Method for whitening kaolin by using surface cladding method

A surface coating, kaolin technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve the problems of low whiteness value and difficult control of the reaction process, and achieve simple technical process and less equipment. , the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: The kaolin without coating and whitening treatment has a blue light whiteness of 80.5.

[0029] Mix 50g of kaolin, 0.05g of anhydrous sodium carbonate, and 70ml of distilled water, adjust pH=7, ball mill 400r / m, and ball mill for 60min. Weigh 2.5 g of aluminum sulfate and dissolve it in 20 ml of distilled water, add the solution to the kaolin mud (diluted to a concentration of 10%), and continue to stir for 15 minutes. Take 2ml of 20% ammonia water and add it dropwise to the kaolin mud for 10 minutes. After the reaction, let it stand for 30 minutes. Filter and dry at 105°C for 10 hours. The measured blue light whiteness of the product is 85.5. The coating whitening technology improves the whiteness of the product by 5 degrees.

Embodiment 2

[0030] Example 2: The kaolin without coating and whitening treatment has a blue light whiteness of 79.9.

[0031] Mix 50 g of kaolin, 0.05 g of sodium hexametaphosphate, and 50 ml of distilled water, adjust pH=8, ball mill 400r / m, and ball mill for 90 minutes. Weigh 5 g of aluminum nitrate and dissolve it in 20 ml of distilled water, add the solution to the kaolin mud (diluted to a concentration of 8%), and continue to stir for 15 minutes. Take 5ml of 20% ammonia water and add it dropwise to the kaolin mud for 10 minutes. After the reaction, let it stand for 40 minutes. After filtering and drying at 105°C for 10 hours, the whiteness of the product was measured to be 85.2. The coating whitening technology improves the whiteness of the product by 5.3 degrees.

Embodiment 3

[0032] Example 3: The kaolin without coating and whitening treatment has a blue light whiteness of 77.7.

[0033] Mix 50g of kaolin, 0.1g of anhydrous sodium carbonate, and 35ml of distilled water, adjust pH=8, ball mill 400r / m, and ball mill for 120min. Weigh 7.5 g of aluminum sulfate and dissolve it in 20 ml of distilled water, add the solution to the kaolin mud (diluted to a concentration of 5%), and continue to stir for 15 minutes. Take 7.5 ml of 20% ammonia water and add it dropwise to the kaolin mud for 15 minutes. After the reaction, let it stand for 30 minutes. After filtering, drying at 105°C for 10 hours, powdering, the whiteness of the product is measured to be 86.6, and the whiteness of the product is improved by the coating whitening technology by 8.9 degrees.

