Elastic heat-insulation fluorocarbon coating and preparation method and use method thereof

A thermal insulation coating, fluorocarbon technology, applied in reflective/signal coatings, coatings, etc., can solve problems such as the lack of elasticity of the paint film, the discount of thermal insulation effect, the inability to resist thermal bridges, etc., and achieve excellent weather resistance and gloss retention. The effect of color, excellent weather resistance, excellent stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

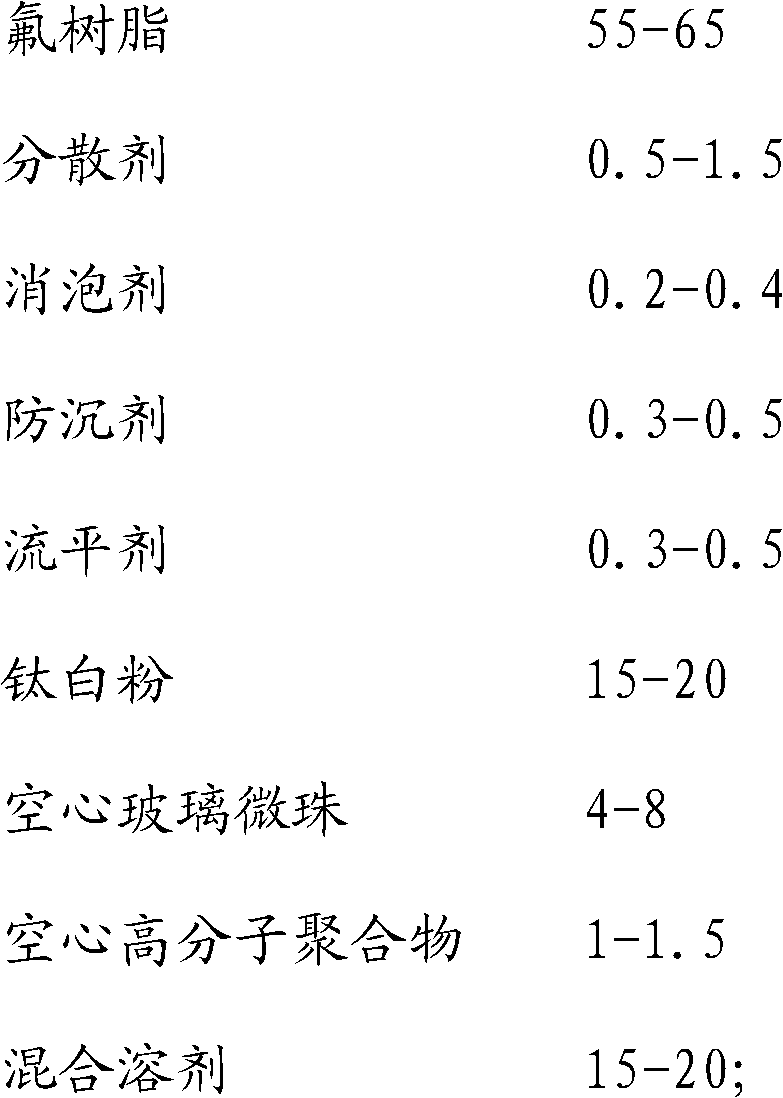

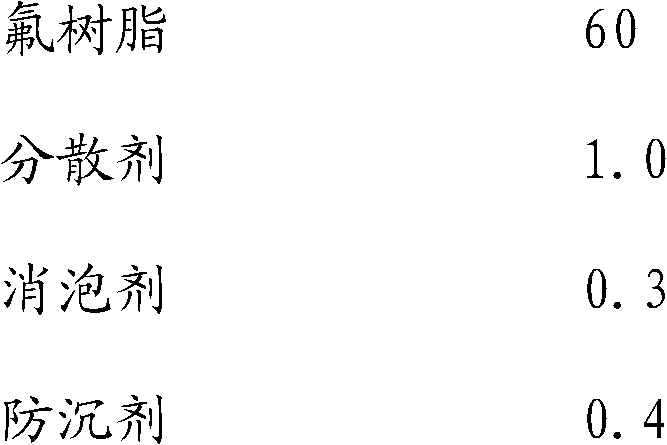

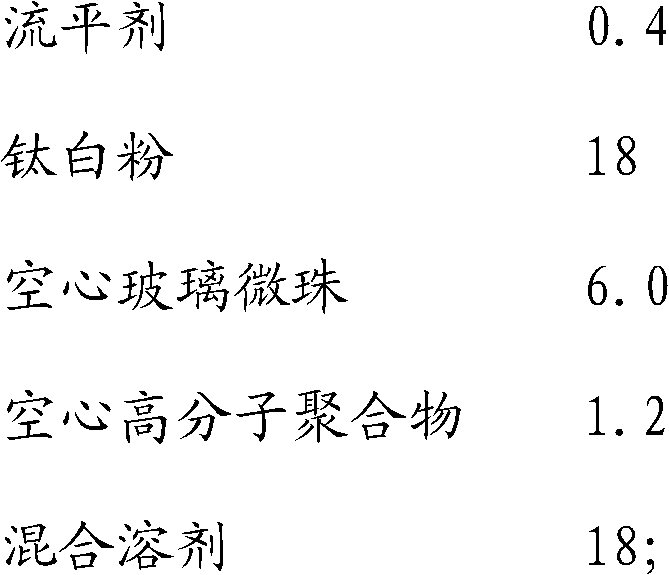

[0050] Prepare the main agent of the fluorocarbon heat-insulating coating of the present invention:

[0051] According to the weight shown in Example 1 in Table 1, each component is taken, and the preparation method is as follows:

[0052] Step 1: Dispersion of titanium dioxide: Weigh 9 kg of GK570 fluororesin, add it to the dispersion tank, then add 0.5 kg of BYK-163 dispersant, disperse at medium speed (600-800 RMP) for 3 minutes, then add BYK-066N defoamer 0.2 kg, disperse at medium speed for 5 minutes, then add 0.3kg of SD-1 anti-sedimentation agent, disperse at high speed (1200-1500RMP) for 5 minutes, then slowly add 15kg of titanium dioxide RCL-595 under low speed (about 400RMP) stirring, finish adding high speed Disperse for 15-30 minutes until the fineness is ≤20 μm to obtain titanium white paste.

[0053] Step 2: Preparation of fluorocarbon paint: Add the remaining 46kg of GK570 fluororesin, 5kg of butyl acetate, 10kg of propylene glycol methyl ether acetate and 0.3k...

Embodiment 2

