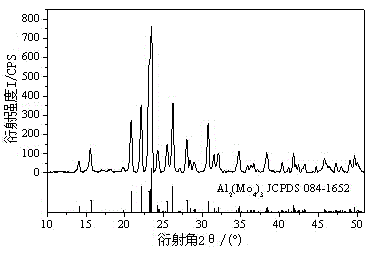

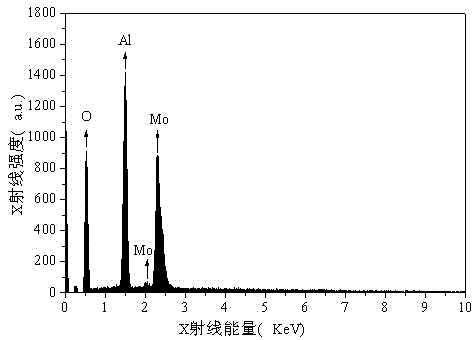

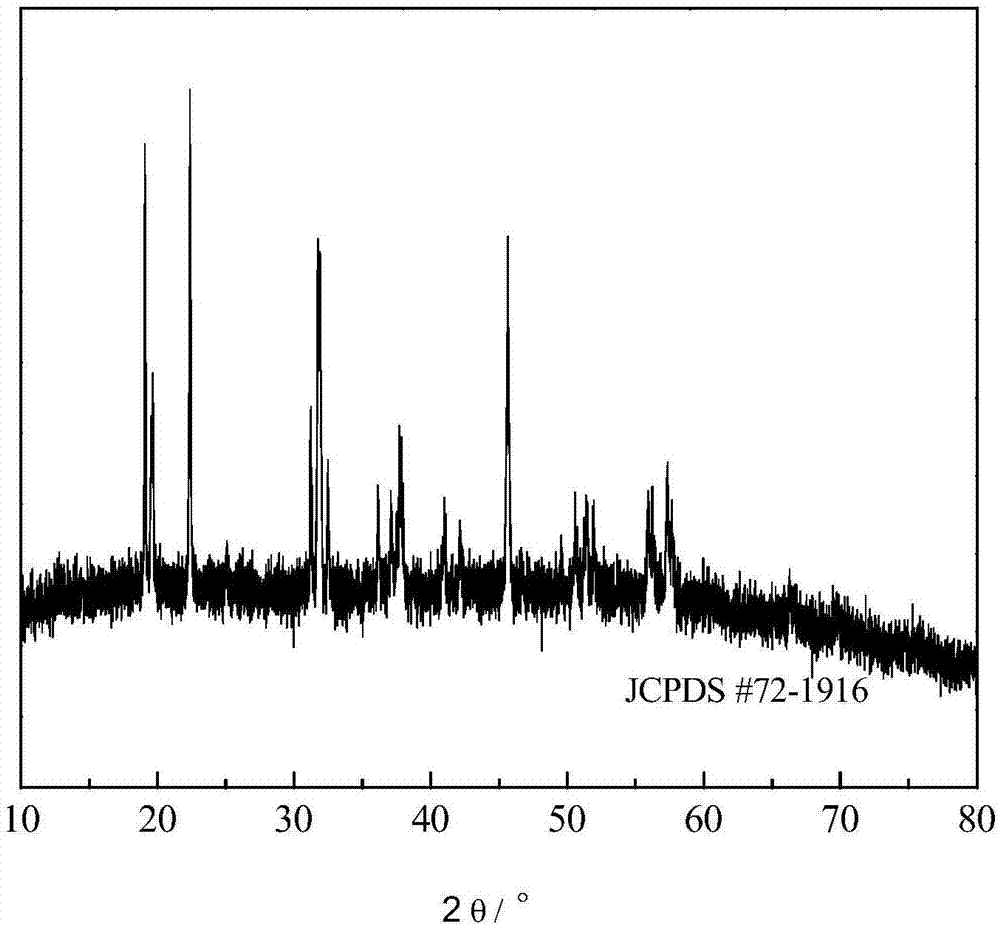

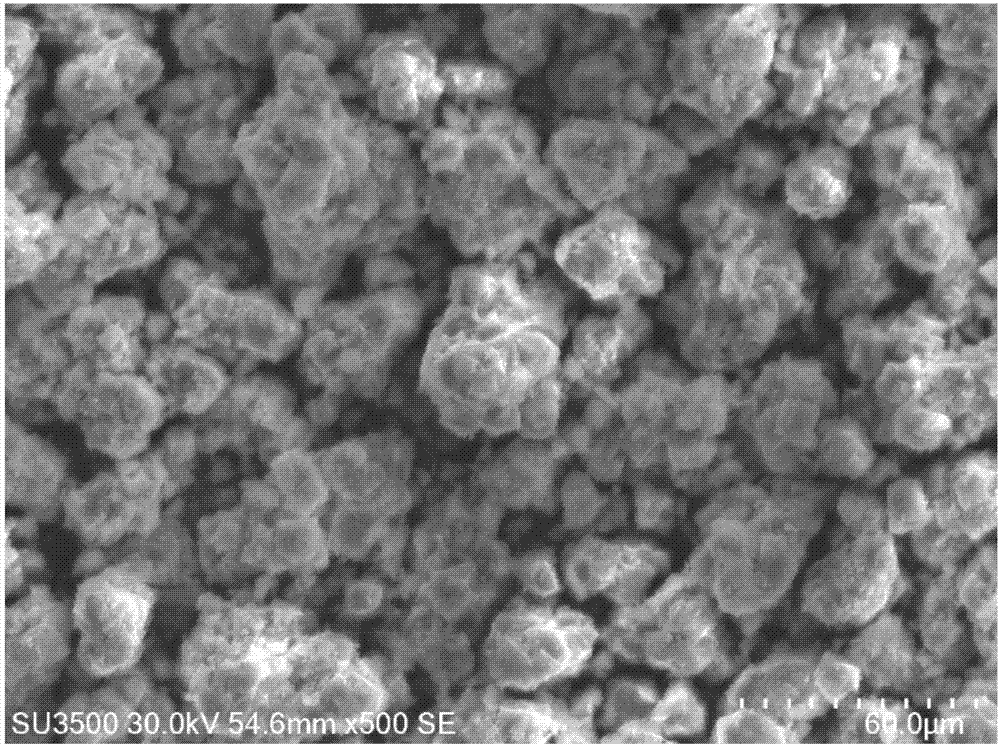

Method for preparing aluminum molybdate with cationic membrane electrolysis method

InactiveCN104789983AHigh purityShort reaction timeElectrolysis componentsAqueous solutionAluminium molybdate

The invention discloses a method for preparing aluminum molybdate with a cationic membrane electrolysis method. An aluminum sheet is taken as an anode, an inert electrode is taken as a cathode, an aqueous solution containing a depolarizer and sodium molybdate is taken as an anolyte, an acid solution, an alkaline solution or a salt solution is taken as a catholyte, and the aqueous solution containing the depolarizer and the sodium molybdate is electrolyzed in a double-chamber electrolytic cell with a cationic membrane serving as a diaphragm with the temperature controlled to range from the room temperature to 90 DEG C in a constant-current electrolysis or constant-voltage electrolysis manner until all Na<+> ions are transferred to a cathode chamber; a product obtained in an anode chamber is washed and filtered with deionized water, an obtained filter cake is dried at the temperature of 300-400 DEG C for 1-4 h, and the aluminum molybdate which is high in purity and free of impurity phases is obtained. According to the method, the effect of cationic membrane electrolysis is used, the Na<+> ions are transferred to the cathode chamber, the effect caused by the Na<+> ions is eliminated, the reaction time is short, and the finally obtained aluminum molybdate product is high in purity and free of the impurity phases.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Preparation method of positive material sodium hexafluoroferrate applicable for sodium or lithium ion batteries and clad material thereof

InactiveCN107293712AReduce energy consumptionShort processCell electrodesSecondary cellsIonChemistry

The invention discloses a preparation method of positive material sodium hexafluoroferrate applicable for sodium or lithium ion batteries and a clad material thereof. Sodium hexafluoroferrate sediment is prepared in a water solution by controlling the conditions of synthetic process, the sodium hexafluoroferrate material can be obtained through filtering and drying, and then the sodium hexafluoroferrate is mixed with a clad layer substance or a precursor thereof, so that the sodium hexafluoroferrate clad material is prepared through calcinations under different atmospheres. The sodium hexafluoroferrate material obtained in the invention is good in crystallization property and free of impurity phase; the particle morphology is regular, the particle size is uniform and controllable, and the mobility is good; and the sodium hexafluoroferrate and the clad material thereof are high in specific capacity and high in cycle stability. The preparation method is simple in technology, low in energy consumption, little in pollution and good in product performance, and is extremely applicable for industrial production.

Owner:HUNAN INSTITUTE OF ENGINEERING

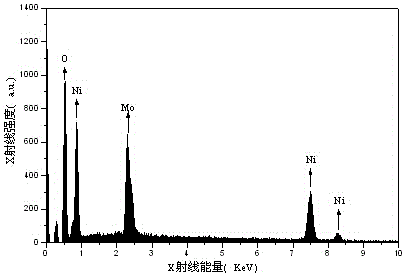

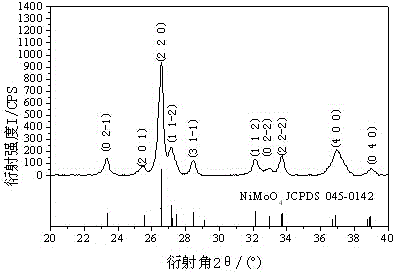

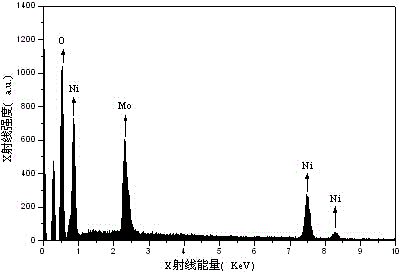

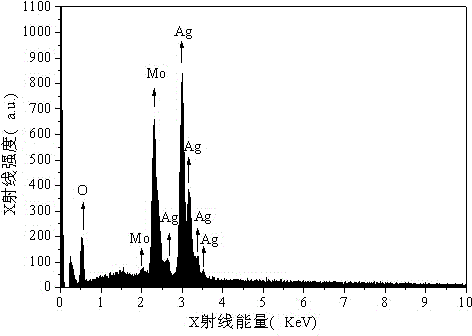

Method for preparing nickel molybdate by using cationic membrane electrolysis process

The invention provides a method for preparing nickel molybdate by using a cationic membrane electrolysis process. The method comprises the steps of utilizing a nickel sheet as an anode, a noble electrode as a cathode, an aqueous solution containing a depolarizer and sodium molybdate as an anode liquor, and an acid / alkali / salt solution as a cathode liquor; in a double-compartment electrolytic cell with a cationic membrane as a diaphragm, controlling the temperature from room temperature to 90 DEG C to electrolyze the aqueous solution containing the depolarizer and the sodium molybdate in a constant-current electrolysis or constant-voltage electrolysis manner till all Na<+> ions are transferred to a cathode compartment; simultaneously cleaning and filtering products from the anode by using deionized water to obtain a filter cake, drying the filter cake, and then increasing the temperature to 500-700 DEG C under air atmosphere at the speed of 2.5-10 DEG C / min to perform high-temperature roasting on the dried filter cake for 1-5 hours; naturally cooling down the temperature of the roasted product to the room temperature, and then obtaining the nickel molybdate with high purity and no impure phase. According to the method for preparing the nickel molybdate by using the cationic membrane electrolysis process, all the Na<+> ions are transferred to the cathode compartment under the action of the cationic membrane electrolysis, so that the Na<+> influence is eliminated and the reaction time is short.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

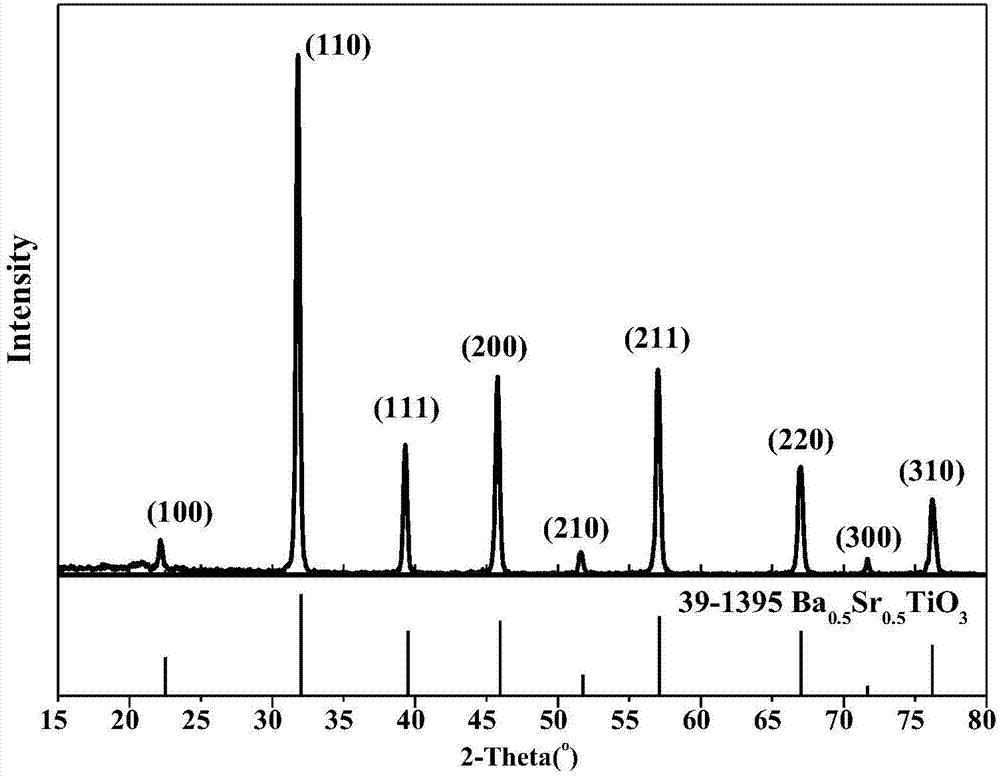

Method for preparing (Ba, Sr) TiO3 nano powder by virtue of Mg<2+> doped hydro-thermal method

ActiveCN104773755AHigh purityGrain refinementMaterial nanotechnologyTitanium compoundsNanoparticleThermal methods

The invention relates to a method for preparing (Ba, Sr) TiO3 nano powder by virtue of a Mg<2+> doped hydrothermal method. The method comprises the following steps: taking BaTiO3 powder and SrTiO3 powder which are synthesized by a hydrothermal method, adding water, mixing fully, then adding MgCl2, and mixing uniformly to obtain a mixed solution; and pouring the mixed solution into a hydrothermal kettle, preserving the heat at 120-180 DEG C for 4-8 hours to perform hydrothermal reaction, and performing centrifugal drying on a generated precipitate to obtain Mg<2+> doped (Ba, Sr) TiO3 nano powder. According to the method provided by the invention, the BaTiO3 powder and SrTiO3 powder which are prepared by the hydrothermal method are adopted as raw materials, then a minute quantity of MgCl2 is doped into the raw materials, and then the Mg<2+> doped (Ba, Sr) TiO3 powder is prepared by using the hydrothermal method under the condition that a mineralizer is not added, so that secondary reaction is effectively avoided, and the prepared powder is high in purity and uniform and meticulous in crystal grain, reaches a nano scale, and can effectively improve the energy storage characteristic and the breakdown resistance of ceramic when used for preparing the ceramic.

