Patents

Literature

68 results about "Kaolin product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment and production technique for calcining kaolin

A process for preparing the calcined kaolinite includes such steps as dressing ore, crushing, pulverizing by 325 meshes, mixing with water and disperser, pulverizing by 4500-6000 meshes, drying, pulverizing, calcining at 970-990 deg.C for 30-40 min while adding whitening agent, and breaking. Its features high whiteness and fineness.

Owner:SANBAO KAOLINIE CLAY INNER MONGOLIA

Production technology of high

InactiveCN101117004AImprove performancePerformance impactClay processing apparatusThermal insulationKaolin clay

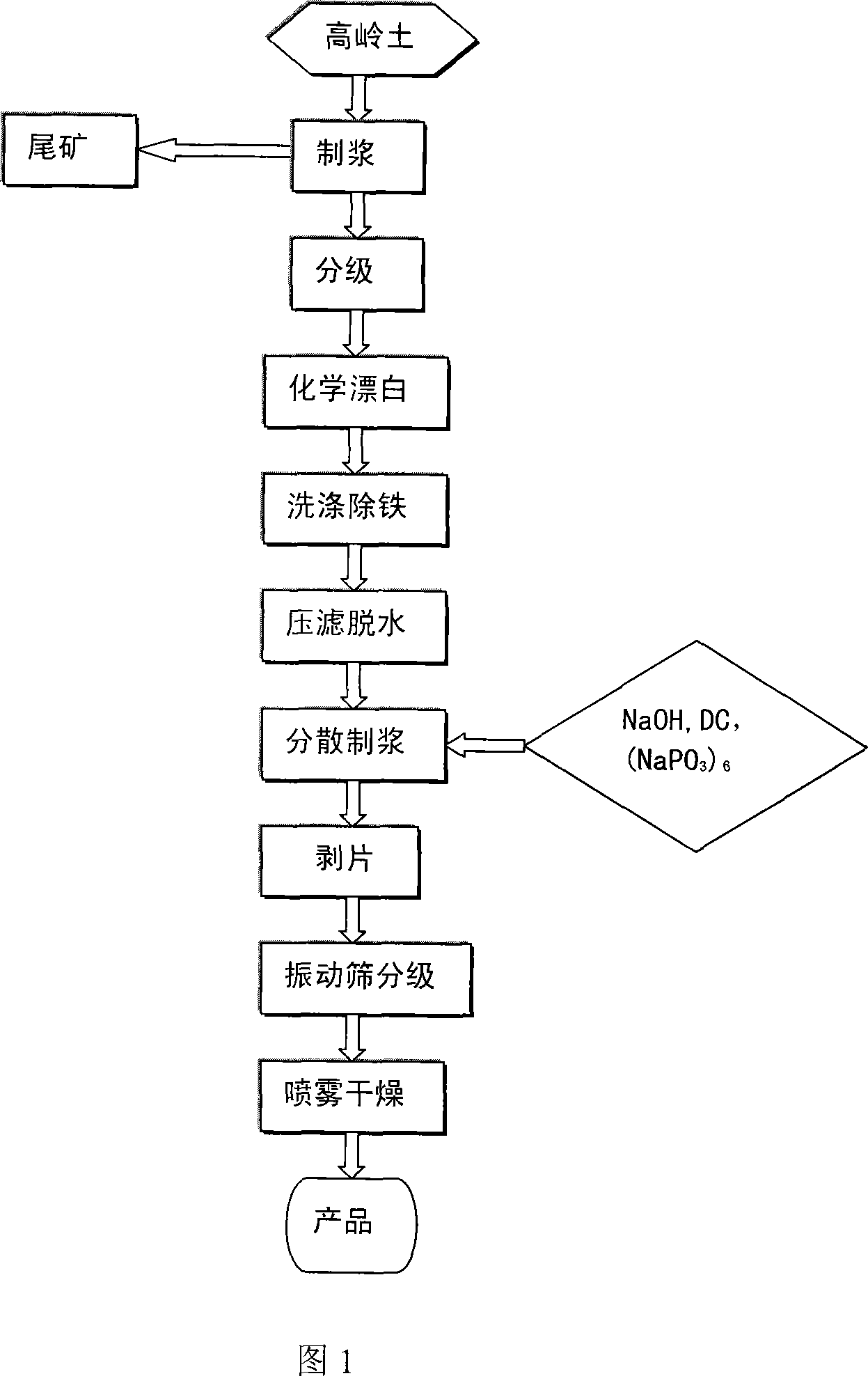

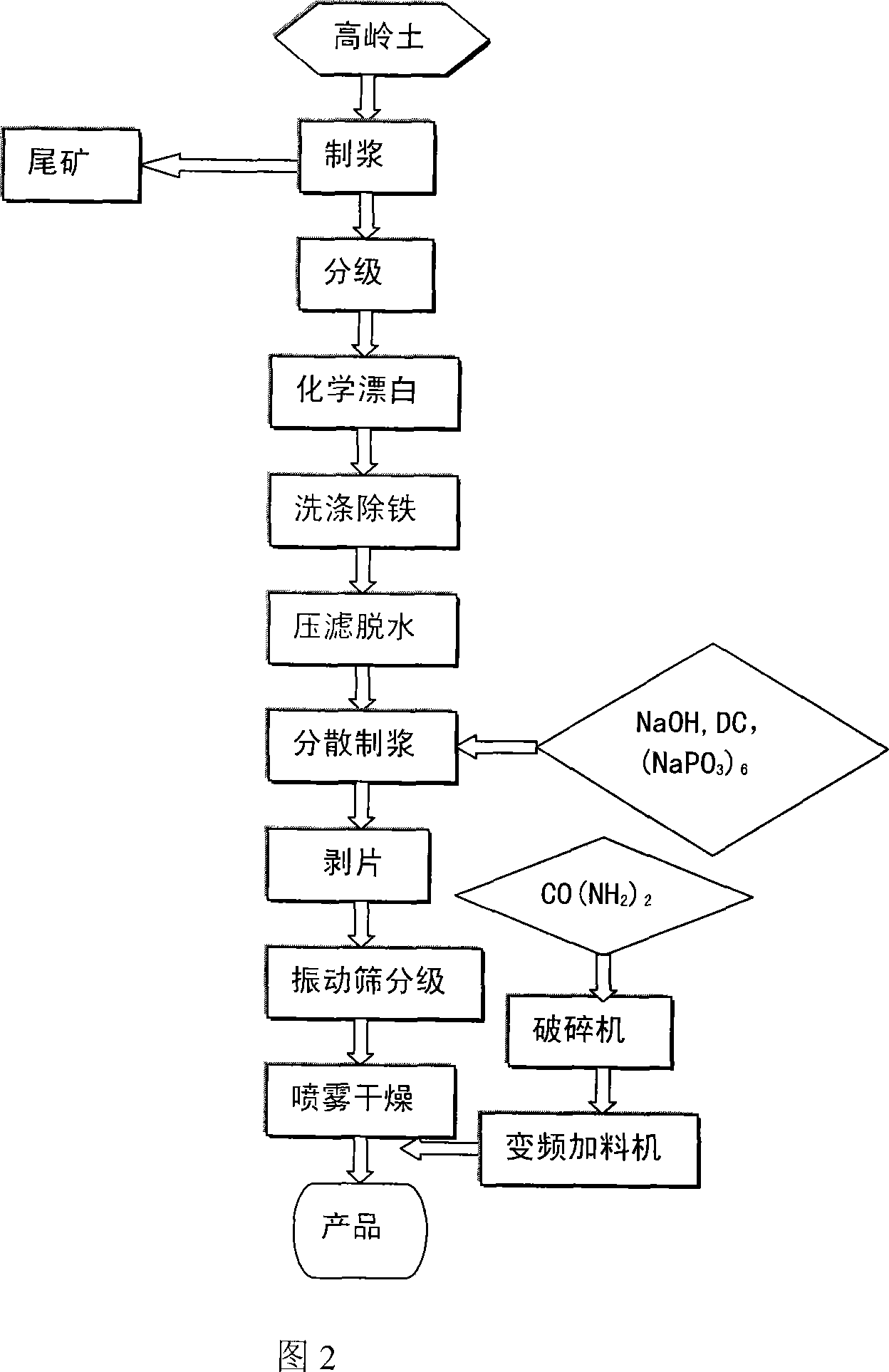

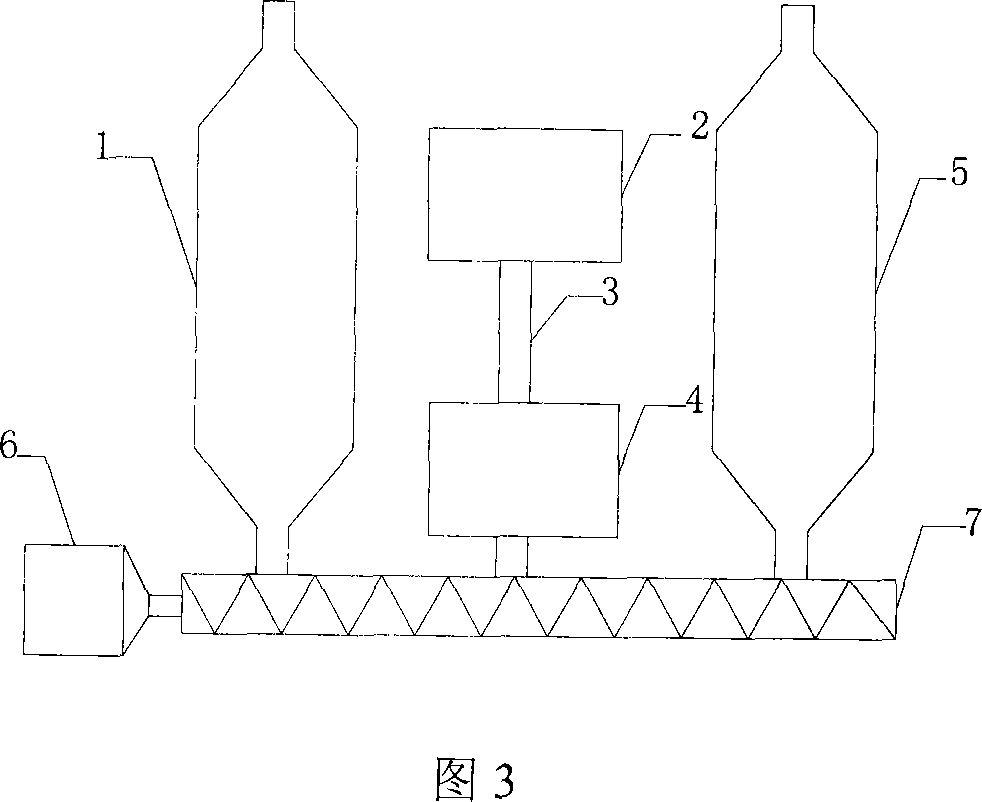

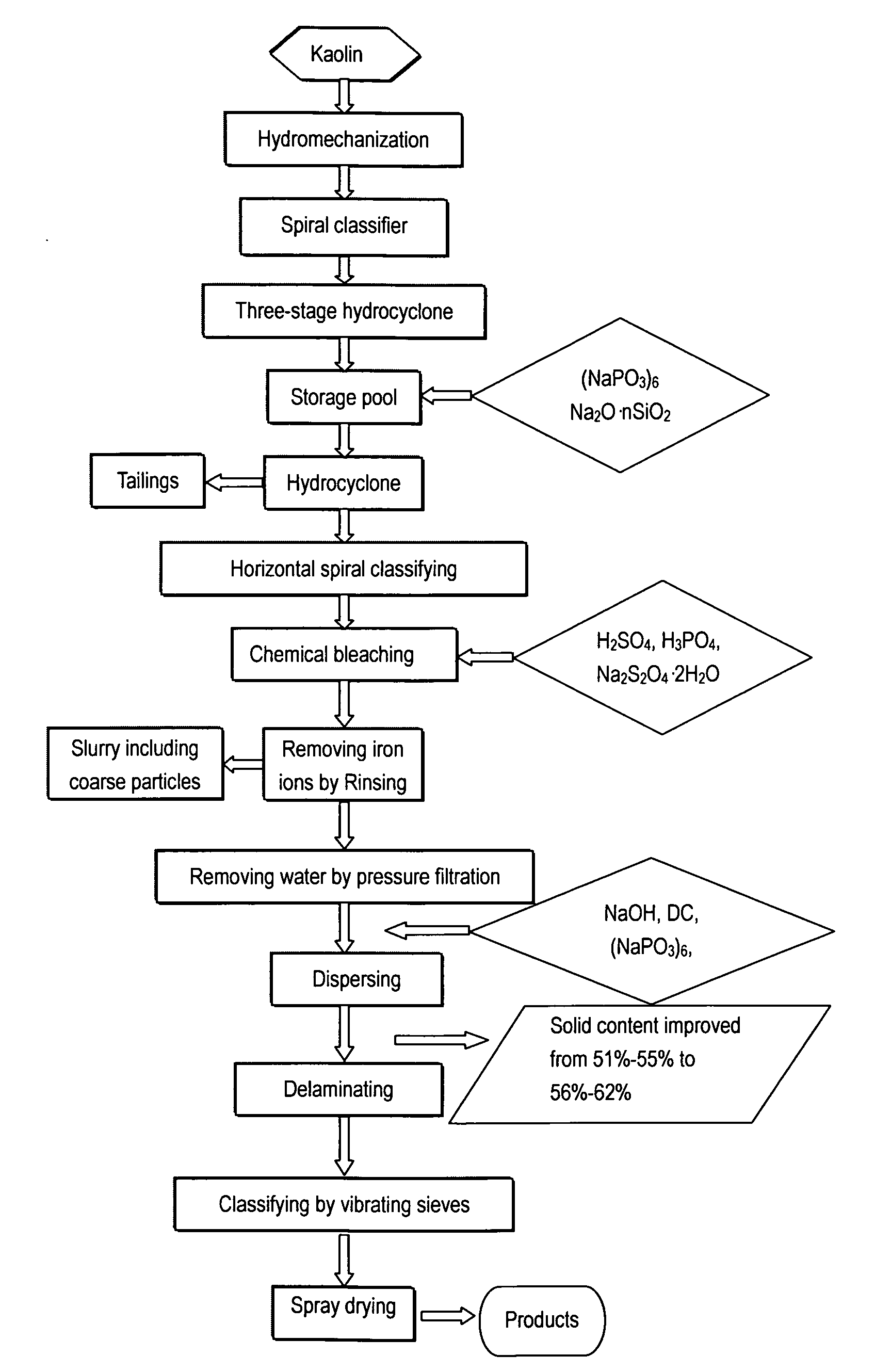

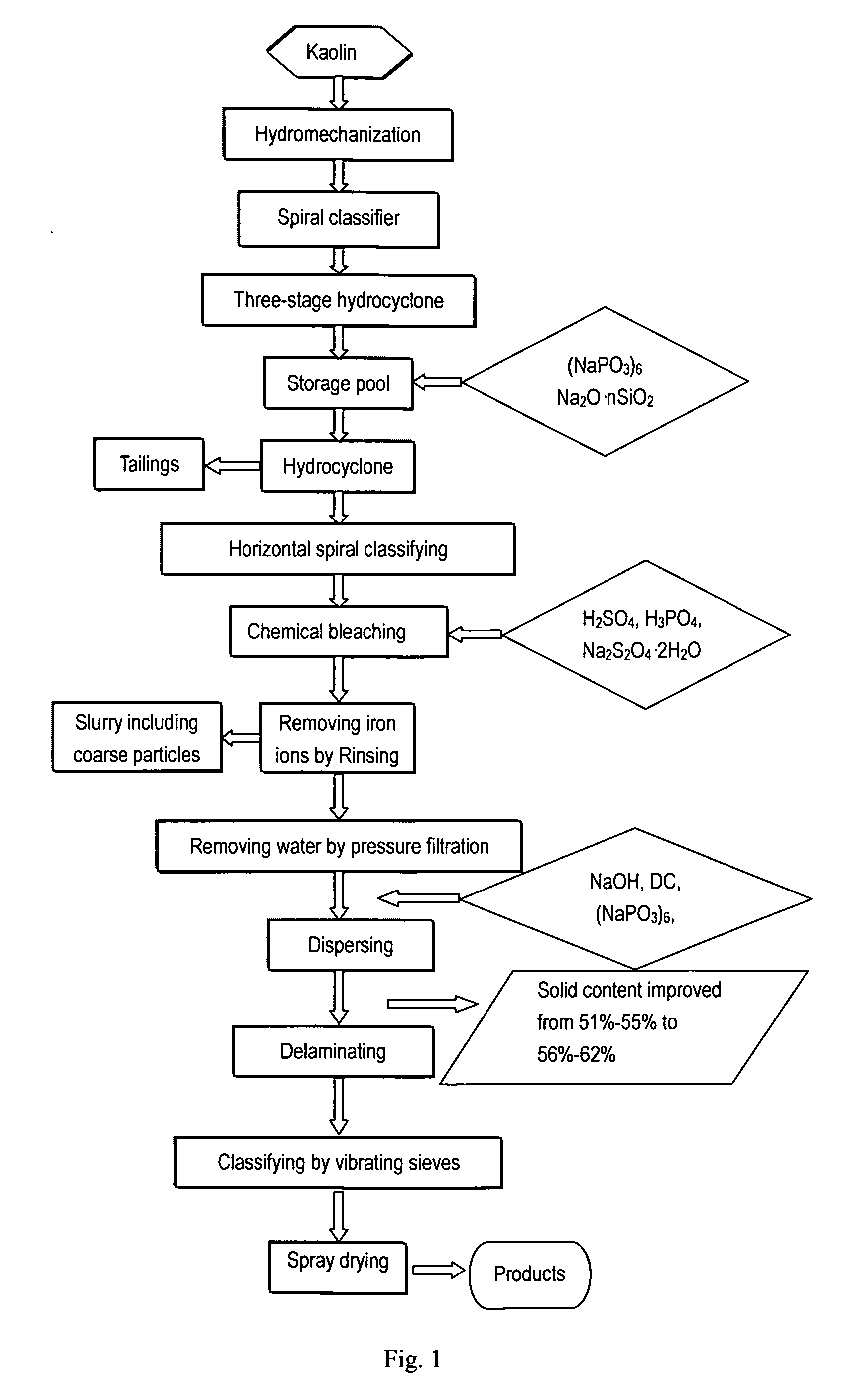

The present invention relates to a manufacturing technique of kaolin with high viscosity and concentration. A manufacturing technique of kaolin with high viscosity and concentration is characterized by comprising following procedures: 1) manufacturing kaolin slurry J with kaolin extracted by hydraulic machinery method undergoing pulping, classification, chemical bleaching, iron removal by washing, dehydrating through pressure filters, dispersed pulping, exfoliation, vibration screen classification ; 2) spray drying and intercalation which is accomplished by a) firstly, improving product lines of a spray drying equipment, that is, adding a thermal insulation layer to a packing auger, a lift pot and a storage hopper of the spray drying equipment, and then arranging a variable frequency feeding machine communicated with a urea crusher through pipelines on the packing auger of the bottom of a spray drying mouth of the spray