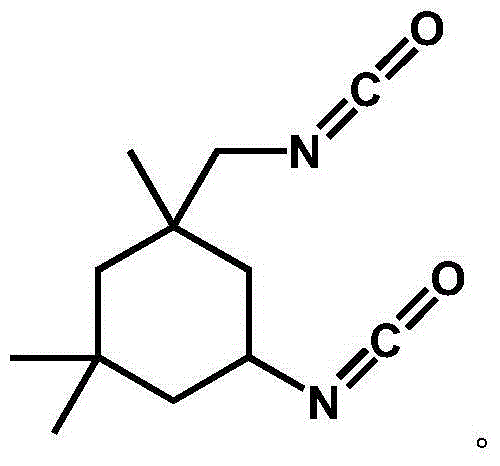

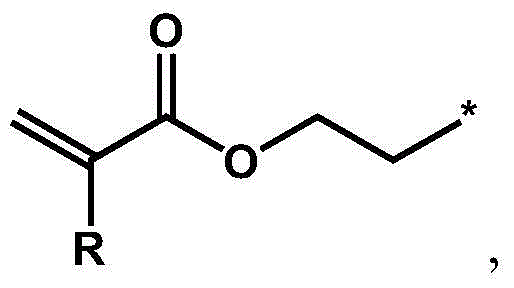

(Methyl) Acrylic compound, polyurethane (methyl) acrylic ester, and synthetic method

An acrylate and urethane-based technology, applied in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve problems such as the impact on display device performance, and achieve good storage stability and anti-yellowing properties , Good storage stability, not easy to oxidize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

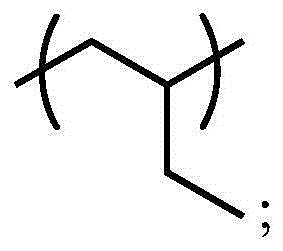

[0098] Experimental Example 1: Oligomer C

[0099] The synthesis method of oligomer C can be divided into two stages, the first stage is roughly the same as that of Comparative Example 1, the difference is that when IEA is added, the equivalent ratio of isocyanate group / hydroxyl group is controlled to about 0.25. Afterwards, after confirming that the isocyanate group content in the mixture in the four-necked bottle is less than 0.5% by weight, the temperature is raised to 60° C. and IPDI is continued to be added dropwise to react with the hydroxyl group of about 50% molar equivalent (the 50% equivalent here is Polytail Based on all hydroxyl groups, including those that have reacted with IEA). After three hours of reaction, the end point of the reaction was determined by measuring the residual isocyanate group content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com