Method for preparing ball milling free spherical crystal type fluorescent powder

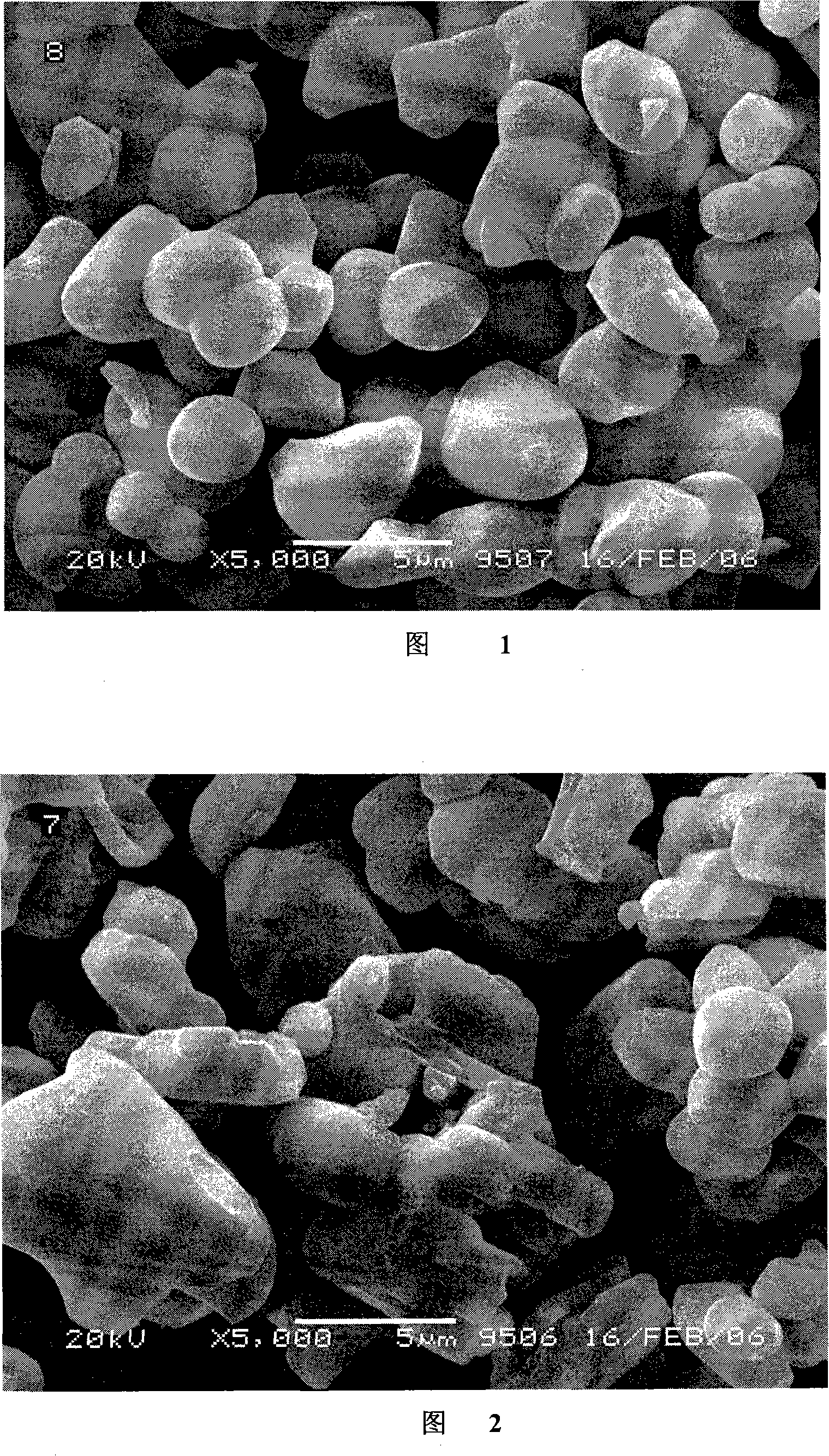

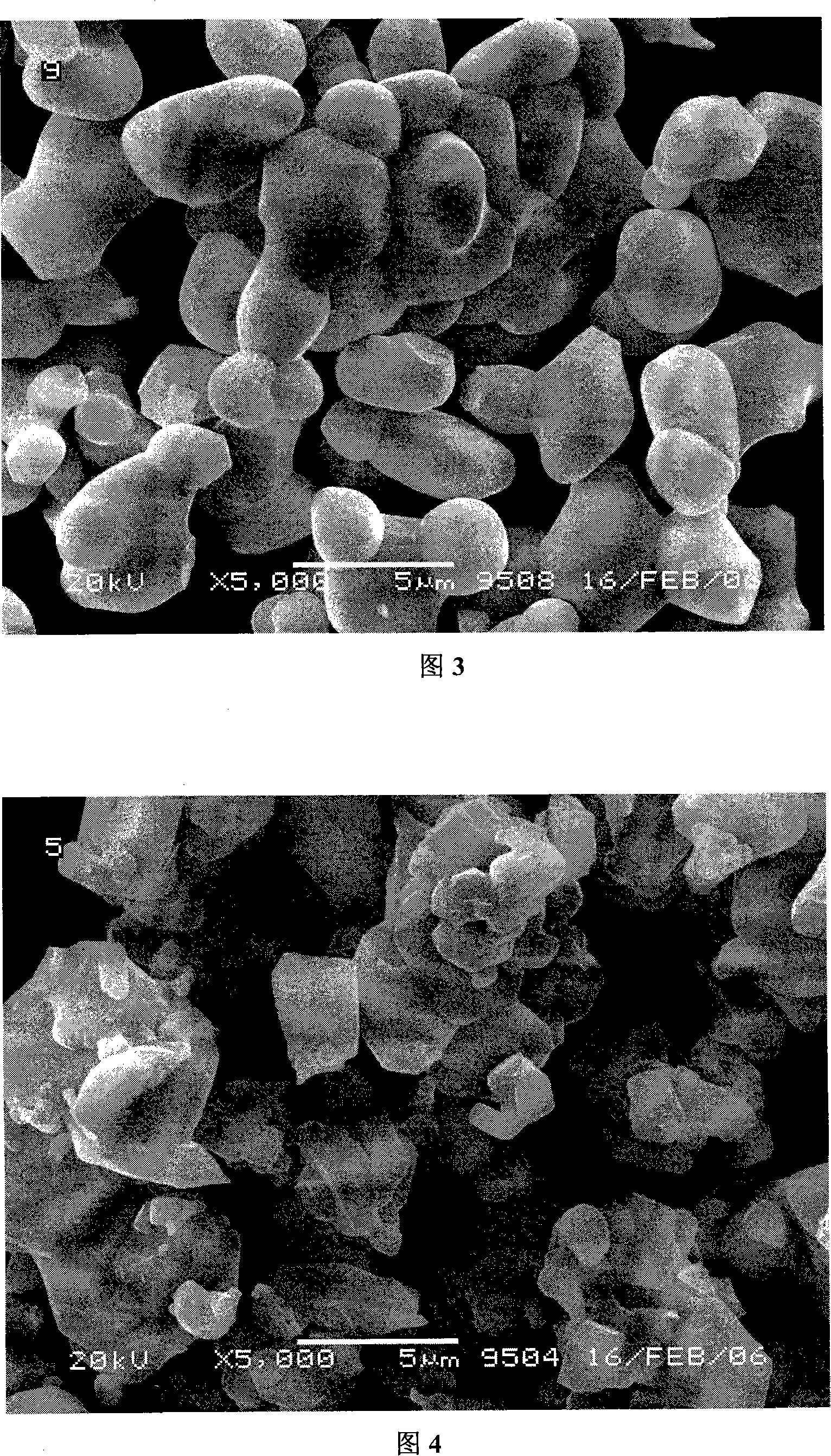

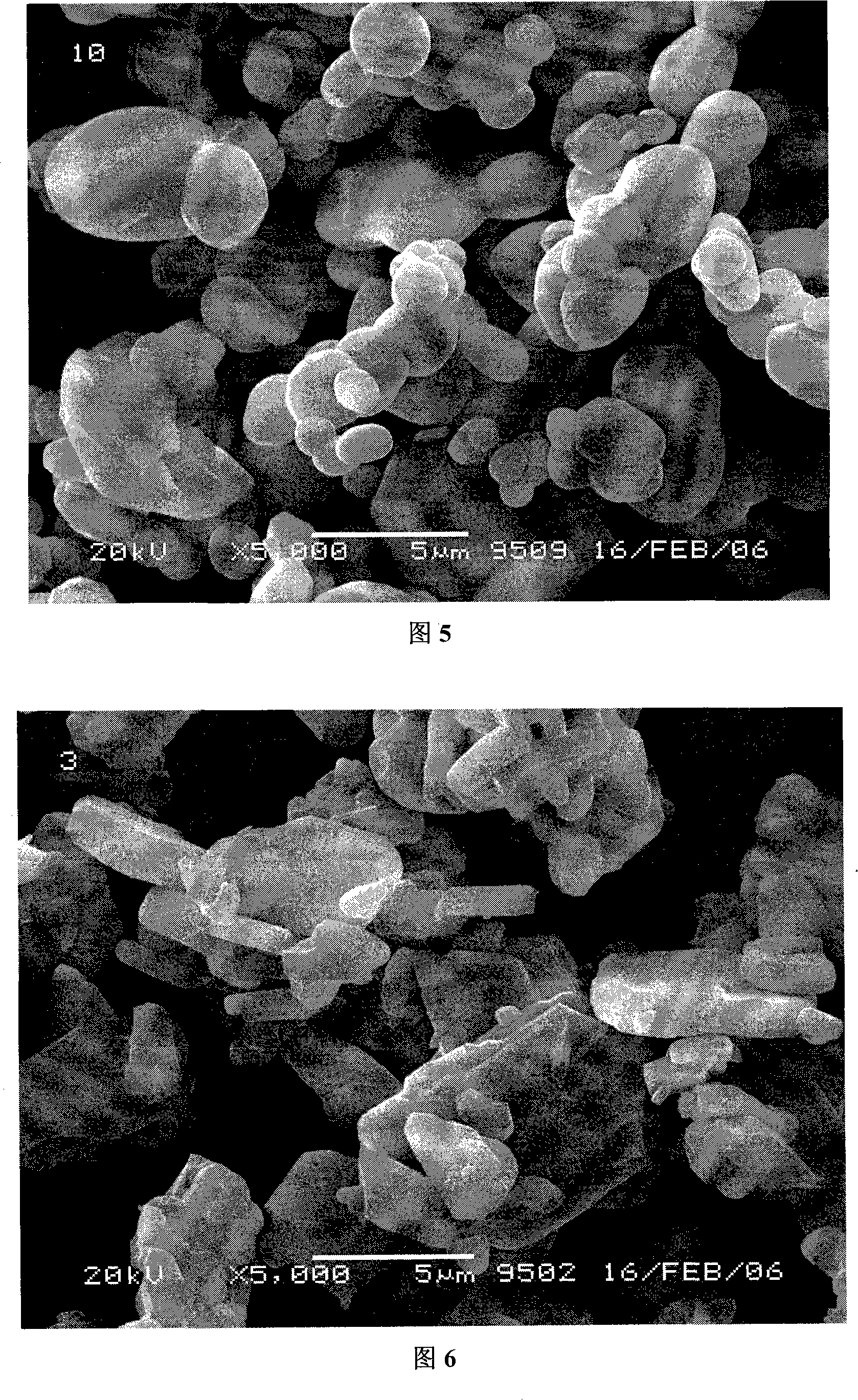

A fluorescent powder and ball-milling-free technology, which is applied in the preparation of blue fluorescent powder, yttrium aluminum garnet fluorescent powder and tricolor green, can solve the problems of reducing particle size, large powder particles, long heat preservation time, etc., and achieve sintering hardness Reduced, complete crystal structure, small central particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, the process flow of the YAG fluorescent powder of the present invention is: batching-→jet milling-→mixing to make uniform-→high temperature pre-burning (1400-1450 degrees)-→detection-→crushing, washing through a 400-mesh wet sieve -→centrifugation-→drying-→airflow crushing-→100 mesh sieving-→testing-→low temperature reduction (1150-1250 degrees)-→testing-→crushing, coarse sieving-→washing, wet sieving, centrifugation, drying Drying-→100 mesh screening-→comprehensive testing-→finished product.