drying equipment; b) spray drying to achieve kaolin powder; c) intercalating intercalation agent urea with the kaolin powder through the variable frequency feeding machine with parameter of a fresh feed pump between 2 HZ and 8 HZ and with additional of mass of the intercalation agent urea between 2 percent and 10 percent of the mass of the kaolin powder; thereby getting final kaolin products with viscosity and concentration between 72 percent and 73.7 percent. The manufacturing technique can produce kaolin with high viscosity and concentration.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

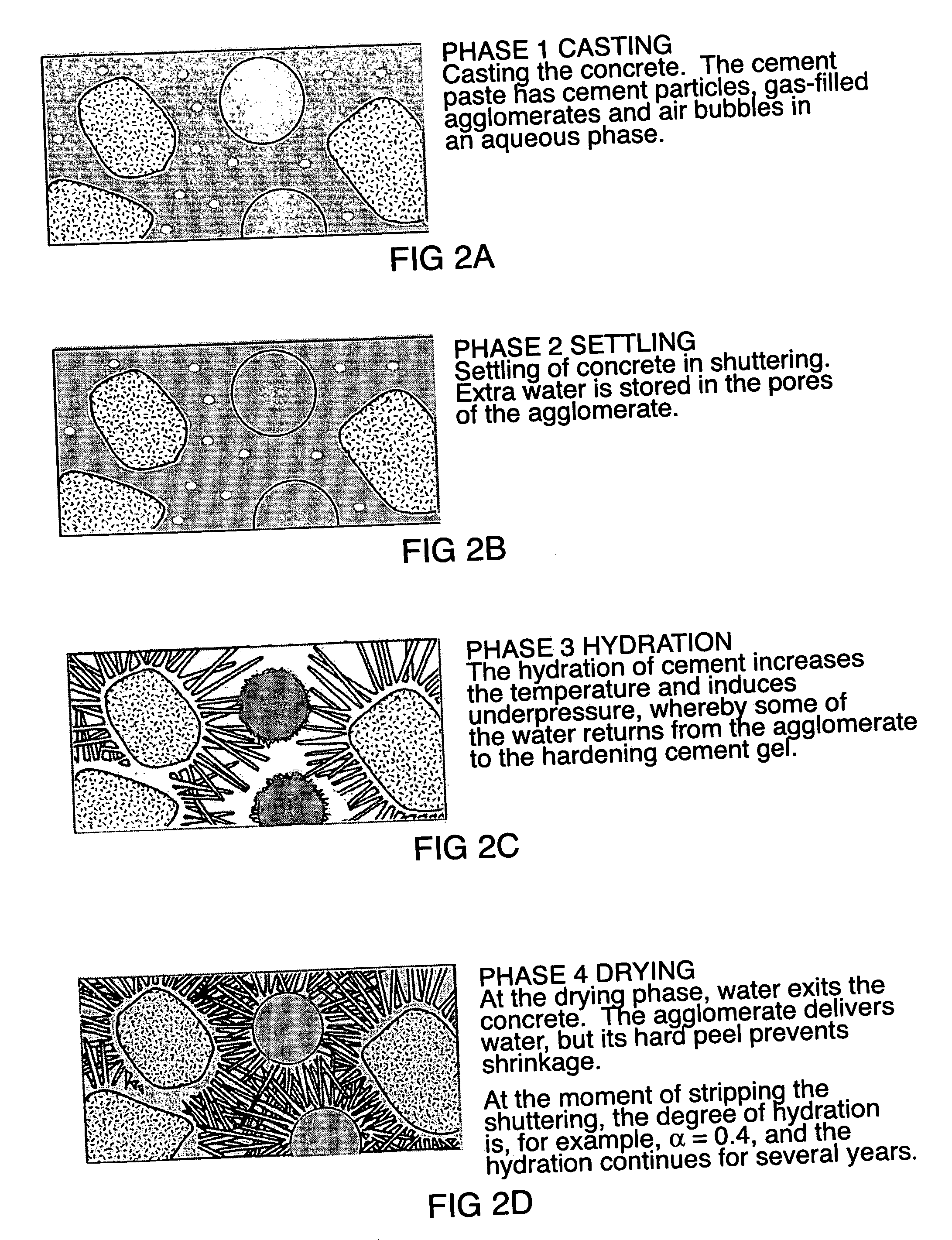

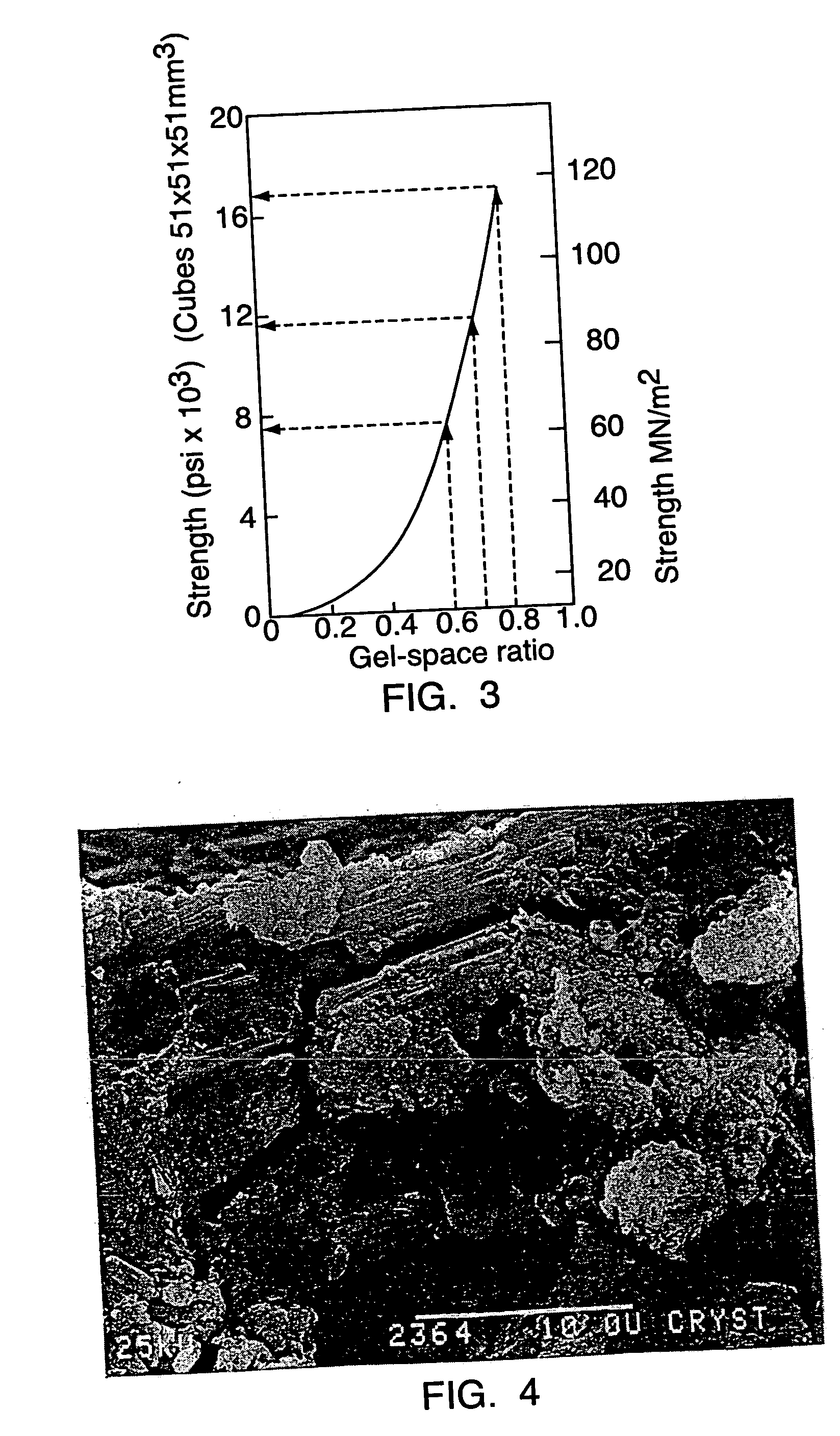

Binder admixture, kaolin product and their manufacture

InactiveUS20050000393A1Improve propertiesImprove the mixing effectClaywaresSolid waste managementFrostKaolin clay

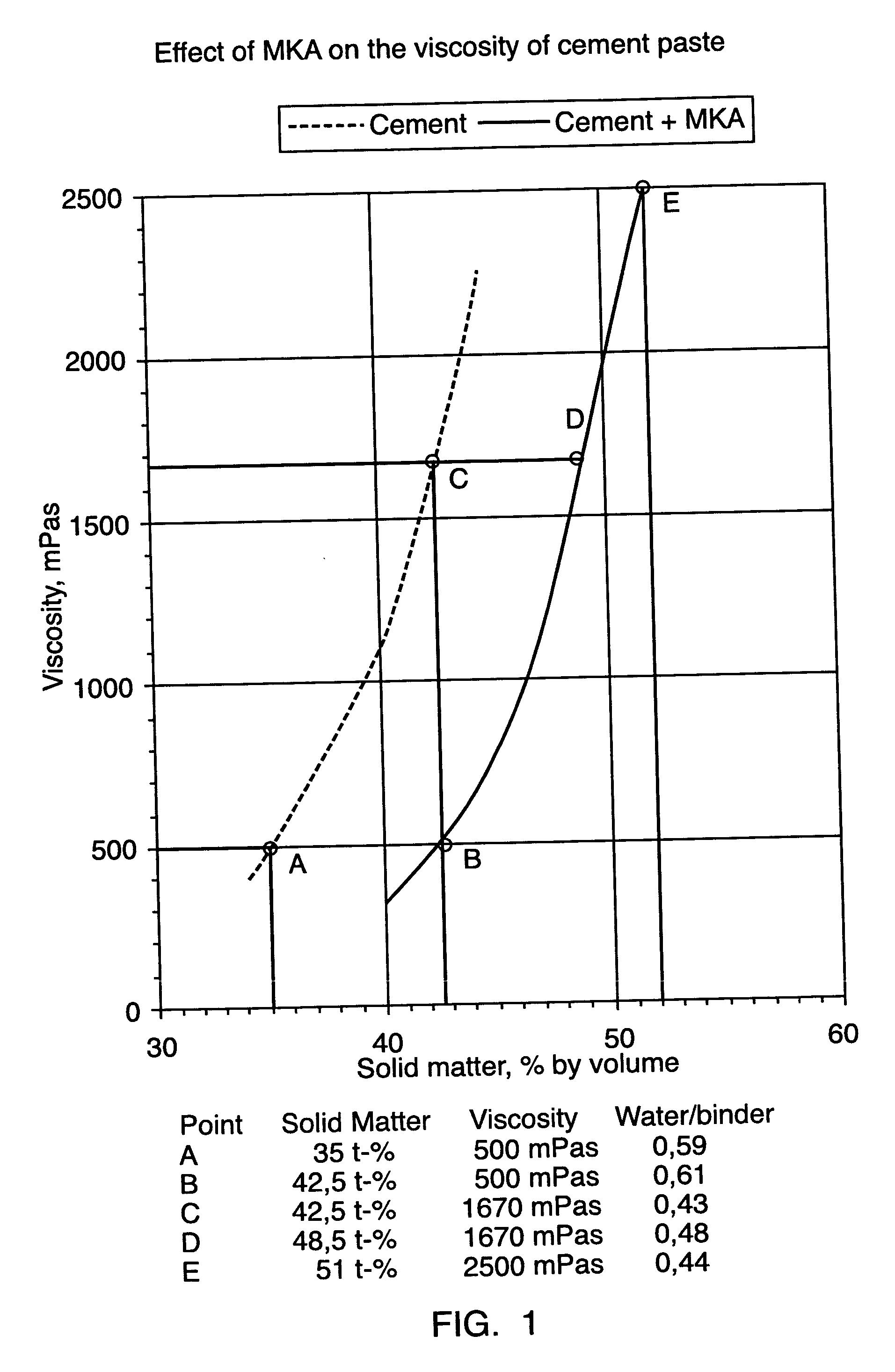

A binder mix containing a hydraulic binding agent and an admixture mixed therewith, a process for preparing a hydraulically hardened binder mass, a calcinated kaolin product and a process for preparing the same. A paste-like composition is formed from the hydraulically hardening binding agent, a pozzolanically reacting admixture and water, which, when so desired, contains stone aggregate or similar filler, the paste-like composition is worked and the worked composition is allowed to harden to form the binder mass. The admixture comprises spherical, porous metakaolin agglomerates, the size of which is 2-200 microns and which have an open pore structure. The invention can be used to improve the manufacturing methods of cast concrete products and shorten the manufacturing times, and to provide concrete with better mechanical and chemical properties, as well as improve the fire and frost resistance of concrete.