Owner:SHAANXI UNIV OF SCI & TECH

Prepn process of nanometer tricalcium phosphate powder with slowly released metal ion

InactiveCN1772603AHigh activityUniform particle distributionPhosphorus compoundsProsthesisPolyethylene glycolTri calcium phosphate

The present invention discloses the preparation process of nanometer tricalcium phosphate powder with slowly released metal ion. The preparation process adopts metal ion compound, calcium containing compound and phosphide as main material, and polyglycol as stabilizer, and includes reaction inside water solution at 0-5 deg.c to produce amorphous calcium phosphate containing metal ion, and the subsequent sintering at 800-1100 deg.c. The said preparation process can obtain nanometer tricalcium phosphate powder with controllable metal ion releasing rate and small particle size, and the nanometer tricalcium phosphate powder is used as bioactive material capable of promoting bone growth and inhibiting bone absorption. The preparation process is simple, feasible, simple in operation, low in cost and easy for industrial production.

Owner:ZHEJIANG UNIV

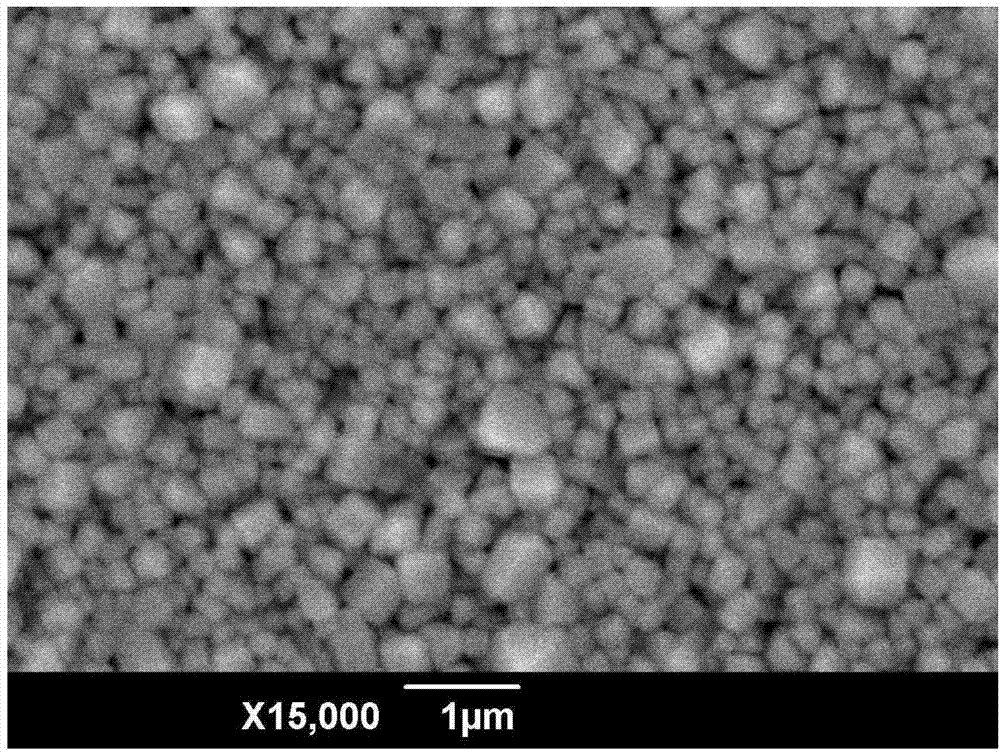

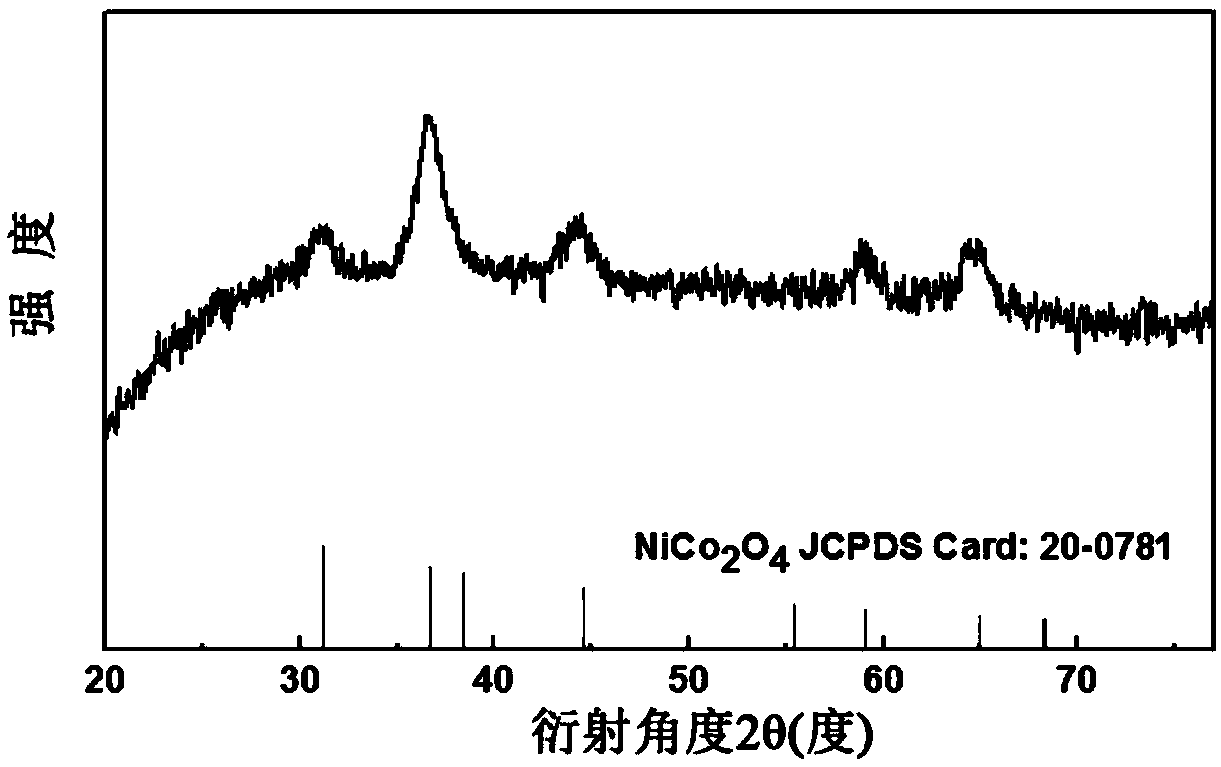

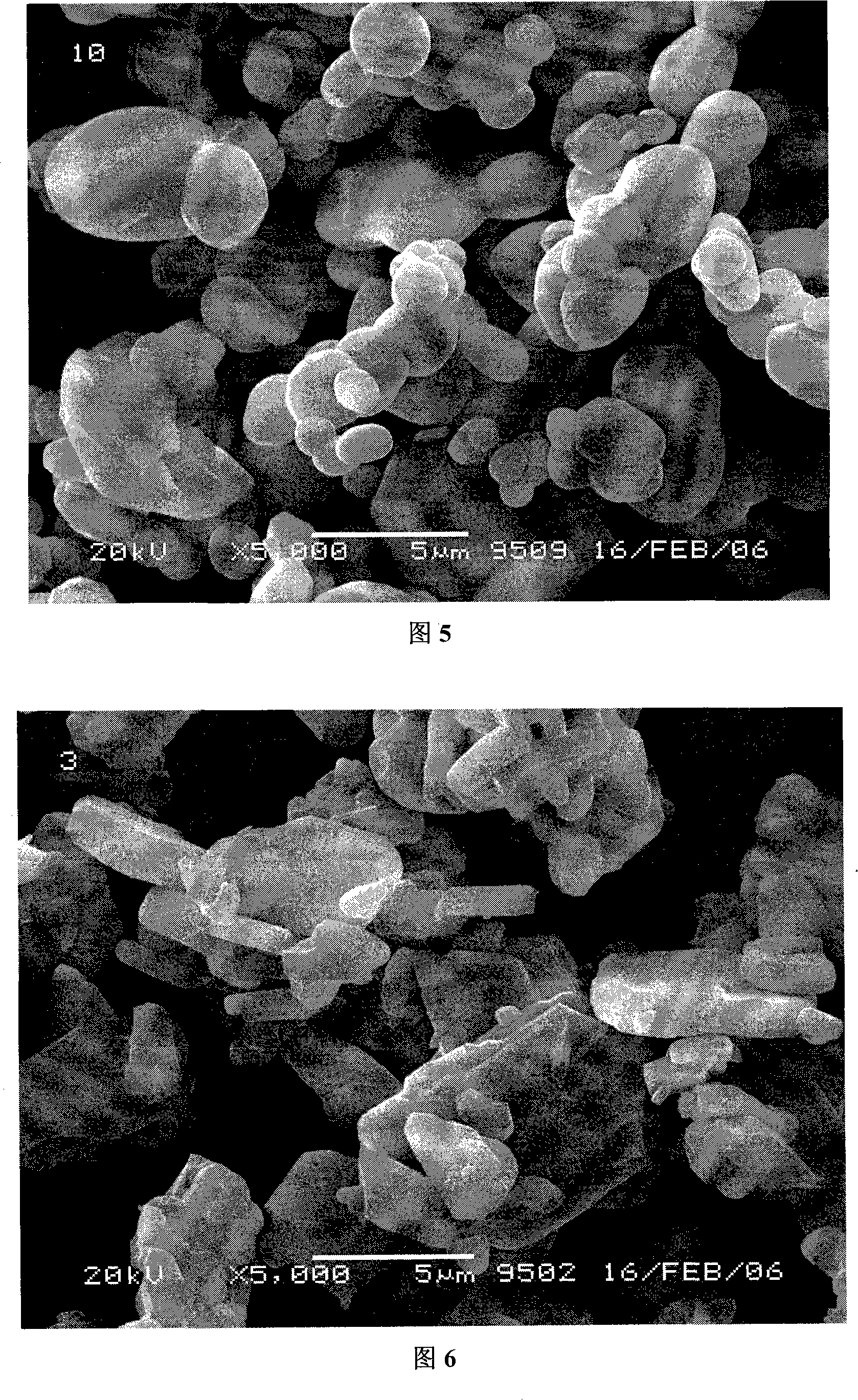

NiCo2O4, preparation method and application thereof

The invention discloses a preparation method of NiCo2O4. The method includes: taking an ammonia water solution as the mother liquor, injecting a metal source solution and a precipitant into the motherliquor for reaction, controlling the pH value of the reaction system in the reaction process at 11.5-12.5 and the temperature at 70-90DEG C, washing and drying the obtained product to obtain a basicnickel cobalt carbonate composite precursor, wherein the metal source solution is obtained by adding a nickel salt, a cobalt salt and a surfactant into deionized water and mixing the substances evenly; and calcining the basic nickel cobalt carbonate composite precursor to obtain a powder material, i.e. NiCo2O4. The invention also discloses a structure and application of the NiCo2O4 accordingly. The NiCo2O4 prepared according to the invention has a novel structure and porous double-hemisphere structure, and when the NiCo2O4 is used as a lithium ion battery negative electrode material, a crack between the hemispheres endows the material with a large surface area, thus being beneficial to contact of the material with an electrolyte solution. In addition, the special porous double-hemisphere structure is beneficial to diffusion of lithium ions into the material, so that the rate performance and cycle performance of the material can be effectively improved.

