Ultra-wear-resistant flow coating UV coating material, preparation method and applications thereof

A super wear-resistant, shower coating technology, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of poor wear resistance and single functional characteristics, and achieve special smoothness, chemical bond High energy and high electronegativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

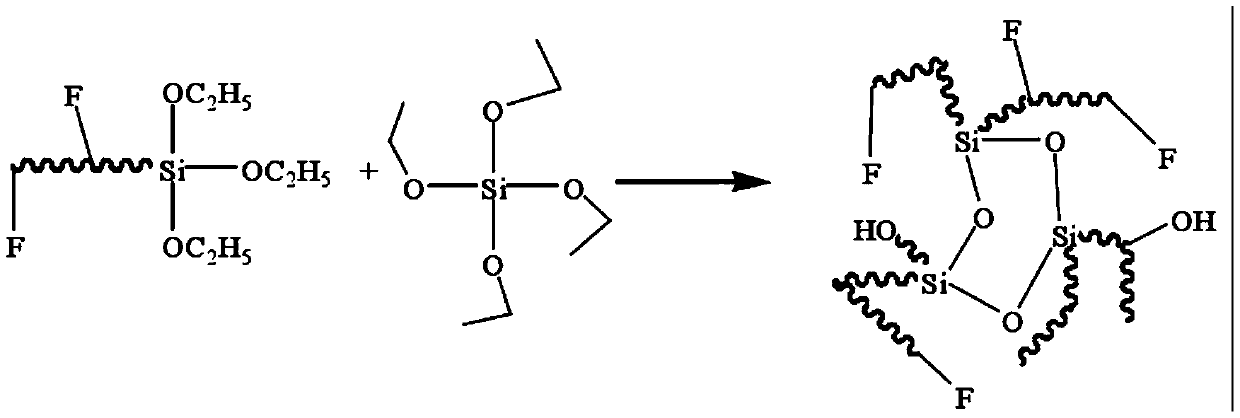

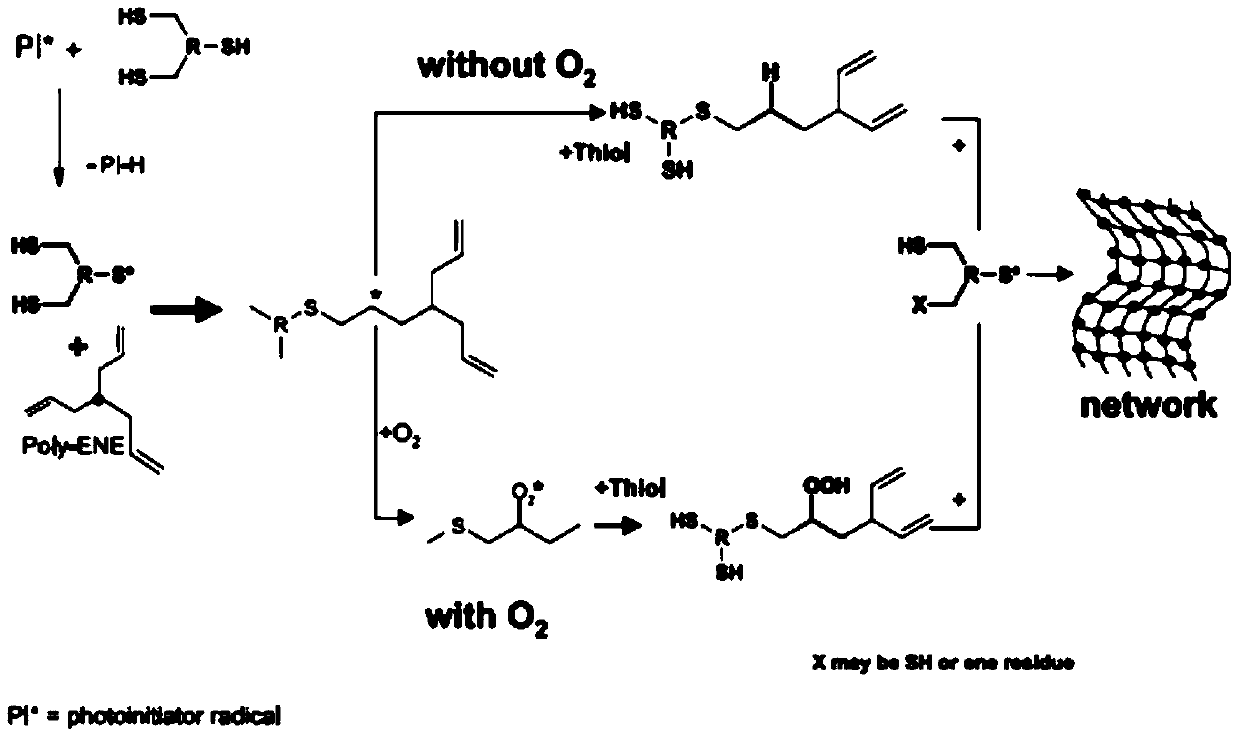

Method used

Image

Examples

preparation example Construction

[0027] According to another aspect of the present invention, there is also provided a preparation method for preparing the above-mentioned super wear-resistant curtain coating UV coating, comprising the following steps: S1, mixing a photoinitiator, a functional additive and a solvent, and stirring until dissolved , forming a mixed solution; S2, adding nano-hybrid modified UV resin 1, nano-hybrid modified UV resin 2 and active monomers to the mixed solution in step S1, stirring, and filtering to obtain a super wear-resistant flow coating UV coating. The invention is used for the preparation method of the above-mentioned super wear-resistant flow coating UV coating, and the preparation process is simple, easy to operate, low in cost, stable in effect, good in product performance, and suitable for large-scale industrial production. The paint film formed by the super wear-resistant curtain coating UV coating obtained by the above preparation method has water repellency, oil repelle...

