Method for preparing kaoline products for catalytic cracking catalyst

A catalytic cracking and kaolin technology, applied in catalytic cracking, chemical instruments and methods, cracking, etc., can solve the problems of ineffective control of the proportion of crystal components, and achieve the effects of improving performance, avoiding pollution, and ensuring uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment one: a kind of preparation method of catalytic cracking catalyst kaolin product is made up of following steps successively:

[0045] (1) pulping

[0046] The raw kaolin ore containing 35% kaolinite by mass, water and dispersant are pounded to make the first slurry with a pH value of 7.2.

[0047] The raw kaolin ore containing halloysite with a mass of 45%, water and a dispersant are pounded to make a second slurry with a pH value of 7.4. The pH values of the first slurry and the second slurry may be the same or different.

[0048] Wherein, the mass ratio of above-mentioned two kinds of kaolin raw ores and water is 1:1, and the mass ratio of above-mentioned two kinds of kaolin raw ores and dispersant is 1:0.0014, and described dispersant is the mixture of water glass and sodium hexametaphosphate, The mass ratio of water glass and sodium hexametaphosphate is 3.5:1;

[0049] (2) Grading

[0050] The first slurry is classified, and the obtained first overfl...

Embodiment 2

[0060] Embodiment two: a kind of preparation method of catalytic cracking catalyst kaolin product, the kaolin that will be taken from Suzhou Yangdong Mine joins in the slurry tank, adds water, dispersant (the ratio of water glass and sodium hexametaphosphate is 2.5: 1) After being separated by five-stage hydrocyclones (Φ200, Φ150, Φ75, Φ25, Φ10), kaolin slurry A is obtained; kaolin obtained from Suzhou Yangxi Mine is also processed to obtain kaolin slurry B. Sampling and analysis showed that the contents of halloysite in slurry A and slurry B were 46% and 72%, respectively.