[0040] The pretreatment of each raw material in the preparation process, the intermediate treatment after high temperature pre-calcination, the firing temperature and the post-treatment method are the key factors affecting the product quality. BaF used as flux 2 、H 3 BO 3 Dry ball milling, passing through a 200-mesh sieve; according to chemical formula Y 3-3x al 5 o 12 : xCe stoichiometric ratio relationship, weighing alumina, yttrium oxide, cerium oxide and o...

Embodiment 2

[0042] The technological process of the three-color green fluorescent powder of the present invention is: batching-→airflow crushing-→mixing to make uniform-→high temperature pre-burning (1400-1450 degrees)-→detection-→crushing, washing through a 400-mesh wet sieve-→ Centrifugation-→drying-→airflow crushing-→100 mesh sieving-→testing-→low temperature reduction (1150-1250 degrees)-→testing-→crushing, coarse sieving-→washing, wet sieving, centrifugation, drying- →100 mesh screening-→comprehensive testing-→finished product.

[0043] BaF used as flux 2 Dry ball milling, passing through a 200-mesh sieve; according to the chemical formula MgAl 11 o 19 : Ce, Tb stoichiometric ratio relationship, weigh alumina, terbium oxide, cerium oxide, magnesium oxide and other raw materials, add flux BaF accounting for 1 to 5% of the chemical formula 2 , to obtain the mixture; use a supersonic jet mill to crush the mixture so that the central particle size is 4.0±0.5um; put the crushed mixture...

Embodiment 3

[0045] The technological process of the three-color blue fluorescent powder of the present invention is: batching-→airflow crushing-→mixing to make uniform-→high temperature pre-burning (1400-1450 degrees)-→detection-→crushing and washing through a 400-mesh wet sieve- →centrifugation-→drying-→airflow crushing-→100 mesh sieving-→detection-→low temperature reduction (1150-1250 degrees)-→detection-→crushing, coarse sieving-→washing, wet sieving, centrifugation, drying -→100 mesh screening-→comprehensive testing-→finished product.

[0046] BaF used as flux 2 、H 3 BO 3 Dry ball milling, passing through a 200-mesh sieve; according to the chemical formula Ba, MgAl 10 o 17 : Eu, Mn stoichiometric ratio relationship, weigh aluminum oxide, europium oxide, magnesium oxide, barium carbonate, manganese carbonate and other raw materials, add flux BaF accounting for 1 to 5% mole of the chemical formula 2 、H 3 BO 3 , to obtain the mixture; use a supersonic jet mill to crush the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com