Owner:CENT SOUTH UNIV

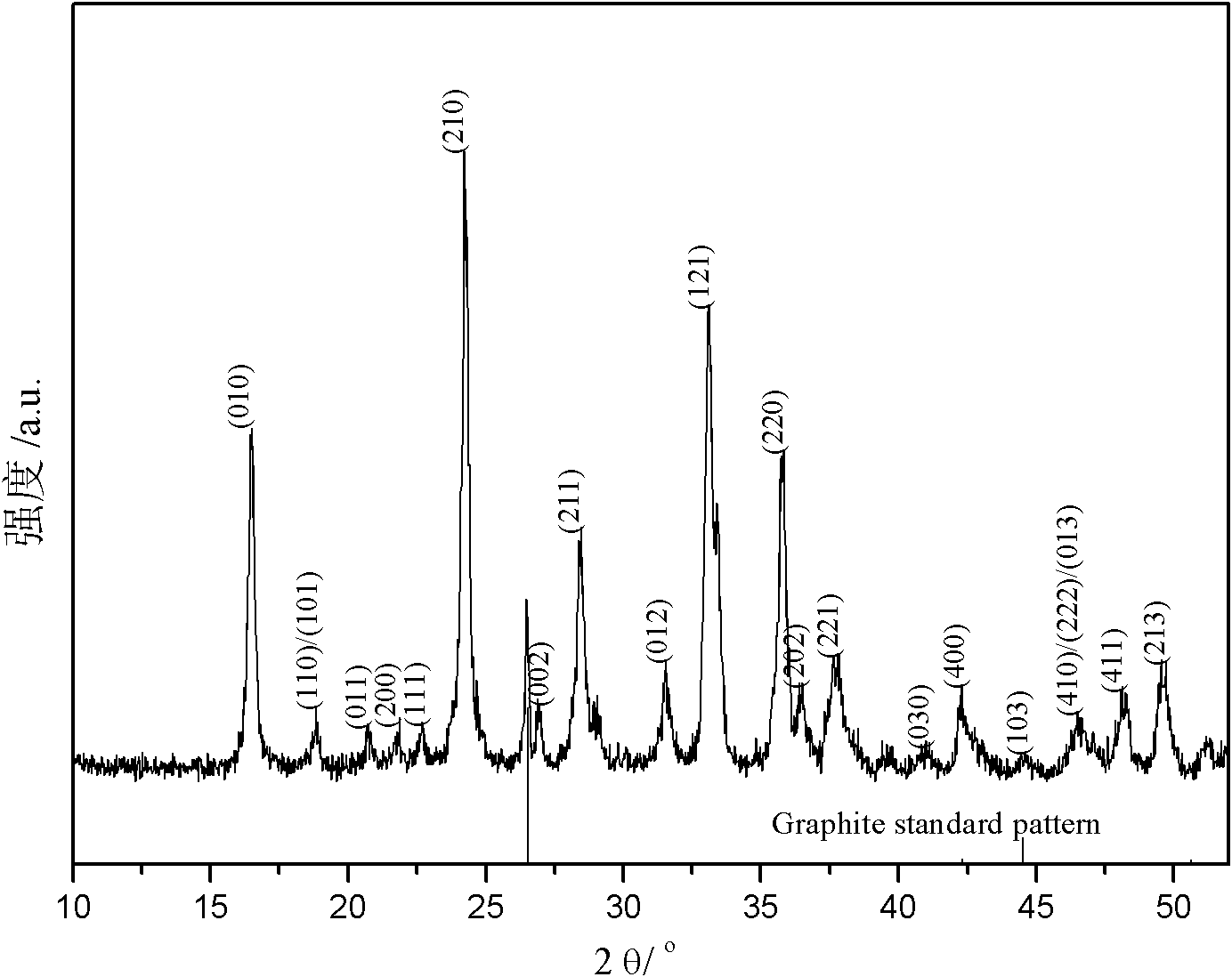

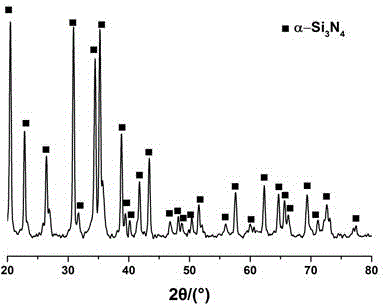

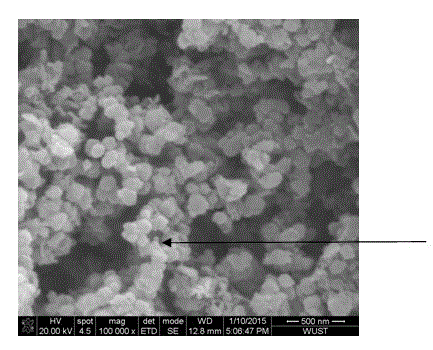

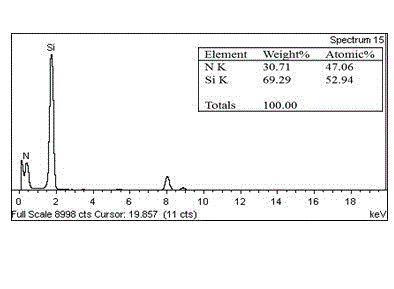

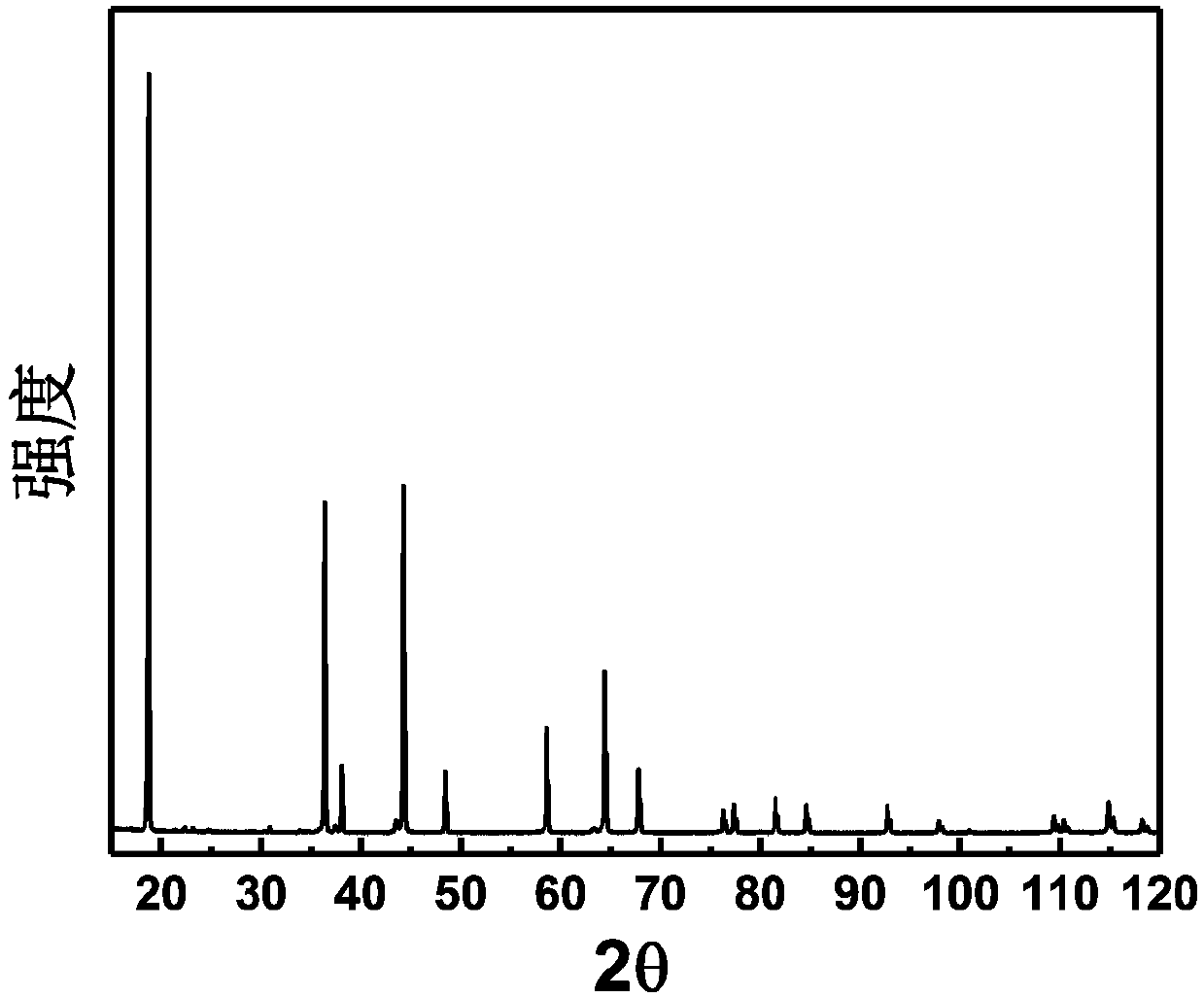

Single-phase alpha-Si3N4 micropowder and preparation method thereof

The invention relates to a single-phase alpha-Si3N4 micropowder and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: uniformly mixing 5-30 wt% of simple substance silicon powder, 15-45 wt% of solid nitrogen source and 40-80 wt% of halide powder to prepare a mixture; putting the mixture into an electric tube furnace, heating to 1000-1300 DEG C at the heating rate of 2-10 DEG C / minute in a nitrogen atmosphere, and keeping the temperature for 2-6 hours; repeatedly washing the product with deionized water until no white precipitate appears when respectively titrating with AgNO3 and Ca(NO3)2 solutions; and finally, drying at 110 DEG C for 10-24 hours to obtain the single-phase alpha-Si3N4 micropowder. The preparation method has the characteristics of low reaction temperature, low cost, simple synthesis technique, controllable process, high yield and wide industrialization prospects. The particle size of the prepared single-phase alpha-Si3N4 micropowder is 100-500nm; and the single-phase alpha-Si3N4 micropowder has the advantages of no impurity phase, high activity, small particle aggregation and uniform particle size distribution.

Owner:WUHAN UNIV OF SCI & TECH

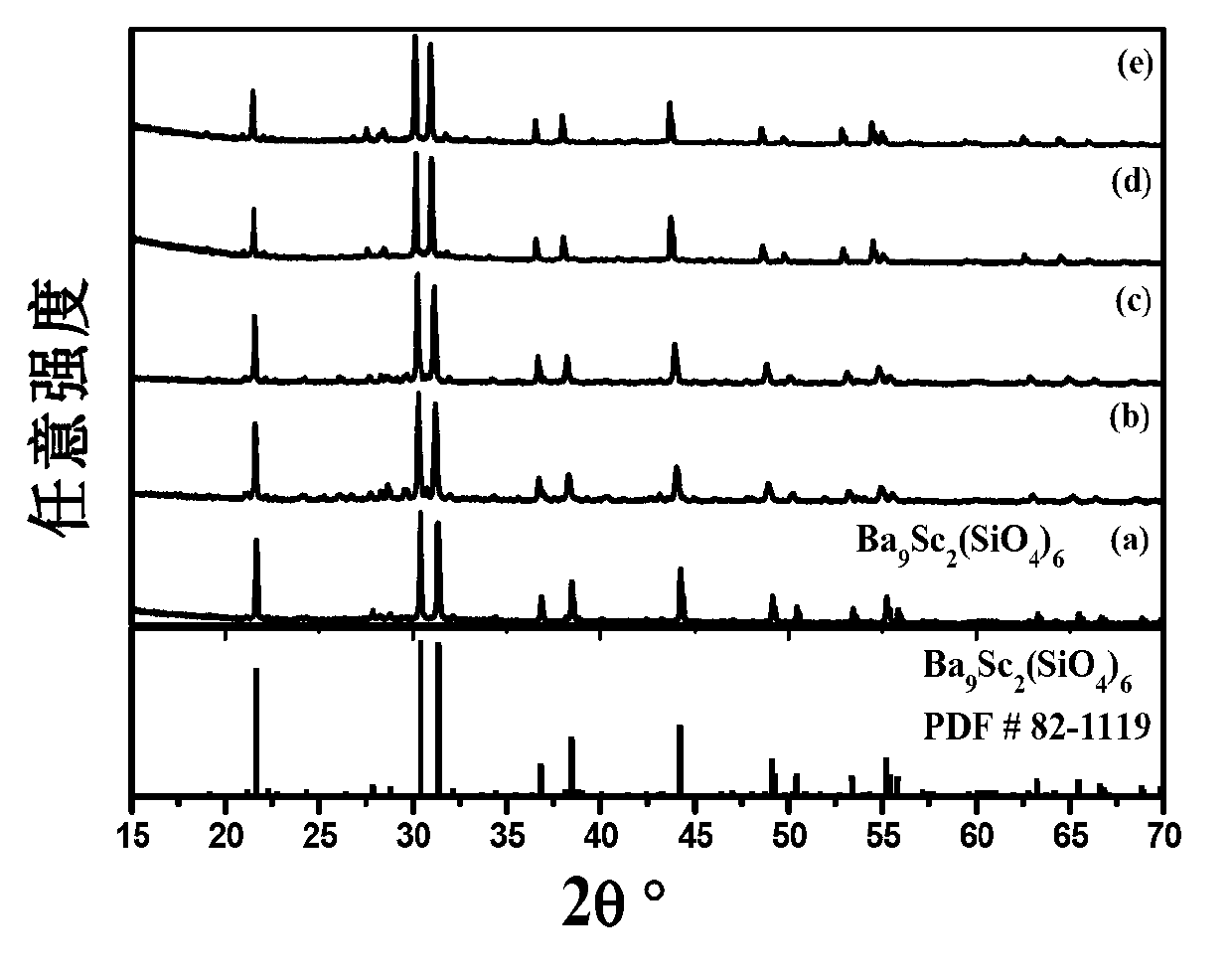

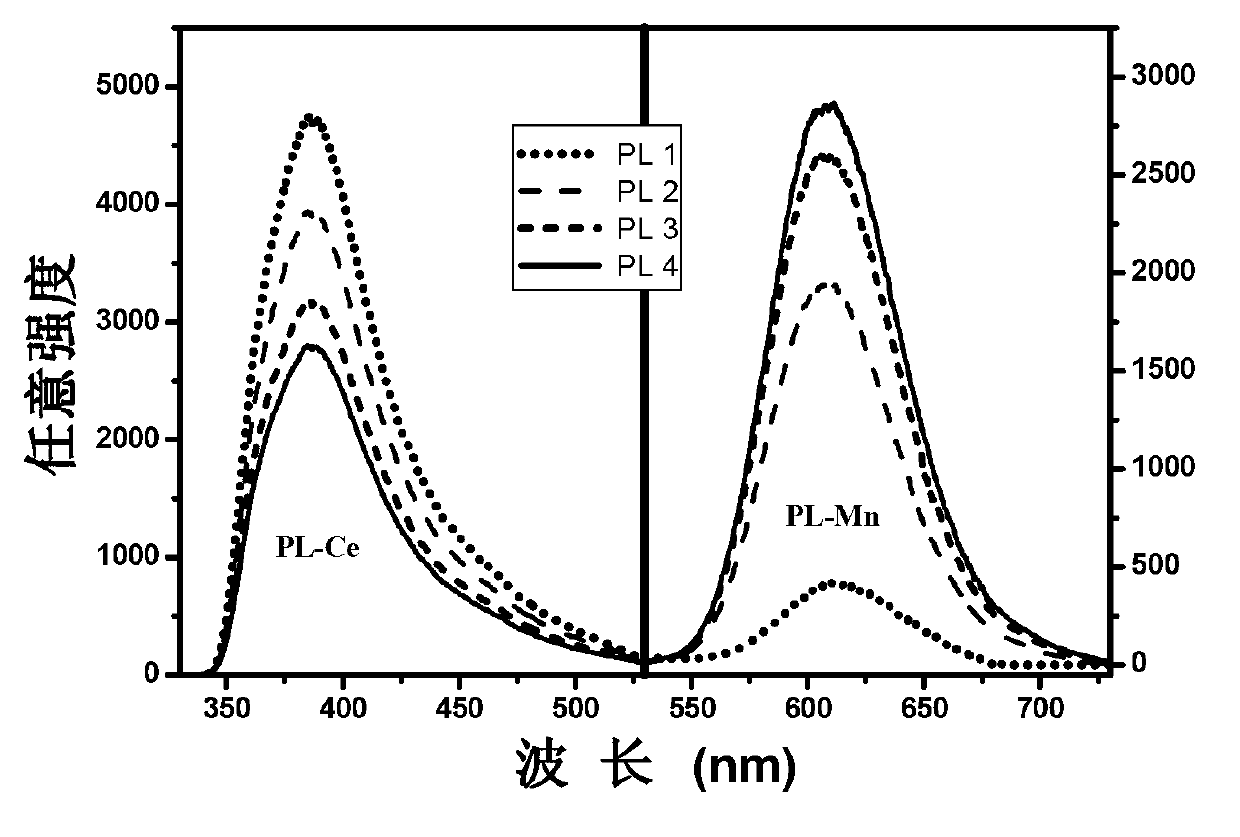

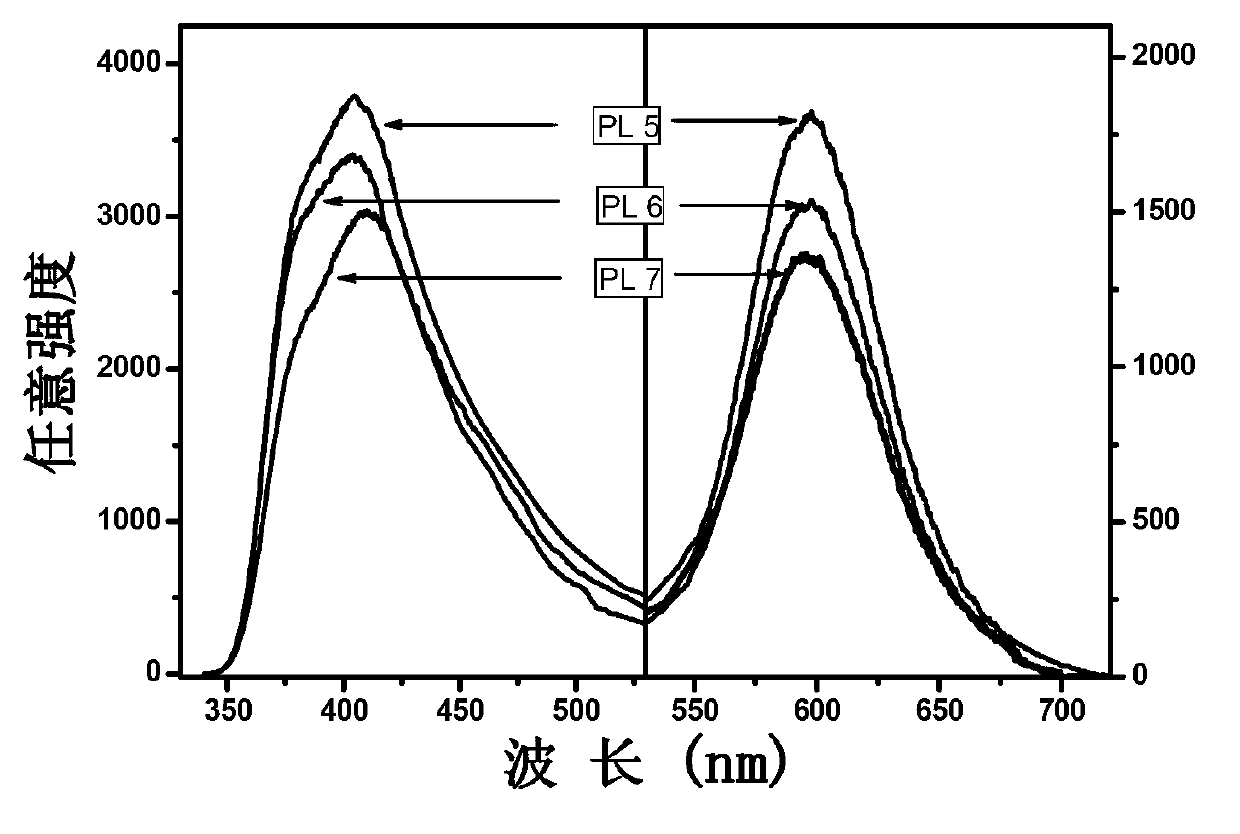

Red phosphor suitable for ultraviolet light excitation, and preparation method thereof

InactiveCN102994086ANo impurityEnhanced red light emissionGas discharge lamp usageLuminescent compositionsUltraviolet lightsCarbonate