Owner:NORDKALK AB

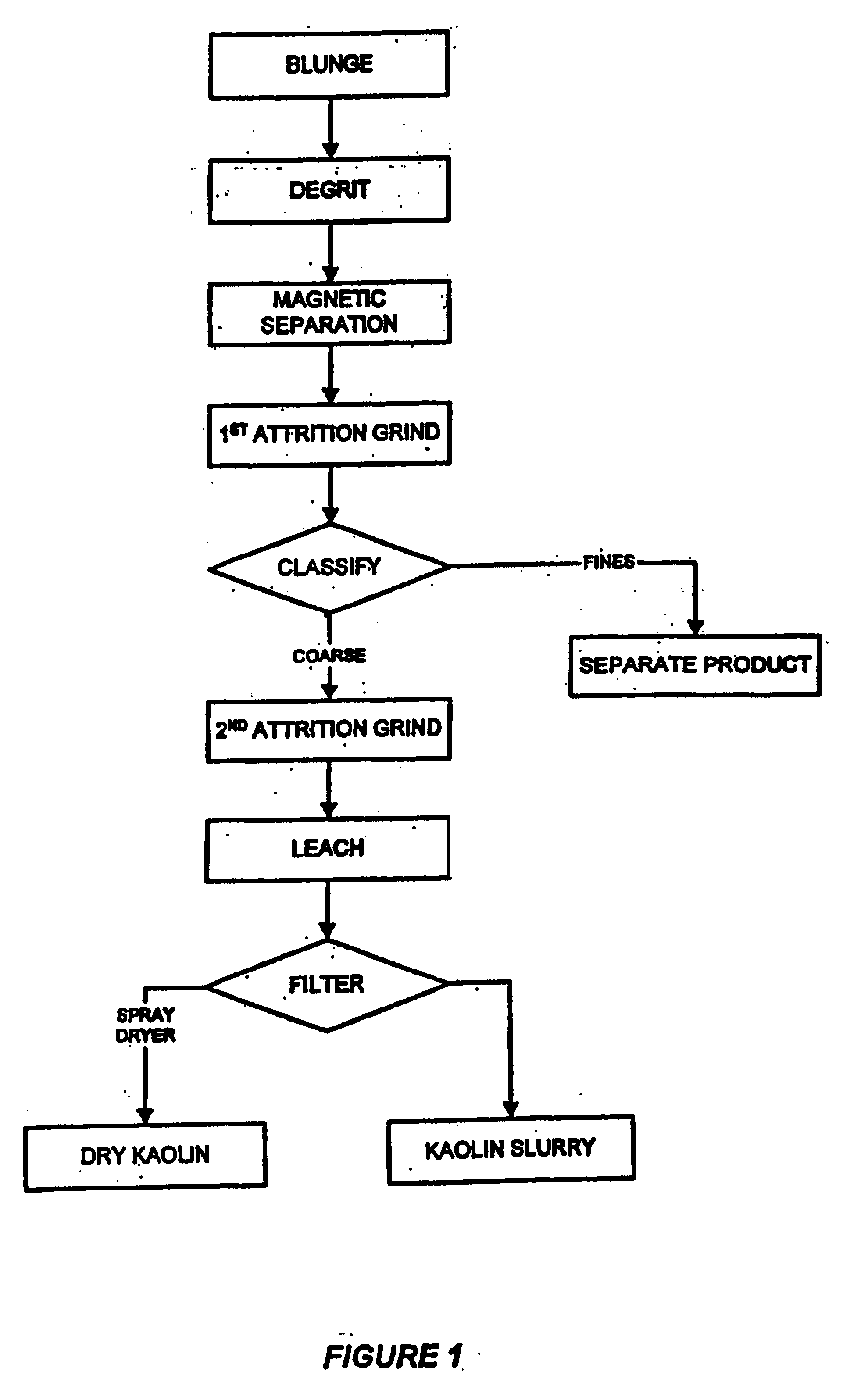

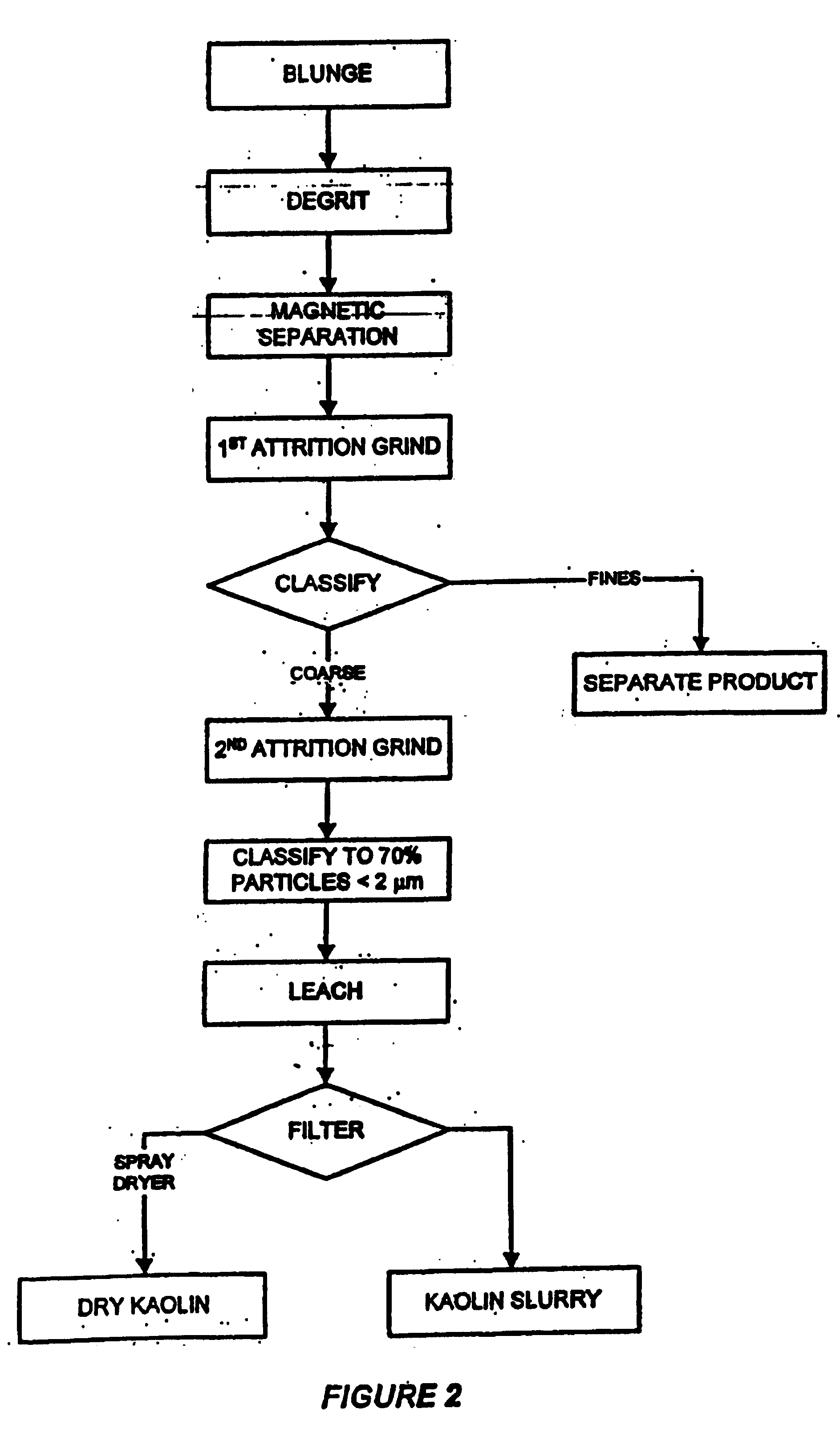

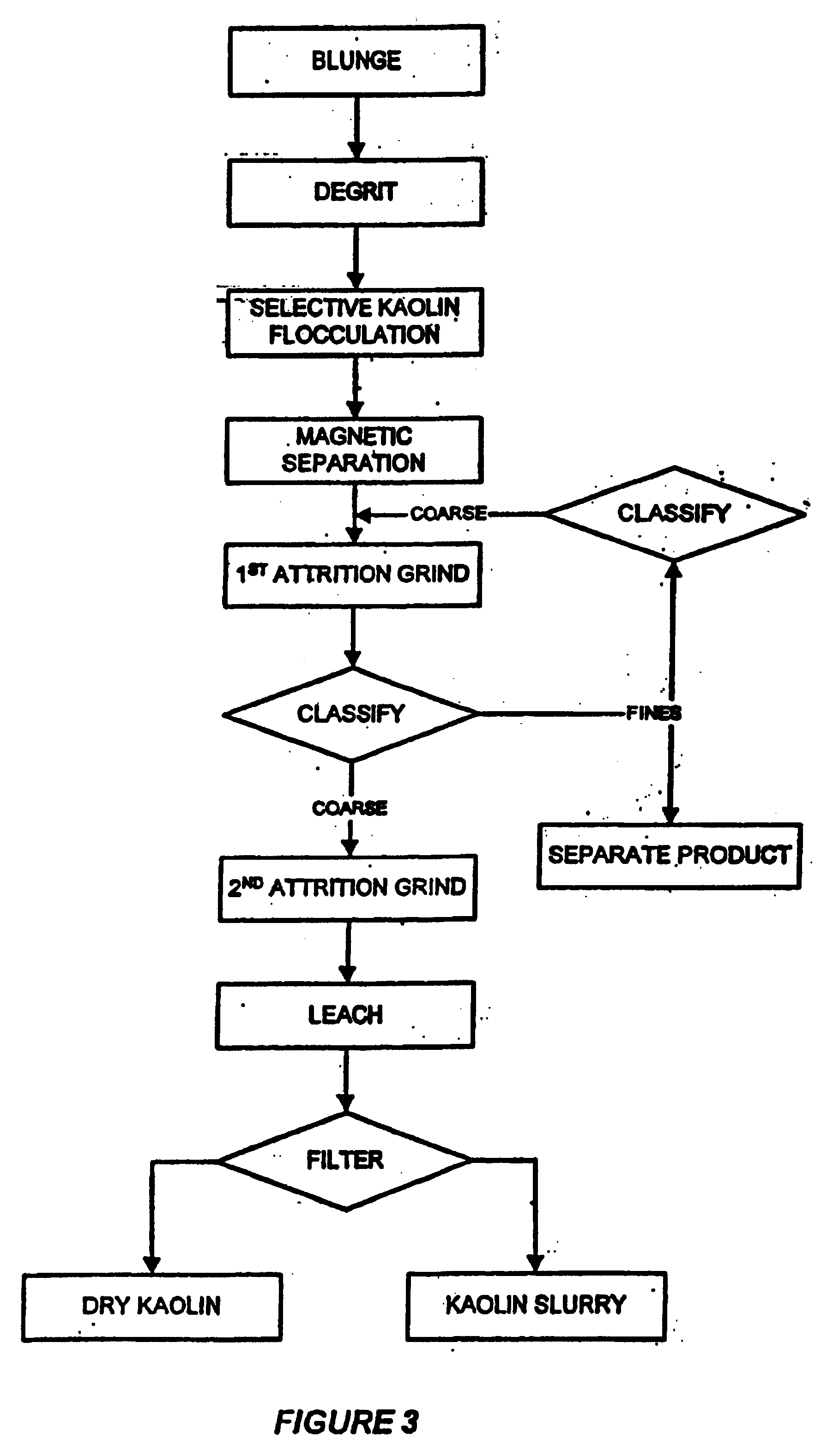

Hyperplaty clays and their use in paper coating and filling, methods for making same, and paper products having improved brightness

InactiveUS20060009566A1High crystallinityLight scattering is detrimentalPigmenting treatmentPaper coatingOptical propertyPulp and paper industry

The present invention relates to a hydrous kaolin product having improved optical properties, for example, when used in the production of paper products. The present invention comprises an improved barrier coating for paper and a method of making the coated paper. The present invention also comprises an improved method from making filled and coated paper products. The present invention uses a composition comprising kaolin having a shape factor of at least about 70:1, such as at least about 80:1 or at least about 100:1.

Owner:IMERYS USA INC

Kaolin product for catalytic cracking catalyst and preparation method thereof

ActiveCN101250427AEasy to replaceQuick changeCatalytic crackingSilicon compoundsPtru catalystKaolinite

The invention relates to a kaolin product for catalytic cracking catalyst and the process for preparation. The process for preparation comprises the following steps: stirring to evenly mix kaolin raw ore, water and dispersing agent to get slurry, wherein slurry is combined through a hydraulic cyclone in turn to sort to get overflow, bleaching overflow to get pulp, and getting kaolin product for catalytic cracking catalyst after pulp is dewatered. Particle size distribution of kaolin product is that 325order sieve residue <=5ppm, the content which is less than 2um is bigger or equal to 92%, the average partial size is 0.5-0.8um, the composition control of kaolin product is that the content of Al2O3 is bigger or equal to 38%, the content kaolin group mineral is bigger or equal to 90%, wherein the proposition of galapectite and kaolinite is 1.2-2.5:1, the content of harmful impurity is that the content of K2O+Na2O is less than or is equal to 0.6%, and the content of Fe2O3 is less or equal to 0.4%. Catalytic cracking catalyst which is prepared by the invention has the advantages of little specific area, bigger hole volume, excellent antiwear property, strong capabilities of alkali resistant and anti-heavy metal pollution and the like.

Owner:中国高岭土有限公司

Papermaking coating kaoline brightening and viscosity reducing process

InactiveCN1528979AReasonable designControllablePigmenting treatmentPaper coatingCentrifugationKaolin clay

The invention bleaching and viscosity decreasing process for paper-making paint kaolin clay. The method adds in water, and sodium hexametahposphate into raw ore, and they are classified through triple-stage whirlcone. The tail ore are abolished, then carries on spiral classification, the bottom current is carried on with filler process, the outputted pulp are processed with high grad magnetic concentration, the iron-containing tail ore is abolished, then carries on centrifugation and desiccation, filtering desiccation, surface activating process, and dries them. The scheme is reasonable, easy to be controlled, the quality of the product is stable, the white rate of kaolin clay reach aboe 70%.