Embodiment 1

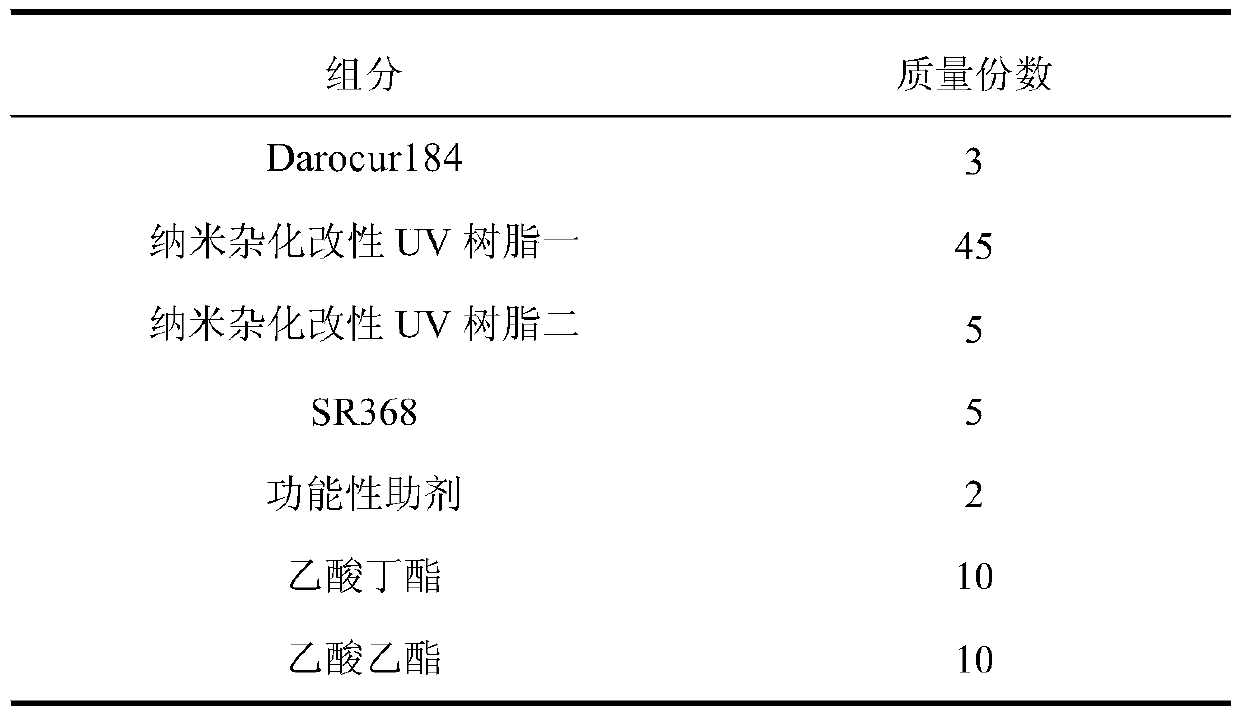

[0040] A super wear-resistant curtain coating UV coating, its composition is shown in Table 1.

[0041] The super wear-resistant curtain coating UV coating of table 1 embodiment 1

[0042]

[0043]

[0044] The preparation method of above-mentioned super wear-resistant curtain coating UV coating is:

[0045] S1. Mix Darocur184 with functional additives, butyl acetate, ethyl acetate, n-butanol and propylene glycol methyl ether, and stir until dissolved to form a mixed solution;

[0046] S2. Add nano-hybrid modified UV resin 1, nano-hybrid modified UV resin 2 and SR368 into the mixed solution in step S1, stir, the stirring speed is 400 rpm, the time is 18 min, and the filter is 0.1 μm Net filtration, to obtain super wear-resistant flow coating UV coating.

[0047] Application of the above super wear-resistant coating UV coating on the surface of plastic composite panels:

[0048] Dilute the super wear-resistant flow coating UV coating with diluent, the volume ratio is 1...

Embodiment 2

[0050] A kind of super wear-resistant curtain coating UV coating, its composition is as shown in table 2.

[0051] The super wear-resistant curtain coating UV coating of table 2 embodiment 2

[0052]

[0053] The preparation method of above-mentioned super wear-resistant curtain coating UV coating is:

[0054] S1. Mix Irgacure1173 with functional additives, butyl acetate, ethyl acetate, n-butanol and propylene glycol methyl ether, and stir until dissolved to form a mixed solution;

[0055] S2. Add nano-hybrid modified UV resin 1, nano-hybrid modified UV resin 2 and PET3A, SR368 into the mixed liquid in step S1, stir, the stirring speed is 480 rpm, the time is 16min, using 0.1μm Filtered by a special filter to obtain super wear-resistant curtain coating UV coatings.

[0056] Application of the above super wear-resistant coating UV coating on the surface of plastic composite panels:

[0057] Apply the super wear-resistant UV coating on the surface of the plastic composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light intensity | aaaaa | aaaaa |

| Light intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com