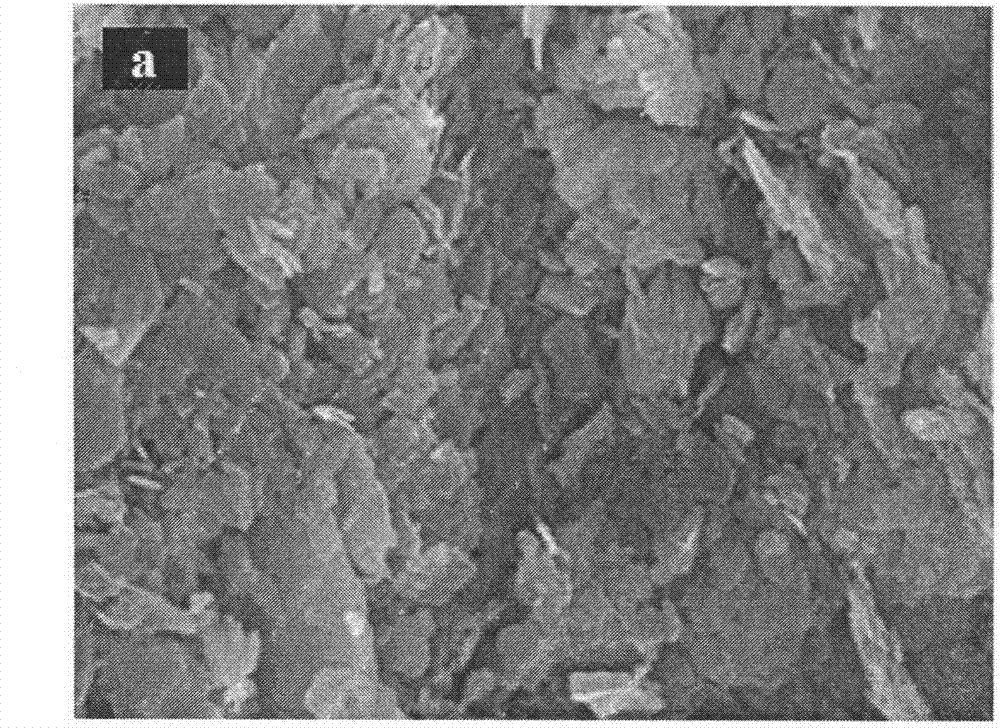

[0034] Attached figure 1 It can be seen that the lamellar structure of the original sample of kaolin in Example 1 of the present invention is clear, and the particle surface is smooth and flat;

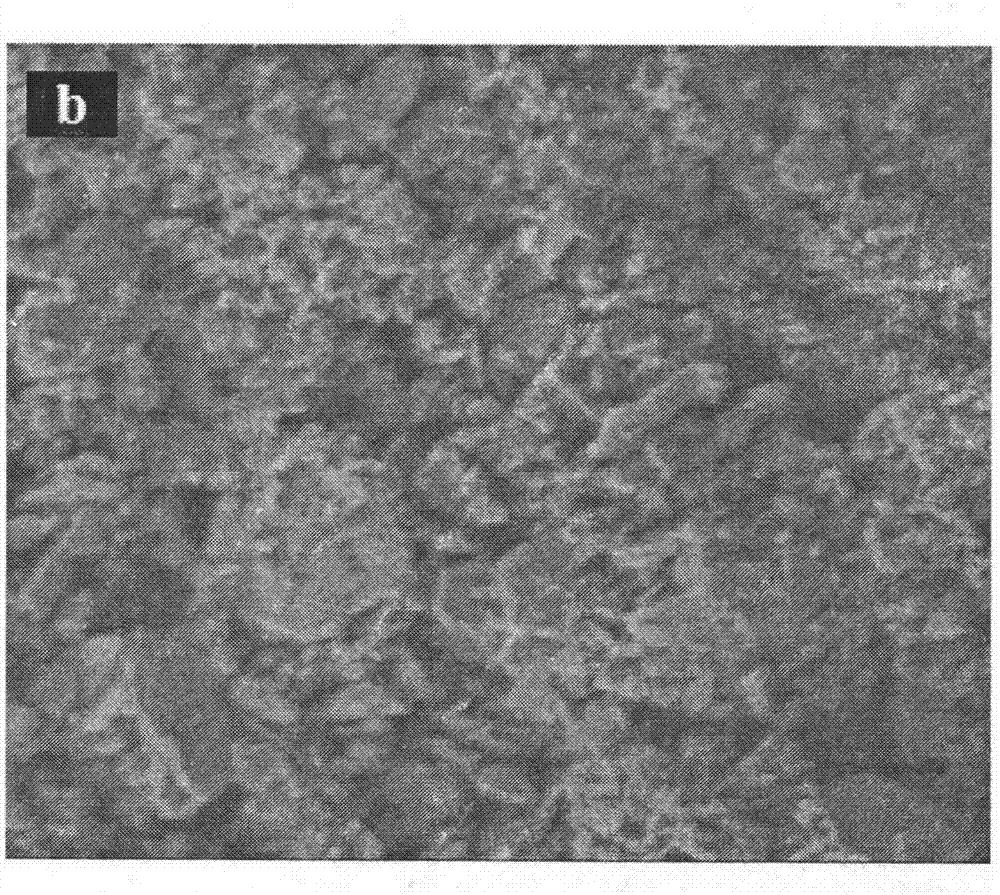

[0035] Attach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com