Patents

Literature

53results about How to "Excellent weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

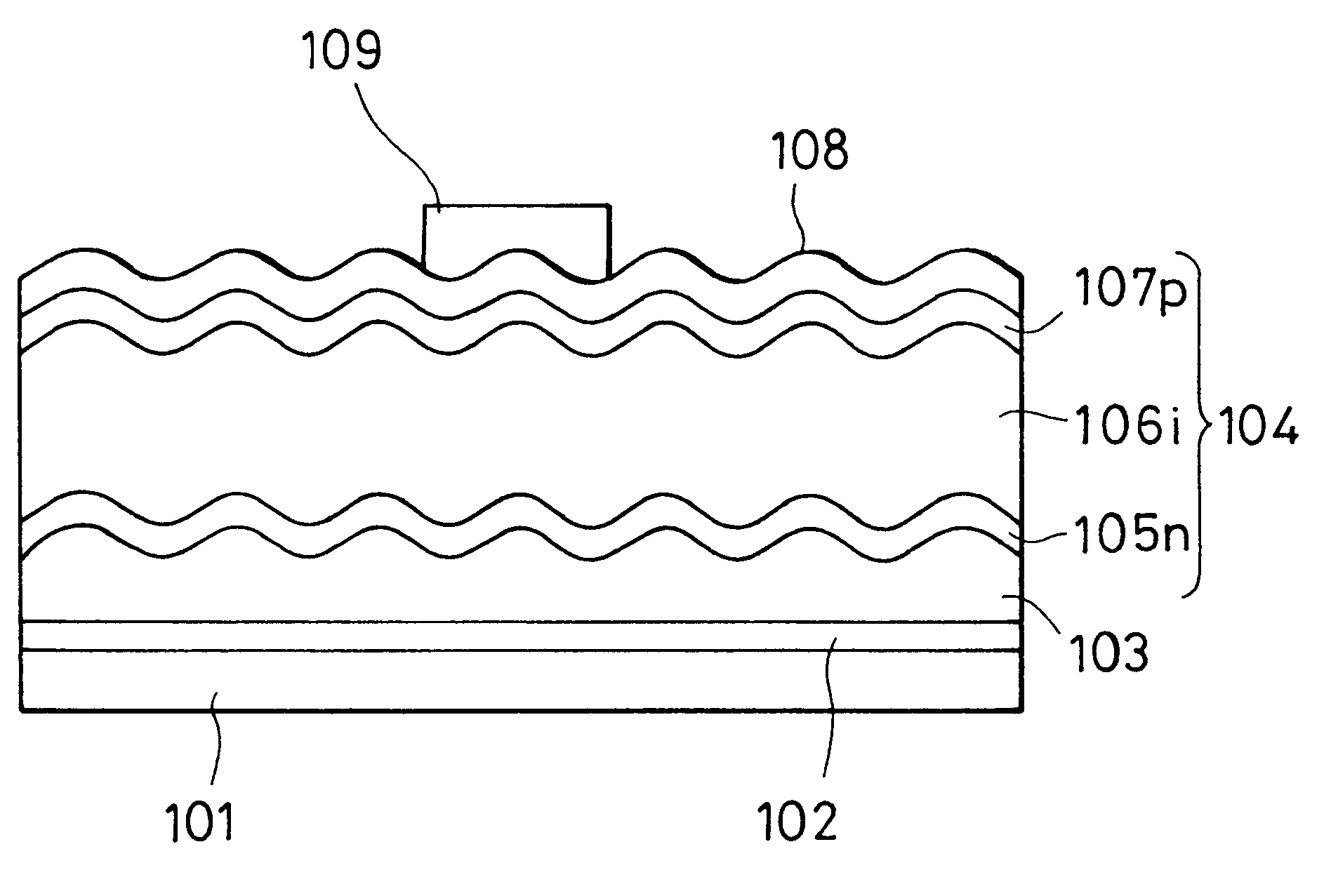

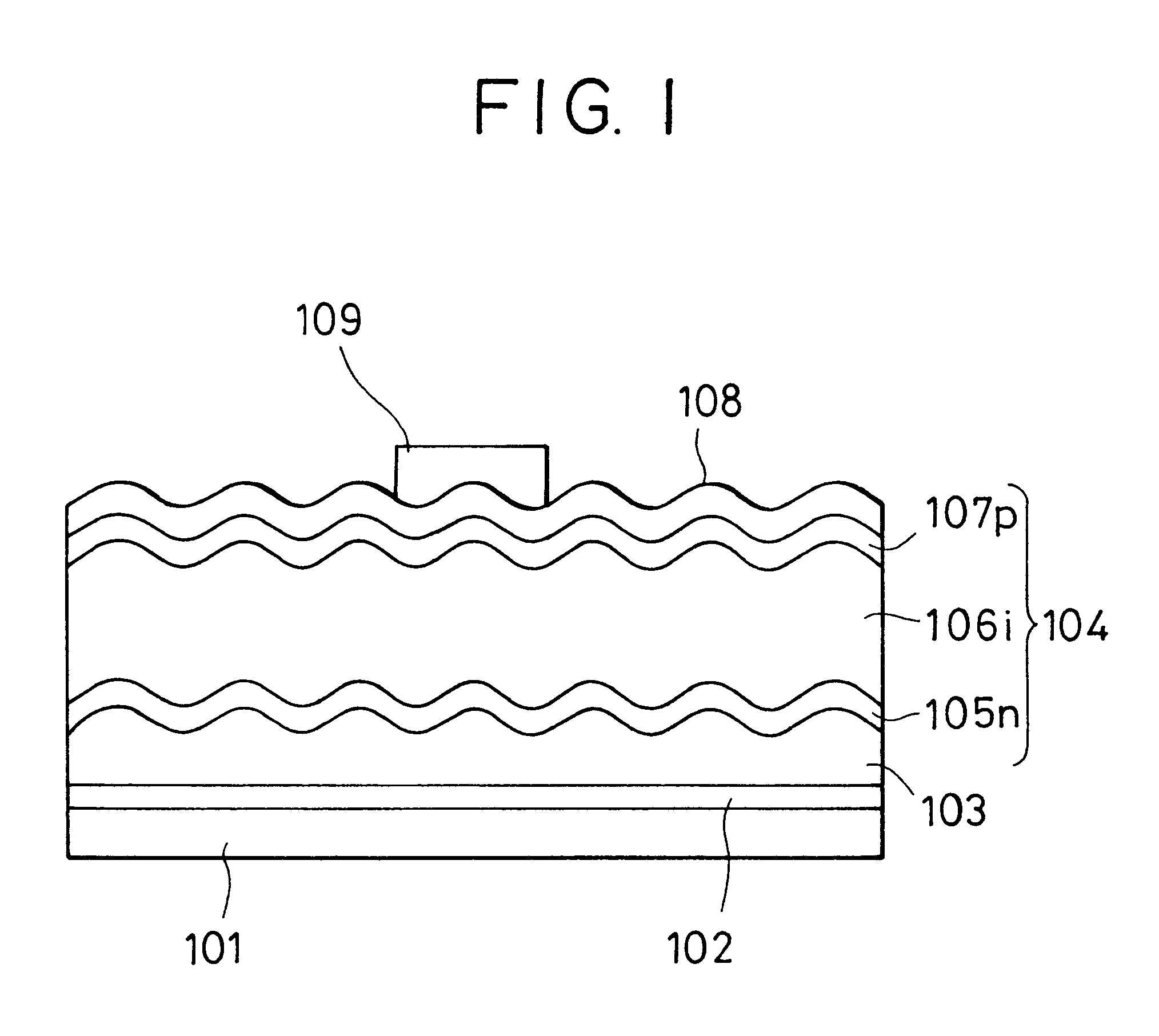

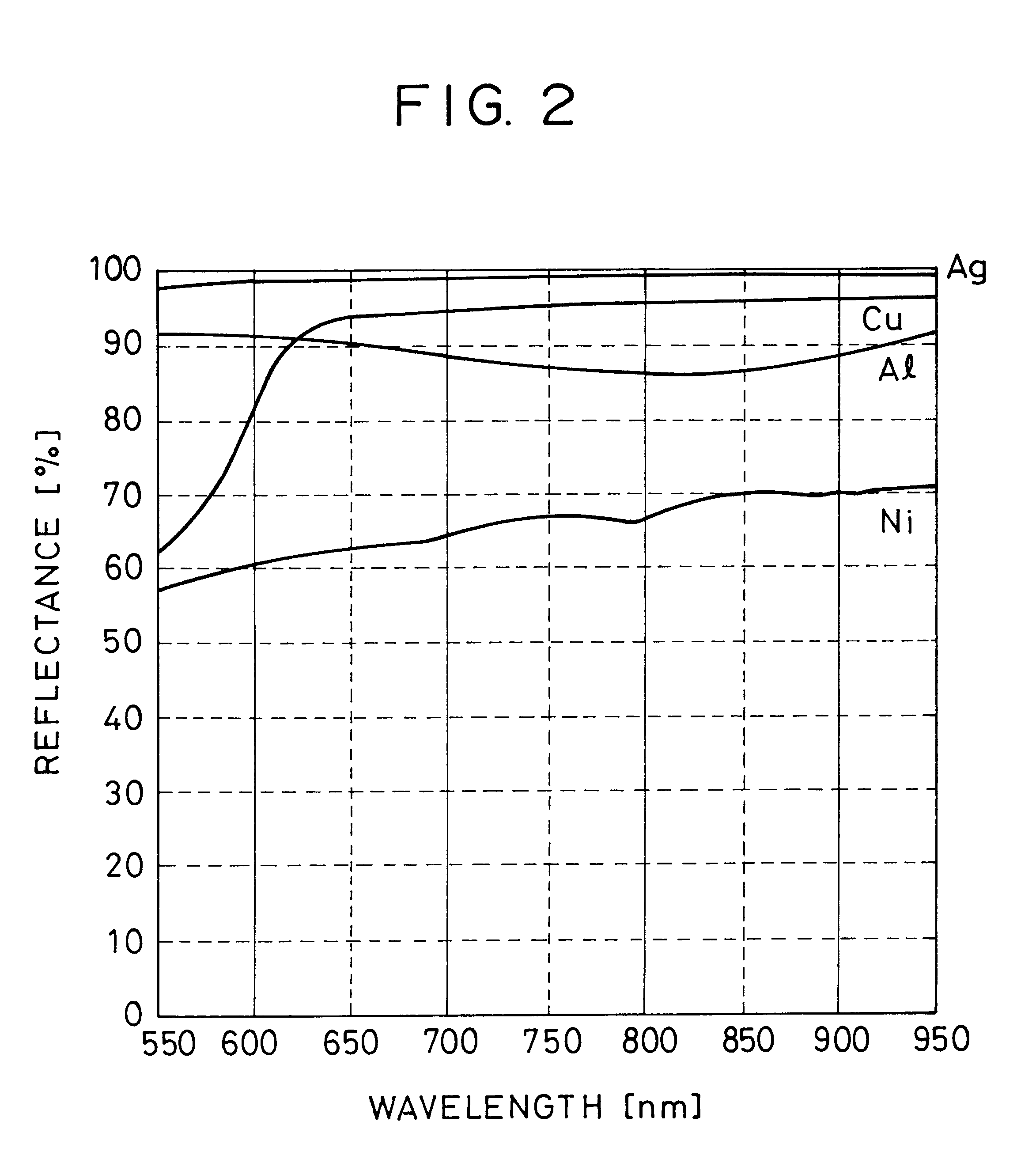

Photovoltaic cell

InactiveUS6172296B1Improve adhesionExcellent weather resistancePhotovoltaic energy generationSemiconductor devicesAluminiumMetal

A photovoltaic cell in accordance with the present invention includes at least a metal layer, a semiconductive layer and a transparent electrode formed on a substrate. The metal layer is composed of a metal mainly containing aluminum; and has an x-ray diffraction pattern in which a (111) peak intensity is enhanced to at least 2.1 times a (200) peak intensity, at least 4.4 times a (220) peak intensity and at least 4.1 times a (311) peak intensity. The metal layer essentially consists of an aluminum-titanium alloy or an aluminum-magnesium alloy. An interlayer may be provided between the metal layer and the substrate.

Owner:CANON KK

Heat-conducting silicone rubber electronic casting glue and preparation method and application thereof

InactiveCN103756327AExcellent weather resistanceImprove thermal conductivityCell component detailsChemistryWeather resistance

The invention relates to the technical field of organic silicone rubber, and aims to solve the problems of poor liquidity and heat-conducting property of an existing silicone rubber electronic casting glue. The invention provides a heat-conducting silicone rubber electronic casting glue and a preparation method thereof. The casting glue is prepared by mixing a glue A and a glue B, has excellent weather resistance, heat resistance, ozone resistance, high heat-conducting property and excellent flow properties, and is used for sealing of lithium battery materials.