The invention provides a red phosphor suitable for ultraviolet light excitation, and a preparation method thereof, and belongs to the field of luminescent technology. A chemical formula of the red phosphor is (Ba9-yMny)(R2-xCex)(SiO4)6, wherein R represents two of Lu, Y and Sc or one of Lu or Y; and x and y are molar fractions, wherein x value is equal to or larger than 0.005 but smaller than or equal to 0.25; and y value is equal to or larger than 0.01 but smaller than or equal to 0.6. An oxide, a fluoride, a carbonate and a nitrate which contain Ba, Mn, R and Ce respectively and a Si oxide are used as raw materials; and the phosphor is obtained by the steps of grinding the above materials; mixing the materials uniformly; putting the mixture in a crucible; high-temperature roasting under a reducing atmosphere; and cooling naturally. The phosphor can emit red light with the wavelength ranging for 570 nm to 630 nm under effective excitation of the ultraviolet light with wavelength ranging for 300 nm to 350 nm, and can be used as a red light component in a white LED excited by the ultraviolet light.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

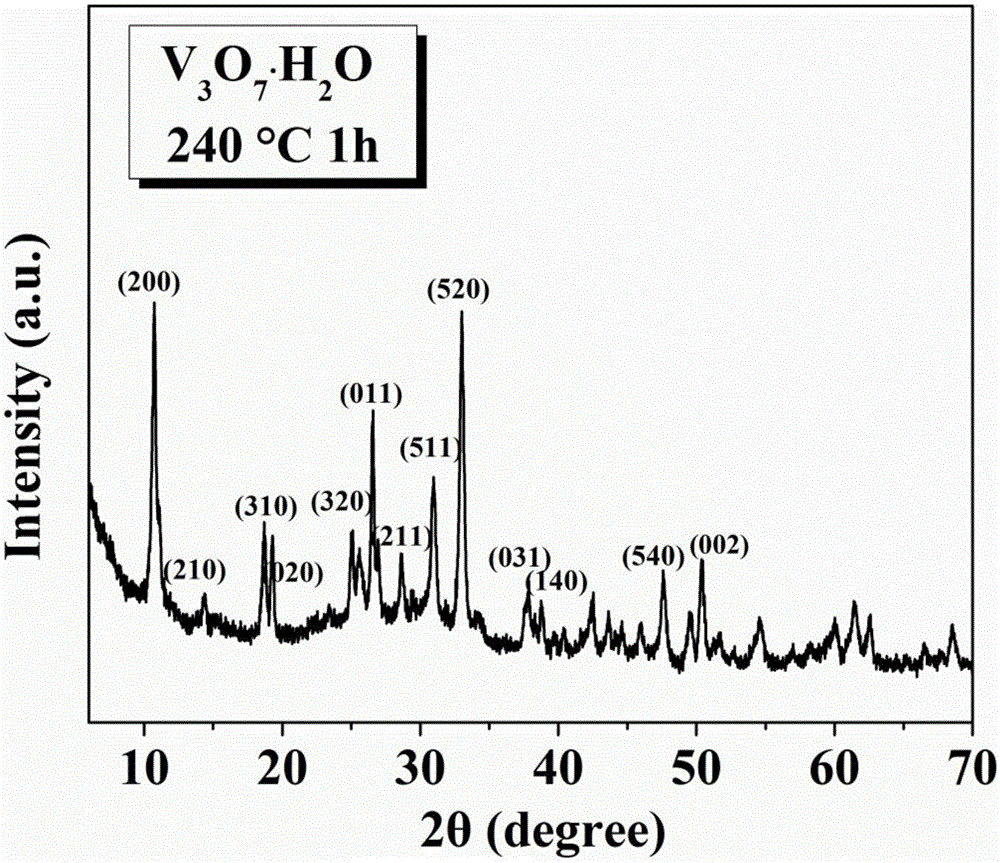

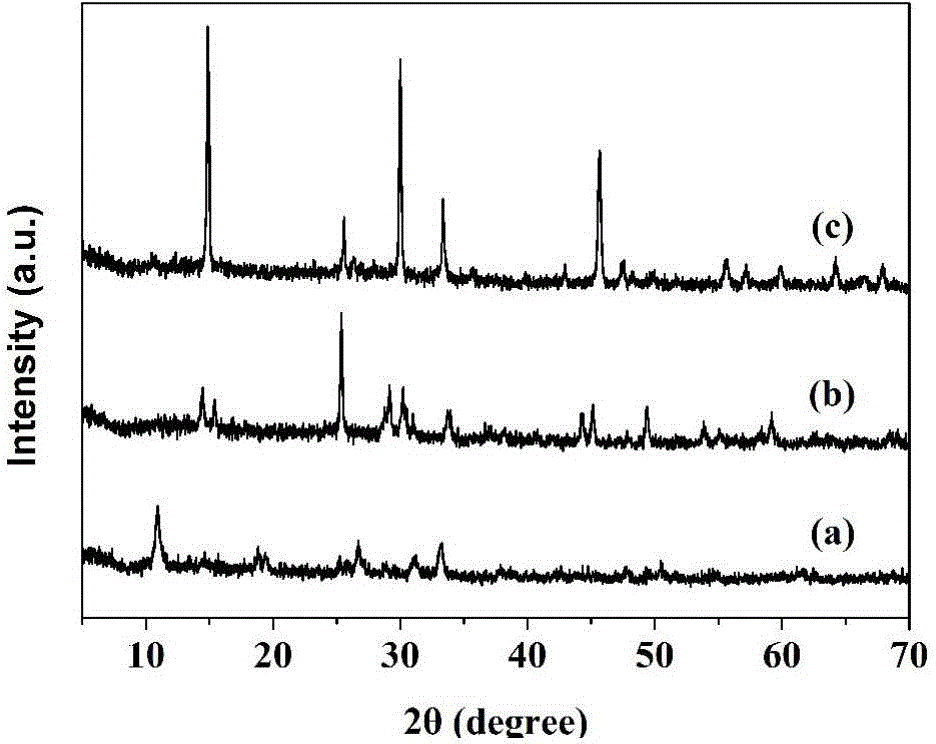

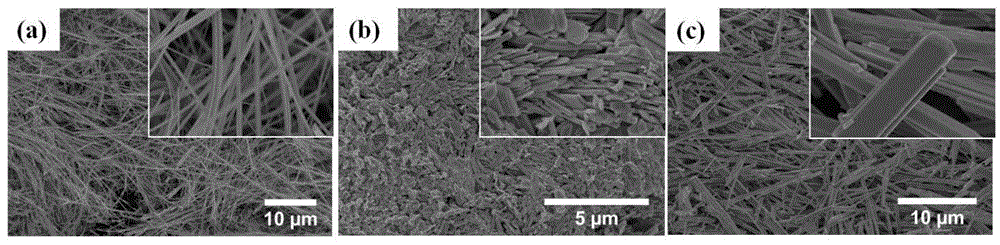

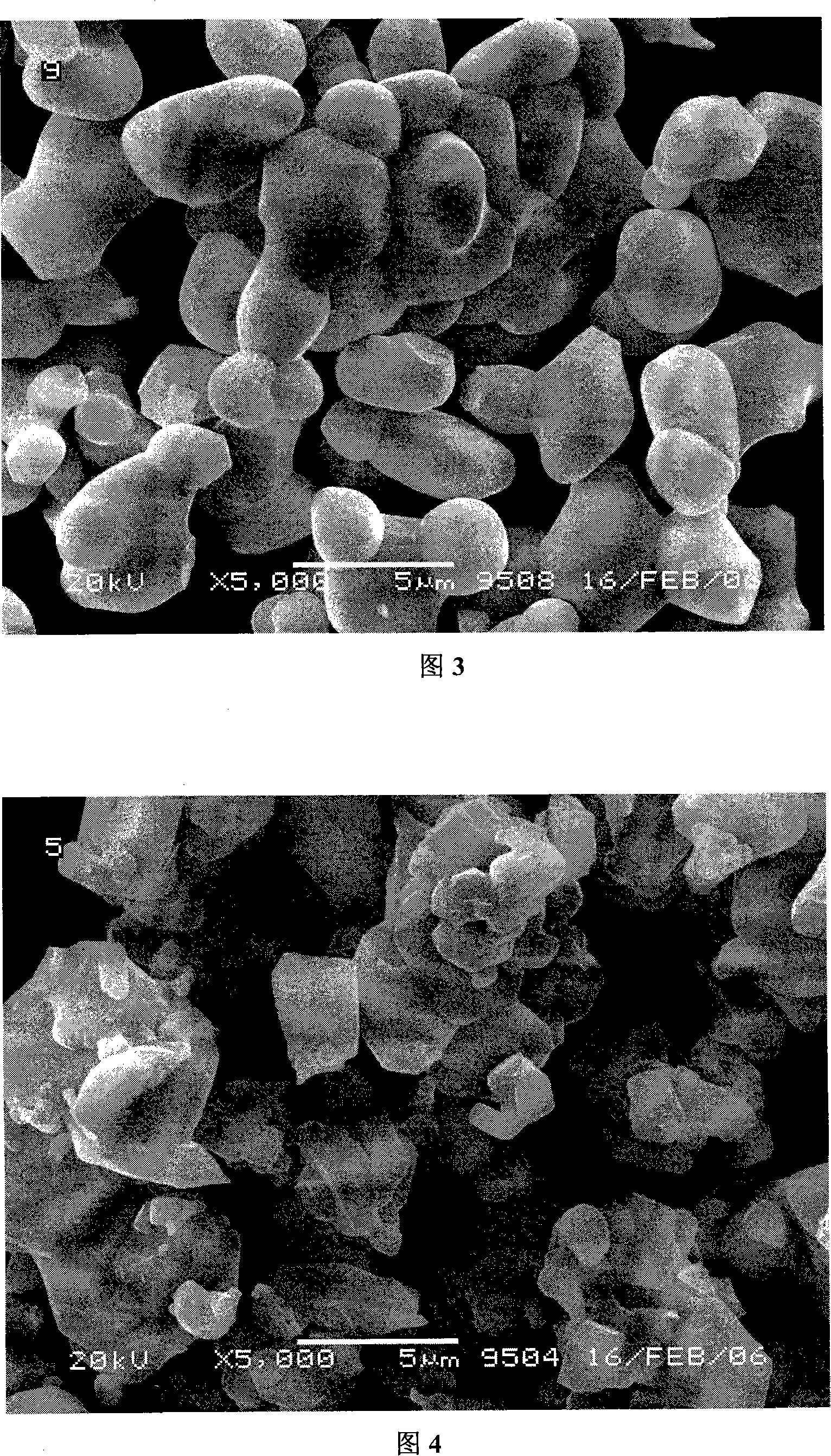

Synthetic method of high-performance one-dimensional nanostructure vanadium oxide lithium ion battery electrode material

InactiveCN104617264APromote crystallizationHigh crystallinityMaterial nanotechnologyCell electrodesNano structuringCrystallinity

The invention discloses a synthetic method of a high-performance one-dimensional nanostructure vanadium oxide lithium ion battery electrode material. Meta-stable-phase VO2 (B), meta-stable-phase VO2 (A) and stable-phase V3O7.H2O powder is synthesized by the utilization of a high-temperature hydrothermal mixing method, so that the repeatability and the crystallinity of powder synthesis are improved, and the surface appearance of the powder is controlled. The synthetic method disclosed by the invention is the high-temperature hydrothermal method and not only has the advantages owned by the high-temperature hydrothermal method self, but also has the advantages that the repeatability is high, an obtained product is good in crystallinity, easy in appearance control and the like, therefore, the electrochemical performance of the synthetic method can be effectively optimized; the three kinds of vanadium oxide (VO2 (B), VO2 (A) and V3O7.H2O) powder synthesized by the utilization of the high-temperature hydrothermal mixing method are simple in synthetic method, high in purity, good in crystallization, uniform and unified in appearance and have no intermediate phase; the synthetic method is very simple, effective and feasible and plays a great role in improving the application performance of the vanadium oxide electrode material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

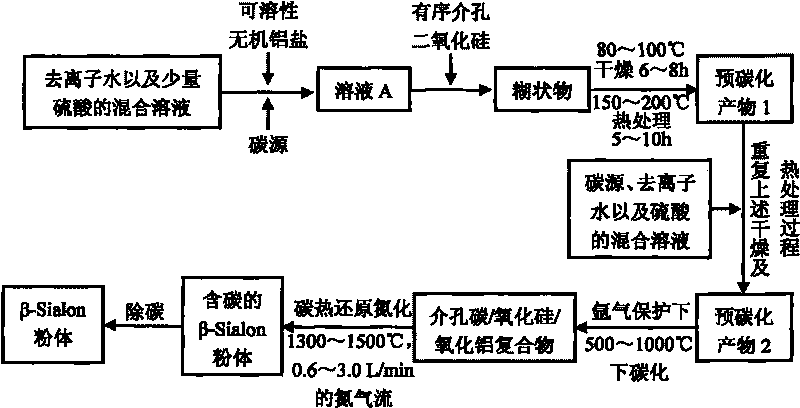

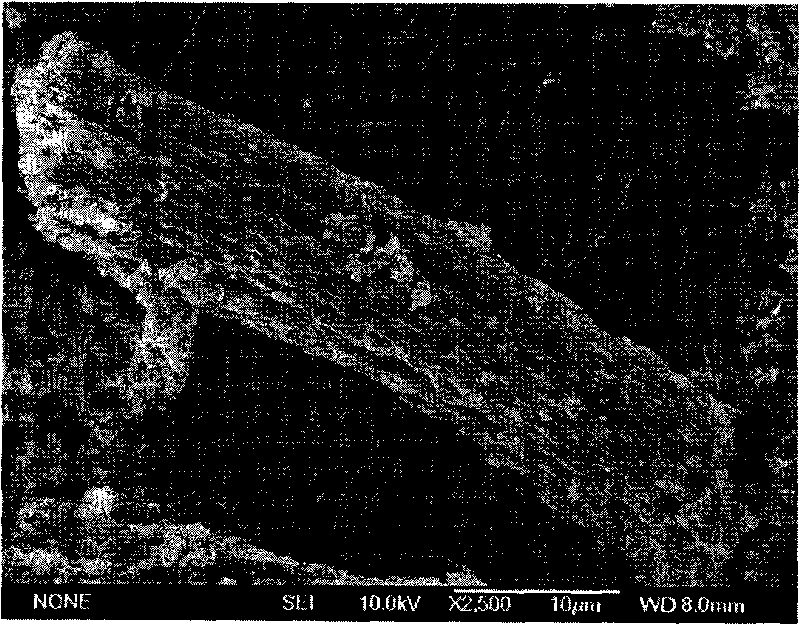

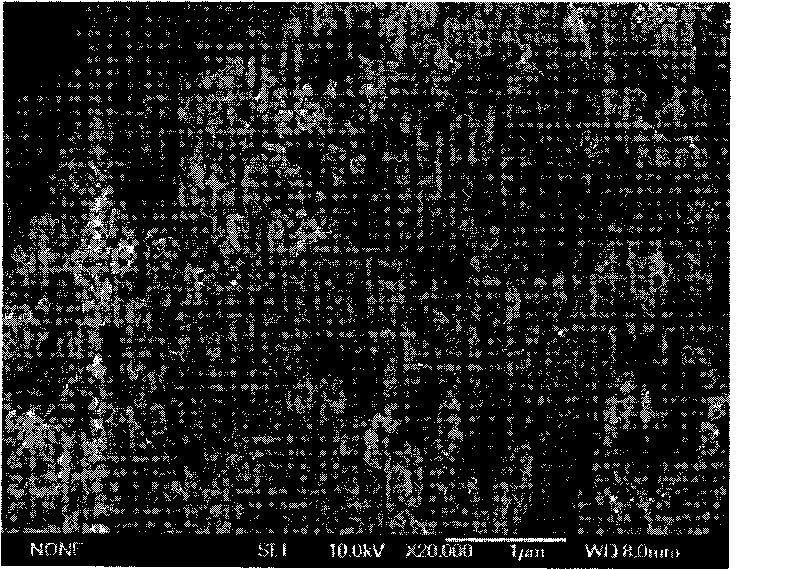

Method for preparing highly-pure beta-Sialon ceramic powders

The invention provides a method for preparing highly-pure beta-Sialon ceramic powders, which combines a carbothermal reduction nitridation process and nano-pouring technology and comprises the following specific steps: firstly, taking ordered mesoporous silicon dioxide as a main raw material, taking soluble inorganic aluminum salt as an aluminum oxide precursor, taking an organic small molecular compound as a carbon source, and preparing a compound of mesoporous carbon / silicon oxide / aluminum oxide through nanometer pouring; then performing carbothermal reduction nitridation on the compound of the mesoporous carbon / the silicon oxide / the aluminum oxide to prepare a sample; and finally, calcining the sample in air to remove residual carbon, and cooling the sample after residual carbon is removed to prepare a product. The method has the advantages that the synthesis temperature of the preparation method is relatively low, and is favorable for reducing the required energy consumption in production; and the purity of the prepared beta-Sialon ceramic powders is high, and the particle shapes are mainly in a long rod-like shape. The preparation method can be widely used in fields of space flight, metallurgy, chemical industry and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