Owner:茂名高岭科技有限公司

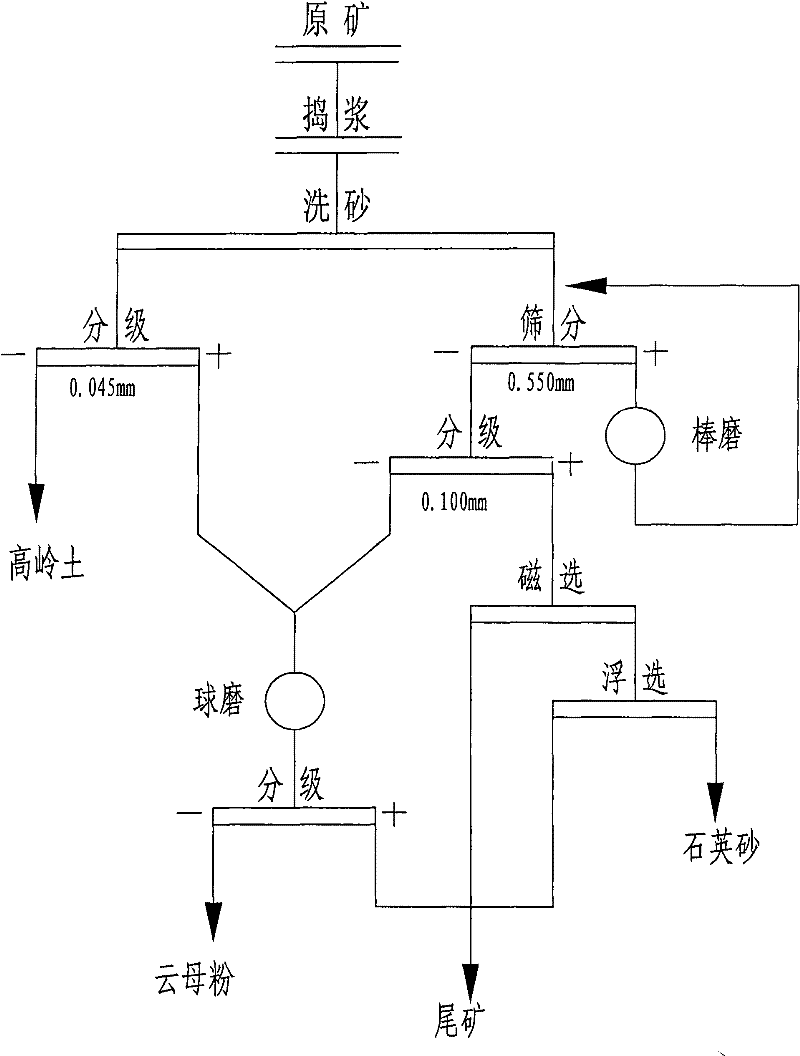

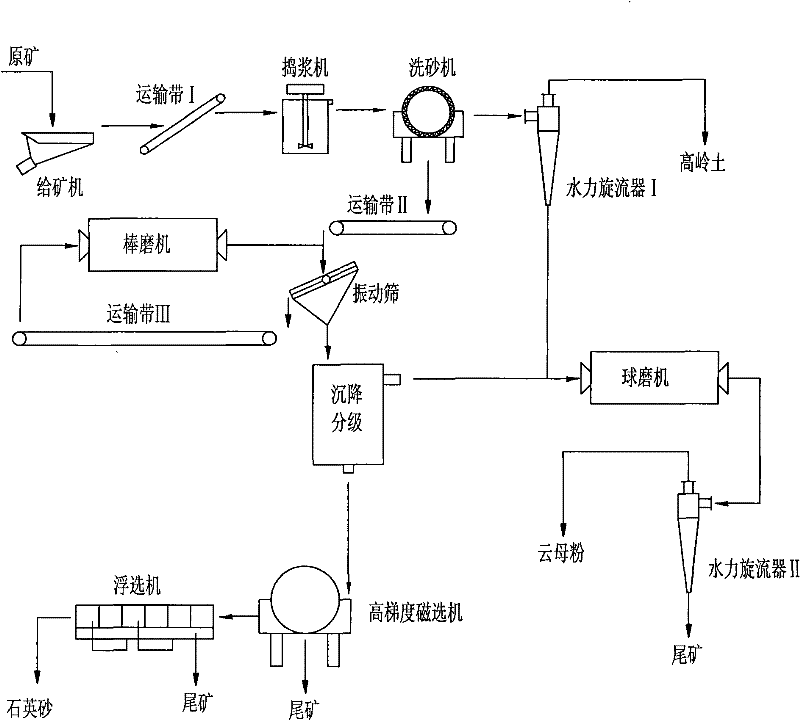

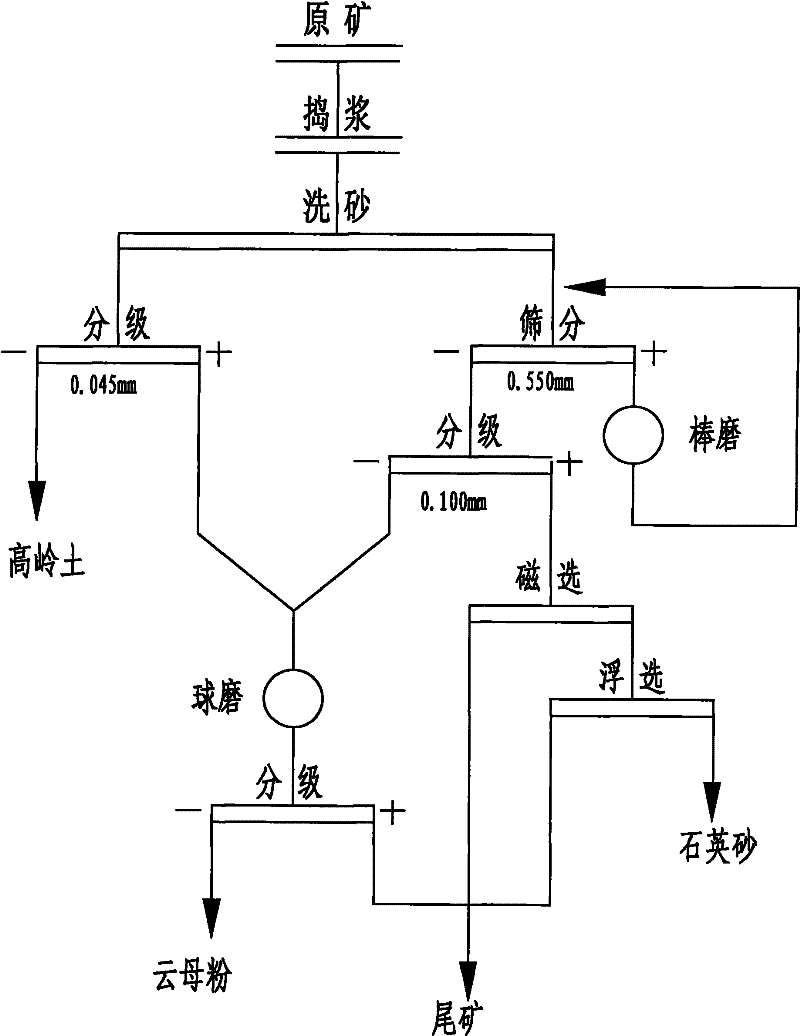

Method for processing low-grade kaolinite ore

InactiveCN102357400AImprove resource utilizationReasonable design of processing technologyWet separationResource utilizationNon magnetic

The invention discloses a method for processing low-grade kaolinite ore. The method comprises the following steps of: pulping crude kaolinite ore, washing sand, classifying fine mortar with a hydraulic cyclone I, overflowing to obtain a kaolinite product, screening coarse sand with a vibration screen of 0.55 millimeter, feeding screen overflow into a rod mill, feeding screen underflow into a sedimentation classifying process, making overflow and bottom flow of the hydraulic cyclone I enter a ball mill together, performing ore grinding, classifying with a hydraulic cyclone II, and separating overflow serving as mica powder and bottom flow serving as tailings; magnetically separating sedimentation-classified settled sand with a high-gradient magnetic separator to obtain a nonmagnetic product serving as concentrated ore and a magnetic product serving as tailings; and floating the magnetically-separated nonmagnetic product to obtain concentrated quartz sand. The method has a reasonable process design, a stable production process and good economic and social benefits, and is easy to control; kaolinite, mica and quartz can be separated from low-grade kaolinite ore; and meanwhile, the resource utilization ratio is increased.

Owner:HEPU HUTIAN KAOLIN

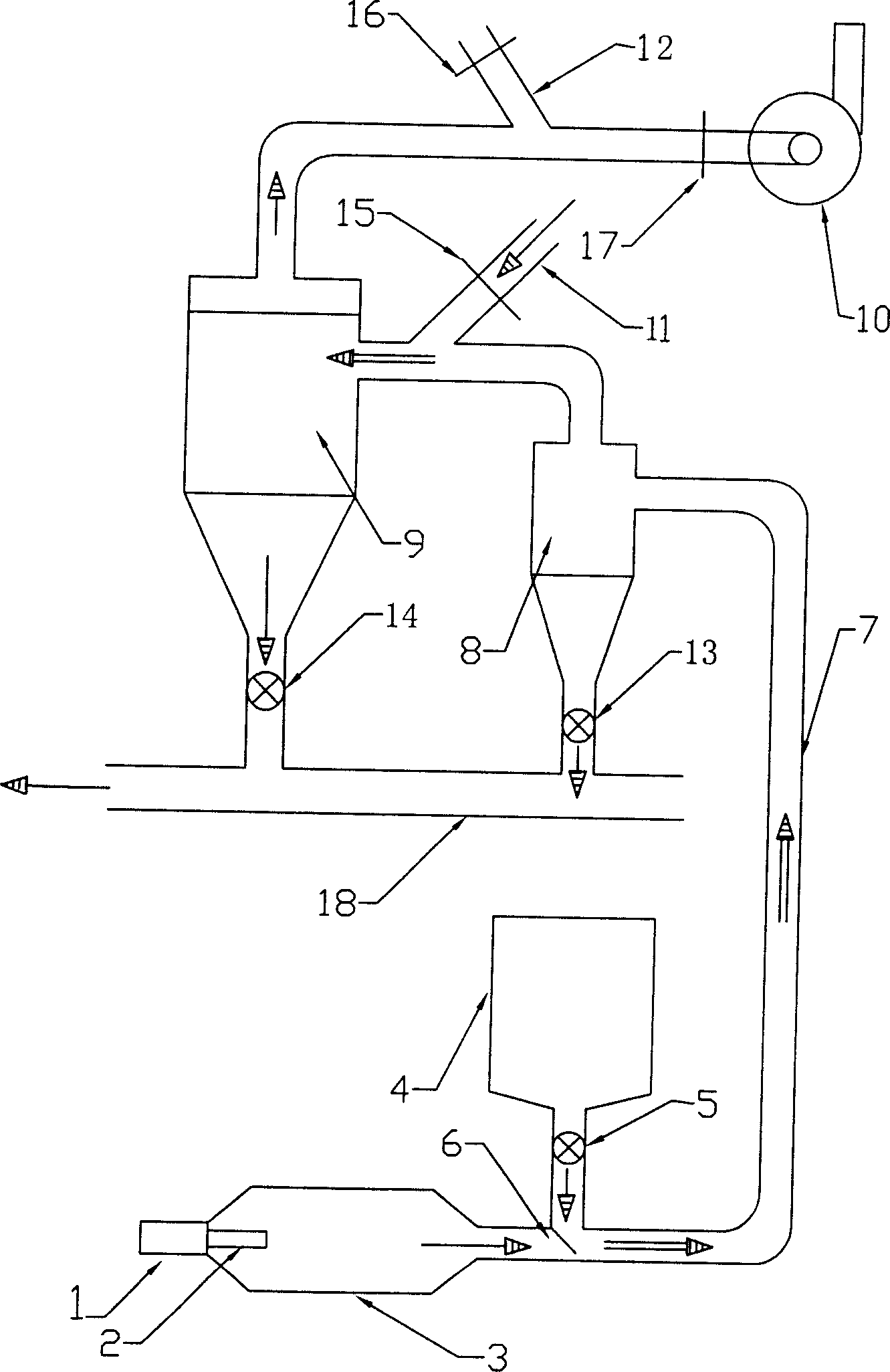

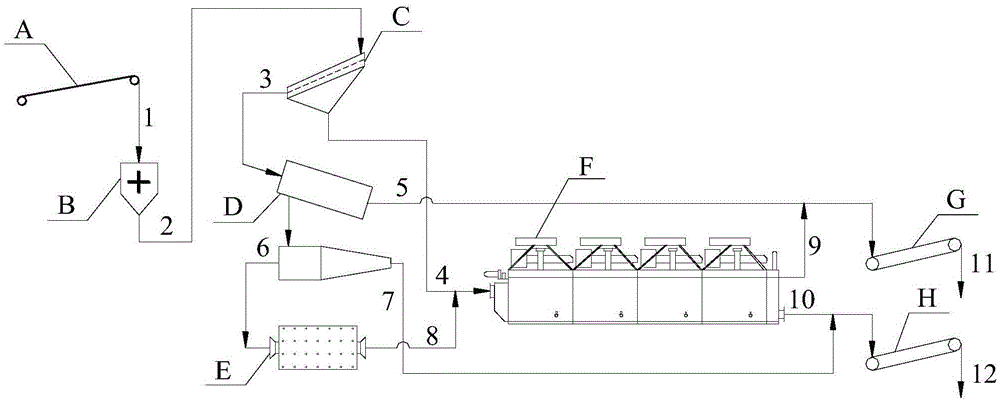

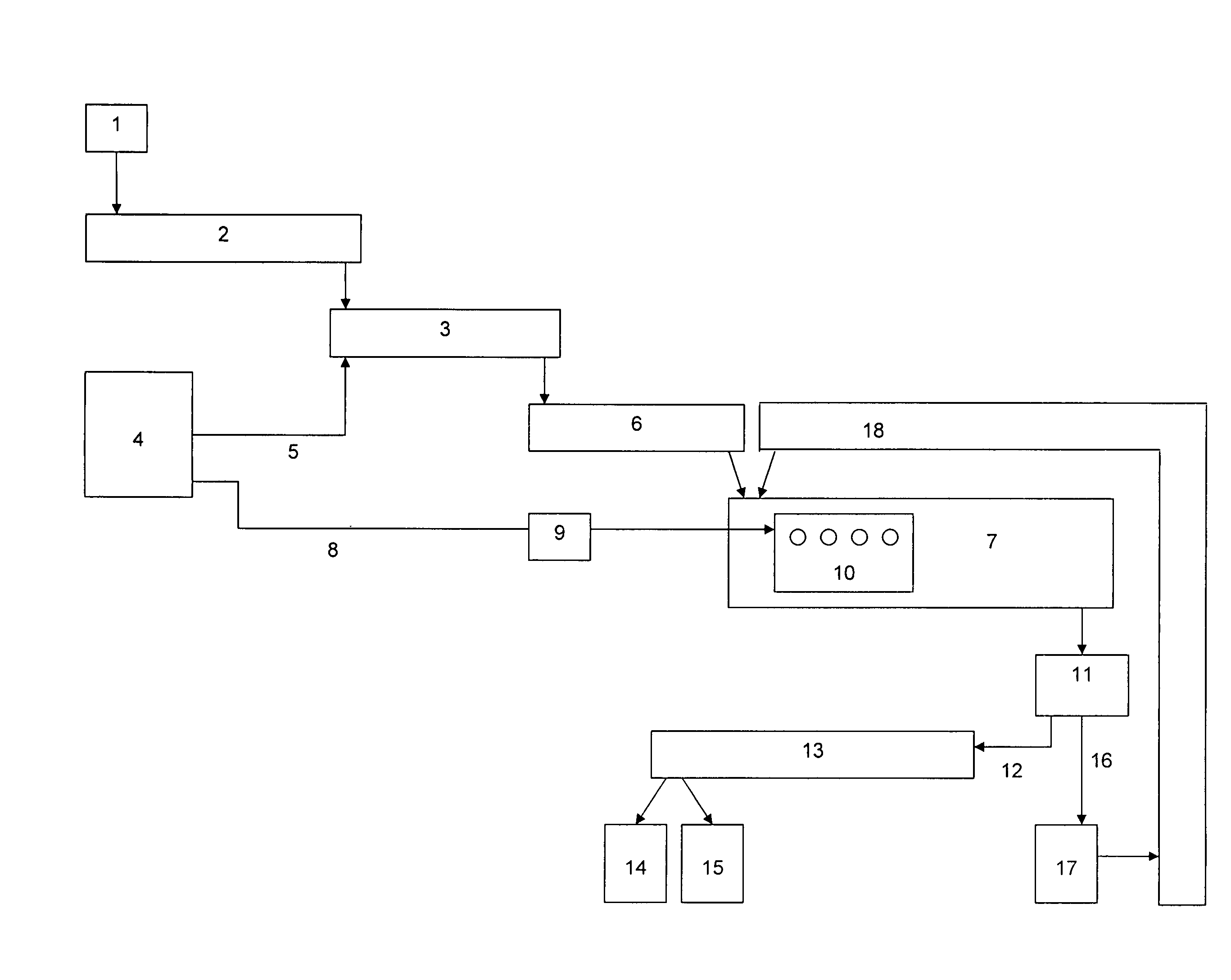

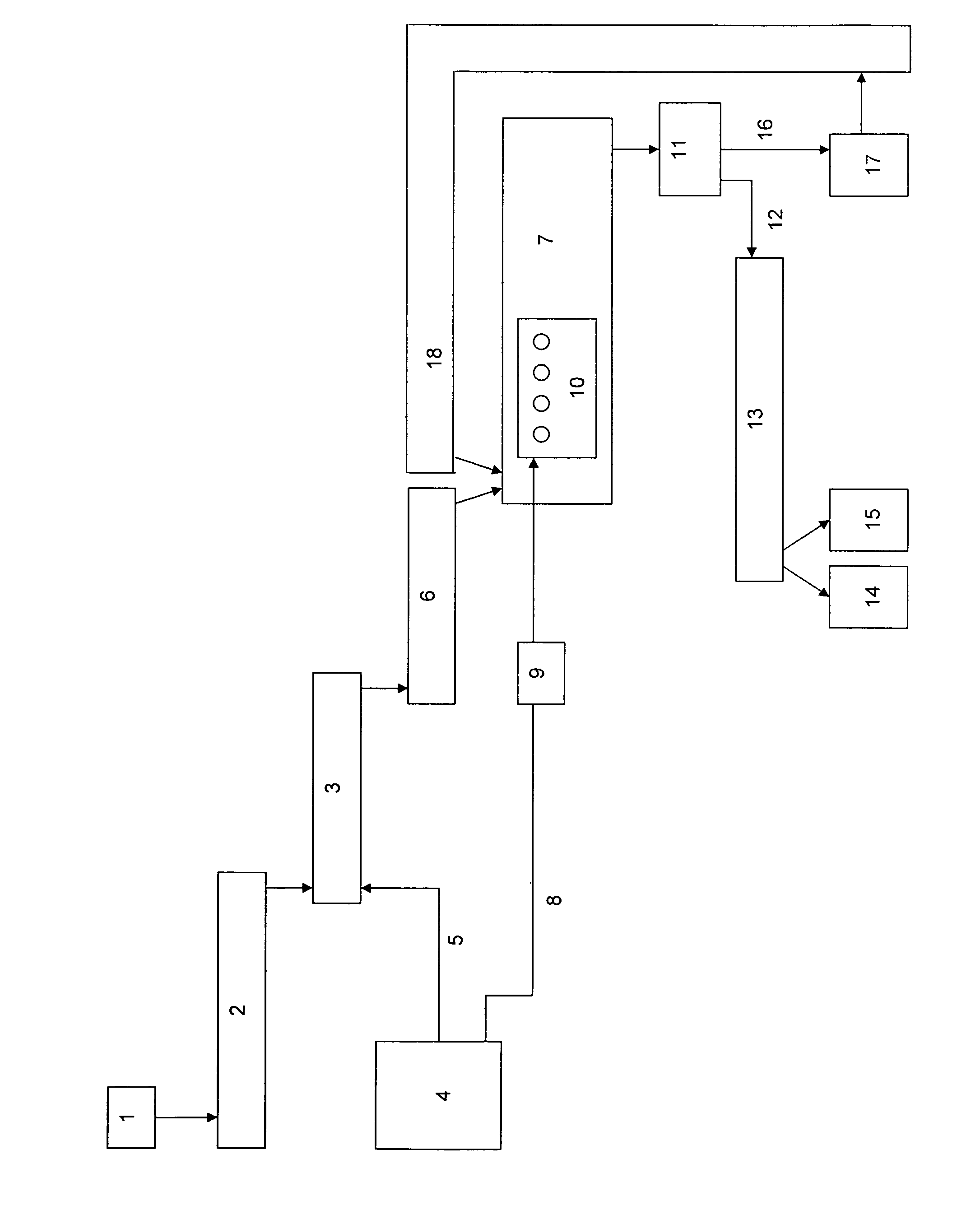

Technique of fluidized instant calcinations of kaolin in coal series

InactiveCN1915814AGood dispersionLarge gas-solid heat transfer areaPigmenting treatmentAluminium silicatesFlue gasEngineering

