Functional leather with super-hydrophobic self-cleaning surface coating

A surface coating and hydrophobic coating technology, applied in the field of clothing, can solve the problem of not taking into account the waterproof and oil-proof ability and moisture permeability and air permeability, and achieve the effects of good wear resistance, good performance and good structure compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

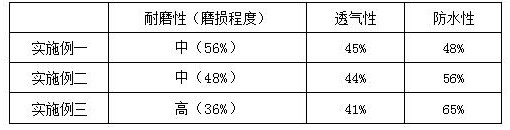

Embodiment 1

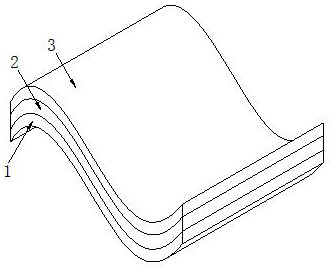

[0024] Leather having a functional self-cleaning superhydrophobic surface coating, comprising a substrate 1 stacked together, a hydrophobic coating 2, the plastic surface layer 3, the hydrophobic coating material 2 comprising: a hydrophobic paste fusion resin; plastics skin 3 the materials include ETFE, perfluoroalkoxy compounds, polyvinylidene fluoride.

[0025] In the present embodiment, the hydrophobic coating material 2, the hydrophobic material slurry comprising a mass fraction of 50 parts of an aqueous polyurethane resin, the ultrafine micronized modified polyethylene wax 0.5 parts of aqueous silicone 1 part of polyacrylic acid sodium 0.1 parts of glycerol 0.1 parts of polyoxyethylene ether, 0.5 parts of dicumyl peroxide, 0.5 parts of ultra-fine silica, 5 parts of ammonium stearate emulsion, 0.2 parts of silicone softener, 3 parts of the aqueous colorant.

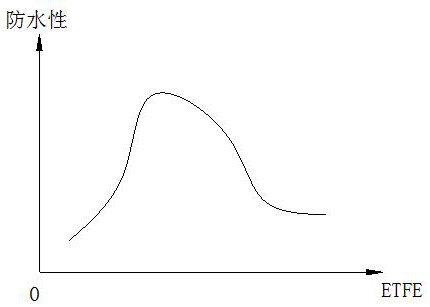

[0026] In the present embodiment, the surface layer of the plastic material comprising in mass percent, 3 ETFE60 parts,...

Embodiment 2

[0035] Leather having a functional self-cleaning superhydrophobic surface coating, comprising a substrate 1 stacked together, a hydrophobic coating 2, the plastic surface layer 3, the hydrophobic coating material 2 comprising: a hydrophobic paste fusion resin; plastics skin 3 the materials include ETFE, perfluoroalkoxy compounds, polyvinylidene fluoride.

[0036]In the present embodiment, in the raw material of the hydrophobic coating 2, the raw material of the hydrophobic slurry includes 70 parts by mass fraction, 1.0 parts of ultrafine modified micronized polyethylene wax, 5 parts of aqueous siloxane, polyacrylic acid 0.8 sodium, 0.4 parts of glycerol polyoxyethylene ether, 2 peroxide, 2 parts of ultrafine white carbon, 15 of stearate emulsion, 1.0 parts of silicone soft agent, 15 water-based colorants.

[0037] In the present embodiment, the raw material of the plastic surface layer 3 includes ETFE70 parts, 20 parts of fluorine oxide, 15 parts of fluoride, 15 parts of polyvinyl...

Embodiment 3

[0046] A functional leather having superhydrophobic self-cleaning surface coating comprising substrate 1, hydrophobic coating 2, plastic surface layer 3, hydrophobic coating 2, a plastic surface layer 3, a hydrophobic slurry, a fusion resin; plastic surface 3 The raw materials include ETFE, fluorine-based alkyl, polyvinylidene fluoride.

[0047] In the present embodiment, in the raw material of the hydrophobic coating 2, the raw material of the hydrophobic slurry includes 55 parts of the mass fraction, 0.5 parts of aqueous polyurethane resin, 0.5 parts of ultrafine modified micronized polyethylene wax, 4 parts of aqueous siloxane, polyacrylic acid 0.7 sodium, 0.3 glycerol polyoxyethylene ethers, 1.2 parts peroxide, extra-white carbon 0.7 parts, 10 stearate emulsions, 0.8 silicone soft agents, 5 water colorants.

[0048] In the present embodiment, the raw material of the plastic surface layer 3 includes ETFE65 parts, 17 parts of fluorine oxide, 12 parts of polyvinylidene, 12 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com