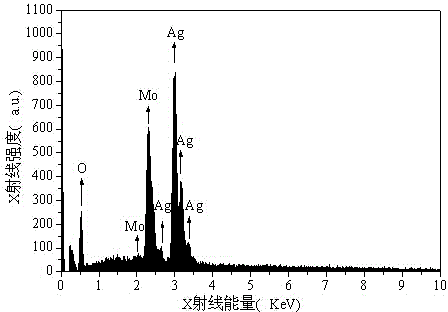

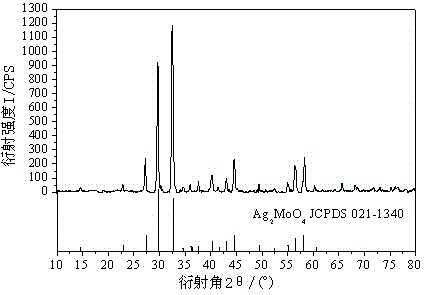

Method for preparing silver molybdate with cationic membrane electrolysis method

InactiveCN104789982AHigh purityShort reaction timeElectrolysis componentsAqueous solutionFilter cake

The invention discloses a method for preparing silver molybdate with a cationic membrane electrolysis method. A silver sheet is taken as an anode, an inert electrode is taken as a cathode, an aqueous solution containing a depolarizer and sodium molybdate is taken as an anolyte, an acid solution, an alkaline solution or a salt solution is taken as a catholyte, and the aqueous solution containing the depolarizer and the sodium molybdate is electrolyzed in a double-chamber electrolytic cell with a cationic membrane serving as a diaphragm at the room temperature of 90 DEG C in a constant-current electrolysis or constant-voltage electrolysis manner until all Na<+> ions are transferred to a cathode chamber; a product obtained in an anode chamber is washed and filtered with deionized water, an obtained filter cake is dried at the temperature of 100-200 DEG C for 1-2 h, and the silver molybdate which is high in purity and free of impurity phases is obtained. According to the method, the effect of cationic membrane electrolysis is used, the Na<+> ions are transferred to the cathode chamber, the effect caused by the Na<+> ions is eliminated, the reaction time is short, and the finally obtained silver molybdate product is high in purity and free of the impurity phases.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

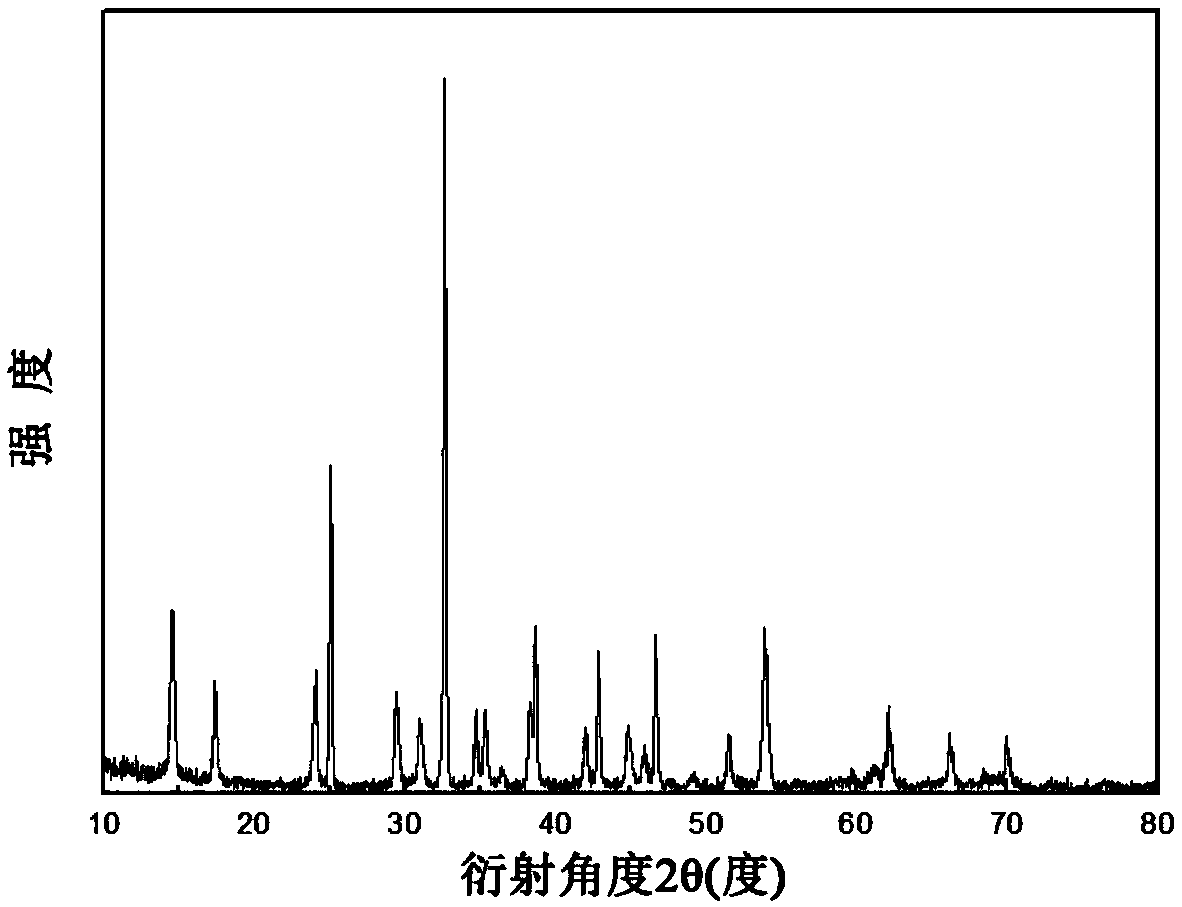

Low-temperature non-calcination preparation method of pollucite

InactiveCN109704351APromote crystallizationHigh purityAluminium silicatesTemperature resistanceCalcination

The invention discloses a low-temperature non-calcination preparation method of pollucite. The low-temperature non-calcination preparation method of the pollucite is characterized by comprising the steps of taking an aluminium and / or silicon raw material and cesium hydroxide, mixing the aluminium and / or silicon raw material and the cesium hydroxide to obtain solid powder, making a molar ratio of Cs to Al to Si in the solid powder equal to 1 to 1 to 2, mixing the solid powder and water which is less than or equal to 10% of the mass of the solid powder, conducting compression moulding on a water-containing solid mixture in a tablet machine at 3-5 MPa, then drying a specimen subjected to demolding, placing the dried specimen in a steam-pressing reaction kettle, conducting crystallization at 120-220 DEG C in a vapour environment for 4-24 h, and conducting cooling to prepare the pollucite. According to the low-temperature non-calcination preparation method of the pollucite, under mild conditions, low-temperature synthesis of the pollucite few in natural resource is achieved, and the situation that the Cs volatilizes at high temperature to pollute the environment is avoided; meanwhile, the prepared pollucite is good in crystallization and high in purity, and other crystal substance impure phases do not exist; and the prepared pollucite can be used as a cesium radioactive source corematerial, and can also be used as a high-temperature resistance material of the field of aerospace.

Owner:SOUTHWEAT UNIV OF SCI & TECH

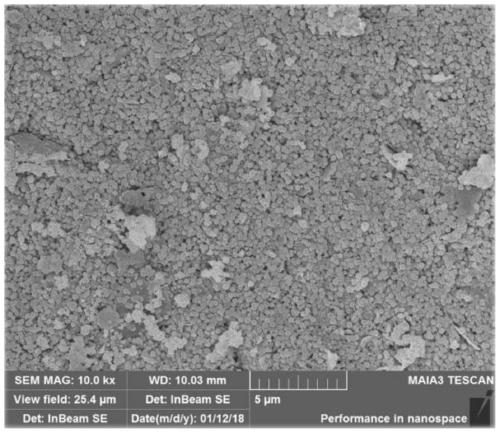

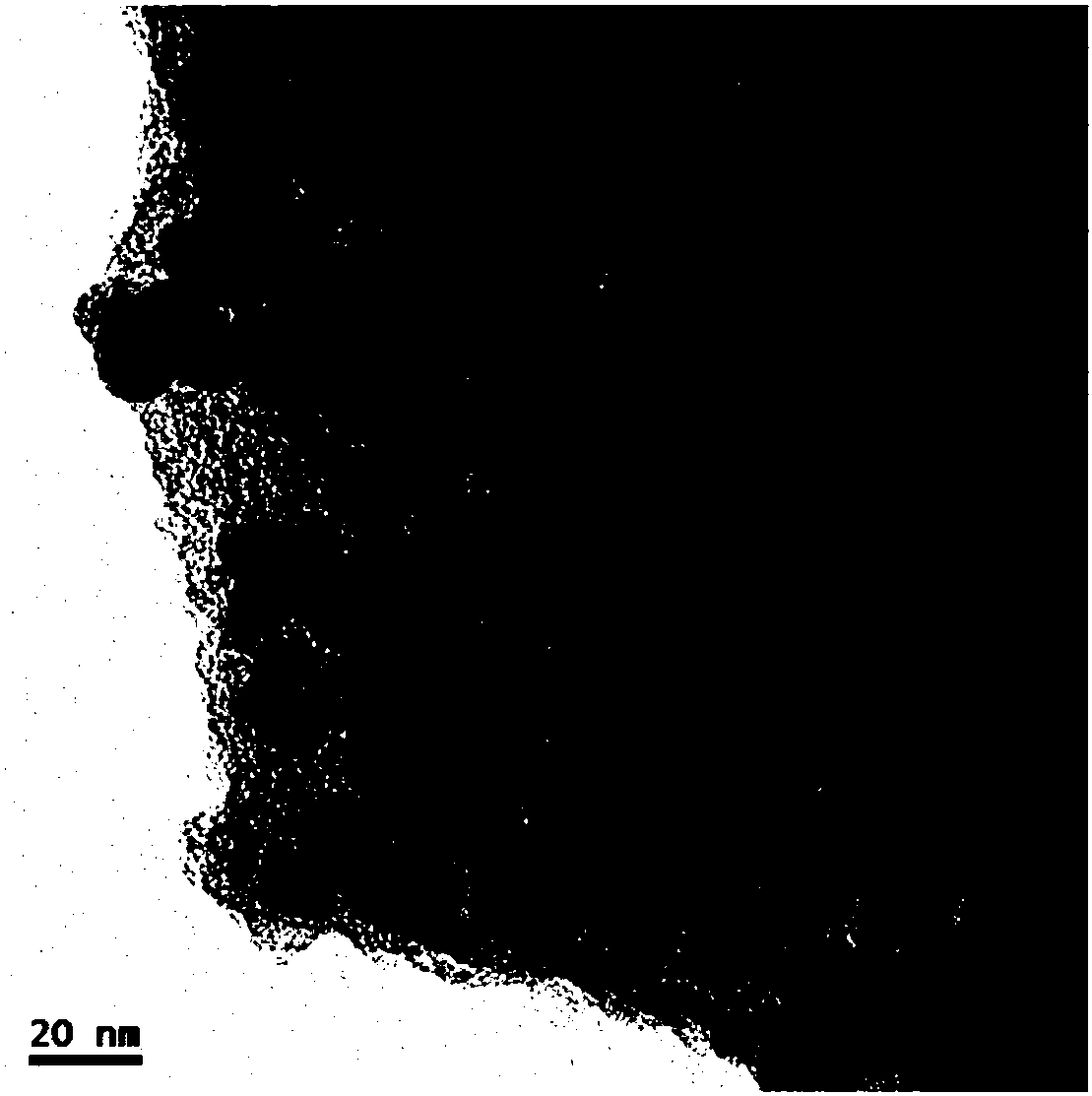

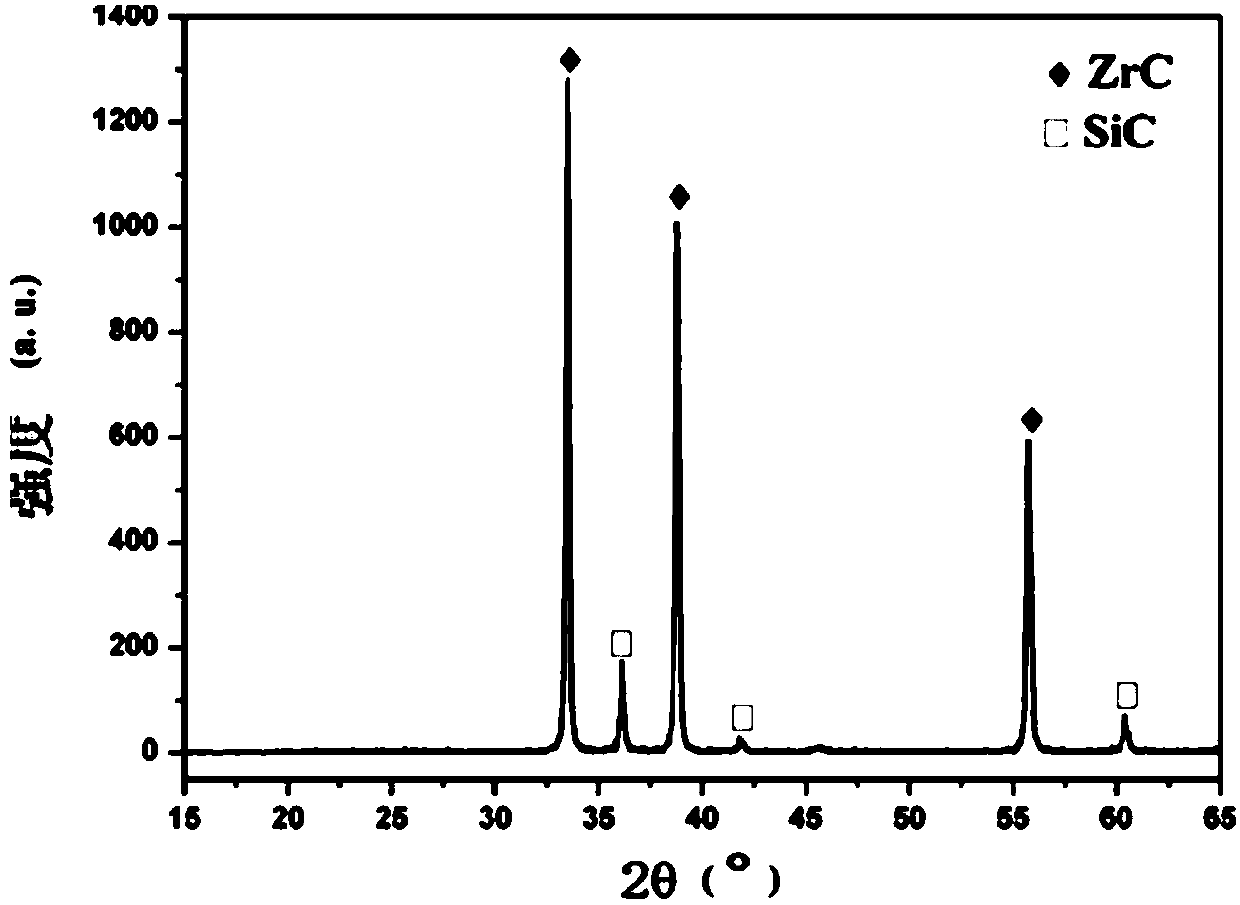

Zirconium carbide-silicon carbide composite powder material and preparation method thereof