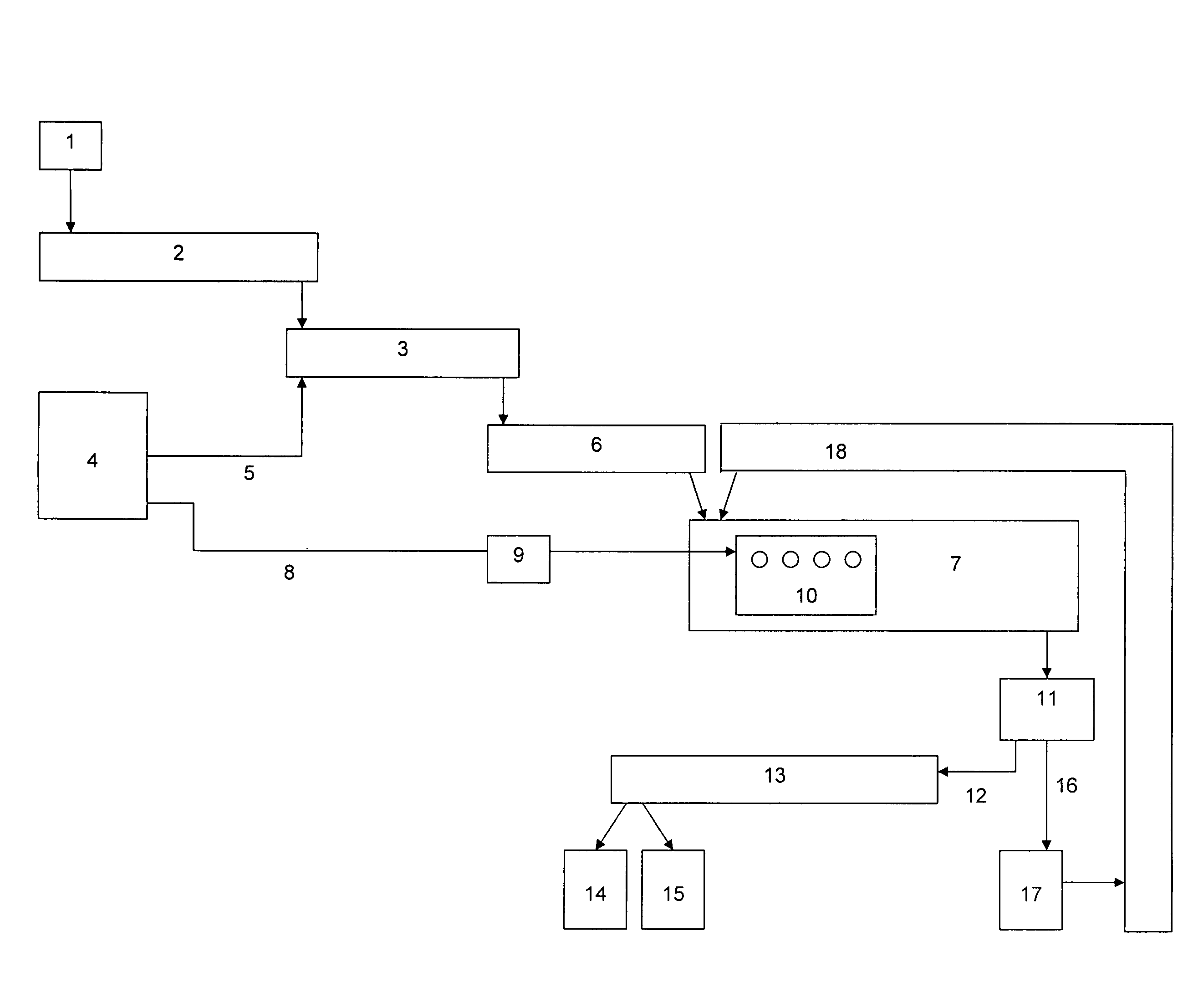

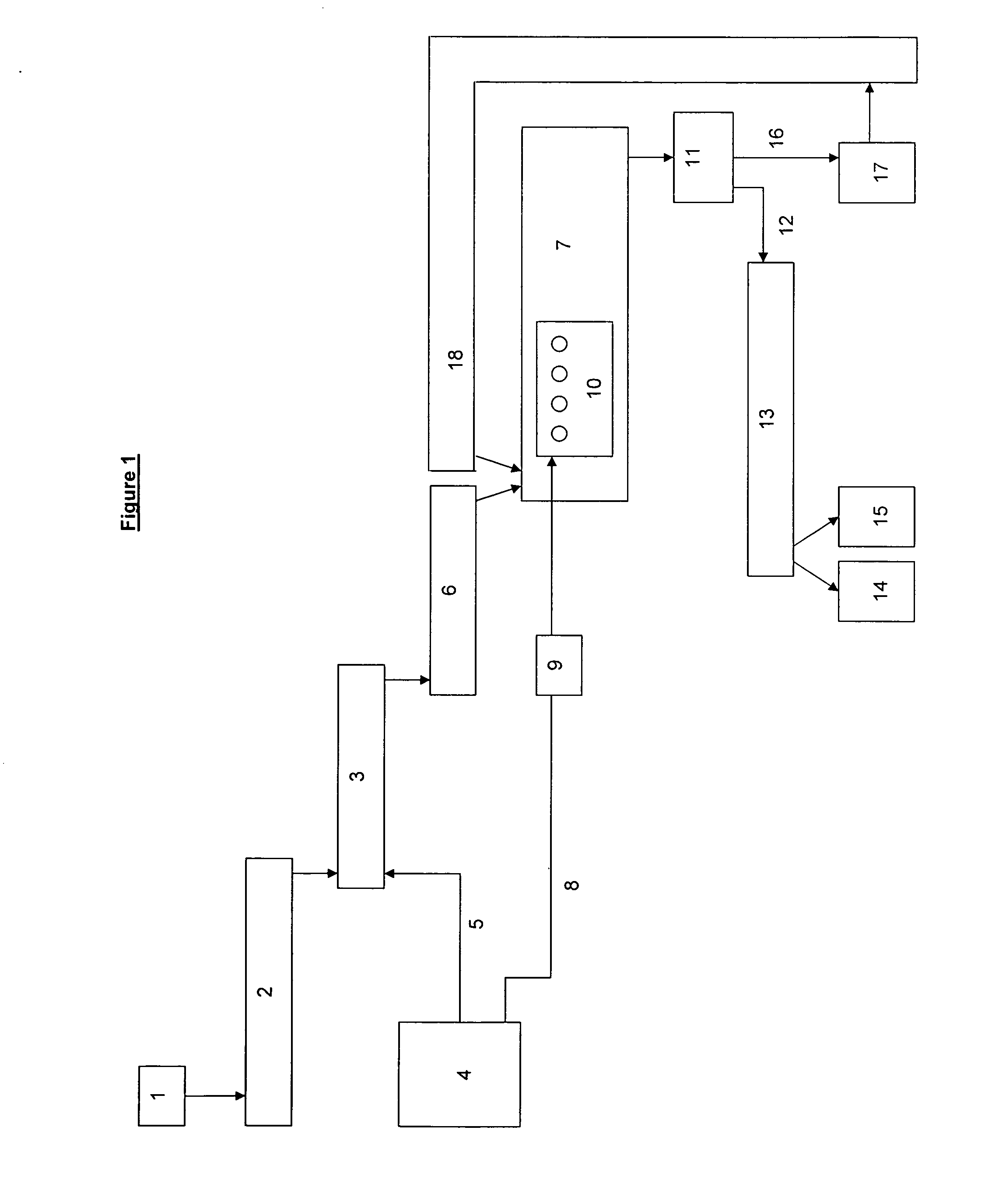

This invention relates to a fluid-state instantaneous calcining technique for calcining kaolin. The technique comprises a flue gas generating system, a loading system, a fluid-state calcining system, a gas-solid separating system and a post-calcining system. The material is loaded into the fluid-state calcining system by the loading system, where it is mixed with high-temperate flue gas flow generated by the flue gas generating system for instantaneous calcining. The calcined material is introduced into the gas-solid separating system, and the collected solid is then introduced to the post-calcining system for whitening treatment. The instantaneous calcining time is adjusted by the valve. The method can realize large-scale and continuous industrial manufacture, and can effectively reduce the time and energy consumption of post-calcining whitening treatment. The calcined kaolin product has improved oil-absorbency, hiding contrast rate and light extinction performance.

Owner:内蒙古蒙西高岭粉体股份有限公司

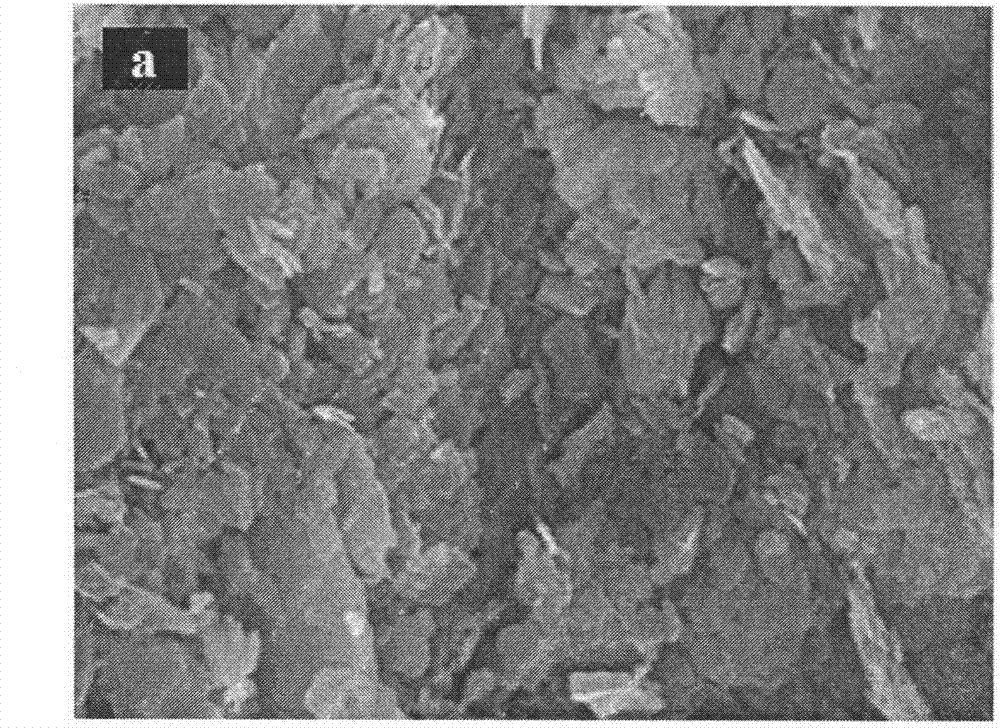

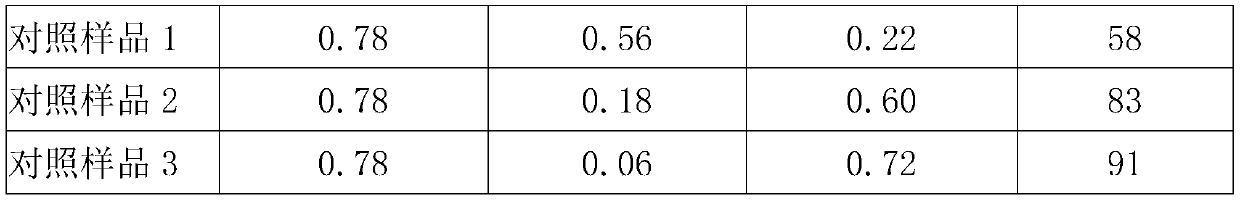

Preparation method of nano kaolin

InactiveCN102745702ALarge specific surface areaGood dispersionNanotechnologySilicon compoundsActive agentKaolin clay

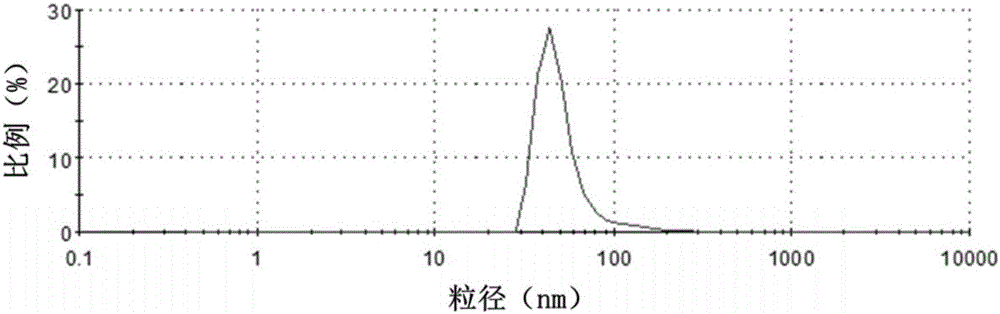

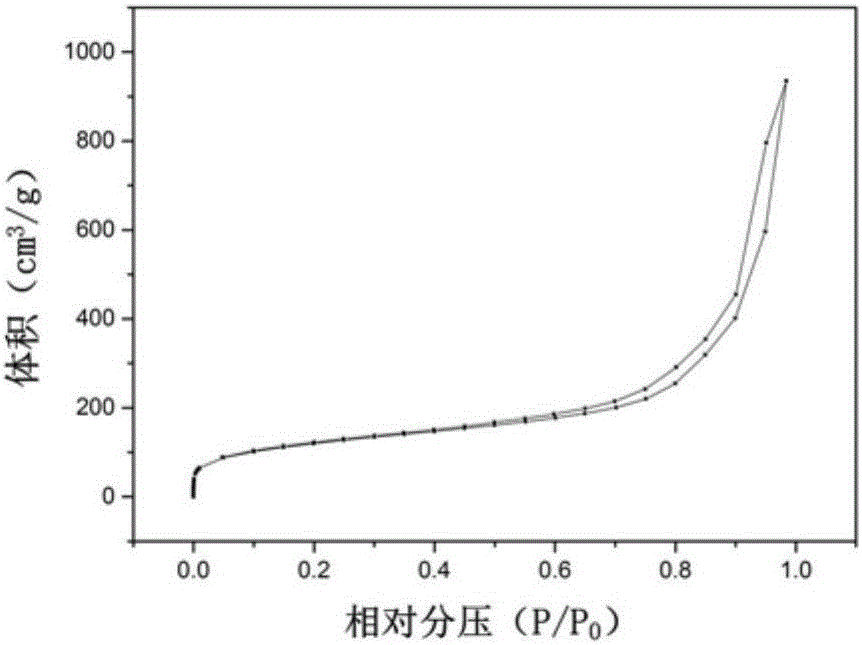

A preparation method of nano kaolin comprises steps of: adding kaolin ore into water by a weight ratio of 1:75 for magnetic force stirring; successively adding deferrization agent, intercalator and surfactant in the slurry solution for continuous normal temperature stirring; filling the mixed solution into an autoclave, screwing a cover of the autoclave, carrying out a constant temperature hydrothermal reaction at 150-170 DEG C, and naturally cooling the autoclave to room temperature; taking out solid powder in the autoclave, and washing the solid powder till a pH of a washing liquid close to 7; and finally drying the solid powder to obtain a target nano kaolin product with high grade. The whole process of the invention has the characteristics of simple operation, low cost and strong feasibility; especially, steps of mixing the three reagents including deferrization agent, intercalator and surfactantand, with the kaolin slurry, and then conducting hydrothermal reaction obviously have advantages of simple process, high repeatability and no secondary pollution; and the nano kaolin prepared by the reparation method has a scale-like micro-morphology, large specific surface area, and good dispersibility in water.