Owner:HANGZHOU SILICONE WAY TECH

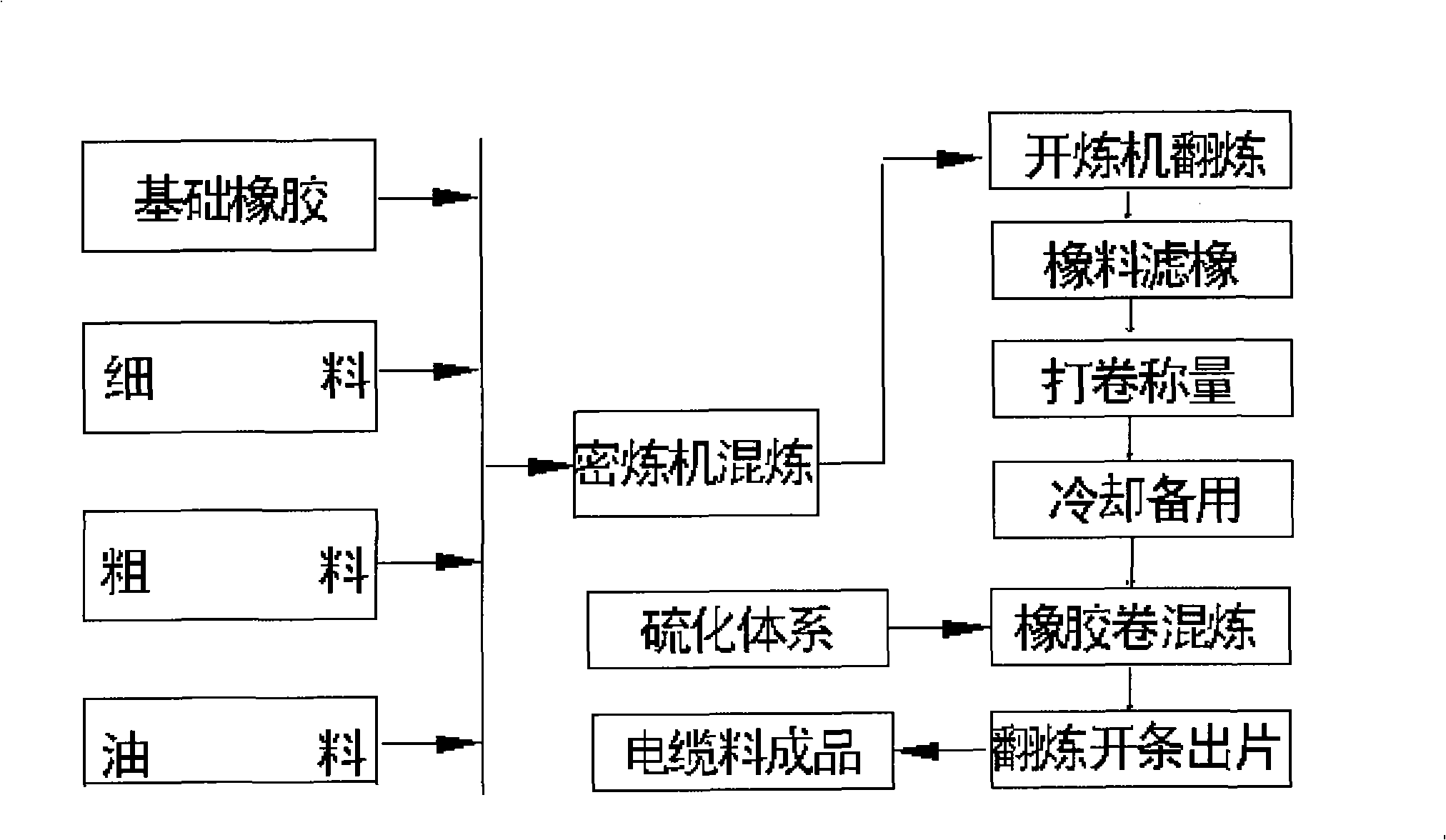

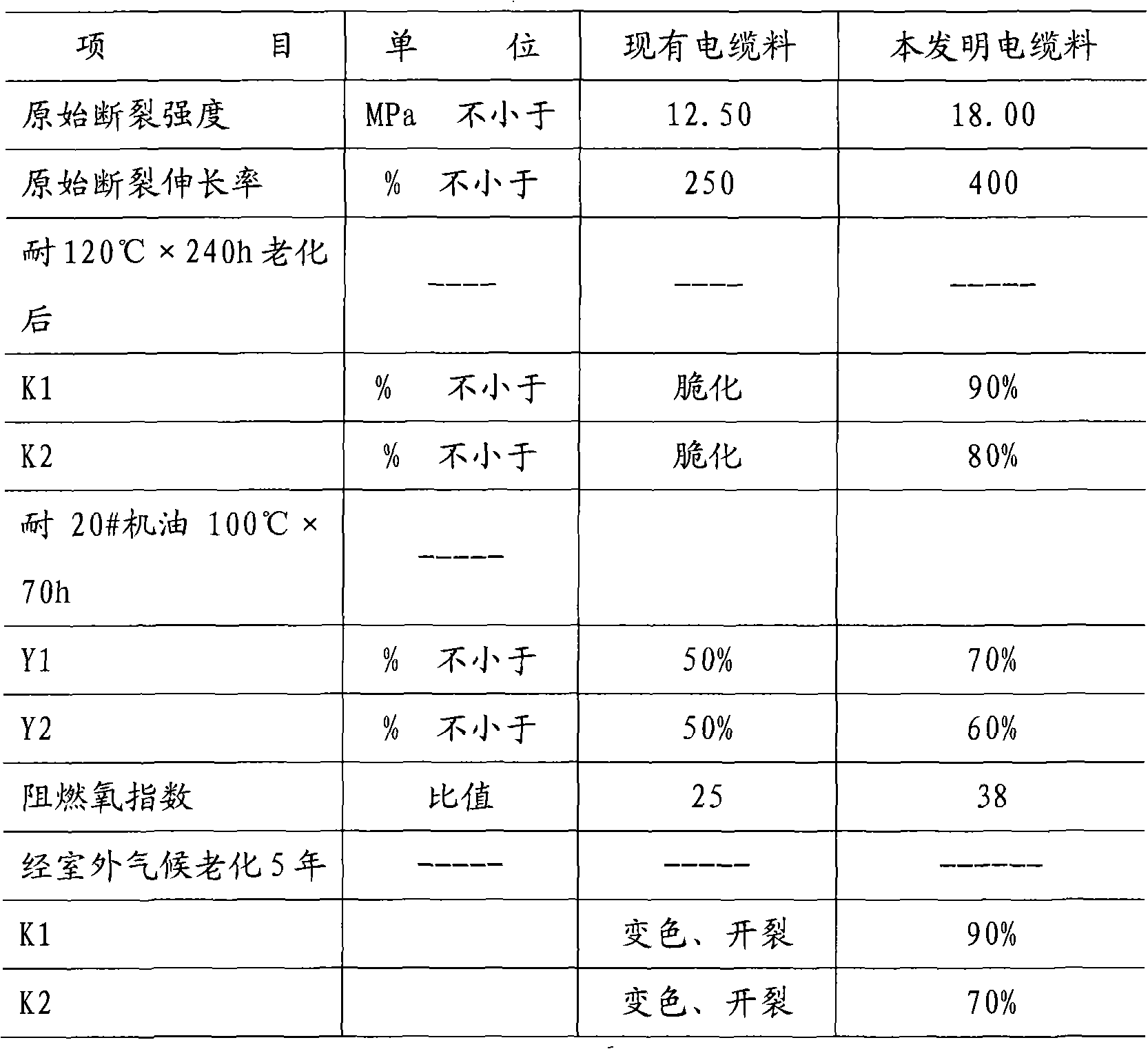

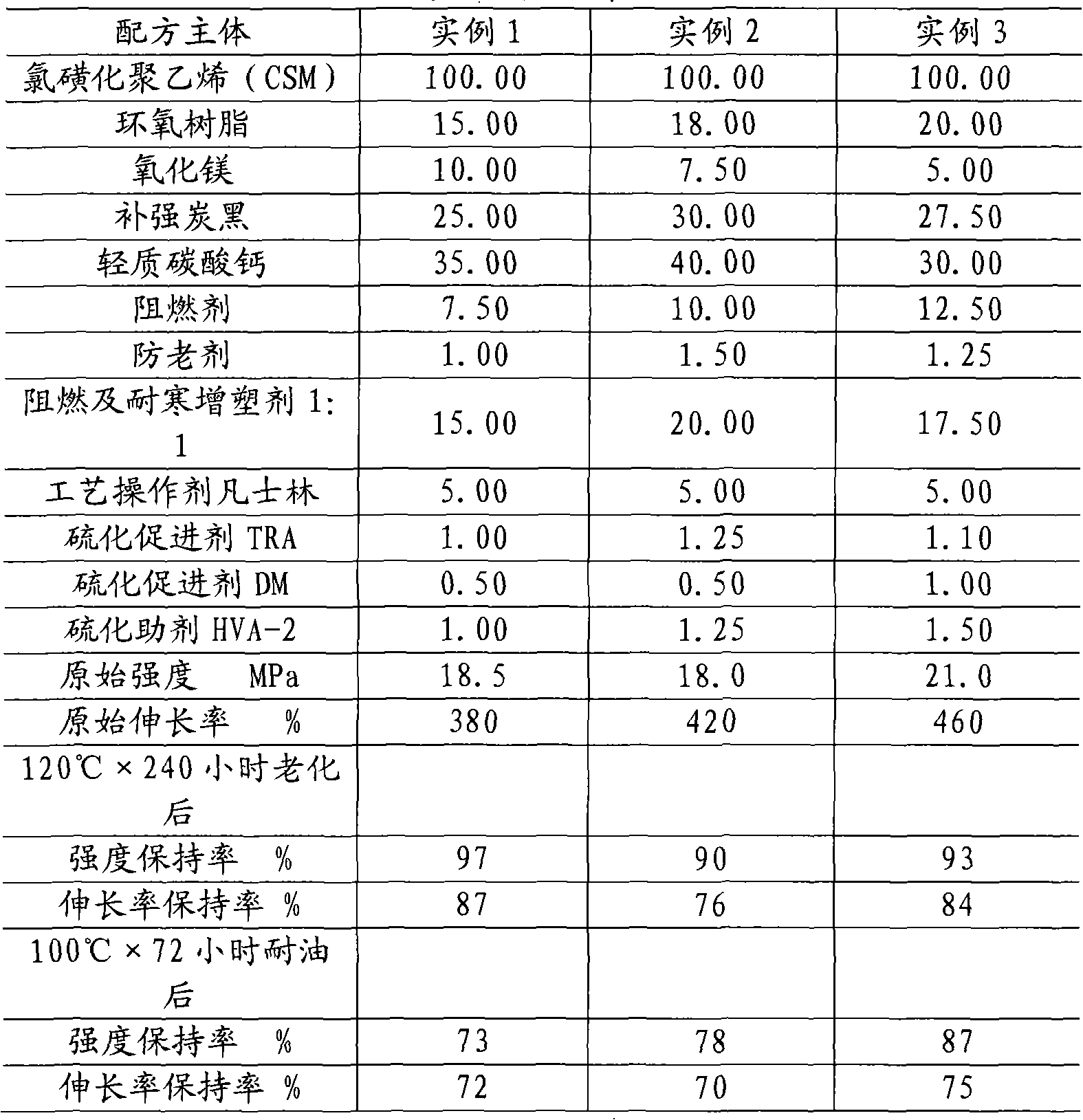

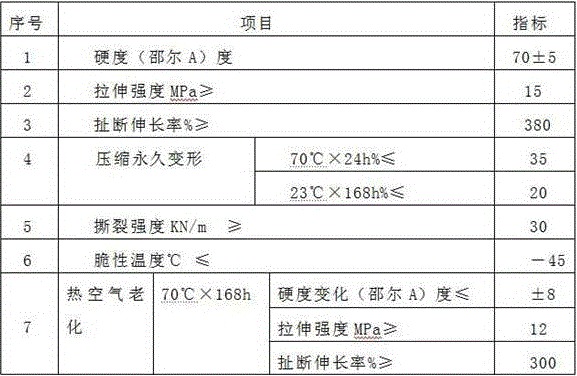

External rubber sleeve material of cable for wind power generation

InactiveCN101538391AEasy to operateImprove water resistanceInsulated cablesInsulated conductorsEpoxyVulcanization