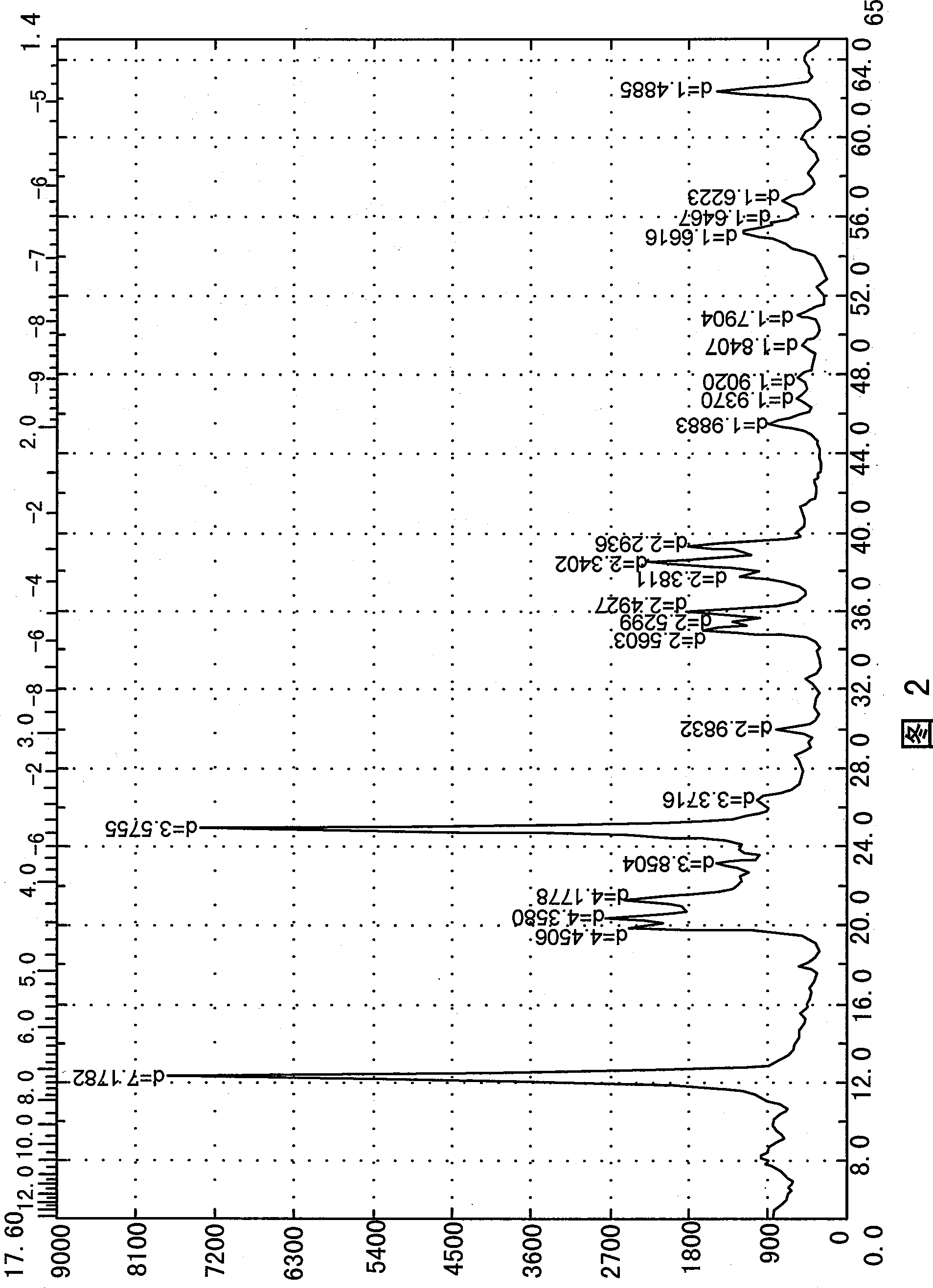

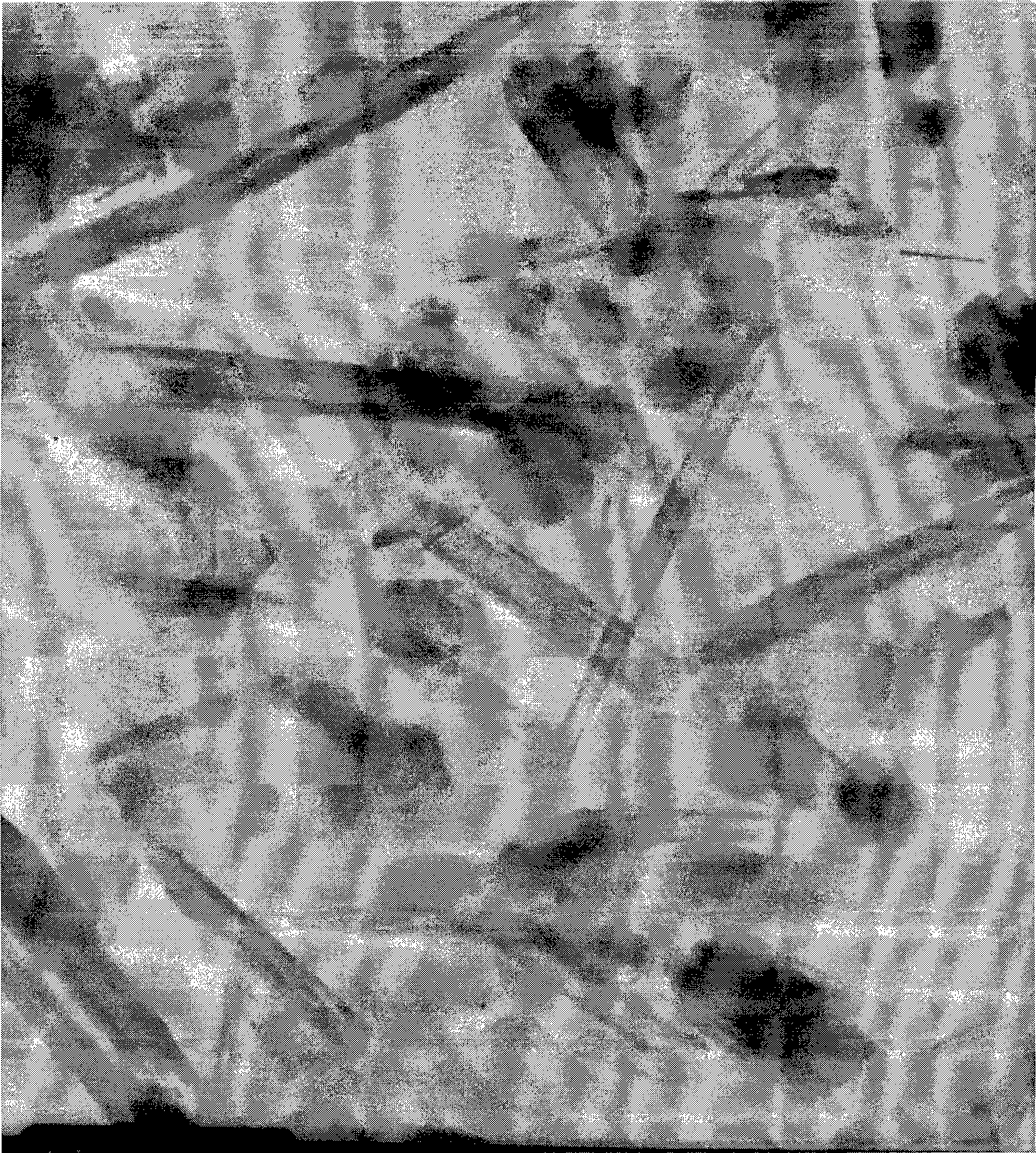

[0061] Mix slurry A and slurry B according to the ratio of 0.35:1 (dry weight), press filter to dehydrate and dry to obtain product A. Sampling and analysis showed that the halloysite content of the final product was 65.35%. attached figure 1 The SEM photos show that the number of flakes and tubes in the product is approximately equal. The XRD pattern of accompanying drawing 2 shows that the product ha...

Embodiment 3

[0063] Put the rough concentrate of kaolin from Maoming into the slurry tank, add water and dispersant (the ratio of water glass to sodium hexametaphosphate is 2.5:1), and pass through the two-stage hydrocyclone (Φ150, Φ75), A horizontal centrifugal classifier was used for further classification, and the slurry was bleached with sodium hydrosulfite (sodium hyposulfite) to obtain kaolin slurry C. The kaolin treatment steps of Suzhou Yangxi Mine are the same as above to obtain kaolin slurry D. Sampling and analysis showed that the contents of halloysite in slurry C and slurry D were 10% and 73%, respectively.

[0064] Mix slurry C and slurry D at a ratio of 0.12:1, press filter for dehydration, and dry to obtain product B. Sampling and analysis showed that the halloysite content of the final product was 65.26%. attached image 3 The SEM photos show that the number of flakes and tubes in the product is approximately equal. The XRD pattern of accompanying drawing 4 shows that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com