Owner:MINNAN NORMAL UNIV

Coal series kaolinite rock calcining method capable of reducing calcining temperature

The invention belongs to the field of comprehensive utilization of coal series kaolinite rock, and in particular relates to a coal series kaolinite rock calcining method capable of reducing calcining temperature. The calcining method comprises the following steps of: mixing crushed coal series kaolinite rock with water and sylvite to obtain an intercalation composite slurry; centrifugally separating the intercalation composite slurry to obtain an intercalation composite binder and intercalator solution; putting the intercalation composite binder into a calcining furnace, raising the temperature to 350-450 DEG C, keeping the temperature constant for 2-2.5 hours, then raising the temperature to 600-700 DEG C, and then keeping the temperature for 0.5-1 hour; washing and filtering; preparing the filtered coal series kaolinite rock into slurry, and performing spray drying to obtain a finished superfine calcined kaolin product. The calcining method provided by the invention reduces energy consumption, and the calcined kaolin has high activity.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for whitening kaolin by using surface cladding method

InactiveCN102786818APlay a shielding roleHigh whitenessPigment physical treatmentMineral SourcesAluminum sulphate

The invention relates to a method for whitening kaolin by using a surface cladding method. The method comprises adding water and a dispersant into the kaolin to prepare slurry with a concentration of 40 to 60 %, adjusting a pH value to 7 to 8, and ball milling for 60 to 120 minutes with a high speed so as to fully activate the surface of the kaolin particles; and then adding an aluminum sulfate or aluminum nitrate solution into the kaolin slurry, fully mixing with stirring, slowly adding ammonia water, continuing to stir and react, standing, filtering and drying to obtain the highly whitened kaolin product. Through detection, the surface of the kaolin product is coated with an Al(OH)3 deposited layer which can shield dyeing substances in the kaolin and significantly improve whiteness of the product. The whitened kaolin through cladding can be used as papermaking paint, and especially as high-quality filling materials in the fields of plastic, rubber, etc. The implementation of the method can greatly increase added value of the low-quality kaolin, enlarge application scope of the low-quality kaolin and improve utilization efficiency of mineral resources.

Owner:赵曰浩

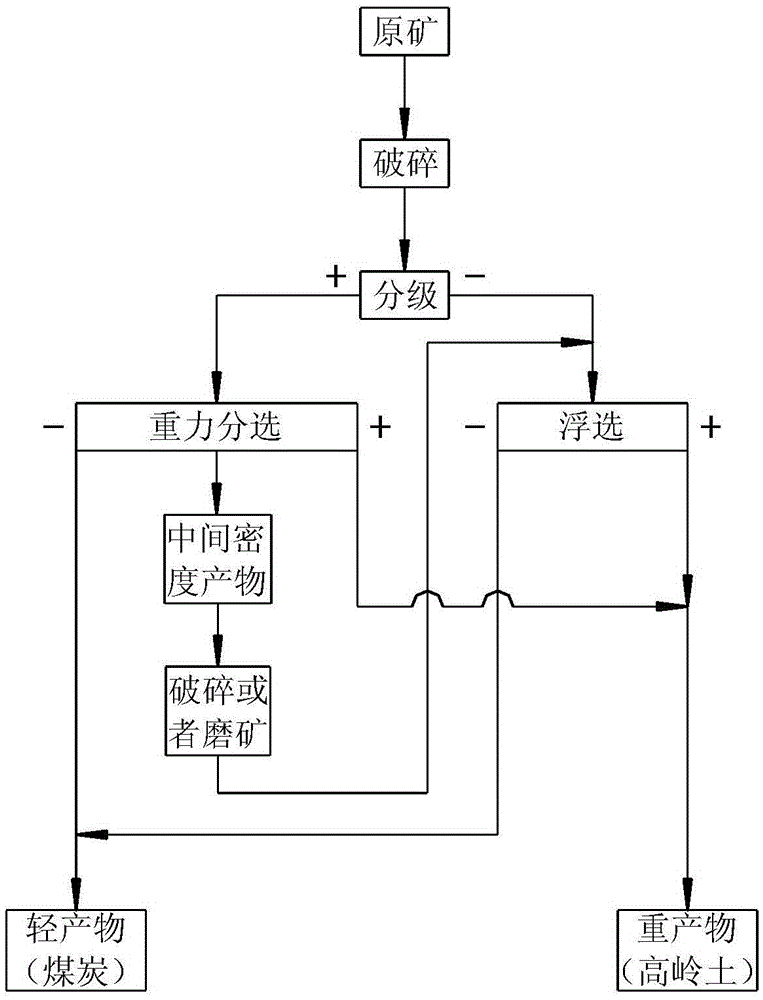

Decarbonization process for coal series kaolin

The invention discloses a decarbonization process for coal series kaolin. The decarbonization process comprises crushing, grading, reselection, reselected medium-density product crushing or ore grinding, and flotation and specifically comprises the steps of crushing coal series kaolin raw ore, and grading crushed products; feeding coarse particle products obtained by grading into reselection equipment for sorting to obtain reselected low-, medium- and high-density products; mixing the reselected medium-density products subjected to crushing or ore grinding with fine particle products obtained by grading and feeding into flotation equipment for sorting to obtain flotated foam products and products in a flotation tank; recycling the reselected low-density products and the flotated foam products which are coal resources, and recycling the reselected high-density products and the products in the flotation tank which are kaolin. According to the process, organic carbon in the coal series kaolin can be efficiently removed, and kaolin products which are higher in purity and more applicable to further deep processing are obtained; furthermore, the decarbonization process can efficiently recycle and use the organic carbon, so that waste of the coal resources is avoided, and the environment is protected.

Owner:CHINA UNIV OF MINING & TECH

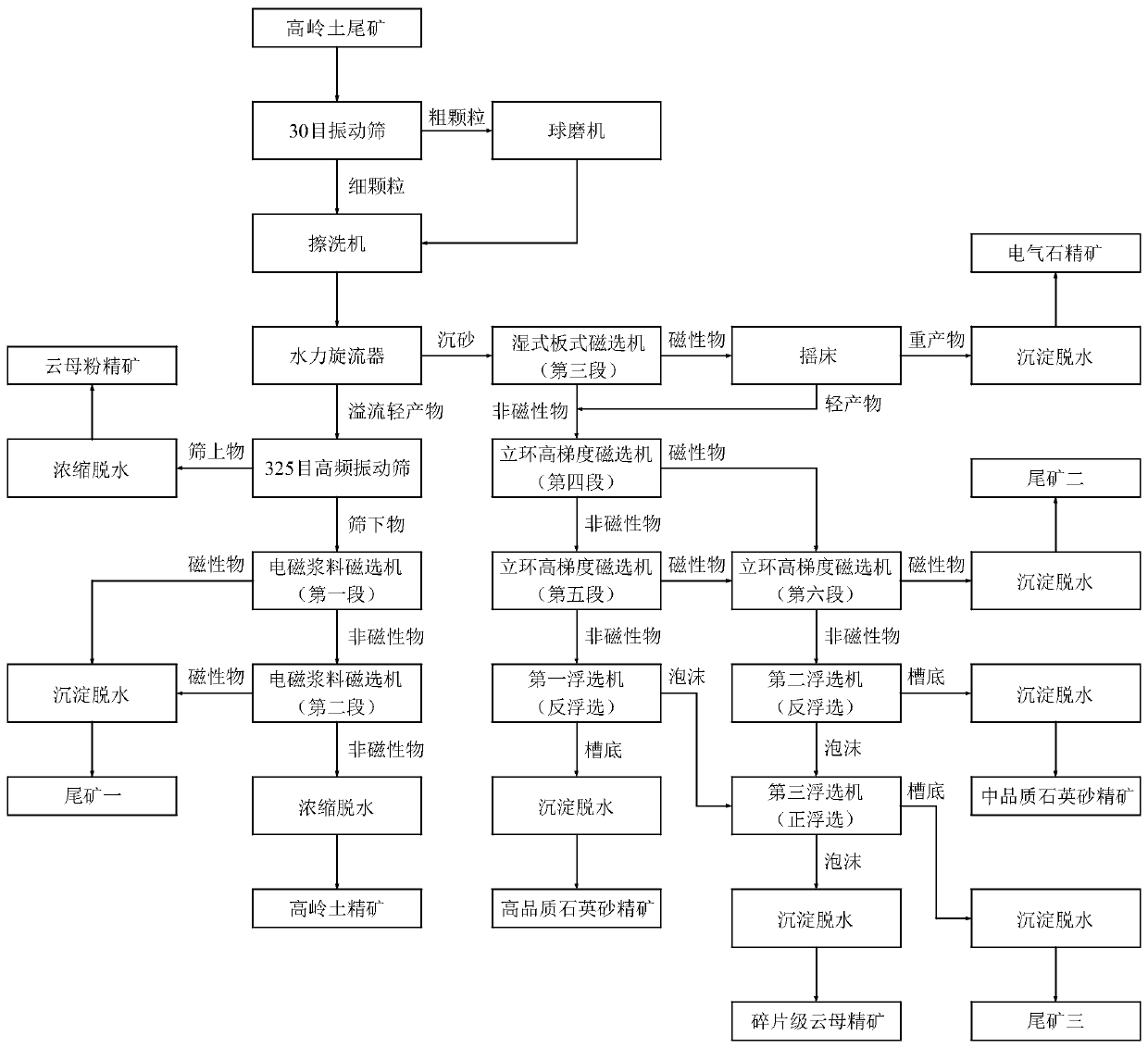

Comprehensive utilization method of sandy kaolin tailings containing tourmaline, muscovite and quartz sand

ActiveCN110201791AEffective control of granularityImprove recycling ratesSolid separationMechanical material recoveryKaolin claySlurry

The invention discloses a comprehensive utilization method of sandy kaolin tailings containing tourmaline, mica and quartz sand. The method comprises the following steps that after the sandy kaolin tailings are subjected to screening operation, various products such as mica powder, kaolin, the tourmaline, fragment-grade mica, quartz sand, and magnetic tailings are separated through grinding of coarse products, stirring and rinsing of fine products, hydrocyclone classification, high-frequency vibrating screen screening, and magnetic separation, gravity separation and flotation combined beneficiation process flows by using an electromagnetic slurry magnetic separator, a wet-type plate magnetic separator, a vertical-ring high-gradient magnetic separator, a shaking table, a flotation machine and like. According to the method, the magnetic separation, the gravity separation and the flotation combined beneficiation process is adopted, concentrate products such as the high-quality quartz sand, the tourmaline, and the mica are obtained, meanwhile, the residual kaolin products are recovered; and magnetically separated ferric silicate minerals can be used as building materials or cement rawmaterials, the comprehensive recovery utilization rate of secondary resources of the kaolin tailings is improved to the greatest extent, zero discharge of the tailings is achieved, and high economicaland social benefits are achieved as well.

Owner:SHANDONG HUATE MAGNET TECH

Production method of superfine kaolin

The invention relates to a production method of superfine kaolin, comprising the steps of collecting slurry, removing impurities, preparing kaolin pulp, classifying by adopting a horizontal screw centrifuge, chemical bleaching, washing to remove the iron, filter pressing, dispersing to prepare the slurry, sieving, spray drying and the like. The invention has simple operation, low cost and stable product quality. The kaolin product with mass percentage of 93-99.9 percent and with the grain diameter of -2 microns can be obtained by classifying with the horizontal screw centrifuge without delaminating.

Owner:MAOMING PETROCHEM MINING IND

Method for bleaching high-concentration kaolin pulp

InactiveCN101445249AImprove product qualityReduce consumptionSilicon compoundsHigh concentrationKaolin clay

The invention relates to a method for bleaching high-concentration kaolin pulp. The kaolin pulp concentration is 25%-30%. The method comprises the following steps: adding an alkaline agent to water, mixing and adding rongalite to prepare rongalite aqueous solution, wherein, the weight ratio of sodium hydroxide to sodium carbonate in the alkaline agent is 0.33-0.47:10, the weight ratio of the rongalite to the alkaline agents is 100:10.3-10.5, rongalite volume concentration of the rongalite aqueous solution is 10-15% and the pH value of the rongalite aqueous solution is 7.0-8.0; delivering the rongalite aqueous solution and the high-concentration kaolin pulp to a conduit by a pump for mixing, and delivering the mixture to a pulp storage tank, wherein, the added amount of the rongalite aqueous solution is 1.4-2.3% of that of the high-concentration kaolin pulp; and keeping standing and bleaching for 15-20 hours, and adjusting the pH value of the pulp to 2.5-3.0 after bleaching. The method has the advantages of reasonable technical proposal, easy control of operation, stable process, and the bleached high-concentration pulp is beneficial to subsequent filter pressing dehydration processing, which improves the production capacity, reduces the energy consumption and medicament consumption, lowers the production cost and stabilizes quality of kaolin products.

Owner:梁明

Preparation method for high-oil-factor ultra-fine kaolin

ActiveCN103496710AIt will not cause the sieve residue to exceed the standardWill not cause excessiveSilicon compoundsSodium dithioniteSlurry

The invention discloses a preparation method for high-oil-factor ultra-fine kaolin. The preparation method comprises the following steps of (1) drying kaolin raw ores in a drying box, and then smashing the kaolin raw ores; (2) mixing the smashed kaolin and water to obtain serous fluid, adding sodium dithionite and sodium polyacrylate in the serous fluid, electrically stirring the mixture at normal temperature, then adding sulfuric acids or hydrochloric acids and hydrogen peroxide in the mixture, and continuing stirring the mixture intensely; (3) pumping the serous fluid prepared from the step (2) in a grinding mill, grinding the serous fluid, and adding sodium dodecyl sulfate in the serous fluid in a grinding process; (4) performing solid and fluid separation on the serous fluid prepared from the step (3) by using a filter press to obtain filter cakes; (5) drying and distributing the filter cakes, and spraying the filter cakes by using a spraying machine to obtain kaolin raw powder; and (6) scattering and roasting the kaolin raw powder, annealing naturally, cooling the roasted kaolin powder at normal temperature, and scattering the kaolin powder to obtain the high-oil-factor ultra-fine kaolin products. In a preparation process, screen tailings of the products do not exceed standards, the obtained products is non-corrosive, is low in viscosity, and can be scattered in liquor easily.

Owner:广东科进应用技术研究有限公司

Kaolin bleaching method

InactiveCN105329908AImprove utilization efficiencyHigh market priceSilicon compoundsEthylene diamineHydrogen

A kaolin bleaching method is characterized by comprising steps as follows: water is added to kaolin raw ore, a raw stock is formed and subjected to sand removal and stage treatment by a hydrocyclone, and slurry is prepared; sulfuric acid is added to the slurry, the pH (potential of hydrogen) is adjusted to range from 2.0 to 3.0, and the slurry is placed in a closed container with a stirring function; the solid content of kaolin in the slurry in the closed container is measured, sodium hydrosulfite is added, and the adding amount of sodium hydrosulfite is 0.5%-1% of the solid content of the kaolin; then, the mixture is stirred for 4-8 min each time and reacts for 4-8 h; sodium hydrosulfite is added to the slurry obtained in the third step, and the adding amount of sodium hydrosulfite is 0.5%-1% of the solid content of the kaolin; the mixture is stirred again for 4-8 min each time and reacts for 4-8 h; after a reaction ends, EDTA (ethylene diamine tetraacetic acid) is added, the adding amount of EDTA is 0.1%-0.5% of the solid content of the kaolin, and the mixture is stirred uniformly; filter pressing is performed, and a bleached kaolin product is obtained. By means of the bleaching method, a remarkable deironing and whitening effect can be achieved, and the market price of the kaolin product is greatly increased.

