Fire retardant coating and preparation method thereof

A technology of fire-resistant coatings and flame-retardant materials, applied in the direction of fire-resistant coatings, coatings, etc., can solve mechanical properties such as compressive strength, elastic modulus, yield point, load capacity decline, lack of support, and mechanical strength reduction and other problems, to achieve the effect of excellent decoration, high foaming efficiency and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

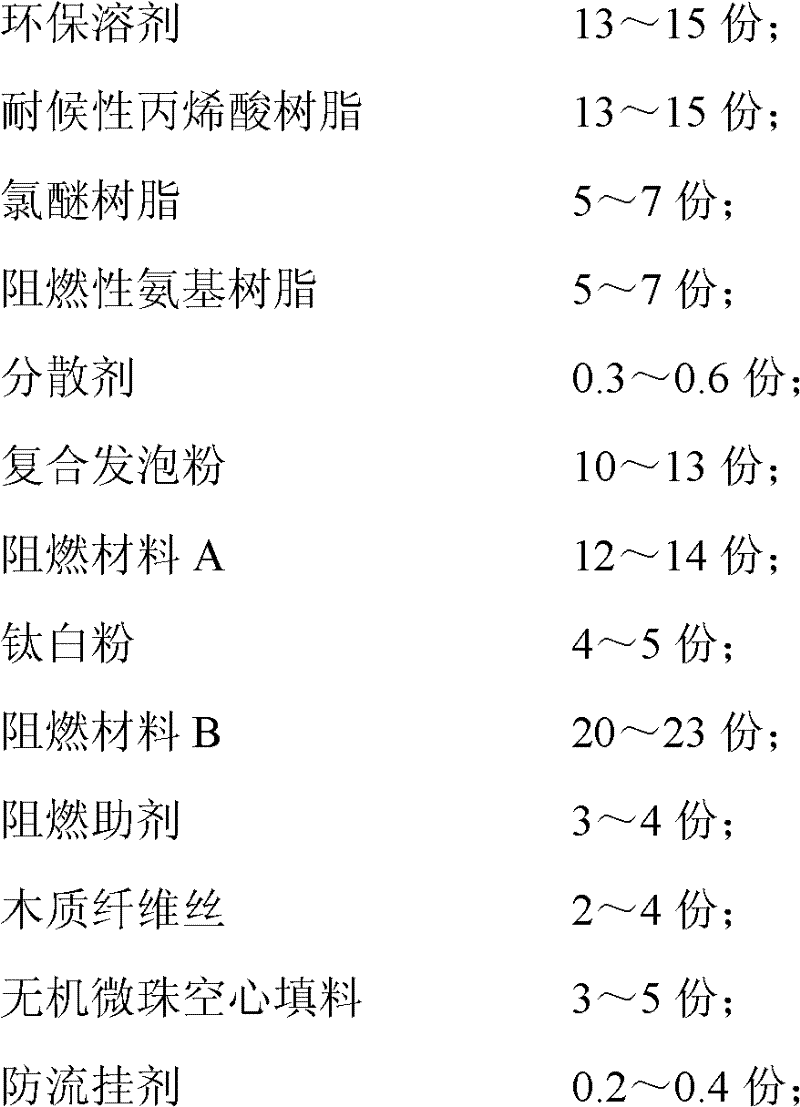

[0051] A kind of fireproof coating, it comprises the component of following parts by weight:

[0052]

[0053] The preparation method of above-mentioned fireproof coating, comprises the steps:

[0054] (1) Add the environmental protection solvent, weather-resistant acrylic resin, chloroether resin, flame-retardant amino resin and dispersant in the formulated amount in sequence, stir at 1000 rpm for 10 minutes, and mix well;

[0055] (2) To the mixed material of step (1), sequentially add composite foaming powder, flame retardant material A, titanium dioxide, flame retardant material B and flame retardant additives of formula quantity, stir at 1000 rev / min for 25min, mix Grind to a fineness of ≤60μm after uniformity;

[0056] (3) When the fineness of step (2) reaches the requirement, add inorganic microbead hollow filler, anti-sag agent and wood fiber in turn, stir at 700 rpm for 30 minutes, disperse and stir evenly to obtain.