The application discloses a zirconium carbide-silicon carbide composite powder material, wherein a molar ratio of components in the zirconium carbide-silicon carbide composite powder material satisfies ZrC:SiC=1:0.1-1:10; a preparation process is easy, the cost is low, and the process is easy to control; and the obtained zirconium carbide-silicon carbide composite powder material has the advantages of submicron level, uniform composition and high purity.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI +1

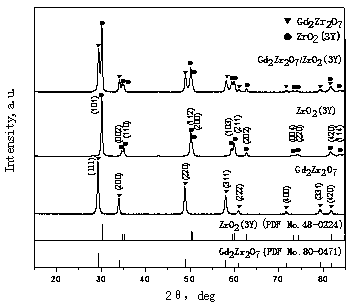

In situ synthesis method for Gd2Zr2O7/ZrO2(3Y) nano-powder

The invention provides an in situ synthesis method for Gd2Zr2O7 / ZrO2(3Y) nano-powder, relating to the method for preparing the nano-powder for a thermal barrier coating material. The method comprises steps of accurately weighing raw materials Gd2O3, ZrOC12.8H2O and Y2O3 according to chemical proportion; then respectively dissolving into HNO3 so as to prepare a rare earth mixed solution, wherein ammonia water (NH3.H2O) is taken as a precipitator, pH value of precursor precipitate is controlled to be 9-12; titrating by a peristaltic pump so as to obtain white flocculent precipitate, wherein 1-4 hours of magnetic stirring goes with titration so as to allow the reaction to be carried out completely; after washing and filtering the white flocculent precipitate, drying for 24 hours in a vacuum drying oven at 60-80 DEG C; ball milling for 12-24 hours through a wet method; putting into a muffle furnace and calcining for 2-4 hours at high temperature so as to obtain the Gd2Zr2O7 / ZrO2(3Y) nano composite powder. The Gd2Zr2O7 / ZrO2(3Y) nano composite powder prepared by the method has the advantages that the appearance is near-spherical, the particle size is small, and the crystal particles are uniformly distributed and are not agglomerated; phase grain size is easy to control, and the method is simple and is very suitable for industrial production.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

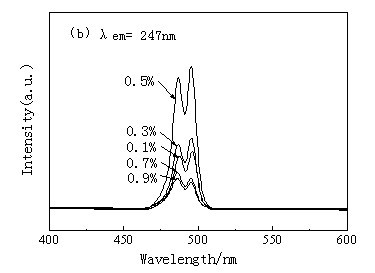

Method for preparing SrZr03:Ce nanometer powder with composite coprecipitator

A method for preparing SrZr03:Ce nanometer powder with a composite coprecipitator relates to a blue fluorescent powder preparing method. Sr(NO3)2, ZrOC12 8H20 and CE(NO3)3 which are weighed according to accurate stoichiometric ratio are dissolved in alcohol-water solution to be mixed into metal salt solution with 0.01-1 ml / L concentration. Ammonia water with 0.1-1 mol / L concentration and ammonium bicarbonate with 0.1-0.5 mol / L concentration are adopted to serve as mixed precipitator, and polyacrylamide (PAM) with 0.1-5*10-3mol / L is adopted to serve as dispersing agent. The mixed precipitator and the PAM dispersing agent are added into the metal salt solution dropwise, precursor precipitate is obtained, and samples are obtained after aging, filtering, washing, grinding, screening, calcining and ball-milling. SrZr03:Ce nanometer powder obtained through the method is good in dispersity, and average primary particle size is about 50 nm. In addition, the method for preparing SrZr03:Ce nanometer powder with the composite coprecipitator is simple in preparing process, short in period, low in cost and suitable for massive production.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

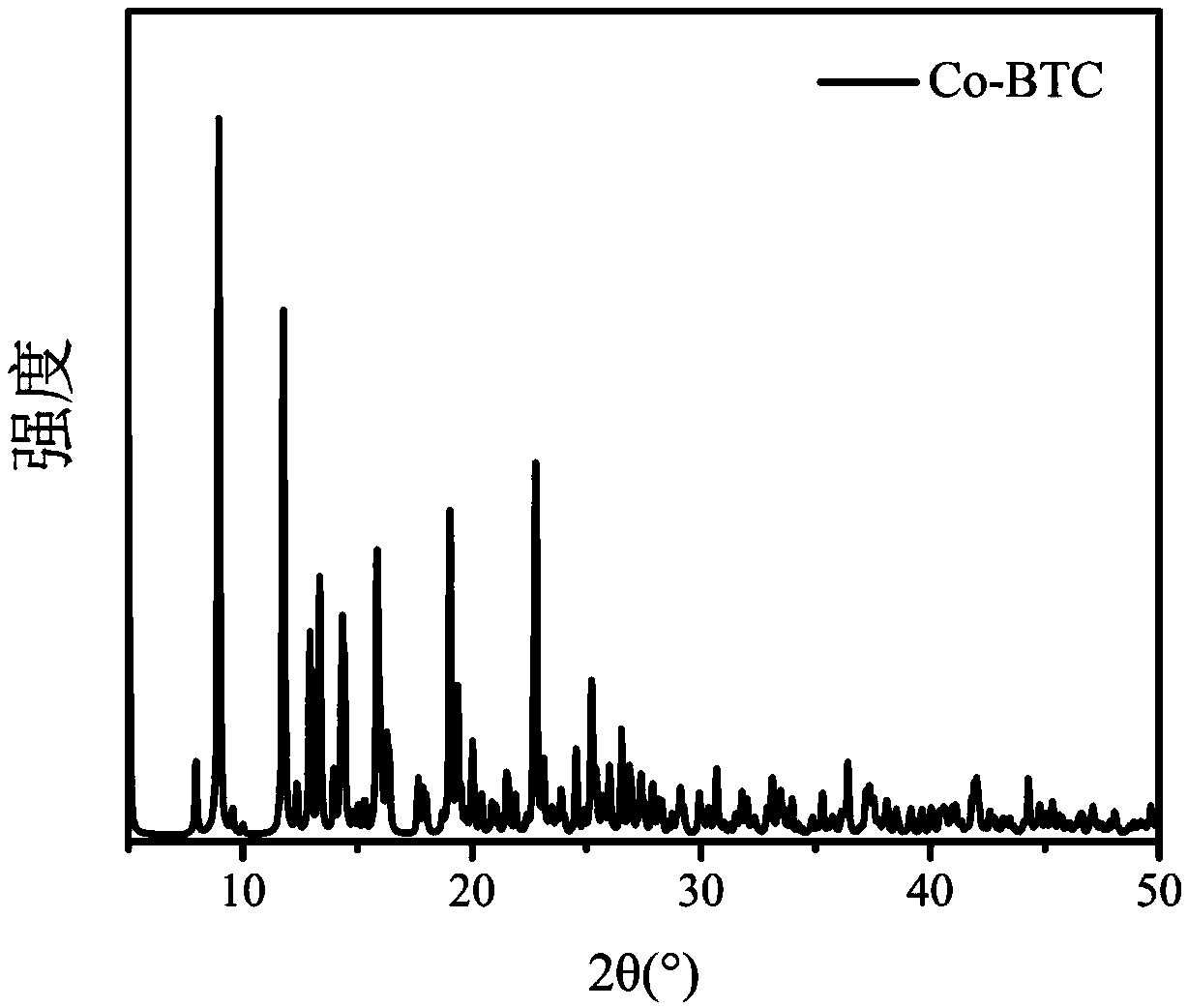

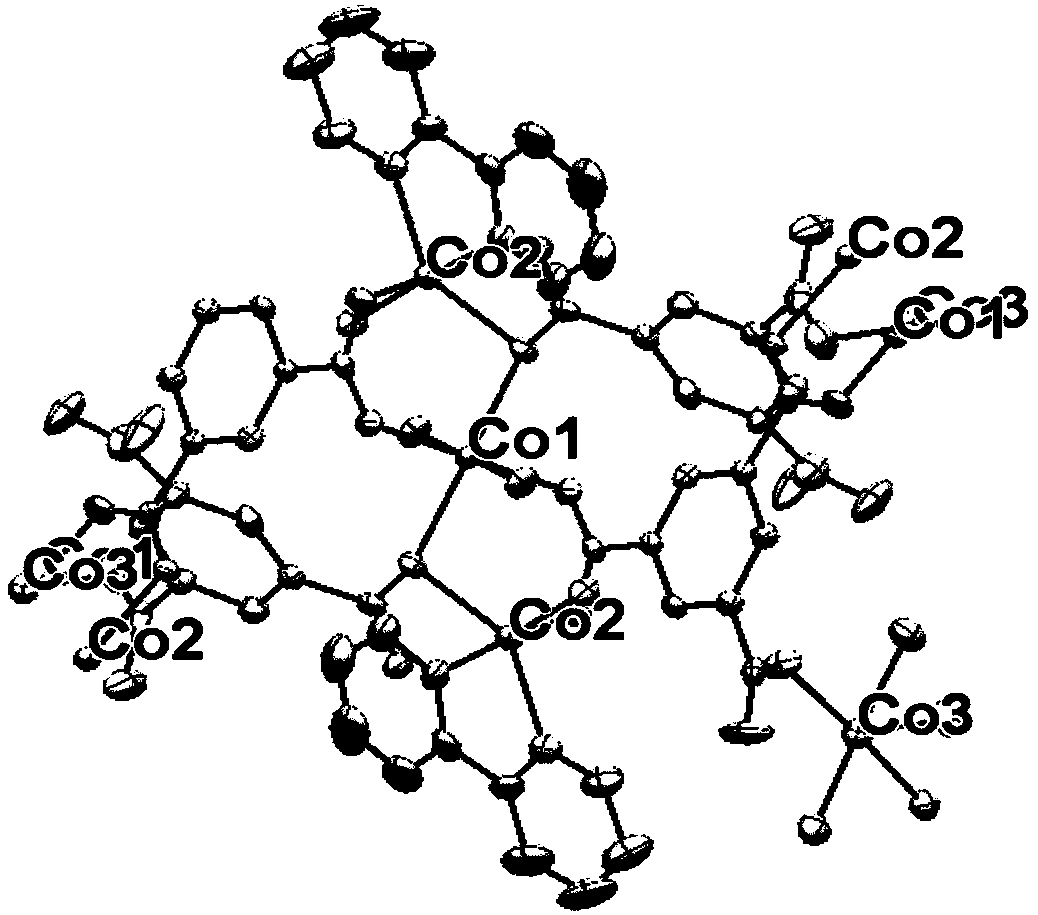

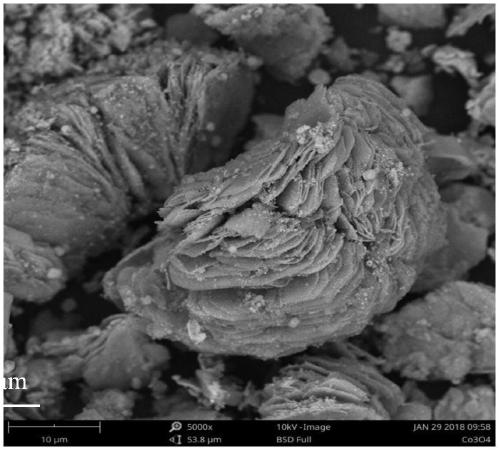

Preparation method for carbon-nitrogen co-doped tricobalt tetroxide

ActiveCN109663577AEfficient manufacturingImprove adsorption capacityOther chemical processesWater contaminantsMicrowaveOrganic dye

The invention belongs to the production field of engineering material, particularly relates to a method for preparing carbon-nitrogen co-doped tricobalt tetroxide by vacuum calcination of a metal organic complex precursor, wherein a metal organic framework material Co-BTC is synthesized as a precursor by hydrothermal method; and a target product carbon-nitrogen co-doped tricobalt tetroxide is obtained by the high temperature treatment of the precursor under vacuum conditions. The preparation method of the precursor includes the following steps that organic ligands, cobalt salts and alkaline regulators are dispersed in aqueous solution, placed in a reactor after being magnetically stirred, then cooled by heating and insulation treatment, and the precursor is obtained after being filtered out, washed and dried. The target product has the characteristics of controllable doping amount, uniform morphology, high product purity, strong microwave absorption and adsorption performance of organic dyes.

Owner:SHENYANG POLYTECHNIC UNIV

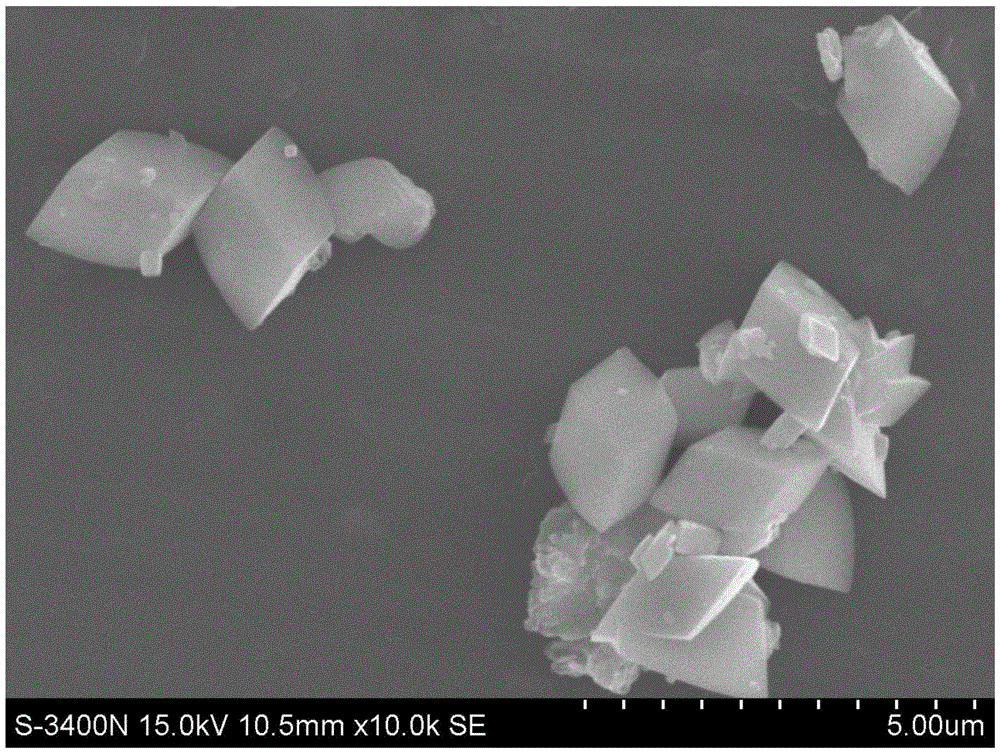

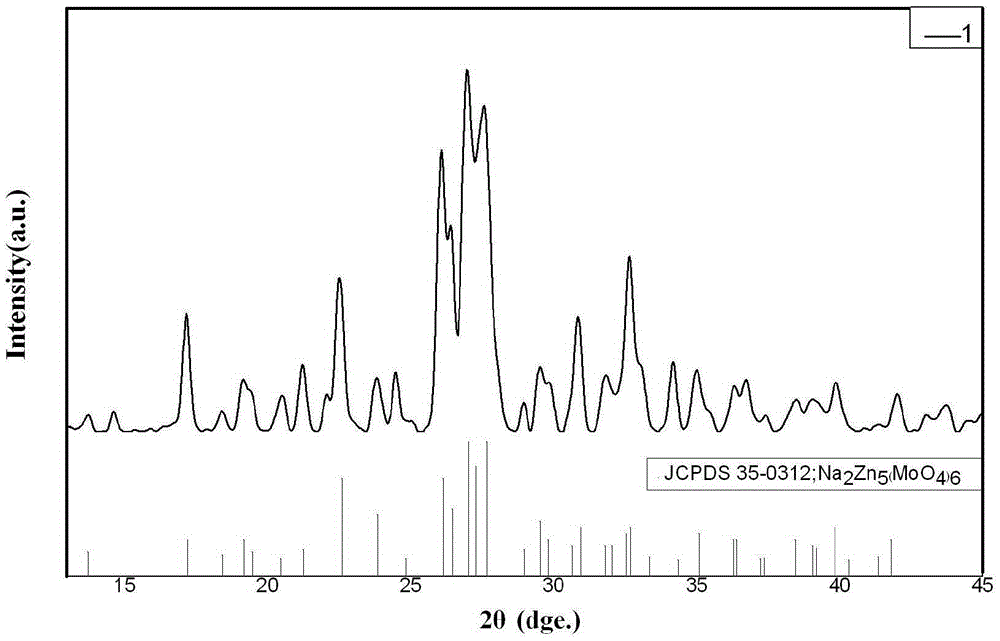

Novel crystal form multi-metal molybdate micro-nano-particles and preparing method thereof

