Decarbonization process for coal series kaolin

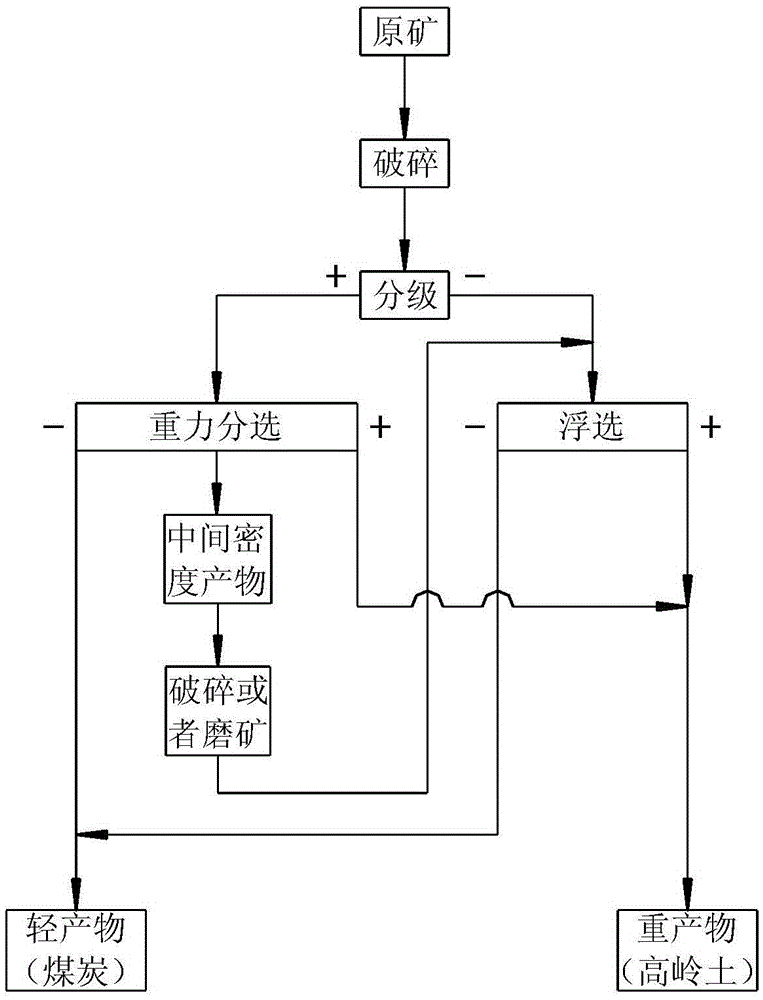

A coal-based kaolin and decarbonization technology, which is applied in the direction of solid separation, can solve the problems of environmental pollution, high cost, waste of coal resources, etc., and achieve the effects of low operating cost, improved quality, and reduced kaolin amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

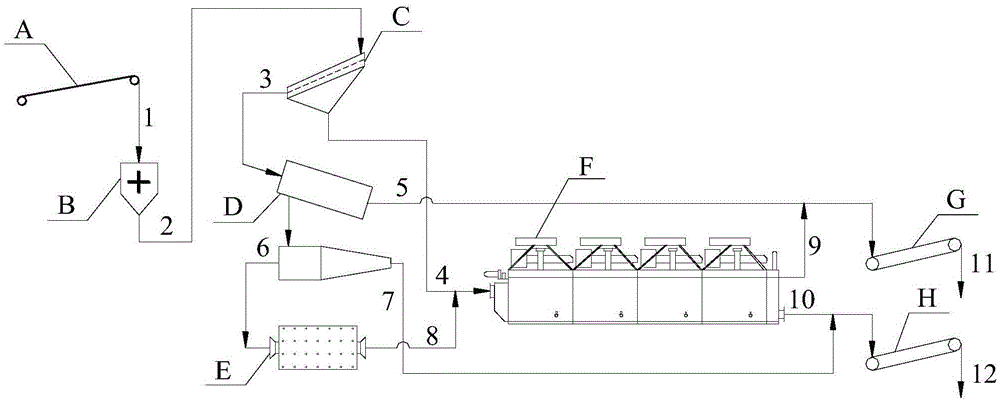

[0029] Example 1, such as figure 2 As shown, the equipment used in coal series kaolin decarburization process includes raw ore conveyor belt A, crusher B, grading screen C, three-product dense medium cyclone D, ball mill E, flotation machine F, coal product conveyor belt G, kaolin Product conveyor belt H. The working process is as follows:

[0030] The raw ore 1 transported from the raw ore conveyor belt A enters the crusher B for crushing operation, and the crushed product 2 that is fully dissociated from coal and kaolin is obtained;

[0031] The crushed product 2 enters the grading sieve C through the chute for grading operation, and the coarse product 3 on the sieve and the fine product 4 under the sieve are obtained;

[0032] The coarse-grained product 3 on the sieve enters the three-product dense-medium cyclone D for sorting operation, and obtains three products: the re-selected low-density product 5, the re-selected intermediate density product 6 and the re-selected h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com