The invention discloses an external rubber sleeve material of a cable used for wind power generation, comprising the following components by weight parts: 100.00 parts of chlorosulfonated polyethylene rubber, 15.00-20.00 parts of vulcanizing agent epoxy resin, 5.00-10.00 parts of magnesium oxide acid acceptor, 1.00-1.50 parts of vulcanization aid, 0.20-1.50 parts of vulcanization accelerator, 10.00-15.00 parts of fire-retardant plasticizer, 5.00-10.00 parts of cold resistant plasticizer, 30.00-40.00 parts of reinforcing agent, 40.00-50.00 parts of filling agent, 0.50-2.00 parts of anti-ageing agent, 0.50-2.00 parts of process operation agent, and 10.00-15.00 parts of flame retardant. The external rubber sleeve material of the cable used for wind power generation has the greatest advantages of extremely high physical and mechanical performance, excellent oil resistance and climate resistance, extremely softness and flame retarding, and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

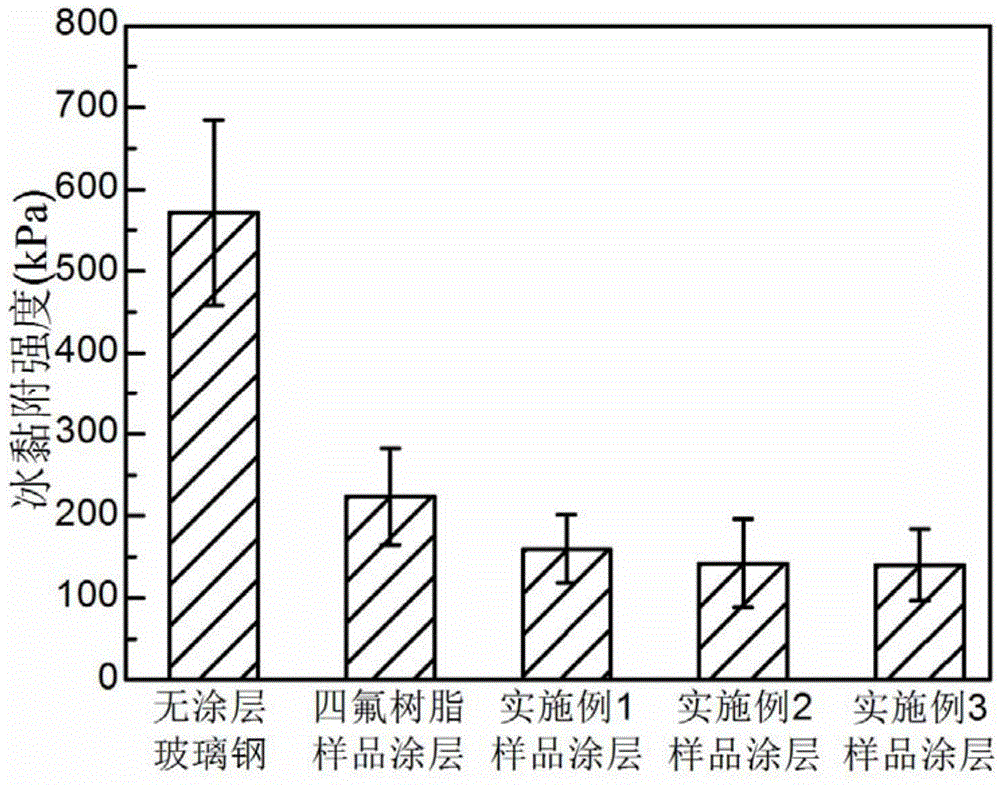

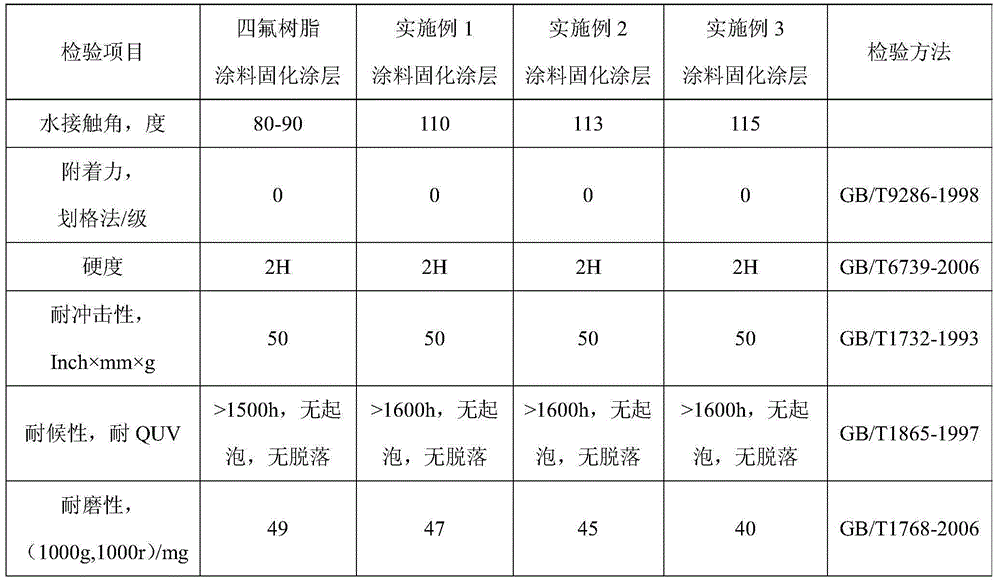

Anti-icing paint, as well as preparation and application thereof

ActiveCN104530974AExcellent weather resistanceLower surface energyOther chemical processesCoatingsSolventSurface energy

The invention discloses an anti-icing paint. The paint comprises a component A and a component B in a mass ratio of (4-7):1, wherein the component A is prepared from the following ingredients in percentage by mass: 20-80 percent of fluorosilicon resin with solid content of 20-70 percent, 0.05-2 percent of a defoaming agent, 0.05-2 percent of a flatting agent, 0.05-2 percent of a rheological agent, 0.05-5 percent of a light stabilizer, 0.05-2 percent of a matting agent, 0.05-2 percent of drier, 10-60 percent of rutile titanium dioxide, 0.1-20 percent of a dispersant and 20-70 percent of a solvent A; and the component B is prepared from the following ingredients in percentage by mass: 20-80 percent of a polyisocyanate curing agent and 20-80 percent of a solvent B. The anti-icing coating formed by the anti-icing paint has low surface energy and good hydrophobicity, can be used for effectively reducing the ice adhering strength of a base material, has excellent weather resistance and abrasion resistance, has high hardness and strong adhesive force to the base material, can be applied to wind blades, electric wires and cables and other cold surfaces with anti-icing requirement, and can be used for effectively relieving the icing phenomenon of cold surfaces, guaranteeing efficient working of the wind blades, the electric wires and cables and the like and prolonging the service lives of the wind blades, the electric wires and cables.

Owner:NINGBO NOVO NEW MATER TECH

Curable composition

InactiveUS20070021563A1Good at tension property and storage stabilityExcellent weather resistanceOther chemical processesVehicle sealing arrangementsMethacrylate polymersChemistry

A curable composition which comprises a polyoxypropylene polymer (A) having crosslinkable silicon groups in the molecule, a (meth)acrylic acid ester polymer (B) having crosslinkable silicon groups in side chains thereof, and a (meth)acrylic acid ester polymer (C) having a crosslinkable silicon group at an end only. The curable composition has excellent weatherability, gives a cured composition having excellent tensile properties, and is useful as a sealing material having excellent storage stability.

Owner:KANEKA CORP

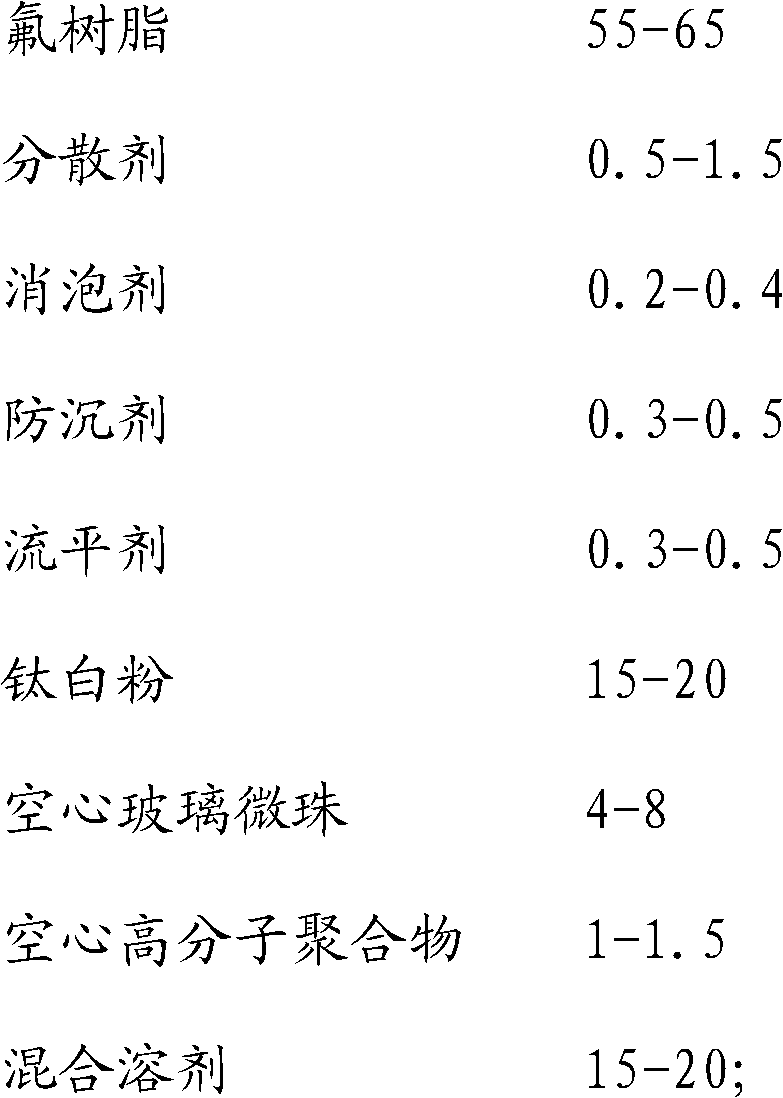

Elastic heat-insulation fluorocarbon coating and preparation method and use method thereof

InactiveCN102492338AGood weather resistanceGood gloss and color retentionReflecting/signal paintsButyl acetateTitanium

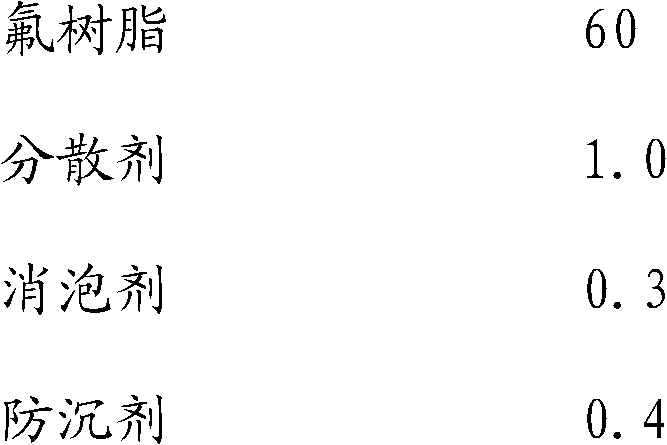

An elastic heat-insulation fluorocarbon coating consists of a host and curing agent. The host is prepared by the following components, by weight, 55 to 65 parts of fluororesin, 0.5 to 1.5 parts of dispersant, 0.2 to 0.4 part of defoamer, 0.3 to 0.5 part of anti-settling agent, 0.3 to 0.5 part of flatting agent, 15 to 20 parts of titanium white, 4 to 8 parts of hollow glass microballs, 1 to 1.5 parts of hollow macromolecular polymer and 15 to 20 parts of mixed solvent. The curing agent is manufactured by the following components, by weight, 90 parts of E405 to 80T, 5 parts of butyl acetate and 5 parts of propylene glycol methyl ether acetate. The weight proportion of the host and the curing agent can be calculated according to the hydroxyl value of the fluororesin and the NCO (isocyanate) content of the curing agent, namely OH / NCO=1:(1.05 to 1.15). The elastic heat-insulation fluorocarbon coating has the advantages of excellent weatherability, stain resistance, washability, decoration performance, excellent normal-temperature and low-temperature elasticity, capability of resisting to fine fissures, improved heat insulation effect and benefits to transport and settlement.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