InactiveCN105420810AIncrease the number of effective collisionsShort reaction timePolycrystalline material growthFrom normal temperature solutionsSodium molybdateMolybdate

The invention discloses novel crystal form multi-metal molybdate micro-nano-particles. The molecular formula of the novel crystal form multi-metal molybdate micro-nano-particles is Na2Zn5(MoO4)6. The invention also provides a preparing method of the novel crystal form multi-metal molybdate micro-nano-particles. According to the method, a zinc sheet is taken as an anode plate, a noble electrode is taken as the cathode, sodium molybdate aqueous solution is taken as anode liquor, hydrochloric acid is taken as catholyte, and ultrasonic electrolysis is conducted on the sodium molybdate aqueous solution with the constant-current-density electrolysis method in a double-chamber electrolytic cell with a positive ion film as the partition film; after electrolysis, products obtained in an anode chamber are cleaned and filtered with deionized water, dried, calcinated and cooled naturally in sequence to obtain pure Na2Zn5(MoO4)6 crystals. Most Na+ ions are transferred into a cathode chamber by means of the positive ion film, ions in the solution move at a higher speed under ultrasonic electrolysis, effective collision frequency of ions during crystal formation is increased, and pure Na2Zn5(MoO4)6 crystals with different shapes can be obtained.

Owner:SHANGHAI INST OF TECH

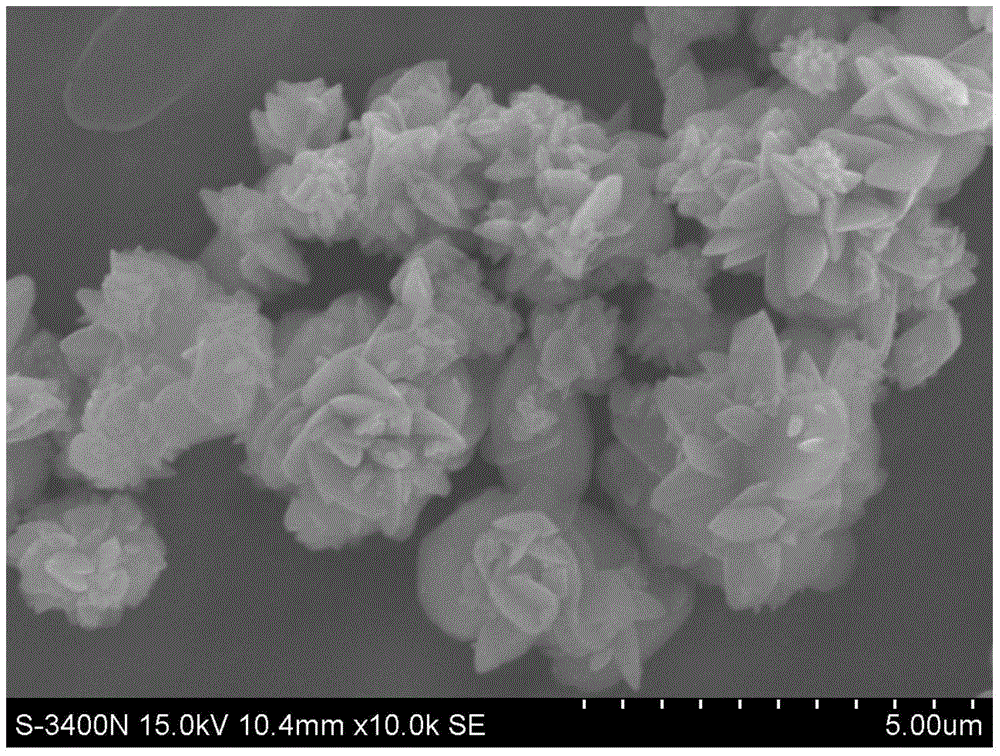

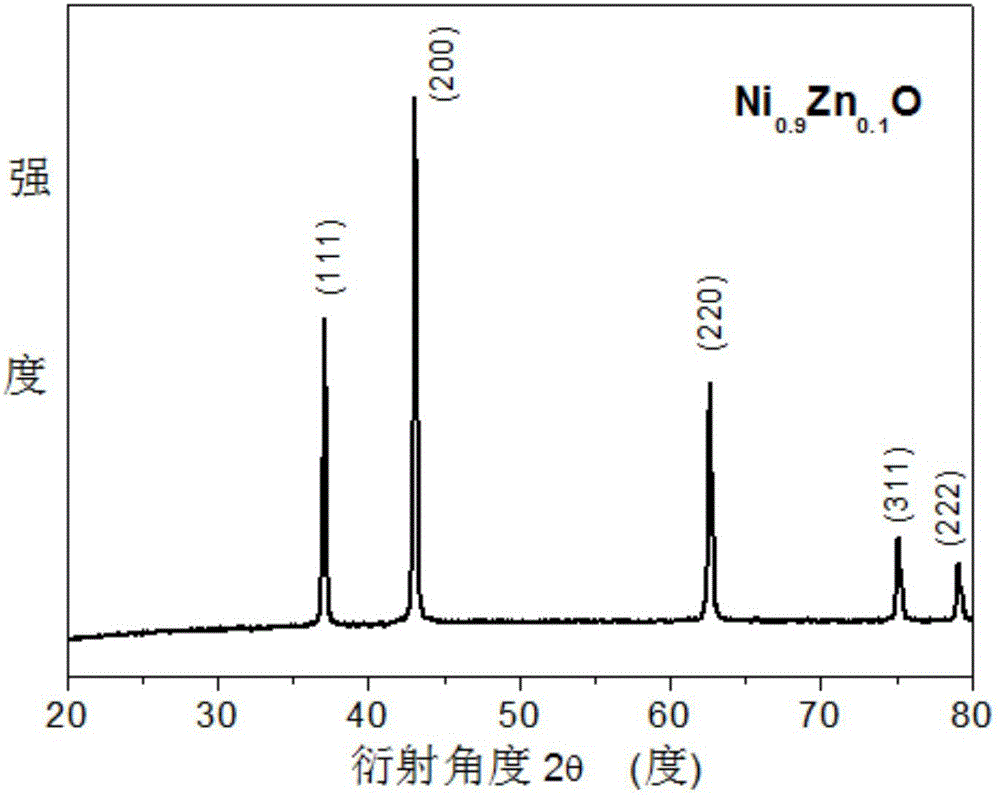

Preparation method of Ni0.9Zn0.1O and prepared Ni0.9Zn0.1O and application of Ni0.9Zn0.1O

The invention discloses a preparation method of Ni0.9Zn0.1O and the prepared Ni0.9Zn0.1O and an application of the Ni0.9Zn0.1O. The preparation method comprises the following steps: with a zinc salt and a nickel salt as metal sources, and dihydric alcohol and deionized water as a mixed solvent, carrying out synthesis by a hydrothermal method to obtain an organic metal composite precursor; and then burning the organic metal composite precursor to obtain the Ni0.9Zn0.1O. The prepared Ni0.9Zn0.1O is a single-phase nickel-zinc composite oxide and is used as an anode material for a lithium-ion battery for the first time. An electrochemical performance test result shows that the reversible specific capacity after 100 cycles under the condition of 0.8A / g is still greater than 600mAh / g; a three-dimensional network structure of the material is beneficial to infiltration and contact of an electrolyte; intercalation and deintercalation of lithium ions are facilitated; the introduced zinc element can improve the conductivity of the material; and the rate capability and the cycle performance are excellent.

Owner:CENT SOUTH UNIV

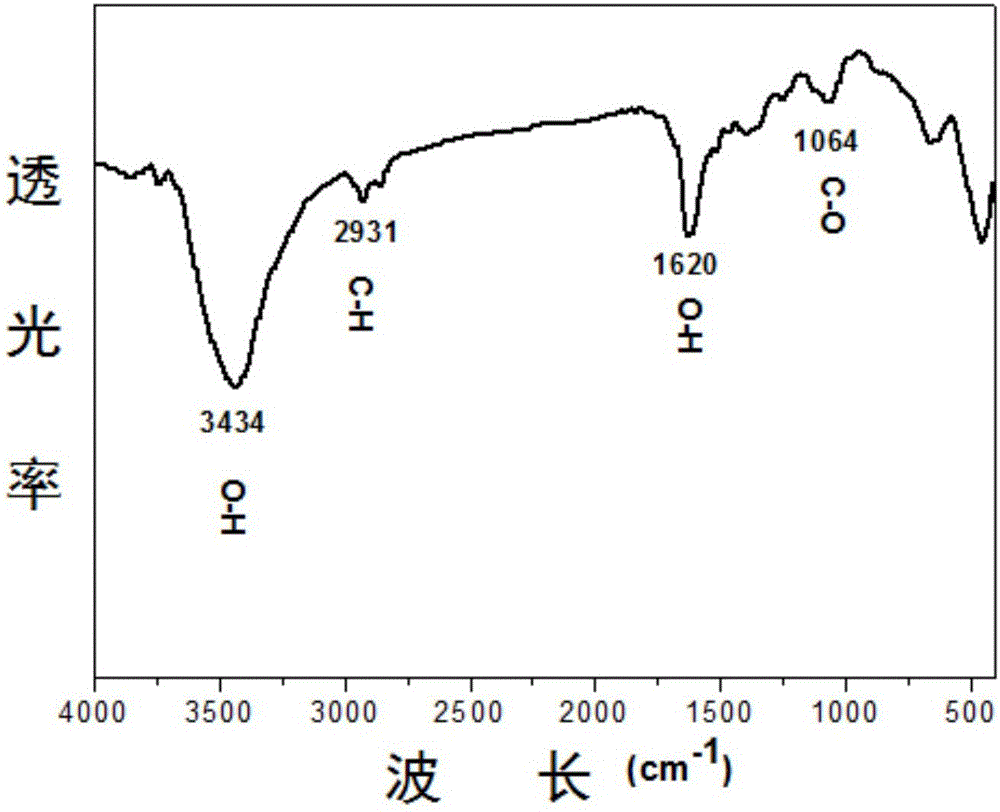

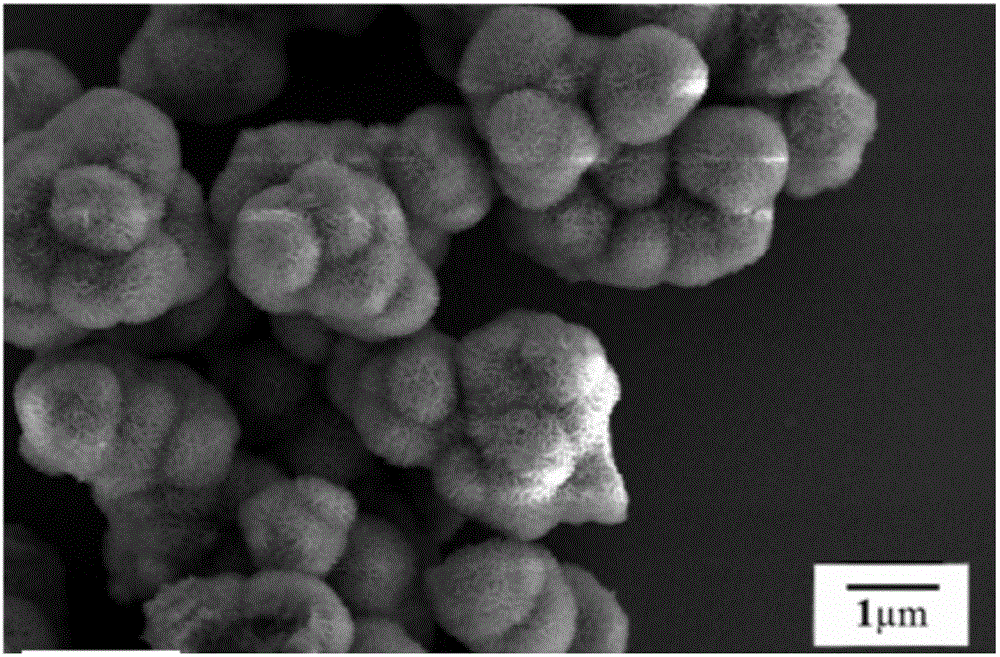

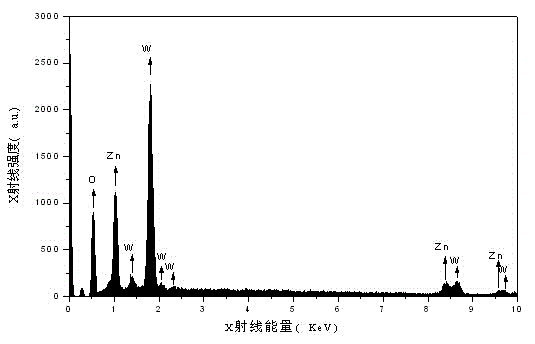

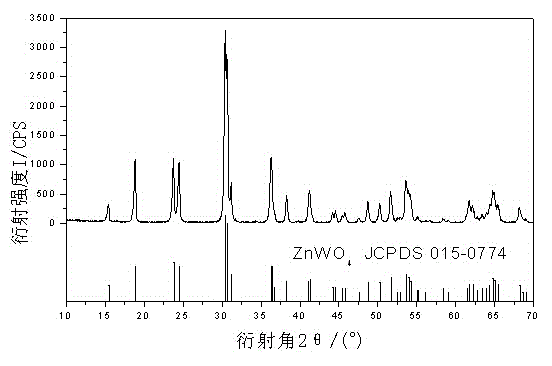

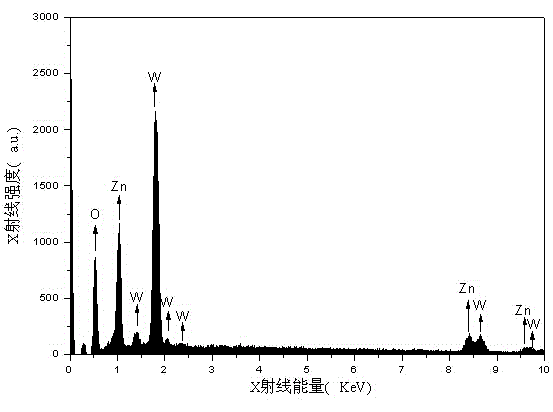

Method for preparing zinc tungstate by using cationic membrane electrolysis process

The invention provides a method for preparing zinc tungstate by using a cationic membrane electrolysis process. The method comprises the steps of utilizing a zinc sheet as an anode, a noble electrode as a cathode, an aqueous solution containing sodium tungstate as an anode liquor, and an acid / alkali / salt solution as a cathode liquor; in a double-compartment electrolytic cell with a cationic membrane as a diaphragm, controlling the temperature from room temperature to 90 DEG C to electrolyze the aqueous solution containing sodium tungstate in a constant-current electrolysis or constant-voltage electrolysis manner till all Na<+> ions are transferred to a cathode compartment; simultaneously cleaning and filtering products from the anode by using deionized water to obtain a filter cake, drying the filter cake, and then increasing the temperature to 450-600 DEG C under air atmosphere at the speed of 2.5-10 DEG C / min to perform high-temperature roasting on the dried filter cake for 1-5 hours; naturally cooling the roasted product to the room temperature, and then obtaining the zinc tungstate with high purity and no impure phase. According to the method for preparing the zinc tungstate by using the cationic membrane electrolysis process, all the Na<+> ions are transferred to the cathode compartment under the action of the cationic membrane electrolysis, so that the Na<+> influence is eliminated and the reaction time is short.

