Active and anticorrosive water-based paint and preparation method thereof

An anti-corrosion coating and active technology, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor dispersion stability of water-based coatings against strong mechanical forces, single function of anti-corrosion coatings, and low solid content. Excellent weather resistance, stable conductivity, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

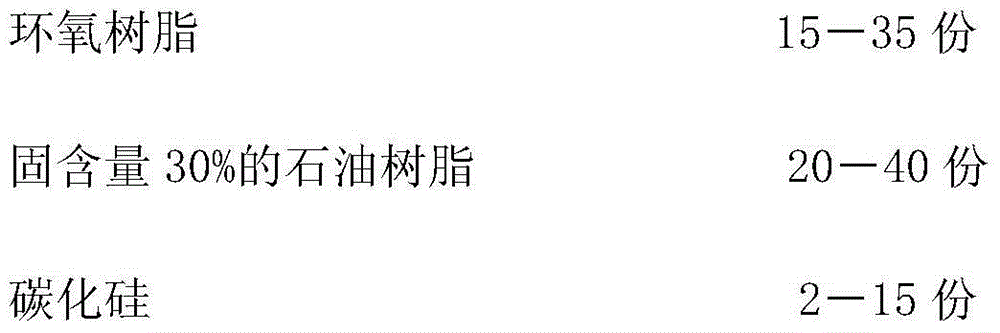

[0043] The present embodiment provides a kind of water-based active anticorrosion coating, and its composition is as follows by mass parts:

[0044]

[0045] The present embodiment also provides a kind of preparation method of water-based active anticorrosion coating, and the preparation steps are as follows:

[0046] Step (1): first prepare petroleum resin with a solid content of 30%, mix the petroleum resin and organic solvent in a mass ratio of 3:7, and stir and disperse in the stirring tank, the stirring speed is 500r / min, and the stirring time is 90min. Stir until colorless transparent viscous liquid, set aside;

[0047] Step (2): Then add the petroleum resin, epoxy resin, silicon carbide, organic active agent and water-based solvent with a solid content of 30% prepared in step (1) into the stirring tank and stir evenly at a stirring speed of 500r / min , stirring time 90min;

[0048]Step (3): Finally, add zinc naphthenate and a surfactant and stir at a low speed for 3...

Embodiment 2

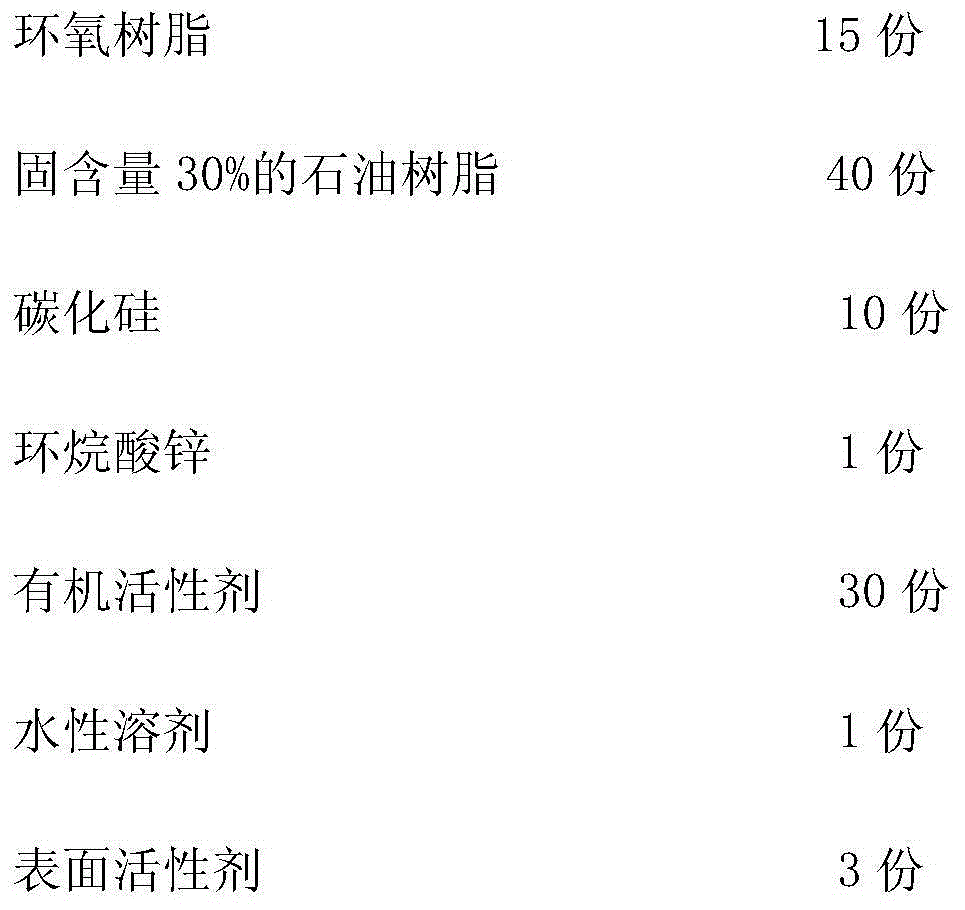

[0054] The present embodiment provides a kind of water-based active anticorrosion coating, and its composition is as follows by mass parts:

[0055]

[0056] The present embodiment also provides a kind of preparation method of water-based active anticorrosion coating, and the preparation steps are as follows:

[0057] Step (1): first prepare petroleum resin with a solid content of 30%, mix the petroleum resin and organic solvent in a mass ratio of 3:7, and stir and disperse in the stirring tank, the stirring speed is 800r / min, and the stirring time is 60min. Stir until colorless transparent viscous liquid, set aside;

[0058] Step (2): Then add the petroleum resin, epoxy resin, silicon carbide, organic active agent and water-based solvent with a solid content of 30% prepared in step (1) into the stirring tank and stir evenly at a stirring speed of 800r / min , stirring time 60min;

[0059] Step (3): Finally, add zinc naphthenate and a surfactant and stir at a low speed for ...

Embodiment 3

[0064] The present embodiment provides a kind of water-based active anticorrosion coating, and its composition is as follows by mass parts:

[0065]

[0066] The present embodiment also provides a kind of preparation method of water-based active anticorrosion coating, and the preparation steps are as follows:

[0067] Step (1): first prepare petroleum resin with a solid content of 30%, mix the petroleum resin and organic solvent in a mass ratio of 3:7, and stir and disperse in the stirring tank, the stirring speed is 650r / min, and the stirring time is 75min. Stir until colorless transparent viscous liquid, set aside;

[0068] Step (2): Then add the petroleum resin, epoxy resin, silicon carbide, organic active agent and water-based solvent with a solid content of 30% prepared in step (1) into the stirring tank and stir evenly at a stirring speed of 650r / min , stirring time 75min;

[0069] Step (3): Finally, add zinc naphthenate and surfactant and stir at a low speed for 32...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gel time | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com