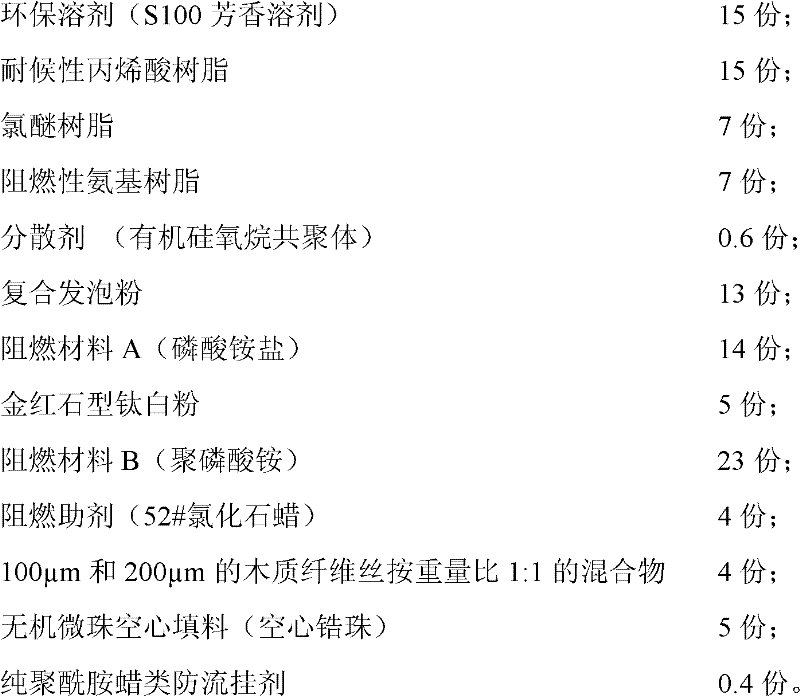

Fire retardant coating and preparation method thereof

ActiveCN102408802AExcellent weather resistanceStrong adhesion and durabilityFireproof paintsSolventWeather resistance

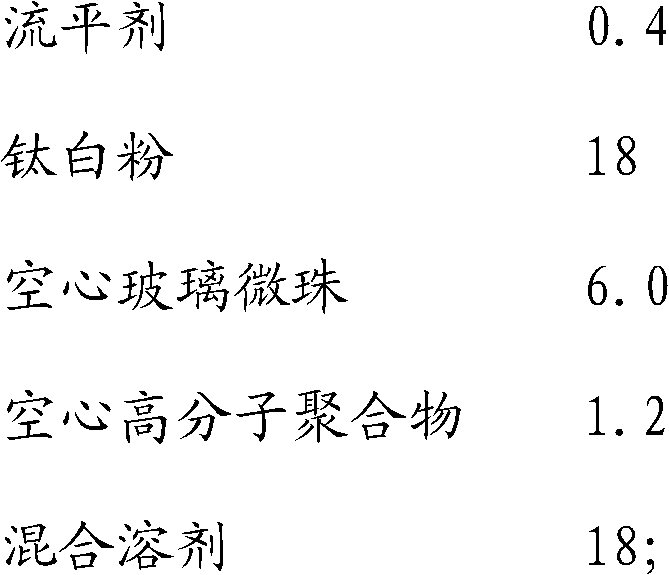

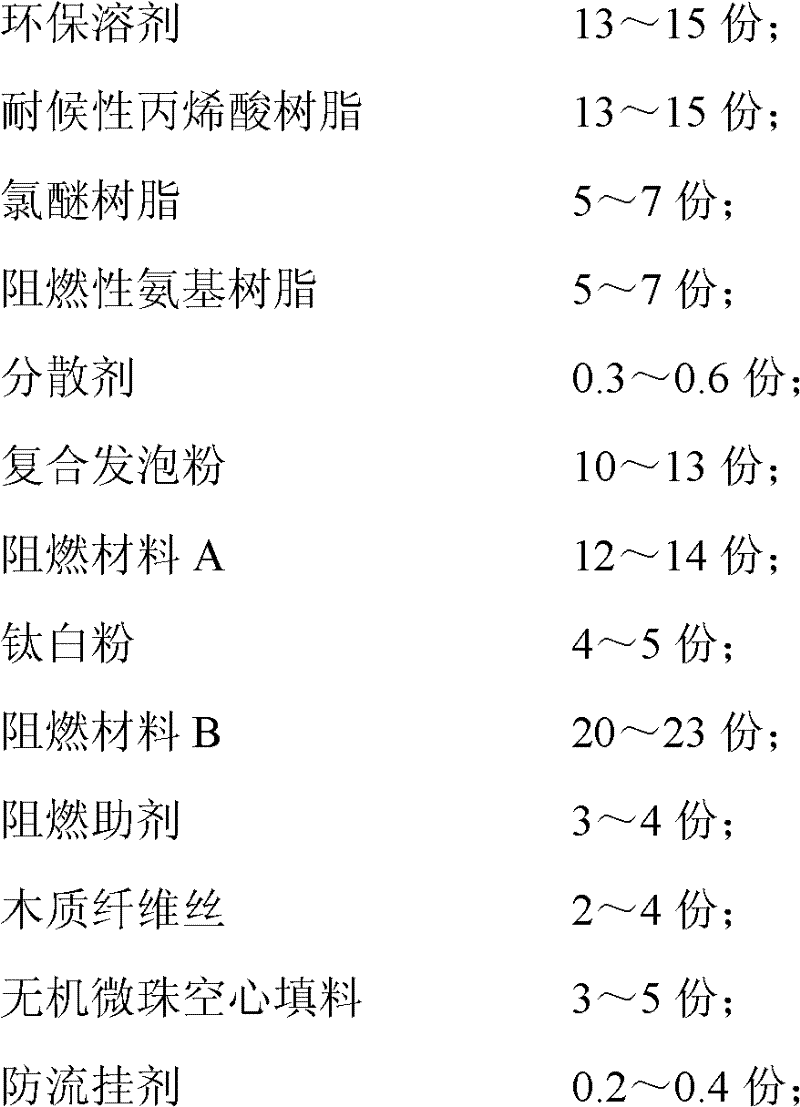

The invention discloses a fire retardant coating, which comprises the following components: an environment-friendly solvent, weather-proof acrylic resin, chlorinated polyether resin, flame retardant amino resin, a dispersing agent, composite foaming powder, a flame retardant material A, titanium white, a flame retardant material B, a flame retardant aid, wood fibers, an inorganic microbead hollowfiller and an anti-sagging agent. The invention also provides a preparation method for the fire retardant coating. The fire retardant coating can be coated on various substrates, is extra-thin, efficient and durable, is specially used outdoors, is resistant to the fire combustion of hydrocarbons, and has high chemical properties such as weather resistance, acid resistance, alkali resistance and the like, high adhesion and an attractive decorative effect, and paint films are fine; the fire retardant coating is uniformly expanded, and has a special foam structure and a high fireproof effect; and the product is environment-friendly and pollution-free, a production process is simplified, and the fire retardant coating is convenient to construct and can be used for coating with various fireproof requirements.

Owner:WUXI HUHUANG PAINT

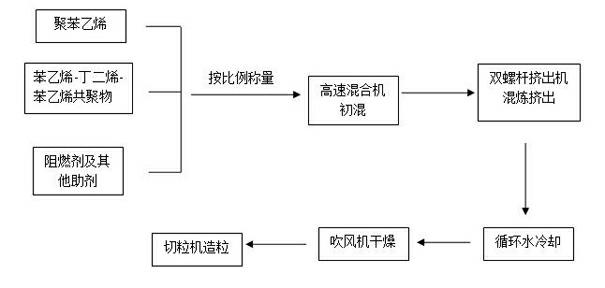

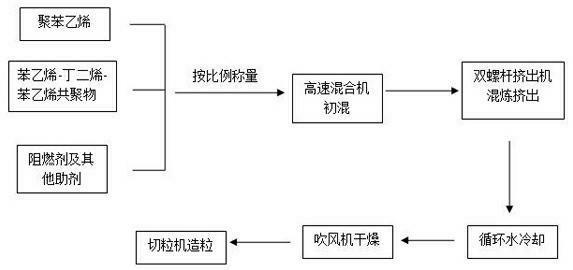

Flame-retarding toughening polystyrene master batch and preparation method thereof

The invention provides a flame-retarding toughening polystyrene master batch and a preparation method thereof, which can achieve the purposes of being high in flame resistance rate and free of dust in production environments. The technical scheme is that the master batch comprises the following components, by mass: 25-35 parts of polystyrene, 10-20 parts of styrene-butadiene- styrol copolymers, 15-25 parts of decahromopdipenyl ethane, 15-25 parts of brominated epoxy resin, 8-14 parts of antimonous oxide, 0.2-0.6 parts of lubricant zinc stearate, 0.3-0.8 parts of lubricant ethylene bis stearamide, 0.3-0.6 parts of calcium oxide, 0.1-0.3 parts of polytetrafluoroethylene and 0.2-0.4 parts of antioxygen. The flame-retarding toughening polystyrene master batch can be directly mixed with high impact polystyrene (HIPS) resin to produce plastic injection parts. The flame-retarding toughening polystyrene master batch with different contents can produce products with various flame-retarding grades, and is wide in application, convenient and fast.

Owner:QINGDAO GON TECHNOLOGY CO LTD

Alkyd resin for amino baking paint and preparation method thereof

The invention discloses alkyd resin for amino baking paint and a preparation method thereof. The alkyd resin for amino baking paint is prepared from the following components: 10 to 15 parts of dry or half-dry vegetable oil acid, 10 to 15 parts of triatomic alcohol with side chains, 5 to 10 parts of dihydric alcohol with side chains, 20 to 30 parts of phthalic anhydride, 1 to 3 parts of adipic acid, 0.05 to 0.2 part of esterification catalyst, 1 to 5 parts of dimethylbenzene, and 30 to 40 parts of organic solvent. The compositions and the proportions of the raw materials are screened through a lot of experiments, the component proportion is scientific and reasonable, and the alkyd resin for the amino baking paint has good flexibility, shock resistance, rigidity and weather resistance, and is wide in application range. The preparation method of the alkyd resin for amino baking paint is low in production cost, high in preparation efficiency, reasonable in whole process design, strong in operability and easy to implement.

Owner:江苏三木化工股份有限公司

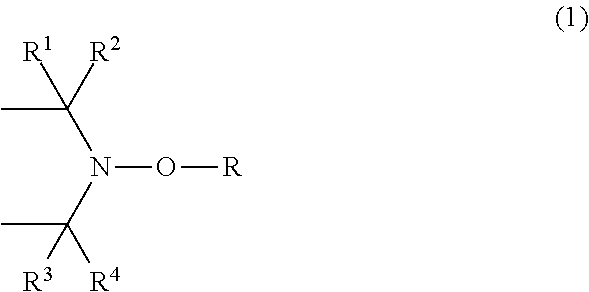

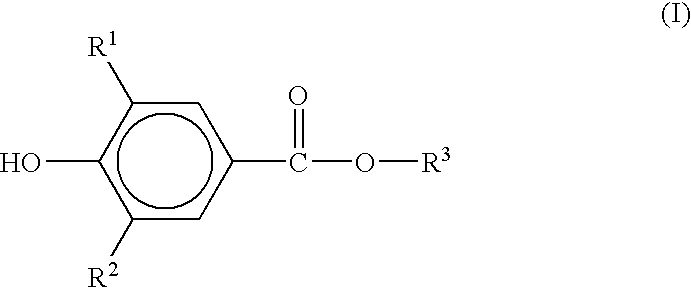

Woody synthetic resin composition having improved weather resistance and molded body thereof

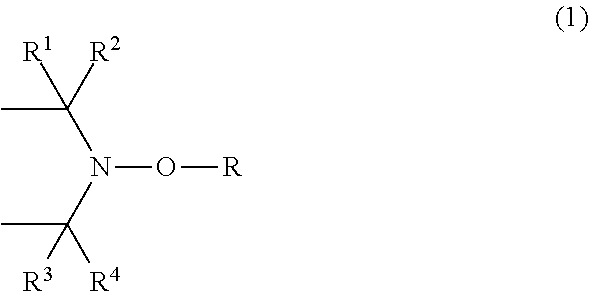

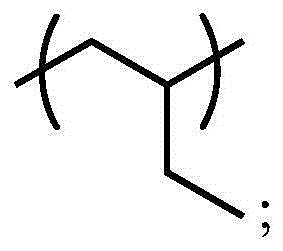

ActiveUS20110015307A1Excellent weather resistanceGood weather resistanceHindered amine light stabilizersWeather resistance

The invention provides a woody synthetic resin composition having excellent weather resistance, and a molded body thereof.The synthetic resin composition contains a wood flour in an amount of 5 to 200 parts by mass and a hindered amine compound having a partial structure represented by the following general formula (1)(wherein R1, R2, R3 and R4 each independently represents an alkyl group having 1 to 4 carbon atoms, and R represents an alkyl group having 1 to 18 carbon atoms, an alkyl group substituted by hydroxyl group having 1 to 18 carbon atoms or a cycloalkyl group having 5 to 8 carbon atoms), in an amount of 0.01 to 5 parts by mass, with respect to 100 parts by mass of a synthetic resin, and a molded body thereof.