Owner:中国高岭土有限公司

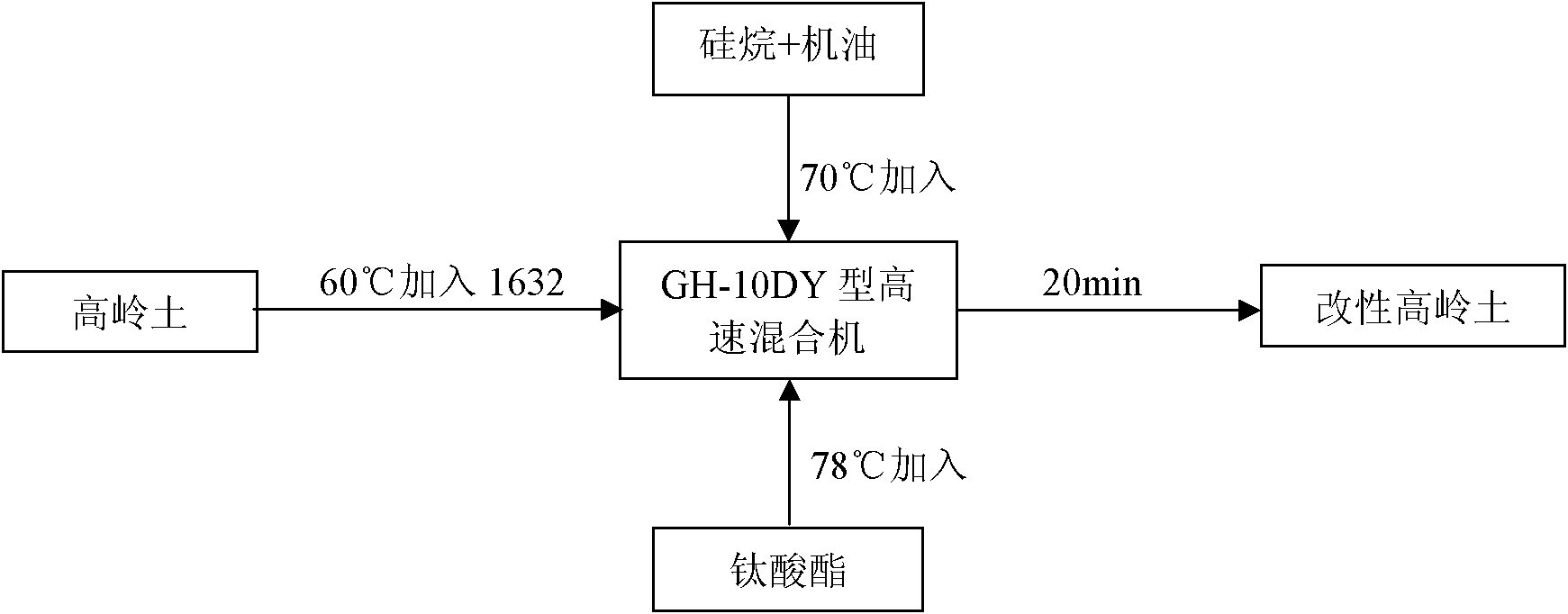

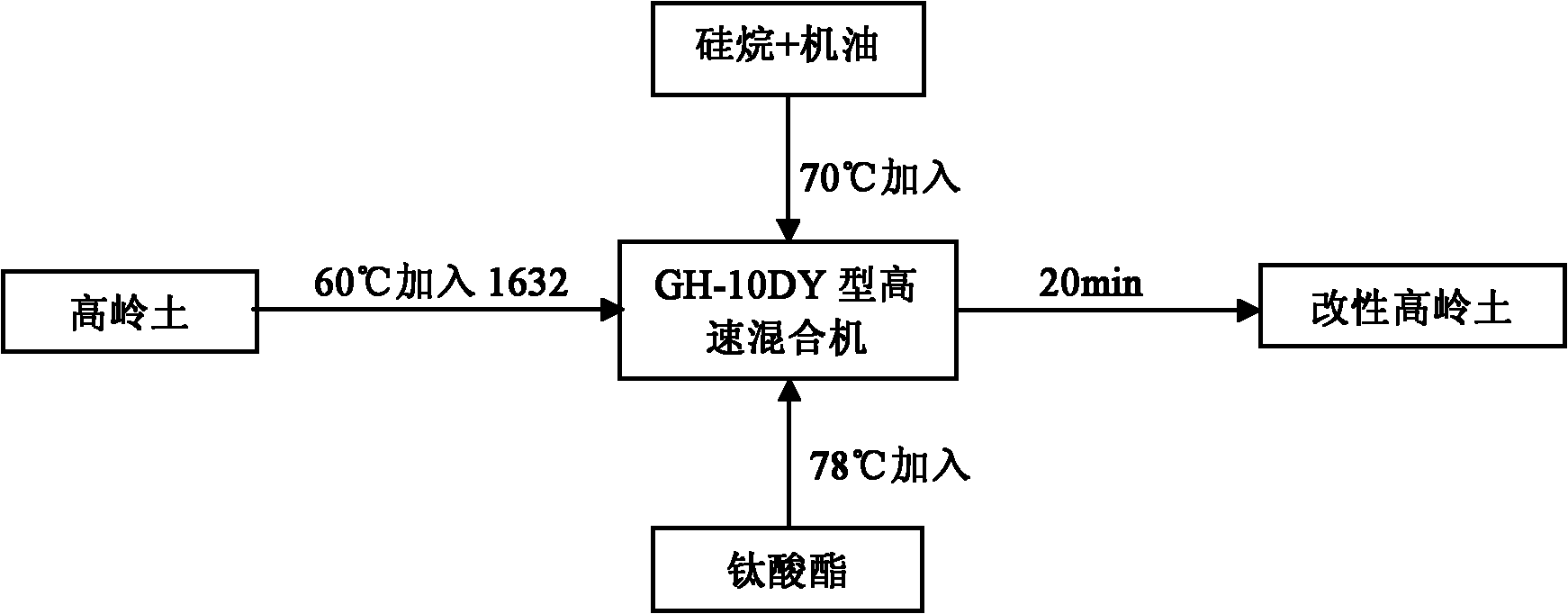

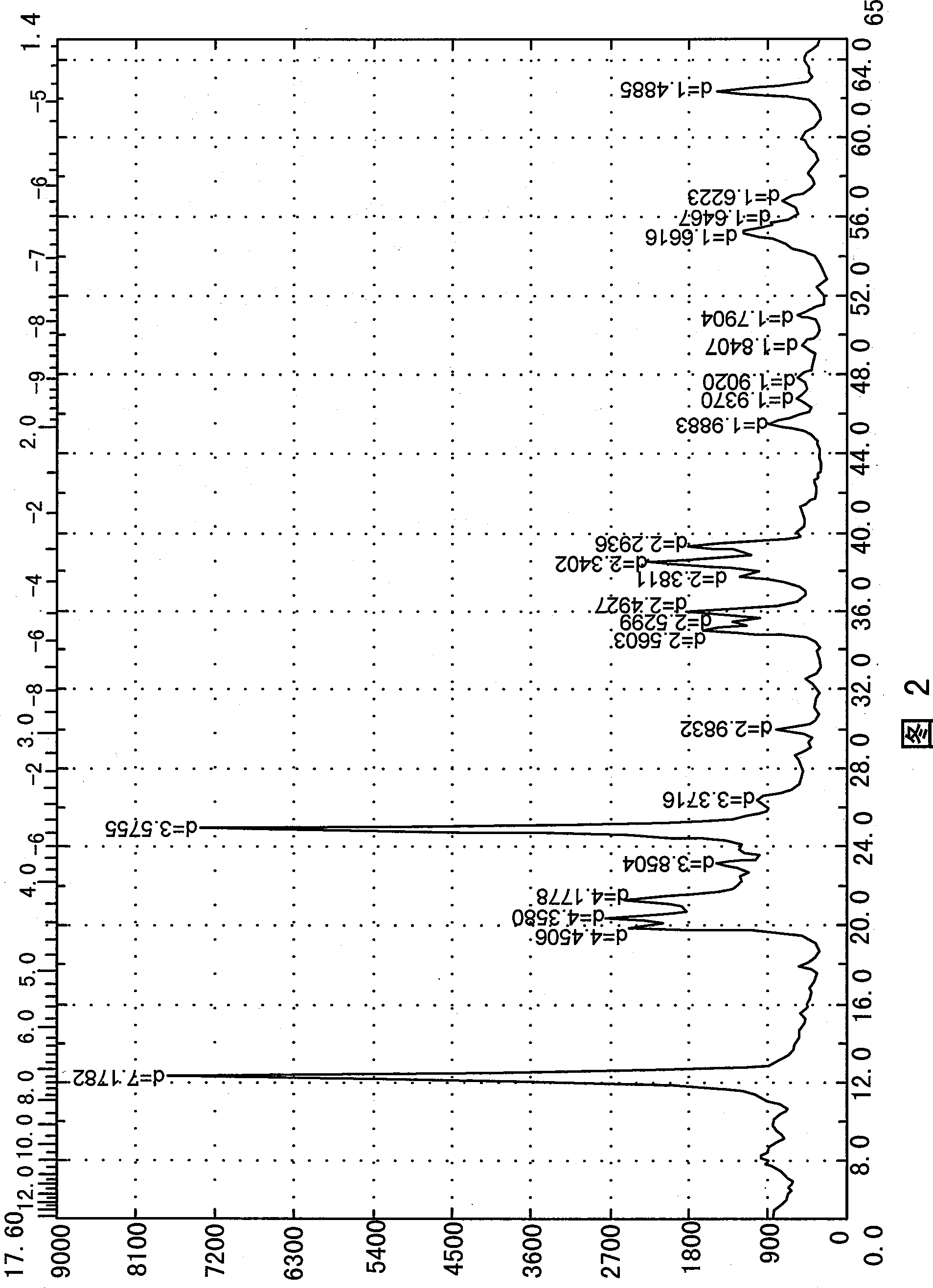

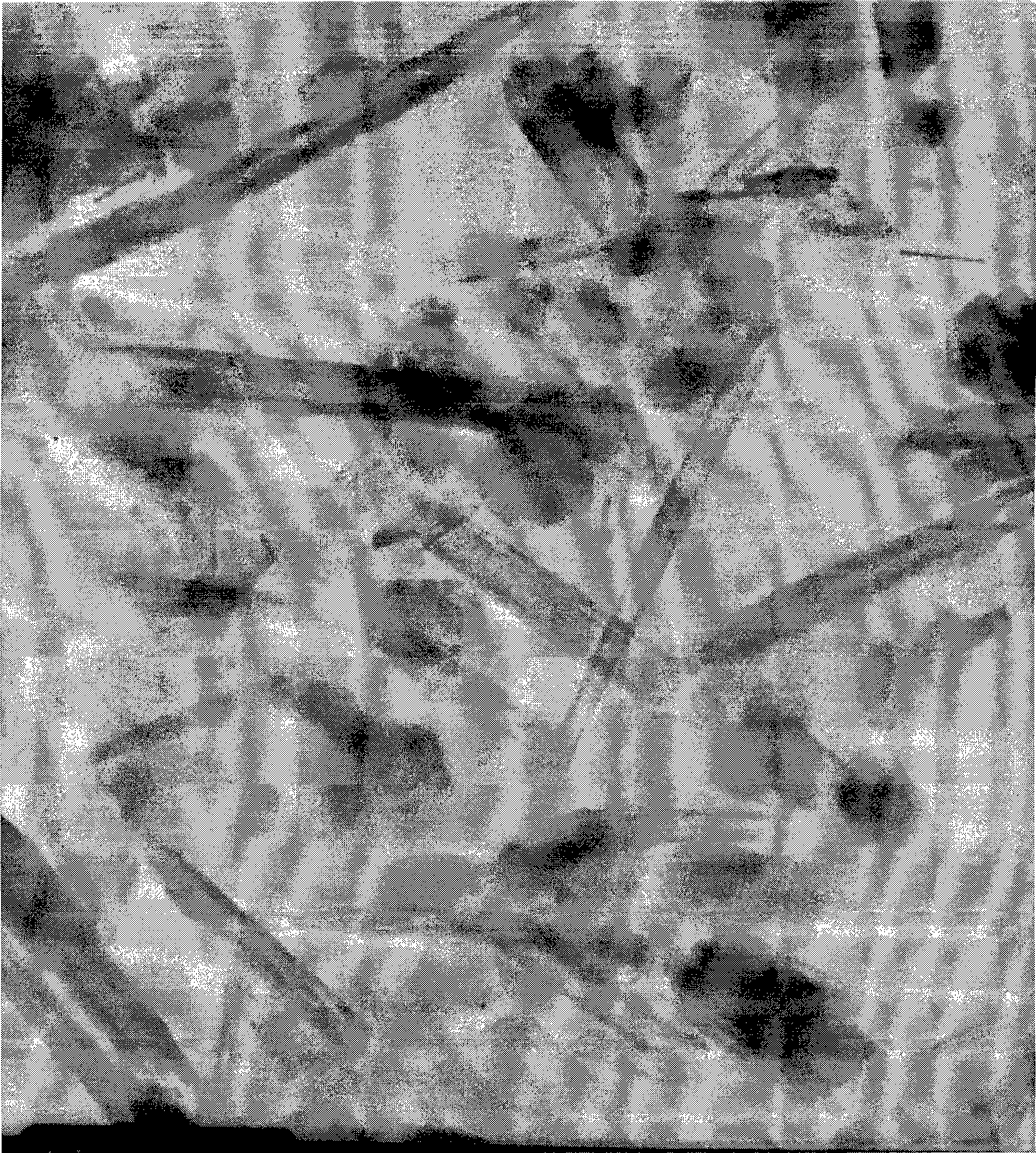

Preparation and application of modified kaolinic

InactiveCN101942123AReduce energy consumptionReduce pollutionSpecial tyresPigment treatment with organosilicon compoundsPolymer scienceVulcanization

The invention relates to a preparation method of modified kaolinic, which comprises the steps of surface modification and vulcanization of the kaolinic, particularly comprises the steps of: adding the kaolinic to a high-speed mixer to be stirred; and sequentially adding 1.5% of hexadecyl trimethyl ammonium bromide, the mixture of 2% of engine oil and 2% of silane, 2% of titanate in parts by mass of the karolinic at 50 to 80 DEG C and continuously stirring for 20min to prepare modified kaolinic products. The modified kaolinic is filled into butadiene styrene rubber to prepare kaolinic / butadiene styrene rubber composite materials by utilizing the vulcanization formula; and the mechanical property of the composite materials reaches the requirements on Import and Export Bicycle Tyre Physical and Mechanical Property National Standards GB / T1153-2002. The invention provides a simple modification technology and an industrial modification medicament to the surface modification of the kaolinic; the modification effect is good; and the prepared kaolinic / butadiene styrene rubber composite materials have the advantages of excellent mechanical properties, high cost performance and wide application prospects.

Owner:WUHAN UNIV OF TECH +1

Method for preparing kaoline products for catalytic cracking catalyst

ActiveCN101392183AControl contentImprove performanceCatalytic crackingSilicon compoundsChemical industryHalloysite

Owner:中国高岭土有限公司

Method for preparing kaolin from coal gangue

InactiveCN105692639ASolve the effect of whitenessSolve the problem of insufficient whitenessSilicon compoundsGranularityMicrometer

The invention belongs to the technical field of coal gangue treatment, and in particular relates to a method for preparing kaolin from coal gangue. To solve the problems of poor performance and low quality of kaolin produced by calcining kaolin from coal gangue, the steps include (1) ore washing: (2) adding calcium oxide, (3) suspension preheating, (4) adding titanium dioxide for mixing, (5) Calcination (6) Send nitrogen-oxygen mixed gas for cooling, and the oxygen content accounts for 5% of the total mass of the mixer. (7) Break up and classify: use a breaker to control the particle size of the materials in the silo to 1-2 μm. The kaolin processing process of the present invention is optimized, which solves the problem of insufficient whiteness of the product due to difficult carbon removal during the calcination process; only a small amount of high-quality titanium dioxide is added to improve the whiteness of the overall kaolin product.