Embodiment 2

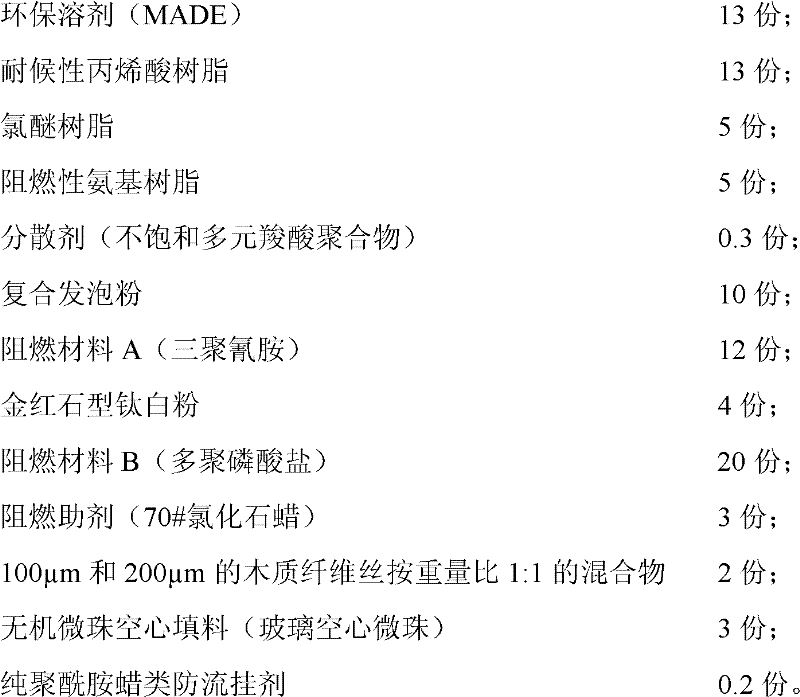

[0058] A kind of fireproof coating, it comprises the component of following parts by weight:

[0059]

[0060] The preparation method of above-mentioned fireproof coating, comprises the steps:

[0061] (1) Add the environmental protection solvent, weather-resistant acrylic resin, chloroether resin, flame-retardant amino resin and dispersant in the formulated amount in sequence, stir for 5 minutes at 1200 rpm, and mix well;

[0062] (2) To the mixed material in step (1), sequentially add composite foaming powder, flame retardant material A, titanium dioxide, flame retardant material B and flame retardant auxiliary agent of formula quantity, stir at 1200 rpm for 25min, mix Grind to a fineness of ≤60μm after uniformity;

[0063] (3) When the fineness of step (2) reaches the requirement, add inorganic microbead hollow filler, anti-sagging agent and wood fiber in turn, stir at 800 rpm for 25 minutes, disperse and stir evenly to obtain.

Embodiment 3

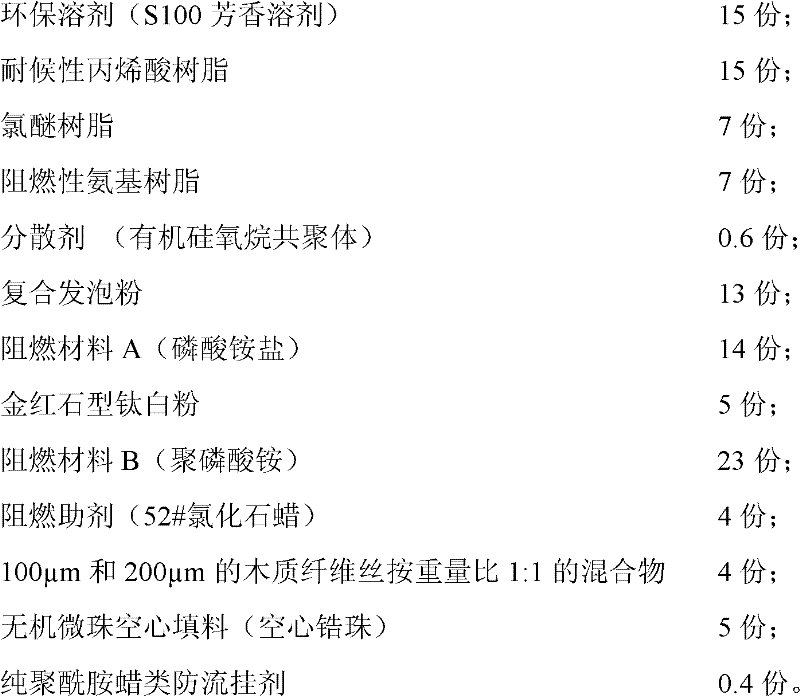

[0065] A kind of fireproof coating, it comprises the component of following parts by weight:

[0066]

[0067] The preparation method of above-mentioned fireproof coating, comprises the steps:

[0068] (1) Add the environmental protection solvent, weather-resistant acrylic resin, chloroether resin, flame-retardant amino resin and dispersant in the formulated amount in sequence, stir at 1100 rpm for 8 minutes, and mix well;

[0069] (2) To the mixed material of step (1), add the composite foaming powder of formula quantity, flame retardant material A, titanium dioxide, flame retardant material B and flame retardant aid successively, stir 28min under 1100 rpm, mix Grind to a fineness of ≤60μm after uniformity;

[0070] (3) When the fineness of step (2) reaches the requirement, add inorganic microbead hollow filler, anti-sagging agent and wood fiber in sequence, stir at 700 rpm for 28 minutes, disperse and stir evenly to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fire resistance time | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com