Surface protection sheet

A protective sheet and one-sided technology, applied in the direction of film/sheet adhesive, adhesive type, application, etc., can solve the problem of insufficient weather resistance, achieve excellent weather resistance, and suppress the increase in adhesive force , the effect of preventing glue marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

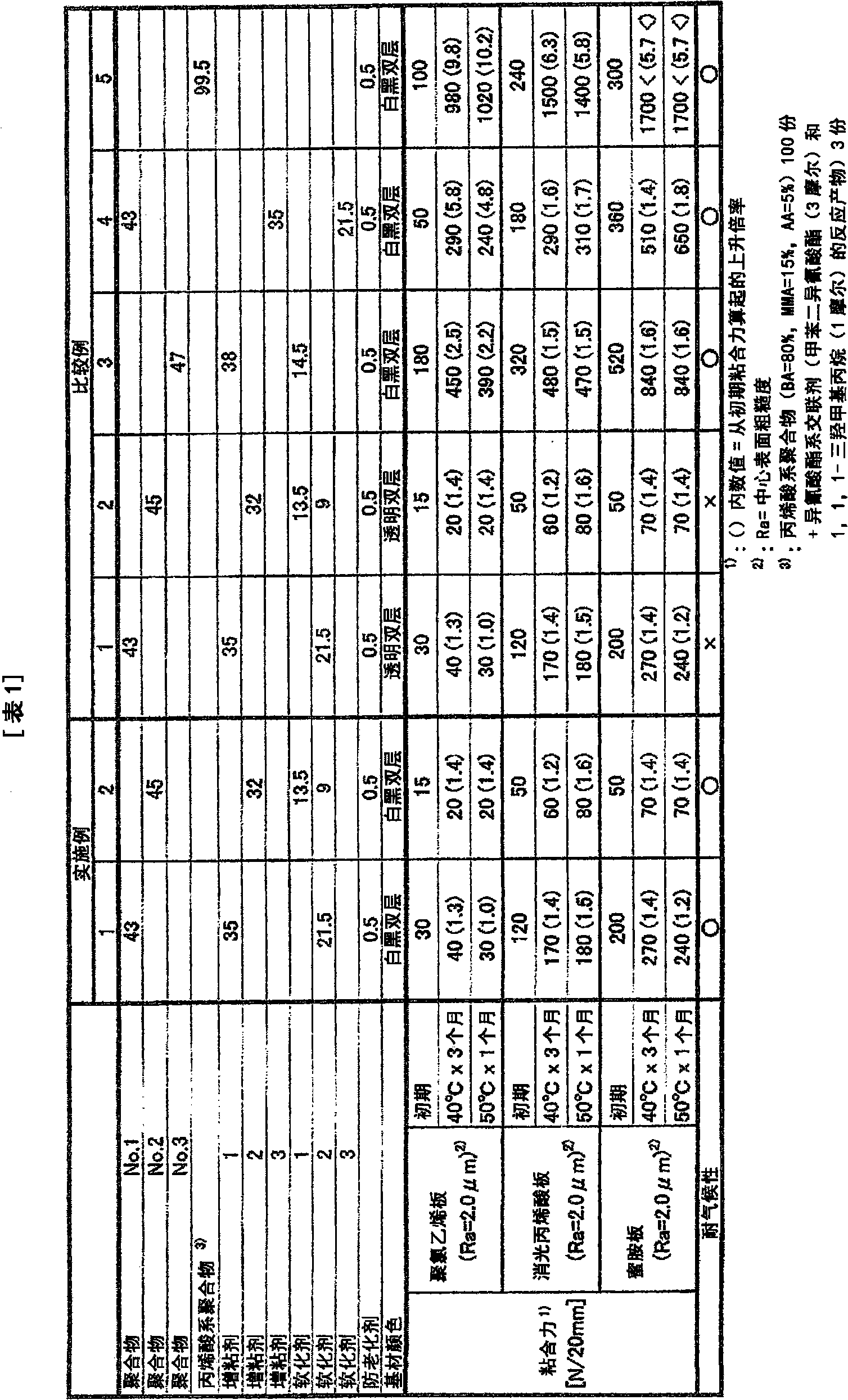

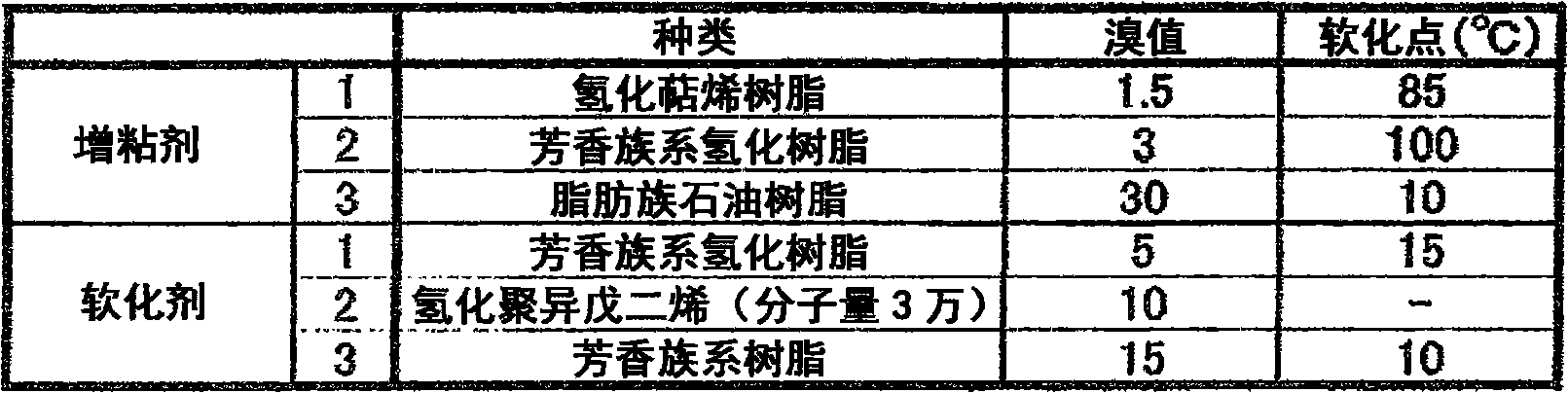

Examples

manufacture example 1

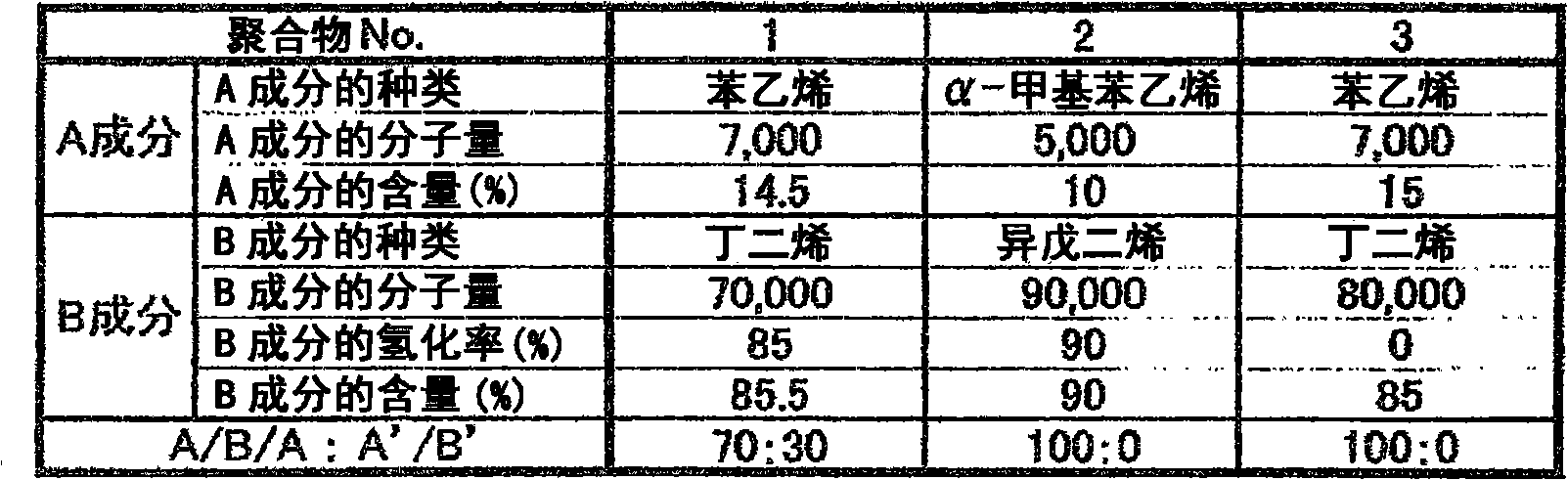

[0067] [Manufacture Example 1]: Manufacture of Polymer 1

[0068] 40 g of styrene and 400 g of cyclohexane were charged into the autoclave, nitrogen substitution was performed, and 0.003 mol of sec-butyl lithium dissolved in cyclohexane was charged. After reacting at 60° C. for 1 hour, 400 g of butadiene and 2,000 g of cyclohexane were added thereto, and then reacted at 60° C. for 2 hours. After the reaction, 40 g of styrene and 400 g of cyclohexane were added again, and reacted at 60° C. for 1 hour. Using this reaction, SBS block polymers were prepared. As a catalyst, 1.5 millimoles of nickel acetylacetonate and 3 millimoles of triethylaluminum were reacted in 500 ml of cyclohexane at 25° C. for 10 minutes, and added to the reaction system of the SBS block copolymer obtained above. Thereafter, use hydrogen in the autoclave at 30kg / cm 3 Pressurization was applied to raise the reaction temperature to 50°C, and hydrogenation was stopped after 20 minutes. Thus, Polymer 1 as s...

manufacture example 2

[0069] [Manufacture Example 2]: Manufacture of Polymer 2

[0070] Polymer 2 shown in Table 2 was obtained in the same manner as in Production Example 1 except that it was changed as shown in Table 2.

manufacture example 3

[0071] [Manufacture Example 3]: Manufacture of Polymer 3

[0072] Polymer 3 shown in Table 2 was obtained in the same manner as in Production Example 1 except that it was changed as shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com