Owner:ADEKA CORP

Organosilicon waterproofing agent and preparation method thereof

The invention relates to a building material waterproofing agent, in particular to an organosilicon waterproofing agent and a preparation method thereof. The organosilicon waterproofing agent is a composition obtained by cracking organosilicon resin in an organic solvent and then carrying out separation, wherein the organosilicon resin is prepared from hydrogen-containing silicone oil under the action of strong base, the mass ratio of hydrogen-containing silicone oil to strong base is 100: (1-10), and the mass ratio of organosilicon resin to organic solvent is 1: (10-20). When applied to waterproofing paint and waterproofing mortar, the organosilicon waterproofing agent not only can achieves waterproofing effect, but also can maintain the air-permeable effect of a building base material.

Owner:陈国坚

Plastic lens

ActiveUS20140200323A1Excellent weather resistanceGood weather resistanceOptical elementsWeather resistanceChemical compound

A plastic lens having excellent weather resistance, formed by polymerization of a composition containing a polyisocyanate compound having an aromatic ring and a polythiol compound is provided. The plastic lens is formed by polymerization of a composition that contains 100 parts by mass in total of (A) a polyisocyanate compound containing a polyisocyanate compound having an aromatic ring and (B) a polythiol compound, from 0.5 to 5.0 parts by mass of (C) a benzophenone compound having a hydroxyl group on at least the ortho position, and from 0.5 to 5.0 parts by mass of (D) a phenol compound.

Owner:HOYA CORP

Heat-insulating coating for building

The invention discloses a heat-insulating coating for a building, belonging to the technical field of heat-insulating coatings. The heat-insulating coating comprises the following raw materials: 320-380kg of common silicon white cement, 420-480kg of quartz sand, 180-220kg of ground limestone, 2-4kg of cellosilk, 28-32kg of vitrified micro bubbles, and 18-22kg of colloidal crystal, and all the rawmaterials are uniformly mixed when the coating is manufactured. The heat-insulating coating has the beneficial effects that: 1, the sunscreen effect and the heat-insulating effect are good, the solarradiation energy can be reflected by more than 85%; 2, the integrated functions of waterproofing, heat insulation and heat preservation are achieved; 3, the cost performance is high, and the manufacturing cost per square meter can be reduced by 10-15RMB; 4, the construction is simple, the coating is suitable for waterproofing, seepage proofing and heat insulation of various housetop roofs, and the coating can be applied to construction simply after being added with water and uniformly mixed; and 5, the coating has the advantages of favorable weather resistance, corrosion resistance, ageing resistance, favorable caking property, difficulty in shedding, environment friendliness and use safety, and can be used for greatly prolonging the service life of the roofs and wall surfaces.

Owner:董会生

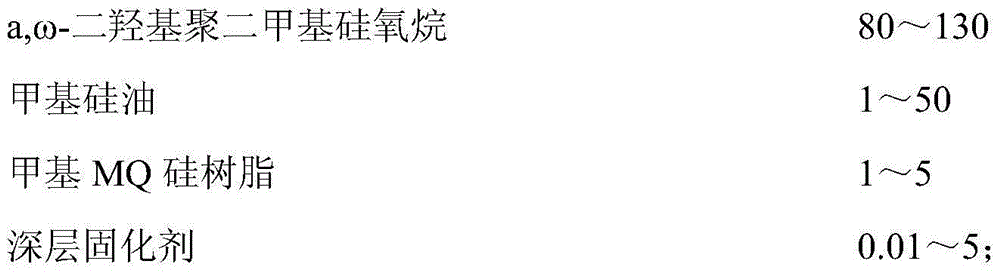

Deep curable and highly transparent condensation-type silicone potting glue, preparation method and application thereof

ActiveCN104371639AGood compatibilityAchieve solidificationNon-macromolecular adhesive additivesOther chemical processesPolymer scienceOmega

The invention discloses a deep curable and highly transparent condensation-type silicone potting glue which is made by the mixing of component A and component B. The component A mainly contains a, omega-dihydroxy polydimethylsiloxane, and the component B mainly contains methyl silicone oil. A preparation method and application of the deep curable and highly transparent condensation-type silicone potting glue are also disclosed. A formula system of the silicone potting glue has the advantages of having good compatibility, maintaining original high transparency when realizing deep and overall curing, better meeting the needs of deep and transparent potting, and thus facilitating widespread use thereof in the field of transparent potting.

Owner:广州市耐力环保科技有限公司

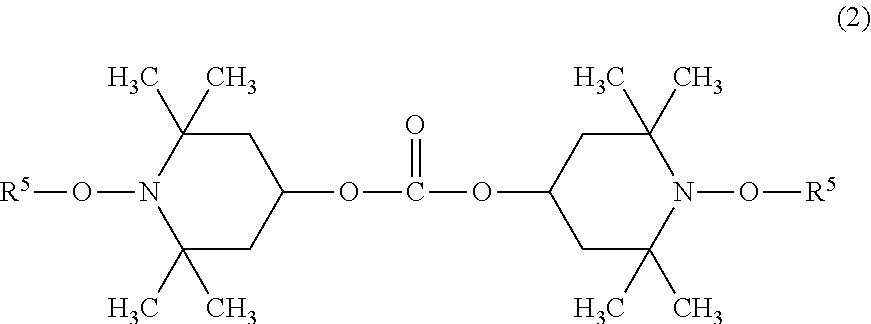

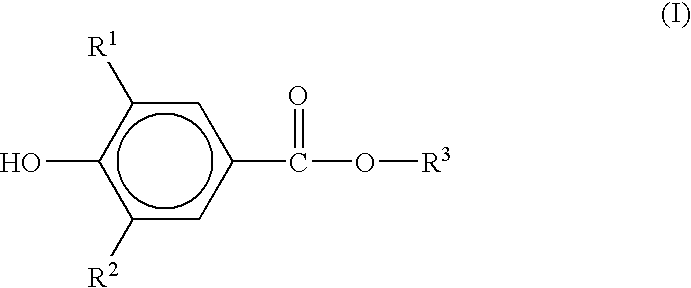

Automobile interior or exterior trim material

InactiveUS6897250B1Excellent weather resistanceGood weather resistanceVehicle componentsWeather resistanceChemistry

An automobile interior or exterior trim material which is formed of a thermoplastic elastomer composition containing 100 parts by weight of a thermoplastic elastomer and 0.001-10 parts by weight of an alkyl benzoate compound of the following formula (I): wherein each of R1 and R2 is a hydrogen atom, a C1-C8 alkyl or cycloalky; grout, or a C6-C12 aryl, alkylaryl, or arylalkyl group; and R3 is a C1-C30 alkyl group. The interior or exterior trim material of the invention has improved weather resistance and resistance to weather-induced coloring.

Owner:ADEKA CORP

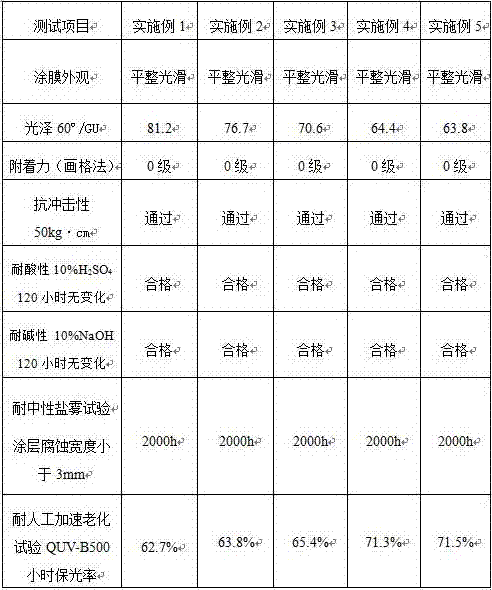

Polyurethane-fluorocarbon composite powder coating suitable for humid and hot marine climatic environment and preparation method of polyurethane-fluorocarbon composite powder coating

InactiveCN107974183AThe recipe is simpleHas super weather resistanceFireproof paintsPolyurea/polyurethane coatingsSalt resistanceHigh humidity

The invention discloses a fluorocarbon-polyurethane composite powder coating suitable for a humid and hot marine climatic environment. The fluorocarbon-polyurethane composite powder coating comprises,in parts by weight, 100-160 parts of polyurethane resin, 40-100 parts of fluorocarbon resin, 20-80 parts of isocyanate resin, 0-5 parts of accelerator, 30-100 parts of filler, 0.5-3 parts of a levelling agent, 0.5-2 parts of defoamer and 0.5-5 parts of pigment. The invention also discloses a preparation method of the polyurethane-fluorocarbon composite powder coating. The powder coating has the characteristics of a simple process formula, super weatherability, acid and alkali resistance, heavy salt resistance, high humidity and heat resistance and other excellent performance, and is suitablefor a protective coating in the humid and hot marine climatic environment, the coating has a long service life, and the comprehensive cost of maintenance is low.

Owner:GUANGZHOU KINTE IND

Heat insulation and corrosion prevention coating and preparation method thereof

InactiveCN104212342AExcellent weather resistanceStable conductivityFireproof paintsAnti-corrosive paintsSilicone resinWeather resistance

The invention discloses a heat insulation and corrosion prevention coating. The heat insulation and corrosion prevention coating comprises the following components in percentage by mass: 35-45% of epoxy-modified organic silicon resin, 6-8% of hollow microspheres, 12-18% of composite flame retardant, 14-18% of hydrotalcite, 10-12% of titanium dioxide, 2-5% of toughener, 1-3% of defoamer and 3-5% of drier. The invention further discloses a preparation method of the heat insulation and corrosion prevention coating. The product disclosed by the invention has excellent weather resistance, aging resistance, radiation resistance, wear resistance, impact resistance, resistance to high temperature and low temperature, stable electric conductivity and strong adhesion; the resistivity can meet the anti-static requirements and further ensure the long service life of the coating; simultaneously, the product is efficient, convenient and simple to construct, and can really realize self-curing of the inorganic coating at normal temperature and realize excellent resistance to salt fog and aging resistance; the coating has self-repair property, local scratches caused by external force can be still protected, the coating can not be damaged by cutting or welding, and the welding quality is not affected by welding with the coating.

Owner:JIANGSU MARINE VICTORY COATING

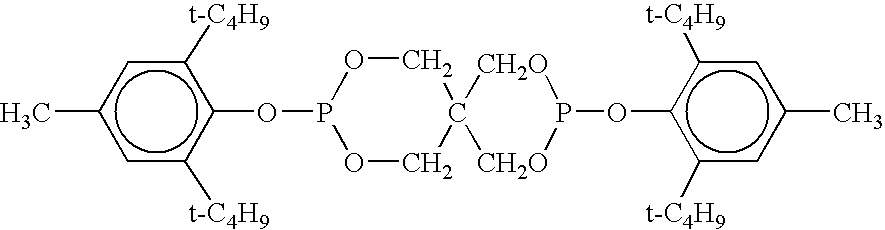

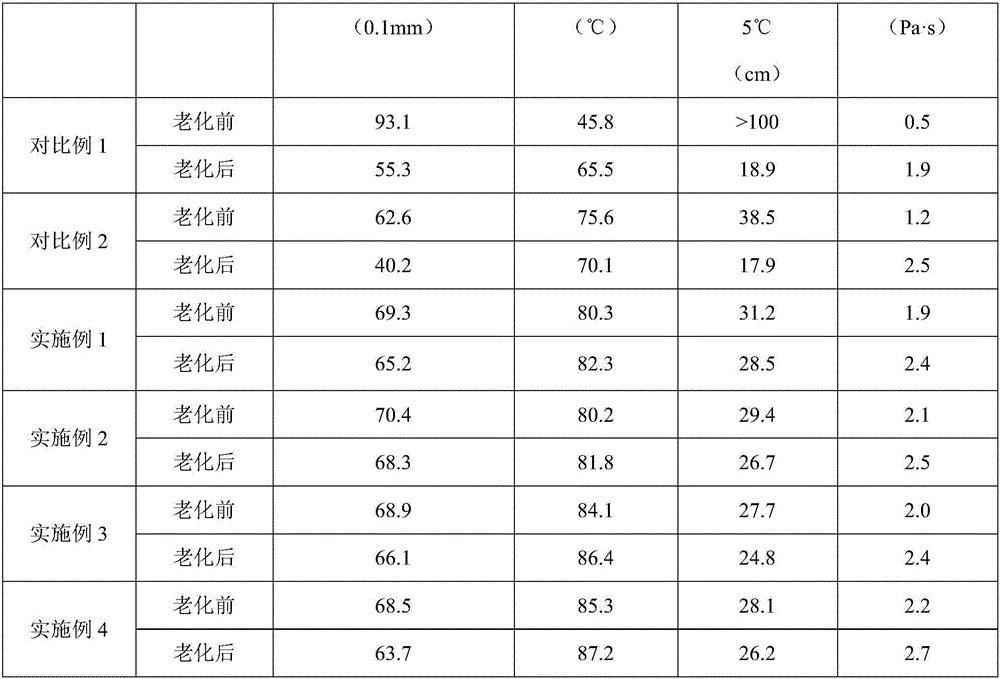

High-aging-resistance modified asphalt and preparation method thereof

InactiveCN106433164AImprove thermal stabilityImprove photostabilityBuilding insulationsMethyl isobutyl ketoneAging resistance

