High-aging-resistance modified asphalt and preparation method thereof

A modified asphalt, high-resistance technology, applied in building components, building insulation materials, buildings, etc., can solve the chemical composition of modifiers, molecular structure differences, asphalt UV aging inhibition is not prominent, low temperature crack resistance of asphalt Adverse effects and other issues, to achieve the effect of improving road performance and durability, good synergistic effect, extending maintenance cycle and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

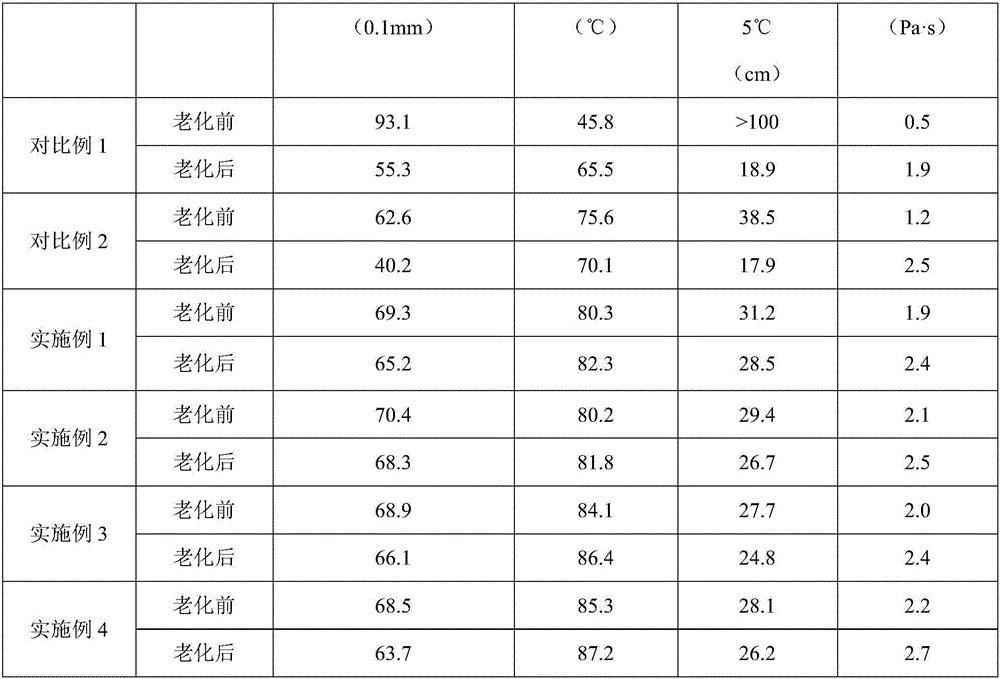

Embodiment 1

[0043] Example 1: High anti-aging modified asphalt

[0044] A high anti-aging modified asphalt, which is composed of the following raw materials in terms of mass fraction: base asphalt 75.5%, hindered amine light stabilizer 2.7%, trilauric phosphite 0.6%, barium stearate 1.2%, diatom Soil 7%, epoxidized soybean oil 5%, methyl isobutyl ketone 8%, the sum of the mass fractions of raw materials is 100%.

[0045] The above-mentioned base asphalt is 90# base asphalt, which can be replaced by other types of asphalt; the above-mentioned hindered amine light stabilizer is compounded with Tinuvin 770 and Chimassorb 944 at a mass ratio of 6:4. The fineness of the above-mentioned diatomite is 2000 mesh; the epoxy value of the above-mentioned epoxidized soybean oil is 8%.

[0046] The above-mentioned raw materials are prepared according to the following steps into highly anti-aging modified asphalt.

[0047] (1) Weigh base asphalt, hindered amine light stabilizers Tinuvin 770 and Chimas...

Embodiment 2

[0051] Example 2: High anti-aging modified asphalt

[0052] The difference between this example and Example 1 is that the proportion of raw materials is different, and it is composed of the following raw materials in terms of mass fraction: 76.8% of base pitch, 2.5% of hindered amine light stabilizer, 0.8% of trilauric phosphite, stearin 1.4% of barium acid, 6.5% of diatomite, 7% of epoxidized soybean oil, 5% of methyl isobutyl ketone, and the sum of the mass fractions of raw materials is 100%.

Embodiment 3

[0053] Example 3: High anti-aging modified asphalt

[0054] The difference between this example and Example 1 is that the proportion of raw materials is different, and it is composed of the following raw materials in terms of mass fraction: base pitch 75.0%, hindered amine light stabilizer 1.8%, trilauric phosphite 1%, stearin 0.7% of barium acid, 8% of diatomaceous earth, 6.5% of epoxidized soybean oil, 7% of methyl isobutyl ketone, and the sum of the mass fractions of raw materials is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com