Owner:张慧

Process for producing kaolin product for paper coating

InactiveUS20090050021A1Improve granulation effectNot contaminatePigmenting treatmentPaper coatingKaolin claySlurry

A process of producing a kaolin product for paper coating includes mining kaolin ores by hydromechanization and then producing kaolin slurry; classifying by centrifugal sedimentation; chemical bleaching; eliminating iron ions by circular rinsing; removing water by pressure filtration; producing slurry by dispersing filter cakes, in which complex dispersants, pH adjustor and intercalator are added; delaminating; classifying by vibrating sieve; and spray drying: spray driers are restructured by adding insulating layers on packing auger, elevator scoop and bunker at first; the kaolin slurry J which has passed through vibrating sieves is dried in high speed centrifugal spray drying tower and the moisture of kaolin powder is controlled in 3 wt. %-5 wt. %, and the kaolin product for paper coating is obtained. The process characterizes in stable properties, high efficiency, and high viscosity content and fine particle size of the kaolin products produced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

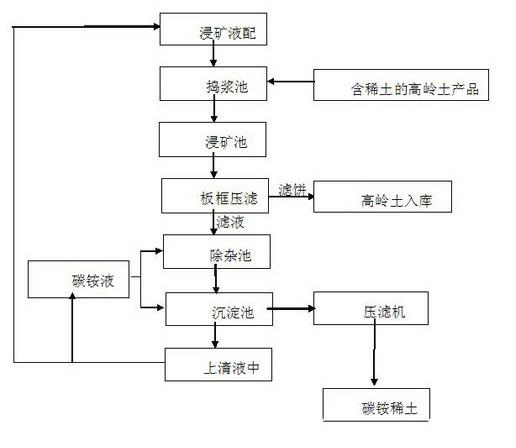

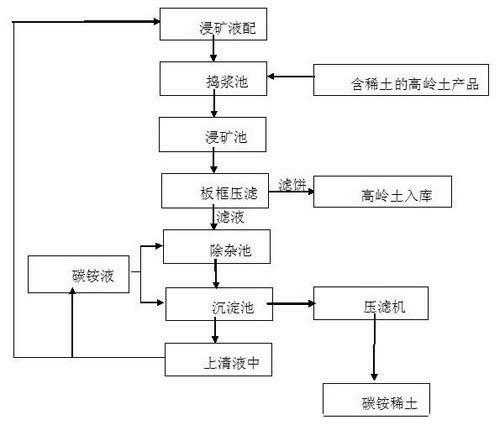

Method for extracting rare earth from kaolin product containing ion-type rare earth

InactiveCN102560159ASolve the defect of poor permeabilityResolve hard-to-separate defectsProcess efficiency improvementClay mineralsPlate pressure

The invention relates to a method for recovering ion-type rare earth from clay mineral, especially to a method for extracting rare earth from a kaolin product containing ion-type rare earth. The technology contains the following steps of: pretreating, smashing into a paste, leaching ore, carrying out plate pressure filtration and carrying out subsequent processing to finally prepare the rare earth product and kaolin. By the paste smashing technology, the kaolin product and a leaching solution are fully mixed, thus solving the defect of poor permeability of kaolin. The plate pressure filtration technology is adopted to solve the defect that it is hard to separate a solid from a liquid in the kaolin. By the adoption of the method, ion-type rare earth in the kaolin product can be fully recovered, resources can be effectively utilized, and enterprise benefits can be greatly increased. The whole technology is adopted to realize fully-closed circulation and thoroughly solve the environmental pollution problem caused by sewage discharge.

Owner:GANZHOU RARE EARTH MINERAL IND +1

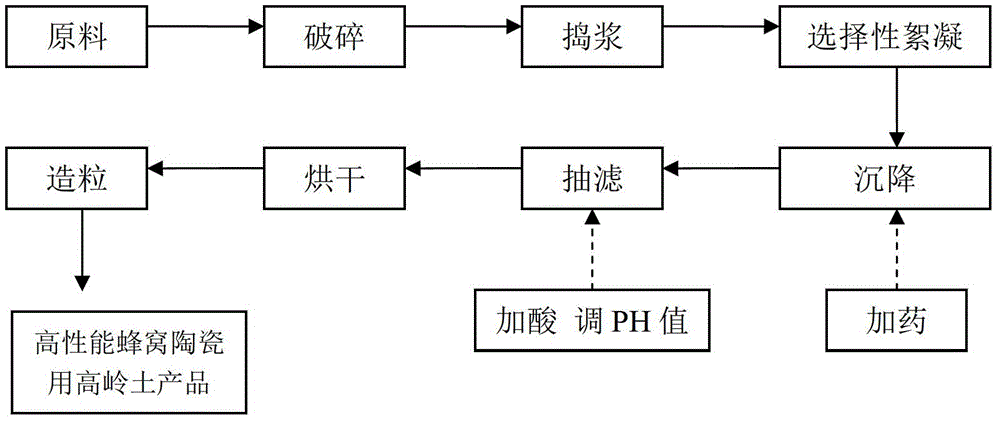

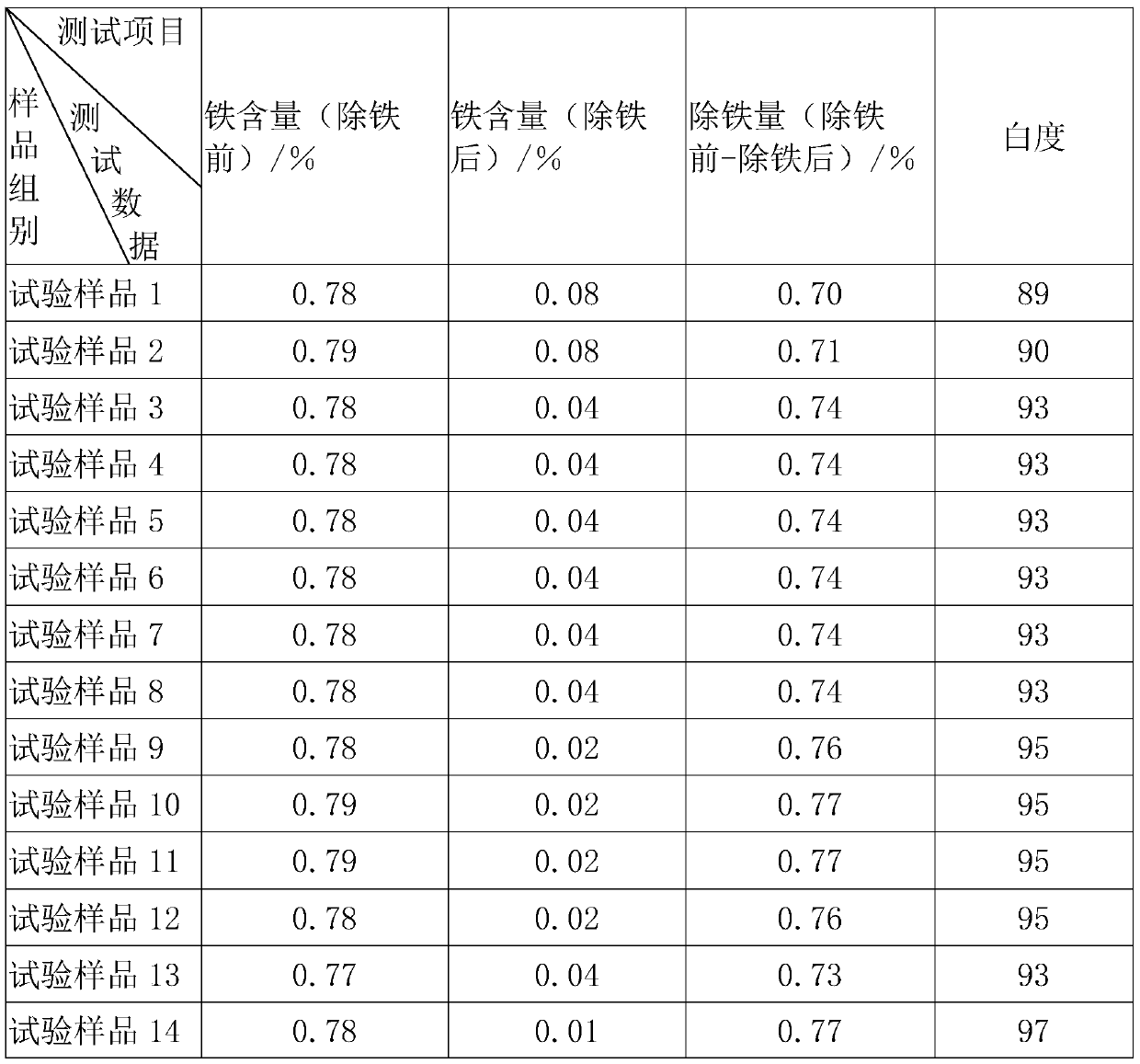

Preparation method of kaolin for high-performance honeycomb ceramic

The invention relates to a preparation method of kaolin for high-performance honeycomb ceramic, which is characterized by sequentially comprising the following steps: crushing; pulping; selectively flocculating; settling, controlling the mass concentration of the ore pulp at 12-18%, adding water glass of which the mass concentration is 7-13% and sodium hexametaphosphate, measuring the temperature and liquid level of the ore pulp in a settling basin, calculating the settling time according to a simplified empirical formula t=Tn*h / d2 based on the Stokes law (wherein d in the simplified formula represents the granule size of granules and is valued at 3), and standing at the settling time, wherein after standing, the granule size of granules of the underlayer ore pulp is more than 3 micrometers, and the granule size of granules of the supernatant ore pulp is less than 3 micrometers; and performing vacuum filtration, drying, and granulating to ensure that the mass percent of Fe2O3 contained in the kaolin product is less than or equal to 0.20%, the sum of the mass percents of contained K2O and Na2O is less than or equal to 0.4%, the content of granules of which the granularity is less than 2 micrometers is more than or equal to 91% and the bulk density is 0.30-0.36g / cm<3>. Thus, the invention satisfies application in high-performance honeycomb ceramic industry.

Owner:中国高岭土有限公司

Deironing process for kaolin

ActiveCN110862093AReduce iron contentLower sub-contentSilicon compoundsKaolin clayPulp and paper industry

The invention discloses a deironing process for kaolin, belonging to the field of kaolin production. The deironing process comprises the following steps: 1, putting a kaolin filter cake into a sulfuric acid pool, and uniformly dispersing the kaolin filter cake; 2, introducing hydrogen peroxide, carrying out stirring for 5-10 minutes, and keeping the pH value of the solution in the sulfuric acid pool to be 1-2; 3, feeding barium thiocyanate into the sulfuric acid pool, wherein a ratio of barium thiocyanate to the kaolin filter cake in the step 1 is 1: (100-150), and carrying out standing for 5-10 min to obtain de-ironed ore pulp; 4, sampling the de-ironed ore pulp, carrying out filtering to obtain a kaolin-removed solution, and if the solution is red, introducing the de-ironed ore pulp in the step 2 into a sulfuric acid solution for replacement and washing and then cyclically repeating the step 3 and the step 4, or if the solution is transparent, carrying out step 5; 5, washing the de-ironed ore pulp obtained in the step 3 with clear water, and carrying out filter pressing to obtain a secondary kaolin filter cake; and 6, drying and pulverizing the secondary kaolin filter cake to obtain a finished kaolin product. The deironing process has the advantages that the iron content in the kaolin is reduced, the whiteness of the kaolin is improved, and the applicability of the process ishigh.

Owner:漳州市龙华矿产有限公司

Process for preparing superfine high-activity metakaolin by utilizing vertical high-pressure mill

InactiveCN102060302ALow investment costReduce production investment costsAluminium silicatesChemical industryGranularityKaolin clay

The invention relates to a process for preparing superfine high-activity metakaolin by utilizing a vertical high-pressure mill, which is characterized by comprising the following steps of: firstly, crushing crude ore of metakaolin into 325+ / -30 meshes, grinding the crushed crude ore by the vertical high-pressure mill to obtain a superfine high-activity metakaolin powdery material with a particle size of 2-2.5mum, then conveying the superfine metakaolin to a rotary kiln feeding system by a fan, adding the superfine metakaolin into a rotary kiln by an automatic feeding machine, then carrying out high-temperature calcining on the superfine metakaolin in the rotary kiln with the temperature of 600-900 DEG C and the calcining time of 1-4 h, and preparing a superfine metakaolin product. The process has the advantages that the production cost is greatly reduced, the occupied area is only 50% of that of a ball mill system, the production efficiency is high, the energy is saved, the environment is protected, the granularity of a product is fine and uniform, the particle size of the product is 2.1-3.0mum, the minimum particle size can be controlled to be 2mum, and the uniformity is over 90%.

Owner:INNER MONGOLIA TIANZHIJIAO KAOLIN CO LTD

Aperture and particle size monodisperse controllable mesoporous silicon rapid hemostatic powder and preparation method

ActiveCN105903062AFast hemostasisGood hemostasisSurgical adhesivesPharmaceutical delivery mechanismAir atmosphereHEMOSTATIC POWDER

The invention discloses an aperture and particle size monodisperse controllable mesoporous silicon rapid hemostatic powder and a preparation method. The preparation method includes: 1) adding cetyl trimethylammonium bromide into water, and conducting nitrogen purging under stirring; 2) under stirring, adding n-octane, methyl methacrylate, tetraethyl orthosilicate and azobis(isobutylamidine hydrochloride) into the liquid obtained in step 1) in order, using lysine or tris(hydroxymethyl)aminomethane to adjust pH, carrying out reaction, and then performing standing to obtain a milky white suspension; 3) centrifuging the milky white suspension, and conducting centrifugal washing with anhydrous ethanol; and 4) in an air atmosphere, conducting calcination to remove a mesoporous template to obtain the white aperture and particle size monodisperse controllable mesoporous silicon rapid hemostatic powder. The hemostatic powder provided by the invention can stop bleeding rapidly, and is suitable for pre-hospital emergency treatment of serious bleeding patients, and has the characteristics of very fast hemostatic rate, hemostatic effect superior to chitosan and kaolin products, good biological and tissue compatibility, and no side effect.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Granulated kaolin compositions and processes for their production

ActiveUS20100107929A1Improve material handlingReduce dustPigmenting treatmentSynthetic resin layered productsSlurryMaceral

Disclosed herein are granulated kaolin compositions exhibiting at least one of improved material handling properties, low dusting during transit, easy make-down into mineral-water slurries, and requiring less energy to produce than spray dried kaolin products. The granulated kaolin compositions may, in one embodiment, be characterized by a moisture content ranging from about 12% to about 23% by weight relative to the total weight of the composition. In another embodiment, the granulated kaolin compositions may have an average granule size of greater than about 10 mesh. Also disclosed herein are granulated kaolin compositions having a moisture content ranging from about 12% to about 23% by weight relative to the total weight of the composition, wherein the composition is friable when subjected to a shear force. Further disclosed herein is a method for producing granulated kaolin compositions comprising mixing at least one kaolin slurry with at least one predispersed spray dried kaolin and agglomerating the resulting mixture. Still further disclosed herein is a system for producing granulated kaolin compositions comprising a first zone for mixing at least one kaolin slurry with at least one predispersed spray dried kaolin and a second zone for agglomerating the resulting mixture.

Owner:IMERYS USA INC

Process for preparing calcined kaolin for electrophoretic paint from gangue

ActiveCN106395839AUniform structurePerformance indicators exceedAluminium silicatesPaints for electrolytic applicationsElectrophoresisGranularity

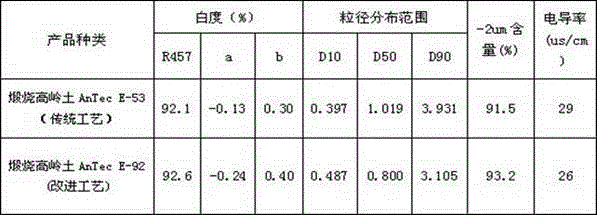

The invention relates to the preparation technology of kaolin from gangue, and concretely relates to a process for preparing calcined kaolin for electrophoretic paint from gangue. The process solves the problem of lower index existed in prior preparation of kaolin from gangue, and the process for preparing calcined kaolin for electrophoretic paint from gangue is provided. A route of the process comprises the following steps: preparation of gangue raw ore; primary dry method deironing; fragmentation; secondary dry method deironing; dry method ore grinding; tap water is added into partial raw materials and partial clinker for pulping; primary wet method deironing; wet method ore grinding; secondary wet method deironing; sieving with a 200 mesh sieve, a 325 mesh sieve, and a 500 mesh vibrating screen; third-time wet method deironing; primary drying; scattering; calcining; scattering; and obtaining of the product. The process solves the problems of fineness and conductivity of calcined kaolin products for electrophoretic paint, and the product quality can satisfy requirements of clients for the granularity index, the conductivity index and the like of the calcined kaolin products for electrophoretic paint.

Owner:山西晋坤矿产品股份有限公司

Granulated kaolin compositions and processes for their production

ActiveUS8388750B2Reduce dustEasy make-downPigmenting treatmentSynthetic resin layered productsSlurryMaceral

Owner:IMERYS USA INC

Hyperplaty clays and their use in paper coating and filling, methods for making same, and paper products having improved brightness

InactiveUS20050178292A1High crystallinityLight scattering is detrimentalPigmenting treatmentPaper coatingOptical propertyPulp and paper industry

The present invention relates to a hydrous kaolin product having improved optical properties, for example, when used in the production of paper products. The present invention comprises an improved barrier coating for paper and a method of making the coated paper. The present invention also comprises an improved method from making filled and coated paper products. The present invention uses a composition comprising kaolin having a shape factor of at least about 70:1, such as at least about 80:1 or at least about 100:1.

Owner:IMERYS USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com