The invention discloses a high-aging-resistance modified asphalt and a preparation method thereof. The high-aging-resistance modified asphalt comprises the following components in percentage by mass: 72-80% of substrate asphalt, 1.3-2.7% of hindered amine light stabilizer, 0.5-1.2% of trilauryl phosphite, 0.5-2% of barium stearate, 6-8% of diatomite, 5-10% of epoxy soybean oil and 5-8% of methyl isobutyl ketone. The preparation method comprises the following steps: adding the hindered amine light stabilizer, trilauryl phosphite and barium stearate into the substrate asphalt at appropriate temperature, uniformly mixing with the asphalt, and adding the diatomite, epoxy soybean oil and methyl isobutyl ketone to obtain the high-aging-resistance modified asphalt. The asphalt has very high heat stability and light stability, is capable of greatly enhancing the pavement performance and durability and prolonging the maintenance period and service life of the high-grade asphalt pavement when being applied to the asphalt pavement, and thus, has very high cost performance and wide application prospects.

Owner:CHANGAN UNIV

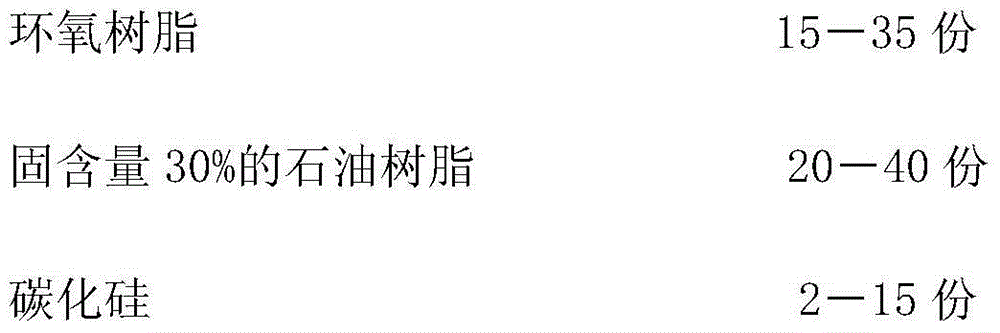

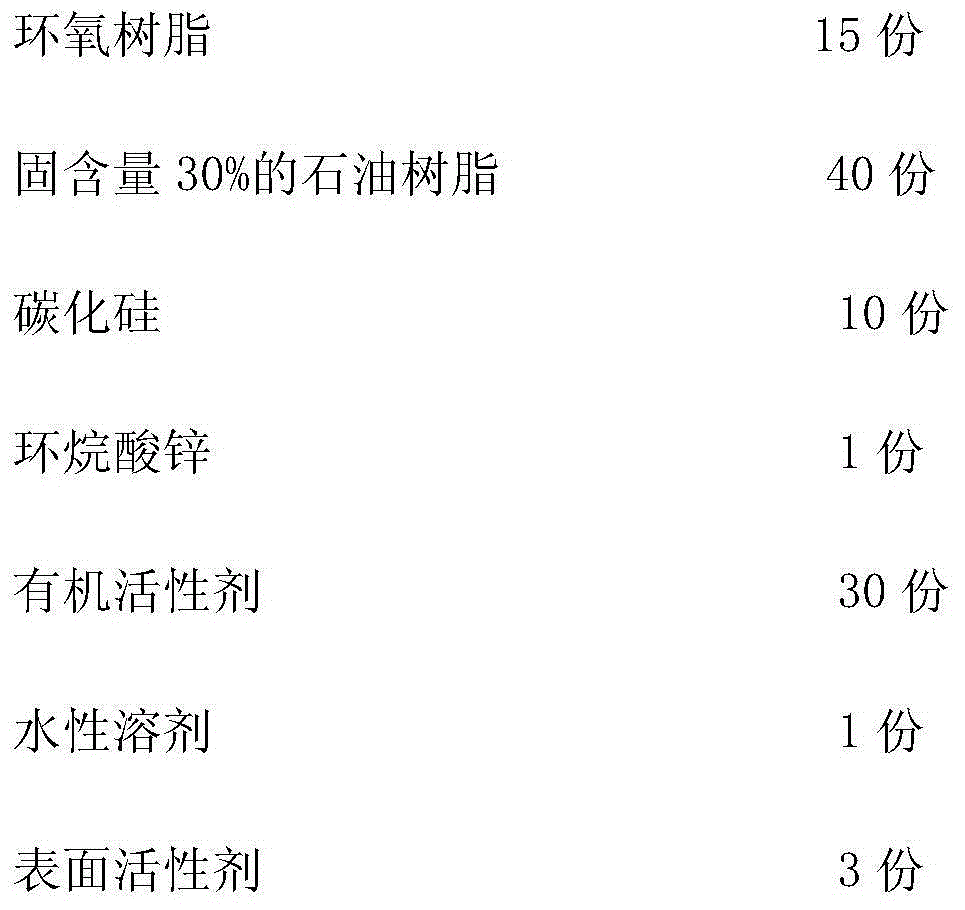

Active and anticorrosive water-based paint and preparation method thereof

ActiveCN105017937AExcellent weather resistanceGood thermal stabilityAnti-corrosive paintsEpoxy resin coatingsChemical industrySolvent

The invention belongs to the field of the chemical industry and relates to anticorrosive paint and in particular relates to active and anticorrosive water-based paint and a preparation method thereof. The paint comprises the following components in parts by mass: 15-35 parts of epoxy resin, 20-40 parts of petroleum resin with solid content of 30%, 2-15 parts of silicon carbide, 0.5-8 parts of zinc naphthenate, 30-45 parts of organic active agent, 2-4 parts of water-based solvent and 1-3 parts of surfactant. The product has the beneficial effects that the product can be used under severe conditions, has long-acting anticorrosive property, has dry film thickness over 300mu m and has excellent weather resistance, aging resistance, radiation resistance, wear resistance and impact resistance and good thermal stability; the paint has strong adhesion and can undergo spray moulding on random curved surfaces, slopes and vertical surfaces, without sagging; the paint is efficient and convenient, a formula system can be randomly adjusted, and normal-temperature self-solidification of inorganic paint can be authentically realized; besides, a coating has self-repair property, can be still protected from local scratches caused by external forces and is free from cutting and welding damages; the quality of tape coating welding is not affected.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

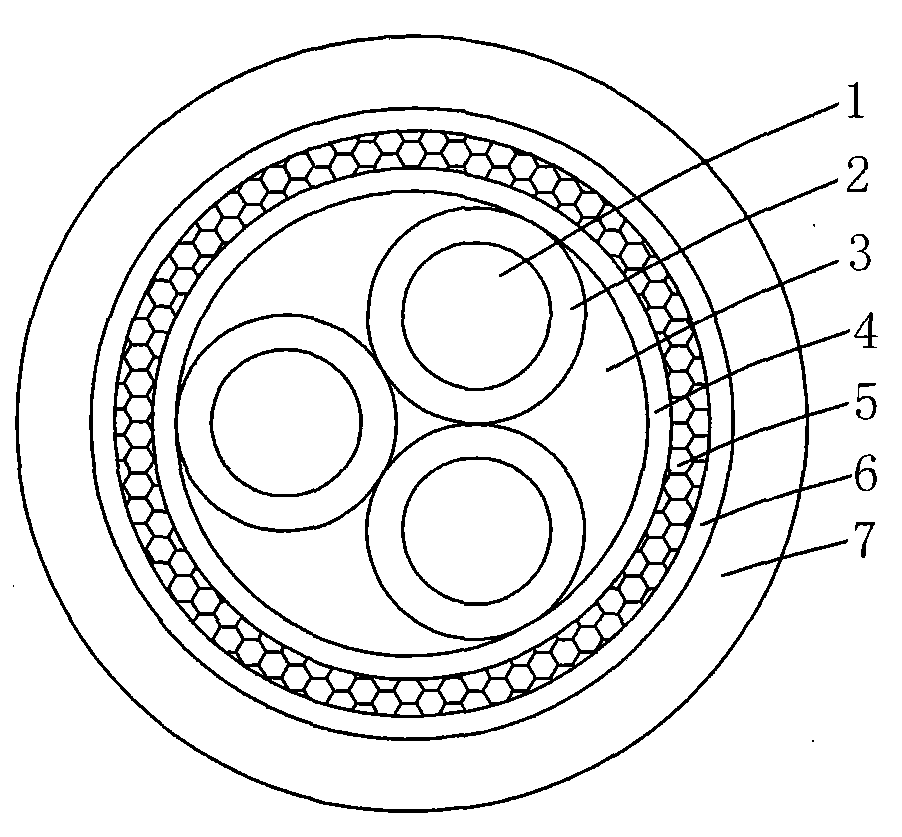

Shielding cable for environment-friendly car and preparing method thereof

InactiveCN104464872AGuaranteed softnessGuaranteed oil and water resistanceRubber insulatorsInsulated cablesShielded cableElastomer

The invention discloses a shielding cable for an environment-friendly car. A thermoplasticity irradiation vulcanized rubber insulation layer is arranged on the outer layer of a copper core soft conductor to form an insulation wire core, a plurality of insulation wire cores are stranded to form a cable wire, filling layers are arranged at gaps of the cable core, a belt wrapping layer, an inner shielding layer and an outer shielding layer are arranged on the outer portions of the filling layers and the cable core in sequence, and an outer protecting sleeve layer is arranged on the outermost layer of a cable. The filling layers are low-smoke-zero-halogen filling ropes. The inner shielding layer is a tinned copper wire braid shielding layer. The outer shielding is an aluminum foil lapping shielding layer. The outer protecting sleeve layer is a 125-DEG-C low-smoke-zero-halogen flame-retarding elastic body protecting sleeve layer. The shielding cable for the environment-friendly car has flame-retarding performance, high-temperature-resisting performance, low-temperature-resisting performance, acid-base-resisting performance, oil-water-resisting performance, anti-tearing performance, softness and environment-protecting performance.