Owner:SHANGHAI INST OF TECH

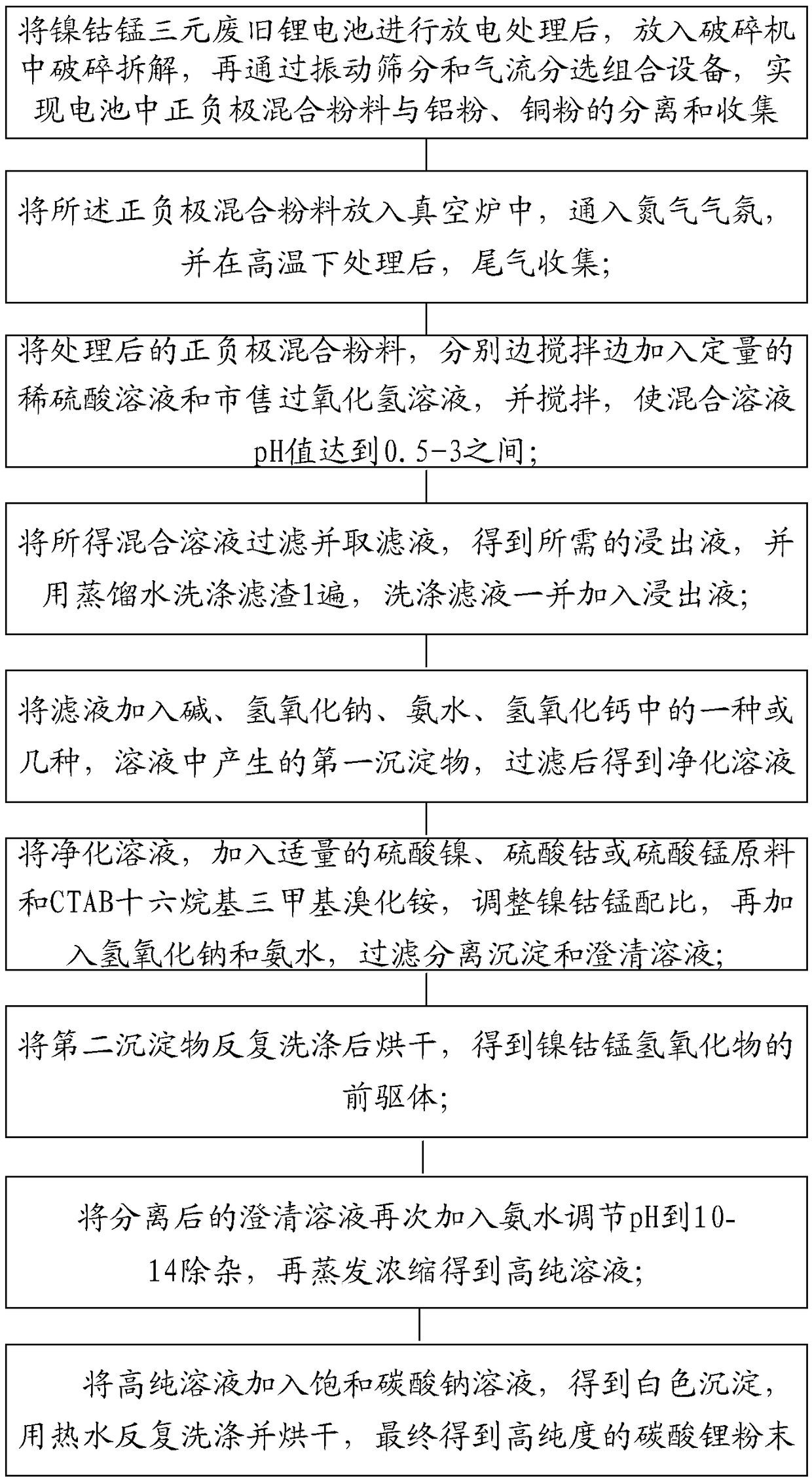

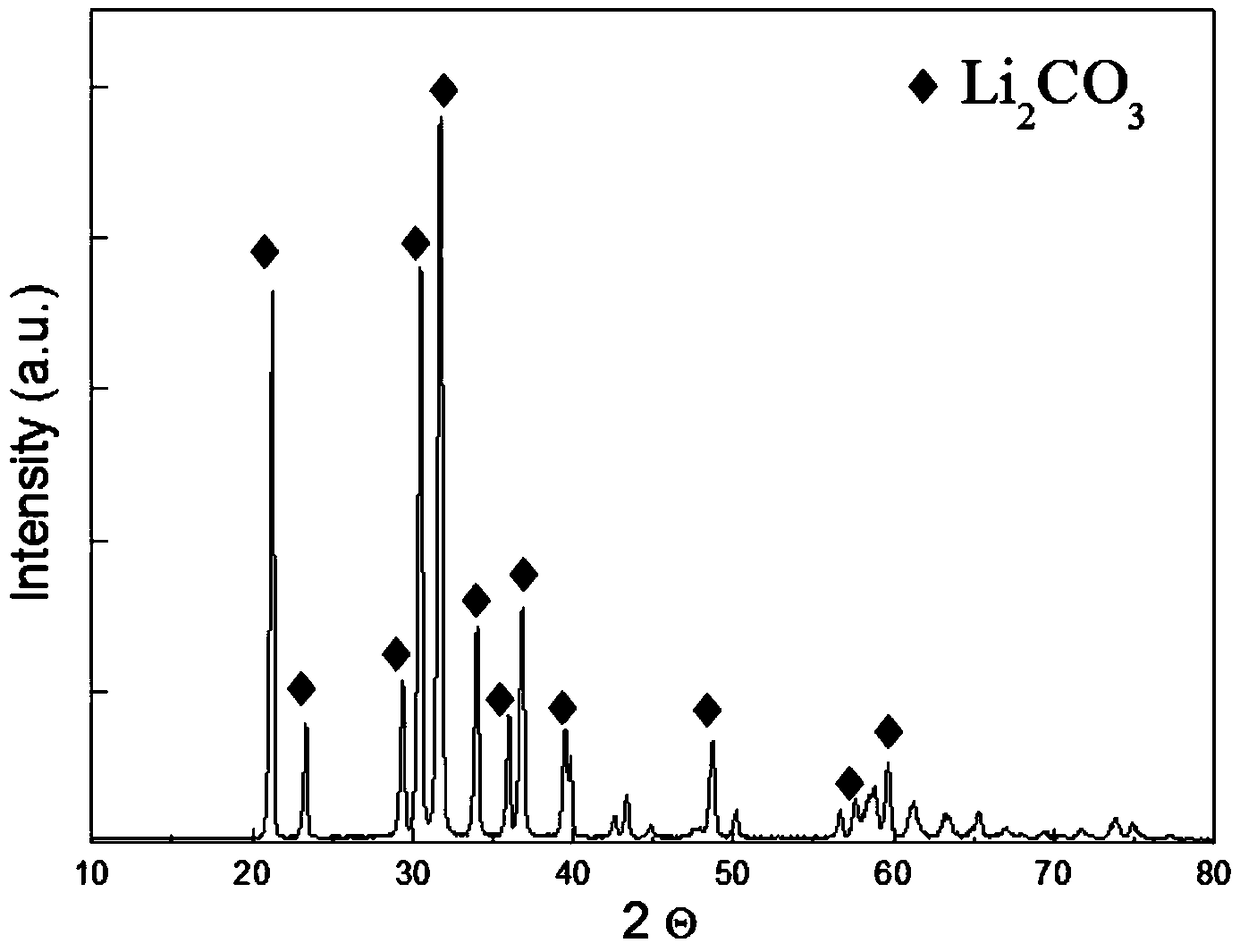

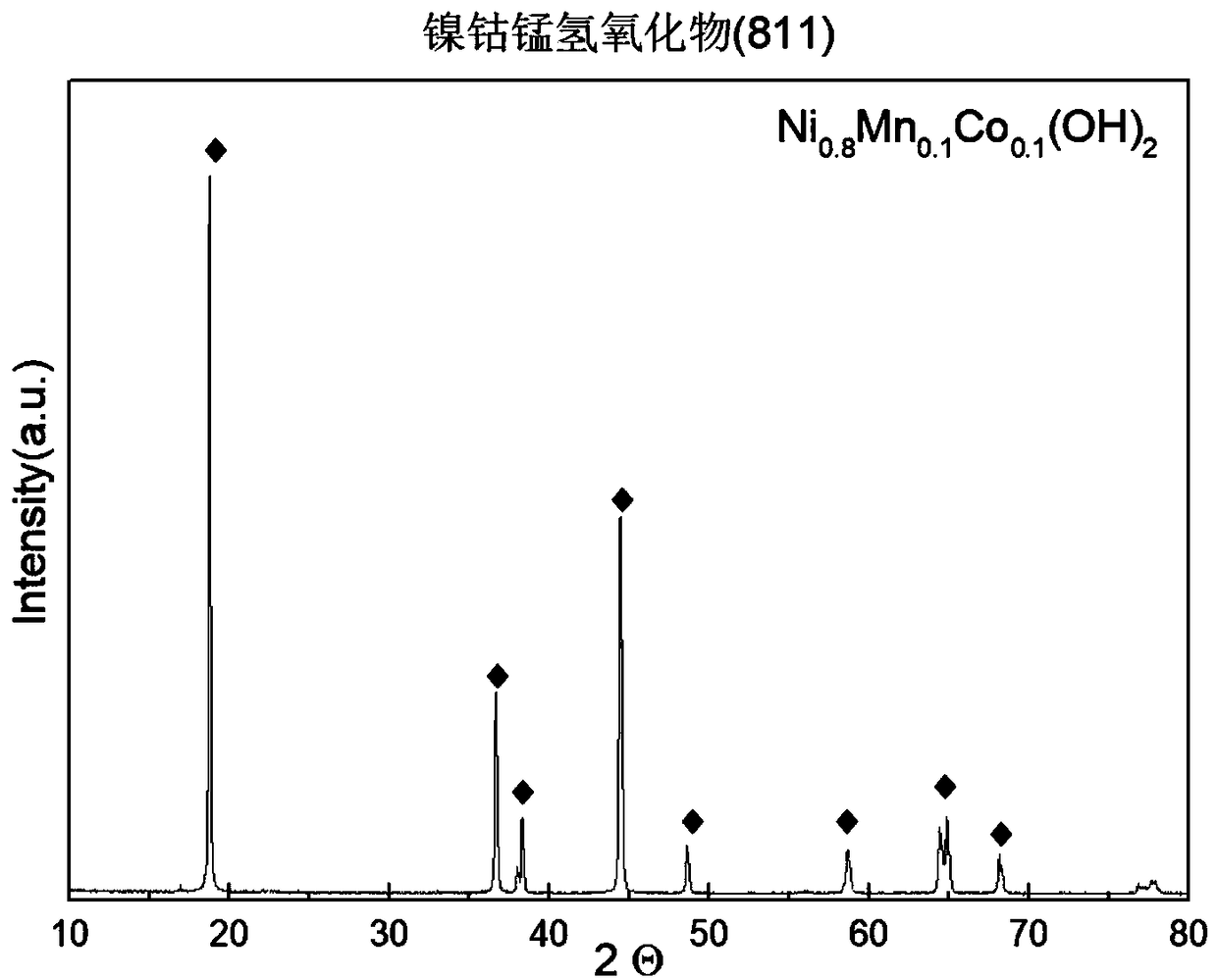

A method for treat Ni-Co-Mn ternary waste lithium battery

PendingCN109256599AHigh economic valueHigh purityWaste accumulators reclaimingProcess efficiency improvementPower batteryLithium carbonate

The invention relates to a treatment method for a Ni-Co-Mn ternary waste lithium battery, which can recover high-purity lithium carbonate powder and Ni-Co-Mn ternary precursor from Ni-Co-Mn ternary waste lithium battery, achieves high purity and no impurity phase, and improves economic value of power battery recovery.

Owner:深圳佳彬科技有限公司

Method for preparing ball milling free spherical crystal type fluorescent powder

The no ball milling spherical crystal phosphor powder preparing process belongs to the field of light-emitting RE material technology and relates to preparation process of YAG phosphor powder and green-blue phosphor powder for LED. By using yttria, cerium oxide, magnesia, barium carbonate, manganese carbonate, barium fluoride and other materials and through one improved high temperature solid phase process, phosphor powder of 5.0-6.0 micron size for use in making LED may be prepared directly without need of ball milling. The present invention has simple technological process, low preparation cost, high yield, capacity of obtaining high purity and high performance phosphor powder and other advantages.

Owner:湖南信多利新材料有限公司

Method for preparing ZrB2-Cu composite powder

InactiveCN104651815AGood dispersionGood crystallinityLiquid/solution decomposition chemical coatingChemical platingPre treatment

The invention provides a method for preparing ZrB2-Cu composite powder, belongs to the field of ceramic / metal composite material preparation and in particular relates to the method for preparing the ZrB2-Cu composite powder having a good internal metal-ceramic binding property. The method comprises two steps of ZrB2 preprocessing and chemical copper plating; the ZrB2 powder is chemically copper-plated by use of a chemical plating method, and then the Cu-coated ZrB2 powder can be prepared. The composite powder prepared by use of the method is good in dispersity; the copper coating is excellent in crystallinity without impurity phase; the surface of the coating is accumulated randomly by fine metal spherical particles; the coating is compact, uniform, flat and smooth, and has wide application prospect.

Owner:裴洁

Method for modifying lithium nickel manganate by replacing Mn with doped P non-equivalently, and application of modified lithium nickel manganate

ActiveCN107611422ASimple methodImprove efficiencyCell electrodesSecondary cellsOxygen vacancyDecomposition

The invention provides a method for modifying lithium nickel manganate by replacing Mn with doped P non-equivalently. A non-metal element P is adopted to replace a small amount of Mn non-equivalentlyto realize doping modification of LiNi<0.5>Mn<1.5>O<4>; and by introducing a small amount of vacancy to the 16d position to adjust content of oxygen vacancy in the material, the ratio of ordered and disordered spinel structures in the material can be optimized. In the preparation process, citric acid is dissolved into a proper amount of deionized water firstly; next, a lithium source, a manganesesource, a nickel source and a phosphorus source are added in sequence to obtain a mixed solution; and heating and stirring are performed until the mixed solution is dried through evaporation, and next, pre-decomposition and thermal treatment are performed to obtain the P non-equivalently doped lithium nickel manganate. The P non-equivalently doped and modified lithium nickel manganate prepared bythe invention is high in tap density and purity, free of impurity phase, and quite high in rate capability and cycle performance; the capacity retention ratio is about 93% at 10C rate after 1,000 cycles; and the capacity retention ratio still can be as high as 87% after 1,600 cycles.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com