[0063] According to the weight of each component in Example 2 in Table 1, repeat the method described in Example 1 to prepare the main agent, curing agent and diluent of the fluorocarbon heat-insulating coating. According to the main agent: curing agent: thinner = 105.3: 19.4: 6, mix evenly, and then carry out airless spraying construction, or according to the main agent: curing agent: thinner = 105.3: 19.4: 10, mix evenly, and then carry out roller coating construction. Both methods should ensure that the thickness of the dry paint film is above 500 μm to ensure the heat insulation performance. Under normal temperature, the paint film will dry for 24 hours, and it will be completely dry for 7 days. The performance testing results are shown in the corresponding data of Example 2 in Table 2.

Embodiment 3

[0065] According to the weight of each component in Example 3 in Table 1, repeat the method described in Example 1 to prepare the main ingredient, curing agent and diluent of the elastic fluorocarbon heat-insulating coating. Mix uniformly according to main paint: curing agent: thinner = 117.4: 27.4: 5, and then carry out airless spraying construction, or according to main agent: curing agent: thinner = 117.4: 27.4: 12, then carry out roller coating construction. Both methods should ensure that the thickness of the dry paint film is above 500 μm to ensure the heat insulation performance. Under normal temperature, the paint film can dry for 24 hours and completely dry for 7 days. The performance testing results are shown in the corresponding data of Example 3 in Table 2.

[0066] Table II

[0067]

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com