Owner:ANHUI HUAXING CABLE GROUP

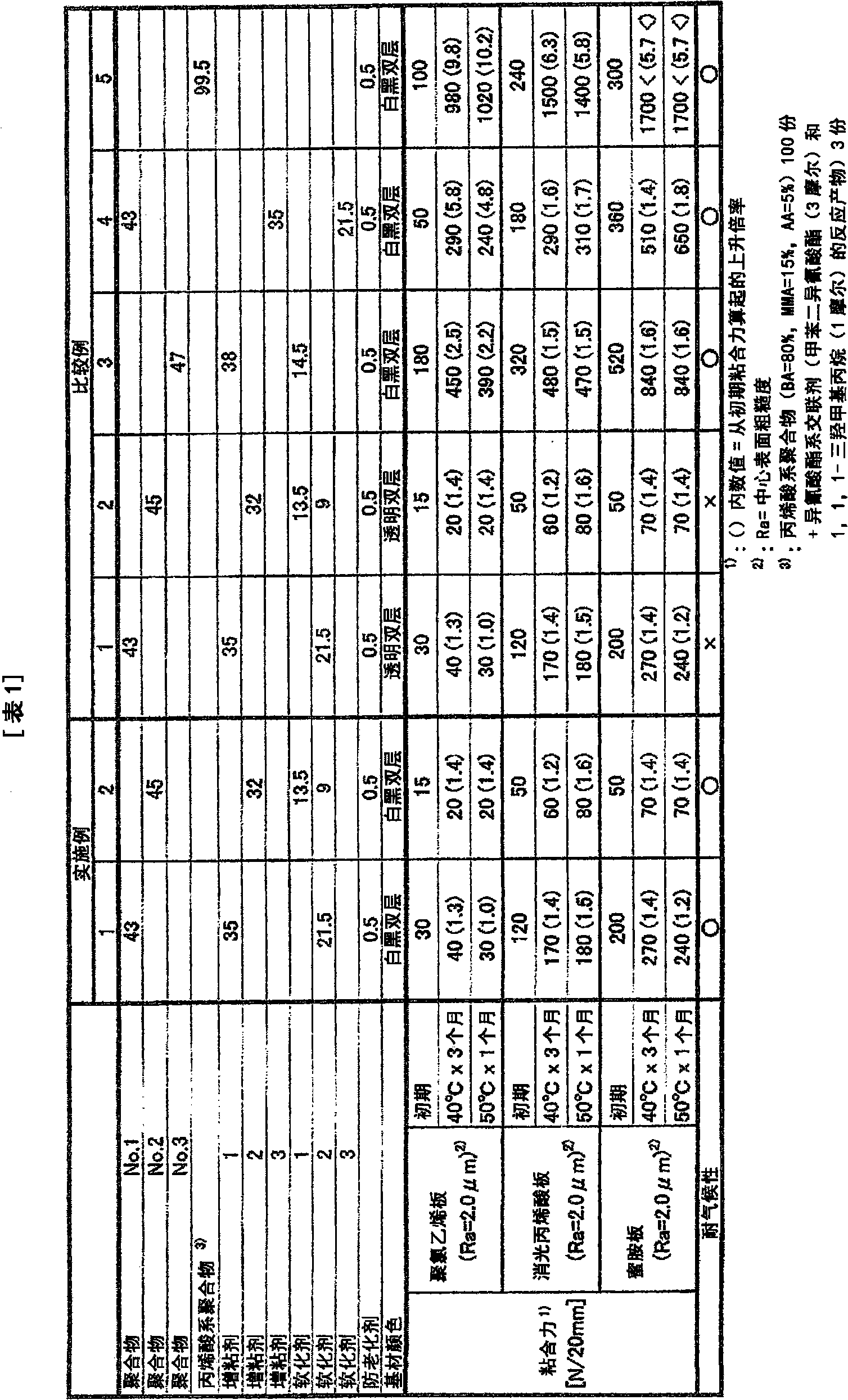

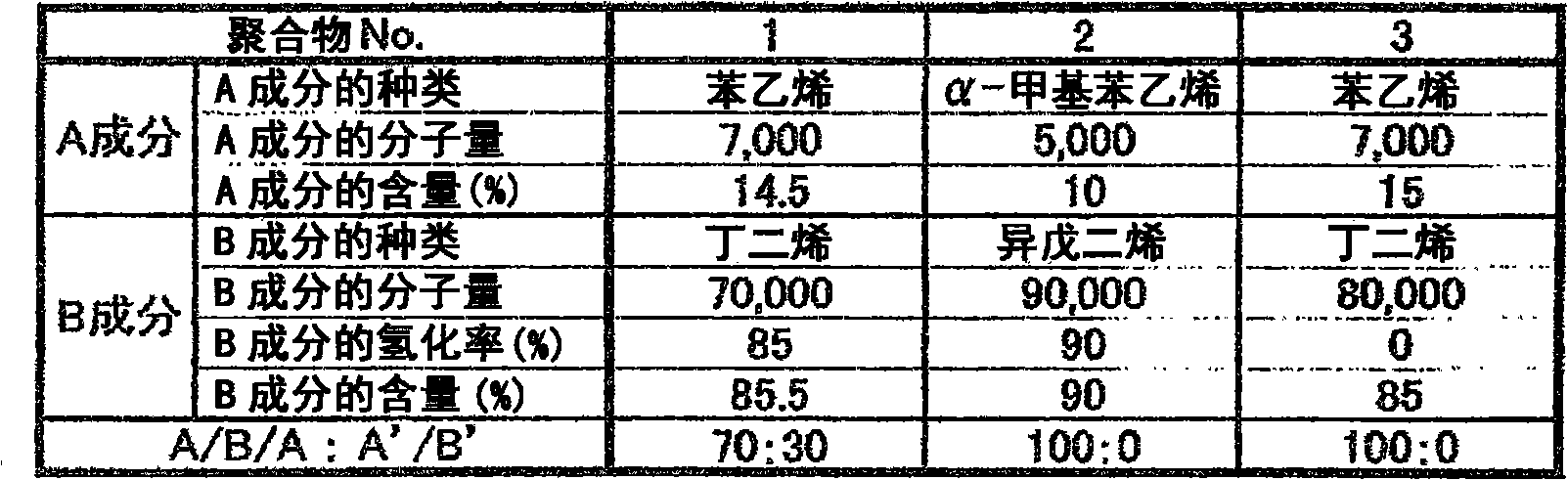

Surface protection sheet

InactiveCN103254812AExcellent weather resistanceSuppresses the rise of adhesive forceFilm/foil adhesivesAdhesive articlesRise rateEngineering

The invention provides a surface protection sheet. The surface protection sheet has the advantages of very excellent weatherability, inhibition of the increase of adhesion during ageing, reduction of a plasticizing dosage transferred from an adhered object, inhibition of the reduction of the cohesiveness of an adhesive during ageing, and prevention of the adhesive residual on the adhered object after attachment and peeling. The surface protection sheet is obtained through forming an adhesive layer on one side of a substrate layer, the adhesive layer includes a styrene series resin, and the rise rate of the adhesion of the surface protection sheet disposed at 40DEG C for 3 months relative to the initial adhesion of each of a polyvinyl chloride plate, an extinction acrylic plate and a melamine plate is below 2 times.

Owner:NITTO DENKO CORP

High pollution-resistant styreneacrylic latex paint

InactiveCN102372957AExcellent water resistanceSuperior Alkali ResistanceAntifouling/underwater paintsPaints with biocidesCrack resistanceUltraviolet

The invention discloses a high pollution-resistant styreneacrylic latex paint, which is mainly prepared by mixing the following raw materials according to the weight proportion: 157 parts of styreneacrylic, 13 parts of dispersing agent, 80 parts of deionized water, 15 parts of oxalic acid adipic dihydrazide, 2 parts of dispersing agent, 4 parts of defoamer, 11 parts of mildew preventive, 23 parts of kaolin, 15 parts of titanium white, 15 parts of heavy calcium powder, 15 parts of texanol and 12 parts of polyethers thickening agent. The invention has the following advantages that: a coating is fine and smooth, and has an elegant mercerizing effect; and the high pollution-resistant styreneacrylic latex paint has good crack resistance, can make up the fine and small cracks of a base layer, has preeminent water resistance, alkali resistance, pollution resistance, weather resistance, and excellent light and color protection performance, can make wall bodies be new for a long time, and has mould resistance, antibiosis and ultraviolet radiation resistance.

Owner:NANTONG TONGZHOU DISTRICT JINCHEN PAINT FACTORY

Double-coated paraffin microcapsule phase change material and preparation method thereof

InactiveCN106433567AExcellent weather resistanceHigh strengthHeat-exchange elementsParaffin waxWeather resistance

The invention discloses a double-coated paraffin microcapsule phase change material and a preparation method thereof. The composite microcapsule is made of paraffin wax as a core material. The coated wall layer of the paraffin microcapsule has two shell structures with different hardness, and is made by the following preparation method. The preparation method includes first, obtaining high stability of the paraffin emulsion through the complex emulsifier; and then through a method of several times of core-shell emulsion polymerization, coating two flexible / hard acrylate layers (hardness of two layers of coating can be adjusted based on actual needs) on the surface of the paraffin emulsion, and then obtaining the double-coated paraffin microcapsule phase change material through the demulsification, suction filtration, and microwave drying. The coated wall layer of the double-coated paraffin microcapsule disclosed in the invention has excellent weathering resistance, heat resistance and anti-blocking property, which solve the problem of poor flexibility, heat resistance and freeze-thaw resistance of microcapsules, and further, strength, toughness and stability of the product are improved, service life is prolonged, and the production process is simple, with good market prospects.

Owner:NANTONG JUREN NEW MATERIAL TECH

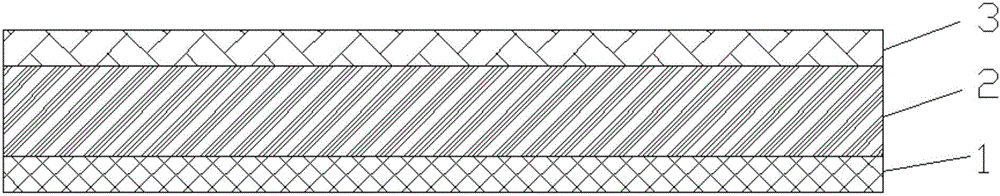

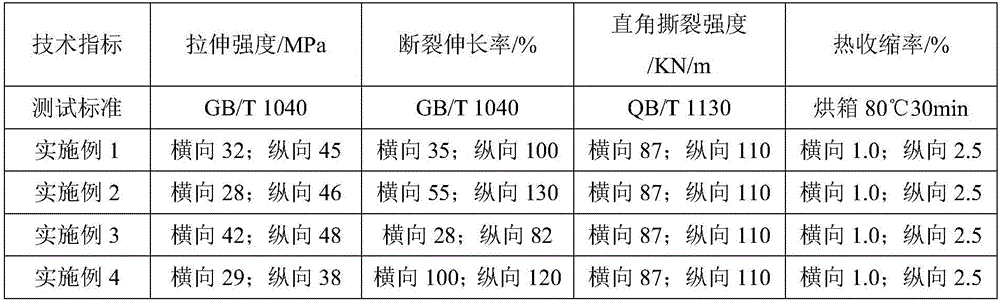

Weather-proof film for plastic floor

InactiveCN106634661AGood chemical resistanceExcellent weather resistanceFlat articlesPressure sensitive film/foil adhesivesChemistryWeather resistance

The invention discloses a weather-proof film for a plastic floor. The weather-proof film is formed by an outer protection layer, a function layer and an adhesion layer of which the thickness ratio is 1 to 3 to 1 through co-extrusion, wherein the outer protection layer is prepared from a fluorine-containing high polymer; the function layer is prepared from 20 to 100 parts of fluorine-containing high polymer, 0 to 60 parts of hot melt glue and 0.5 to 20 parts of functional aid; the adhesion layer is prepared from 0 to 40 parts of fluorine-containing high polymer and 60 to 100 parts of hot melt glue. The weather-proof film for the plastic floor, disclosed by the invention, has the characteristics of strong stain resistance, chemical inertness, high wear resistance, environment friendliness, weather resistance and universality.

Owner:ZHEJIANG GREEN NEW MATERIALS

Heat-conducting gel with good repairable performance and preparation method thereof

InactiveCN111234784AExcellent weather resistanceReduce surface tensionHeat-exchange elementsAntifoam agentFluorocarbon

The invention belongs to the technical field of heat-conducting gel, and particularly relates to heat-conducting gel with good repairable performance and a preparation method thereof. The methyl fluorosilicone oil, the vinyl fluorosilicone oil and the hydrogen-containing fluorosilicone oil are used, they combines dual properties of the silicone oil and the fluorocarbon compound, so that the silicone oil and fluorocarbon compound have excellent weather resistance, high and low temperature resistance, chemical stability, water and oil resistance and extremely low surface tension, and the stability and the repair performance of the heat-conducting gel are greatly improved by adding the silicone oil and the fluorocarbon compound into the heat-conducting gel as a lubricant, a defoamer, a release agent and a surface treating agent. In addition, by utilizing the demoulding property of the fluorosilicone oil, the interface residue of the glue on the electronic component can be reduced, and therepair efficiency is greatly improved. The thermal conductivity coefficient of the heat-conducting gel is 3.0 W / m.K, the heat-conducting gel is used for filling gaps between heating electronic elements such as mobile phones and radiators, the service life of the radiating elements is prolonged, the stability of the radiating elements is improved, and the heat-conducting gel can be used for a longtime at the temperature of -54 DEG C to 200 DEG C.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

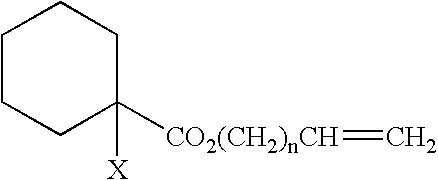

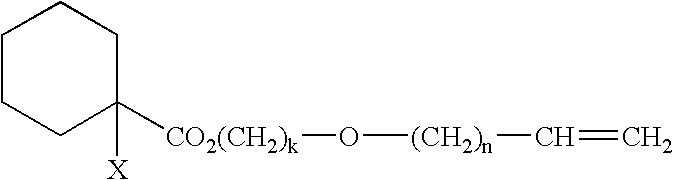

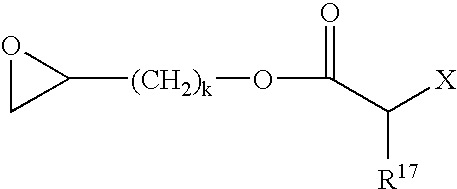

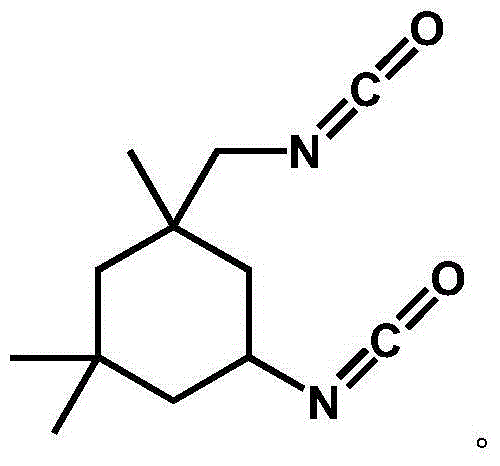

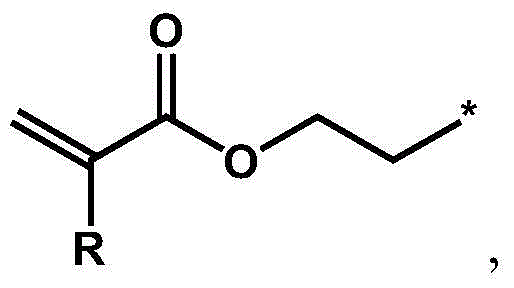

(Methyl) Acrylic compound, polyurethane (methyl) acrylic ester, and synthetic method

ActiveCN104804174AImprove mechanical propertiesGood storage stabilityPolyureas/polyurethane adhesivesMethacrylatePolymer science

The invention discloses polyurethane (methyl) acrylic ester which comprises an ethylene unsaturated group, hydroxide radical, and polyvalent saturated hydrocarbon. The weight ratio of the polyvalent saturated hydrocarbon is greater than 70%, and the average degree of functionality of the ethylene unsaturated group is from 0.5 to 1.5. The average degree of functionality of the hydroxide radical is from 0.5 to 1.5, and the number-average molecular weight of the polyurethane (methyl) acrylic ester is less than 20000 and greater than 3500.

Owner:DAXIN MATERIALS

High-strength flame-retardant PP composite material and preparation method thereof

The invention relates to the technical field of high polymer materials, and concretely relates to a high-strength flame-retardant PP composite material and a preparation method thereof. The high-strength flame-retardant PP composite material is prepared from, by weight, 80 to 110 parts of PP, 16 to 24 parts of polyethylene, 10 to 15 parts of an ethylene-vinyl acetate copolymer, 6 to 12 parts of aninorganic filler, 5 to 10 parts of a glass fiber, 4 to 7 parts of a cross-linking agent, 0.1 to 1.5 parts of an antioxidant and 9 to 15 parts of a flame retardant. The flame retardance is improved byadding the flame retardant to the high-strength flame-retardant PP composite material, the prepared PP composite material has good impact strength and tensile strength, the preparation method is simple and efficient to operate, convenient to control and beneficial to industrial production, and the prepared product is stable in quality.

Owner:东莞市高能高分子材料有限公司

Processing method of colorful compounded rubber floor

The invention discloses a processing method of a colorful compounded rubber floor. The processing method comprises the following processing steps of (1) preparing sizing materials: preparing a rubber-plastic compound rubber piece semi-finished product and a rubber-plastic piece semi-finished product;(2) forming and compounding: putting the two semi-finished products into a mold; (3)vulcanizing: vulcanizing for 30 to 40 minutes at the temperature of 140 to 150 DEG C and the pressure of 20 to 30kg / cm<2>, forming the two rubber pieces together after vulcanizing so as to obtain a compound rubber piece, and respectively forming a rubber-plastic compound layer and a rubber layer; (4) polishing the surface of the rubber-plastic compound layer, and finally spraying a layer of polyurethane resin to form a polyamine particle layer on the surface of the rubber-plastic compound layer, thus obtaining the colorful compounded rubber floor. A pavement paved by the colorful compounded rubber floor prepared by the method is particularly suitable for being regarded as a road used by pedestrians or non-motor vehicles, so that the phenomenon that the the pedestrians slip and fall easily in rainy days when walking on current pavement bricks is avoided.

Owner:刘浩杰

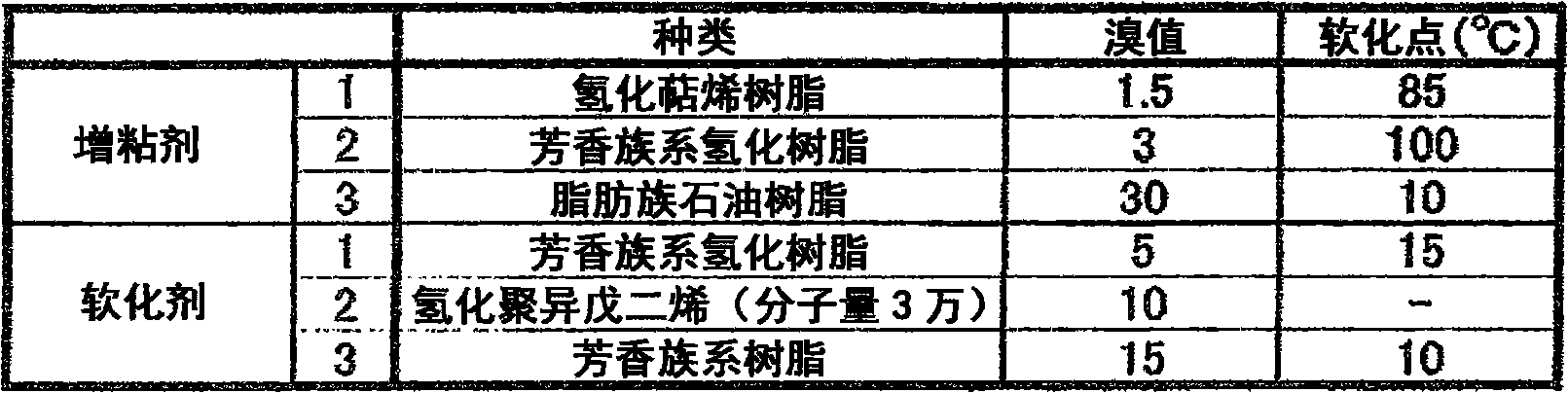

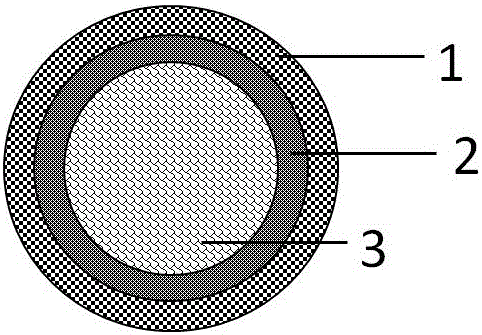

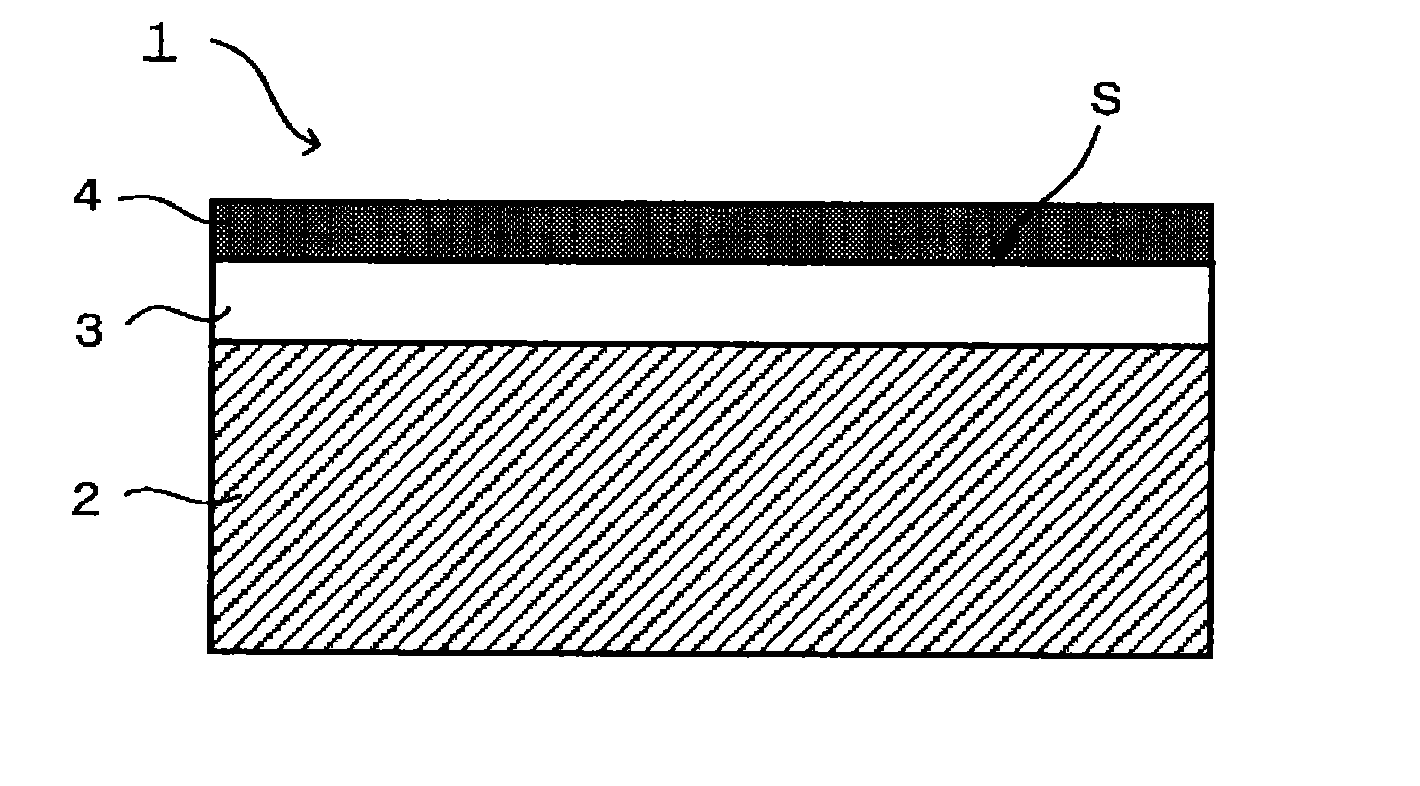

Resin substrate provided with hard coating film, and process for its production

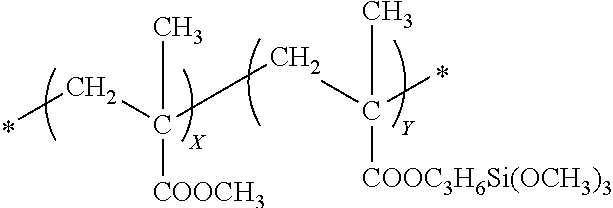

InactiveUS20130309509A1Abrasion resistance be excellentExcellent weather resistanceMaterial nanotechnologyWindowsMethyl methacrylateSide chain

To provide a resin substrate provided with a hard coating film which is excellent in weather resistant adhesion and weather cracking resistance. The resin substrate 1 provided with a hard coating film, comprises a resin substrate 2, and formed on at least one surface thereof, a primer layer 3 containing an acrylic polymer (P) as a main component, and a hard coating layer 4, sequentially from the resin substrate 2 side, wherein the silyl group-containing acrylic polymer (α) contained in the primer layer 3 comprises polymerized units derived from methyl methacrylate (MMA) and silyl group-containing polymerized units and does not contain polymerized units having an aromatic hydrocarbon group in a side chain; and the value of (content of the acrylic polymer (P)) / (total amount of content of the acrylic polymer (P) and content of the silyl group-containing acrylic polymer (α))×100, is from 50 to 98 mass %.

Owner:ASAHI GLASS CO LTD

Method of coating concrete and masonry surfaces

ActiveUS20160083307A1Excellent weather resistanceAlleviates and avoid environmental and health concernPretreated surfacesCoatingsColloidal silicaOrganic base

The present invention is directed to a water-based paint composition for concrete and masonry surfaces, a method of coating a concrete or masonry surface, and a corresponding method of preparing a coated concrete or masonry surface. The paint composition includes about 10-50% by weight water, about 5-40% by weight colloidal silica particles, about 40-85% by weight of an inorganic pigment, and about 1-10% by weight of a polymer binder. The paint composition provides the coated surfaces with excellent resistance to a wide variety of weather conditions, and alleviates health and safety concerns associated with long-term exposure to conventional organic-based paints.

Owner:MAGNECOMETREL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com